Wedge device of bending machine

A bending machine and inclined iron technology, which is applied in the field of bending machine inclined iron device, can solve the problems affecting the accuracy of the machine tool and vibration, and achieve the effects of ensuring consistency, eliminating mechanism intermittent, and eliminating slider shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

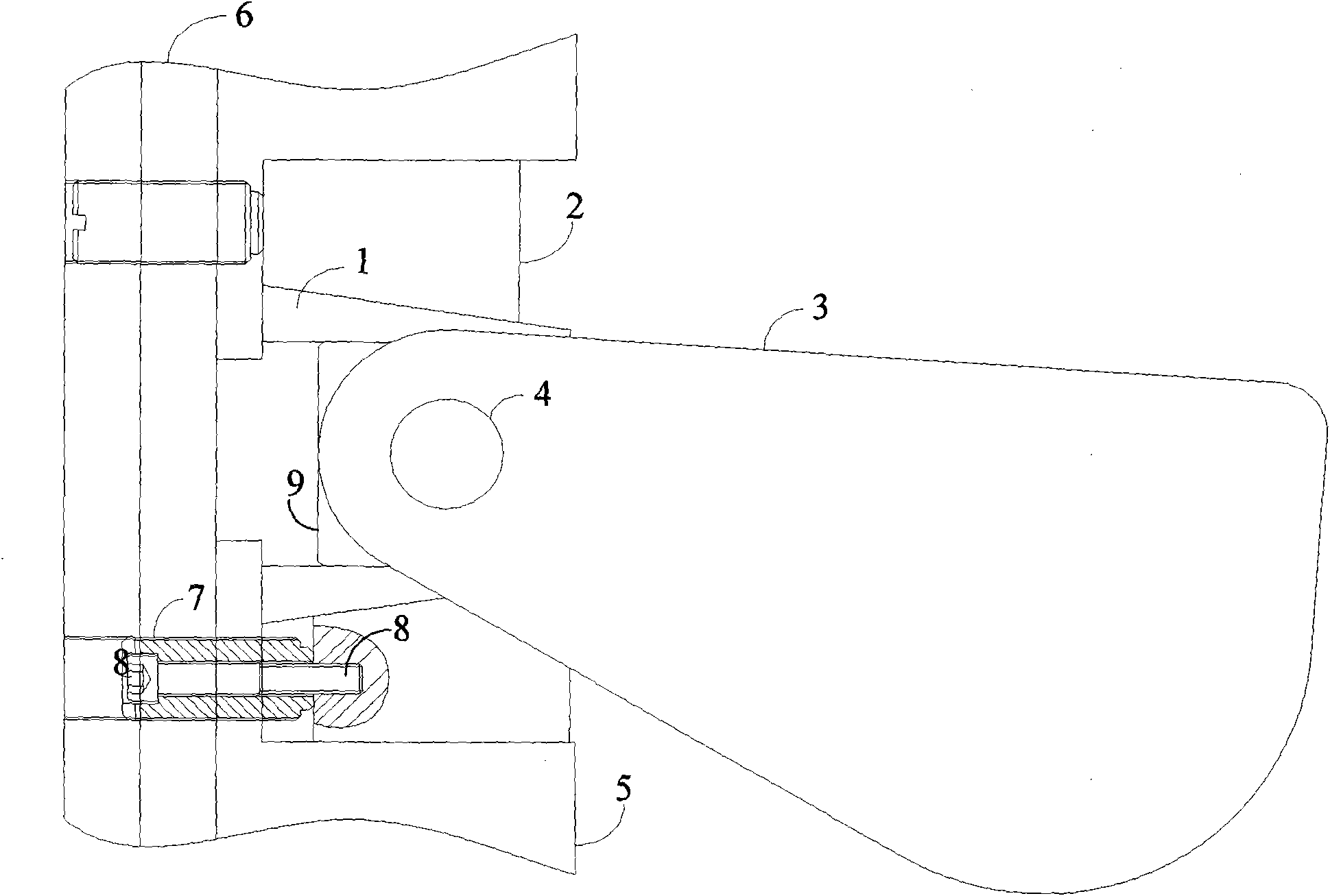

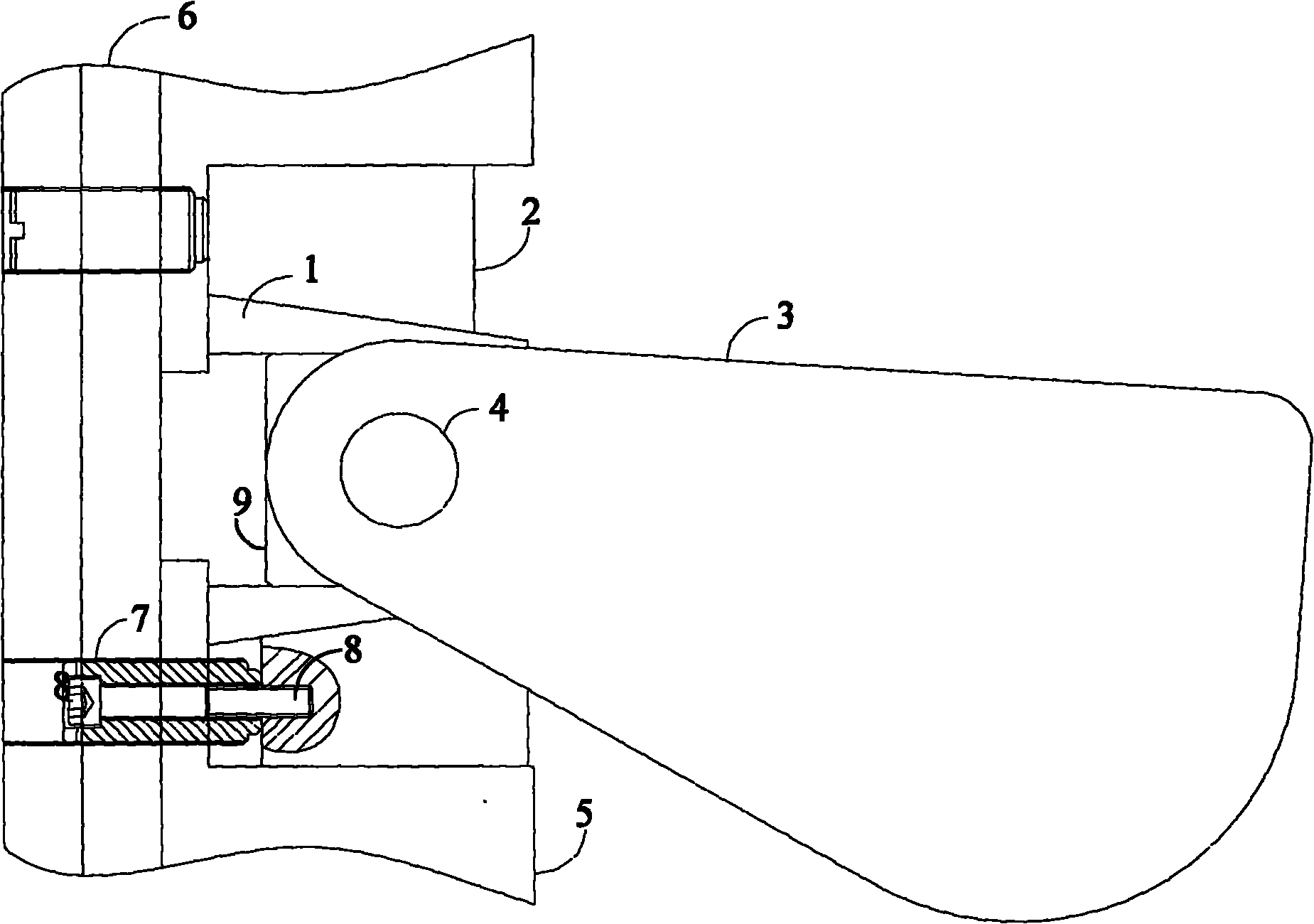

[0014] An inclined iron device for a bending machine, comprising: a slider 6, a sliding block 9, a fixed seat 5, and the fixed seat 5 is fixed on the slider 6, and also includes: two sets of inclined iron components fitted to the fixed seat 5, the inclined iron The components specifically include: the lower inclined iron 1 and the upper inclined iron 2, the lower inclined iron 1 and the upper inclined iron 2 are bonded, the bonding surface is an inclined sliding surface, the two sets of inclined iron components cooperate to form a chute, and the sliding block cooperates with the chute In the same group of inclined iron components, the lower inclined iron 1 or the upper inclined iron 2 and the slider 6 are connected by a telescopic mechanism.

[0015] The telescoping mechanism includes: a tension screw 7 and a push screw sleeve 8 .

[0016] see figure 1 A specific embodiment of the present invention further describes a bending machine inclined iron device of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com