Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Nuclear graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nuclear graphite is any grade of graphite, usually synthetic graphite, specifically manufactured for use as a moderator or reflector within a nuclear reactor. Graphite is an important material for the construction of both historical and modern nuclear reactors, due to its extreme purity and its ability to withstand extremely high temperatures.

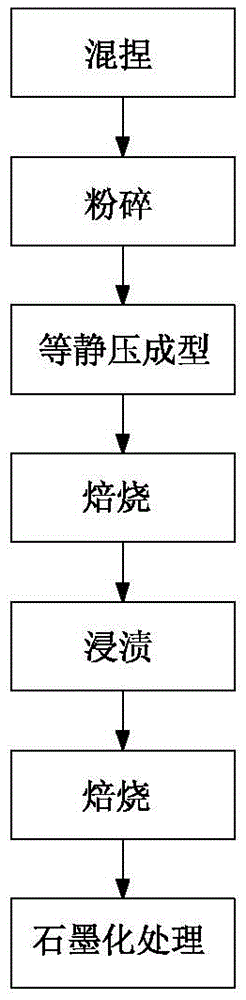

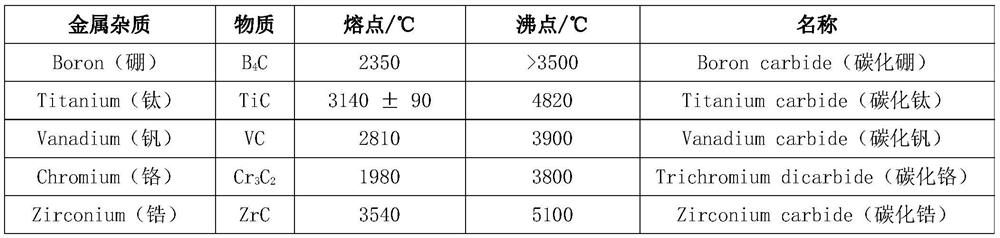

Nuclear graphite material preparation method

ActiveCN104401982AGood for in-depth purificationReduce the presence of impuritiesMaterials preparationHalogen

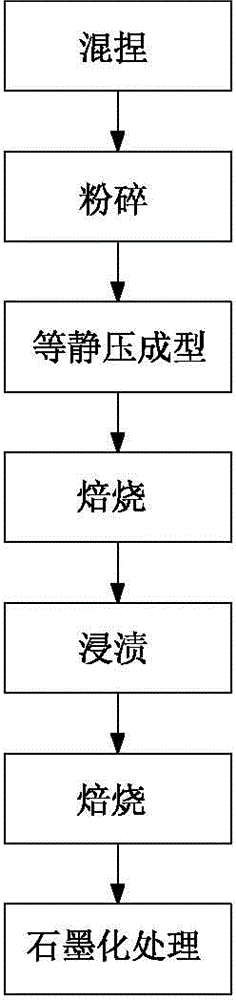

The invention discloses a nuclear graphite material preparation method including the following steps: (1) mixing and kneading; (2) grinding; (3) isostatic compaction; (4) roasting, to be more specific, baking treatment of the product obtained by the step (3) in an atmosphere furnace introduced with halogen or halogenated hydrocarbon at the treatment temperature of 800 to 1100 DEG C; (5) dipping; and (6) roasting; according to the method, in the roasting process, a halogen or halogenated hydrocarbon purified gas is introduced, a purification procedure is inserted in without reduction of the common preparation step, the cost of purification can be greatly reduced, in the roasting process, asphalt volatile components may cause many holes in graphite blocks, the holes greatly facilitate the purified gas to enter into the graphite blocks for purification so as to facilitate further purification of nuclear graphite blocks and great reduction of impurities and boron equivalent; the nuclear graphite material preparation method has the advantages of simple process, convenient operation, less production equipment, can further reduce the cost, and is convenient in popularization and application, and suitable for mass production.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Nuclear graphite material composition and preprocessing method

ActiveCN101935037AReduce manufacturing costThe source of supply is stable and guaranteedPretreatment methodOxidation resistant

The invention discloses a nuclear graphite material composition and a preprocessing method. The nuclear graphite material composition comprises 10 to 20 parts of petroleum coke powder, 70 to 80 parts of tar coke powder, 10 to 15 parts of graphite powder, 40 to 45 parts of coal tar and 1 to 3 parts of surfactant. The nuclear graphite material is prepared by the steps of kneading the raw materials, secondarily crushing the raw materials, isostatically pressing the raw materials, roasting the raw materials and the like. In the invention, the raw materials are made in China, an alkali metal catalyst is not used, isostatic technology is adopted, the prepared nuclear graphite material is low in cost, the uniformity of isotropy is high; and the antioxidant performance is high.

Owner:CHENGDU CARBON

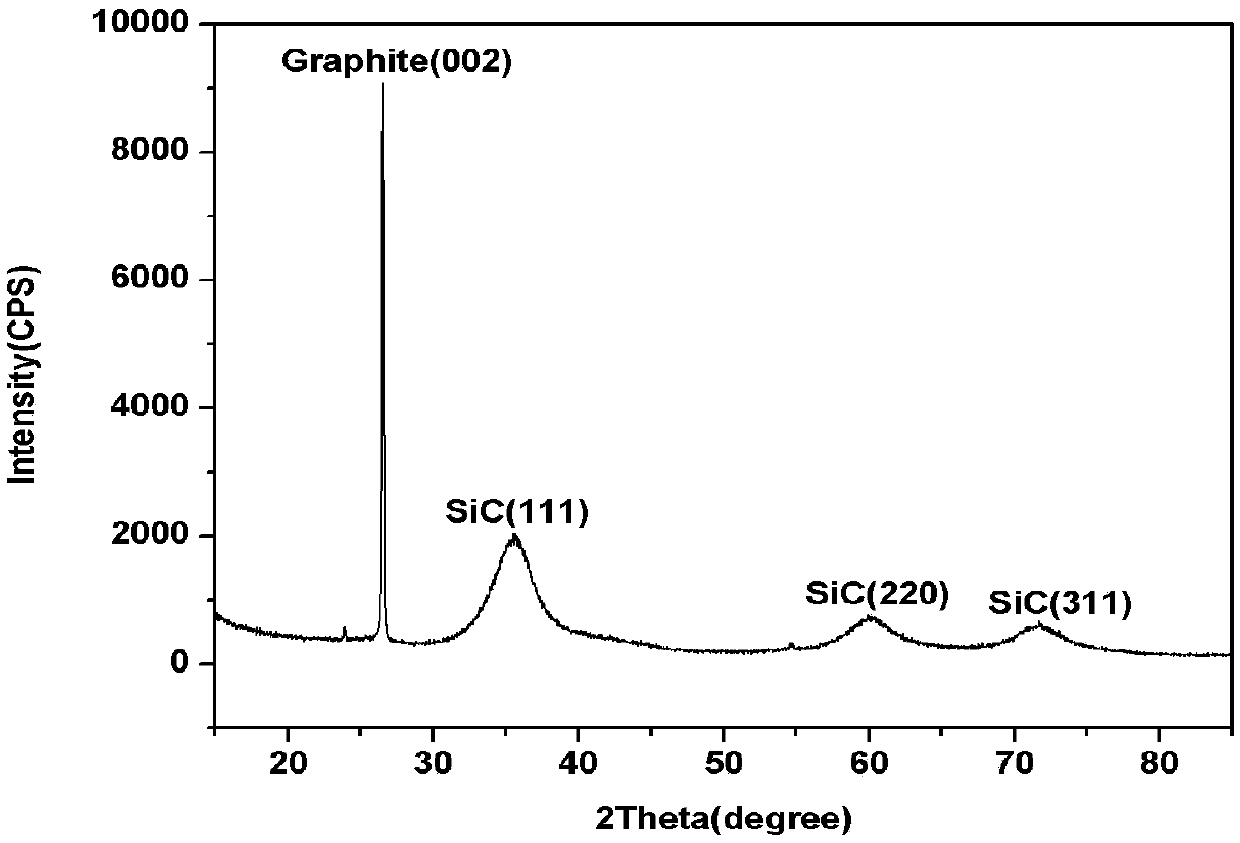

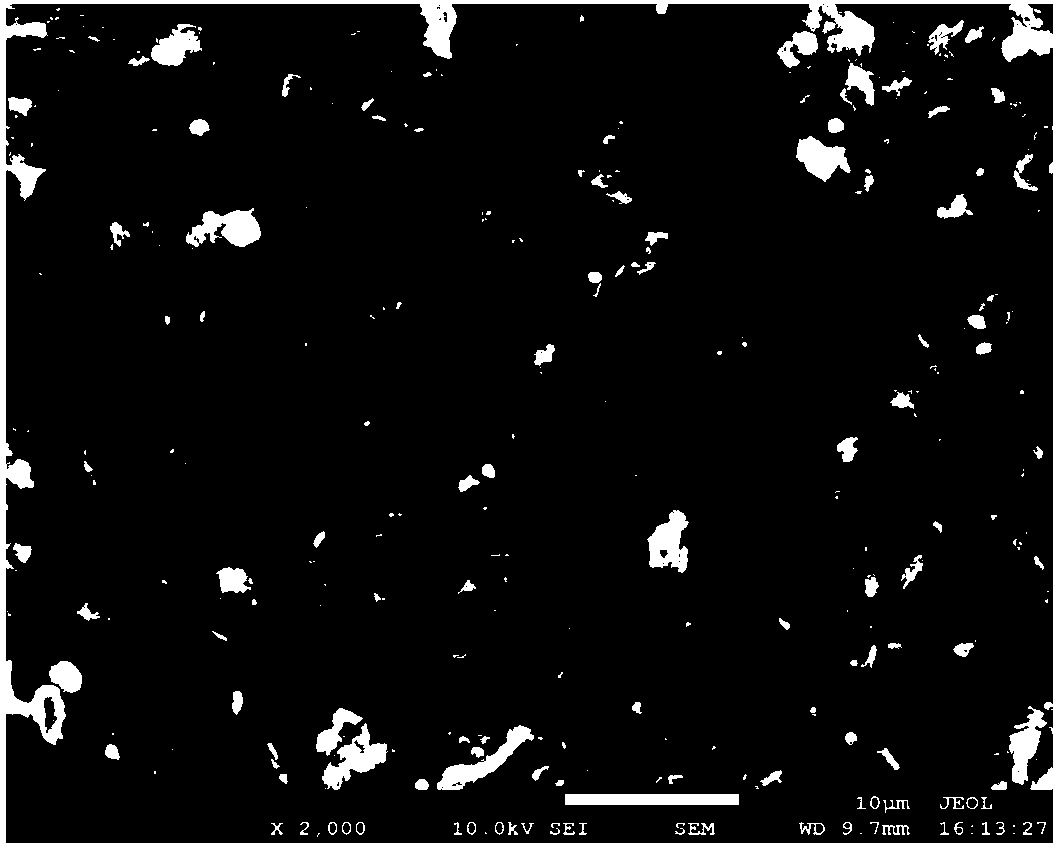

Method for preparing SiC/C ceramic composite material through hot pressing sintering

The invention discloses a method for preparing a SiC / C ceramic composite material through hot pressing sintering. The method comprises the following steps: forming a base material by using 87-91% of submicron beta-SiC micro-powder, 8-12% of aluminum nitride powder and 0.5-1% of a dispersant, adding the base material to an organic solvent, uniformly stirring the base material and the organic solvent, sequentially alcohol-soluble resin, a binder, a lubricant and highly-pure nuclear graphite powder, and uniformly stirring above materials to obtain a mixture; drying the mixture, scattering the dried mixture, and carrying out sealed ageing; and sequentially carrying out green body compacting, drying, pre-burning, vehicle working and high-temperature hot press sintering on the obtained aged powder to obtain the SiC / C ceramic composite material.

Owner:浙江东新新材料科技有限公司

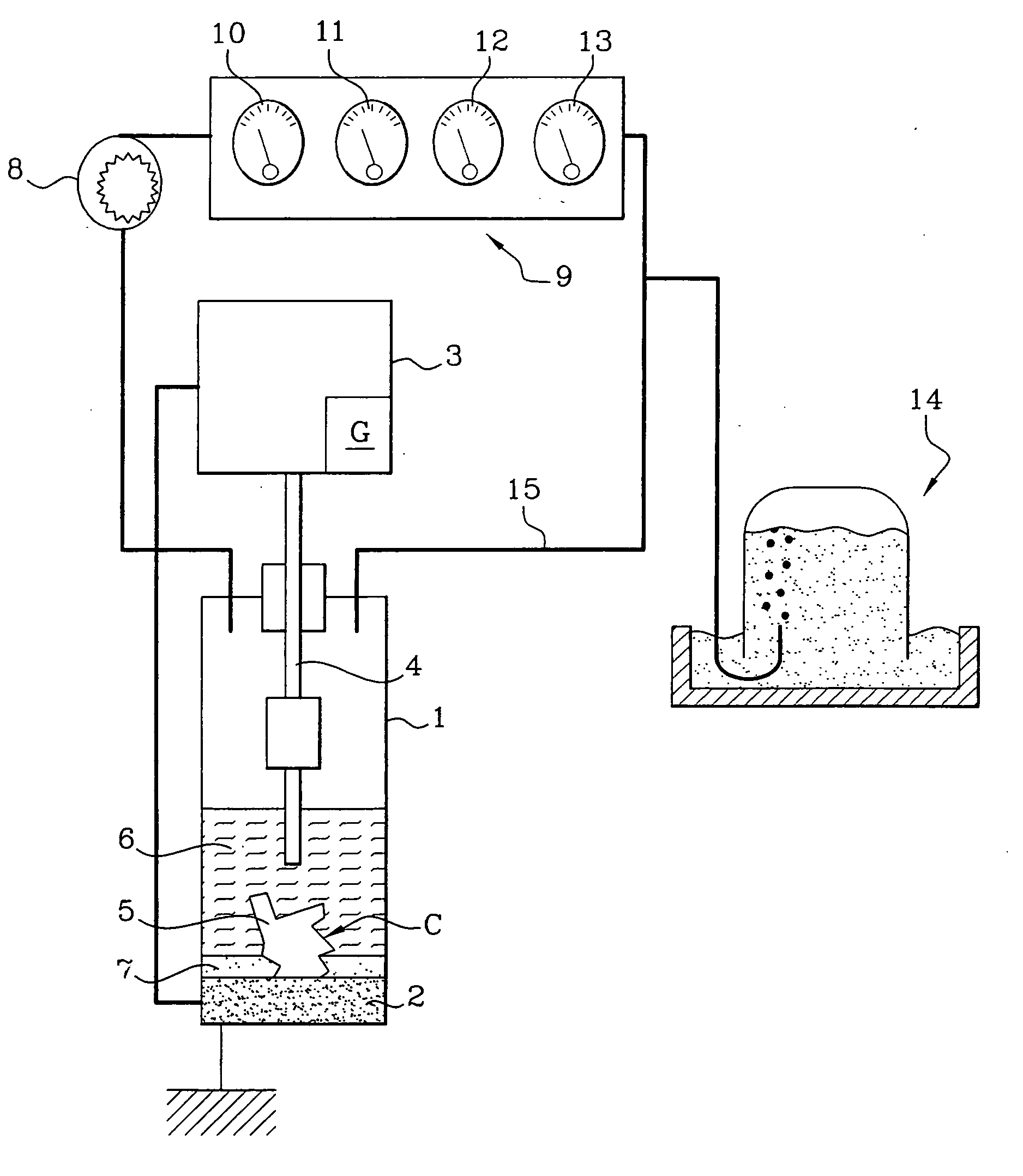

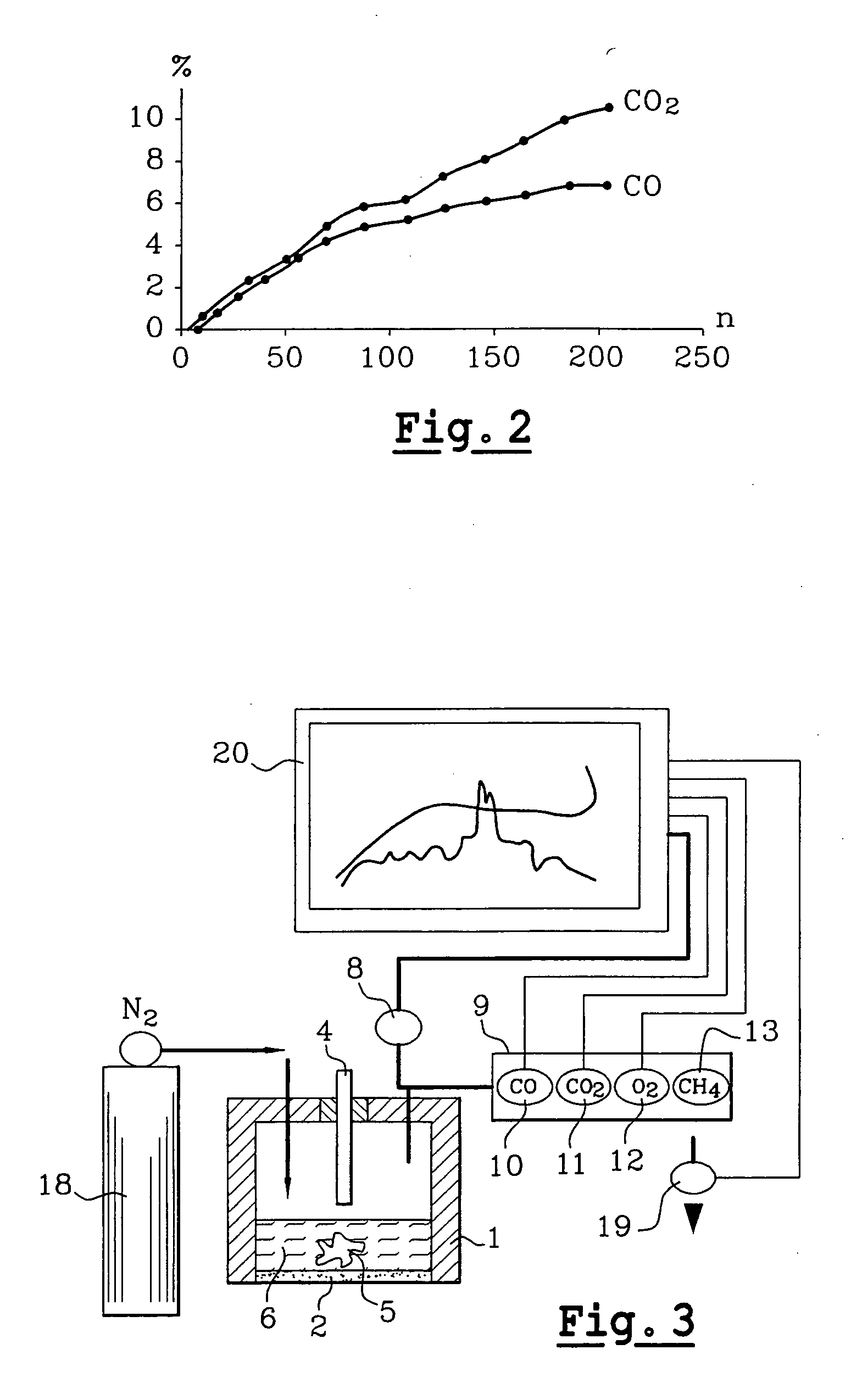

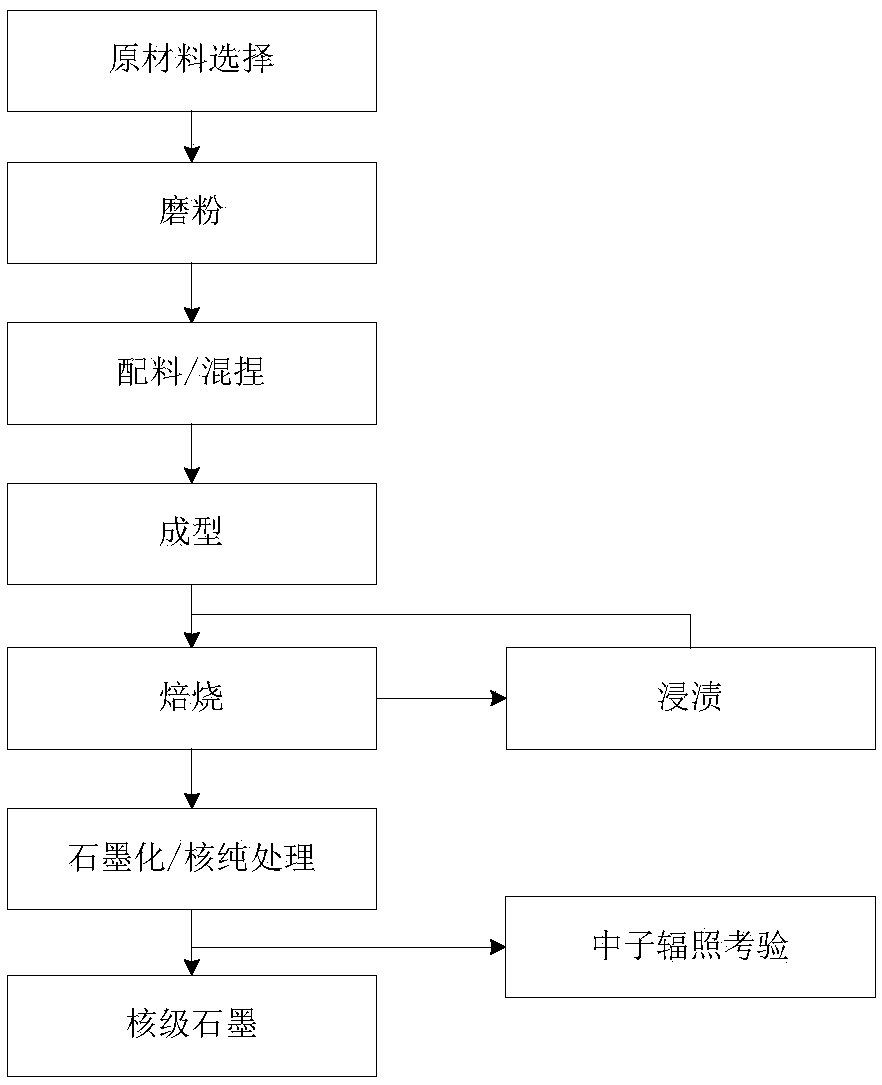

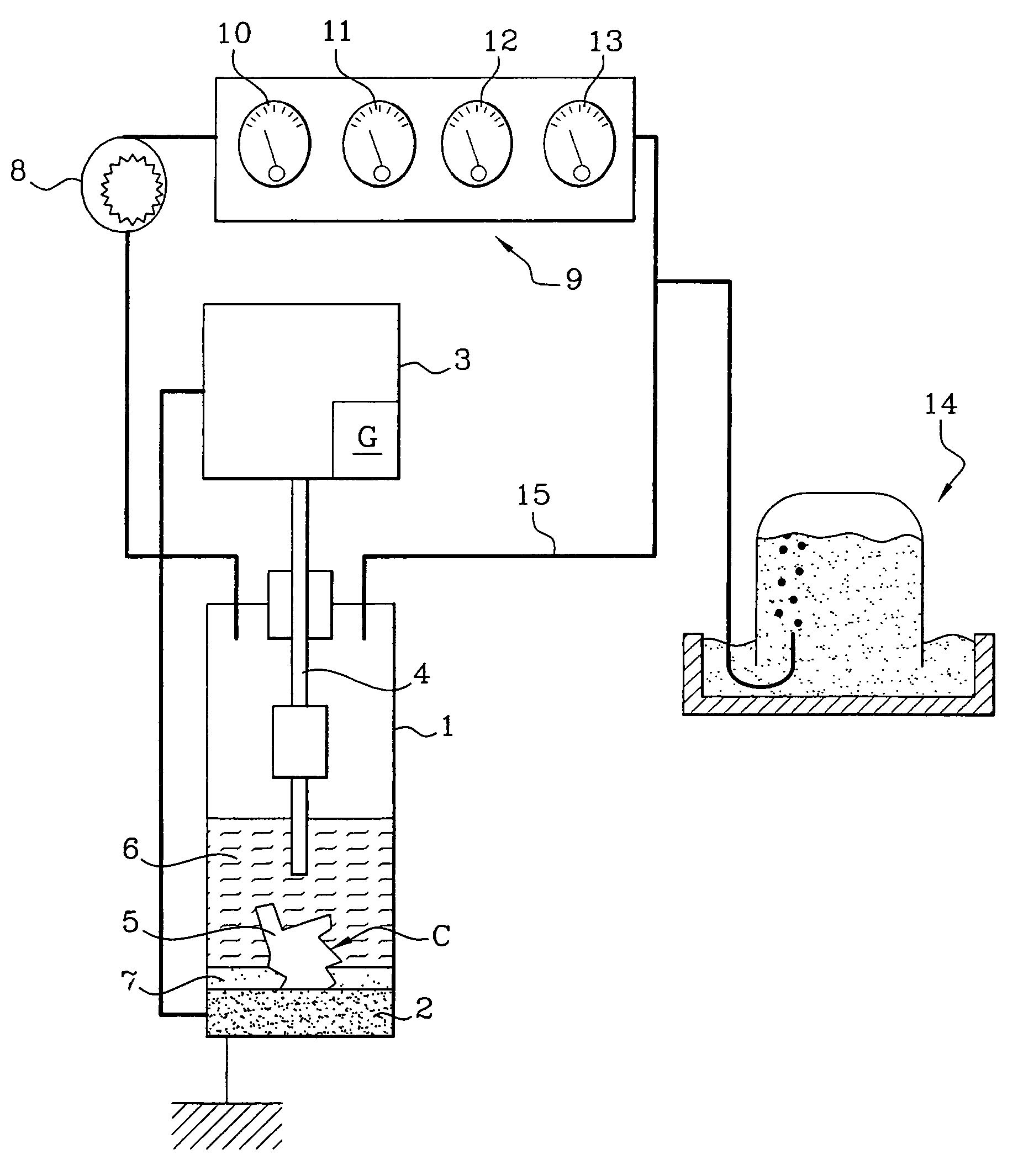

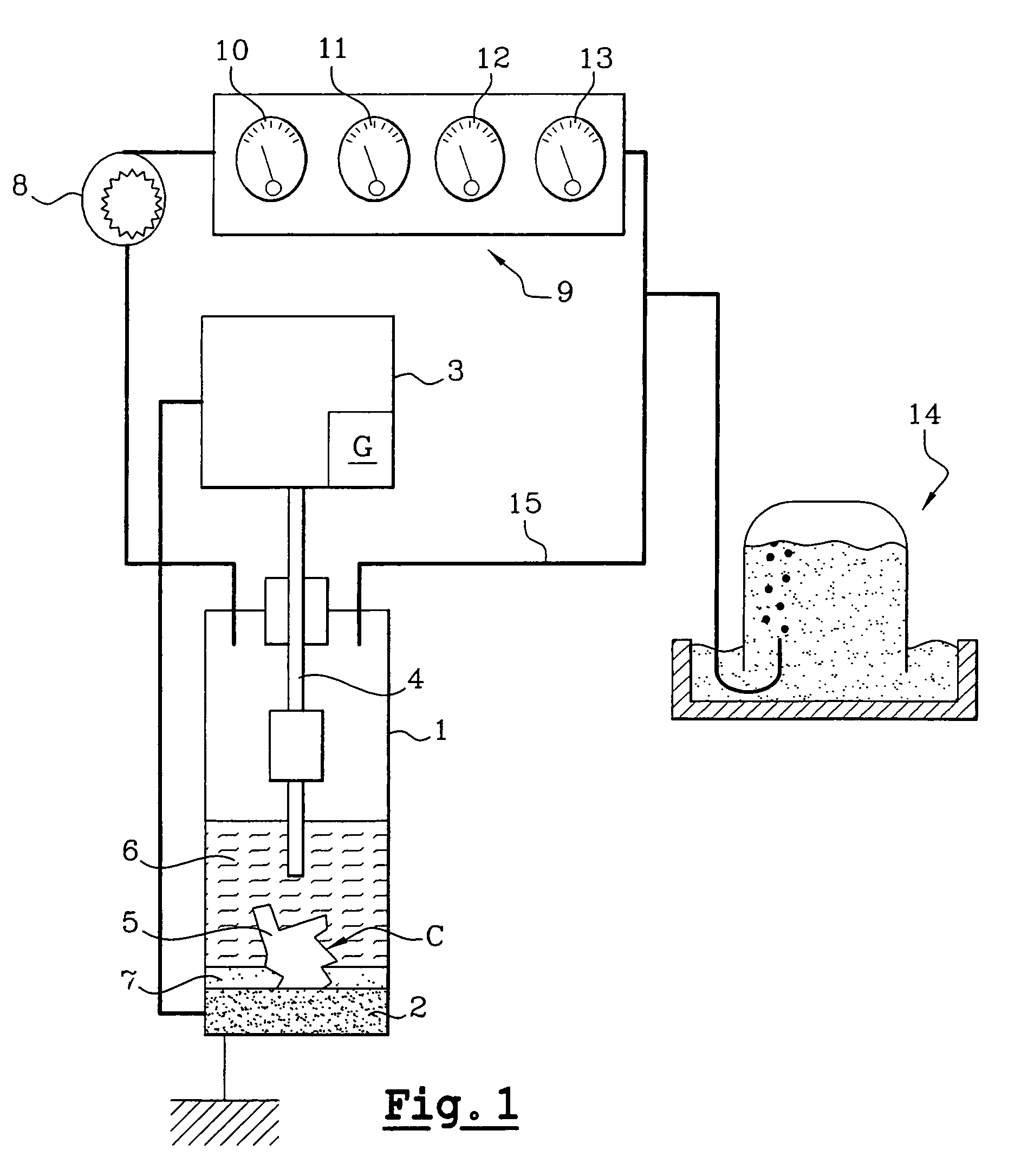

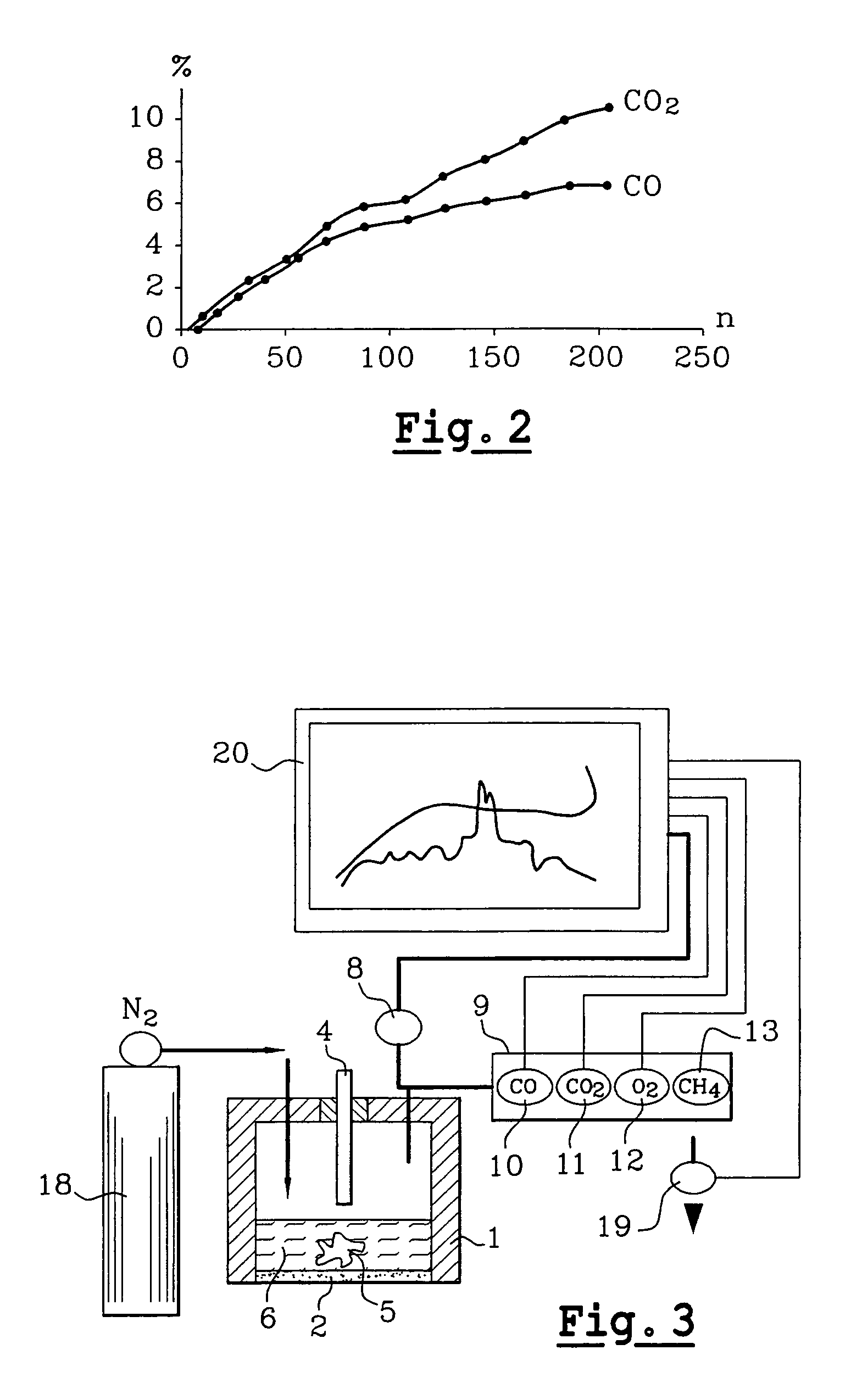

Method for destroying a nuclear graphite by gasification in aqueous medium

A process for the treatment of a nuclear graphite contaminated with radioelements includes subjecting the graphite, immersed in a medium containing water, to high-voltage pulses. The pulses have sufficient energy for electric arcs to be initiated and to break the constituent bonds of the water molecules and the carbon-carbon bonds of the graphite. The number of high-voltage pulses is determined so as to convert the graphite into gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

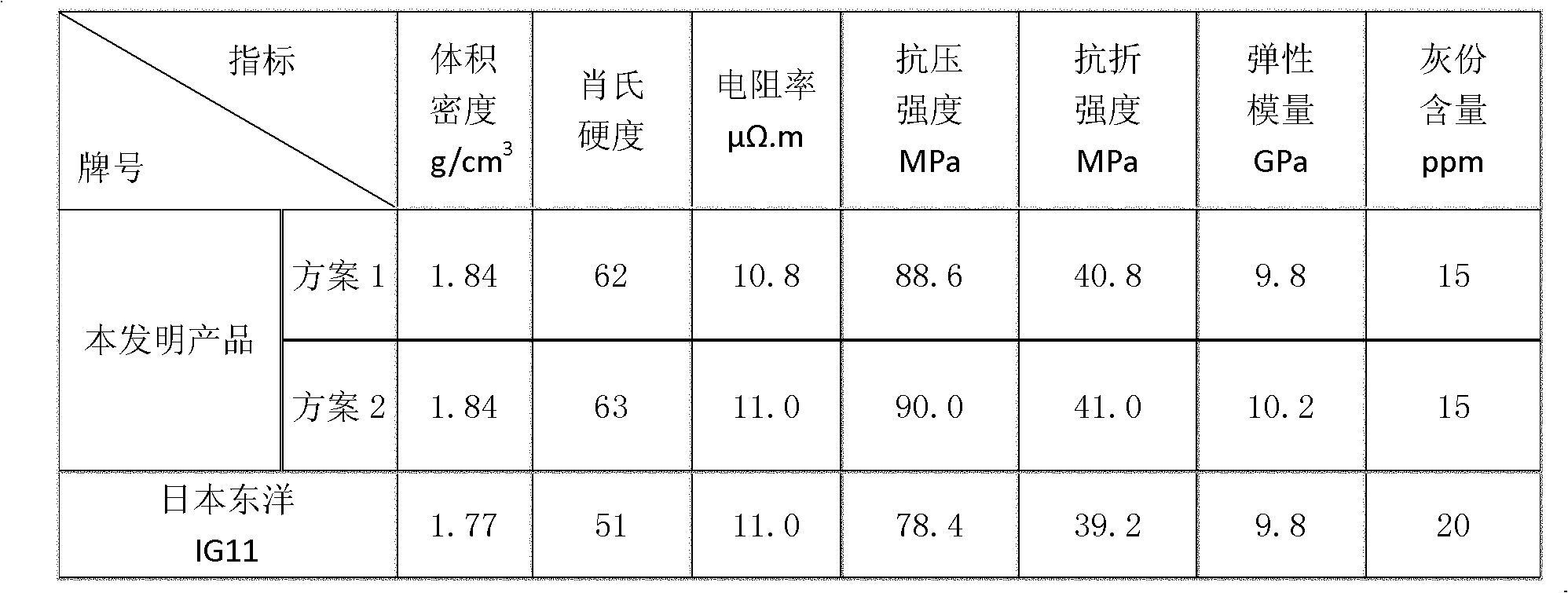

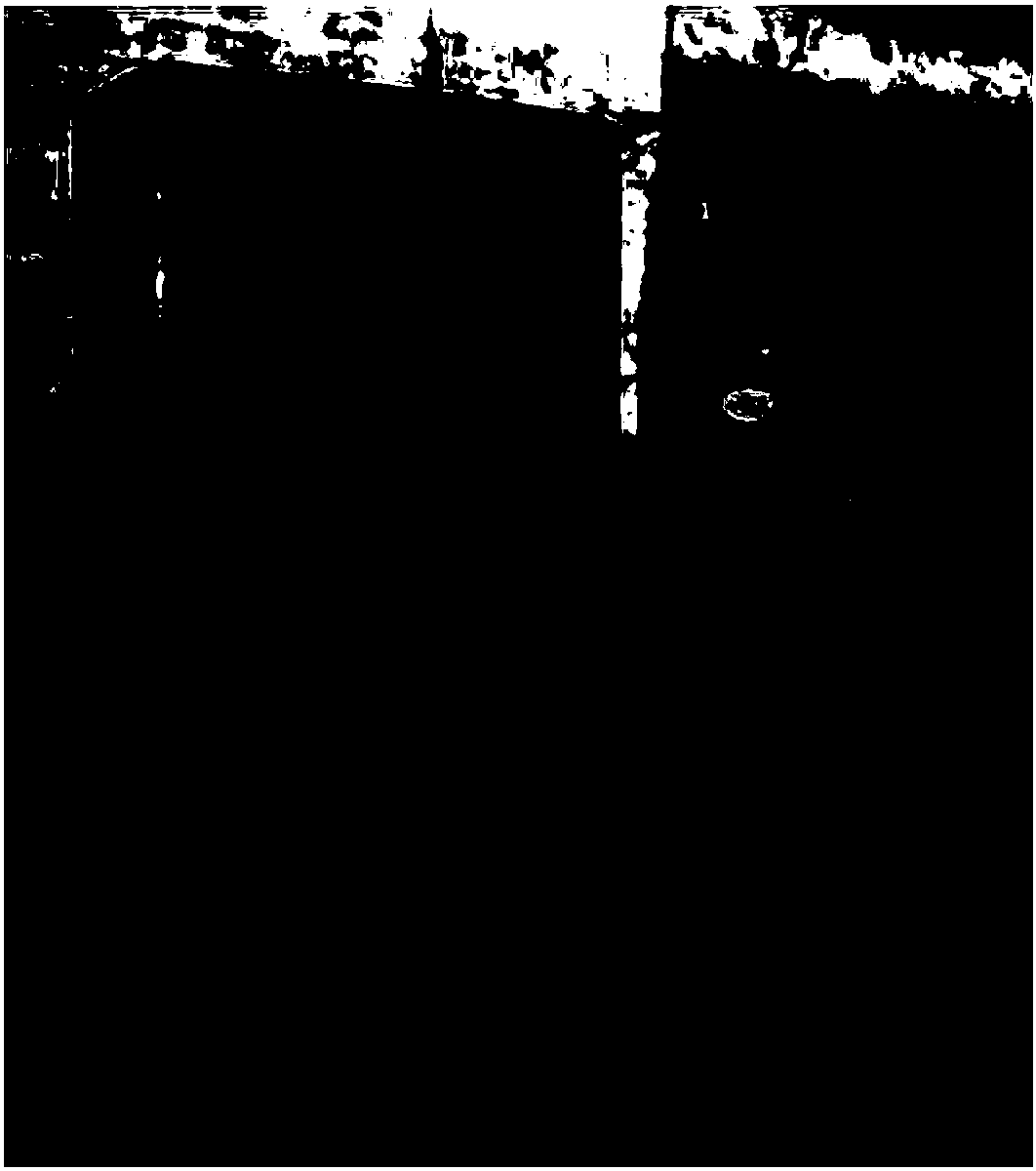

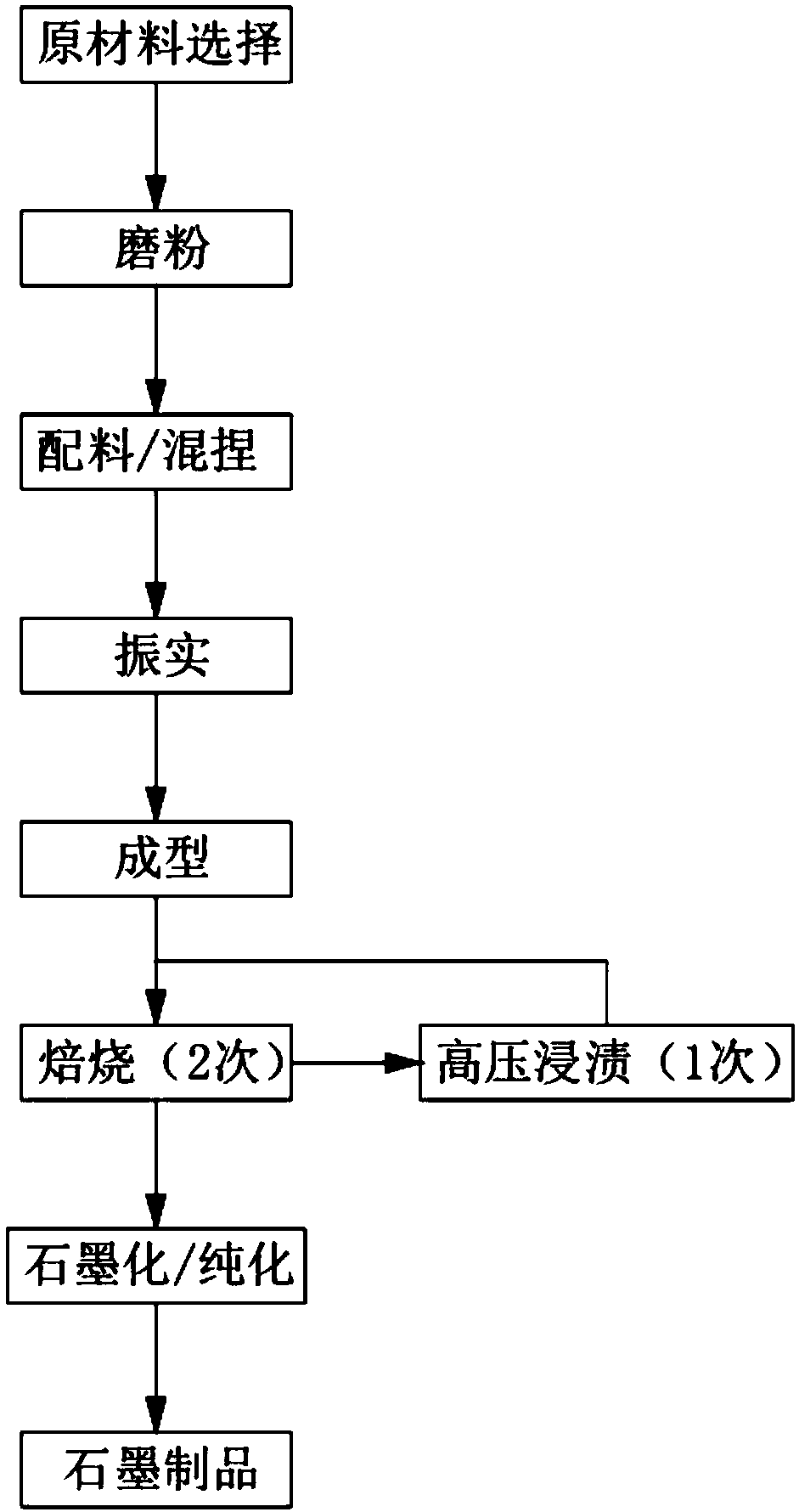

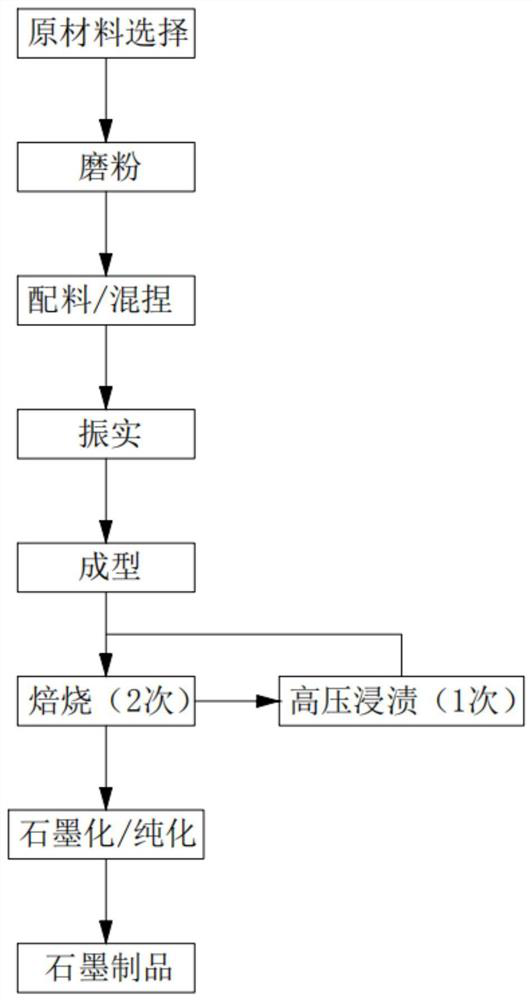

Large-dimension nuclear graphite material for reactor internal of high-temperature gas cooled reactor and preparation method

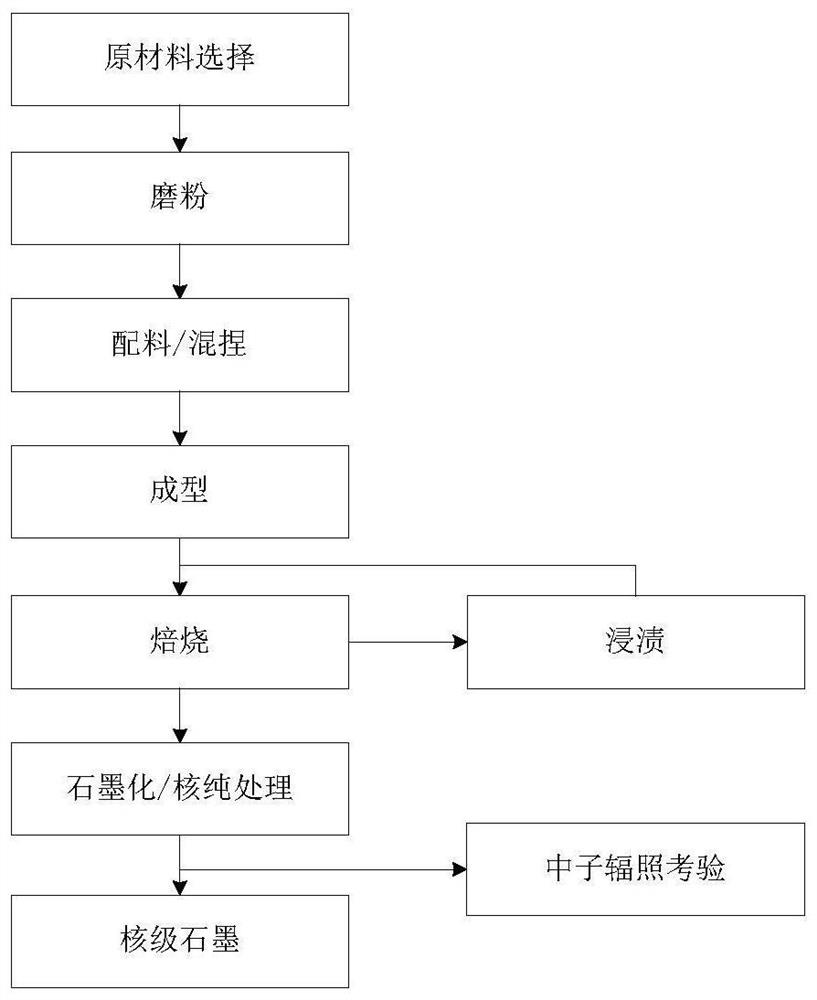

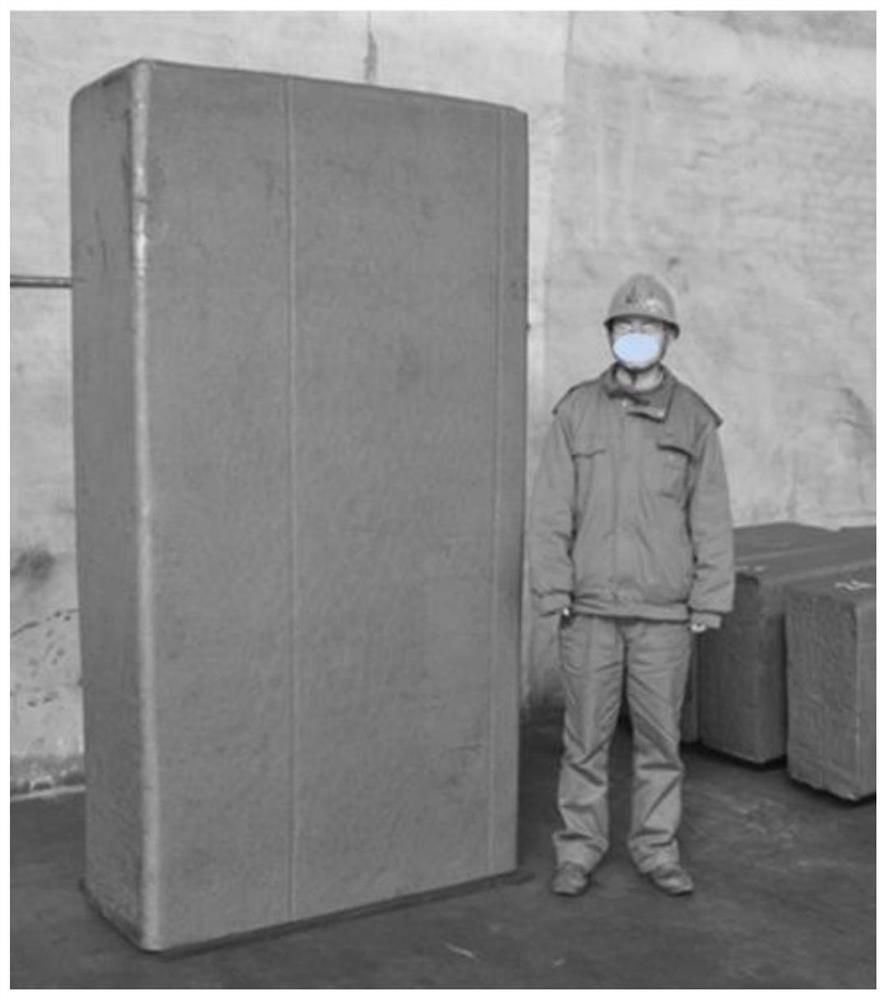

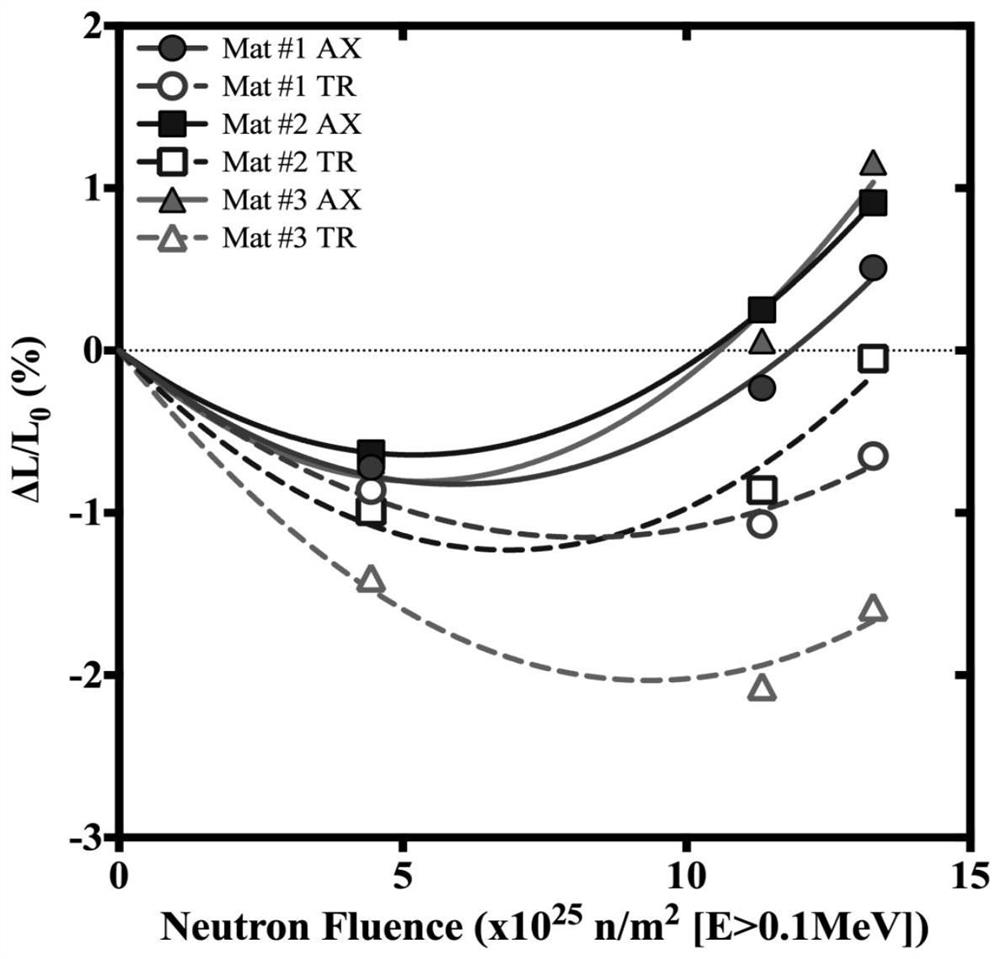

The invention relates to a large-dimension nuclear graphite material for a reactor internal of a high-temperature gas cooled reactor and a preparation method. The method comprises the following stepsof: raw material selection, grinding, mixing-kneading, forming, roasting, 0 to 1 time of impregnation, and graphitization / nuclear-pure processing. The large-dimension nuclear graphite material is simple in process and convenient to operate and adopts little production equipment, so that cost is further reduced; the large-dimension nuclear graphite material is convenient to popularize and apply andis applicable to large-scale production; compared with the prior art, the provided product has a large scale and has neutron irradiation performance data.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

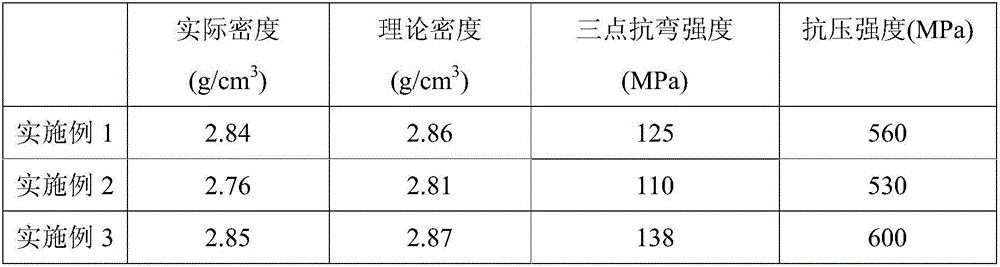

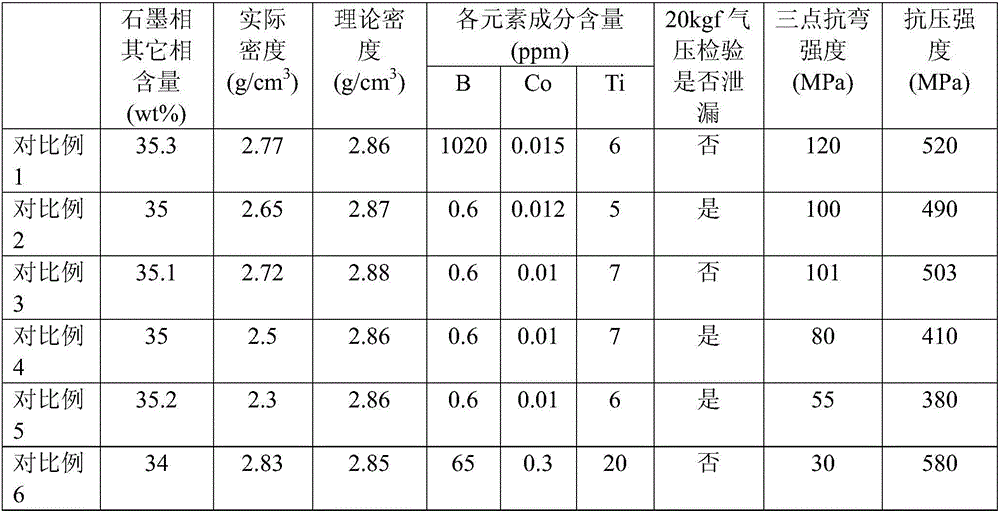

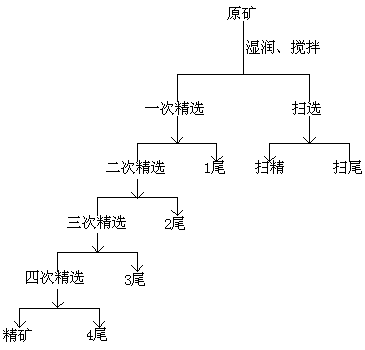

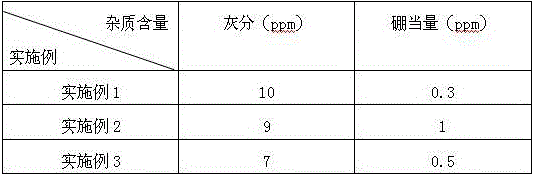

Nuclear graphite based on microcrystalline graphite as raw material and preparation method thereof

InactiveCN107601496AHigh thermal conductivityImprove bending strengthCarbon compoundsFlexural strengthThermal diffusivity

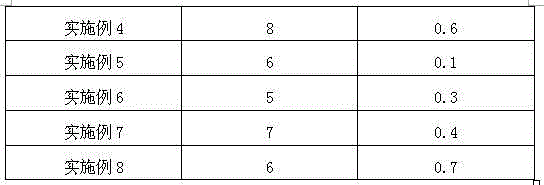

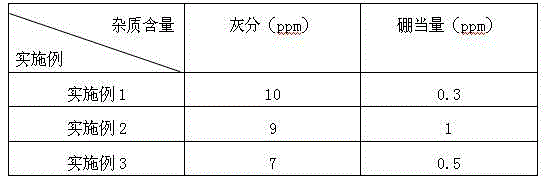

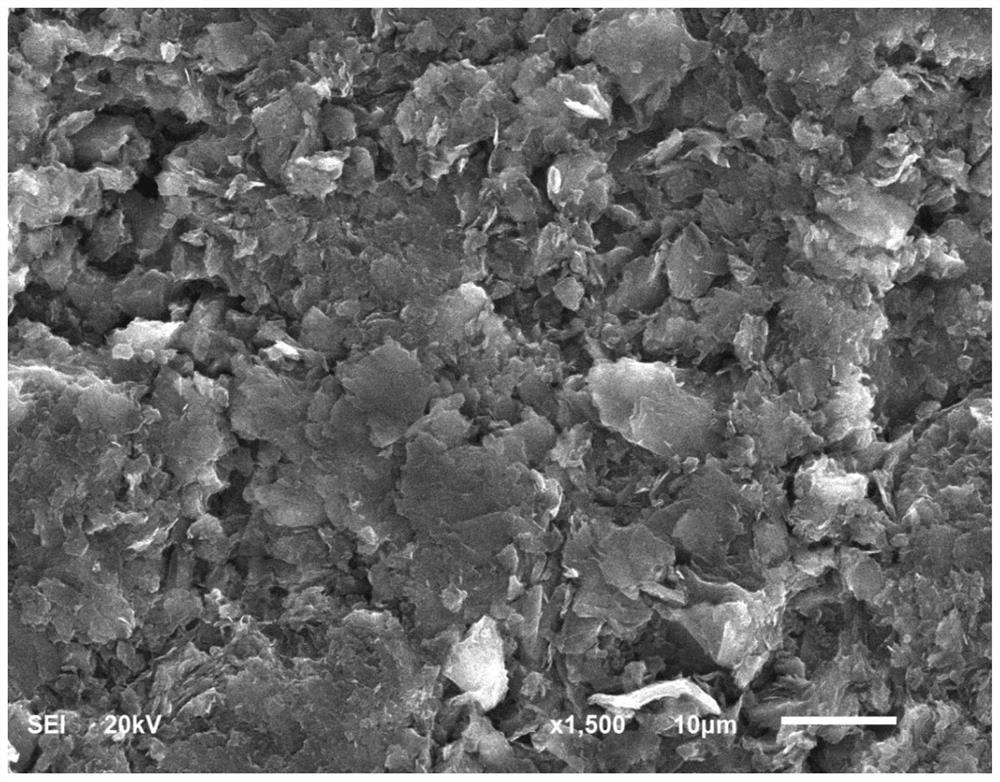

The invention relates to the technical field of microcrystalline graphite production and discloses nuclear graphite based on microcrystalline graphite as a raw material and a preparation method thereof. The nuclear graphite prepared from cryptocrystalline graphite has ultrahigh heat conductivity, high graphitization, low isotropic ratio and higher bending strength; compared with various cokes in the prior art, the nuclear graphite has the advantages that isotropic graphite at isotropic ratio of 1.1-1.15 is easily acquired in the manner of isostatic pressing and the thermal diffusivity of greenware of microcrystalline graphite is far higher than that of green ware of coke powder, so that the microcrystalline graphite is more beneficial to baking; the equivalent weight of ash content and boron in the nuclear graphite prepared according to the invention can meet the impurity requirement of nuclear graphite.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

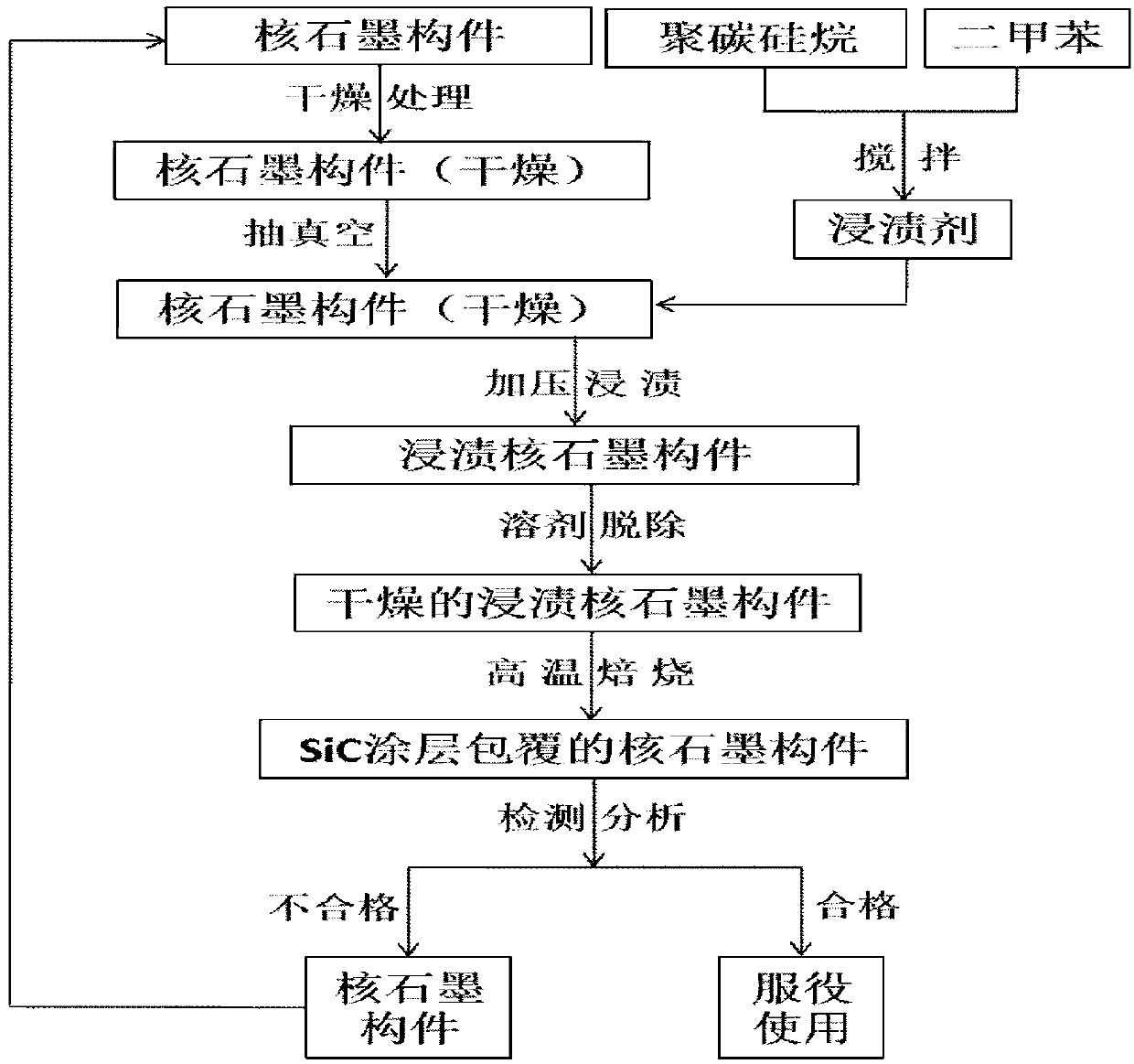

Preparation method for graphite surface SiC coating used for molten salt reactor

InactiveCN107814590AHigh densityImprove mechanical propertiesNuclear energy generationFast fission reactorsSolventHigh pressure

The invention discloses a preparation method for a graphite surface SiC coating used for a molten salt reactor. The preparation method comprises the following steps: adding polycarbosilane or modifiedpolycarbosilane into solvent to be dissolved to obtain polycarbosilane or modified polycarbosilane impregnant; vacuumizing a nuclear graphite construction member in impregnation equipment; adding impregnation liquid into the impregnation equipment for impregnation and drying under high-pressure inert atmosphere; carrying out roasting processing on the dried impregnation nuclear graphite construction member in a high-temperature furnace under the inert atmosphere to obtain the nuclear graphite construction member coated with the SiC coating. The preparation method has the advantages of simpletechnology and low cost and can be produced on a large scale.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Preparation method for high-density, large-size, ultra-fine-pore nuclear graphite materials for fused salt piles

The invention provides a preparation method for high-density, large-size and ultra-fine-pore nuclear graphite materials for fused salt piles from coke aggregates 1-5 micrometers in size. The preparation method has the advantages that in the forming process, paste is compacted through vibration and ramming, calcination as well as temperature rise speeds and in-furnace temperature differences in thegraphitization process are controlled, and the shrinkage rate of graphite green bodies is further controlled, so that the technical problems that the smaller the average particle size of conventionalaggregates is, the larger the specific surface area and the surface energy of particles are, and the large-size nuclear graphite materials cannot be prepared are solved; multiple halogen gases are introduced as purification gases, and simultaneous purification in the graphitization process is realized; the method is clear in procedure, technically reliable and feasible, and suitable for large-scale production.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Preparation method of nuclear graphite material

The invention belongs to the technical field of nuclear graphite material production, and provides a preparation method of a nuclear graphite material. Adopted preparation raw materials comprise asphalt coke, needle coke, graphite powder and asphalt. In the preparation raw materials, the mass ratio of the asphalt coke to the needle coke to the graphite powder is 40:40:20, and the mass of the asphalt accounts for 45% of the total mass of the asphalt coke, the needle coke and the graphite powder. The preparation method comprises the following steps: (1) carrying out grinding: respectively grinding the asphalt coke, the needle coke and the graphite powder into powder with a particle size of 5000 meshes; (2) carrying out mixing and kneading; (3) carrying out crushing and grinding: carrying outcrushing by using a jaw crusher, and carrying out spiral extruding, milling treatment and grinding until the particle size is 4000 meshes and the purity is higher than 85%; (4) carrying out forming and pressing; (5) carrying out roasting, wherein the roasting temperature is 850 DEG C, and the temperature is kept for 48 hours; and (6) carrying out graphitizing: carrying out graphitizing treatmenton fired roasted products at a temperature of 2800-3200 DEG C. The preparation method disclosed by the invention is simple in raw material preparation and low in cost, and can be widely applied to thefield of nuclear graphite material production.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Spherical graphitic corpuscule composite carbon material and preparation thereof

ActiveCN101298326AHigh electrochemical capacityGood chemical stabilityVolumetric Mass DensityCharge discharge

The invention provides a spherical graphite corpuscle compound carbon material, which is a compound graphite composed of spherical graphite with a clad sheet of nonferrous metal; the graphite that is almost the nuclear pure grade is adopted as the raw material, then a PCS system is utilized to collide, curl, knead, compact, conglobate and clad the graphite corpuscle for surface treatment, the rhombus crystal structure of the natural graphite is improved from 20 percent to about 80 percent, then nonferrous elements is clad or inserted into the interlamination of the spherical graphite crystal, the direction of the clad compound material is changed from uniform direction to random direction and the clad compound material has low specific area and high stacking density. The beneficial effect is that: the clad spherical graphite completely changes the crystal structure and microstructure of the natural graphite, and has large electrochemical capacity, good chemical and thermo-stability and high charge-discharge efficiency; meanwhile, the clad spherical graphite can not only be used as the cathode material of the lithium ionization cell but also can be used as the raw materials for isotropic high-end graphite products such as nuclear graphite; In addition, the production technology is simple, the cost is low and the performance is reliable.

Owner:LUOYANG GUANQI INDAL & TRADE +1

High-temperature self-propagating solidifying method for radioactive graphite

The invention discloses a high-temperature self-propagating solidifying method for radioactive graphite, which includes: firstly analyzing components and contents of the components of the radioactive graphite; designing formula of a solidified body by utilizing graphite, aluminum, titanium dioxide and the radioactive graphite as raw materials; mixing, refining and prepressing the raw materials; igniting formed samples at the temperature ranging from 1500 DEG C to 3000 DEG C and finally obtaining the radioactive graphite solidified body to realize solidifying after the samples are burned automatically. The high-temperature self-propagating solidifying method is simple in operation, high in production efficiency, fine in repeatability and capable of massively disposing radioactive graphite discharged from the relevant fields, such as nuclear power plants and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for destroying a nuclear graphite by gasification in aqueous medium

A process for the treatment of a nuclear graphite contaminated with radioelements includes subjecting the graphite, immersed in a medium containing water, to high-voltage pulses. The pulses have sufficient energy for electric arcs to be initiated and to break the constituent bonds of the water molecules and the carbon-carbon bonds of the graphite. The number of high-voltage pulses is determined so as to convert the graphite into gas.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

High-temperature self-propagating curing method for strontium-containing radioactive graphite

InactiveCN102623079AImprove performanceEasy to operateRadioactive decontaminationNuclear powerStrontium

The invention discloses a high-temperature self-propagating curing method for strontium-containing radioactive graphite. The method comprises the following steps of: firstly, analyzing compositions and content of the strontium-containing radioactive graphite; secondly, designing a cured body formulation by using graphite, titanium and the strontium-containing radioactive graphite as raw materials; thirdly, mixing, refining and pre-pressing the raw materials; fourthly, igniting a molded sample at the temperature of between 1,500 and 3,000DEG C; and finally, obtaining a strontium-containing radioactive graphite cured body to realize the curing. The high-temperature self-propagating curing method is simple in operation, high in working efficiency and high in repeatability, and can be widely applied to large-scale disposal of strontium-containing radioactive nuclear graphite discharged by nuclear power plants and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

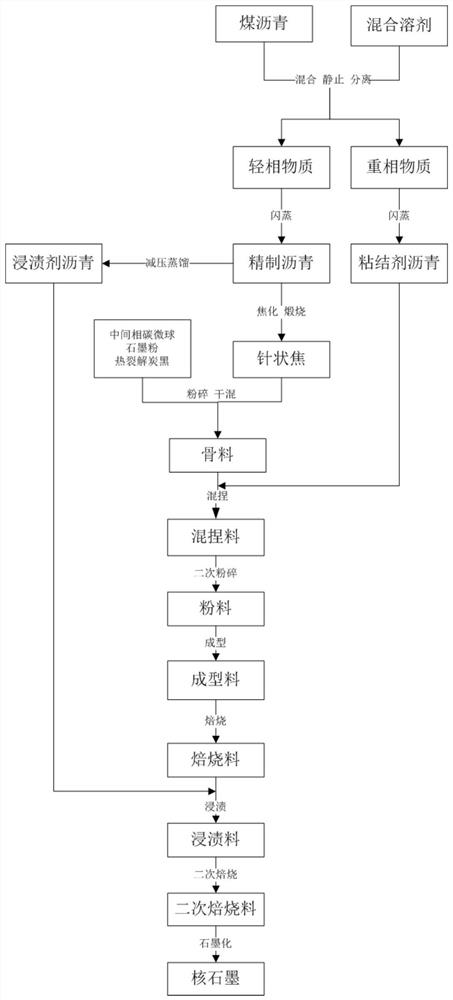

Coal pitch quality-divided treatment method for preparing nuclear graphite material

ActiveCN112694332AImprove qualityReduce low value-added productsCarbon compoundsCoalMaterials science

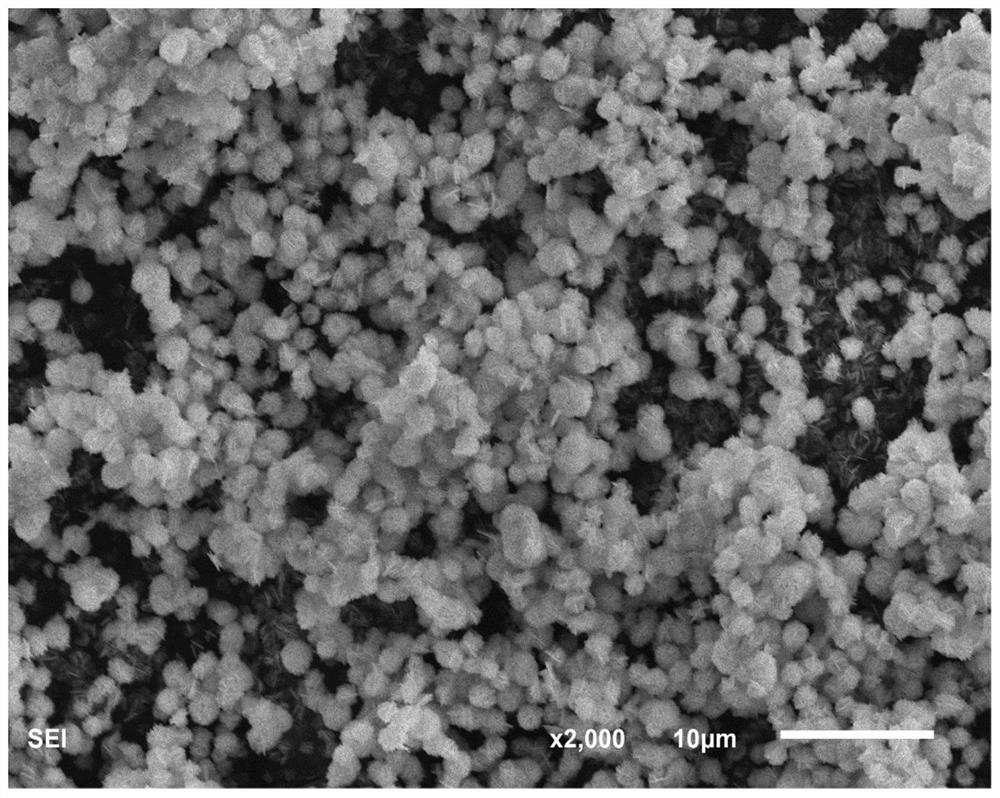

The invention discloses a coal pitch quality-divided treatment method for preparing a nuclear graphite material. According to the method, coal pitch is subjected to quality separation treatment to obtain binder pitch, refined pitch and impregnant pitch, and the binder pitch, the refined pitch and the impregnant pitch are matched with mesocarbon microbeads, thermal cracking carbon black and graphite powder to be used for preparing the nuclear graphite material. According to the method, the quality of the nuclear graphite can be improved, low-additional-value products of the coal pitch are reduced, efficient utilization of the coal pitch can be achieved, and development of the deep processing industry of the coal pitch is promoted.

Owner:鞍山中特新材料科技有限公司

Preparation method of high-purity nuclear graphite

InactiveCN104495799AControllable densityControlled Flexural StrengthFlexural strengthThermal expansion

The invention discloses a preparation method of high-purity nuclear graphite, and provides graphite, wherein the ash content of the graphite is less than about 300 ppm; the boron equivalent of the graphite is less than about 5.0 ppm; and the isotropous ratio of the graphite is about 0.85-1.5, which is calculated by dividing the CTE (Coefficient of Thermal Expansion) in the crosscutting texture direction by the CTE in the texture direction. The preparation method disclosed by the invention comprises the following steps of: grinding uncalcined needle coke into fine powder, mixing the fine coke powder with an adhesion agent, namely asphalt, then, grinding the mixture to form moulding powder, uniformly moulding the powder to form an expected shape of a graphite part, and roasting, densifying and graphitizing the blank product so as to obtain high-purity graphite having high isotropy. The high-purity nuclear graphite prepared by the invention is free from impurities and still has improved isotropy and controllable average density and bending strength; and thus, the high-purity nuclear graphite can be applied to a new generation of nuclear fission and ultra-high-temperature reactors.

Owner:林前锋

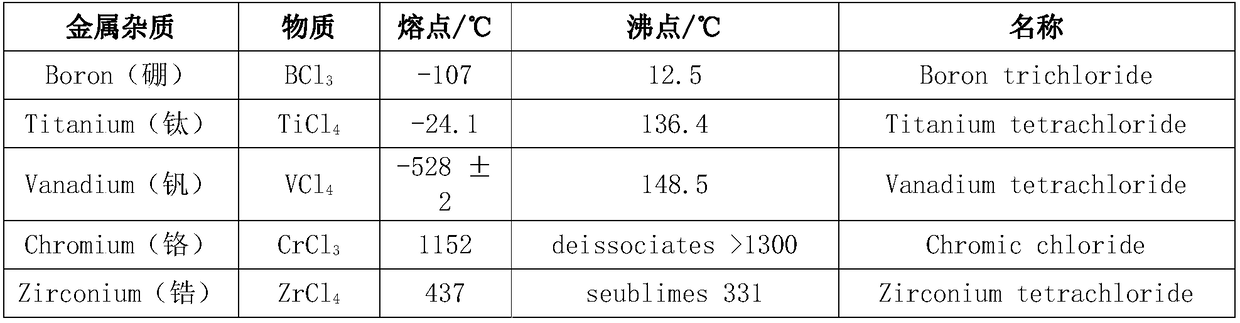

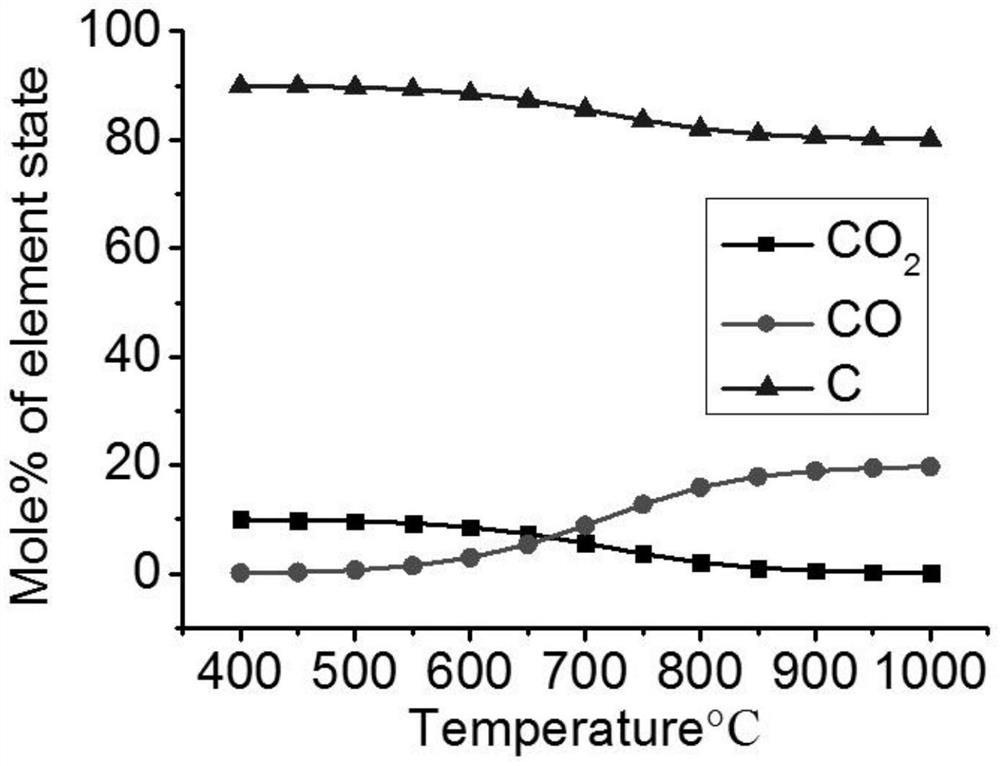

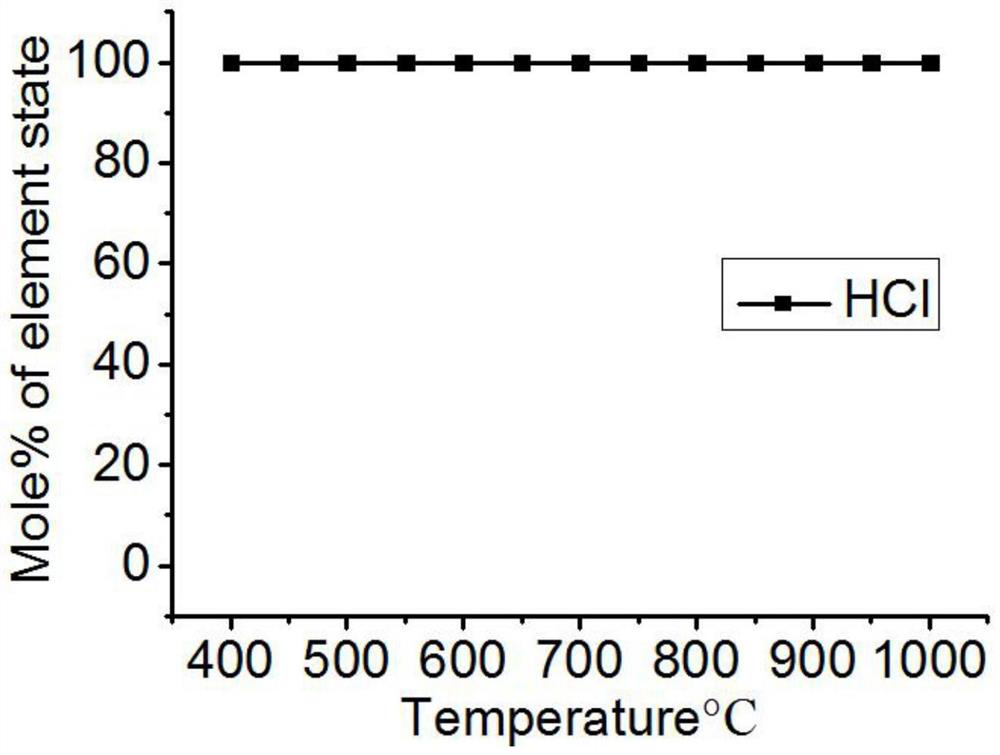

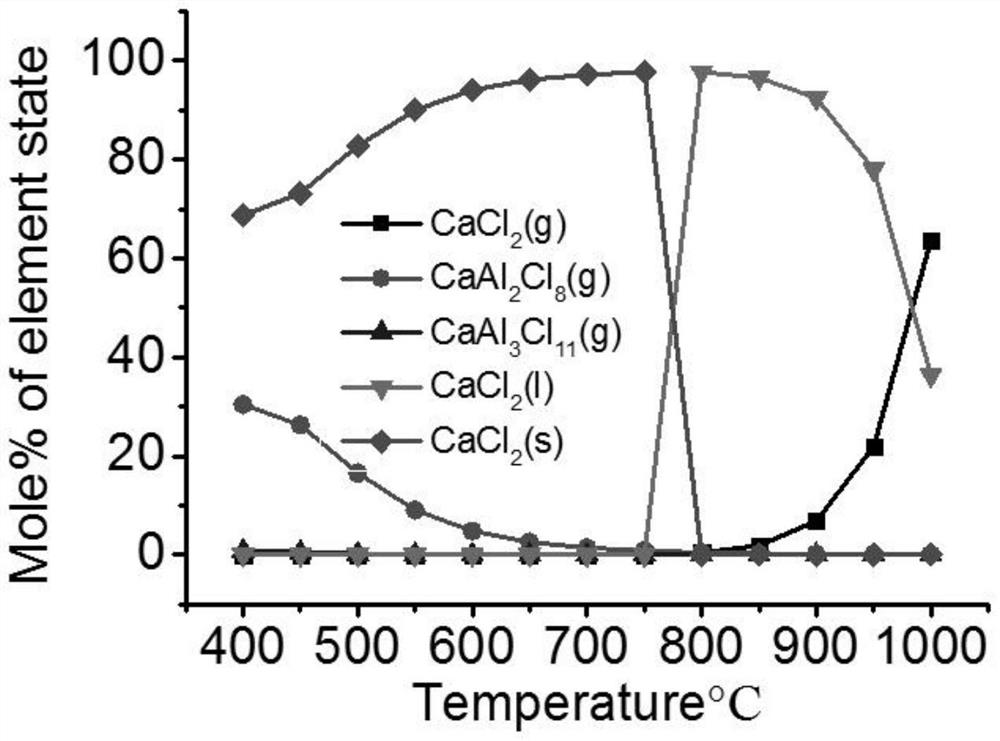

Treatment method of recommissioned radioactive nuclear graphite

PendingCN113257450ATo achieve decontamination effectRadioactive decontaminationMetal chlorideNuclear chemistry

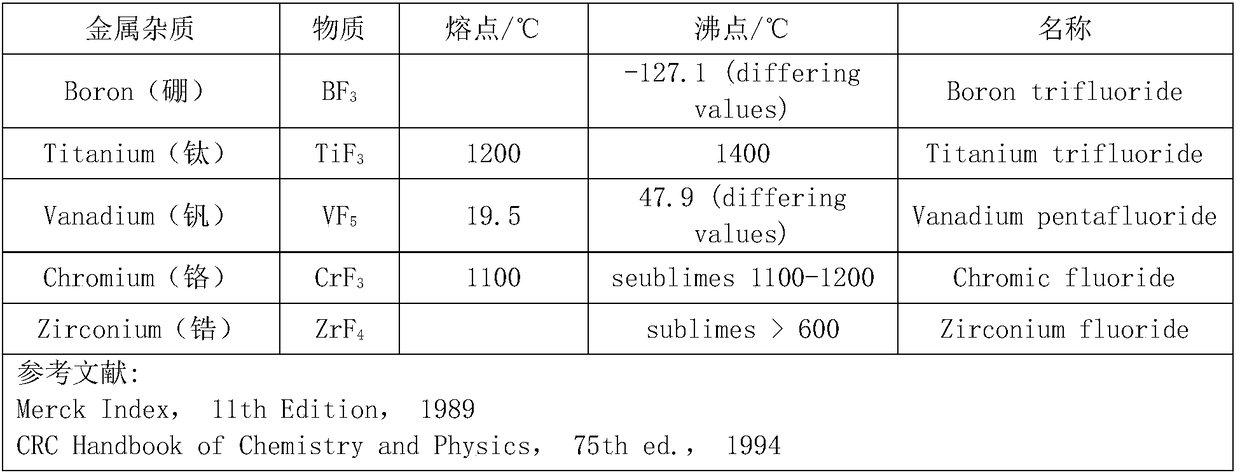

The invention relates to the technical field of radioactive graphite treatment, in particular to a treatment method for treating radioactive graphite. The treatment method comprises the following steps: step 1, crushing a decommissioned nuclear graphite block into powder to obtain nuclear graphite powder; step 2, weighing a certain amount of chlorine source, and mixing the chlorine source with the nuclear graphite powder; and step 3, heating the powder mixed in the step 2 under the mixed atmosphere of inert gas and oxygen for heat treatment. The decommissioned nuclear graphite and a certain amount of chlorine source are mixed and then are heated in an oxygen-containing atmosphere, <14>C is combined with oxygen to form CO and CO2 gases, a large amount of inert graphite matrixes are reserved, <3>H reacts with chlorine elements and the like under the action of high temperature to generate HCl, the radioactive metal in the nuclear graphite can react with the chlorine element to generate a metal chloride with a lower boiling point, and the metal chloride is volatilized at a certain temperature, so that the metal chloride is separated from the nuclear graphite, generated CO2, HCl and gaseous chloride are treated after heat treatment, concentration and enrichment of nuclides are completed, and the decontamination effect of various nuclides of the nuclear graphite is achieved.

Owner:BEIJING JIAOTONG UNIV

Spherical graphitic corpuscule composite carbon material and preparation thereof

ActiveCN101298326BHigh electrochemical capacityGood chemical stabilityCharge dischargeMaterials science

Owner:LUOYANG GUANQI INDAL & TRADE +1

High-temperature gas-cooled reactor internal components with large-scale nuclear graphite material and preparation method

The invention relates to a large-dimension nuclear graphite material for a reactor internal of a high-temperature gas cooled reactor and a preparation method. The method comprises the following stepsof: raw material selection, grinding, mixing-kneading, forming, roasting, 0 to 1 time of impregnation, and graphitization / nuclear-pure processing. The large-dimension nuclear graphite material is simple in process and convenient to operate and adopts little production equipment, so that cost is further reduced; the large-dimension nuclear graphite material is convenient to popularize and apply andis applicable to large-scale production; compared with the prior art, the provided product has a large scale and has neutron irradiation performance data.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

High purity nuclear graphite

Owner:GT ACQUISITION HLDG LLC

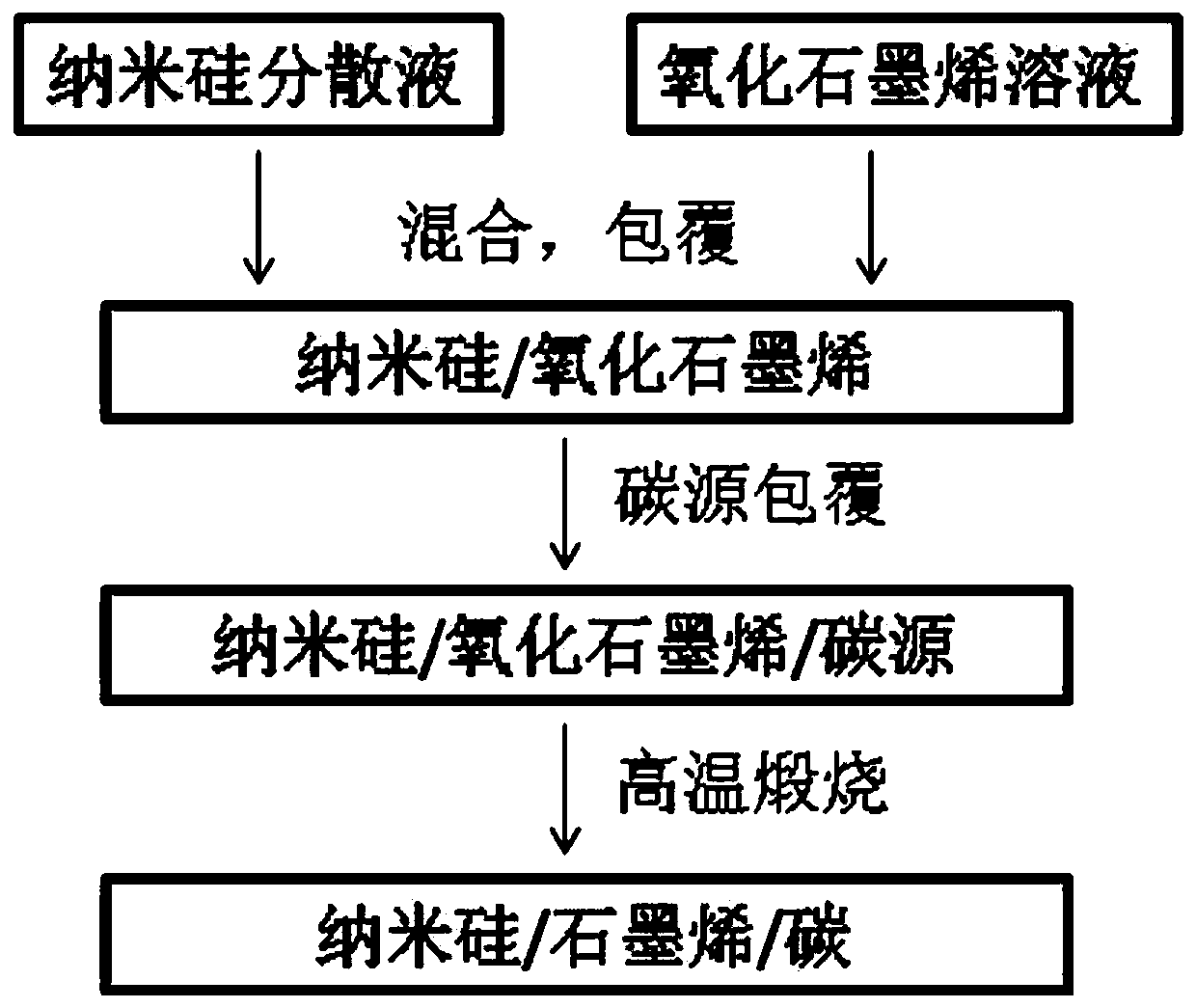

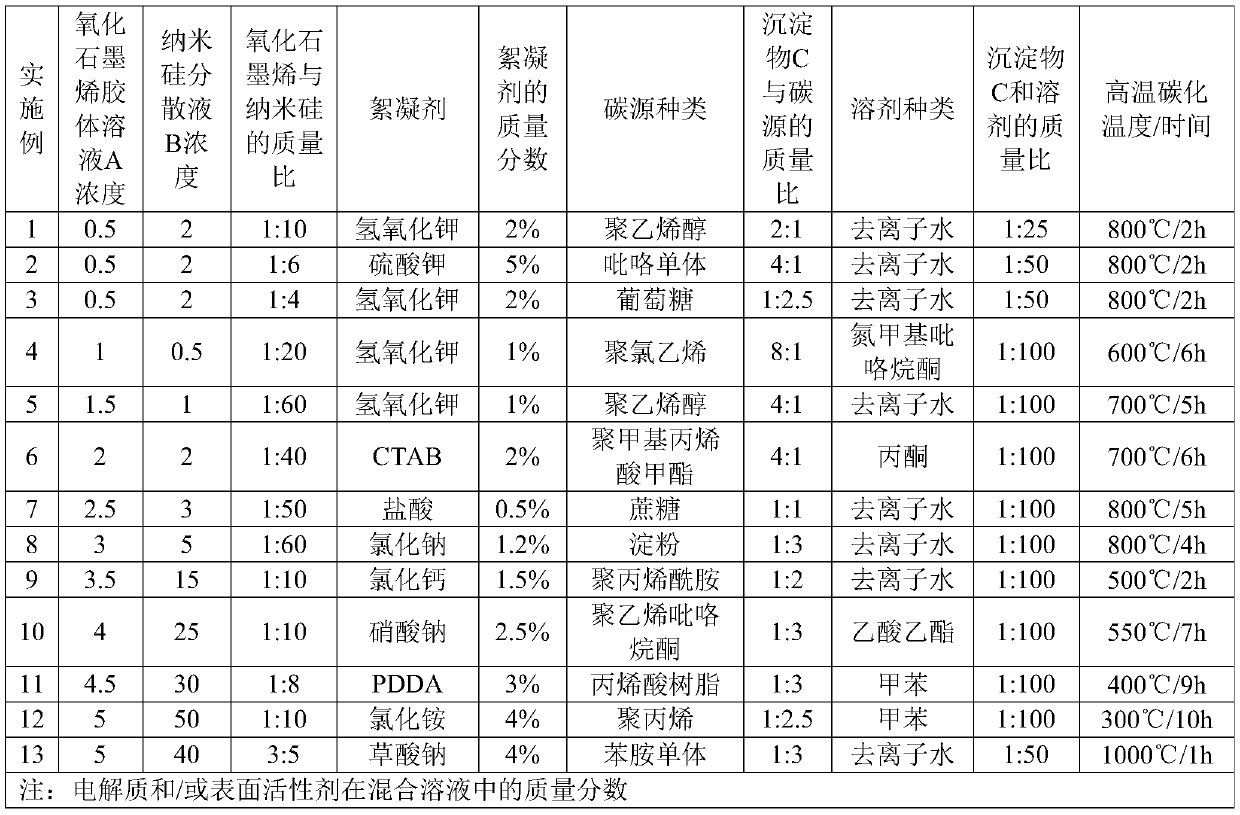

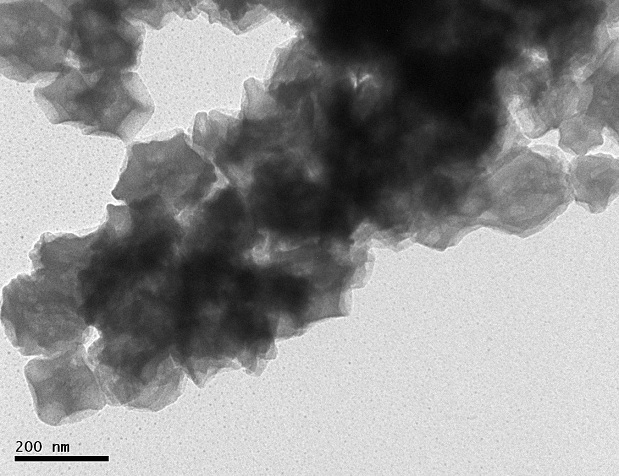

A kind of graphene composite material and preparation method thereof

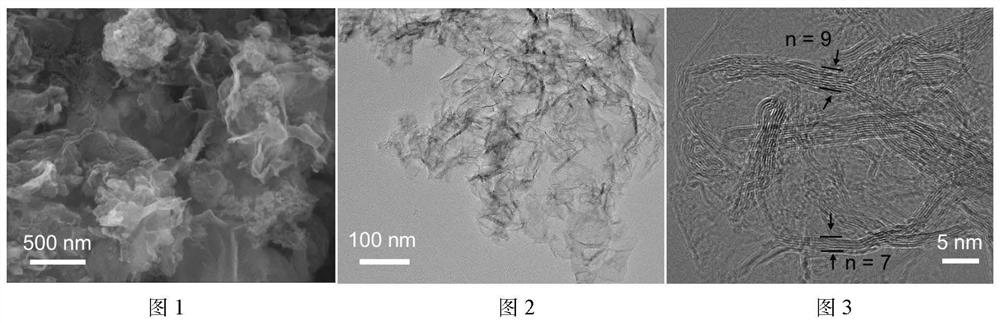

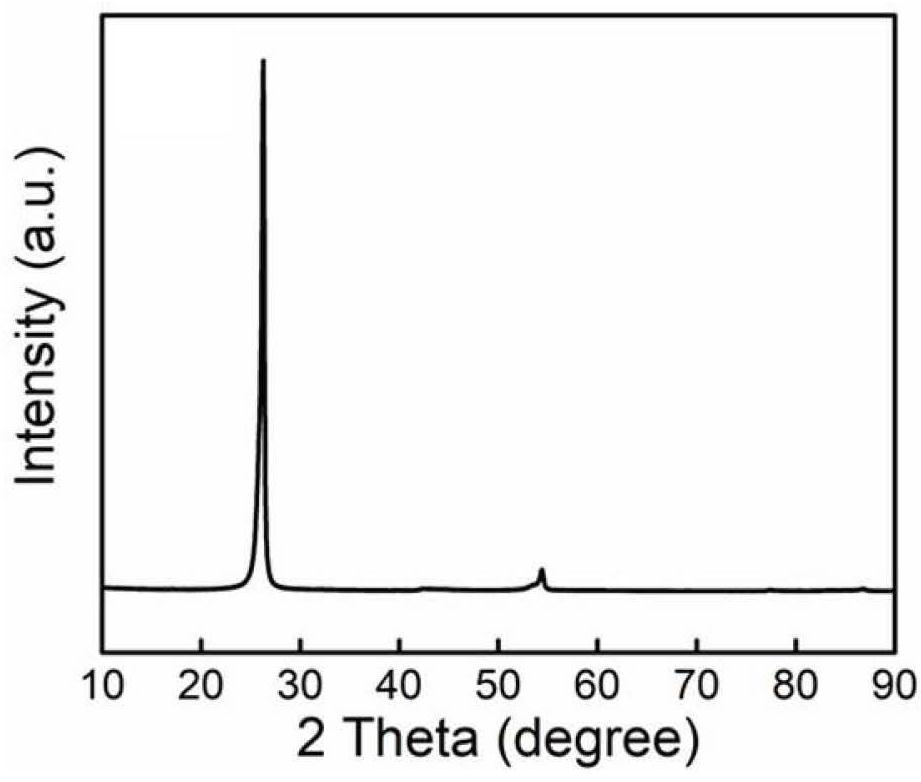

ActiveCN108232139BConducive to inhibiting damageAvoid reunionMaterial nanotechnologyCell electrodesLithium-ion batteryLithium electrode

The invention discloses a graphene composite material and a preparation method thereof. The graphene composite material has a multi-level core shell coating structure, wherein the nanometer silicon isused as the core, the graphene is used as the first coating layer, the carbon is used as the second coating layer, the surface of the nanometer silicon is coated with the graphene, and the surface ofthe graphene is coated with the carbon. The graphene has high conductivity, mechanical strength and flexibility, and provides a conductive network, an elastic space and a folded structure for the nanometer silicon, thereby being good for inhibiting the damage caused by the volume expansion of the silicon; the carbon can maintain the internal structure stability of the composite material, and prevent the composite electrode material from agglomerating and falling down. The composite electrode material has better stability and conductivity performance when being used for a lithium ion battery.The preparation method is simple in reaction and easy to control, and has a extensive application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Three-dimensional graphene composite material with core-shell structure for capacitive desalination electrode and preparation method thereof

ActiveCN107089707BSuppress stackingControl nitrogen contentDispersed particle separationWater/sewage treatment apparatusCapacitanceElectrostatic interaction

The invention relates to a three-dimensional graphene composite material with a core-shell structure for a capacitive desalination electrode and a preparation method thereof. The method uses metal-organic framework as the core and graphene as the shell; through the electrostatic interaction between a certain concentration of graphite oxide solution and the metal-organic framework at a certain temperature, the precursor of the three-dimensional composite material with a core-shell structure is formed; further carbonization, pickling A three-dimensional graphene composite material is obtained; the composite material, acetylene black and polytetrafluoroethylene emulsion are evenly mixed, coated on graphite paper, and dried to obtain a capacitive desalination electrode. The process of the invention is fast, simple, low in cost and can be produced in batches. The obtained electrode has high specific surface area, good conductivity and wettability, and has potential application prospects in capacitive desalination.

Owner:SHANGHAI UNIV

A kind of nuclear graphite material preparation method

ActiveCN104401982BGood for in-depth purificationReduce the presence of impuritiesHalohydrocarbonRoasting

The invention discloses a nuclear graphite material preparation method including the following steps: (1) mixing and kneading; (2) grinding; (3) isostatic compaction; (4) roasting, to be more specific, baking treatment of the product obtained by the step (3) in an atmosphere furnace introduced with halogen or halogenated hydrocarbon at the treatment temperature of 800 to 1100 DEG C; (5) dipping; and (6) roasting; according to the method, in the roasting process, a halogen or halogenated hydrocarbon purified gas is introduced, a purification procedure is inserted in without reduction of the common preparation step, the cost of purification can be greatly reduced, in the roasting process, asphalt volatile components may cause many holes in graphite blocks, the holes greatly facilitate the purified gas to enter into the graphite blocks for purification so as to facilitate further purification of nuclear graphite blocks and great reduction of impurities and boron equivalent; the nuclear graphite material preparation method has the advantages of simple process, convenient operation, less production equipment, can further reduce the cost, and is convenient in popularization and application, and suitable for mass production.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

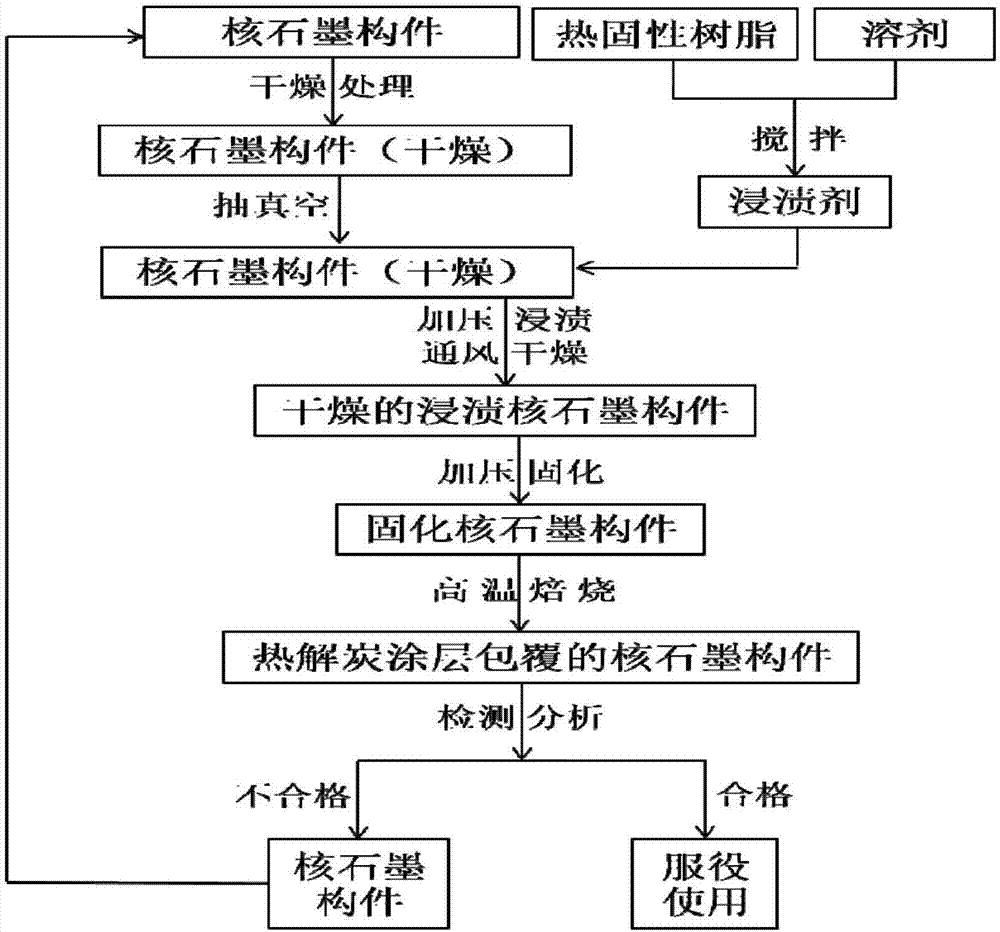

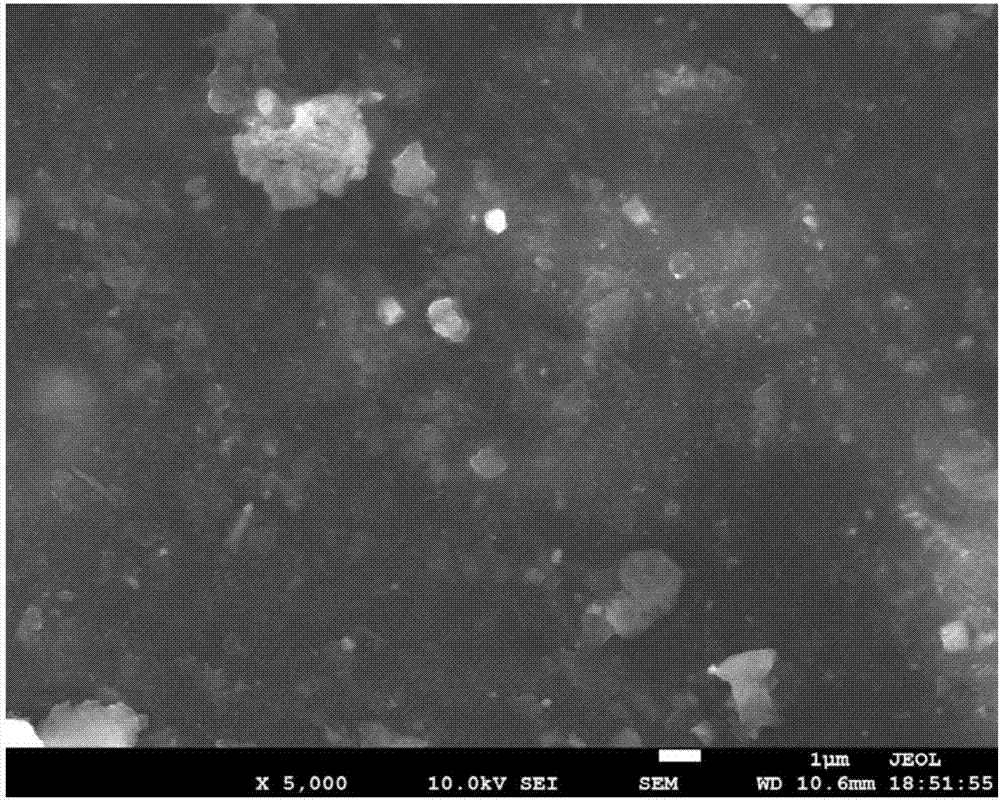

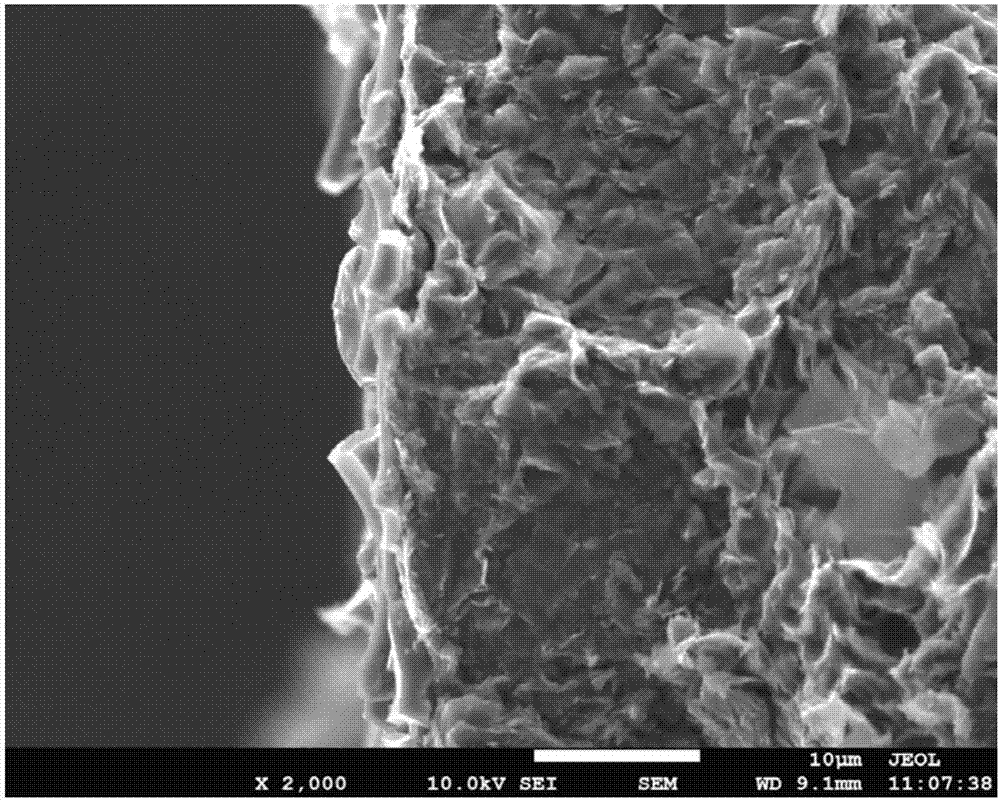

Preparation method of graphite surface pyrolytic carbon coating for molten salt reactor

InactiveCN107887045AImprove compactnessReduce porosityGraphiteNuclear energy generationPyrolytic carbonSolvent

The invention discloses a preparation method of a graphite surface pyrolytic carbon coating for a molten salt reactor. The preparation method comprises the steps: adding thermosetting resin into a solvent to be dissolved to prepare a thermosetting resin dispersion liquid; vacuumizing a nuclear graphite member in impregnation equipment; adding the thermosetting resin dispersion liquid into the impregnation equipment, and carrying out impregnation and drying in the existence of high-pressure inert gases; and after drying, carrying out solidification under pressure and roasting treatment on the impregnated nuclear graphite member at an inert atmosphere to obtain a nuclear graphite member coated by a pyrolytic carbon coating. The preparation method has the advantages of simple process, low cost and large-scale production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

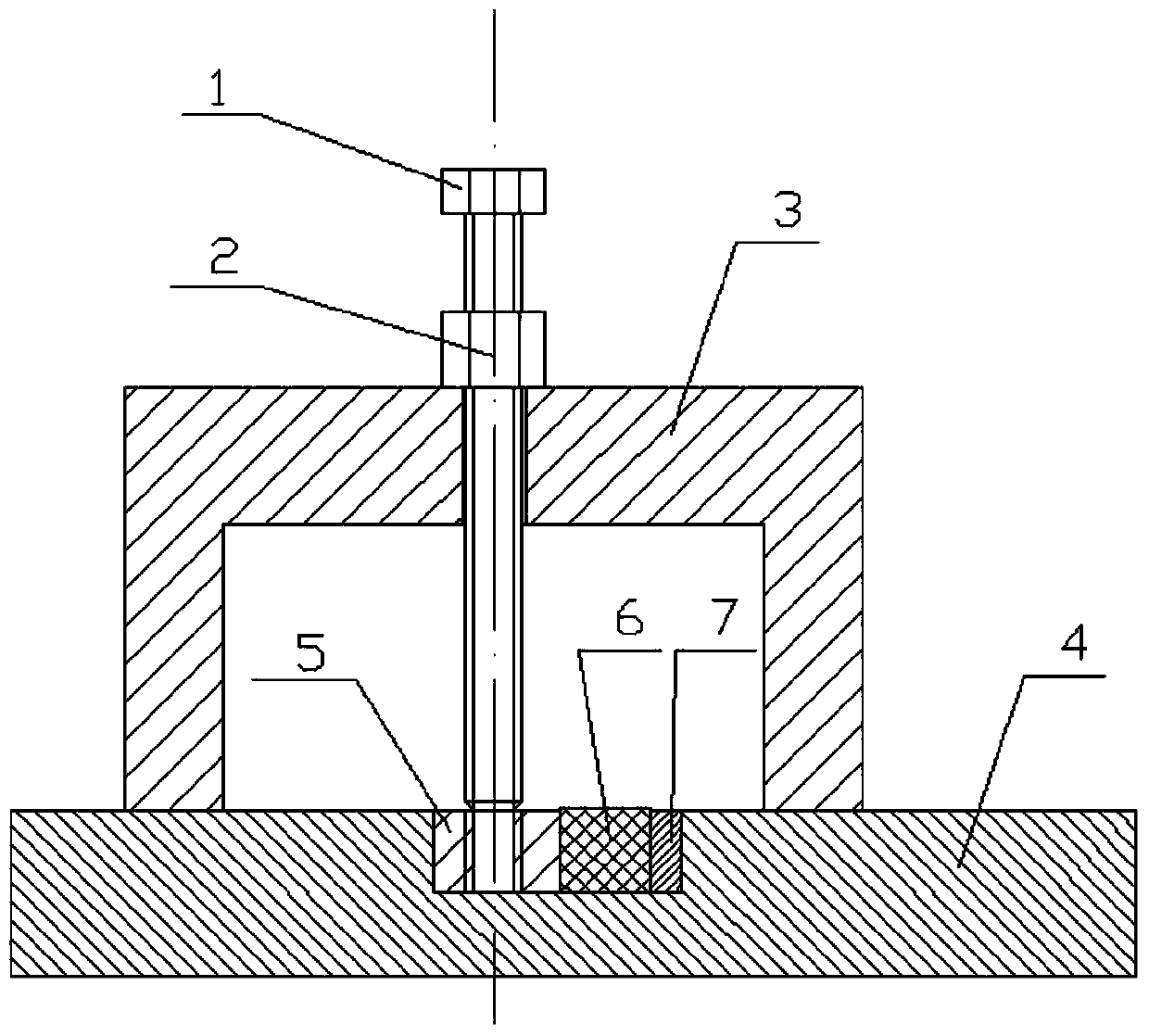

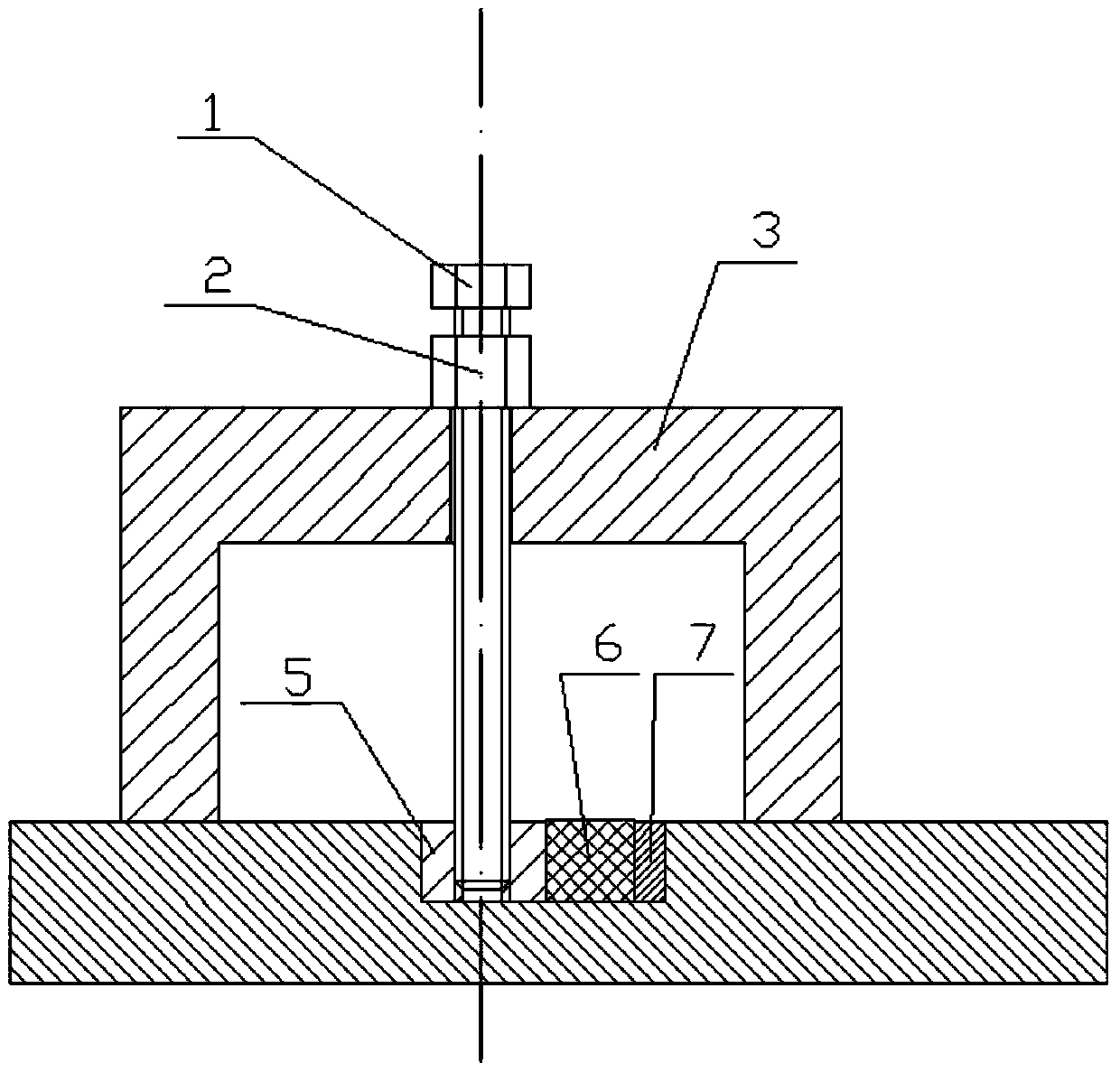

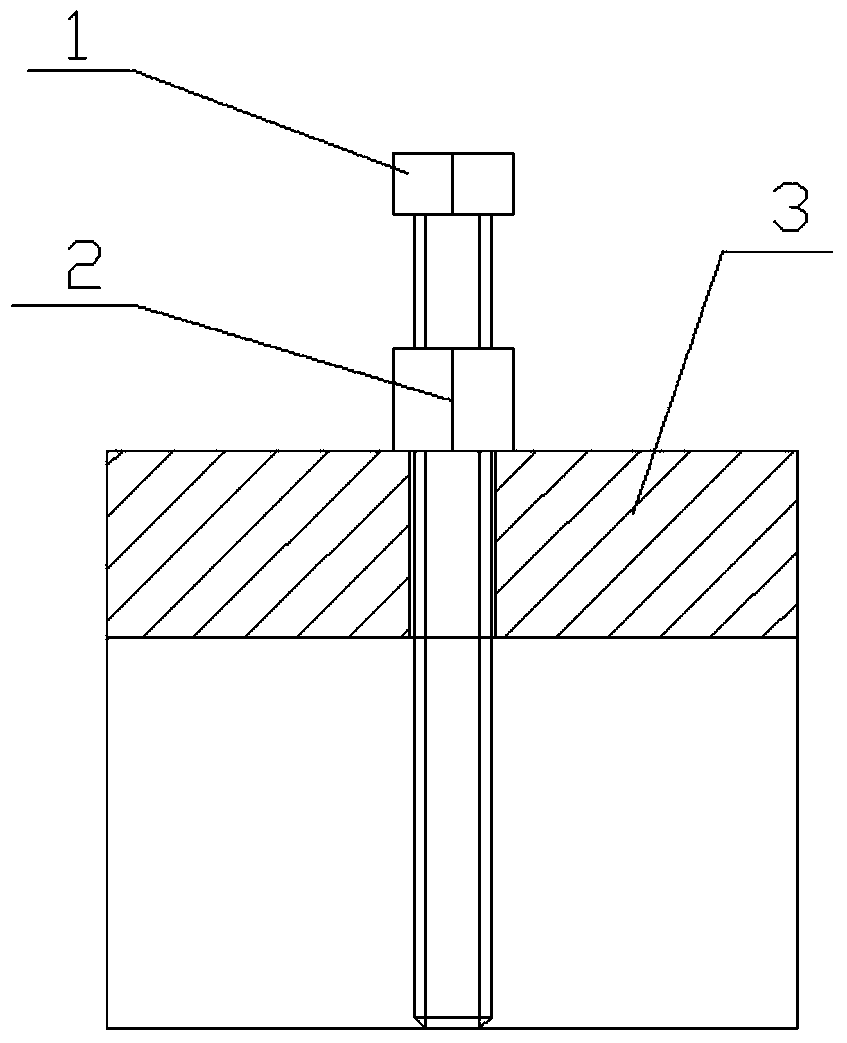

A dismantling device for nuclear power plant metal graphite sealing ring

ActiveCN106808406BQuick releaseComplete disassemblyMetal-working hand toolsNuclear powerArchitectural engineering

The invention belongs to the technical field of nuclear power and particularly discloses a nuclear power plant metal graphite seal ring removal device, comprising a portal frame mounted on a seal channel, a lift bolt inserted in the portal frame, and a nut sleeving the lift bolt; the nut is arranged above the portal frame, the top of the lift bolt is inserted into the top of the portal frame, and the bottom of the lift bolt is arranged above a seal ring outer metal frame mounted in a ring groove of the seal channel. The nuclear power plant metal graphite seal ring removal device is simple and reliable in structure and allows seal rings of different sizes to be removed quickly, completely and safely, and the problem that removing in engineering is not easy is solved.

Owner:JIANGSU NUCLEAR POWER CORP

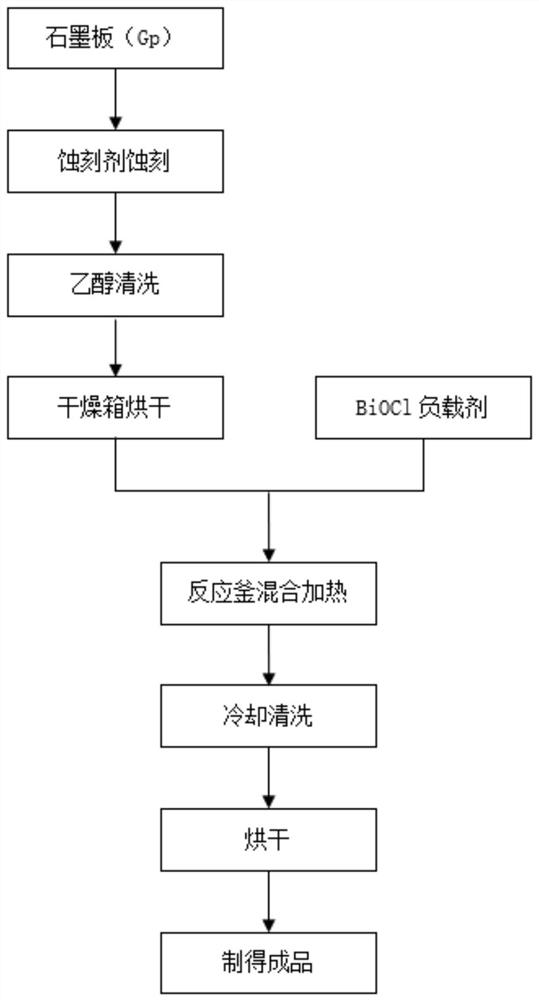

Preparation method of bismuth oxychloride graphite composite electrode material

PendingCN114105263AOptimize process flowLow costDispersed particle separationWater/sewage treatmentHydration reactionEtching

The invention discloses a preparation method of a bismuth oxychloride graphite composite electrode material. The preparation method comprises the following steps: firstly, putting a graphite plate into an etching solution for chemical etching; then cleaning and drying; dissolving bismuth nitrate pentahydrate, potassium chloride and a dispersing agent into ethylene glycol at room temperature, stirring, and transferring into a container to serve as a bismuth oxychloride loading agent for later use; putting the dried graphite plate into a reaction kettle, transferring the bismuth oxychloride loading agent for later use into the reaction kettle, putting the reaction kettle into a drying box for water bath heating, promoting bismuth ions to hydrolyze under the participation of chloride ions at high temperature, and forming bismuth oxychloride crystal nucleuses on the surface of the graphite plate; taking out the reaction kettle, cooling, and washing the graphite plate loaded with the bismuth oxychloride crystal nucleus until only one layer of firmly loaded bismuth oxychloride is left; and drying in a drying oven to obtain the bismuth oxychloride graphite electrode composite material. According to the preparation method, the bismuth oxychloride powder which is difficult to load originally is uniformly and completely loaded on the graphite plate by utilizing a hydrothermal method, and the chemical adsorption activity of the loaded material is maintained to the greatest extent.

Owner:JIANGSU UNIV OF SCI & TECH

High-strength carbon-based material based on combustion synthesis of graphene and preparation method of high-strength carbon-based material

The invention discloses a high-strength carbon-based material based on combustion synthesis of graphene and a preparation method, and belongs to the field of carbon-based materials. The invention aims to solve the problems of complex preparation process and poor mechanical property of the existing carbon-based material. Graphene or doped graphene prepared by a high-temperature self-propagating combustion synthesis method is used as a raw material, and the isotropic high-strength carbon-based material is prepared through high-temperature sintering. The method disclosed by the invention is relatively simple to operate and easy for batch production, and the prepared carbon-based material has the advantages of high strength, electric conduction, heat conduction, light weight and the like, and can be used as nuclear graphite, a tool electrode for electric spark machining, a structural material for rocket technology, an ultrahigh-power electrode, a high-heat-conduction heat dissipation component, a high-performance crucible, a high-temperature high-performance mold and the like.

Owner:HARBIN INST OF TECH

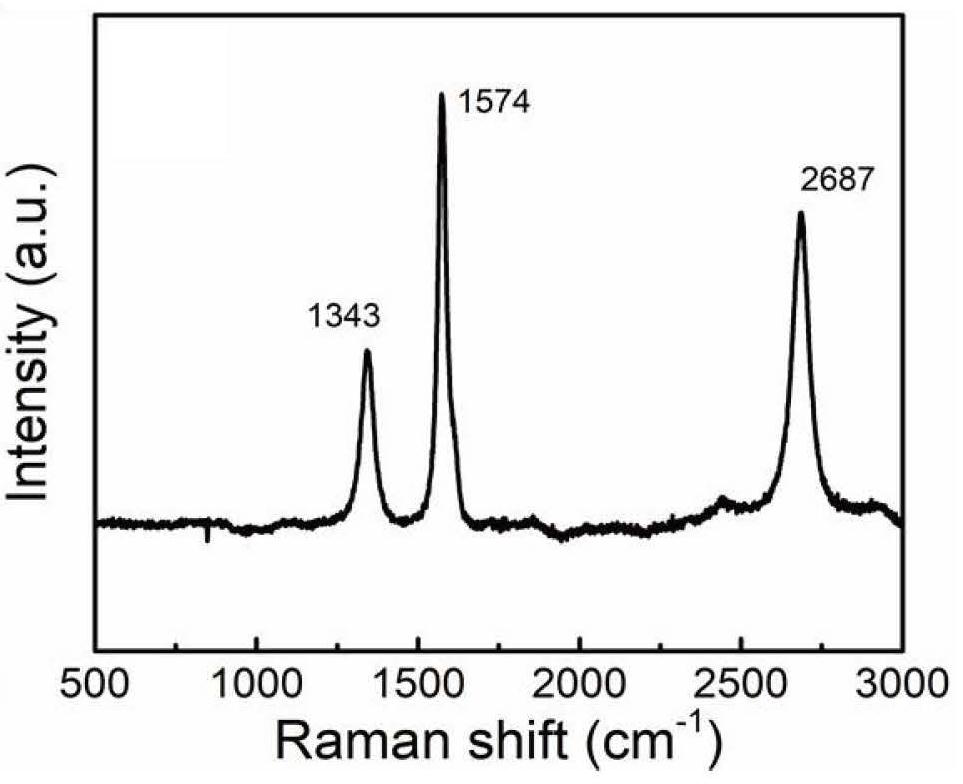

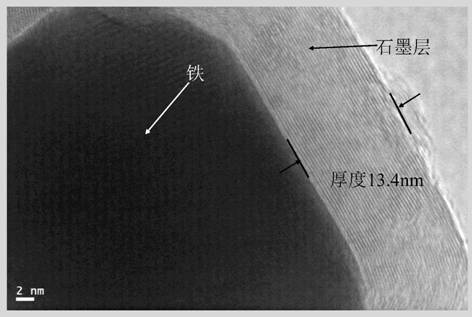

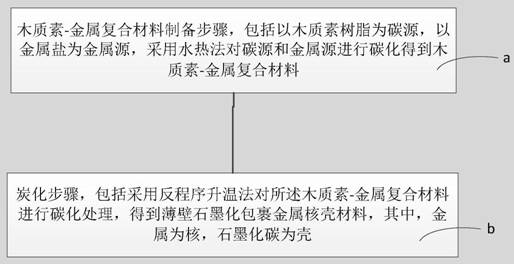

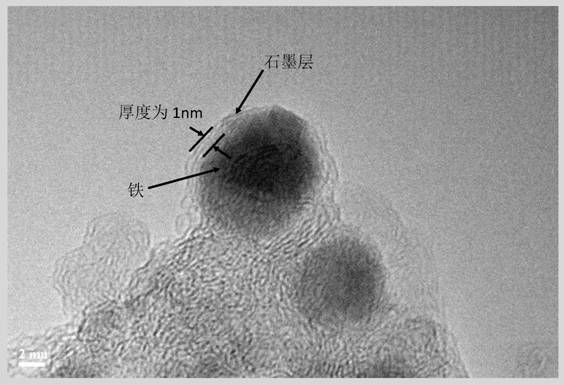

A preparation method of thin-walled graphitized carbon-wrapped metal core-shell structure material

ActiveCN108722414BLarge specific surface areaImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsGraphite carbonCarbon source

The invention provides a method for preparing a thin-walled graphitized carbon-wrapped metal core-shell structure material, comprising: a lignin-metal composite material preparation step, including using lignin resin as a carbon source, metal salt as a metal source, and hydrothermal Carry out carbonization to carbon source and metal source by method to obtain lignin-metal composite material; And carbonization step, comprise adopting inverse programmed temperature method to carry out carbonization treatment to described lignin-metal composite material, obtain thin-walled graphitization wrapping metal core-shell material , in which metal is the core and graphitized carbon is the shell. The invention provides a method for preparing a thin-wall graphitized carbon-wrapped metal core-shell structure material with simple operation and low cost, and the performance of the thin-wall graphitized carbon-wrapped metal core-shell structure material prepared by the method is improved.

Owner:JIANGSU UNIV OF TECH

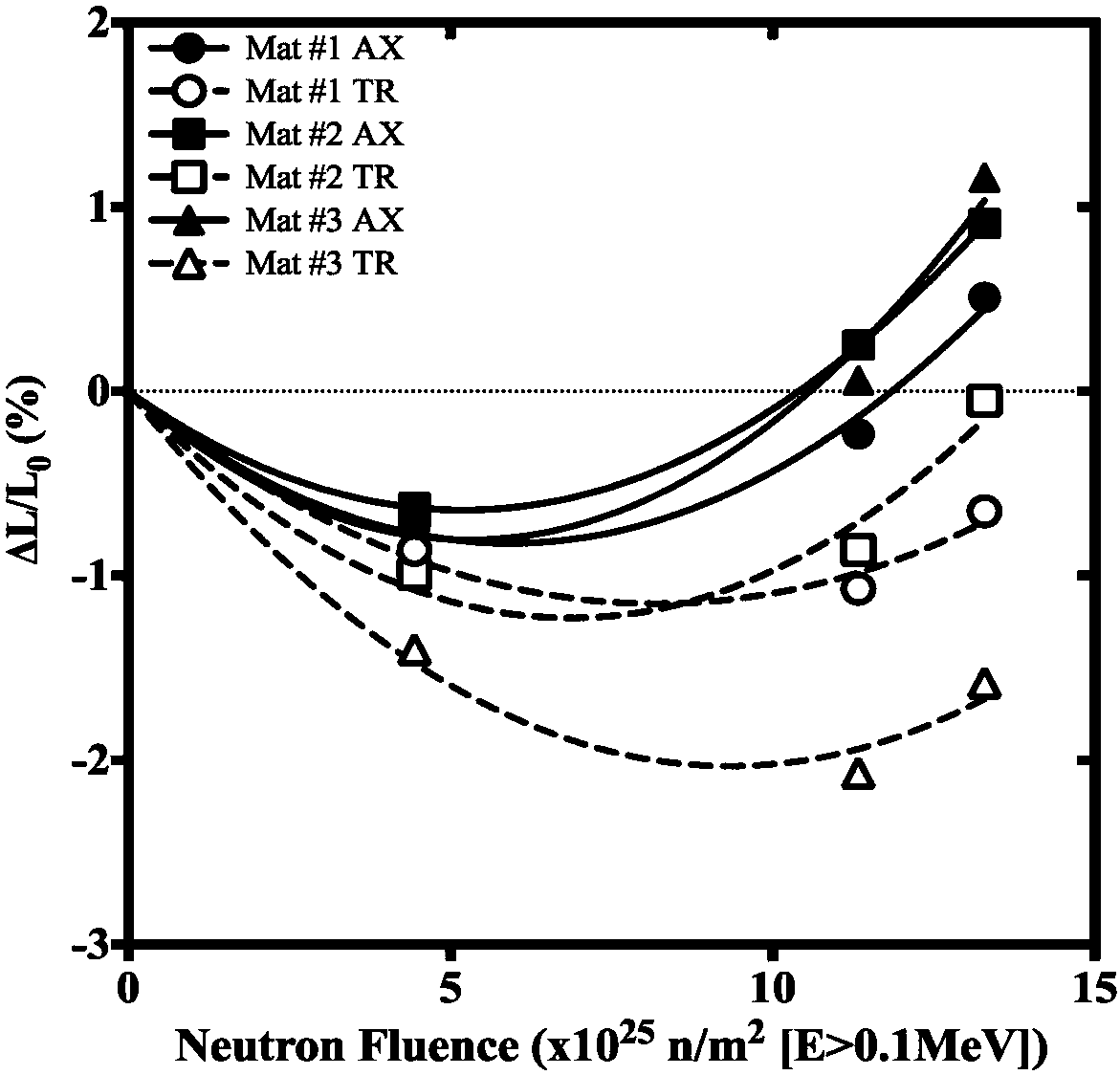

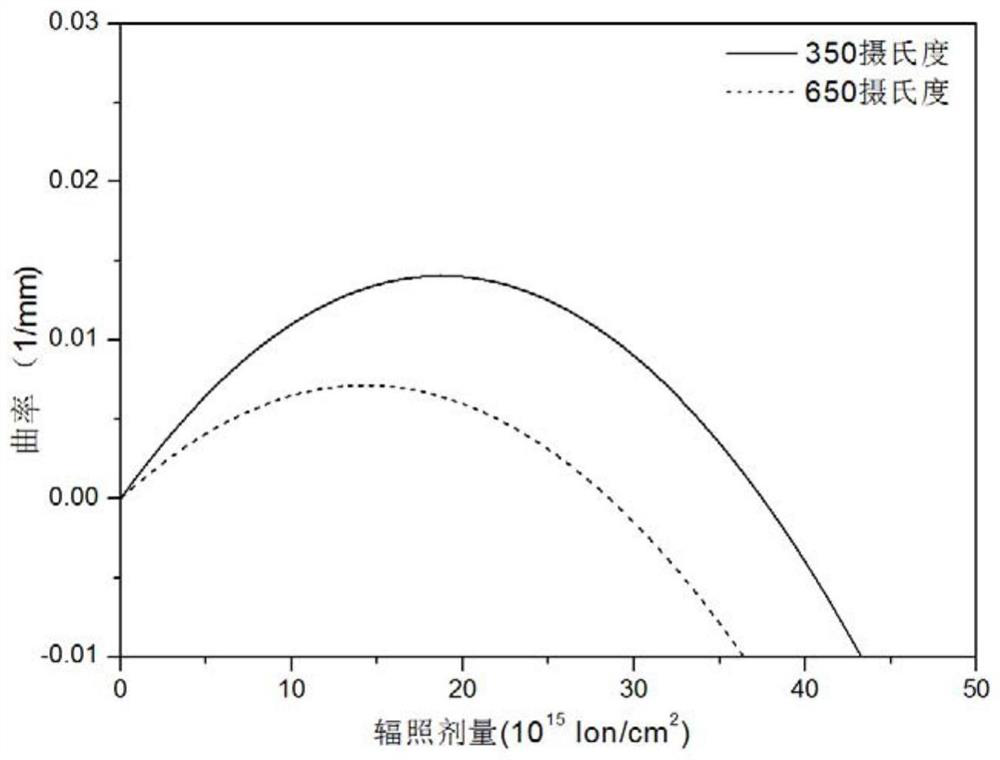

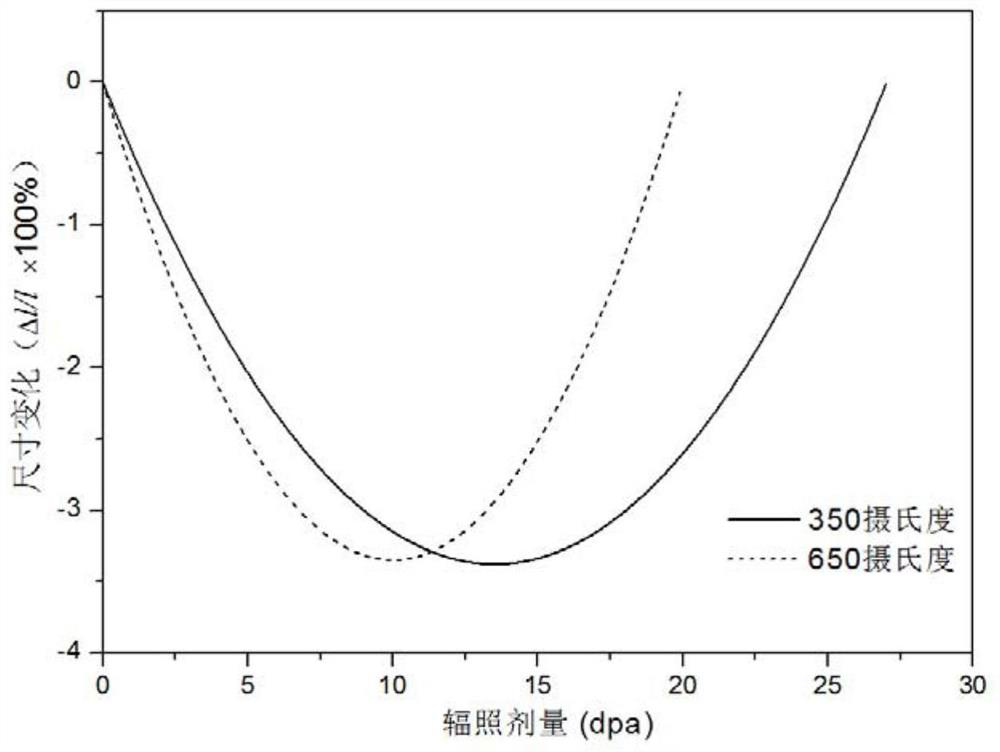

A method for measuring the size change behavior of nuclear graphite under irradiation environment using ion beam irradiation

ActiveCN109916926BEasy to measureQuick measurementMaterial analysis using wave/particle radiationAtomic physicsRadiochemistry

The invention provides a method for measuring the dimensional change behavior of nuclear graphite in an irradiation environment by using ion beam irradiation, comprising the following steps: 1) being beneficial to ion beam irradiation of a nuclear graphite sample of a certain size, so that the irradiated nuclear graphite The shape of the sample changes; 2) measure the shape change, and use the performance characteristics of the nuclear graphite sample to calculate the size change of the nuclear graphite sample under the irradiation environment by mathematical methods; and 3) by controlling the change of the ion beam irradiation dose, And repeat the above process to obtain the size change behavior curve of the nuclear graphite sample under the irradiation environment. The method provided by the present invention has the advantages of low cost and short period compared with the method of testing in the material test pile, and can be used to optimize the production raw materials and process in the nuclear graphite research and development process, and can also be used as a quality control method for nuclear graphite. It can be used as a means of sampling and analyzing graphite core samples of active reactors, and has high economic value and good application prospects.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Preparation method of high-density, large-scale, ultra-fine pore core graphite material for molten salt reactor

The invention provides a preparation method for high-density, large-size and ultra-fine-pore nuclear graphite materials for fused salt piles from coke aggregates 1-5 micrometers in size. The preparation method has the advantages that in the forming process, paste is compacted through vibration and ramming, calcination as well as temperature rise speeds and in-furnace temperature differences in thegraphitization process are controlled, and the shrinkage rate of graphite green bodies is further controlled, so that the technical problems that the smaller the average particle size of conventionalaggregates is, the larger the specific surface area and the surface energy of particles are, and the large-size nuclear graphite materials cannot be prepared are solved; multiple halogen gases are introduced as purification gases, and simultaneous purification in the graphitization process is realized; the method is clear in procedure, technically reliable and feasible, and suitable for large-scale production.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com