Nuclear graphite material composition and preprocessing method

A technology of nuclear graphite and pretreatment, which is applied in the field of graphite production, nuclear graphite material combination and its processing, which can solve the problems of reducing the oxidation resistance of materials, increasing the difficulty of nuclear graphite purification, and increasing the manufacturing process, so as to achieve stable and guaranteed supply sources , easy to purify, and reduce the effect of the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The nuclear graphite material manufacturing raw material of the present embodiment contains the following components by weight:

[0042] 20 parts of petroleum coke powder, 70 parts of pitch coke powder, 10 parts of graphite powder, 1-3 parts of surfactant, 40-45 parts of coal tar pitch. During preparation, the above-mentioned powder is ground to 15-22 μm, kneaded, secondary pulverized, molded preformed, isostatically pressed, roasted, and crushed to become the raw material for nucleated graphite production. The raw material parameters are shown in the table below.

Embodiment 2

[0044] The nuclear graphite material manufacturing raw material of the present embodiment contains the following components by weight:

[0045] 10 parts of petroleum coke powder, 80 parts of pitch coke powder, 15 parts of graphite powder, 1-3 parts of surfactant, 40-45 parts of coal tar pitch. During preparation, the above-mentioned powder is ground to 15-22 μm, kneaded, secondary pulverized, molded preformed, isostatically pressed, roasted, and crushed to become the raw material for nucleated graphite production. The raw material parameters are shown in the table below.

[0046] Other process conditions remain unchanged during the implementation of the above scheme.

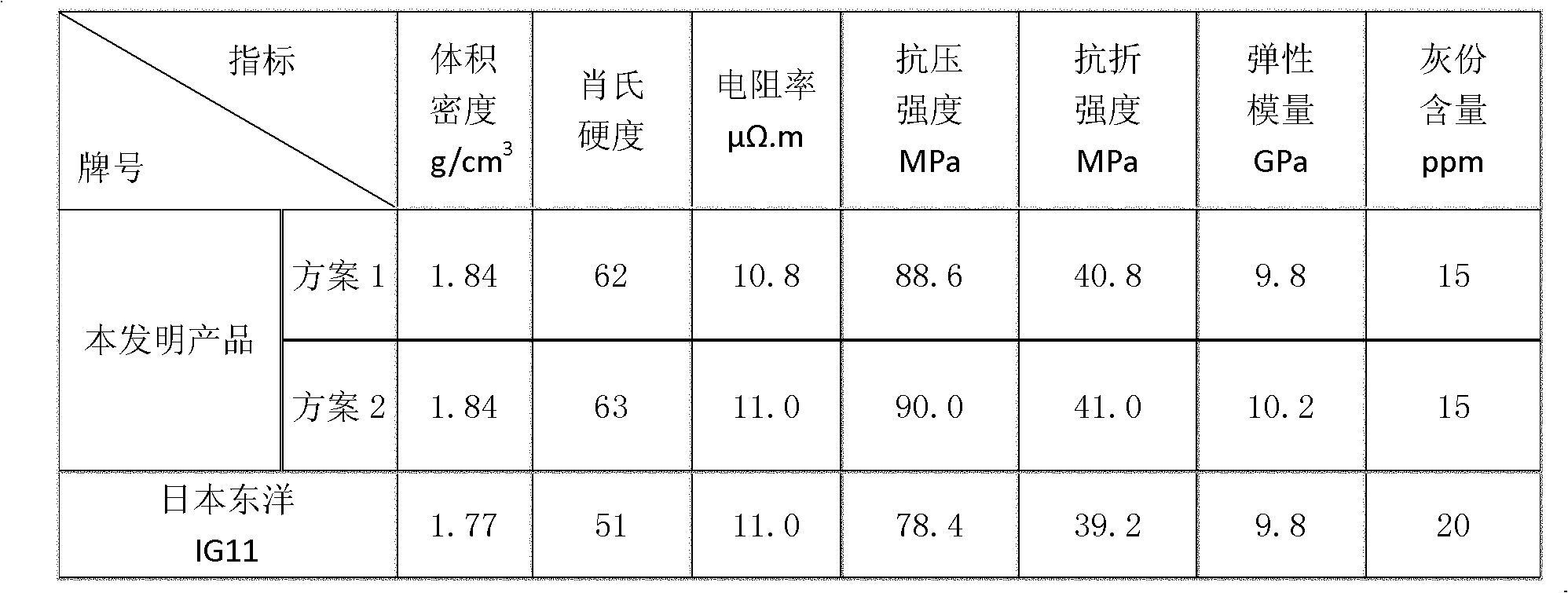

[0047] The physicochemical index of nuclear graphite material made with the pretreatment raw material of the present invention

[0048]

[0049] The present invention pretreats the domestic common raw materials by adopting the granular composition formula and the isostatic pressing method to prepare the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com