Preparation method for austenitic stainless steel used for 316LN nuclear power

A technology of austenitic stainless steel and nuclear power, which is applied in the field of preparation of 316LN austenitic stainless steel for nuclear power, can solve the problems that the performance cannot meet the production and application requirements, the intergranular corrosion resistance and mechanical properties are poor, and the balance control is difficult. Excellent resistance to marine and industrial atmospheric erosion, easy to operate, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

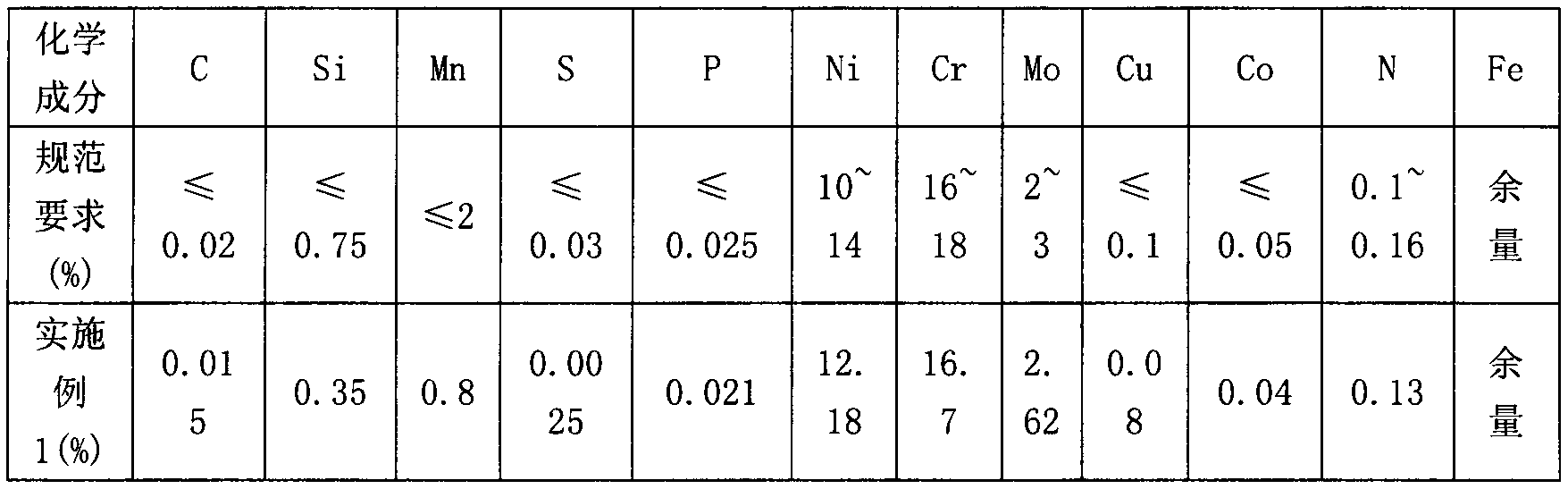

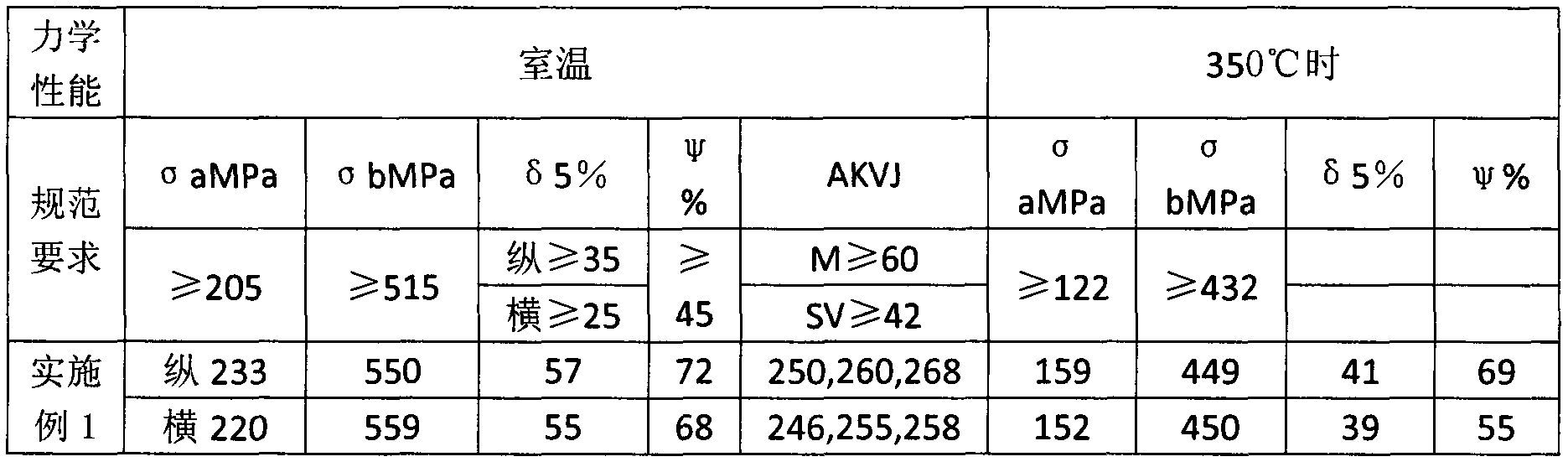

Embodiment 1

[0033] A preparation method for 316LN nuclear power austenitic stainless steel, comprising the following steps:

[0034] (1) Rough refining of EAF electric arc furnace

[0035] Select high-quality steel scrap with original ecological SP≤0.02% as raw material and add it to the EAF electric arc furnace for smelting. During the dephosphorization of ferronickel, control the Cr in the steel to ≤1.5%. Oxygen pressure 0.4~0.5Mpa, removal of P ≤ 0.012%, removal of C ≥ 0.5%; after slag flow during the oxidation period, control the temperature of the molten pool at 1630-1660°C, sample analysis, when P ≤ 0.012%, adjust the composition of molten steel, and raise the temperature to 1680 ℃ against steel, blowing N when mixing with steel 2 , 1100m 3 / h and add CaO, the amount of CaO added is 25Kg / ton of steel.

[0036] (2) AOD refining

[0037] (1) Phase I blowing: O 2 :N 2 = 4:1, the oxygen flow rate is controlled at 1900m 3 / h, the temperature is controlled at 1650-1670°C, and the c...

Embodiment 2

[0052] A preparation method for 316LN nuclear power austenitic stainless steel, comprising the following steps:

[0053] (1) Rough refining of EAF electric arc furnace

[0054] Select GCr15 high-quality scrap steel as raw material and add it to EAF electric arc furnace for smelting. During the dephosphorization of ferronickel, control the Cr in the steel to be ≤ 1.5%. , removal of P≤0.012%, removal of C≥0.5%; after slag flow in the oxidation period, control the temperature of the molten pool at 1630-1660°C, and take samples for analysis. Blow N 2 , 1140m 3 / h and add CaO, the amount of CaO added is 28Kg / ton of steel.

[0055] (2) AOD refining

[0056] (1) Phase I blowing: O 2 :N 2 =4.5:1, the oxygen flow rate is controlled at 1970m 3 / h, the temperature is controlled at 1650-1670°C, and the control components are Cr: 6.80-17.00%, Ni: 10.15-10.30%, Mo: 2.08-2.15%, and C: 0.20-0.30%.

[0057] (2) Phase II blowing: O 2 :N 2 =1:1.6, the oxygen flow rate is controlled at ...

Embodiment 3

[0069] A preparation method for 316LN nuclear power austenitic stainless steel, comprising the following steps:

[0070] (1) Rough refining of EAF electric arc furnace

[0071] Select high-quality steel scrap with original ecological SP≤0.02% as raw material and add it to the EAF electric arc furnace for smelting. During the dephosphorization of ferronickel, control the Cr in the steel to ≤1.5%. Oxygen pressure 0.4~0.5Mpa, removal of P ≤ 0.012%, removal of C ≥ 0.5%; after slag flow during the oxidation period, control the temperature of the molten pool at 1630-1660°C, sample analysis, when P ≤ 0.012%, adjust the composition of molten steel, and raise the temperature to 1700 ℃ against steel, blowing N when mixing with steel 2 , 1150m 3 / h and add CaO, the amount of CaO added is 30Kg / ton of steel.

[0072] (2) AOD refining

[0073] (1) Phase I blowing: O 2 :N 2 =5:1, the oxygen flow rate is controlled at 1950m 3 / h, the temperature is controlled at 1650-1670°C, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com