Crosslinkable, radiation-resistant, highly-flame-retardant, low-smoke and zero-halogen cable material and preparation method of cable material

A high flame retardant and radiation-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as affecting the mechanical properties, aging properties and radiation resistance properties of products, increasing the cost of cable materials, affecting product performance, etc., to achieve low cost. , easy operation, long thermal life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

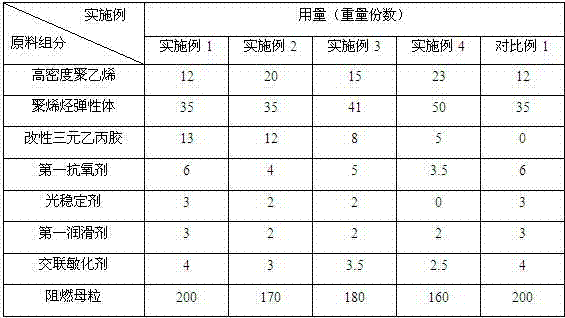

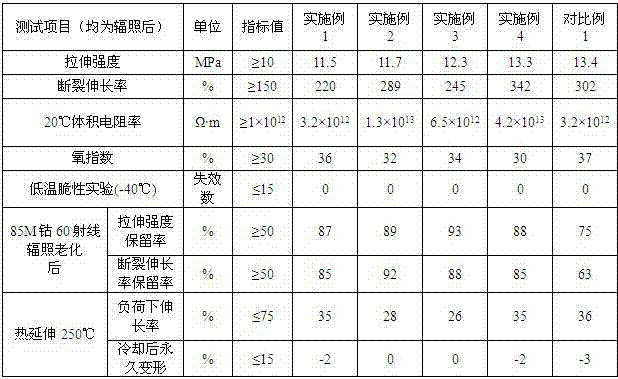

[0049] This example provides a preparation method of a cross-linkable radiation-resistant high flame-retardant low-smoke halogen-free cable material. The raw materials and dosages used are shown in Table 1, wherein:

[0050] High-density polyethylene: composed of high-density polyethylene with a melt index of 2g / 10min and high-density polyethylene with a melt index of 8g / 10min in a weight ratio of 1:0.4;

[0051] Polyolefin elastomer: composed of ethylene-octene copolymer with Shore A hardness of 85 and ethylene-butyl acrylate copolymer with Shore A hardness of 80 in a weight ratio of 1:2;

[0052] Modified EPDM rubber: use methylphenylpolysiloxane organosilicon structure to modify EPDM rubber;

[0053] The first antioxidant: composed of antioxidant RD, antioxidant 300, antioxidant 1010 and antioxidant 1076, and its weight ratio is 0.8:1.2:0.3:2;

[0054] Light stabilizer: 2,2,6,6-tetramethylpyridinol;

[0055] The first lubricant: composed of magnesium stearate, polyethylene ...

Embodiment 2

[0062] This example provides a method for preparing cross-linkable radiation-resistant, high-flame-retardant, low-smoke and halogen-free cable materials. The raw materials and dosages used are shown in Table 1. The raw materials other than high-density polyethylene and the first antioxidant are all the same as Example 1 is the same.

[0063] In this example, the selected high-density polyethylene is high-density polyethylene with a melt index of 0.5 g / 10min.

[0064] In this example, the first antioxidant is antioxidant RD, antioxidant 300, antioxidant 1024 and antioxidant 1076, and the weight ratio is 0.8:1.2:0.3:2.

[0065] The preparation process of the cross-linkable radiation-resistant high flame-retardant low-smoke halogen-free cable material is the same as that in Example 1.

Embodiment 3

[0067] This example provides a preparation method for cross-linkable radiation-resistant, high-flame-retardant, low-smoke and halogen-free cable materials. The raw materials and dosages used are shown in Table 1. The raw materials other than polyolefin elastomer and the first lubricant are the same as those in the implementation Example 1 is the same.

[0068] In this example, the selected polyolefin elastomer is an ethylene-butyl acrylate copolymer with a Shore A hardness of 80.

[0069] In this example, the selected first lubricant is composed of calcium stearate, polyethylene wax and silicone oil in a weight ratio of 1:3:1.5.

[0070] The preparation process of the cross-linkable radiation-resistant high flame-retardant low-smoke halogen-free cable material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com