Preparation method of high-density, large-scale, ultra-fine pore core graphite material for molten salt reactor

A high-density, large-size technology, which is applied in the field of preparation of high-density and large-size ultra-fine-pore nuclear graphite materials for molten salt reactors, can solve the problems of large specific surface area and surface energy of particles, and the inability to prepare large-size nuclear graphite materials. Achieve uniform internal temperature, eliminate voids, and avoid stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

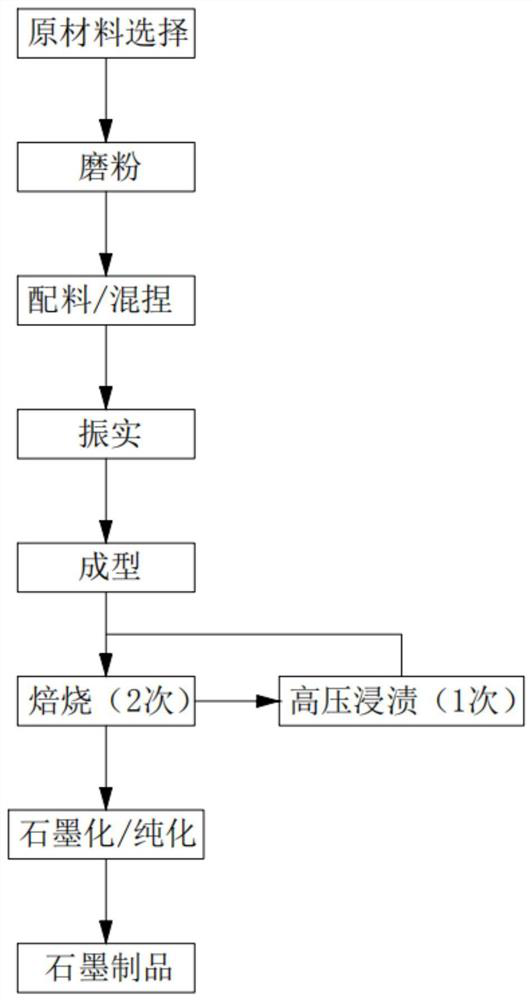

Method used

Image

Examples

Embodiment 1

[0098] 1. Raw materials: 80 parts by weight of pitch coke with an average particle size of 1 μm and 20 parts by weight of pitch;

[0099] 2. Preparation method:

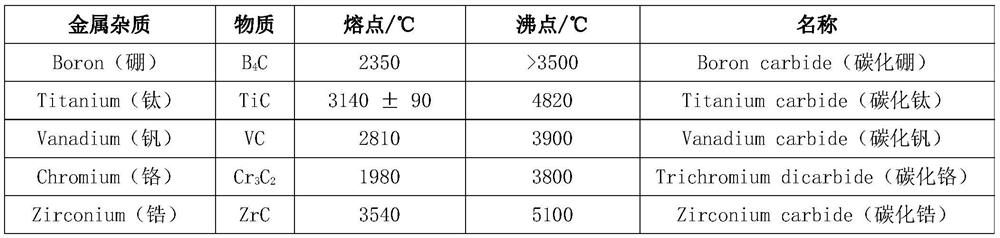

[0100] 1) Selection of raw materials: coke aggregate and binder, fixed carbon content in coke aggregate is ≥98.5%, ash content ≤0.5%, boron (B) and gadolinium (Gd) are less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) are all less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.1%;

[0101] The ash content in the binder is ≤0.5%, the volatile content is 35-60%, the coking value is 40-70%, the softening point is 80-200°C, the quinoline insoluble matter is 8-25%, and the toluene insoluble matter is 25- 55%;

[0102] 2) Raw material grinding: the coke aggregate is ground and pulverized so that the average particle size does not exceed 1 μm;

[0103] 3) Ingredients and kneading: Pour pitch coke and pitch into a kneader and knead at a temperature of 150°C for 80 minutes;

[0104] 4) Molding: put the...

Embodiment 2

[0110] 1. Raw materials: 70 parts by weight of petroleum coke with an average particle size of 3 μm and 30 parts by weight of pitch;

[0111] 2. Preparation method:

[0112] 1) Selection of raw materials: coke aggregate and binder, fixed carbon content in coke aggregate is ≥98.5%, ash content ≤0.5%, boron (B) and gadolinium (Gd) are less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) are all less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.1%;

[0113] The ash content in the binder is ≤0.5%, the volatile content is 35-60%, the coking value is 40-70%, the softening point is 80-200°C, the quinoline insoluble matter is 8-25%, and the toluene insoluble matter is 25- 55%;

[0114] 2) Raw material grinding: the coke aggregate is ground and pulverized so that the average particle size does not exceed 3 μm;

[0115] 3) Batching and kneading: Pour pitch coke and pitch into a kneader and knead at a temperature of 300°C for 120 minutes;

[0116] 4) Molding: put t...

Embodiment 3

[0122] 1. Raw materials: 65 parts by weight of pitch coke with an average particle size of 5 μm and 35 parts by weight of pitch;

[0123] 2. Preparation method:

[0124] 1) Selection of raw materials: coke aggregate and binder, fixed carbon content in coke aggregate is ≥98.5%, ash content ≤0.5%, boron (B) and gadolinium (Gd) are less than 0.1ppm, samarium (Sm), europium (Eu), cadmium (Cd) and lithium (Li) are all less than 0.5ppm, moisture ≤0.5%, sulfur ≤0.1%;

[0125] The ash content in the binder is ≤0.5%, the volatile content is 35-60%, the coking value is 40-70%, the softening point is 80-200°C, the quinoline insoluble matter is 8-25%, and the toluene insoluble matter is 25- 55%;

[0126] 2) Raw material grinding: the coke aggregate is ground and pulverized so that the average particle size does not exceed 5 μm;

[0127] 3) Ingredients and kneading: Pour pitch coke and pitch into a kneader and knead at a temperature of 400°C for 150 minutes;

[0128] 4) Molding: put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com