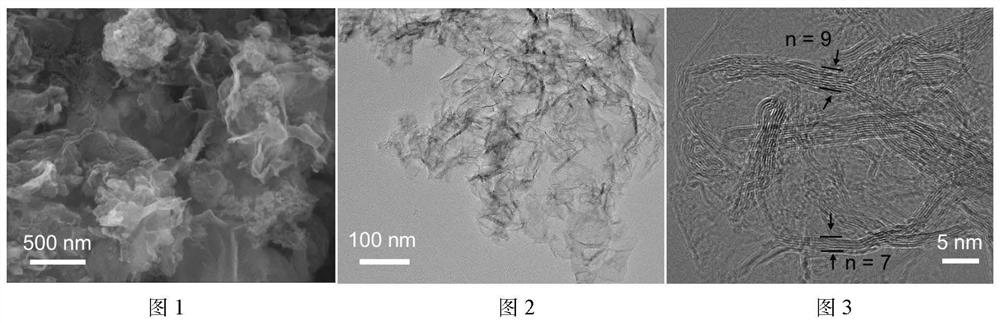

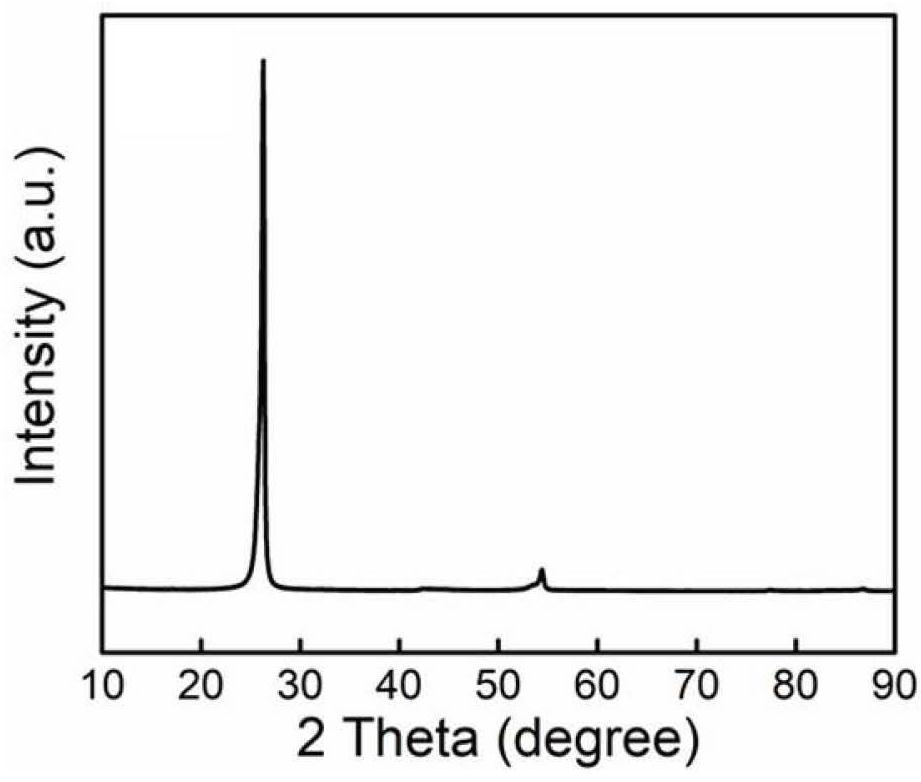

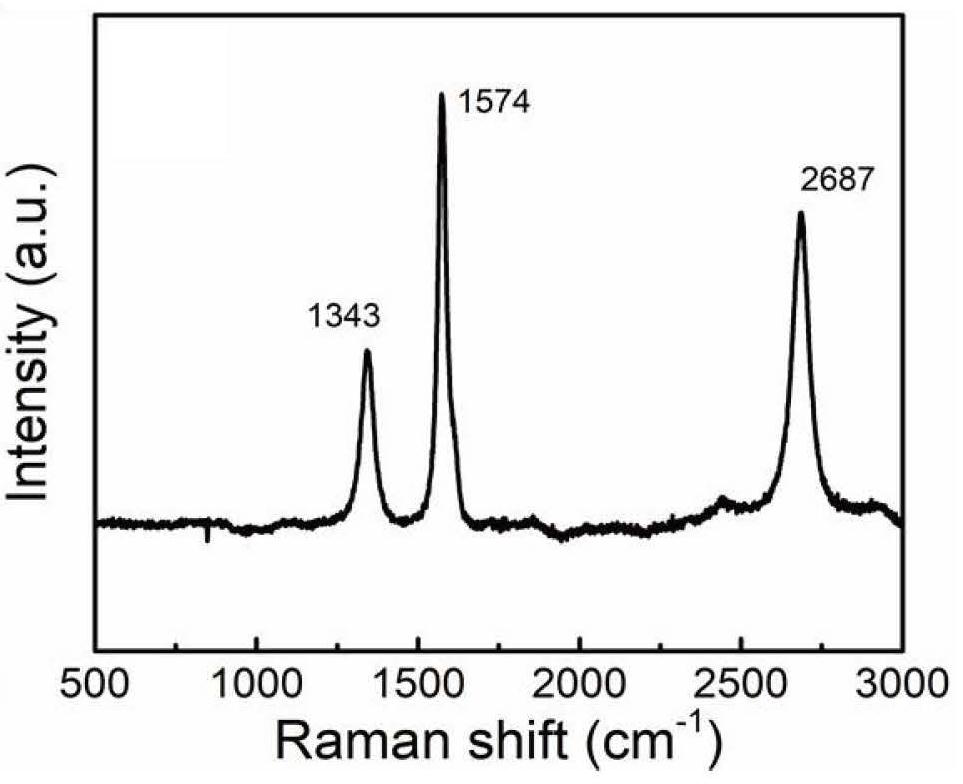

High-strength carbon-based material based on combustion synthesis of graphene and preparation method of high-strength carbon-based material

A technology for combustion synthesis and carbon-based materials, applied in the field of carbon-based materials, it can solve the problems of poor mechanical properties of materials and complex preparation processes, and achieve excellent isotropy, high reactivity, and rich edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The reactants were weighed according to the weight ratio of magnesium powder and calcium carbonate at 24:50, mixed evenly, and put into a ceramic boat. According to 0.5L.s -1 The flow rate is passed into the protective atmosphere of carbon dioxide, and after the protective gas is filled, ignition starts to cause a self-propagating combustion reaction. The ignition device adopts a DC voltage stabilized power supply with a resistance wire, and the self-propagating combustion reaction is caused by setting the current of the DC voltage stabilized power supply to make the end of the resistance wire heat up. After the combustion synthesis reaction is completed, the introduction of carbon dioxide gas is stopped, cooled to room temperature, the reaction product is taken out, the combustion powder is repeatedly washed with hydrochloric acid, and dried to obtain combustion synthesis graphene powder. In parts by weight, weigh 6 parts of burning synthetic graphene, put it into a z...

Embodiment 2

[0060] The reactants were weighed according to the weight ratio of magnesium powder, calcium carbonate, and phosphorus pentoxide at 24:50:6, mixed evenly, and placed in a ceramic boat. According to 0.5L.s -1 The flow rate is passed into the protective atmosphere of carbon dioxide, and after the protective gas is filled, ignition starts to cause a self-propagating combustion reaction. After the combustion synthesis reaction is completed, the introduction of carbon dioxide gas is stopped, cooled to room temperature, the reaction product is taken out, the powder after combustion is repeatedly washed with hydrochloric acid, and dried to obtain phosphorus-doped combustion synthesis graphene powder.

[0061] In parts by weight, weigh 10 parts of phosphorus-doped combustion-synthesized graphene, and put it into a zirconia tank together with 90 parts of zirconia balls. Ball milled for 48 hours at 300 rpm. After the ball milling is completed, the zirconia balls are screened out to ob...

Embodiment 3

[0063] Weigh urea, magnesium powder and calcium carbonate in a weight ratio of 8:24:50, mix them evenly, and put them into a ceramic boat after mixing them evenly. According to 0.5L.s -1 The flow rate is passed into the protective atmosphere of carbon dioxide, and after the protective gas is filled, ignition starts to cause a self-propagating combustion reaction. After the combustion synthesis reaction is completed, the introduction of carbon dioxide gas is stopped, cooled to room temperature, the reaction product is taken out, the powder after combustion is repeatedly washed with hydrochloric acid, and dried to obtain a nitrogen-doped combustion synthesis graphene powder. In parts by weight, 5 parts of nitrogen-doped and combusted graphene were weighed and sintered by vacuum hot pressing, the sintering temperature was 1400° C., the sintering pressure was 40 MPa, and the sintering time was 10 min to prepare a carbon-based composite material. The flexural strength was tested t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com