Intelligent laser cleaning equipment and method for nuclear power industry

A laser cleaning and industrial technology, applied in the field of laser cleaning, can solve problems such as difficult removal, personnel pollution hazards, and personnel exposure to nuclear radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

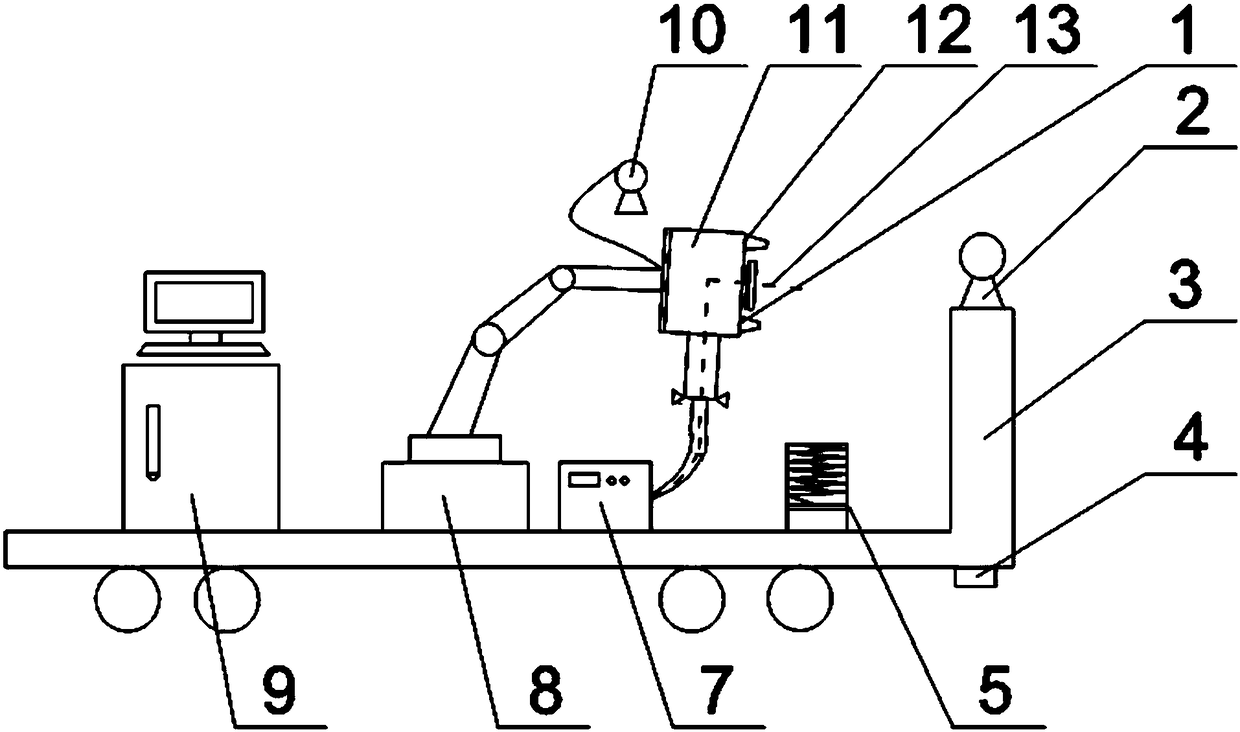

[0027] Such as Figure 1-2 shown. The invention discloses an intelligent laser cleaning equipment used in the nuclear power industry, comprising a vehicle frame 3, an integrated controller 9 arranged on the vehicle frame 3, a cleaning arm mechanism 8, a laser optical fiber integrated system 7, and a compression pump 5;

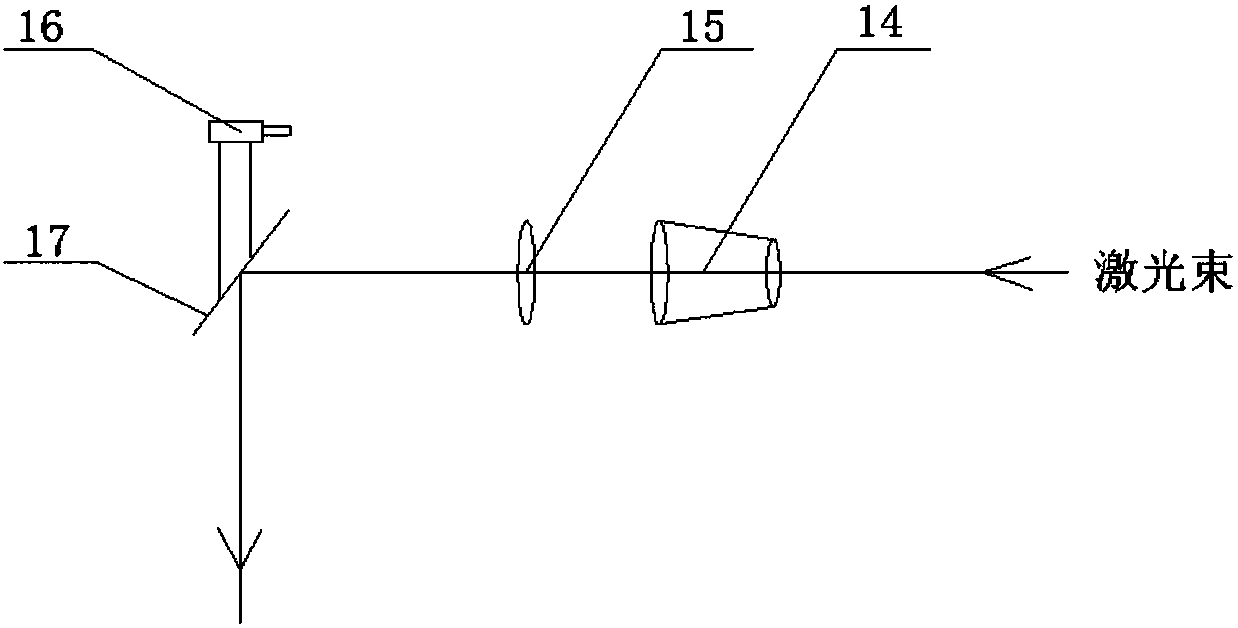

[0028] The cleaning arm mechanism 8 includes a mechanical arm, and the galvanometer integrated system 11 is installed at the front end of the mechanical arm; the front end of the shell of the galvanometer integrated system 11 has a concave suction head 12; the dust suction head 12 is connected to the compression pump 5 through a pipeline ;

[0029] The laser fiber integrated system 7 is connected to the galvanometer integrated system 11 through the optical fiber optical path, and transmits laser light between each other;

[0030] The integrated controller 9 is connected with the laser fiber integrated system 7, the galvanometer integrated system 11, the clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com