Combined type self-reaction-force locknut with high-precision torque coefficient

A technology of anti-loosening nuts and torque coefficients, applied in the direction of nuts, screws, bolts, etc., can solve the problems of impact, reduce equipment output, and huge cost, so as to reduce failure, increase effective production time, and improve operation reliability and safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

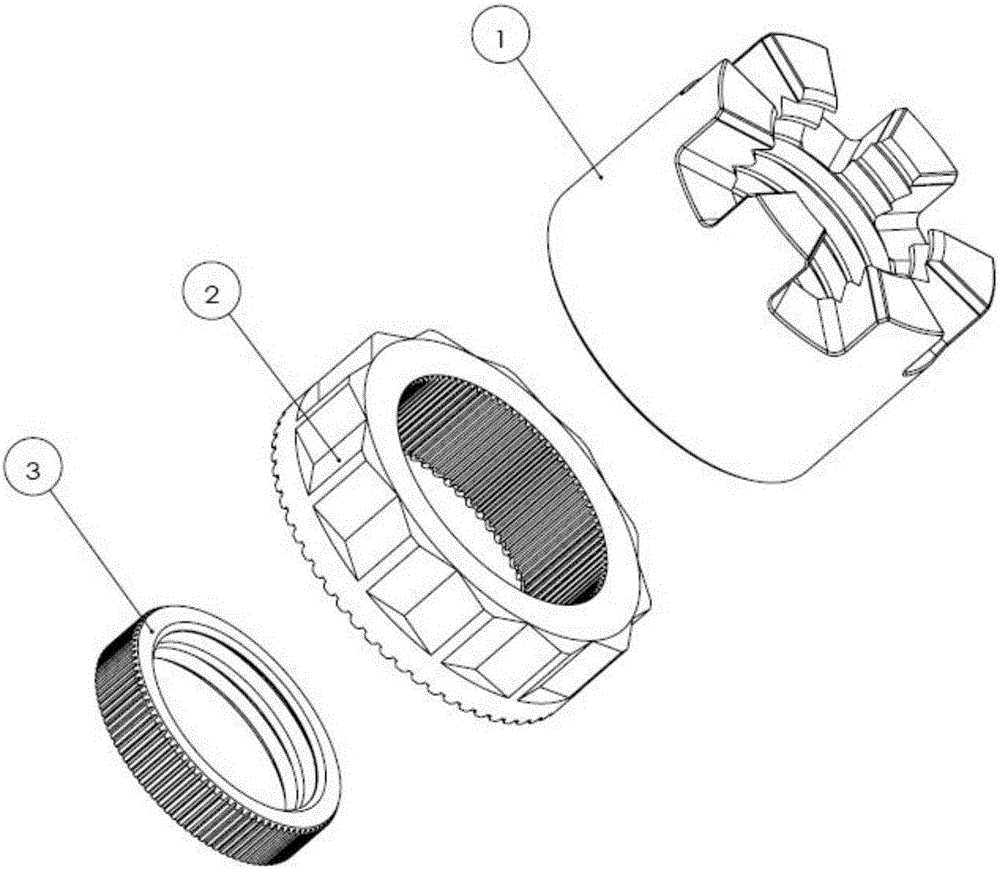

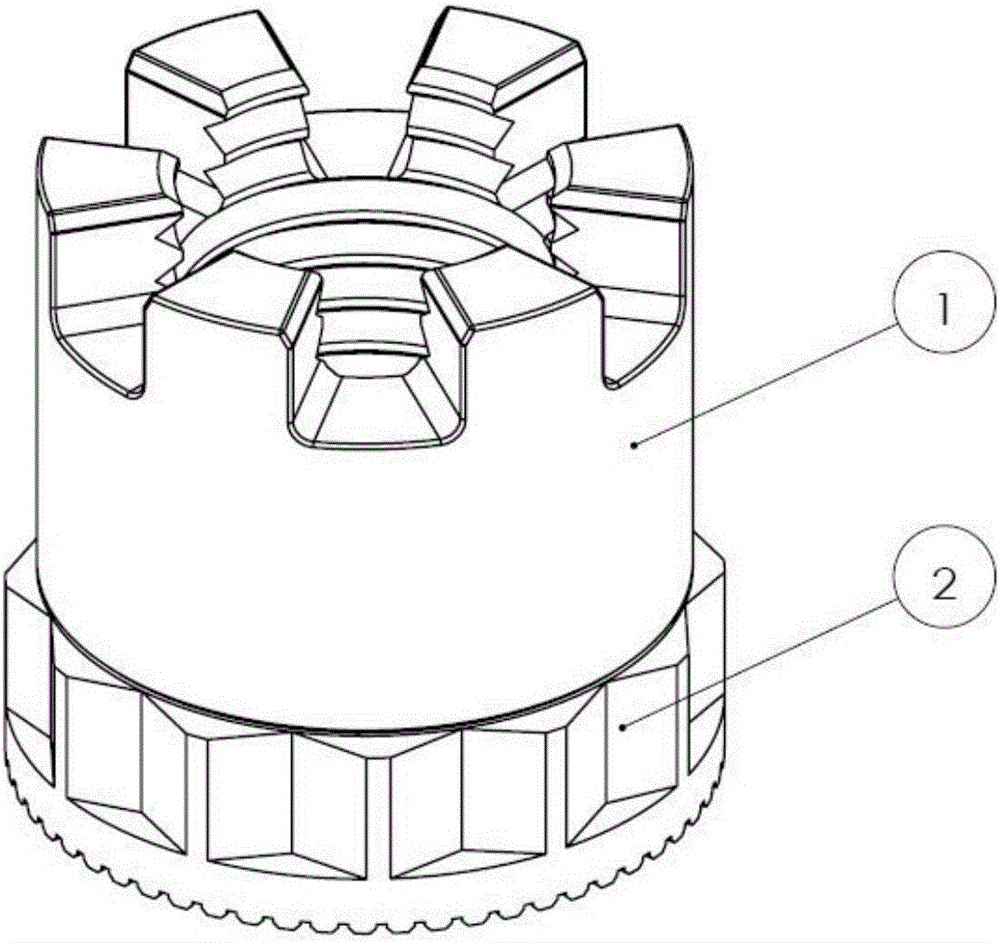

[0031] see figure 1 , the figure is an exploded schematic view of the combined self-reflective locknut with a high-precision torque coefficient of this embodiment, including a slotted nut 1, a washer 2 containing a taper inner spline, and a common Threaded ring 3 with internal thread and small external spline.

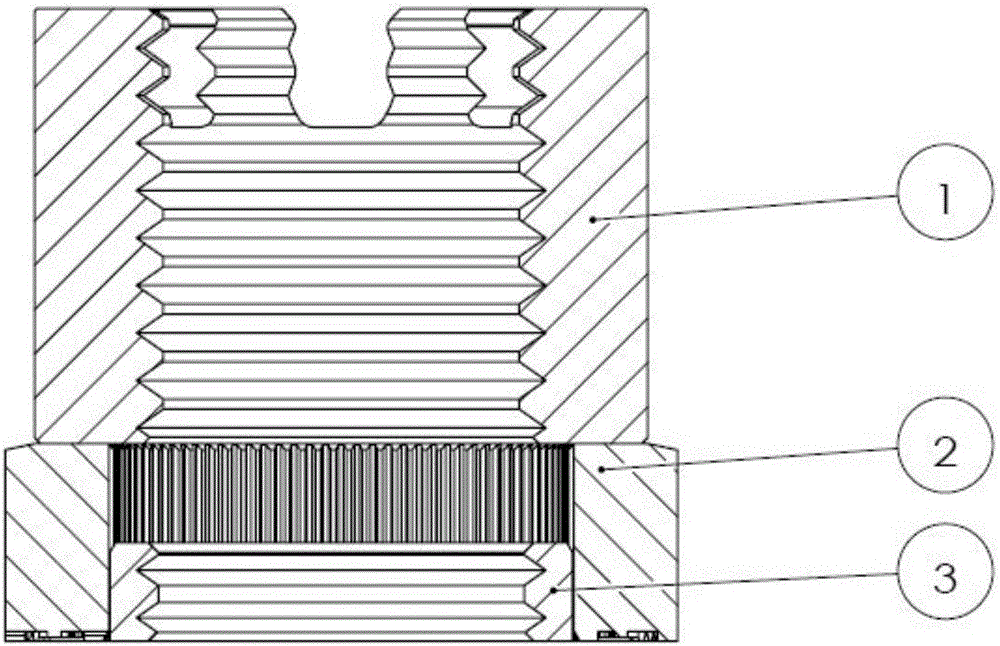

[0032] In this embodiment, the contact surface between the slotted nut 1 and the washer 2 containing the tapered internal spline is a smooth surface, so as to ensure that the friction coefficient between the mating surfaces will not change too much and affect the bolt under the same torque. The deformation accuracy of stretching; the bottom of the gasket 2 is provided with rough anti-slip lines, and the present embodiment is a sawtooth anti-slip line, such as Figure 4 As shown, the bottom surface of the multi-tooth shape is in contact with the surface of the base part 4 of the mechanical equipment when the bolt is tightened, and is used to increase the friction betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com