Preparation method of hexagonal dense boron nitride block body

A boron nitride block and cubic boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as reducing high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

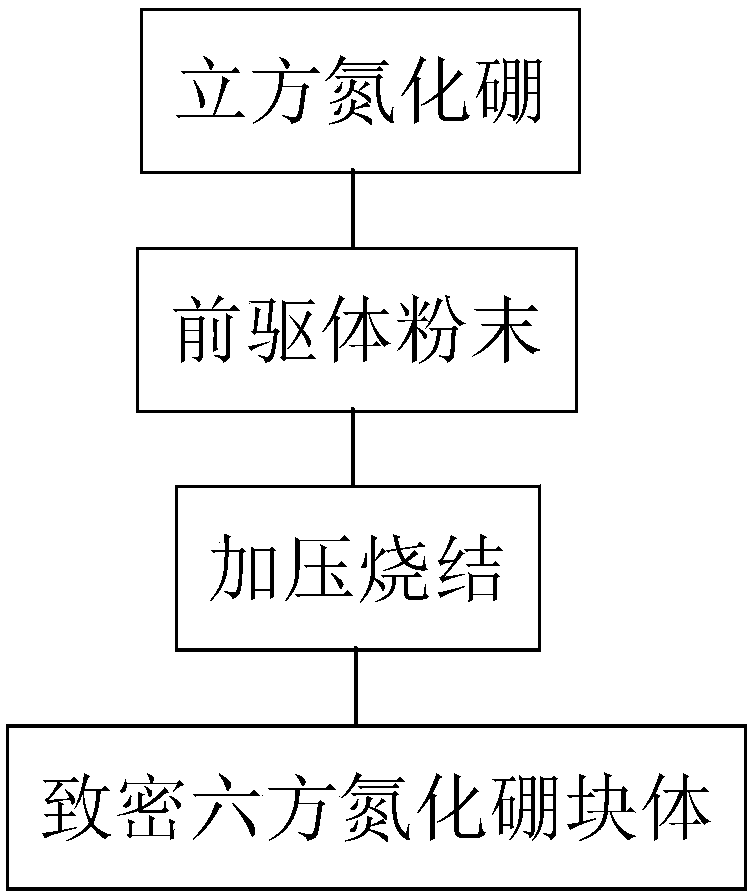

[0026] as attached figure 1 The process shown in the process, the preparation method of dense hexagonal boron nitride block, including the preparation of composite boron nitride powder, sintering of dense boron nitride block, the specific steps are as follows:

[0027] (1) Preparation of composite boron nitride powder: first weigh 2.5g of 200nm and 0.25g of 100nm cubic boron nitride powder respectively, mix them in a mortar, grind for 10min, and put the ground mixed powder into a beaker , and then measure 50ml of absolute ethanol, pour it into a beaker with mixed powder, put the beaker into an ultrasonic cleaner, and use 120W power to ultrasonically disperse for 20min; then ultrasonically oscillate the dispersed solution and place it under constant temperature magnetic stirring On the mixer, at a temperature of 65°C, stir slowly to evaporate the solvent until the solution becomes a paste, then put the obtained sample in an oven at 60°C and dry until it is basically dry; take i...

Embodiment 2

[0030] A method for preparing a dense isotropic hexagonal boron nitride block is characterized in that it comprises two steps of preparation of composite boron nitride powder and sintering of the dense boron nitride block, and the specific steps are as follows:

[0031] (1) Preparation of composite boron nitride powder: first weigh 2.5g of 200nm and 0.25g of 100nm cubic boron nitride powder respectively, mix them in a mortar, grind for 10min, put the ground mixed powder into a beaker , then measure 50ml of absolute ethanol, pour it into a beaker with mixed powder, put the beaker into an ultrasonic cleaner, and use 120W power to ultrasonically disperse for 20min; Stir slowly on a stirrer at a temperature of 65°C to evaporate the solvent until the solution becomes a paste, then put the obtained sample in an oven at 60°C and dry until it is basically dry; take it out and put it in a mortar, drip Add a few drops of absolute ethanol to grind until dry, and repeat the operation 4 ti...

Embodiment 3

[0034] A method for preparing a dense isotropic hexagonal boron nitride block is characterized in that it comprises two steps of preparation of composite boron nitride powder and sintering of the dense boron nitride block, and the specific steps are as follows:

[0035] (1) Preparation of composite boron nitride powder: first weigh 2.5g of 200nm and 0.25g of 100nm cubic boron nitride powder respectively, mix them in a mortar, grind for 10min, put the ground mixed powder into a beaker , then measure 50ml of absolute ethanol, pour it into a beaker with mixed powder, put the beaker into an ultrasonic cleaner, and use 120W power to ultrasonically disperse for 20min; Stir slowly on a stirrer at a temperature of 65°C to evaporate the solvent until the solution becomes a paste, then put the obtained sample in an oven at 60°C and dry until it is basically dry; take it out and put it in a mortar, drip Add a few drops of absolute ethanol to grind until dry, and repeat the operation 4 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com