Method for preparing SiC/C ceramic composite material through hot pressing sintering

A ceramic composite material and hot pressing sintering technology, which is applied in the field of hot pressing sintering to prepare SiC/C ceramic composite materials, can solve the problems of inability to contain, and achieve the effects of high density, high mechanical strength and uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1. A method for preparing a SiC / C ceramic composite material by hot pressing and sintering, followed by the following steps:

[0050] 1). Preparation of compacted body powder:

[0051] First mix 91wt% of β-SiC (D50=0.8μm, purity ≥99%), 8wt% of aluminum nitride powder (D50=1.0μm, purity ≥99%) and 1wt% of dispersant polyethylene glycol 400 As a base material, it is added to a stirring mill lined with polyurethane, 50wt% of the base material is added with absolute ethanol, high-speed stirring (rotating speed is 120r / min) for 2h, and 10wt% of the base material is sequentially added every 1.0h 2124 phenolic resin (50wt% high-temperature pyrolysis carbon residue), 8wt% of the base material with a mass concentration of 10% PVPK90 solution, 3wt% of the base material, analytical pure oleic acid is uniformly stirred, and finally added 35wt% of the base material High-purity graphite powder (particle size 45-120μm, purity ≥99%; and also meet the following conditions: elemental ...

Embodiment 2

[0065] In step 1 of Example 1, "adding high-purity graphite powder accounting for 35 wt% of the base material" was changed to "adding high-purity graphite powder accounting for 45.5 wt% of the base material", and the rest was equivalent to Example 1. The performance test results are as follows: The bulk density is 2.76g / cm 3 , 20kgf air pressure detection did not leak, the graphite phase accounted for 49wt% of the content of other phases, the content of B, Co, Ti in the material was tested, the content of elemental boron (B) was 0.6ppm, and the content of metal cobalt (Co) At 0.02ppm, the metal titanium (Ti) content is 8ppm, which meets the element content requirements of mechanical seal materials for nuclear main pumps.

Embodiment 3

[0067] Change "91wt% of submicron β-SiC, 8wt% aluminum nitride powder" in step 1 of Example 1 to "87wt% of submicron β-SiC, 12wt% aluminum nitride powder", and the rest is equivalent to the implementation Example 1, the performance test results are as follows: the bulk density is 2.85g / cm 3 , 20kgf air pressure detection did not show leakage phenomenon, graphite phase accounted for 35.2wt% of the content of other phases, the content of B, Co, Ti in the material was detected, element boron (B) content was 0.5ppm, metal cobalt (Co) The content is 0.01ppm, and the metal titanium (Ti) content is 6ppm, both of which meet the element content requirements of mechanical seal materials for nuclear main pumps.

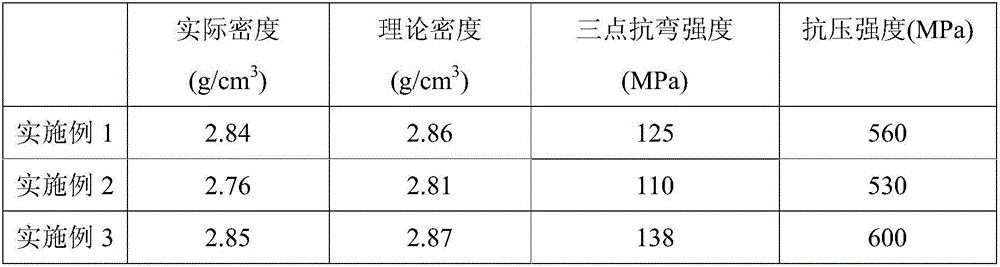

[0068] The various mechanical properties of the SiC / C ceramic composite materials obtained in the foregoing Examples 1 to 3 are described in Table 1 below.

[0069] Table 1

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com