Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Nuclear power industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

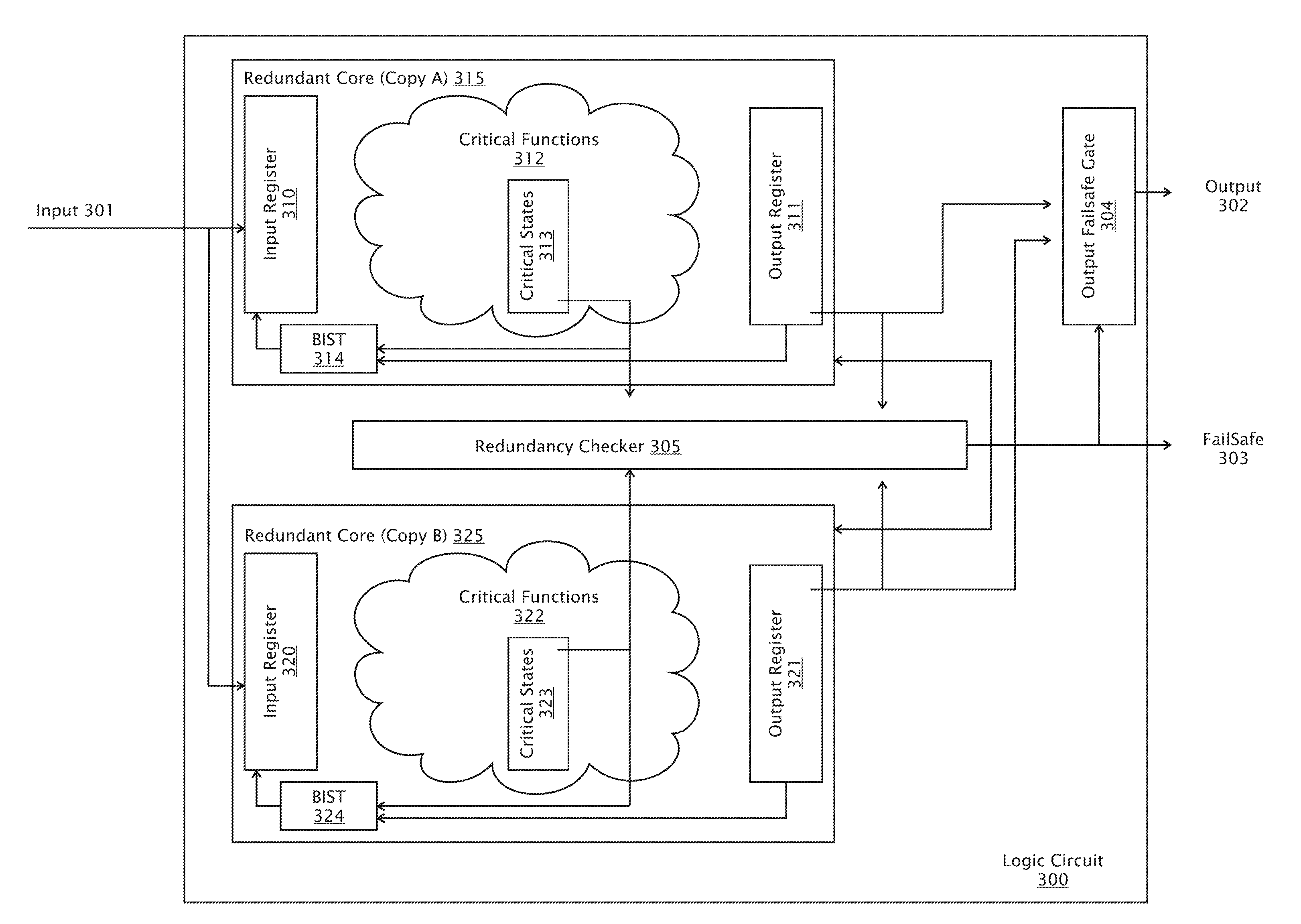

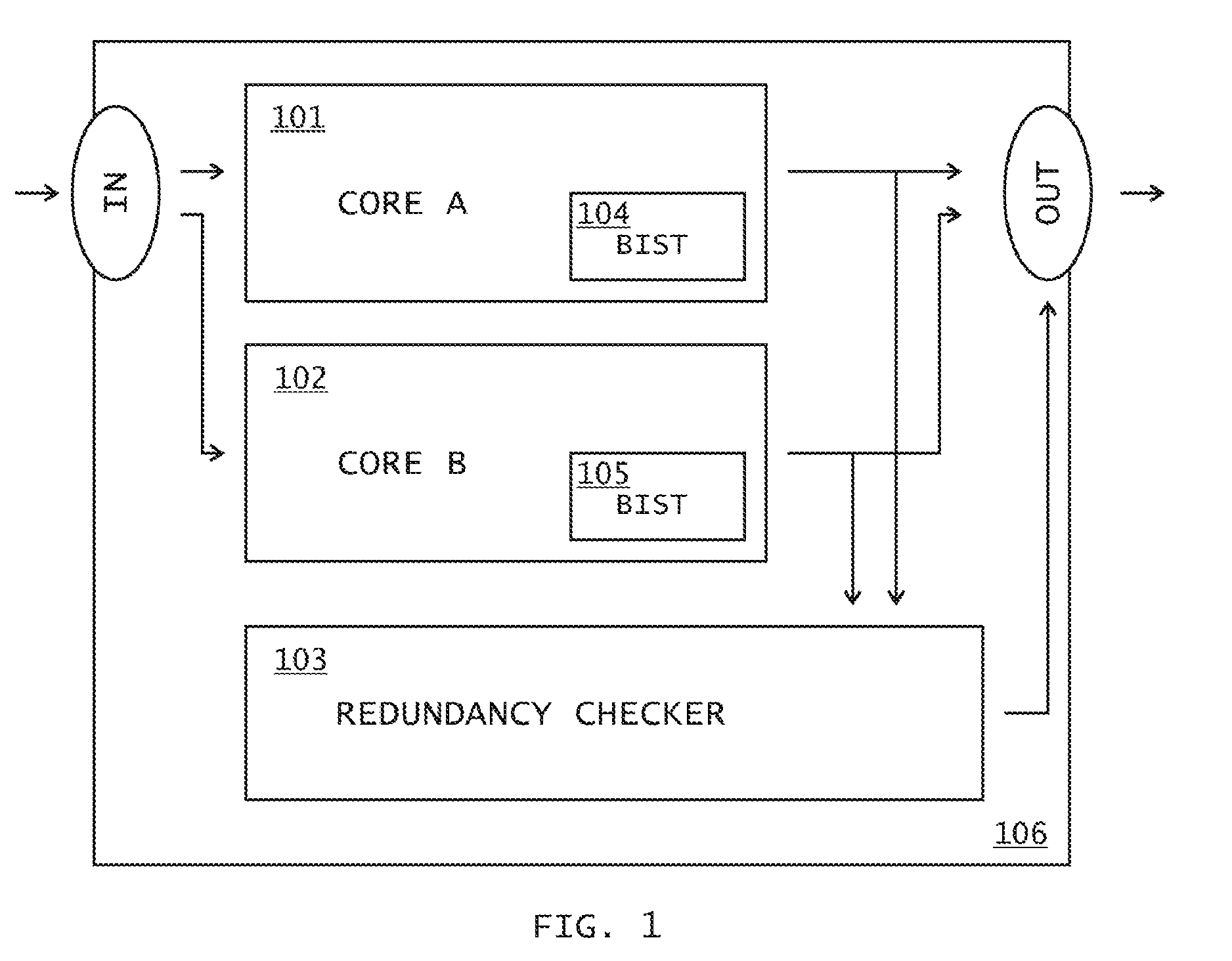

Failure Detection and Mitigation in Logic Circuits

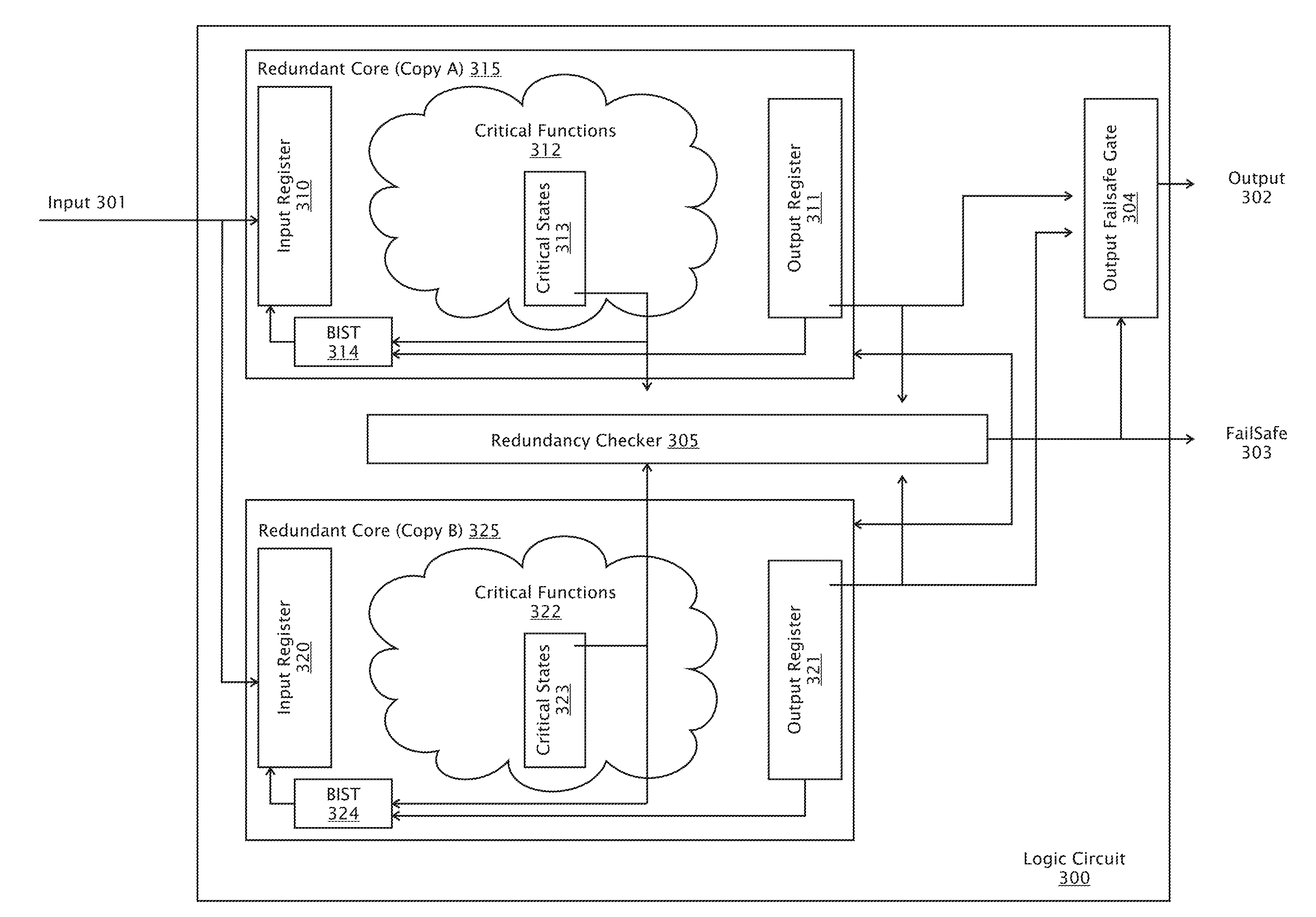

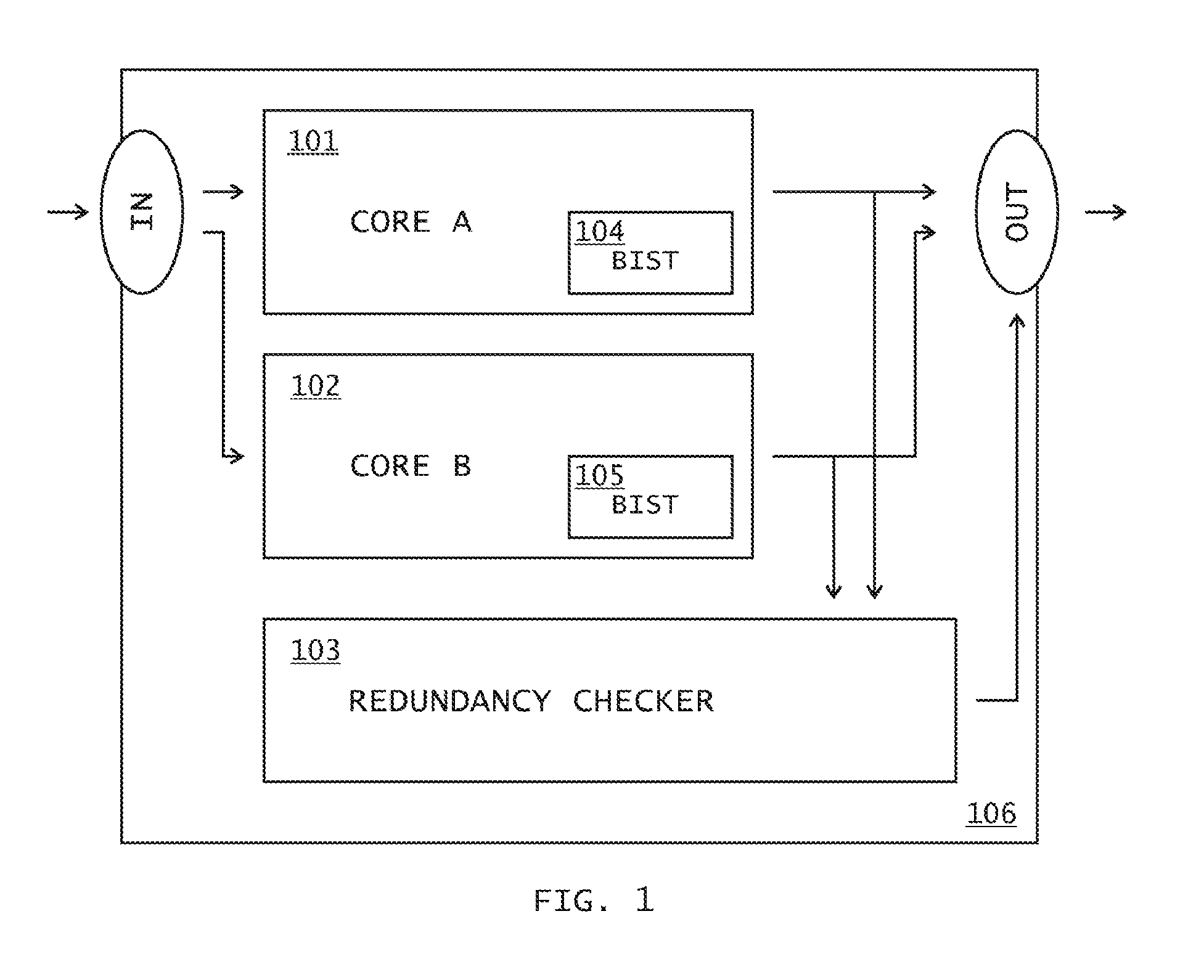

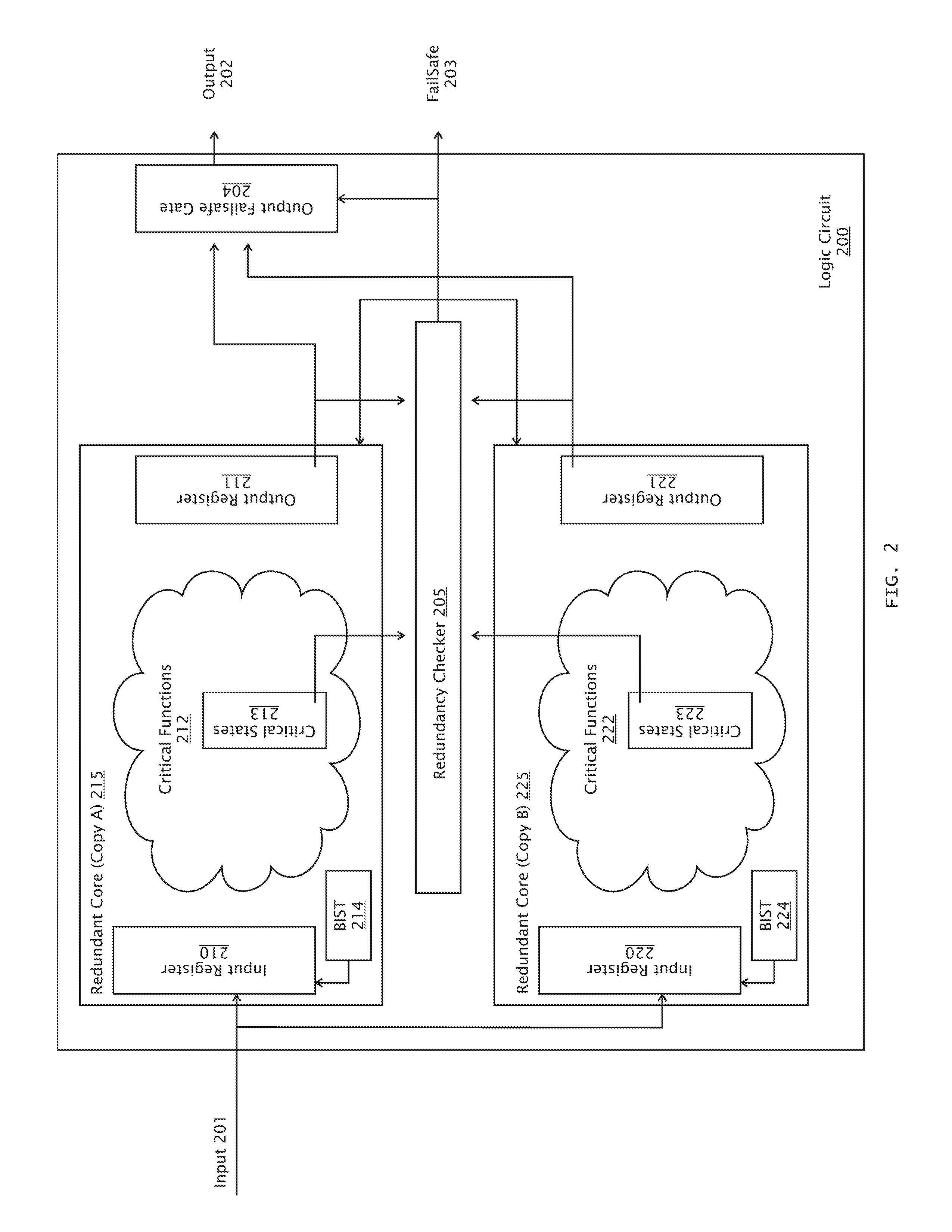

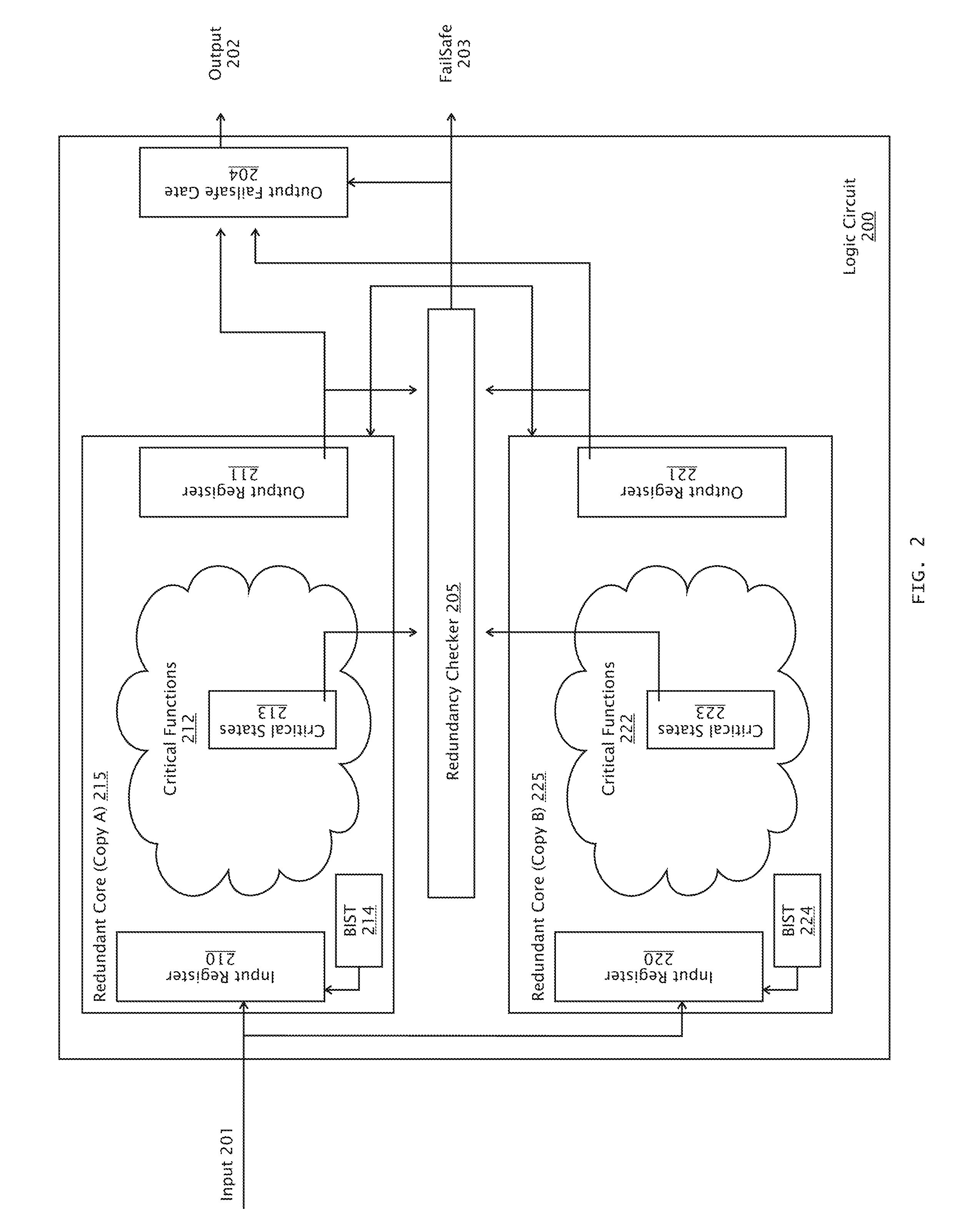

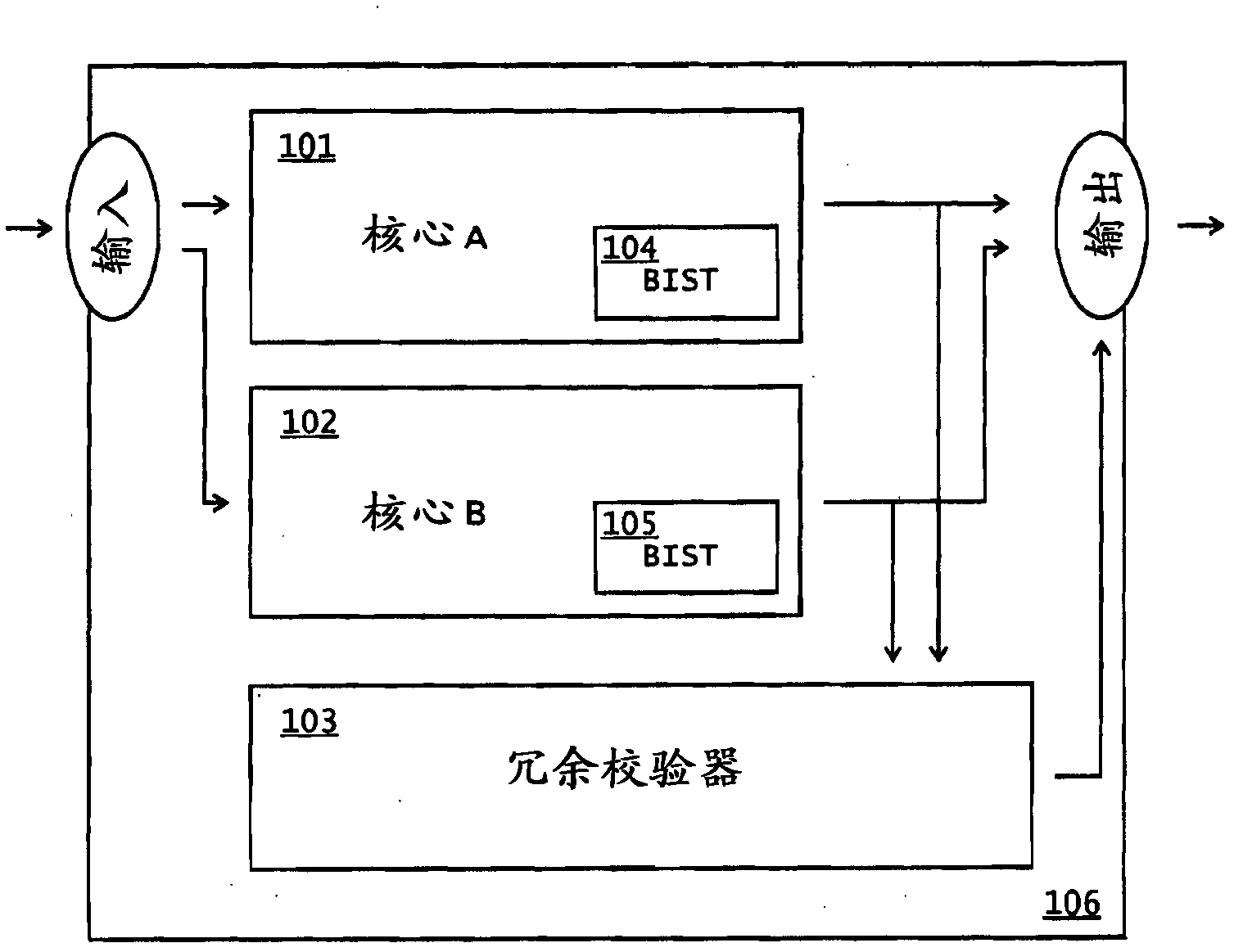

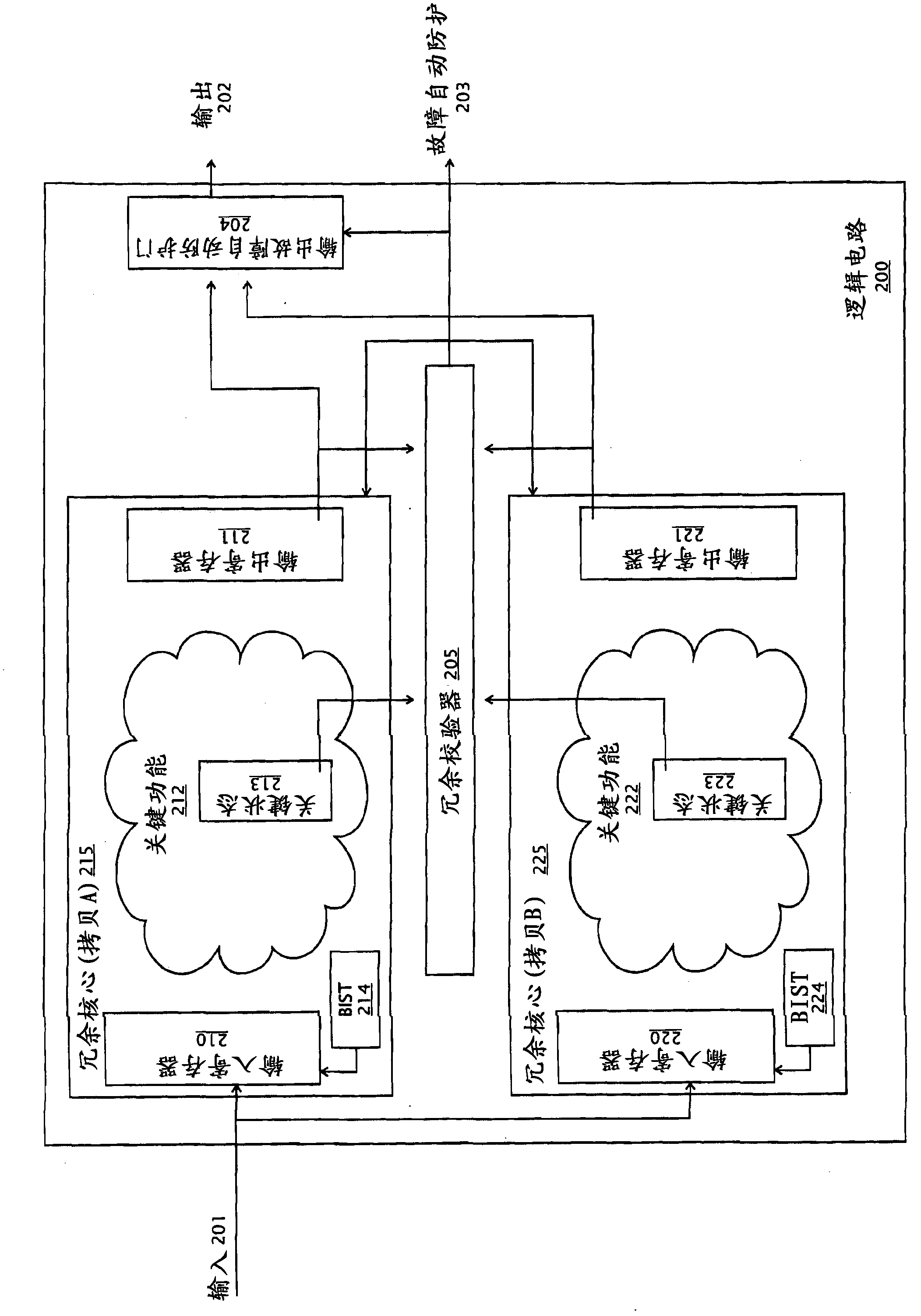

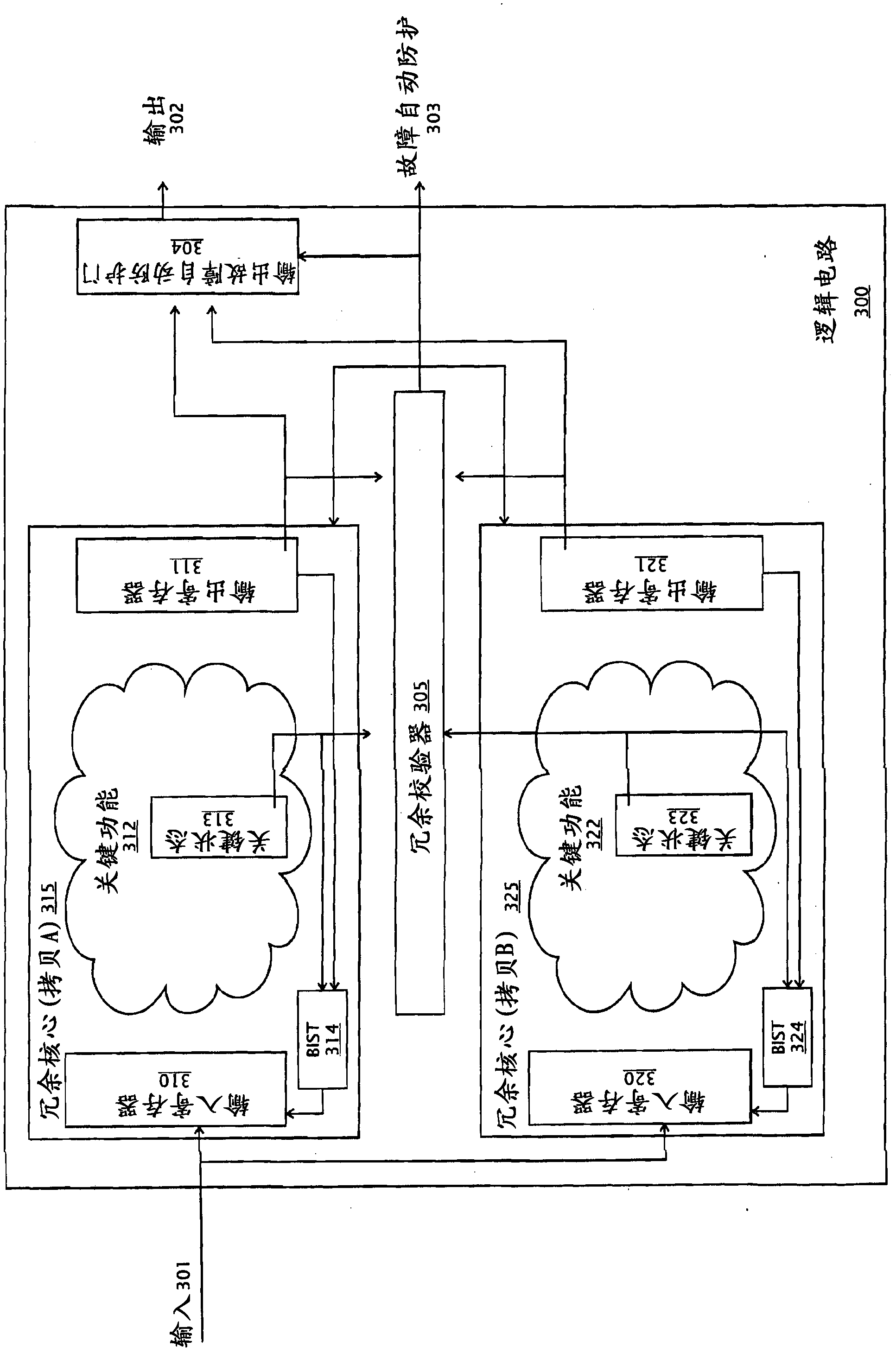

The present invention is directed to methods of monitoring logic circuits for failures. In particular, the methods are directed toward establishing parallel logic cores where failures are detected by comparing the parallel paths for equivalence at key locations by a redundancy checker. Any mismatch will result in a predetermined failsafe operational mode. In addition, important techniques are applied to periodically exercise individual parallel paths to ensure that logic cores are verified in a way that does not disturb any process being monitored or controlled. This feature is important in some industries, such as the nuclear power industry, where safety critical operations require a high state of reliability on logic circuit blocks which may be infrequently utilized.

Owner:WESTINGHOUSE ELECTRIC CORP

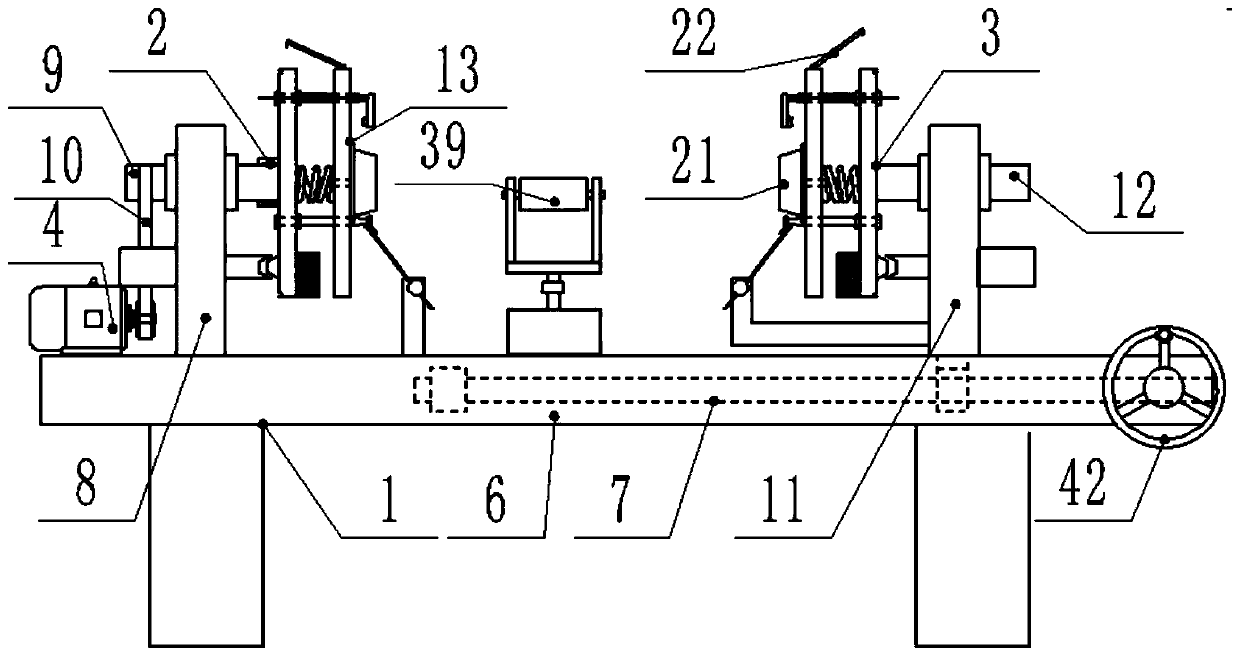

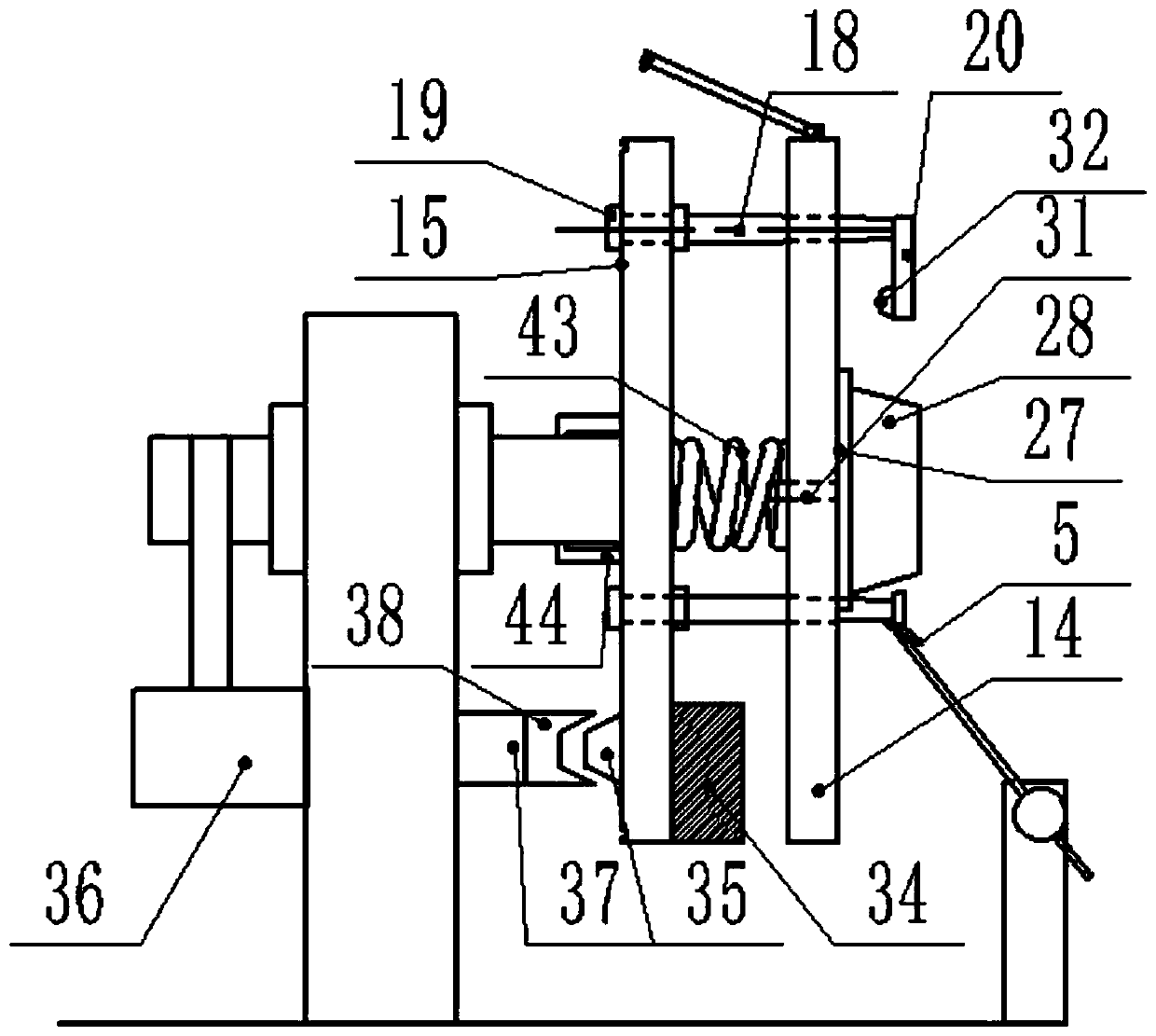

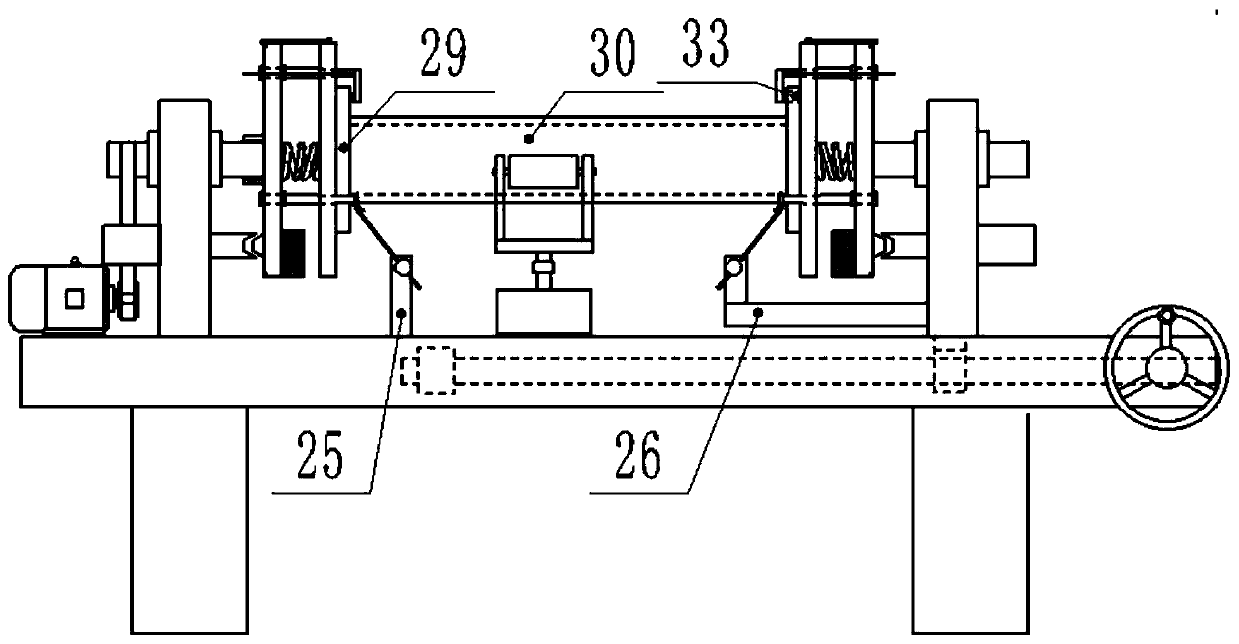

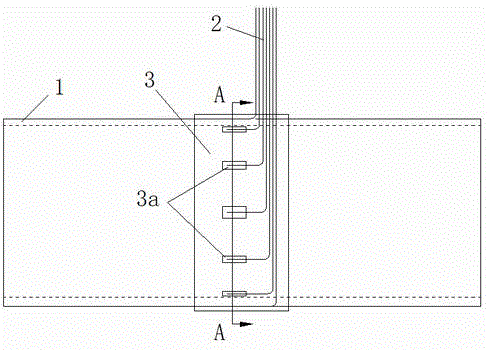

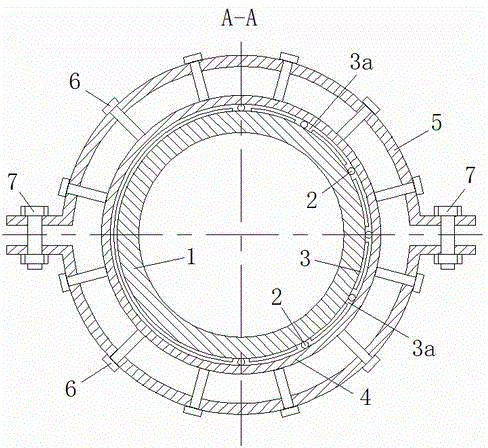

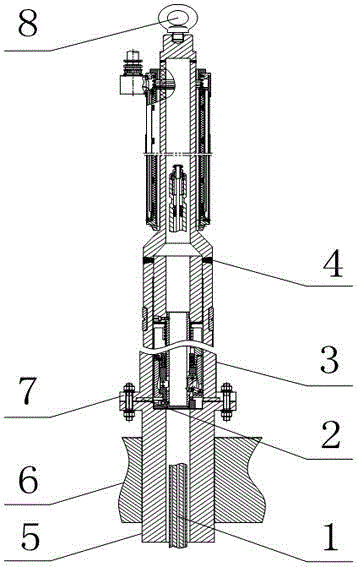

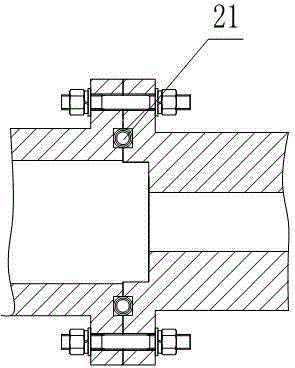

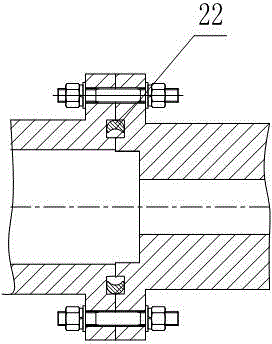

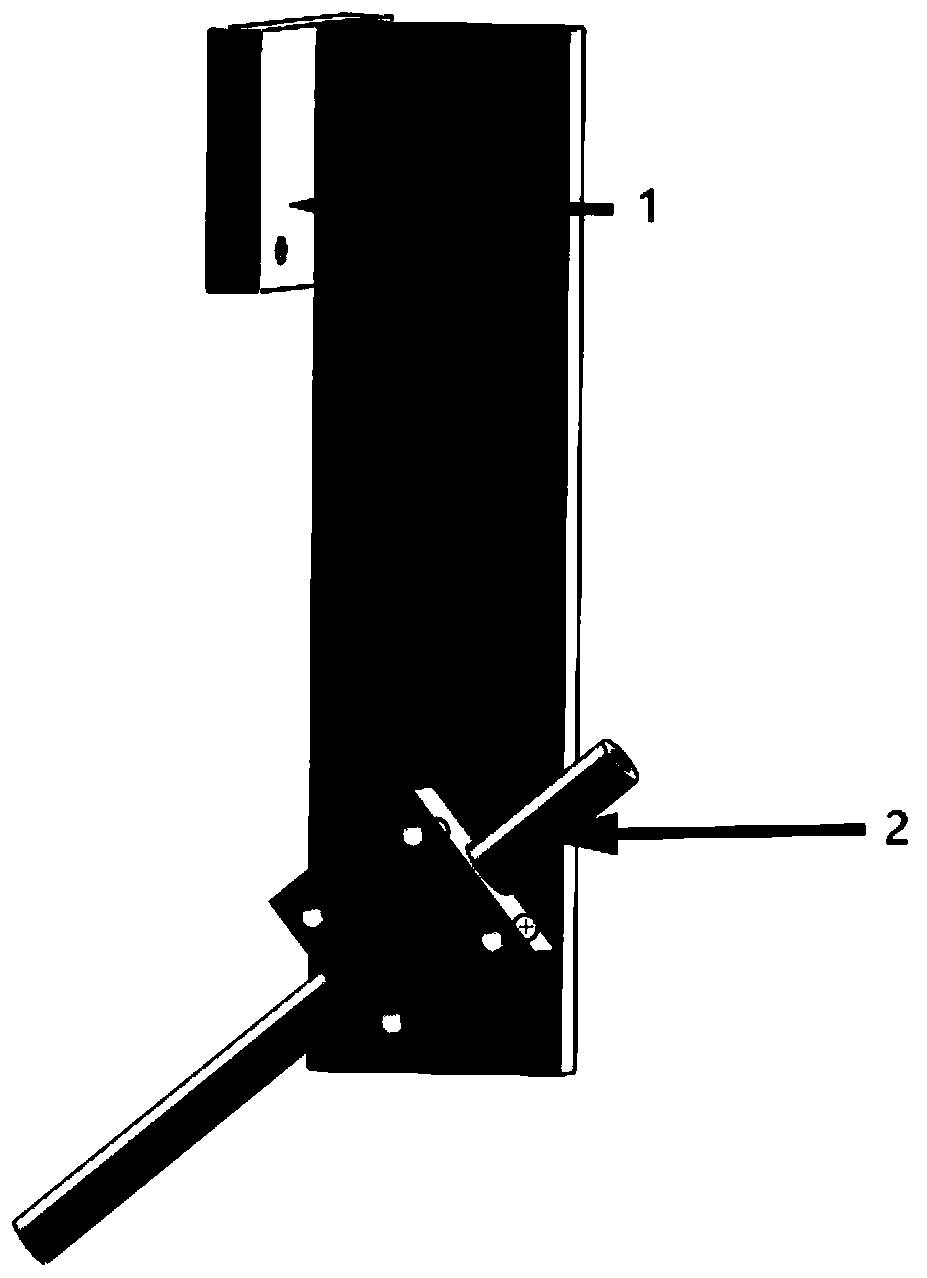

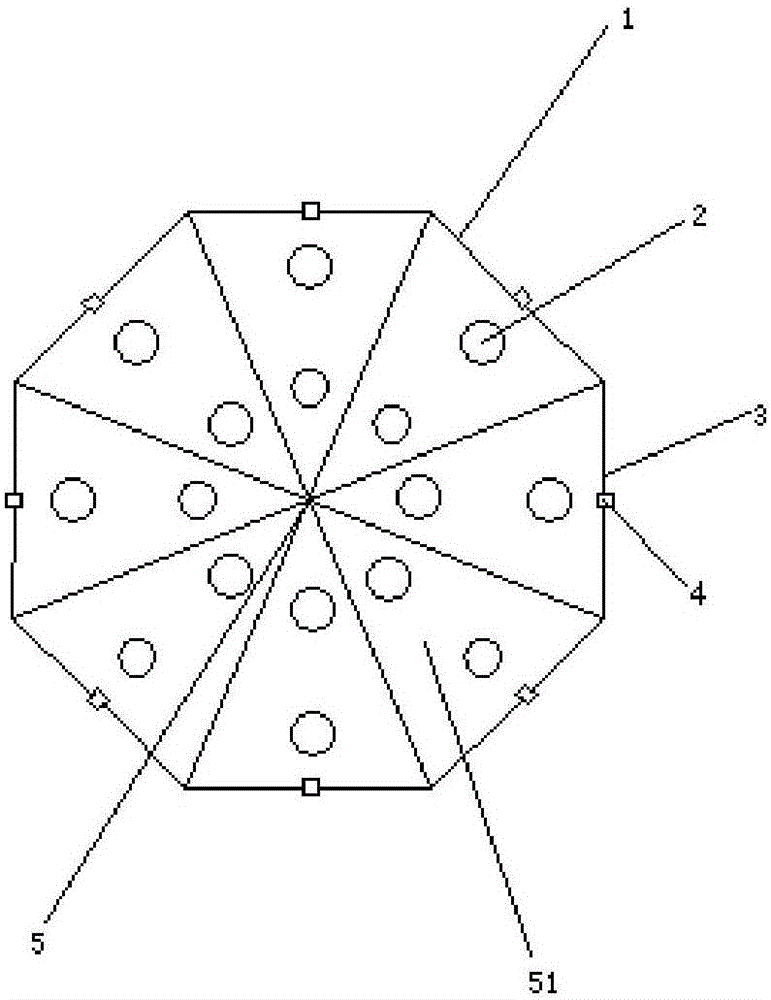

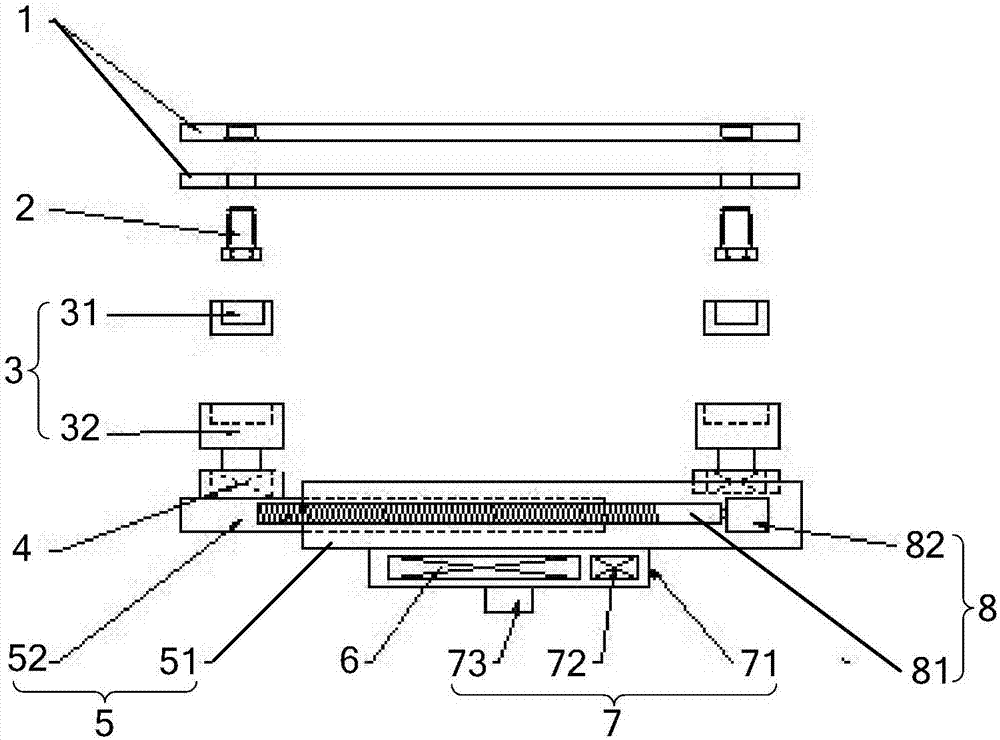

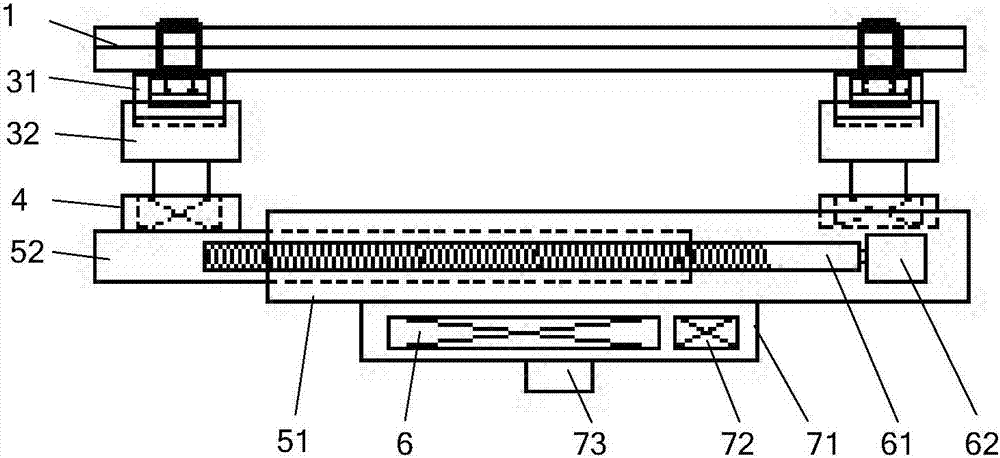

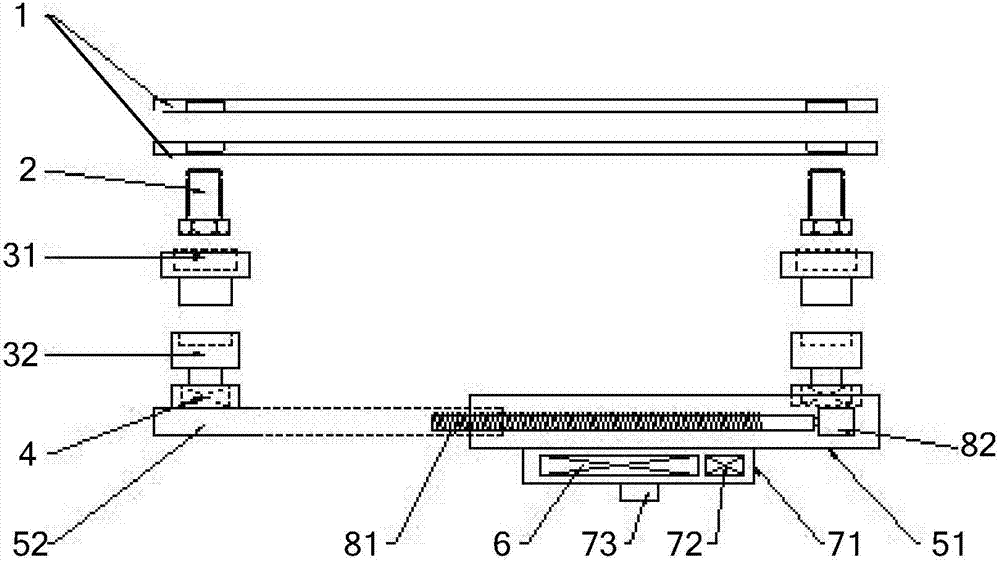

Pipeline flange precision welding device

ActiveCN110303287AGuaranteed clamping concentricityEasy to weld laterWelding/cutting auxillary devicesAuxillary welding devicesChemical industryUltimate tensile strength

The invention discloses a pipeline flange precision welding device. The pipeline flange precision welding device achieves that flange threaded holes of two flange plates welded to one pipeline are automatically aligned in a one-to-one manner, which cannot be achieved in an existing pipeline flange welding technology, and calibration and alignment must be manually conducted inch by inch in the prior art. The flange threaded hole alignment solution provides convenience for follow-up rapid accurate pipeline connection; the pipeline flange precision welding device can be used for welding multipletypes of pipelines and flange plates, it is just need to correspondingly replace matching pipeline centering abutting blocks and matching flange threaded hole calibration conical bosses; the pipelineflange precision welding device can guarantee precision welding of the pipeline flanges and suitable for the nuclear power industry, the chemical industry, the building industry and the industry having high pipeline connection and seal intensity requirements.

Owner:广东网纳智能装备有限公司

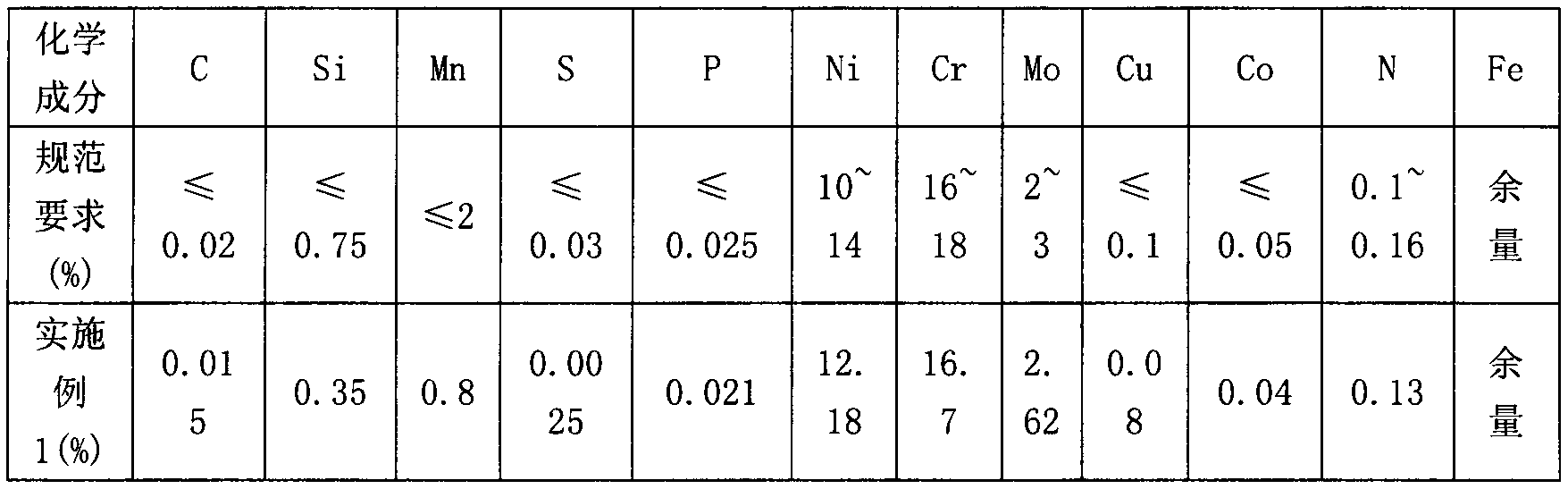

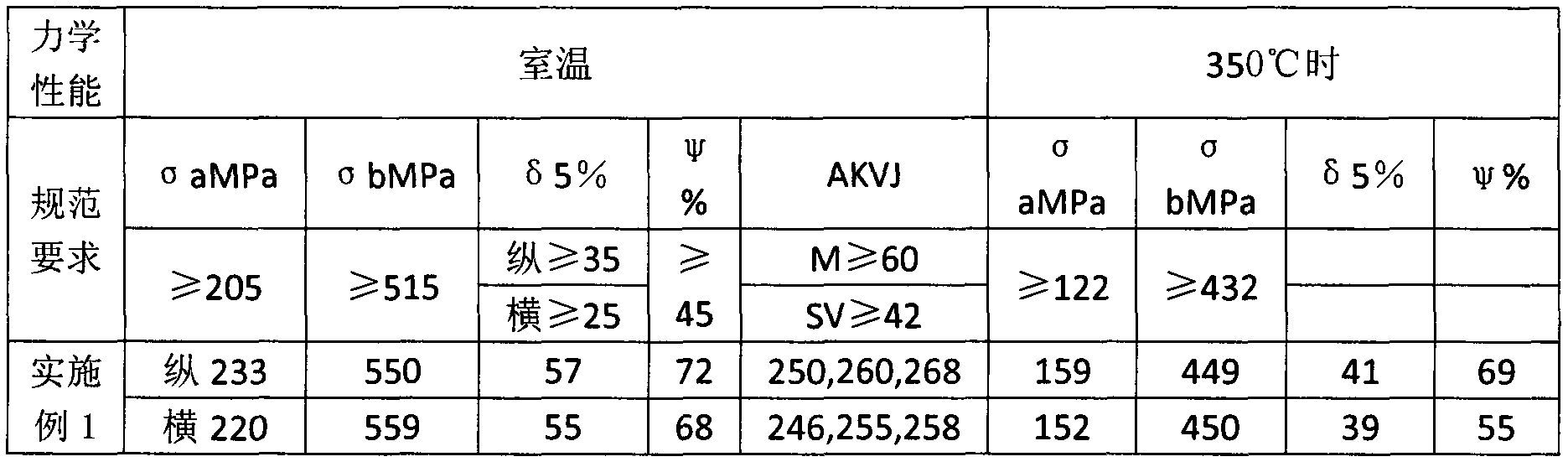

Z2CND18-12N control nitrogen stainless steel forging technology

ActiveCN102601282AMeeting the requirements of the nuclear power industrySolution to short lifeMetal-working apparatusChemical compositionNitrogen

The invention provides a Z2CND18-12N control nitrogen stainless steel forging technology relates to the processing method of stainless steel material. The invention uses raw materials controlling chemical compositions and selects lower solid solution treatment temperature through three-section temperature rise method and heat treatment. The temperature rise speed in the heat treatment is not greater than 150 degrees centigrade and the heat holding time is calculated according to 1.5min / mm and not less than 2.5h. The Z2CND18-12N control nitrogen stainless steel forging material processed by the method of the invention has strength above 460Mpa stably at high temperature of 350 DEG C to meet the component manufacturing requirements of nuclear power industry. The processing method is applied for manufacturing important components such as nuclear power pipe flange.

Owner:无锡市法兰锻造有限公司

Failure detection and mitigation in logic circuits

The present invention is directed to methods of monitoring logic circuits for failures. In particular, the methods are directed toward establishing parallel logic cores where failures are detected by comparing the parallel paths for equivalence at key locations by a redundancy checker. Any mismatch will result in a predetermined failsafe operational mode. In addition, important techniques are applied to periodically exercise individual parallel paths to ensure that logic cores are verified in a way that does not disturb any process being monitored or controlled. This feature is important in some industries, such as the nuclear power industry, where safety critical operations require a high state of reliability on logic circuit blocks which may be infrequently utilized.

Owner:WESTINGHOUSE ELECTRIC CORP

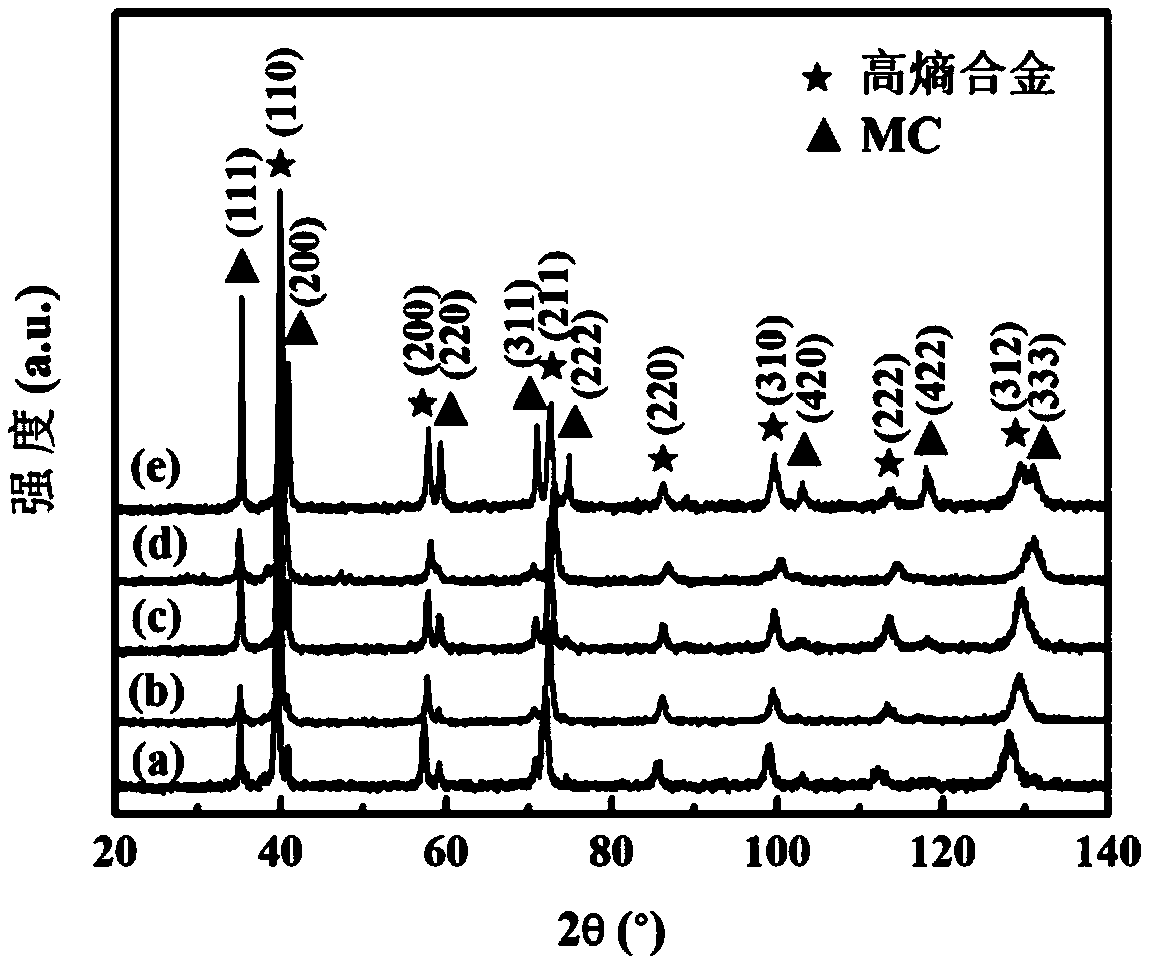

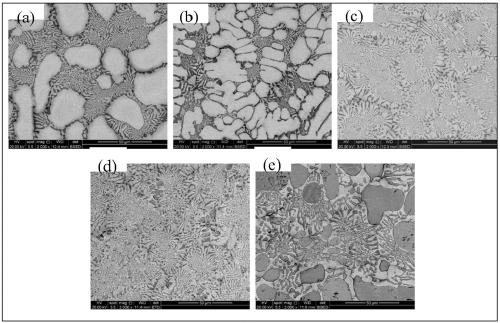

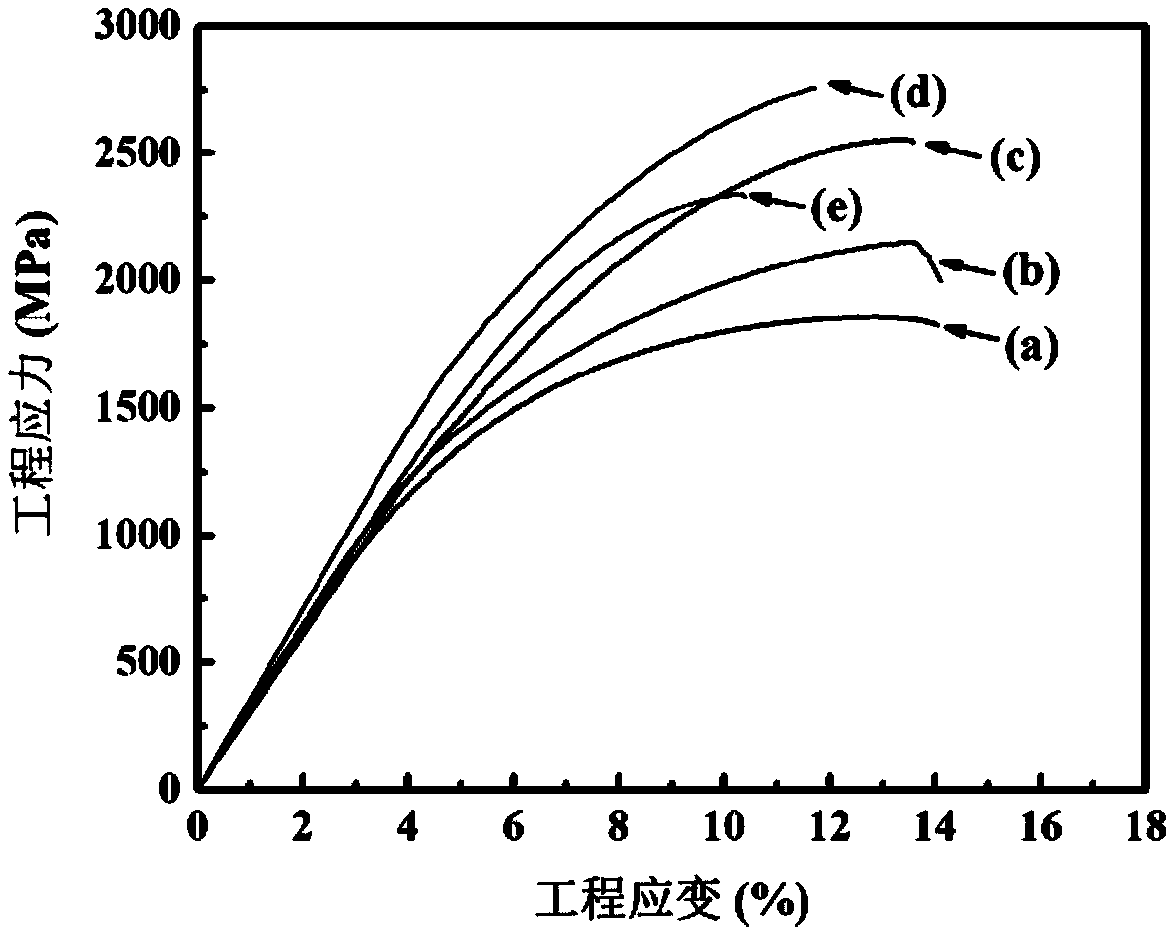

High-entropy alloy and multi-component carbide eutectic composite material and in-situ preparation method

The invention provides a high-entropy alloy and multi-component carbide eutectic composite material and an in-situ preparation method. A vacuum arc melting is adopted, powder of pure Re, Mo, Nb, and Wand TaC powder are subjected to high temperature melting, and in-situ generated high-entropy alloy phase and a multi-component carbide phase form the eutectic composite material. The composite material is composed of primary dendritic crystals and fine, regular, and layered eutectic tissues; the phase interface is clean, the binding force is high; the toughness is high at a room temperature; theyield strength is greater than 1.1 GPa; the average extreme compression strength is greater than 1.8 GPa; the plastic strain is more than 5% at a room temperature; the hardness is more than 5.8 GPa; and the composite material can be applied to fields such as nuclear power industry, national defense and military industry, and the like.

Owner:WUHAN UNIV OF TECH

Fault detection and reduction in logic circuit

ActiveCN102841828AElectronic circuit testingRedundant hardware error correctionCritical positionOperation mode

The invention relates to fault detection and reduction in a logic circuit. The invention provides a method for monitoring faults of the logic circuit. Particularly, the method aims at building a parallel logic circuit core; the fault is detected by comparing equivalent parallel paths at a key position through a redundancy check device, and any mismatching can result in a preset fault automatic protection operation mode. In addition, with the application of an important technology and the assurance of each parallel path served at a fixed period, the parallel core is checked in a manner of not disturbing any monitored or controlled process. The characteristics are important in some industries, such as a nuclear power industry. At this point, a safe key operation requires a high reliability state as to a logic circuit block which is not always frequently utilized.

Owner:WESTINGHOUSE ELECTRIC CORP

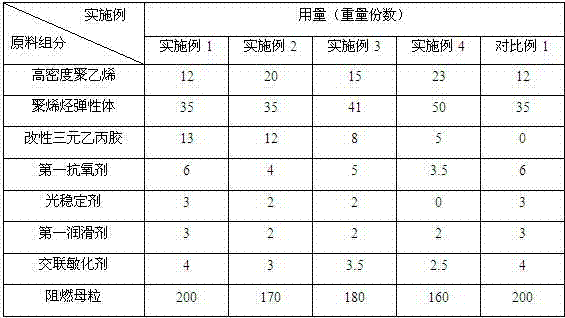

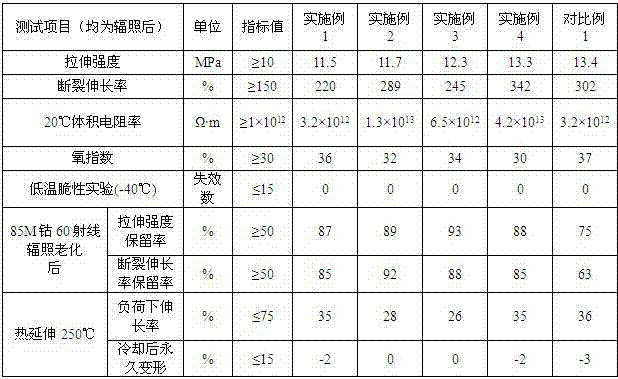

Crosslinkable, radiation-resistant, highly-flame-retardant, low-smoke and zero-halogen cable material and preparation method of cable material

ActiveCN103172917AGood compatibilityImprove performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to a crosslinkable, radiation-resistant, highly-flame-retardant, low-smoke, zero-halogen cable material and a preparation method of the cable material. The cable material comprises the following raw materials by weight parts of 5 to 30 parts of high density polyethylene, 20 to 60 parts of a polyolefin elastomer, 5 to 20 parts of modified ethylene-propylene diene copolymer, 160 to 200 parts of flame retardant masterbatches, 3 to 8 parts of a first antioxidant, 0 to 5 parts of a light stabilizer, 1 to 5 parts of a first lubricating agent, and 1.5 to 6 parts of a crosslinking sensitizer. The cable material provided by the invention can be used for the fields of electric wires and cables in the nuclear power industry, communication cables and sheathes in a space technology, irradiation disinfection products of medical instruments, and the like by adding the flame retardant masterbatches in combination with the high-efficiency antioxidant and radiation-resistant resin without additionally adding any anti-radiation agent. The preparation method of the crosslinkable, radiation-resistant, highly-flame-retardant, low-smoke and zero-halogen cable material provided by the invention has the advantages of being simple in process, easy to operate and low in cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

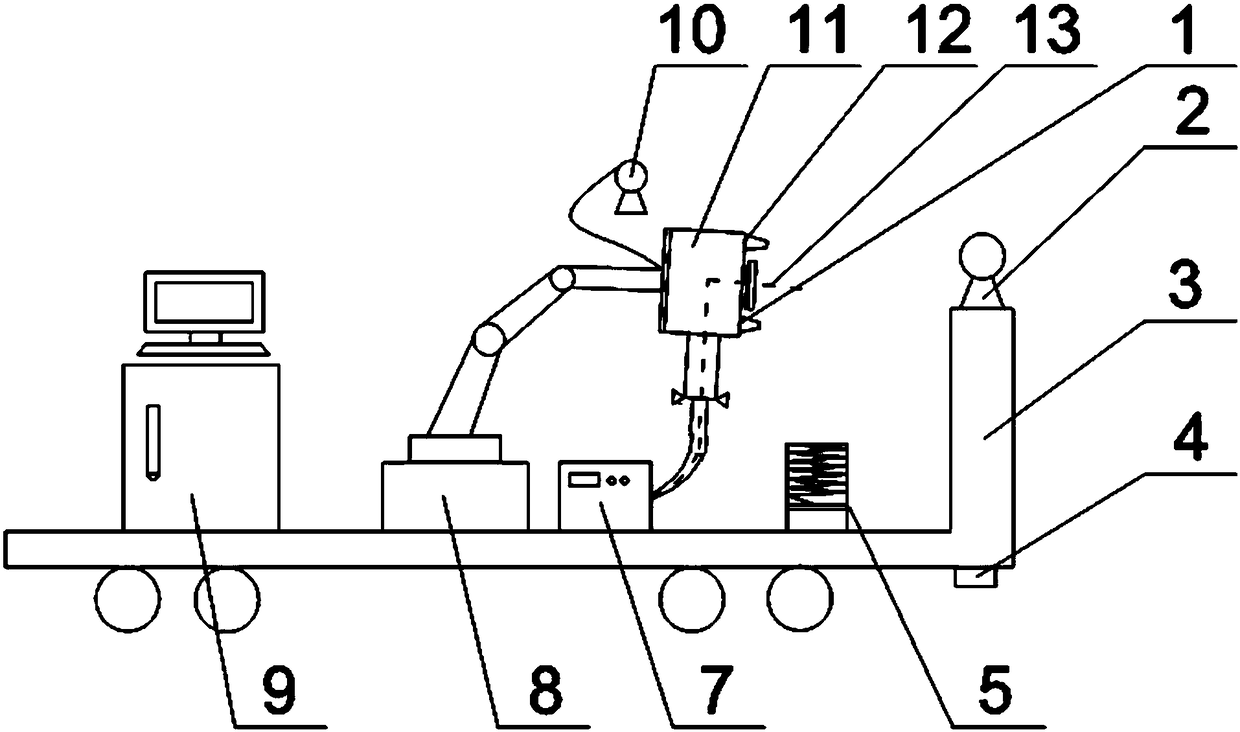

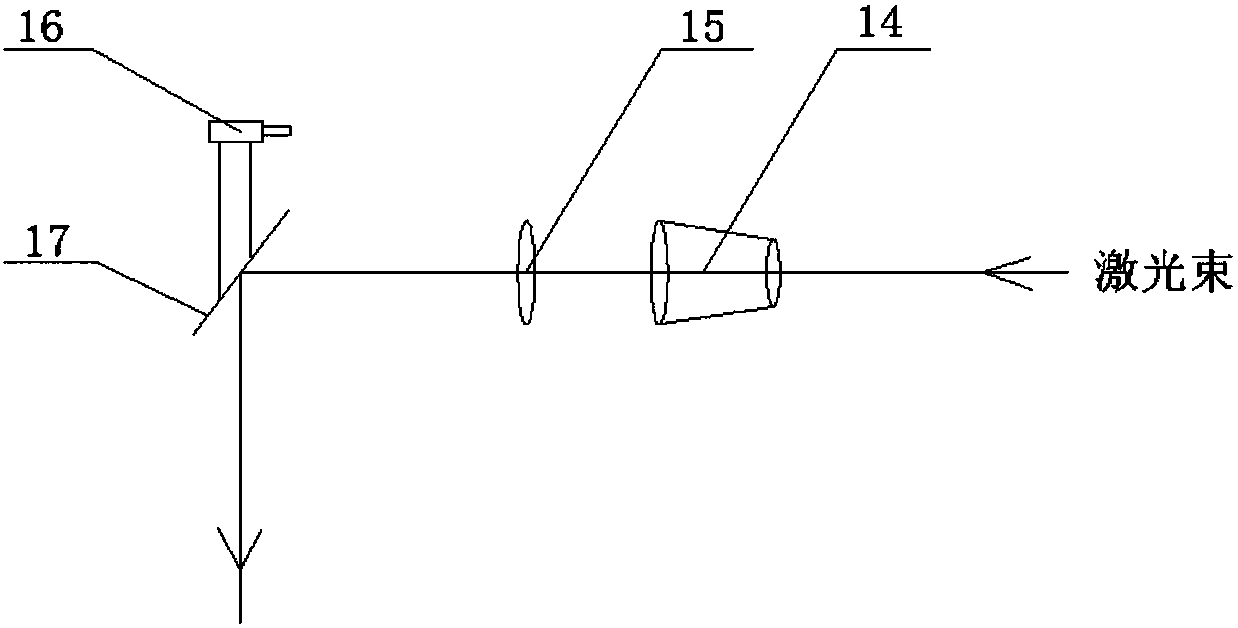

Intelligent laser cleaning equipment and method for nuclear power industry

PendingCN108554938AAutomatically adjusts laser cleaning parametersCleaning adjustmentCleaning processes and apparatusVehicle frameCompression Pump

The invention discloses intelligent laser cleaning equipment and a method for nuclear power industry. The intelligent laser cleaning equipment comprises a vehicle frame, an integration controller, a cleaning arm mechanism, a laser optical fiber integration system and a compression pump, wherein the integration controller, the cleaning arm mechanism, the laser optical fiber integration system and the compression pump are arranged on the vehicle frame; the cleaning arm mechanism comprises a mechanical arm; a galvanometer integrating system is arranged at the front end of the mechanical arm; a concave dust suction head is arranged at the front end of a casing of the galvanometer integrating system, and is connected with the compression pump through a pipeline. The intelligent laser cleaning equipment has the advantages that by arranging a derusting gun, the derusting and depainting functions for the metal surface are realized; compared with other laser derusting equipment, an automatic intelligent traction function is realized, pollutants are intelligently identified, and the types of pollutants are determined; the substrate shape, pollutant thickness and other features can be intelligently identified, the technology parameters can be intelligently adjusted, and the pollutants can be cleared; by arranging a precision industrial robot, the precision laser cleaning operation can berealized in wide environments; the human-machine remote control function can be realized, and the nuclear radiation is avoided in the operation process.

Owner:SOUTH CHINA UNIV OF TECH

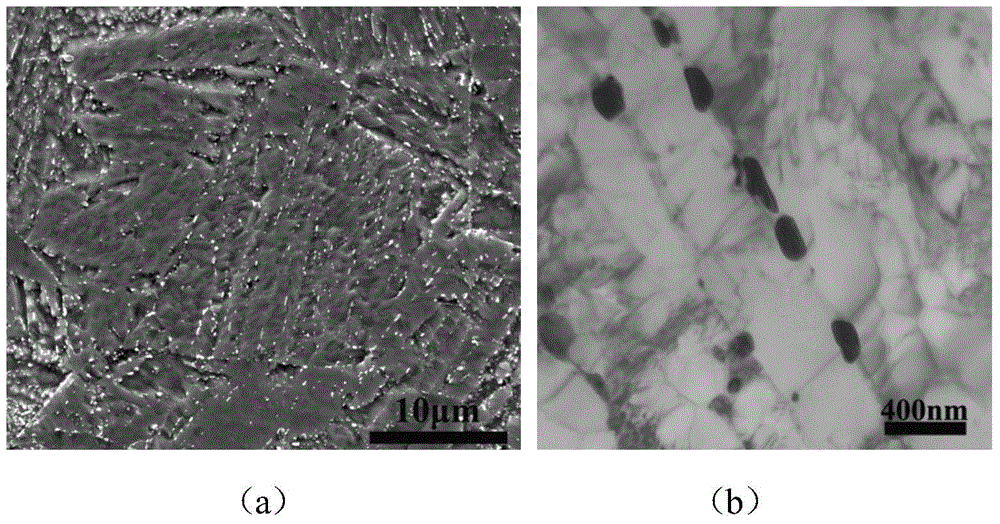

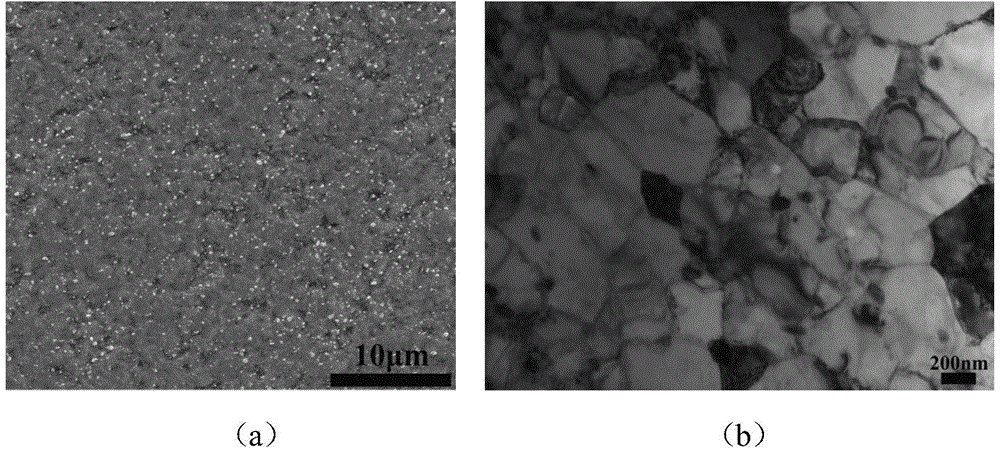

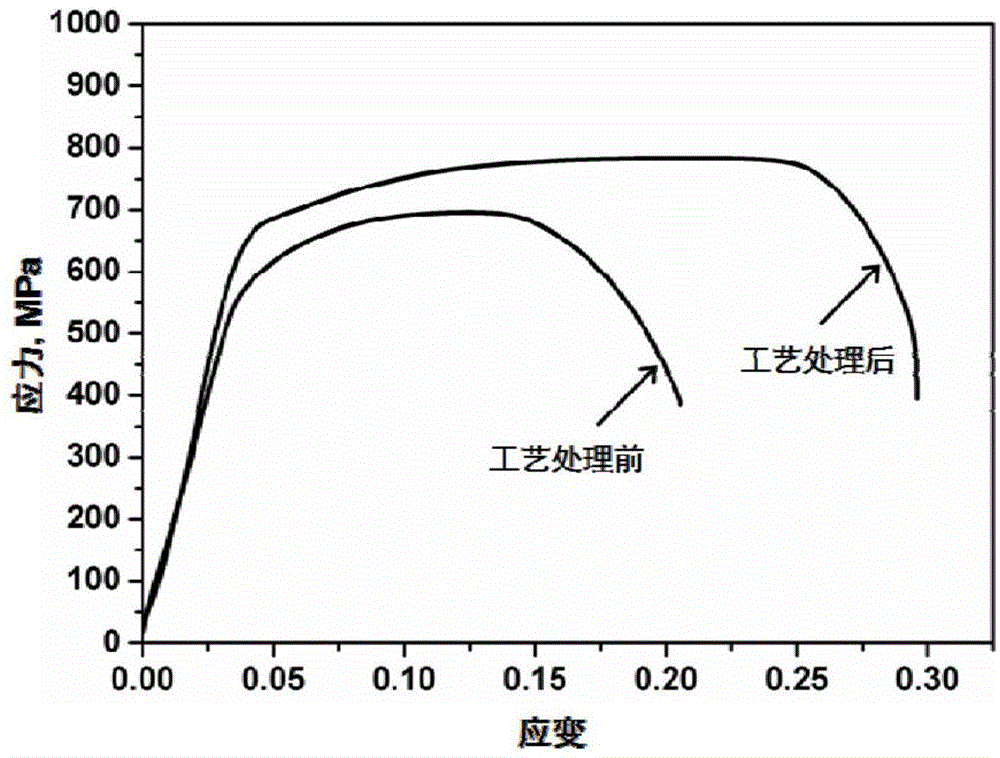

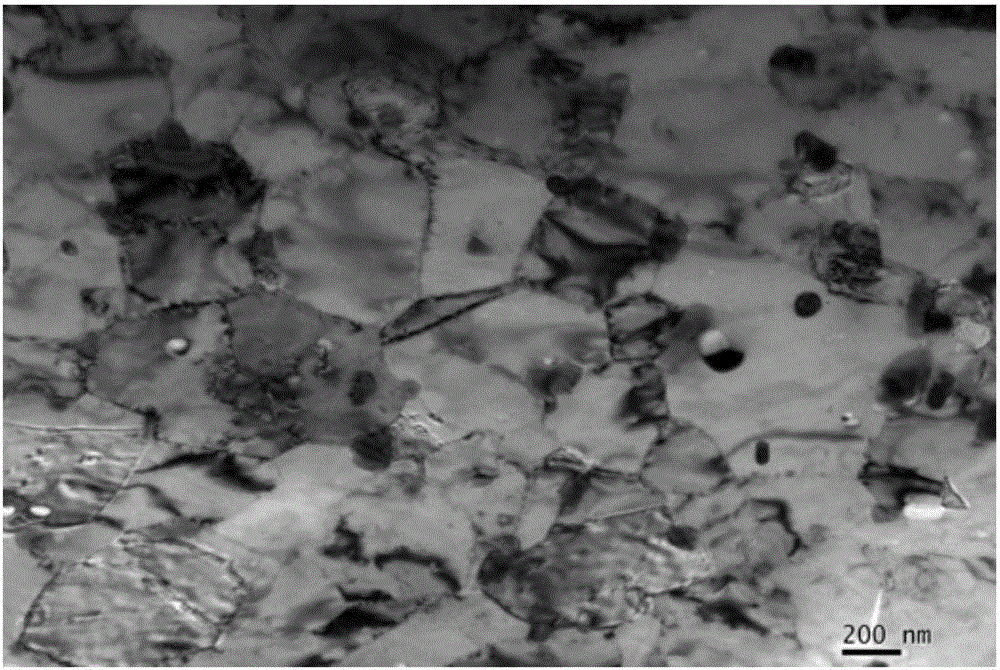

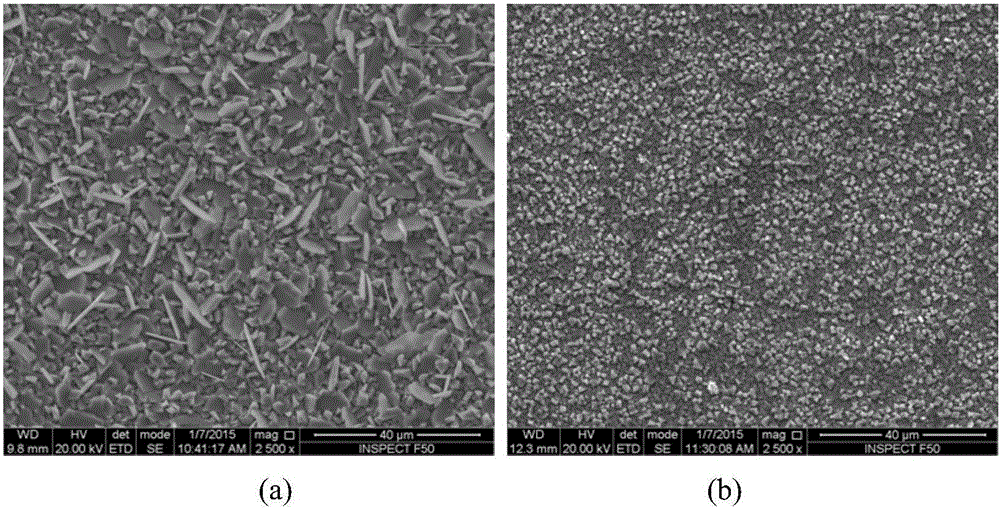

Preparation technique for high-strength and high-plasticity ultra-fine grain low-activity ferrite/martensite steel

The invention discloses a preparation technique for high-strength and high-plasticity ultra-fine grain low-activity ferrite / martensite steel and belongs to the field of low-activity ferrite / martensite steel. According to the preparation technique, a rotary forging and pressing deformation technique is introduced, so that the purposes of refining the sizes of grains and the size of carbide and improving the distribution uniformity of the carbide are achieved; and then dislocation pileup caused by deformation is eliminated through annealing treatment, and preparation of the high-strength and high-plasticity low-activity ferrite / martensite steel is achieved. According to the technique, the strength of the material is improved by means of the dispersion strengthening effect of the ultra-fine grains and the tiny carbide, and the plasticity of the material is improved by means of strain hardening capacity improvement caused by uniform distribution of the carbide. The strength and plasticity of the ultra-fine grain low-activity ferrite / martensite steel are remarkably improved, and novel high-strength and high-plasticity low-activity ferrite / martensite steel can be prepared for the nuclear power industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

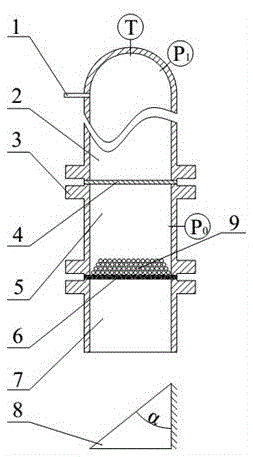

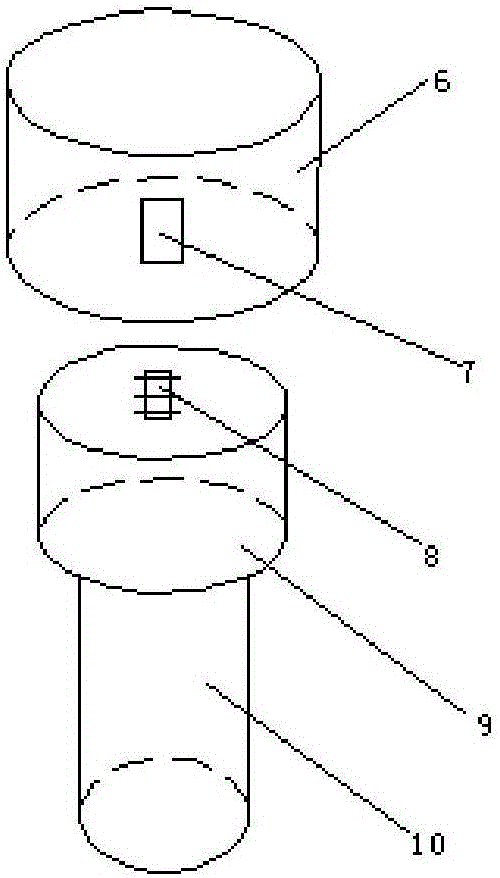

Fixture device for measuring temperature of outer wall of high-temperature pipeline

InactiveCN104535213AReduce vibrationReduce collisionThermometers using electric/magnetic elementsUsing electrical meansMeasurement pointContact type

The invention discloses a fixture device for measuring the temperature of the outer wall of a high-temperature pipeline and is applied to temperature measurement of walls of high-temperature pipelines in the nuclear power industry, the petroleum engineering industry, the chemical engineering industry, the metallurgy industry and the like. The fixture device comprises a detachable type inner layer installation belt, a detachable type outer layer installation belt and two semicircular protective shields, wherein the detachable type inner layer installation belt is provided with 2-8 measurement point grooved holes. The detachable type inner layer installation belt is installed in the manner of being closely attached to the outer wall of the high-temperature pipeline, and induction elements of a contact type temperature sensor are arranged in the measurement point grooved holes and are closely attached to the outer wall of the high-temperature pipeline. The detachable type inner layer installation belt and the induction elements of the contact type temperature sensor are covered with the detachable type outer layer installation belt, and the detachable type outer layer installation belt is fixed by combining fastening bolts and distance bolts on the two semicircular protective shields. The fixture device has the advantages of being capable of fixing the contact type temperature sensor to a measurement area, meanwhile reasonably protecting the contact type temperature sensor, reducing influences of vibration, collision and abrasion, achieving quick, simple and convenient installation and reducing safety risks caused by improper operation.

Owner:DALIAN UNIV OF TECH

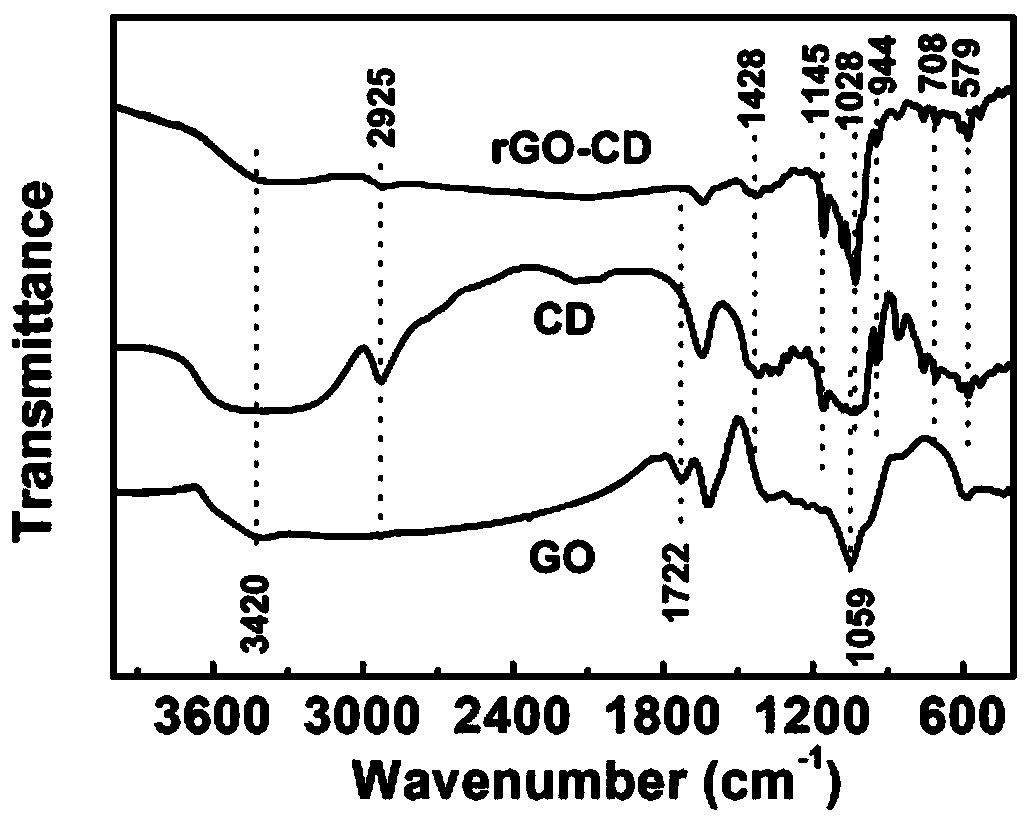

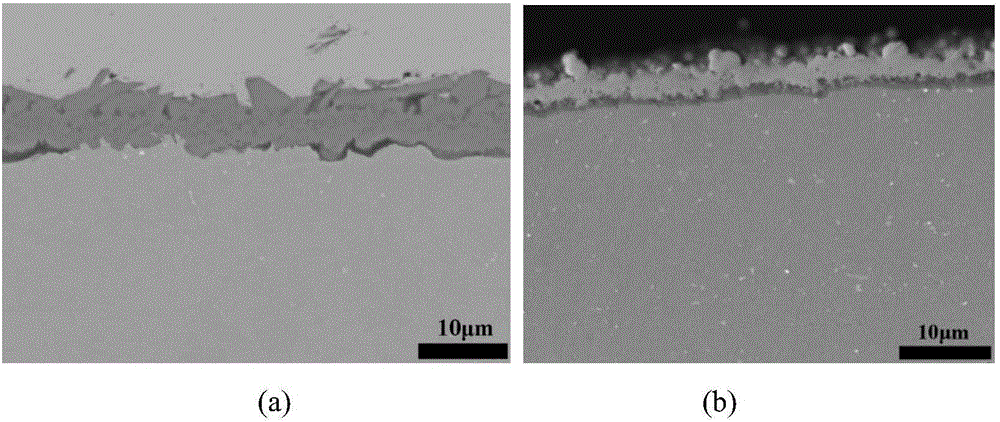

Coating material based on graphene nanometer container, and self-repairing coating, preparation method and applications thereof

ActiveCN110835488AImprove shielding effectImproved self-healingAnti-corrosive paintsEpoxy resin coatingsCyclodextrinFirming agent

The invention discloses a coating material based on a graphene nanometer container, and a self-repairing coating, a preparation method and applications thereof, wherein the coating material comprisesa first component and a second component, the first component comprises 20-40 parts by weight of an epoxy resin, the second component comprises, by weight, 0.1-2 parts of a graphene nanometer container loading a corrosion inhibitor, 1 part of a diluent, 30-60 parts of an epoxy curing agent, 1 part of an antifoaming agent and 1 part of a leveling agent, the graphene nanometer container loading thecorrosion inhibitor comprises graphene grafted with cyclodextrin and a corrosion inhibitor reversibly combined with the cyclodextrin. According to the invention, the preparation process is simple, theraw materials are environmentally friendly, cheap and easy to obtain, and the self-repairing coating formed by the coating material is excellent in protection performance, has good shielding performance (passive corrosion resistance) and self-repairing performance (active corrosion resistance), and can be widely applied to the fields of metal anticorrosive coating materials for ocean facilities,ship equipment, nuclear power industry and the like.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

Preparation method for austenitic stainless steel used for 316LN nuclear power

ActiveCN104294171AControl balanceAccelerated corrosionProcess efficiency improvementElectric arc furnaceNitrogen

The invention discloses a preparation method for austenitic stainless steel used for 316LN nuclear power, and solves the problem that conventional 316LN austenitic stainless steel cannot meet actual requirements of nuclear power industry. The preparation method comprises the steps as follows: firstly, EAF electric-arc furnace coarse refining; secondly, AOD refining; thirdly, pouring; fourthly, hot-work forging; fifthly, thermal treating. The preparation method provided by the invention is simple in technology steps, easy to operate, and is suitable for industrial production; through strictly controlling the chemical components of the stainless steel and through the optimal design of the smelting, the forging and thermal treating technology, the balance of carbon and nitrogen is controlled effectively, and the austenitic stainless steel used for 316LN nuclear power is enabled to have excellent intercrystalline corrosion resistance and mechanical property; besides, the austenitic stainless steel used for 316LN nuclear power is further provided with excellent ocean and industrial air corrosion resistance, and is particularly suitable for high-pressure bowler pipes and locomotive components in nuclear power industries.

Owner:ZHEJIANG YIDA SPECIAL STEEL

Integrated pressure-resistant shell assembly

ActiveCN104616706AO difficultyNon-existent benefitsNuclear energy generationNuclear reaction controlEngineeringOmega

The invention discloses an integrated pressure-resistant shell assembly. The integrated pressure-resistant shell assembly comprises a pressure-resistant shell and a tube base, wherein the pressure-resistant shell is of a columnar structure with a blind hole in an axial direction, the opening end of the pressure-resistant shell and one end of the tube base are both fixed with connecting flanges, two connecting flanges are connected by a plurality connecting bolts, a sealing gasket for sealing the connecting position of two connecting flanges is arranged between two connecting flanges, the sealing gasket is a C-shaped elastic sealing ring or an O-shaped elastic sealing ring; the O-shaped elastic sealing ring is a metal ring of which the cross section is of a crescent shape, the C-shaped elastic sealing ring comprises a ring-shaped elastic ring and at least one metal wrapping layer wrapped on the elastic ring. The integrated pressure-resistant shell assembly can be used for solving the problems of leakage caused by omega welded corrosion, welding of dissimilar metals, high welding difficulty and low economic benefit, and a problem that the existing pressure-resistant shell assembly is not good for safe operation of the nuclear power industry or use in the improved control rod driving mechanism in the prior art.

Owner:喻杰 +1

Method for increasing high-temperature strength and antioxidant property of reduced activation ferritic/martensitic steel

The invention discloses a method for increasing the high-temperature strength and the antioxidant property of reduced activation ferritic / martensitic steel, which belongs to the technical field of reduced activation ferritic / martensitic steel preparation. Rotary forging deformation and annealing treatment are performed on the reduced activation ferritic / martensitic steel in a conventional heat treatment state, so that cooperative control over grain size and carbide is realized; the quick forming of an oxidation film and the binding force with a substrate are promoted by refining the grain size, so that the high-temperature oxidation resistant property of a material is increased; additionally, the size of the carbide is refined, and the dispersion distribution of the carbide is increased, so that the stability of a fine-grained structure is guaranteed, and the high-temperature mechanical property is increased. According to the reduced activation ferritic / martensitic steel prepared by adopting the method, the thermophysical property and the irradiation resistant property are satisfied, the high-temperature strength and the antioxidant property are synchronously increased, and novel high-performance reduced activation ferritic / martensitic steel can be prepared for a nuclear power industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

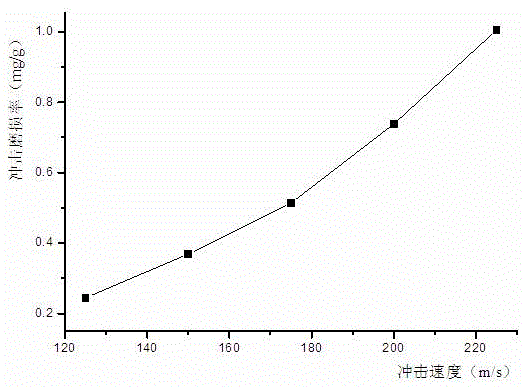

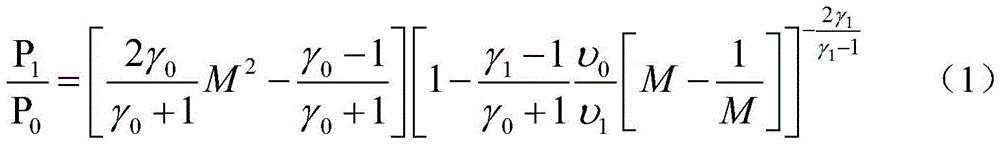

Quantitative forecasting method based on shock wave type impact wear rate speed index

InactiveCN105547886AHigh precisionSimple designInvestigating abrasion/wear resistanceShock waveEngineering

The invention discloses a quantitative forecasting method based on the shock wave type impact wear rate speed index. The method includes the steps of drawing a particle swarm impact wear rate curve and establishing the quantitative forecasting method based on the shock wave type impact wear rate speed index. A forecasting model for the impact wear rate index is established, can be used for rapidly inquiring about the impact wear rate speed index, at a given impact speed and angle, of an assigned material, can provide an important foundation for establishing an impact wear rate correction model under the gas-solid two-phase flow environment, improves the impact wear forecasting precision, and is suitable for risk assessment of device systems such as pressure pipelines and pressure containers. The impact wear rate speed index can be solved and forecasted for impact wear-out failure cases of pipelines and valves of flow industries such as the petrochemical engineering industry, the coal chemical industry and the nuclear power industry, and theoretical support is provided for failure analysis, optimized design, risk assessment and remaining life evaluation of pipelines and valves.

Owner:ZHEJIANG SCI-TECH UNIV

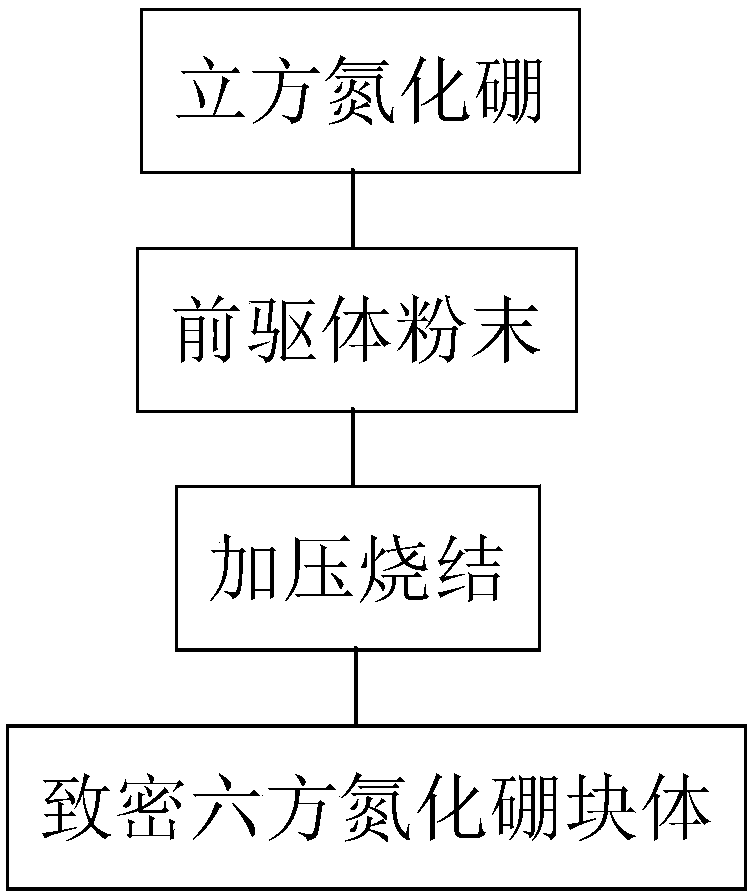

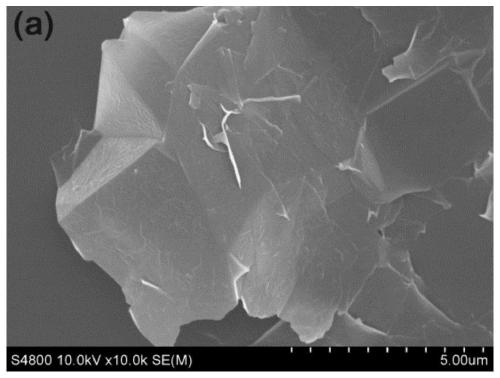

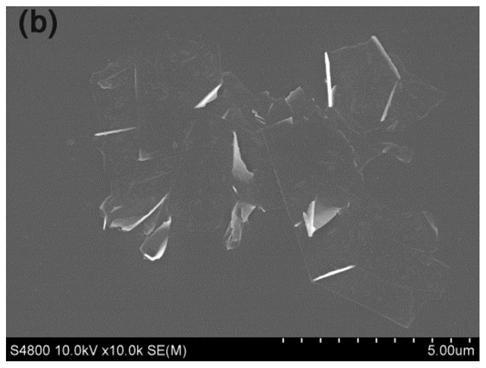

Preparation method of hexagonal dense boron nitride block body

ActiveCN108529572AMeet the use requirementsCompact structureNitrogen compoundsHexagonal boron nitrideCrystal structure

The invention relates to a preparation method of an isotropic hexagonal dense boron nitride block body. The method comprises the steps of: 1, preparation of compound boron nitride powder: uniformly mixing cubic boron nitride powder in two or more different particle sizes as a precursor for preparing the hexagonal dense boron nitride block body, and 2, sintering preparation of the hexagonal dense boron nitride block body: pressing, heating and sintering the mixed cubic boron nitride powder. At a high temperature, cubic boron nitride particles are converted into onion-shaped hexagonal boron nitride and are expanded in volume to form the isotropic hexagonal dense boron nitride block body, no additive is introduced into the hexagonal boron nitride block body prepared by the method, and the block body has a unique crystal structure. The block body can be used for the mechanical and electronic industry, nuclear power industry and the like.

Owner:HAINAN UNIVERSITY

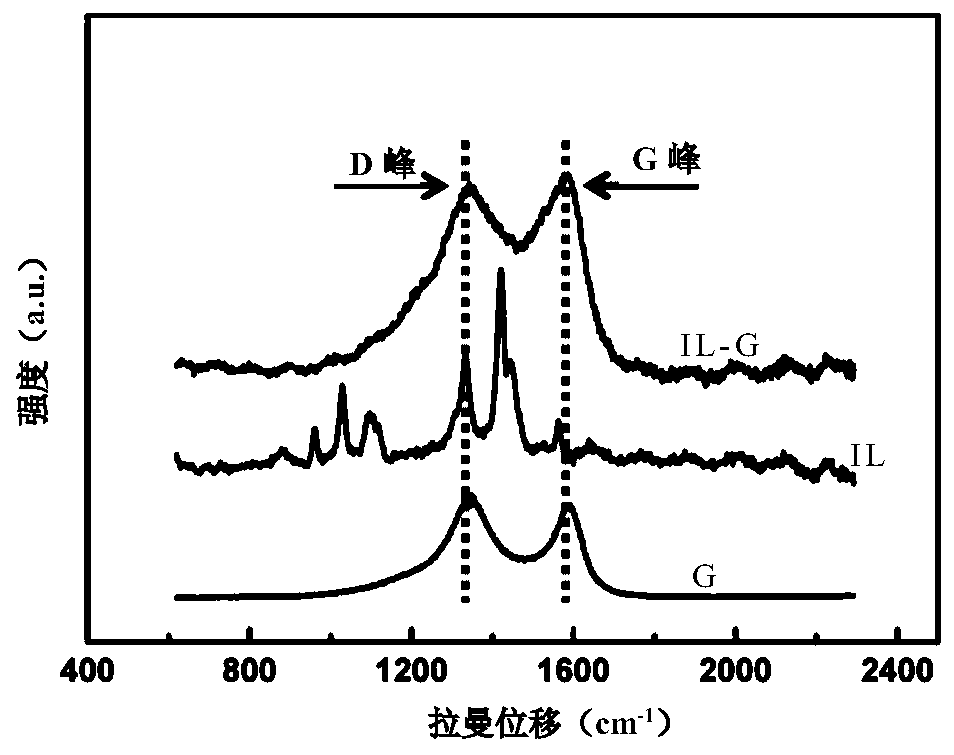

Ionic liquid modified graphene composite anticorrosive wear-resistant coating and preparation method and application thereof

ActiveCN111205739AEasy reunionFix compatibility issuesAnti-corrosive paintsEpoxy resin coatingsFirming agentEthyl group

The invention discloses an ionic liquid modified graphene composite anticorrosive wear-resistant coating and a preparation method and application thereof. The ionic liquid modified graphene compositeanticorrosive wear-resistant coating comprises an ionic liquid modified graphene, a curing agent, epoxy resin and a diluent are used as fillers, the ionic liquid modified graphene is prepared by modifying graphene with an ionic liquid, and the ionic liquid is prepared by reacting 1-ethylimidazole with 1, 8-dibromooctane. The anticorrosive wear-resistant coating prepared by the invention effectively reduces the agglomeration phenomenon of graphene, shows excellent corrosion resistance and wear resistance, is simple and efficient in preparation method, and can be widely applied to metal protective collars of marine equipment, ship equipment, nuclear power industry and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

High-chromium nickel-based high-temperature alloy and preparation method and application thereof

ActiveCN110747377AImprove performanceImprove antioxidant capacityAdditive manufacturing apparatusIncreasing energy efficiencyLiquid argonChromium nickel

The invention relates to the field of advanced manufacturing and high-temperature alloys, in particular to a high-chromium nickel-based high-temperature alloy and a preparation method and an application thereof. The high-chromium nickel-based high-temperature alloy is prepared from the following components in percent by mass: 30-35% of Cr, 1-2% of Ti, 1-2% of Al, 2-3% of Ta, 1-2% of Nb, 2.5-3.5% of Mo, 4-5% of W, 0.2-0.5% of Fe, 0.005-0.03% of C, 0.003-0.01% of B, 0.003-0.01% of Y and the balance Ni. According to the high-chromium nickel-based high-temperature alloy prepared by a laser additive manufacturing method, thermal stress is reduced to reduce deformation and cracks of a workpiece in the laser additive manufacturing process by optimizing parameters of the laser additive manufacturing process and carrying out cooling by way of liquid argon synchronous chilling in the laser additive manufacturing process, and net shaping of the high performance high-chromium nickel-based high-temperature alloy is achieved, so that the high-chromium nickel-based high-temperature alloy which is excellent in comprehensive performance is obtained. The high-chromium nickel-based high-temperature alloy is suitable for the fields of aerospace, petrochemical engineering, nuclear power industry and the like.

Owner:TSINGHUA UNIV

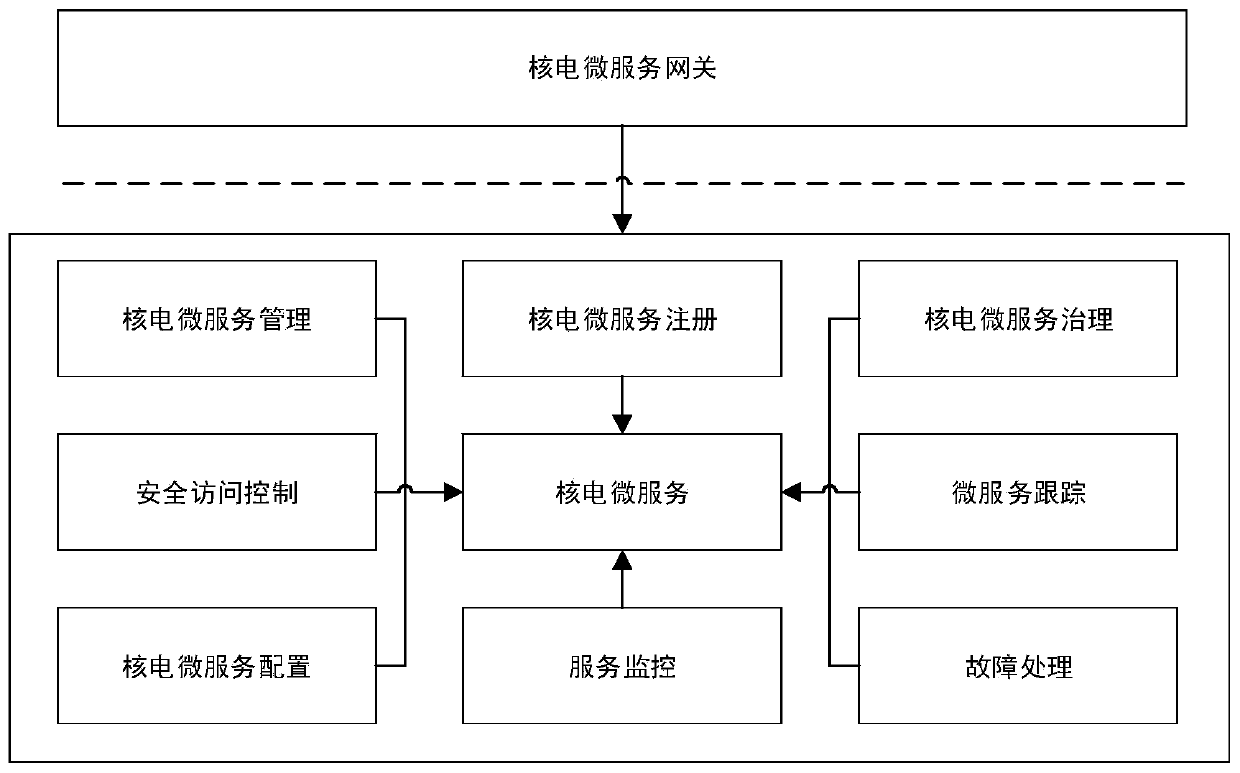

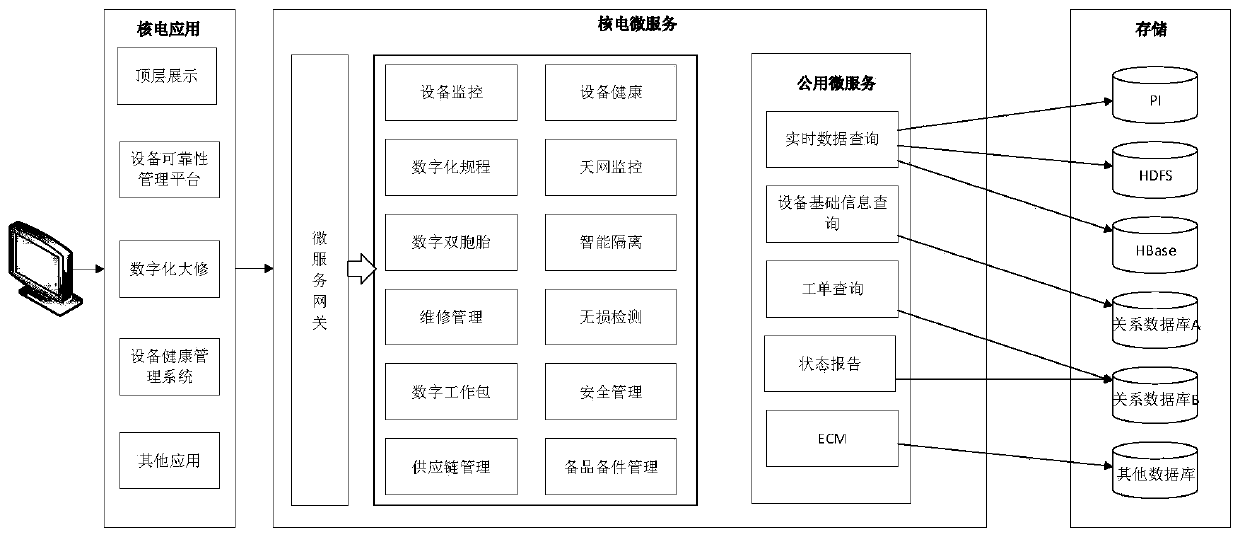

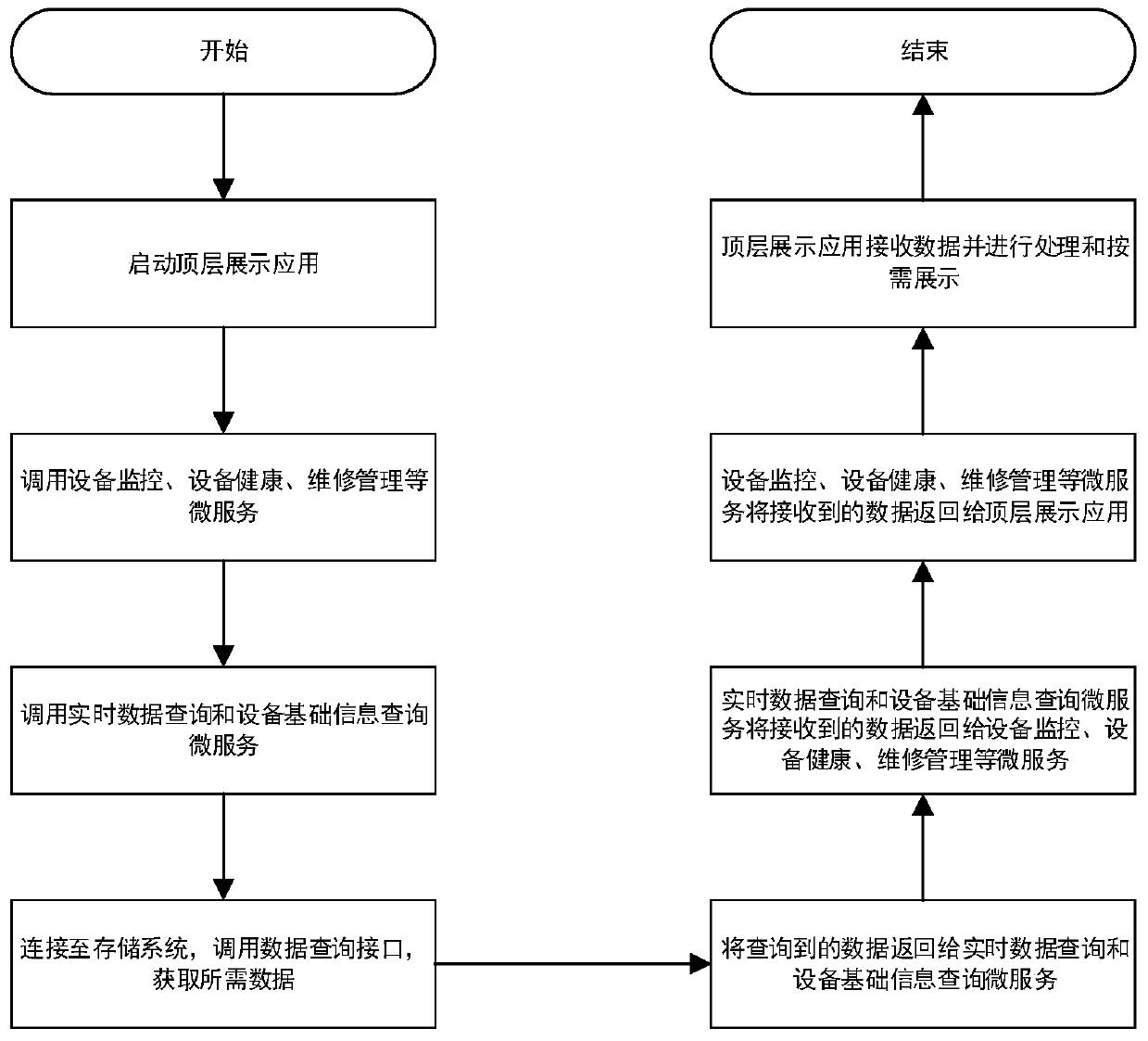

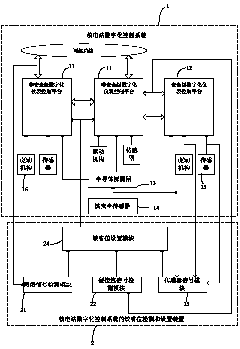

Micro-service architecture and method of nuclear power industry Internet platform

PendingCN111427944AEnsure safetyImprove the efficiency of underlying servicesDatabase management systemsOffice automationSoftware engineeringThe Internet

The invention relates to the technical field of internet micro-service architectures, and particularly discloses a micro-service architecture and method of a nuclear power industry internet platform.The micro-service architecture comprises a nuclear power micro-service module, a nuclear power micro-service management module and a nuclear power micro-service configuration module, and the nuclear power micro-service module is connected with the nuclear power micro-service management module and the nuclear power micro-service configuration module; the nuclear power micro-service management module can control starting and stopping of micro-services in the nuclear power micro-service module, and can set, operate and maintain micro-service parameters; and the nuclear power micro-service configuration module is used for configuring release, change and notification of micro-service configuration items in the nuclear power micro-service module and setting log levels and operating parameters. According to the micro-service architecture, traditional nuclear power services are divided into micro-services one by one, so that the bottom service efficiency is effectively improved, and the micro-service architecture has good expandability.

Owner:CHINA NUCLEAR POWER OPERATION TECH

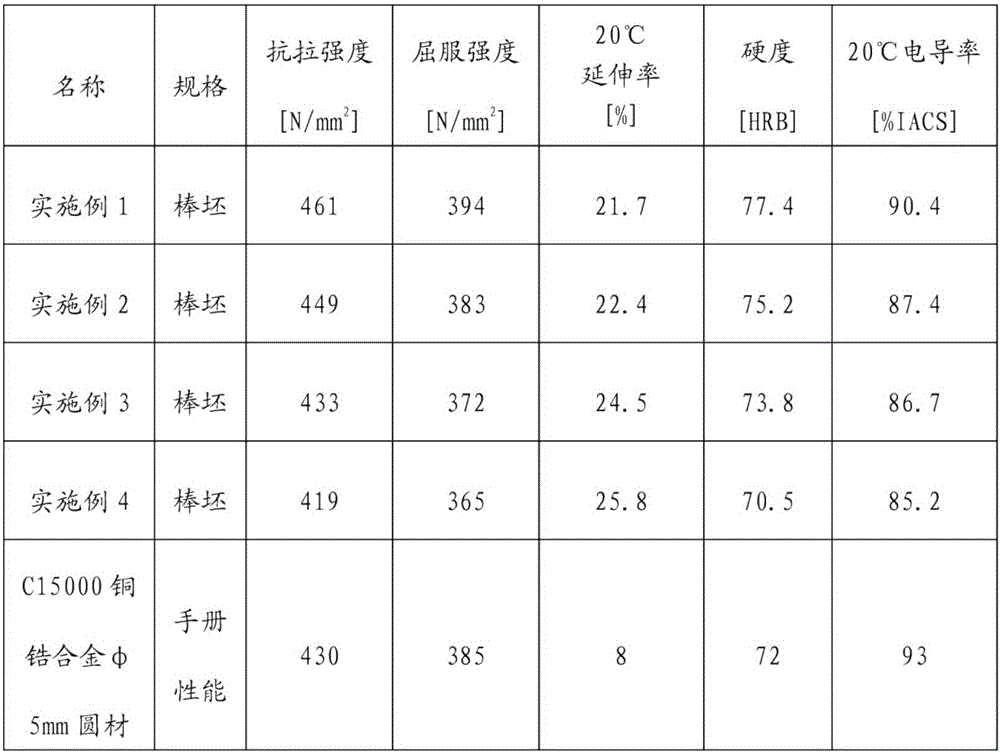

Copper alloy conductive screw for nuclear power and preparation method thereof

InactiveCN105970017AImprove conductivityHigh strengthConductive materialMetal/alloy conductorsHardnessUltimate tensile strength

The invention relates to a copper alloy conductive screw for nuclear power and a preparation method thereof. Based on the percentage of the total weight of the alloy, zirconium accounts for 0.14-0.22%, zirconium+copper≥99.97%, and impurity content≤0.03%. The copper-zirconium alloy conductive screw provided by the invention is used in the field of nuclear power steam turbine half-speed generators, has high core strength and hardness, and can meet the stricter quality requirements of the nuclear power industry.

Owner:HARBIN ELECTRIC MASCH CO LTD

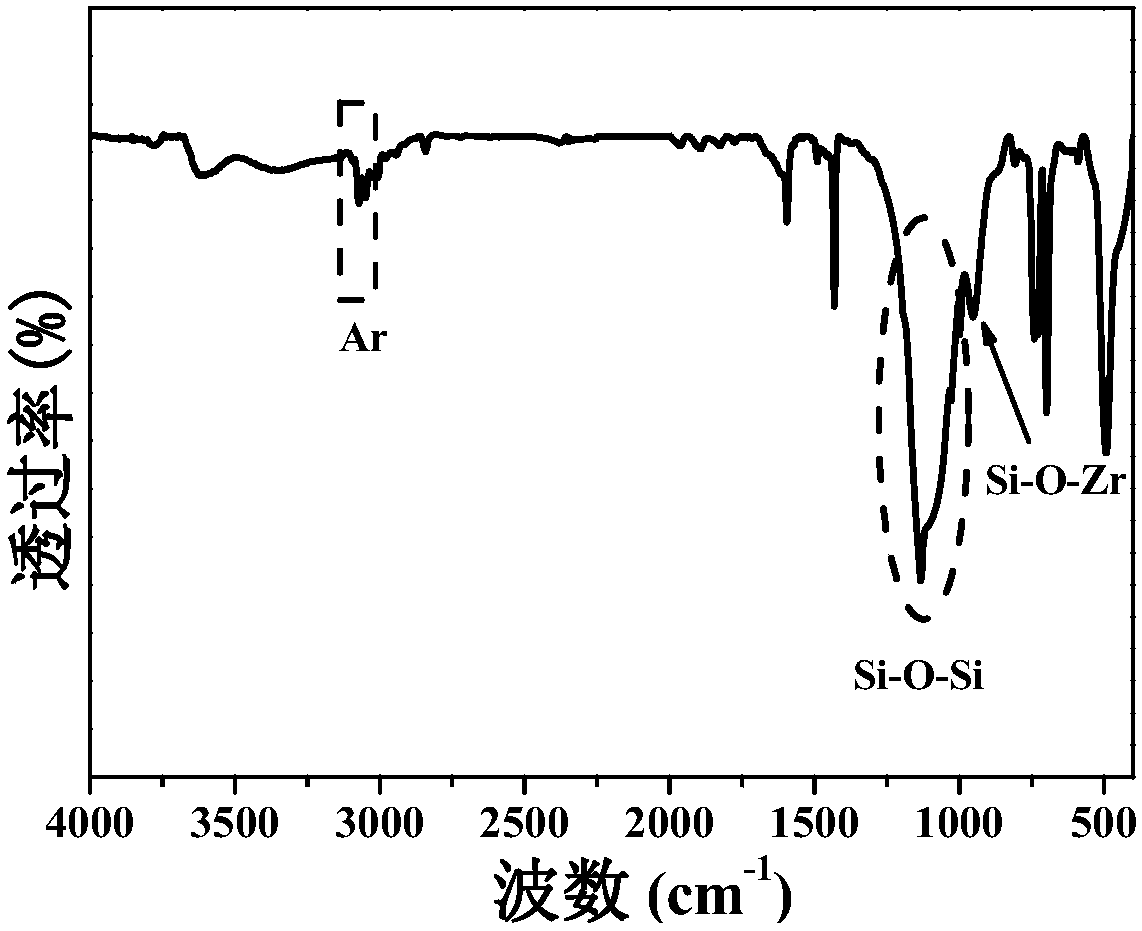

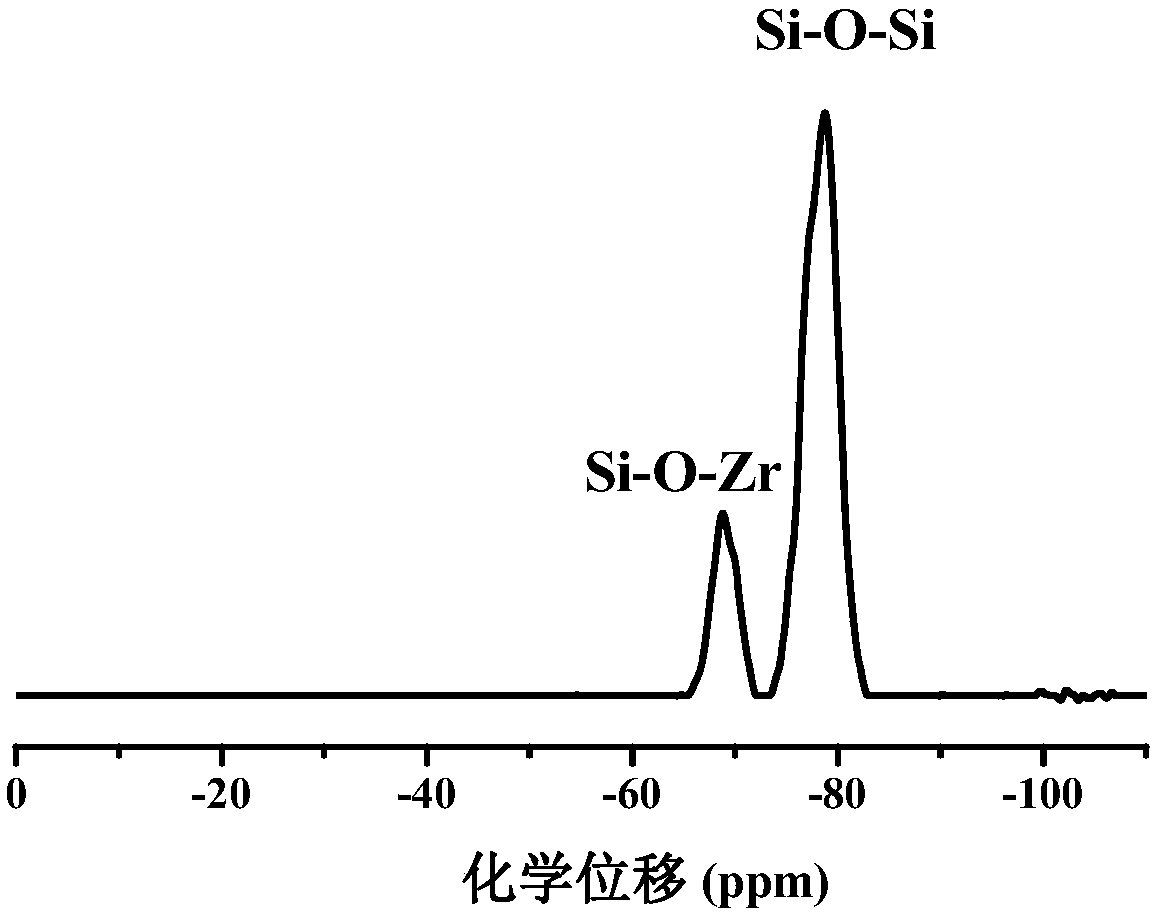

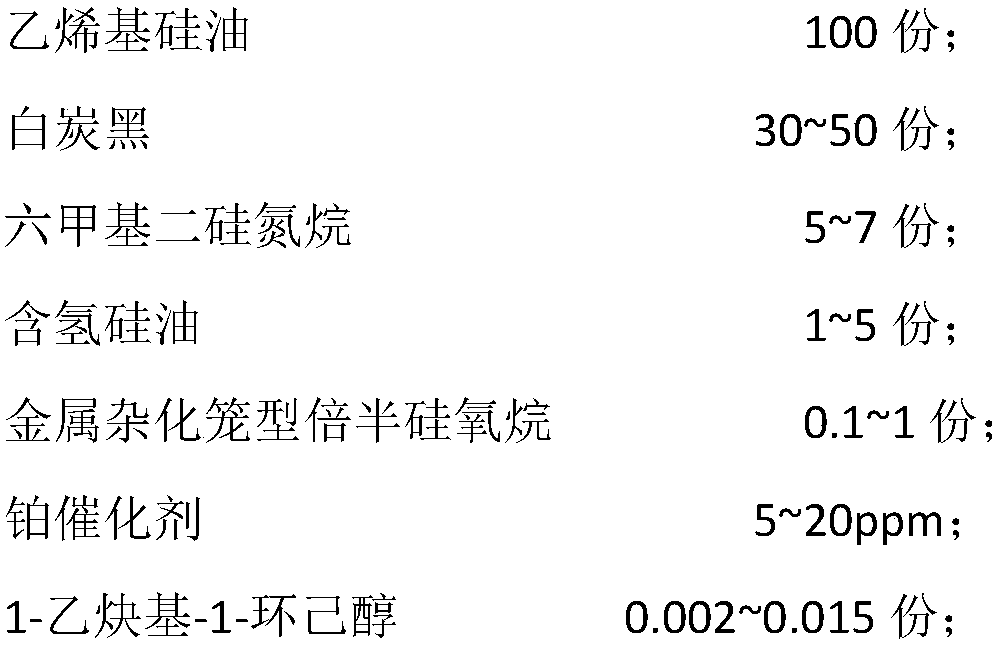

Addition type liquid silicone rubber with high transparency and resistance to thermo-oxidative aging, and preparation method thereof

ActiveCN107936572AOvercome the disadvantage of adding a large amountImprove heat and oxygen aging resistanceAviationVulcanization

The invention discloses an addition type liquid silicone rubber with high transparency and resistance to thermo-oxidative aging, and a preparation method thereof. The addition type liquid silicone rubber comprises the following raw materials by mass: 100 parts of vinyl silicone oil, 30 to 50 parts of white carbon black, 5 to 7 parts of hexamethyldisilazane, 1 to 5 parts of hydrogen-containing silicone oil, 1 to 5 parts of metal hybrid cage silsesquioxane, 5 to 20 ppm of a platinum catalyst and 0.03 to 0.07 part of 1-ethynyl-1-cyclohexanol. The preparation method comprises the following steps:subjecting vinyl silicone oil, white carbon black and hexamethyldisilazane to high-temperature mixing with a vacuum kneader, and then carrying out cooling and grinding with a three-roll grinder so asto obtain masterbatch; and then adding metal hybrid cage silsesquioxane, hydrogen-containing silicone oil, 1-ethynyl-1-cyclohexanol, the platinum catalyst and the like into the masterbatch, and then carrying out mechanical mixing and vulcanization so as to obtain the addition type liquid silicone rubber. The prepared silicon rubber of the invention has excellent resistance to thermo-oxidative aging, high transparency and good mechanical properties, and can be applied to fields such as aerospace and aviation, the nuclear power industry, electronic appliances and medical equipment.

Owner:SOUTH CHINA UNIV OF TECH

Method and device for detecting and setting default value of nuclear power plant digital control system

ActiveCN101826373AConvenient and optimized signal determinationEasy to set upPlant parameters regulationNuclear energy generationValue setControl system

The invention relates to a method and a device for detecting and setting a default value of a nuclear power plant digital control system. The method comprises the following steps of: detecting a network fault signal which is received by a non-safe level digital meter control platform, and setting the corresponding default value to be 0; detecting a hard wire signal, and after determining that the hard wire signal is an ineffective signal, setting the default value corresponding to the hard wire signal; and detecting a sensor signal, and after determining that the sensor signal is the ineffective signal, setting the default value corresponding to the sensor signal. The network signal, the hard wire signal and the sensor signal are subjected to classification detection and default value setting on the basis of a safe level digital meter control platform and the non-safe level digital meter control platform of the nuclear power plant digital control system, and the default value is set by combining the nuclear safe particularity of the nuclear-power industry, so that the signal judgment and the parameter setting work of the default value are convenient and optimized.

Owner:中广核工程有限公司 +1

Intelligent radiation source searching and disposing robot

ActiveCN106324652ASafe and Sustainable Development GuaranteeImprove disposal capacityRadiation intensity measurementSocial benefitsMonitoring system

The invention discloses an intelligent radiation source searching and disposing robot. An intelligent radiation source searching and disposing robot comprises a carrier capable of moving; the carrier is provided with a radiation source orientation detection probe for detecting a radiation source; and the radiation source orientation detection probe comprises a radiation shielding device, a detection collimating window and a detection mechanism. Through configuration of a radiation monitoring and emergency disposing robot, the intelligent radiation source searching and disposing robot improves the radiation monitoring and accident emergency processing capability, and is a strong guarantee for continuous development of the radiation source and nuclear power industry. In the long time run, the development of the emergency disposing robot and the monitoring system not only brings enormous social benefit, boosts development of related industries, relates to the long-run safe development of the nuclear energy industry and has a certain meaning to the economic continuous development.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

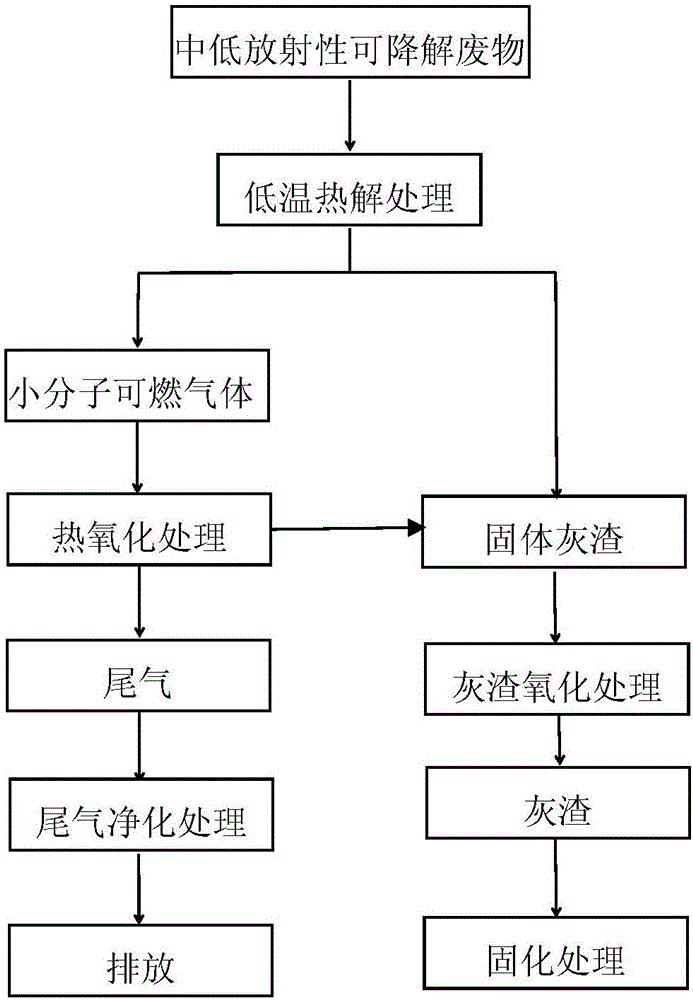

Technology for low-temperature pyrolysis treatment of intermediate-and-low-radioactivity degradable waste

InactiveCN106782737AReduce storageReduce accumulationRadioactive decontaminationReduction treatmentSlag

The invention discloses a technology for low-temperature pyrolysis treatment of intermediate-and-low-radioactivity degradable waste. The technical process includes the steps that the intermediate-and-low-radioactivity degradable waste is subjected to low-temperature pyrolysis and converted into small-molecular combustible gas or solid coal slag, and the coal slag is subjected to a further oxidation reaction so that residual coal in the coal slag or waste which is not completely reacted thoroughly reacts; the gas is completely converted into oxidized gas through a thermal oxidation reaction, the gas is treated through a purification system so as to meet the standard and be exhausted, and the coal slag generated after oxidation is subjected to ceramic-like solidification. The technology solves the problems about storage and accumulation of degradable articles in the nuclear power industry, overcomes the defects of existing related treatment technologies, and achieves harmless volume reduction and weight reduction treatment of intermediate-and-low-radioactivity degradable products in the nuclear power industry or the military industry through pyrolysis heating and oxidation.

Owner:杨红波

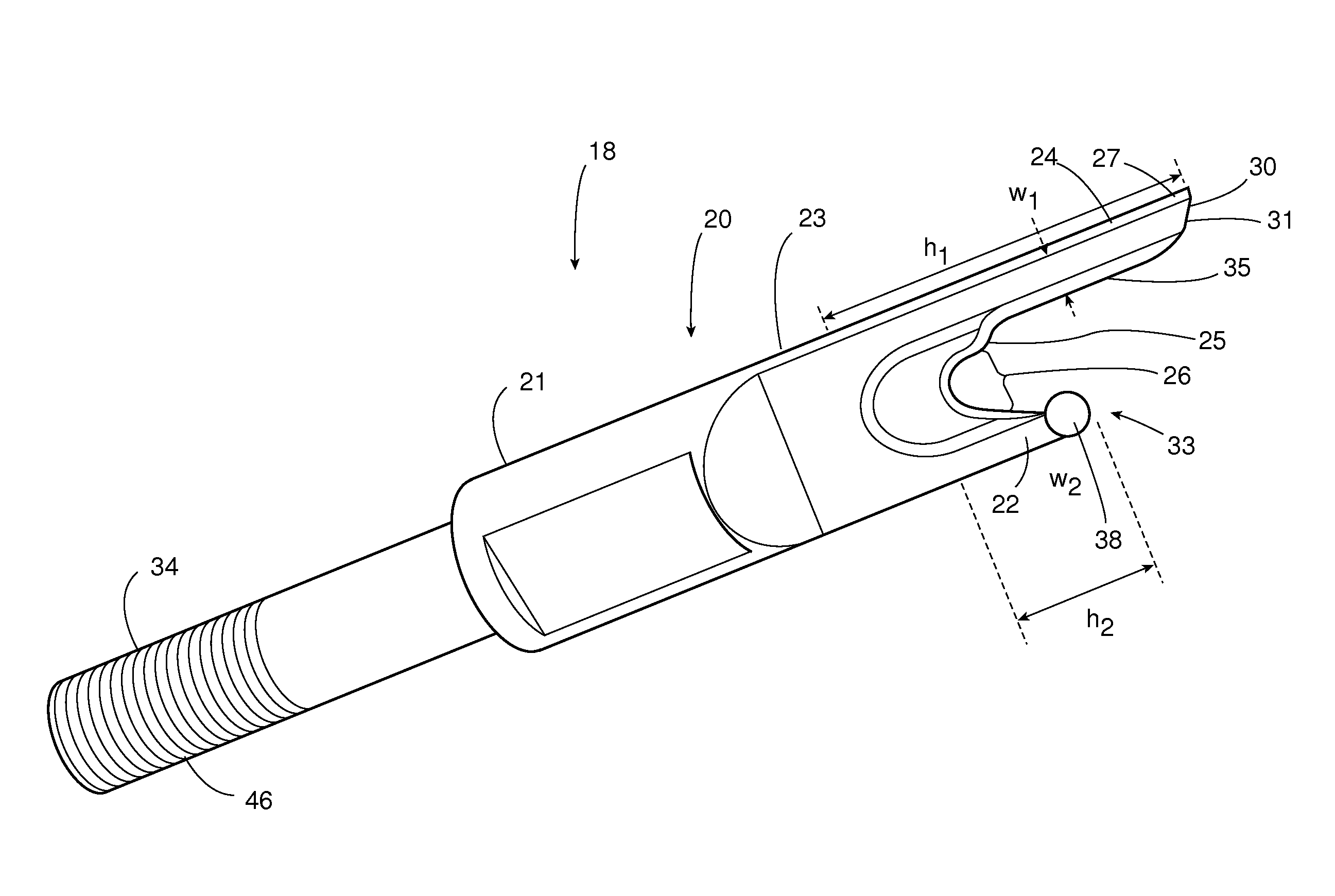

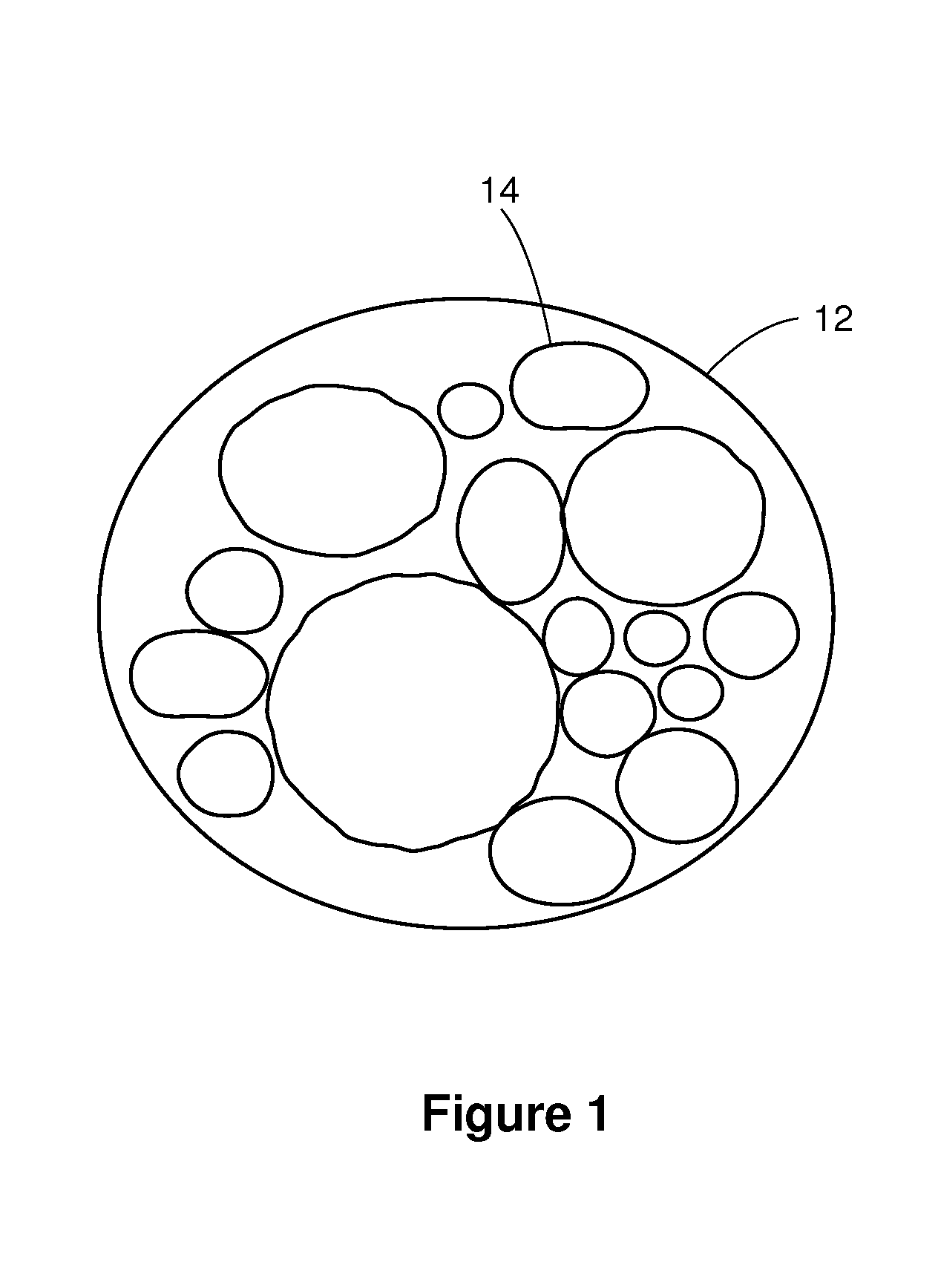

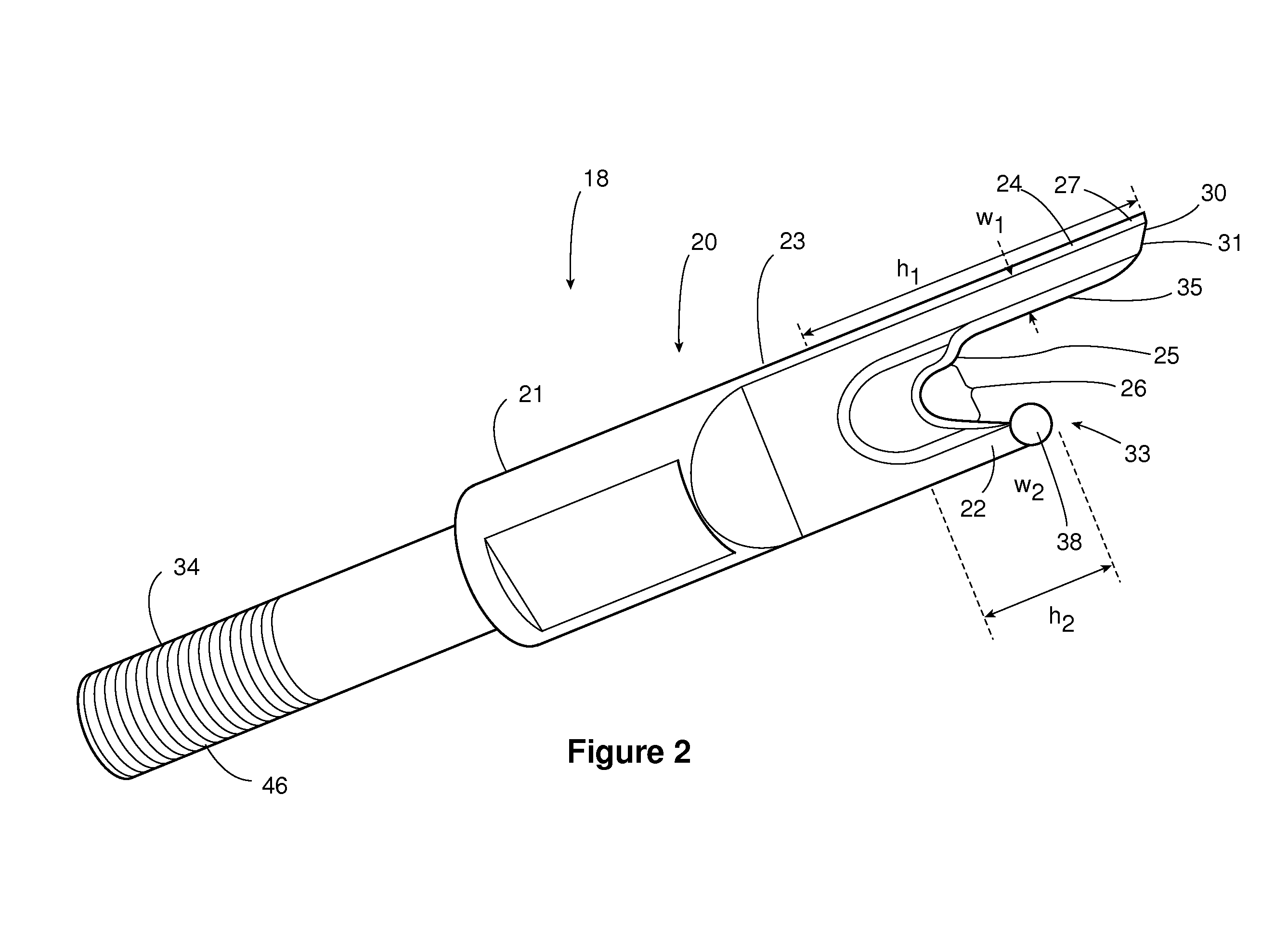

Industrial precision safety cutter

InactiveUS20130233135A1Improve security featuresPrecise cuttingMetal working apparatusMetal-working hand toolsEngineeringMechanical engineering

An industrial precision safety cutter and a method of using the same, the industrial cutter having a cutter head. The cutter head has a reinforcing body, a first prong extending from the body, a second prong extending from the body, and a cutting edge extending from the body. The first prong has a rounded end. The cutting edge extends between the first and second prongs. The industrial cutter has an extendable length handle removably connected to the cutter head. The industrial cutter may be used in applications in the nuclear power industry.

Owner:PANTHER MEDIA & DESIGN

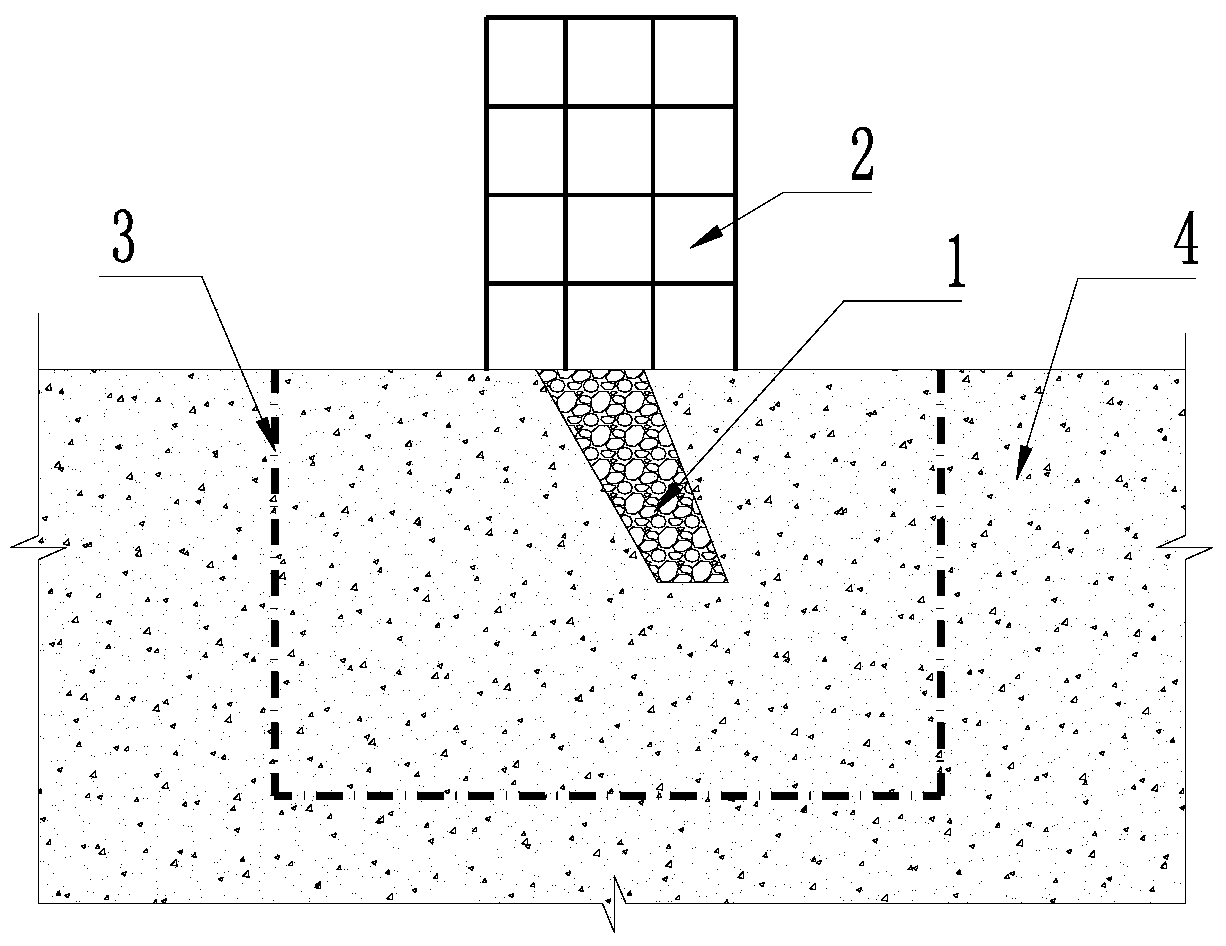

Method for foundation treatment and argument and analysis of vertical weak intercalated layer foundation in nuclear power plant

ActiveCN103882849AImprove adaptabilityIncrease flexibilitySpecial data processing applicationsIn situ soil foundationNuclear engineeringNuclear power plant

The invention relates to a method for foundation treatment and argument and analysis of a vertical weak intercalated layer foundation in a nuclear power plant. The method includes on-the-spot investigation, dynamic calculation analysis, static calculation analysis and foundation treatment scheme. By means of calculation and analysis, a vertical weak intercalated layer in a certain depth is replaced by concrete. The method has the advantages that adaptability of the power plant to nonuniform foundations is improved, flexibility in selection of a nuclear power plant address is improved, selection period of the nuclear power plant address is shortened to some extent, engineering construction cost is lowered, and competitiveness in the nuclear power industry is promoted.

Owner:CHINA NUCLEAR POWER ENG CO LTD

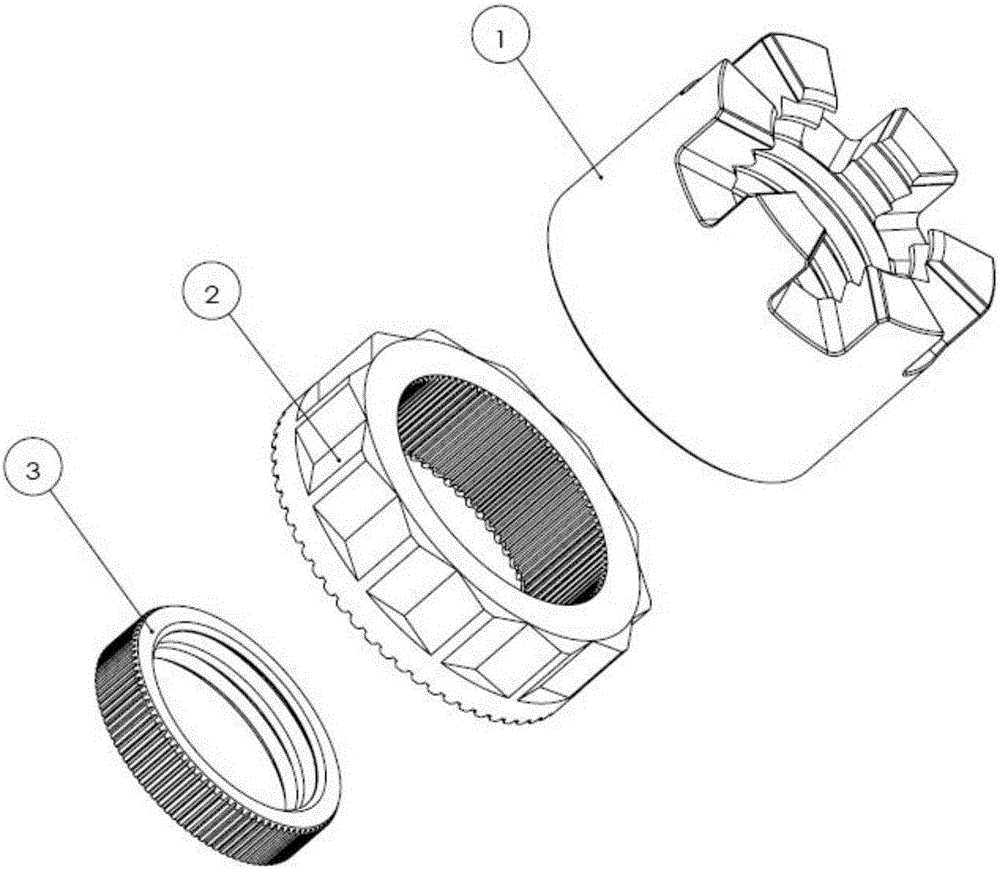

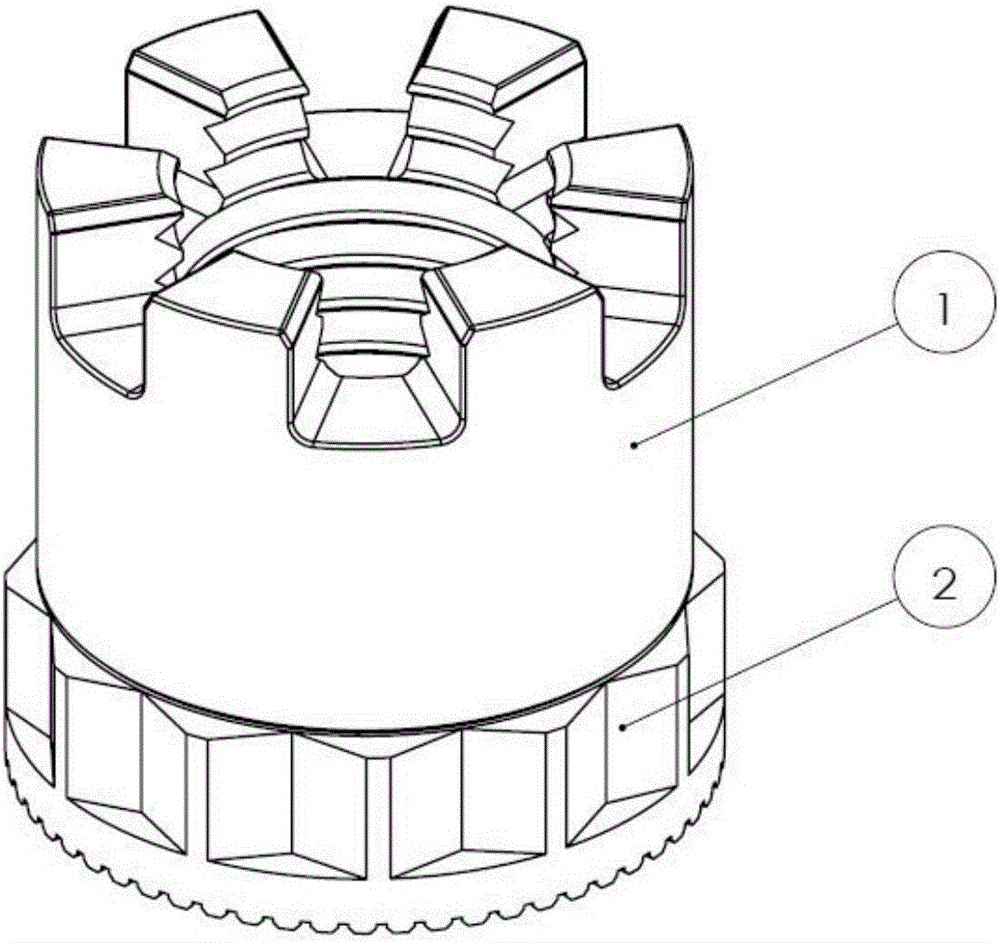

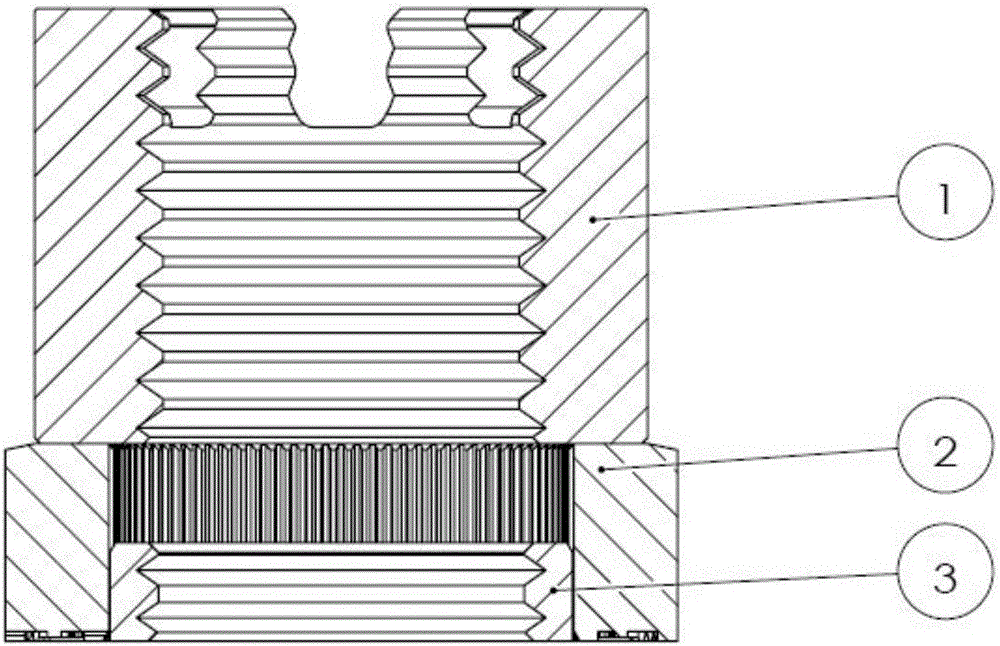

Combined type self-reaction-force locknut with high-precision torque coefficient

ActiveCN106837980AReduce failureImprove operational reliabilityNutsBoltsElectricityOffshore wind power

The invention relates to a combined type self-reaction-force locknut with a high-precision torque coefficient. The combined type self-reaction-force locknut comprises a slotted nut, a gasket and a thread ring. When a working bolt is in a tightened state, the thread ring is embedded between the gasket and the bolt in the form of a wedge-shaped ring, and connection between the working bolt and the nut is effectively prevented from loosening. According to the combined type self-reaction-force locknut, in bolt and nut connection in the mechanical industry, mounting is achieved at the level of the small friction coefficient to obtain precise bolt pre-tightening force, and the anti-loose function is kept all the time in the equipment operating process. According to the combined type self-reaction-force locknut, in the equipment operating process of the mechanical industry, especially the petroleum and petrochemical industry, the power generation industry, the offshore wind power industry, the nuclear power industry, the high-speed rail industry, the bridge industry and the like, the reliability and safety of bolt and nut connection are greatly increased, and therefore the frequency of manual point detection and maintenance of bolts and nuts is greatly reduced. By means of scale use and popularization of the combined type self-reaction-force locknut, unlimited economic value can be generated.

Owner:倍扣(上海)技术开发经营中心

Synchronous wrench

The invention discloses a synchronous wrench which comprises a fixed frame, two drive motors installed on the fixed frame, two bolt screwing components which are in transmission connection with rotary shafts of the two drive motors in a one-to-one correspondence manner and are used for disassembling two bolts which are in opposite corners and a control device which is in control connection with the drive motors. When the synchronous wrench works, the two bolt screwing components are matched with the two bolts in the opposite corners respectively, the control device controls the two drive motors to synchronously rotate, and thus the two bolt screwing components are driven to synchronously rotate, and synchronous mounting or disassembly of the two bolts in the opposite corners is realized. Compared with the existing manner of manually disassembling bolts one by one, by adopting the synchronous wrench, the two bolts in the opposite corners can be automatically and synchronously mounted once, so that the working efficiency is improved; and meanwhile, the two bolts in the opposite corners can be synchronously mounted and disassembled, so that the stress applied to the opposite corners in which the two bolts are located is uniform, and the sealing performance to a flange in the nuclear power industry can be improved.

Owner:FUJIAN NINGDE NUCLEAR POWER +1

Low-viscosity flow-second grouting material capable of being used in a nuclear power industry

The invention aims at the problem that a common cementitious grout has high viscosity after stirred and cannot satisfy a test requirement by a flow cone method, and is intended to prepare a low-viscosity cement-based grouting material without settlement or water segregation when water consumption is high. When the fluidity of the low-viscosity grouting material is measured, the flow second is 18-30s, so as to satisfy of the requirement of equipment manufacturers and design companies on the flowing property of the grouting material. In addition, a composite expanding agent is used to compensate the contraction of the cement-based grouting material, thereby avoiding later-stage contraction cracks of the cementitious grout.

Owner:GAOBEIDIAN CITY DAAO NEW TYPE BUILDING MATERIAL

Separation of metals

The invention provides a process for the separation of metals, the metals being comprised as the metal oxides in a mixed oxide sample, the process comprising: (i) adding the mixed oxide to a molten salt electrolyte and cathodically electrolysing the oxide, the potential of the cathode being controlled so as to favour oxygen ionisation over deposition of metal from the cations present in the molten salt, and the applied potential difference being such as to facilitate selective reduction of one metal oxide at the expense of other metal oxides; and (ii) separating the metal from the remaining metal oxides, wherein the metal oxides comprise oxides of metals from at least one of the transition metal, lanthanide or actinide series The process is applicable to mixed oxide samples comprising mixtures of two or more metal oxides, and a particular application is in the separation of zirconium and hafnium comprised in mixed zirconium and hafnium oxides, the removal of hafnium facilitating the use of the zirconium in fuel cladding for use in the nuclear power industry.

Owner:NEXIA SOLUTIONS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com