Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3088 results about "Press brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

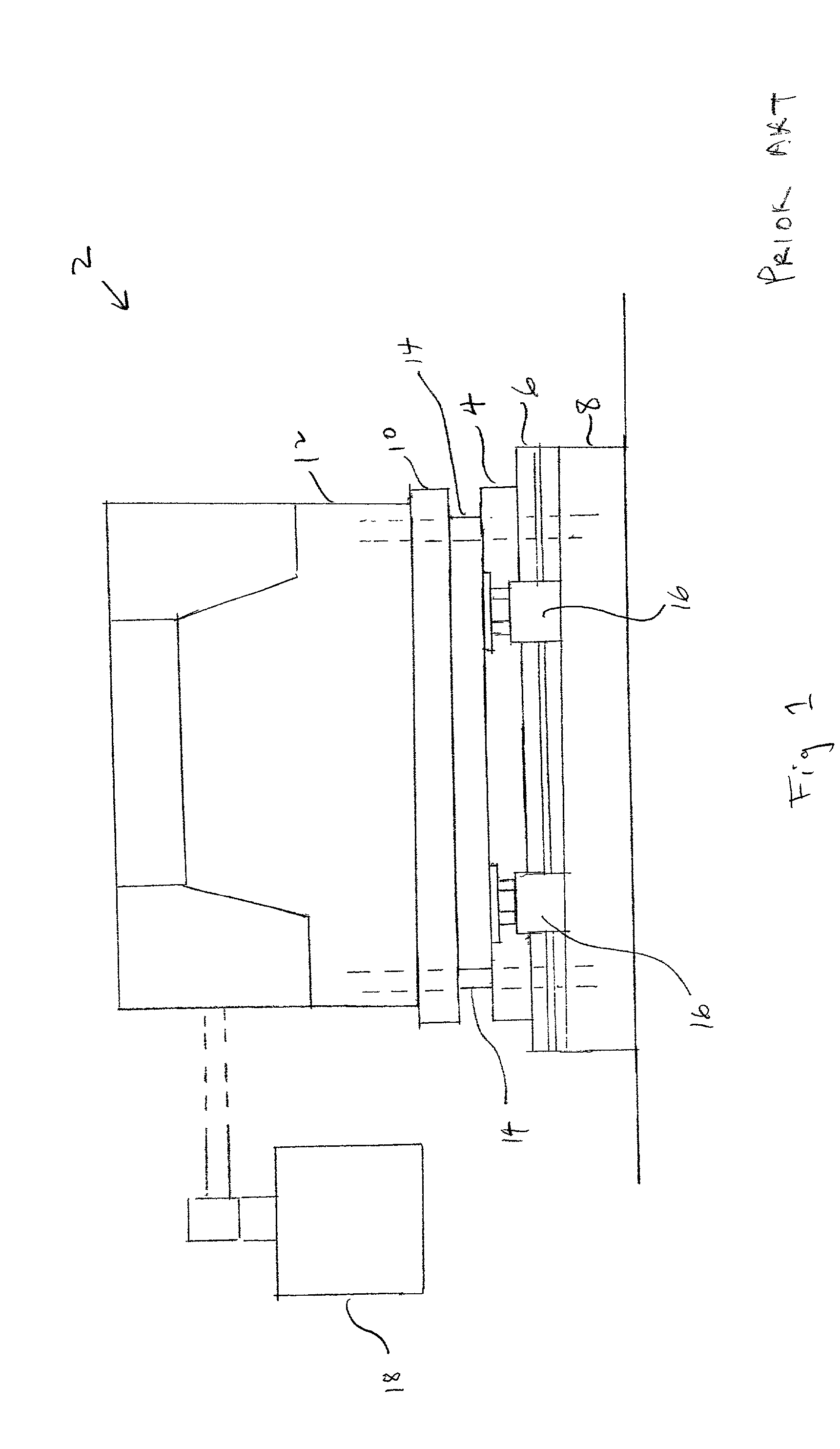

A press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die. Typically, two C-frames form the sides of the press brake, connected to a table at the bottom and on a movable beam at the top. The bottom tool is mounted on the table, with the top tool mounted on the upper beam.

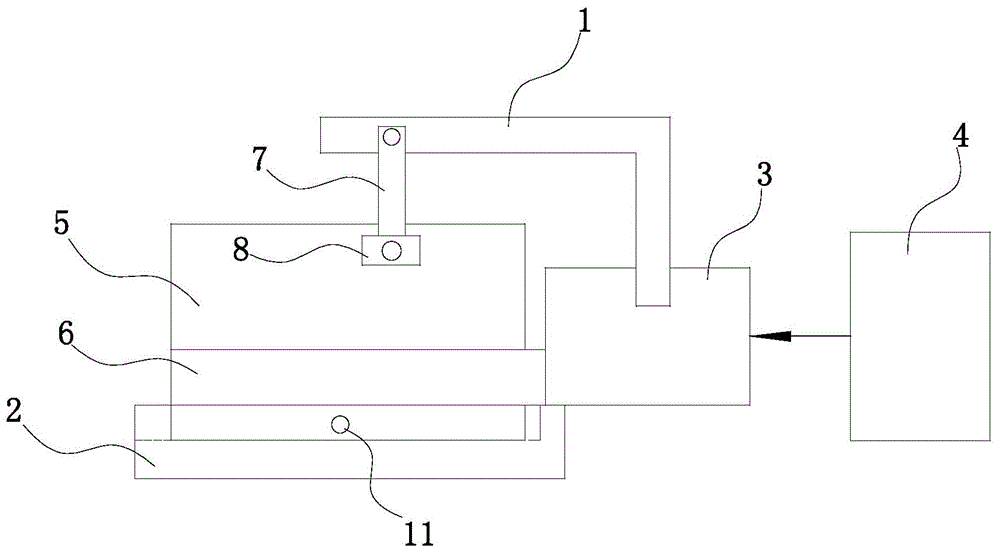

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

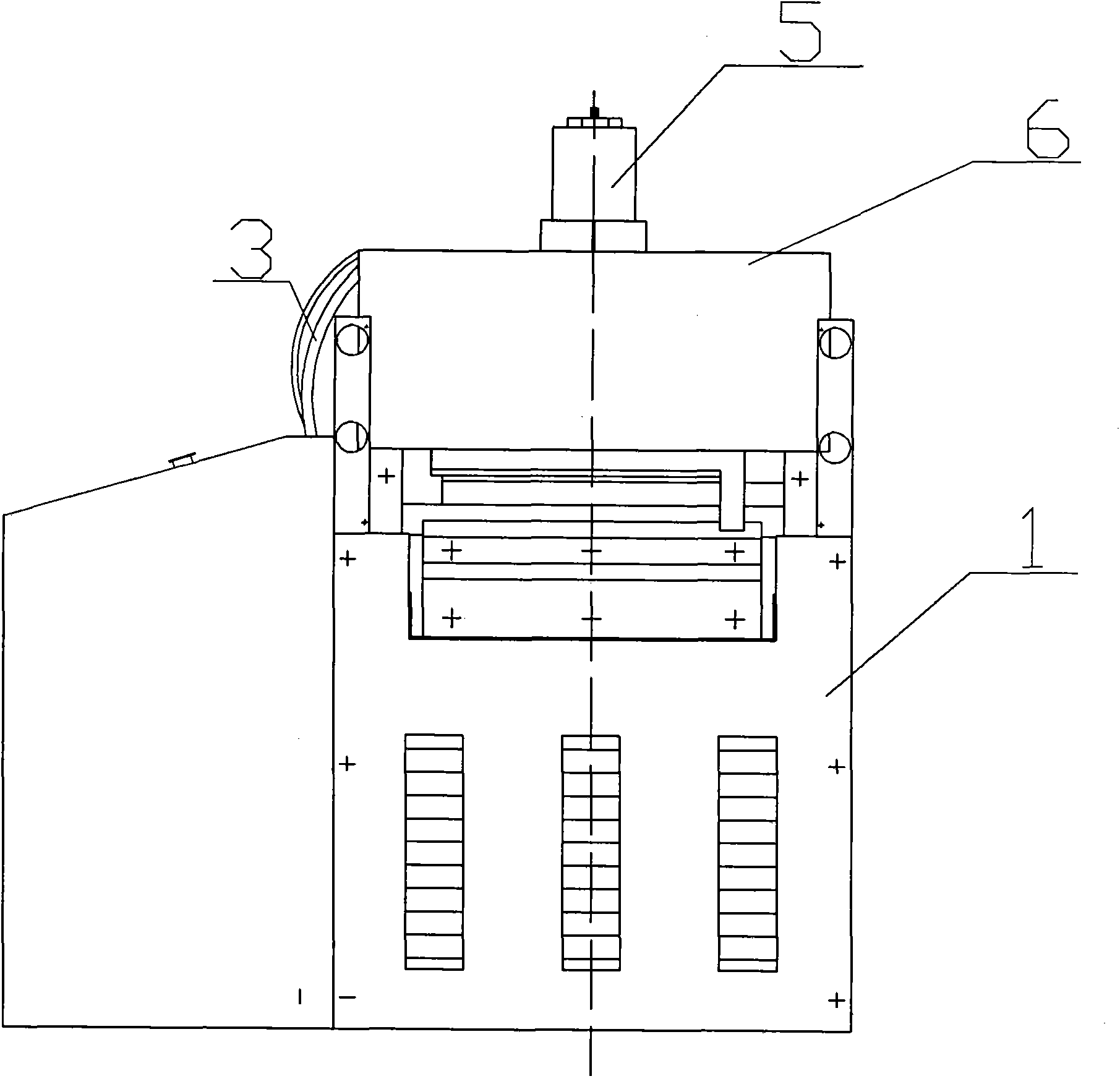

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

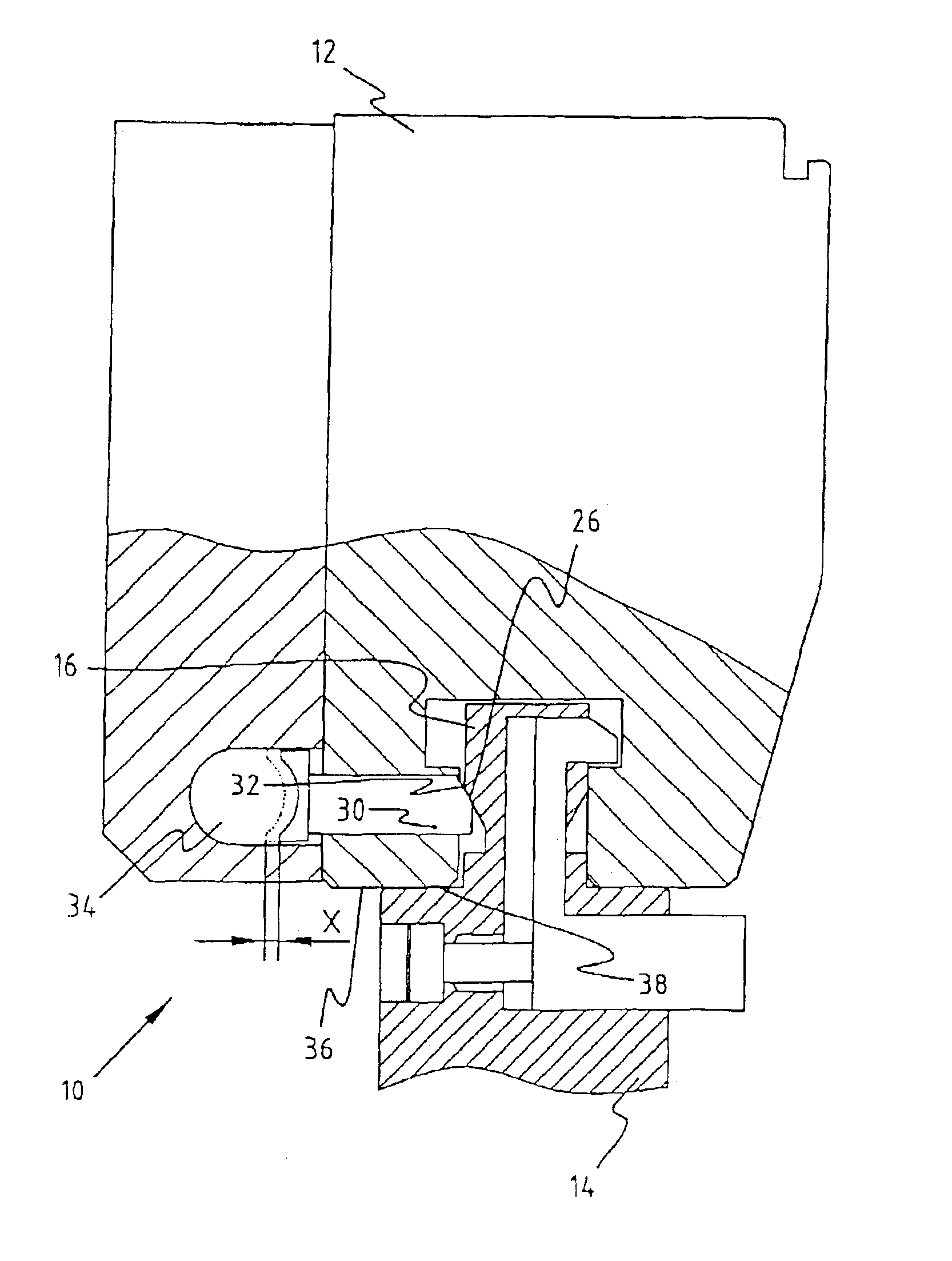

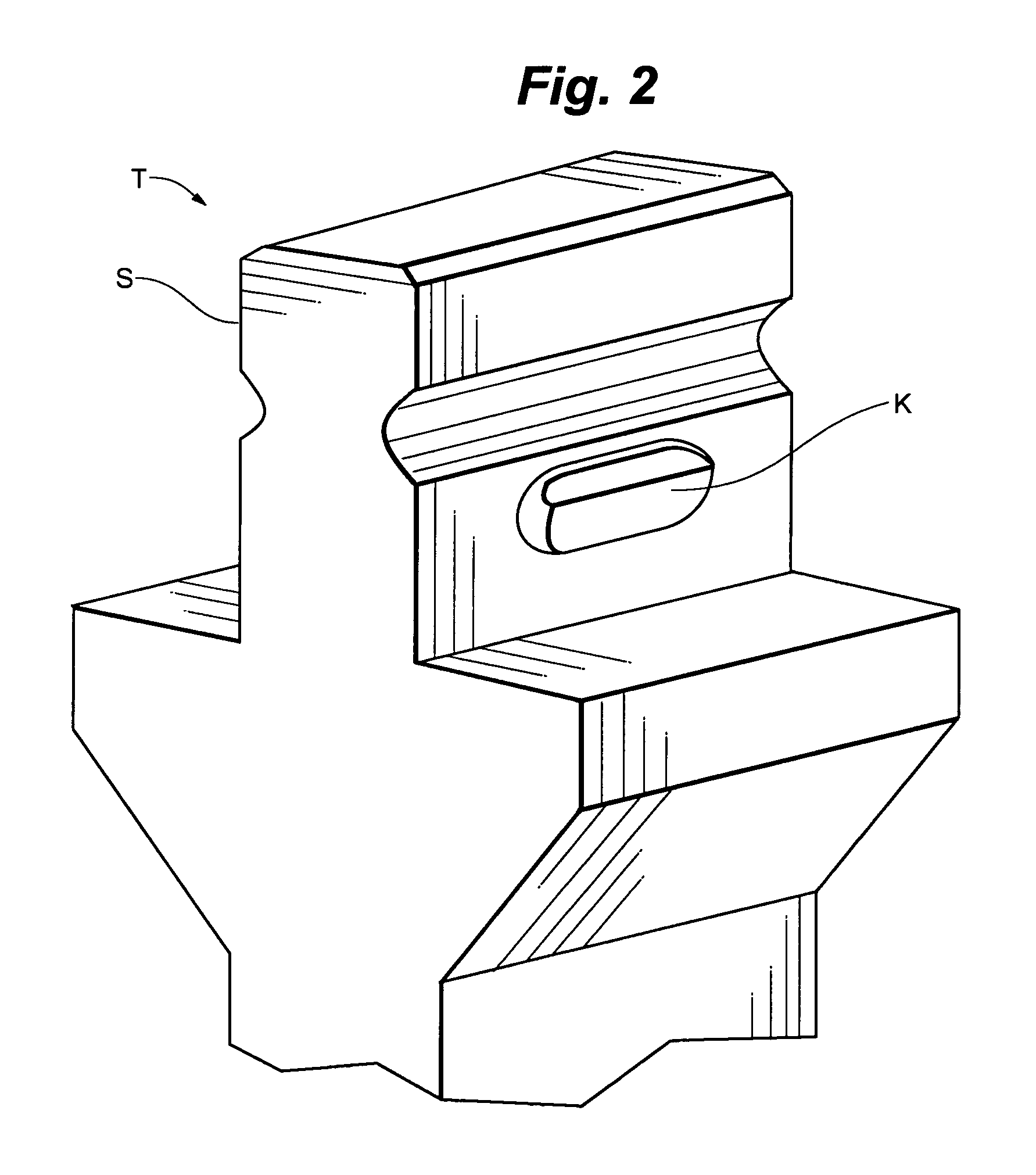

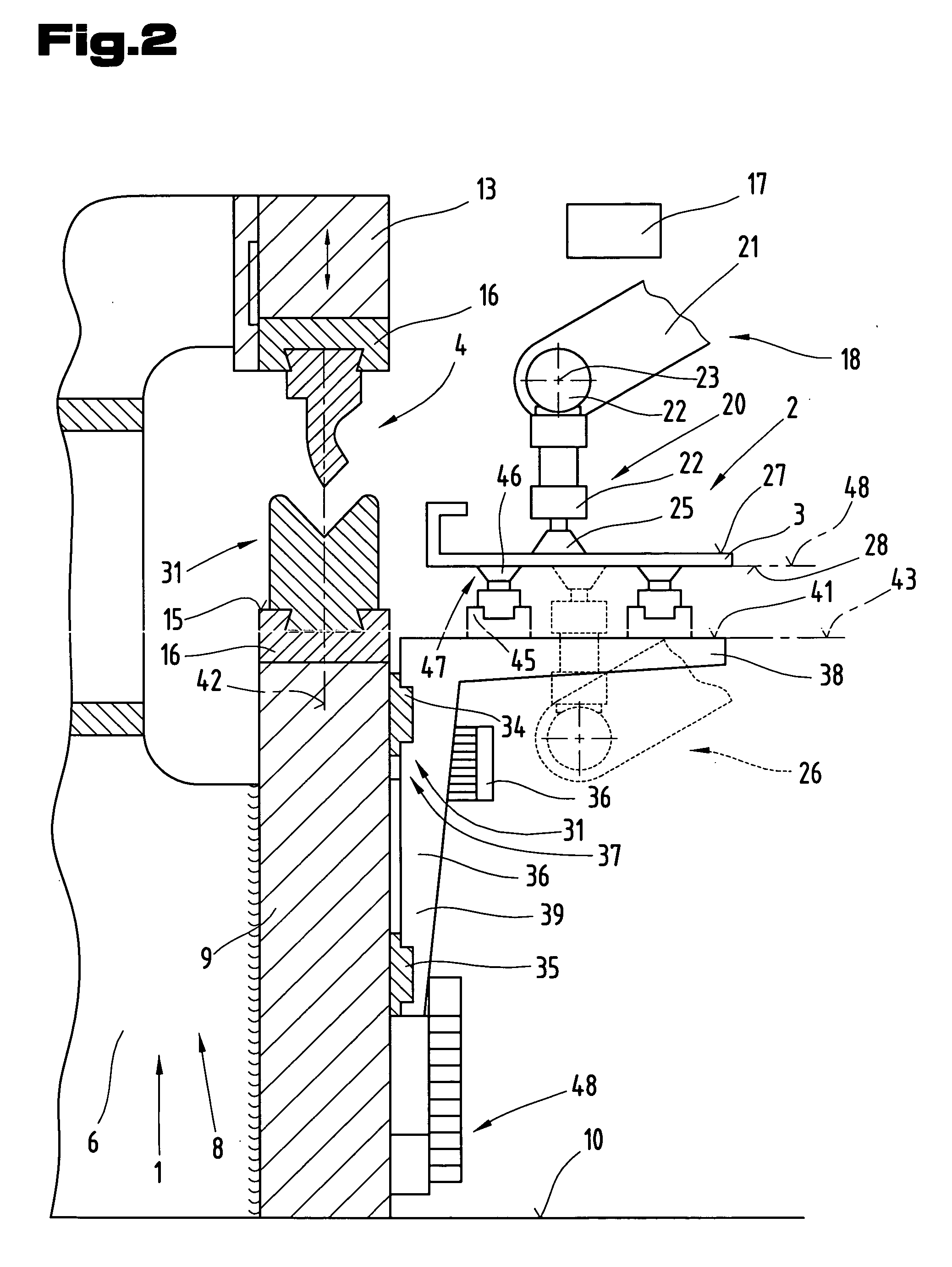

Combination of a press brake clamping system and at least a press brake tool

The invention relates to a combination of a press brake tool and a press brake clamping system for pressing the press brake tool in a press direction, said press brake clamping system comprising:at least one clamp for clamping said tool in a clamping direction substantially perpendicular to the press direction;a positioner for positioning said tool in the press direction; andat least one tool support surface;said tool comprising:a tool body;a clamping part arranged on said tool body for clamping said tool in said clamping system, wherein the clamping part has an engagement part for engagement of the positioner onto the tool;at least one support surface for abutment to said tool support surface; anda safety tang to prevent the tool of falling out;wherein at least one of the positioner and the engagement part comprises a slanting surface for at least partially transforming the clamping force into a positioning force.

Owner:WILA

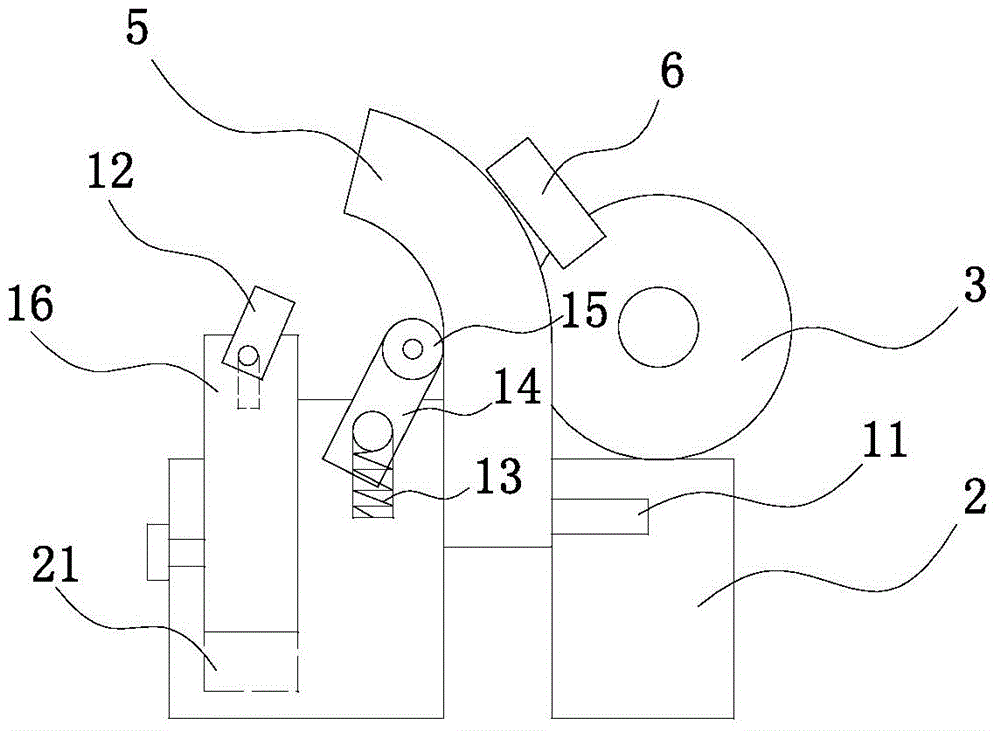

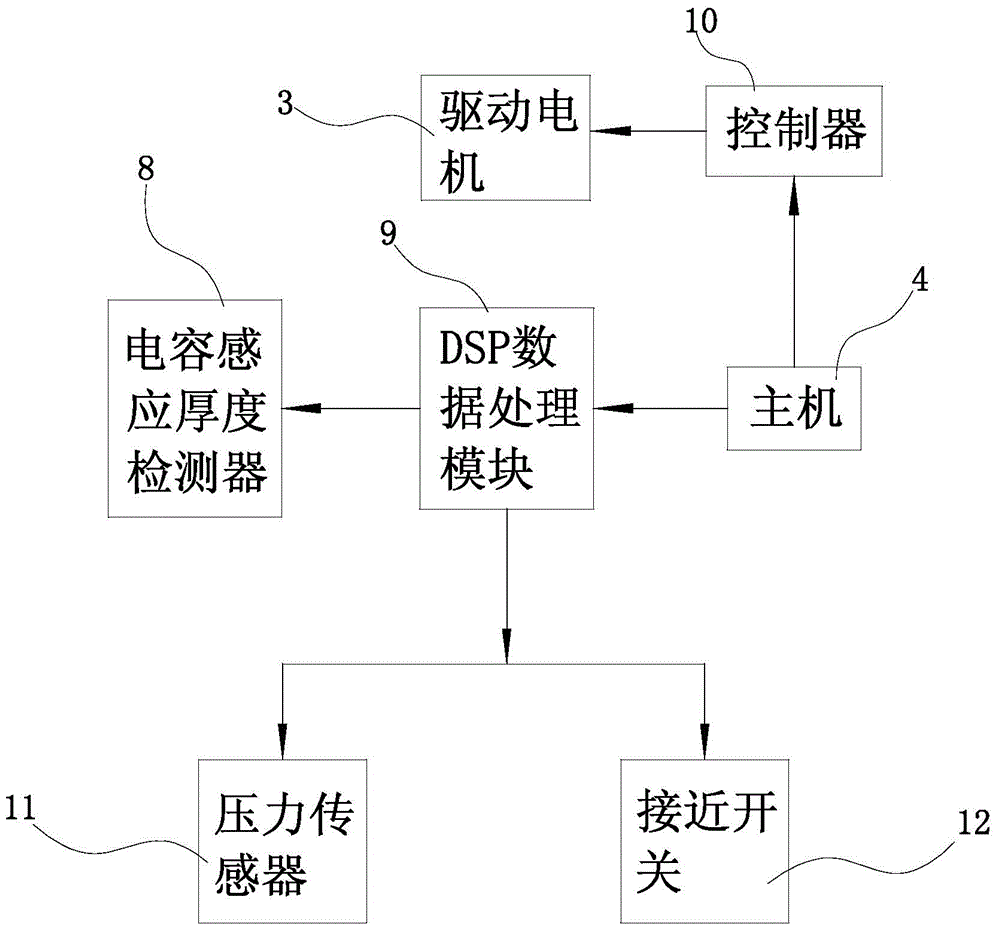

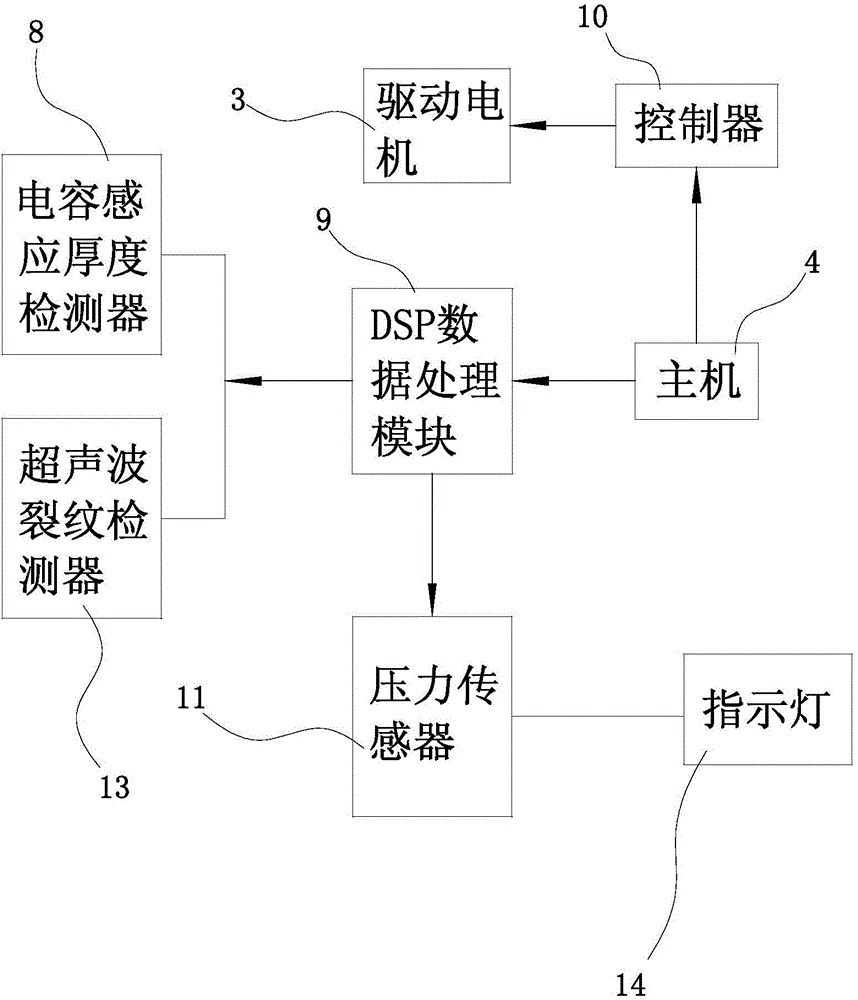

Capacitor thickness detection and crack feedback plate bending machine based on PLC

ActiveCN104624739APerformance impactPrevent excessive deformationMetal working apparatusCapacitanceEngineering

The invention relates to a capacitor thickness detection and crack feedback plate bending machine based on a PLC. The capacitor thickness detection and crack feedback plate bending machine comprises a driving motor, a clamping fixing base and a PLC host machine for controlling the driving motor. A bending shaft is installed on a motor shaft of the driving motor, and a machined piece is arranged on the clamping fixing base. The capacitor thickness detection and crack feedback plate bending machine further comprises a capacitor induction thickness detector installed on a machine frame, a pressure sensor arranged on the lateral side of a clamping groove of the clamping fixing base, a detection feedback device and a controller connected with the PLC host machine. The detection feedback device comprises an ultrasonic crack detector arranged on the clamping fixing base. The capacitor induction thickness detector, the ultrasonic crack detector and the pressure sensor are connected with the PLC host machine through a DSP module. The invention further provides a bending method. According to the capacitor thickness detection and crack feedback plate bending machine and method, sectioned machining is controlled through the PLC, the machined piece is bent at the most proper rotating speed, influences of the excessively-high or excessively-low rotating speed on the machined piece are avoided, bending cracks are reduced, and the machining quality is improved.

Owner:宿州市徽腾知识产权咨询有限公司

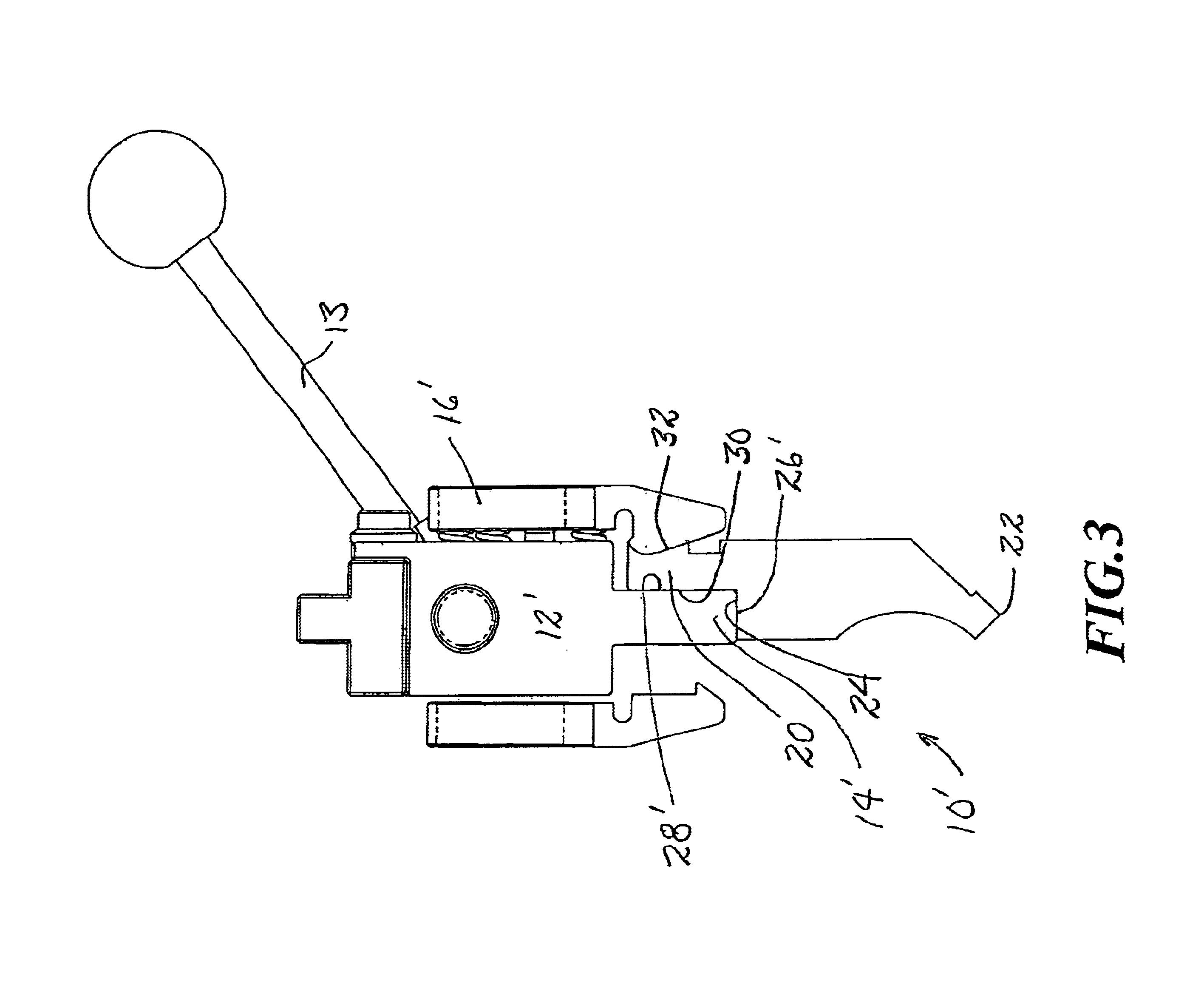

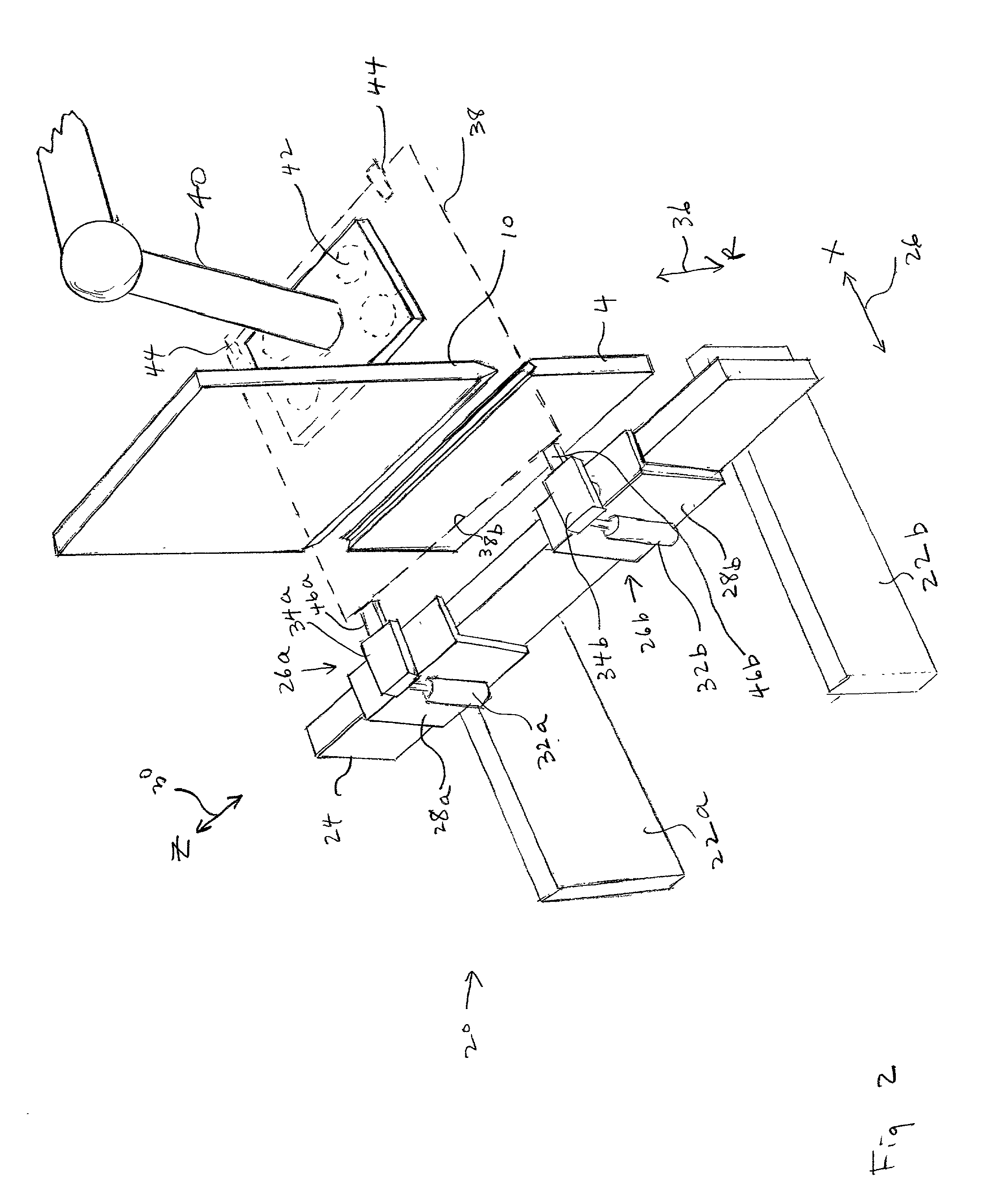

Press brake tooling technology

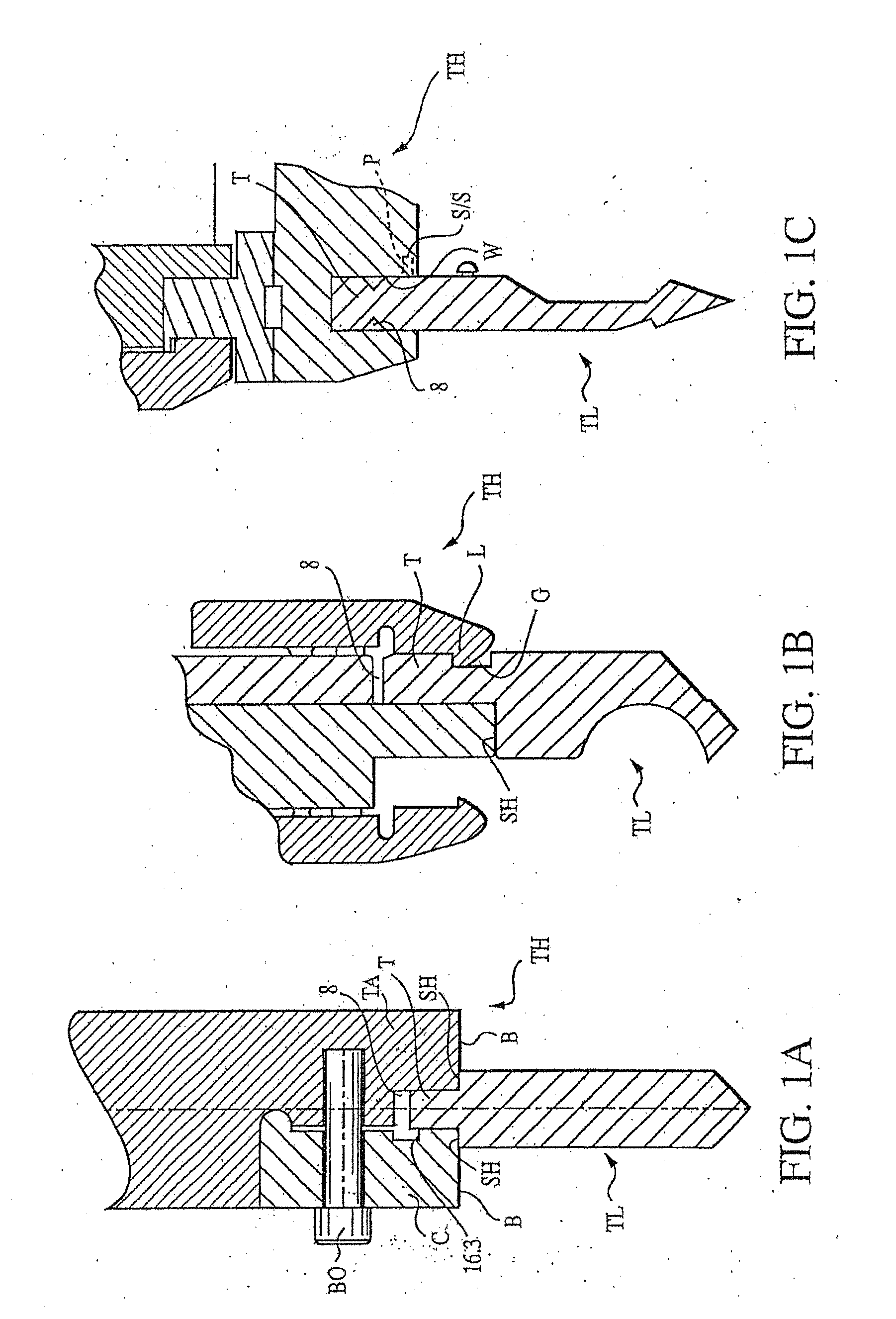

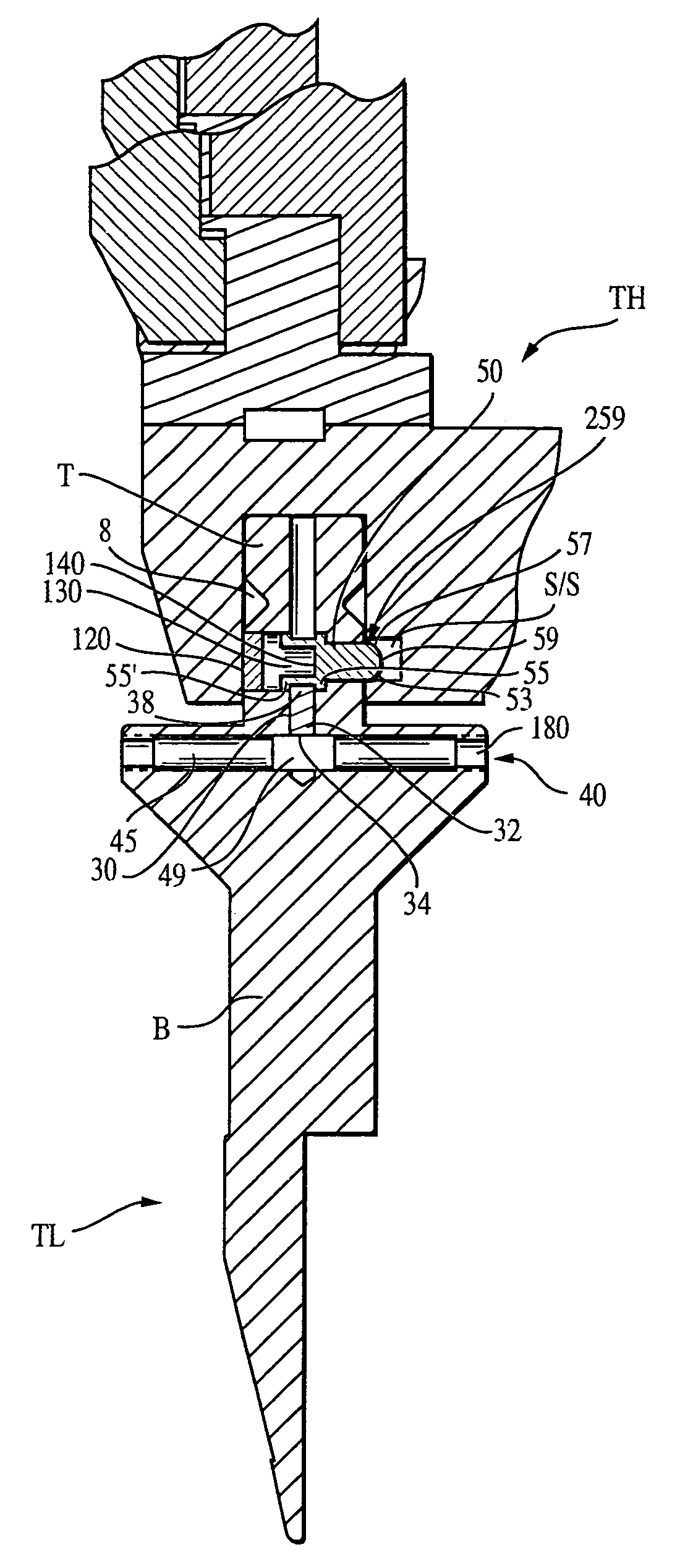

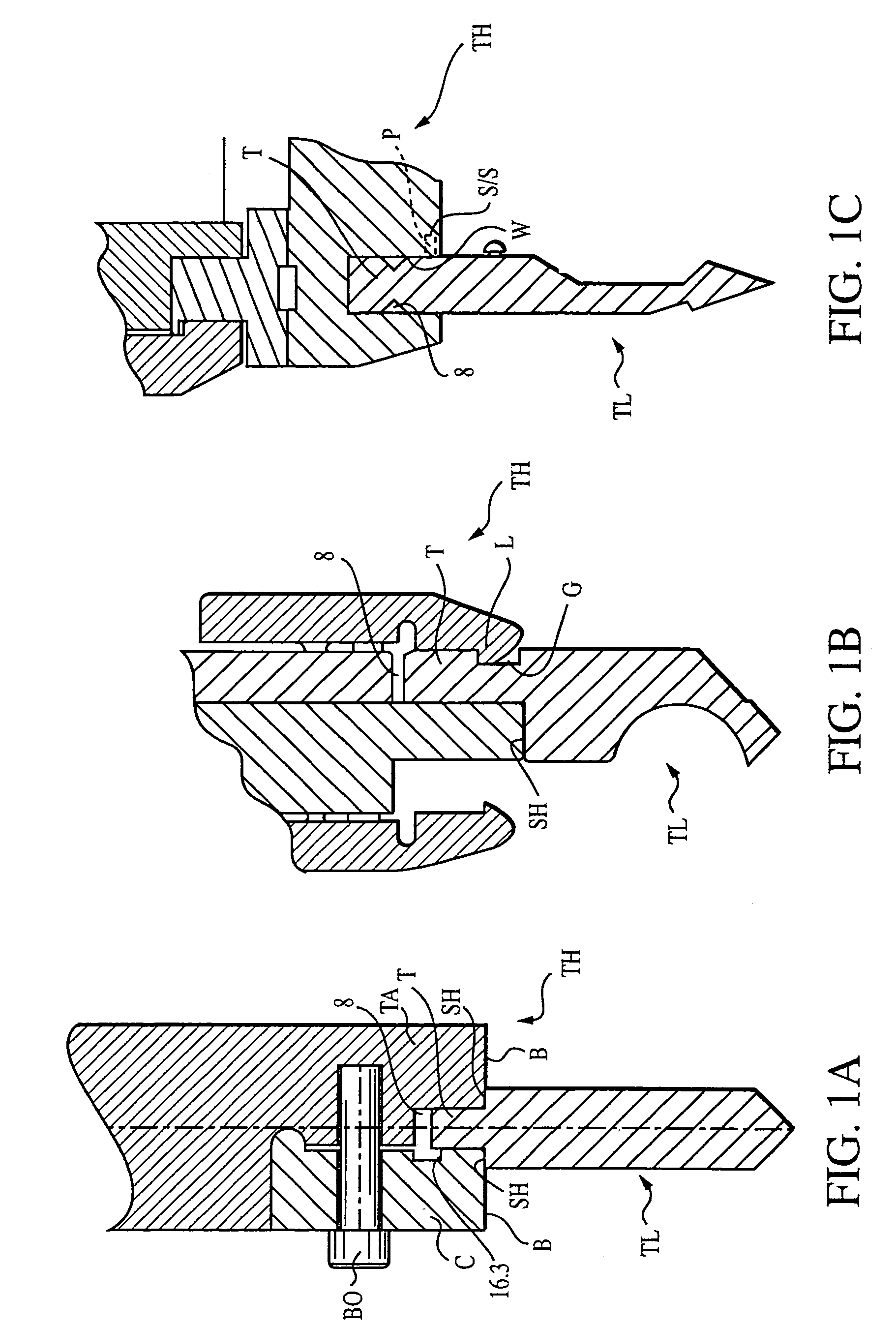

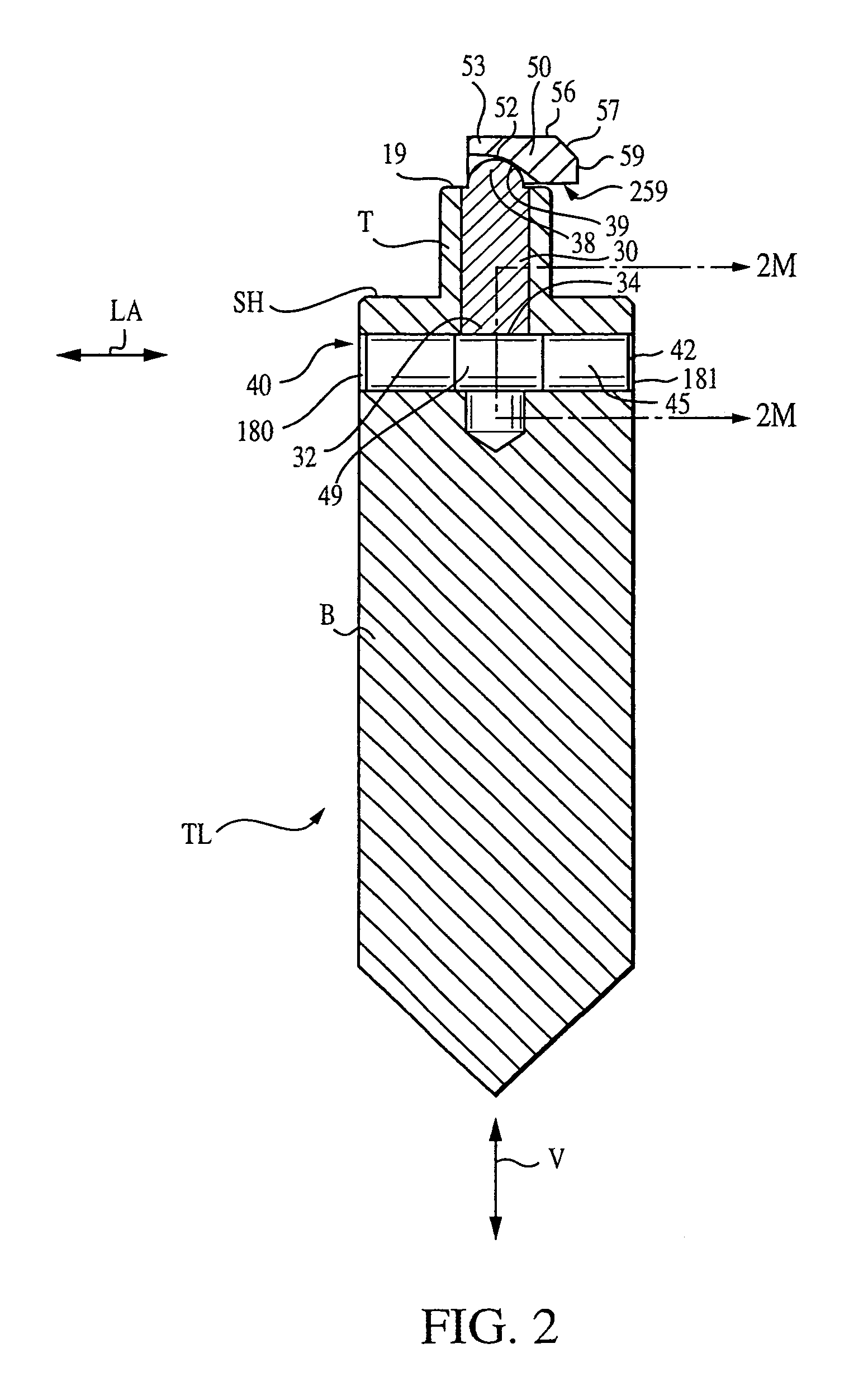

The invention provides press brake and press brake tooling technology. Certain embodiments of the invention provide a press brake tool that has an elongated, retractable safety key. In certain embodiments, the invention provides click-in / slide-out press brake tools. In some of these embodiments, the tool has a safety key defining a flat (i.e., a planar wall section / planar surface) that is adapted for sliding along a surface of a tool holder when the tool is dismounted from the holder by moving the tool horizontally out of the holder. In certain embodiments, the flat has a longitudinal length of at least about 0.008 inch (in some cases, at least about 0.010 inch, at least about 0.015 inch, or at least about 0.020 inch), ranging up to the full longitudinal length of the tool. In certain embodiments, the invention provides a press brake tool and a tool holder in combination. Finally, the invention in some embodiments provides methods of press brake operation.

Owner:WILSON TOOL INT

Double-vortex fluid separator

InactiveUS7811344B1Facilitate separation of oilAvoid mixingCombination devicesAuxillary pretreatmentEddy current separatorEngineering

A fluid separator includes a side-by-side double-vortex fluid generator installed within a pressure vessel. The vortex generator separates the liquid and gas components of the incoming fluid mixture, and the vessel itself helps further separate the liquid into water and oil components, which makes the fluid separator particularly suited for processing fluids extracted from an oil well. The generator includes two diverging vortex tubes each having a polygonal cross-section. Such a cross-section allows the tubes to be formed using a conventional press brake. The vortex tubes also have diverging longitudinal centerlines to help spread the liquid flow pattern discharging into the vessel.

Owner:DUKE BOBBY RAY +1

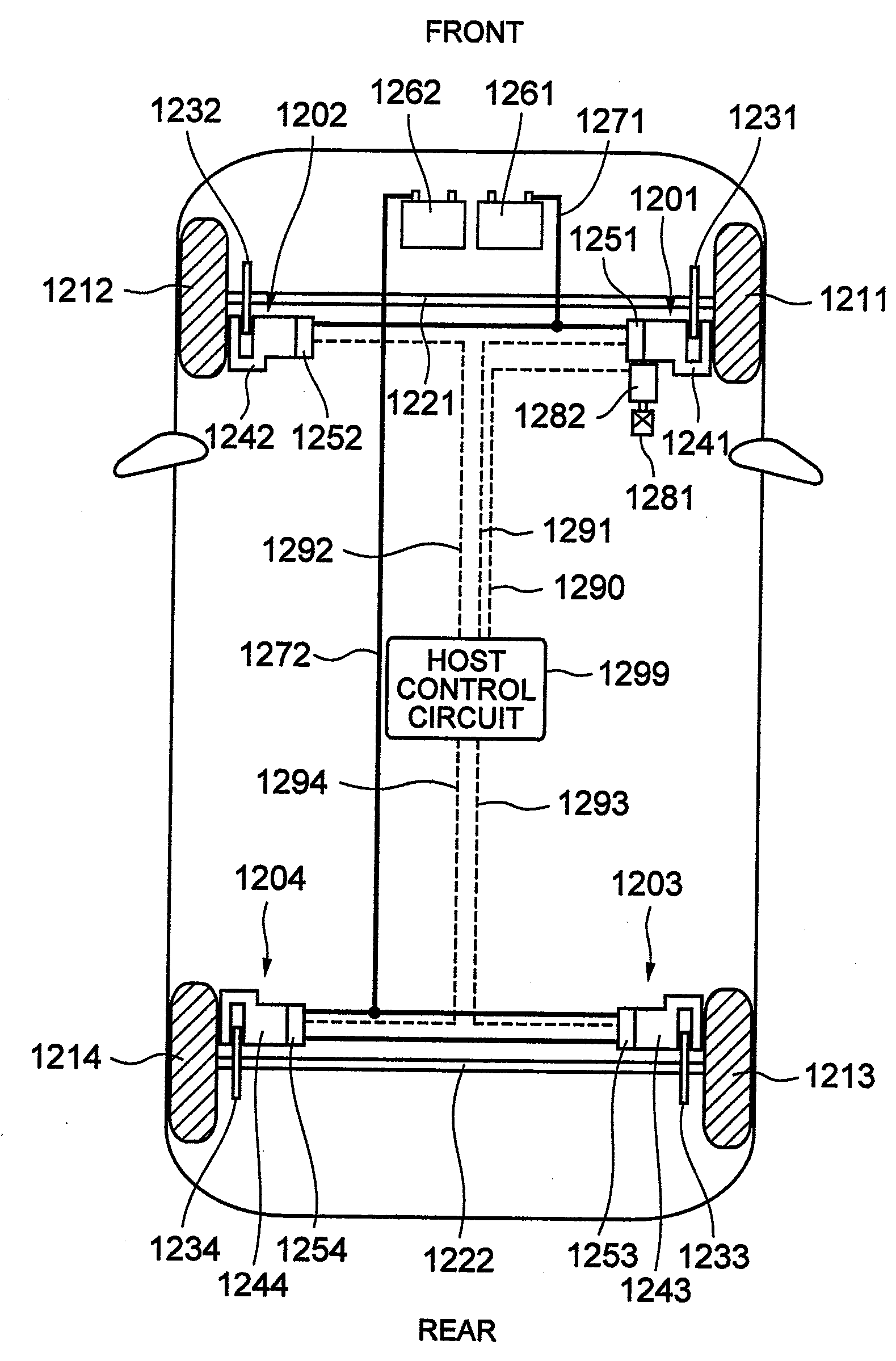

Electric Braking Apparatus

InactiveUS20080236964A1Reduce the impact of noiseQuality improvementAsynchronous induction motorsMechanical energy handlingElectricityElectrical conductor

An electric braking apparatus including a motor for pressing brake pads on disks, a metal housing for housing the motor, a positive-polarity power line for transmitting power from a battery to the electric motor, a negative-polarity ground line for connecting the electric motor to the ground of a vehicle, and a conductor for electrically connecting the metal housing to the negative polarity of battery or the negative-polarity of an inverter.

Owner:HITACHI LTD

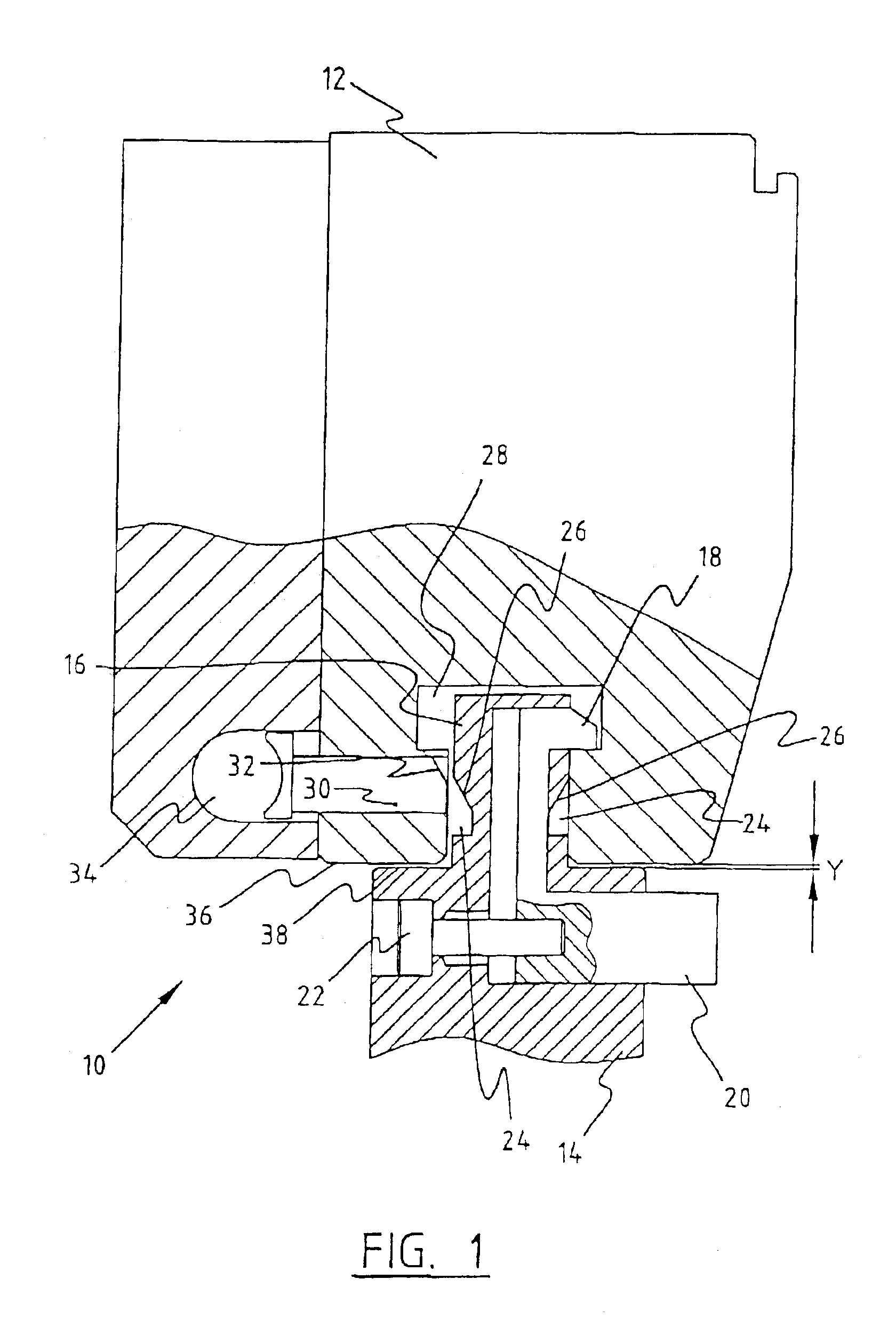

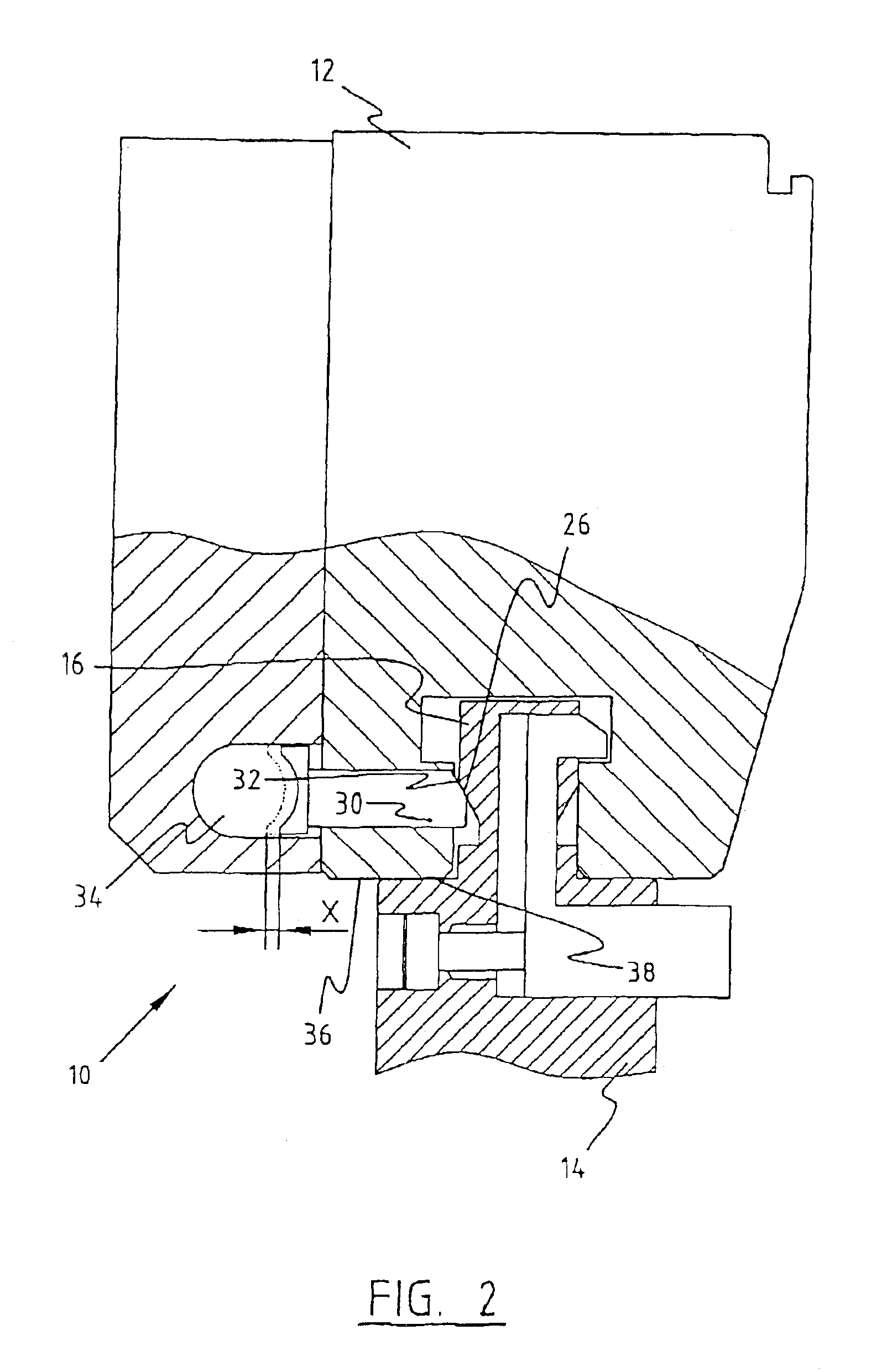

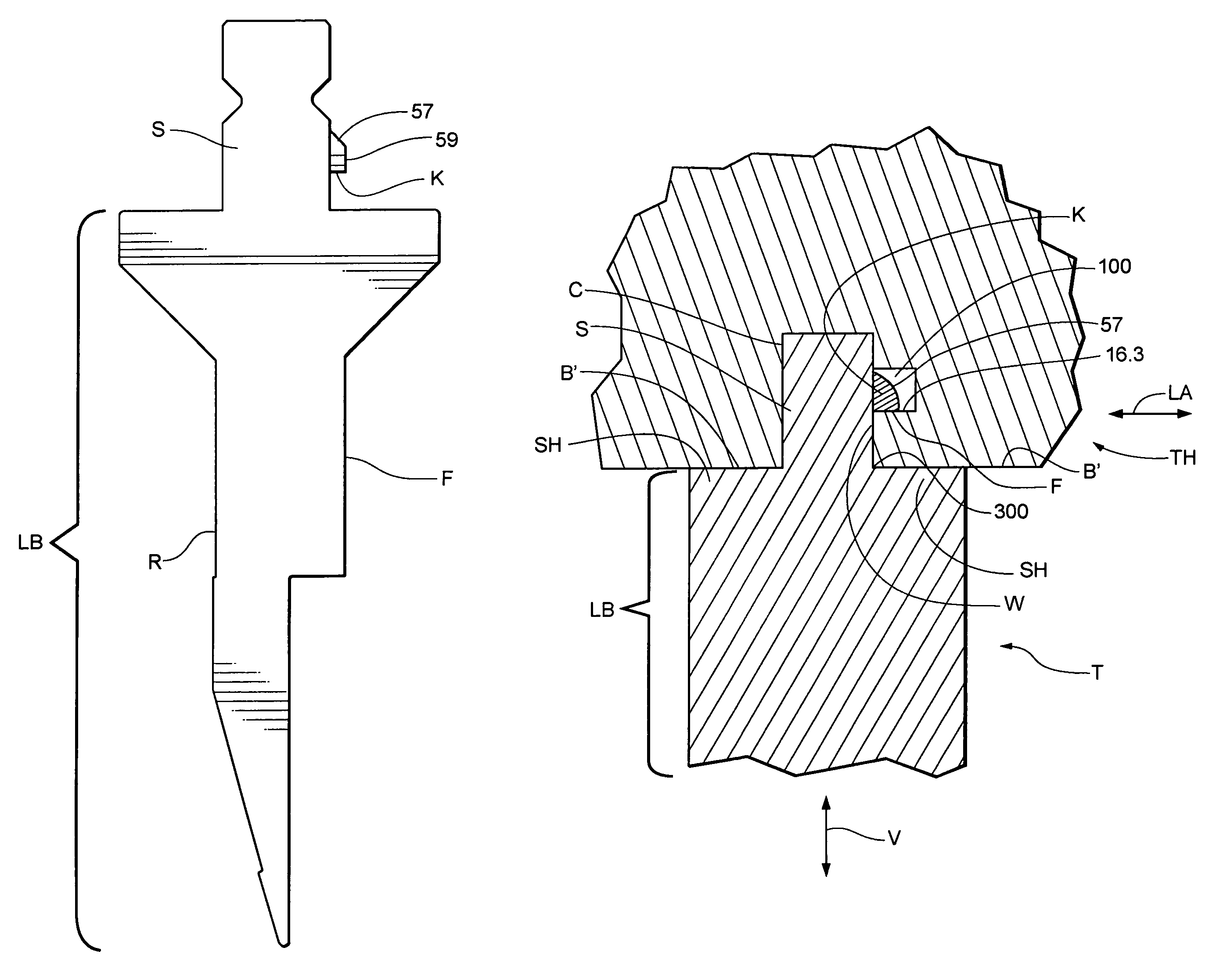

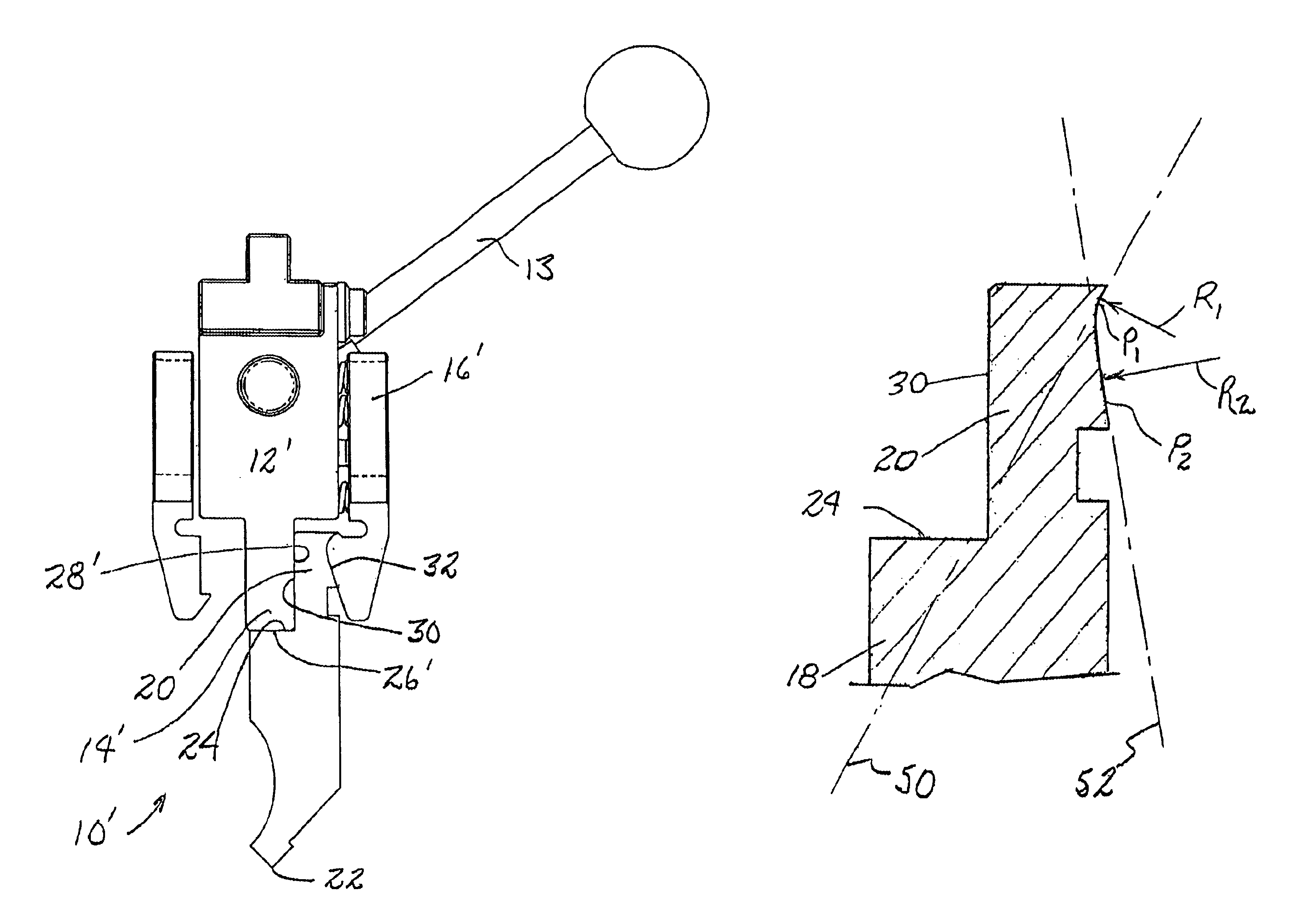

Press brake tool and tool holder

A press brake tool and tool holder. The tool is provided having a body that terminates downwardly in a work piece engaging surface and that includes a tang extending upwardly from the body for reception in a tool holder. The tang has a first wall defining a vertical surface for engagement with a cooperating vertical surface of a tool holder, and a second wall on the reverse side of the tang that defines an arcuate, concave surface engagable with a clamp of the tool holder. The concave surface includes an upper contact surface tangent to a plane that is downwardly convergent with respect to the vertical surface such that a force delivered to the contact surface includes an upward component tending to lift the tang into the tool holder. The upper contact surface may be formed on a first radius about a horizontal axis and is tangent to a first plane that is downwardly convergent with respect to said vertical surface. The concave surface may include a lower contact surface formed on a second, larger radius about a horizontal axis and that is tangent to a second plane that is upwardly convergent with respect to said vertical surface, the angle between the vertical and said first plane being greater than the angle between the vertical and the second plane so that the clamp delivers a net upwardly force to the tool.

Owner:WILSON TOOL INT

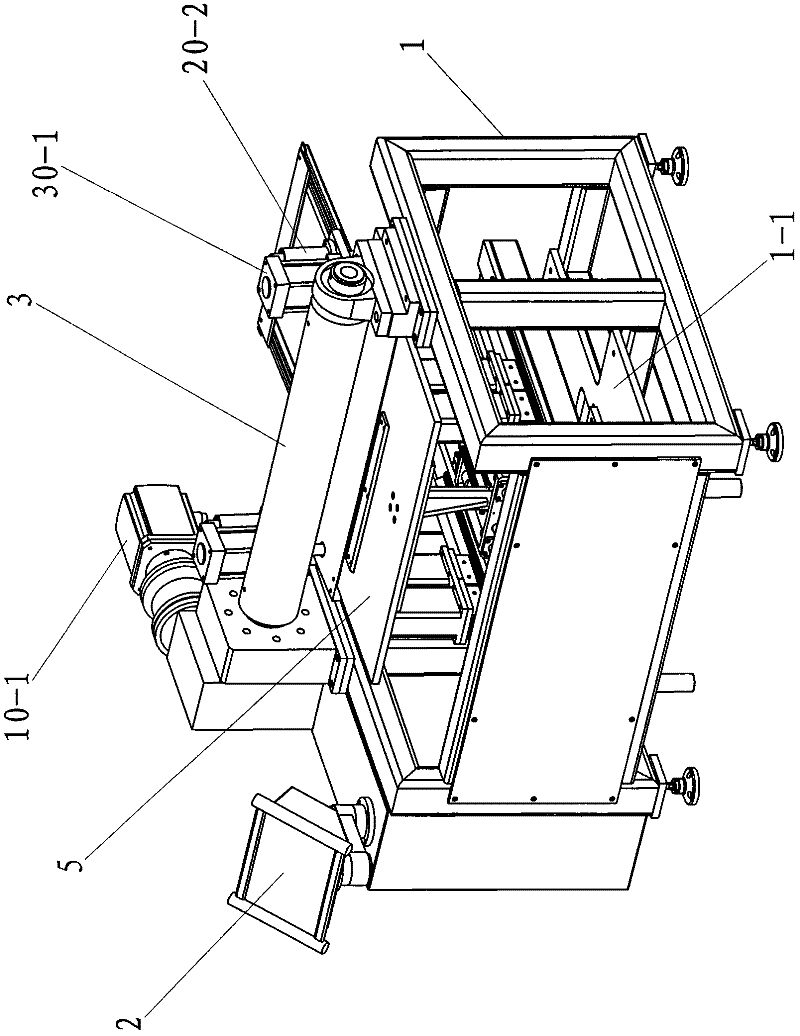

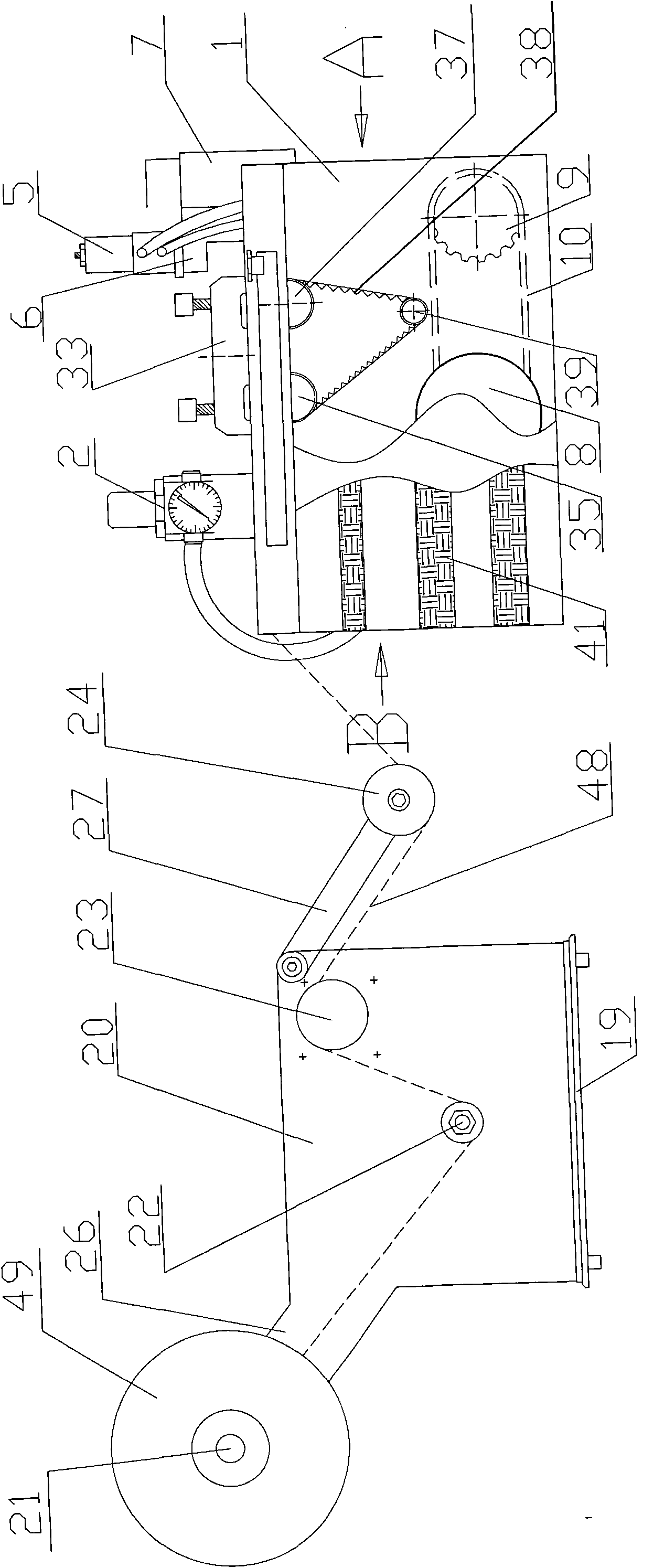

Bending machine

ActiveCN102441594AEnsure bending accuracyEnsure the bending effectHeat exchange apparatusEngineeringMechanical engineering

The invention relates to a bending machine, which comprises a frame. A rotating roller and a rotating roller driving mechanism are arranged on the frame, an upper pressing plate and a lower pressing plate rotating along with the rotating roller are arranged on the rotating roller, and a clamping control device for controlling clamping heat exchangers of the lower pressing plate and the upper pressing plate is arranged between the lower pressing plate and the upper pressing plate. The bending machine is technically characterized in that a lifting mechanism is further arranged on the frame, a lifting platform is arranged on the lifting mechanism, a bending follow-up platform is arranged on the lifting platform, a reset power device is arranged on the bending follow-up platform, a positioning mechanism is arranged at one end of the bending follow-up platform, a positioning power mechanism is arranged on the positioning mechanism, a clamping device and a horizontal power device are further arranged on the frame, an upper clamping plate, a lower clamping plate and a vertical power device are arranged on the clamping device, a clamping power device is arranged between the upper clampingplate and the lower clamping plate, a top side plate mechanism is arranged on one side of the lower pressing plate, a top side plate mechanism pushing device is arranged on the top side plate mechanism, and a feeding plate is further arranged on one side of the lower pressing plate. The bending machine can be used for improving precision of multiple bending and realizing automatic positioning.

Owner:OMS MASCH CO LTD

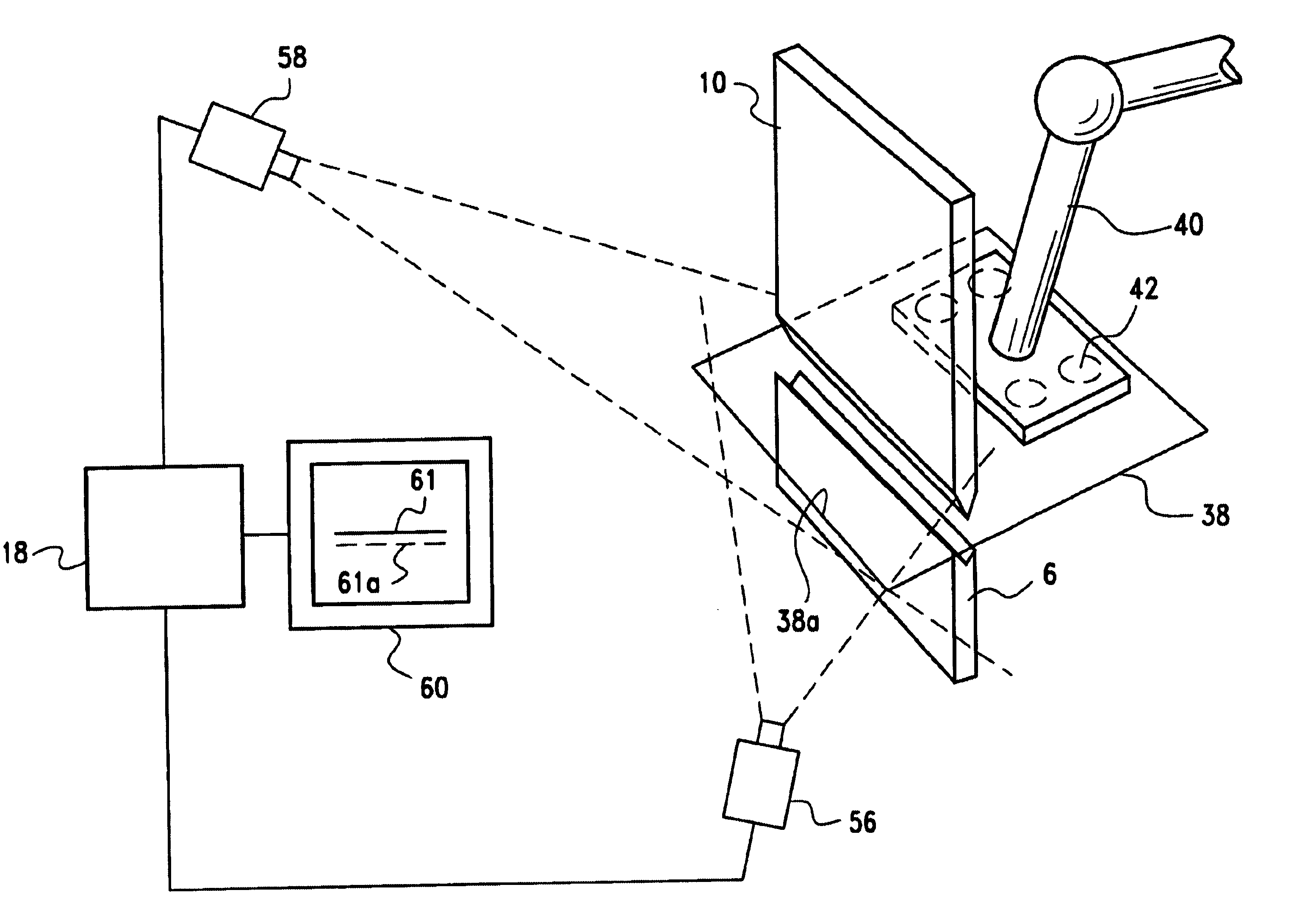

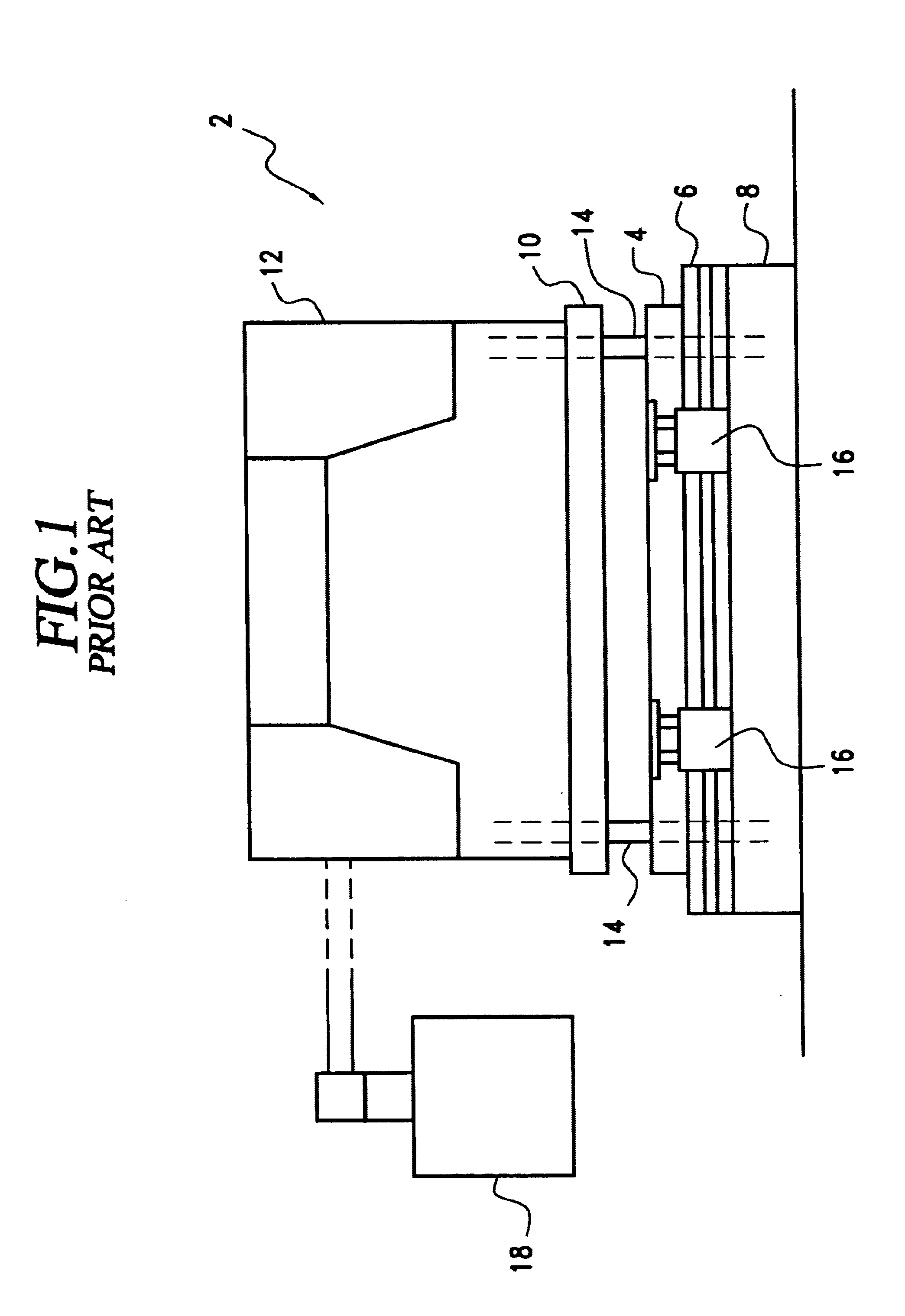

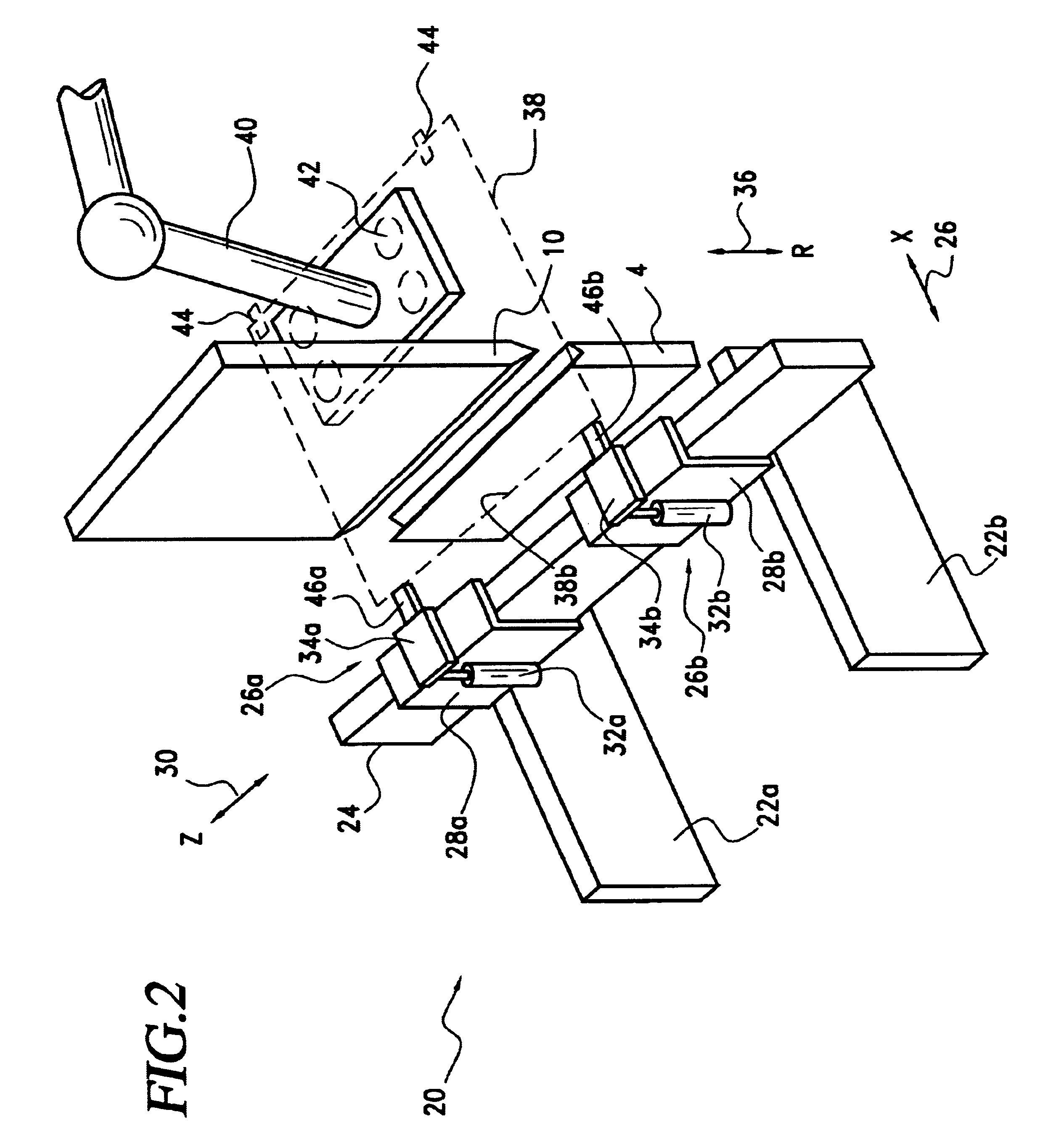

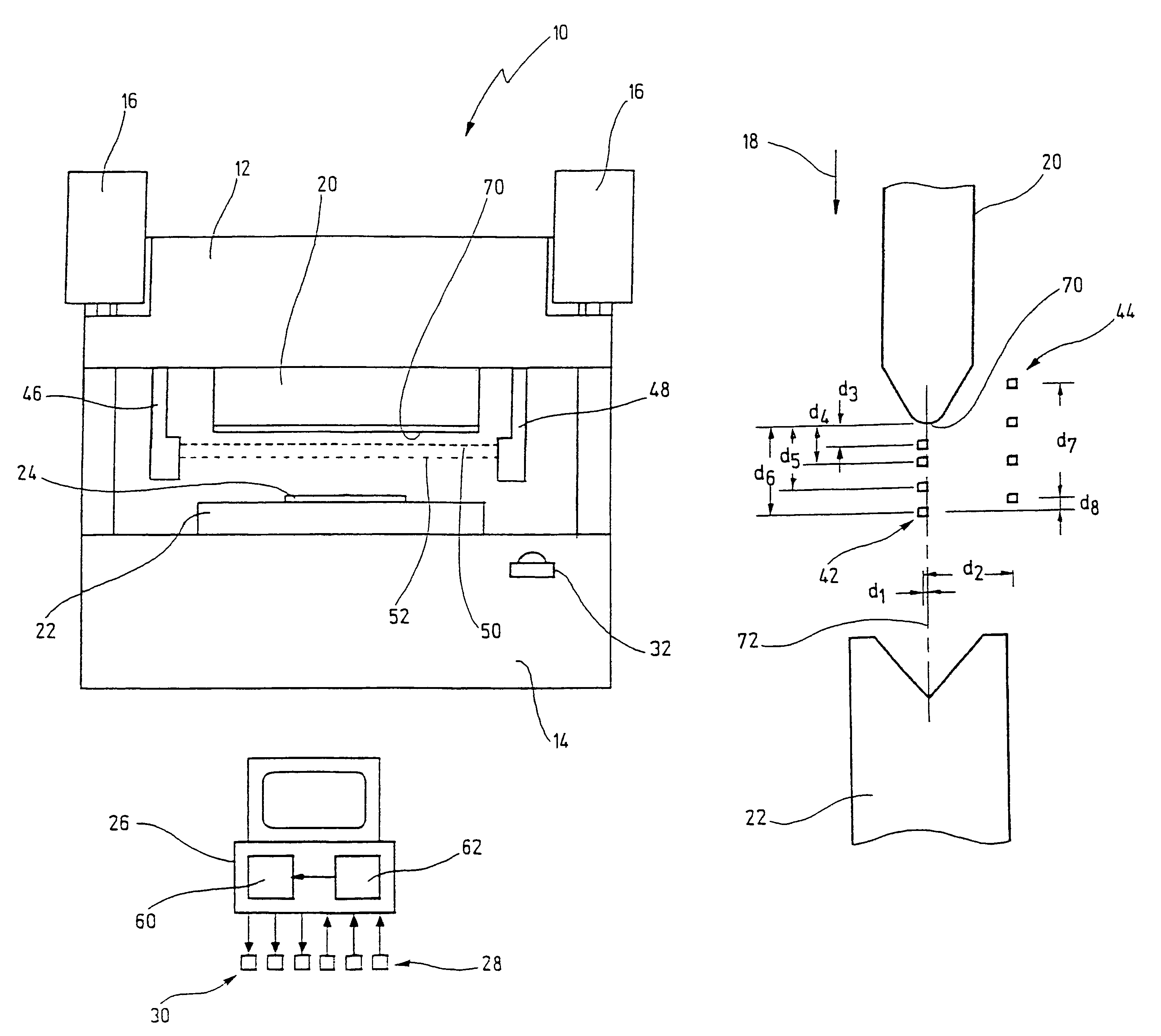

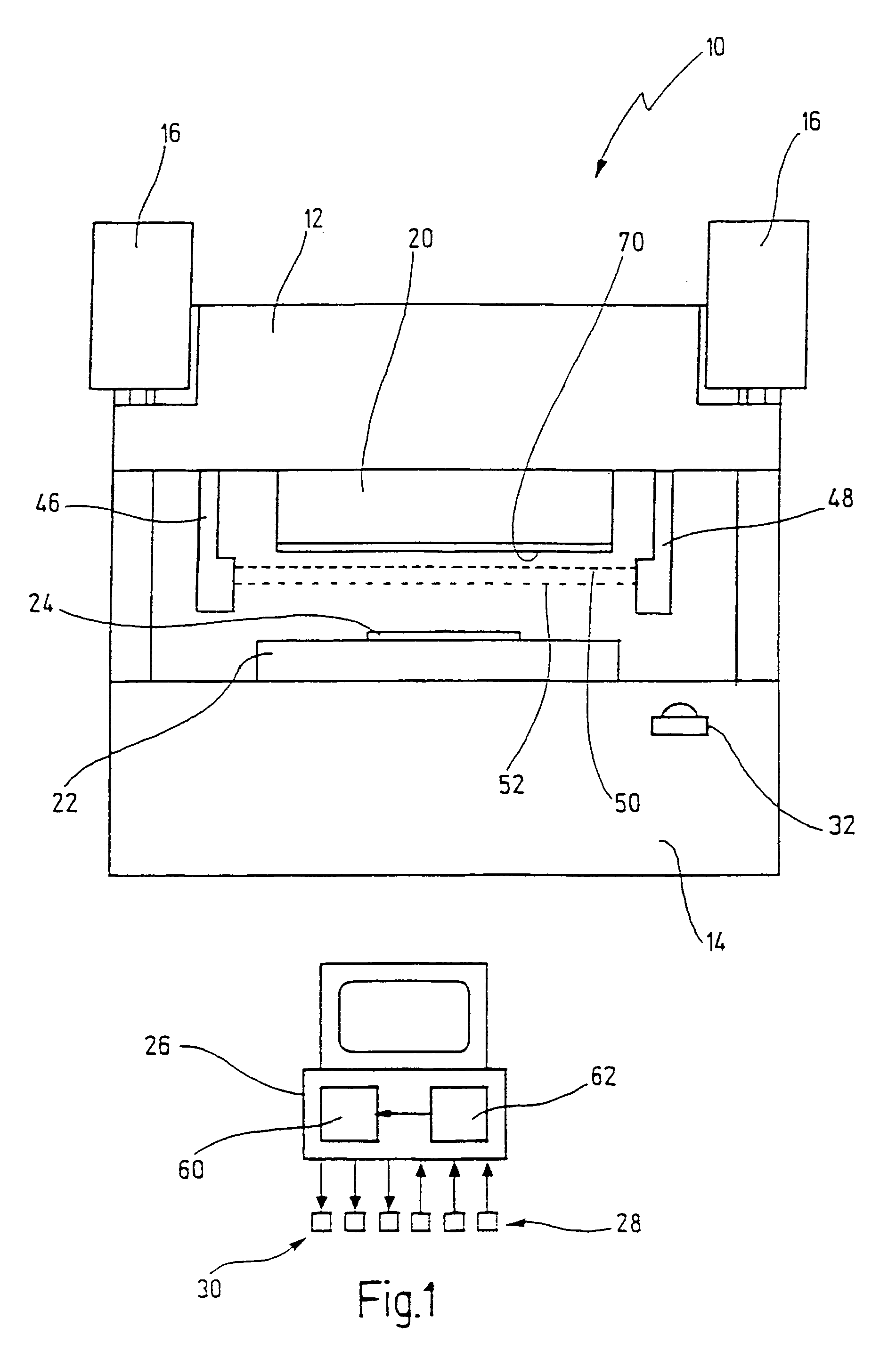

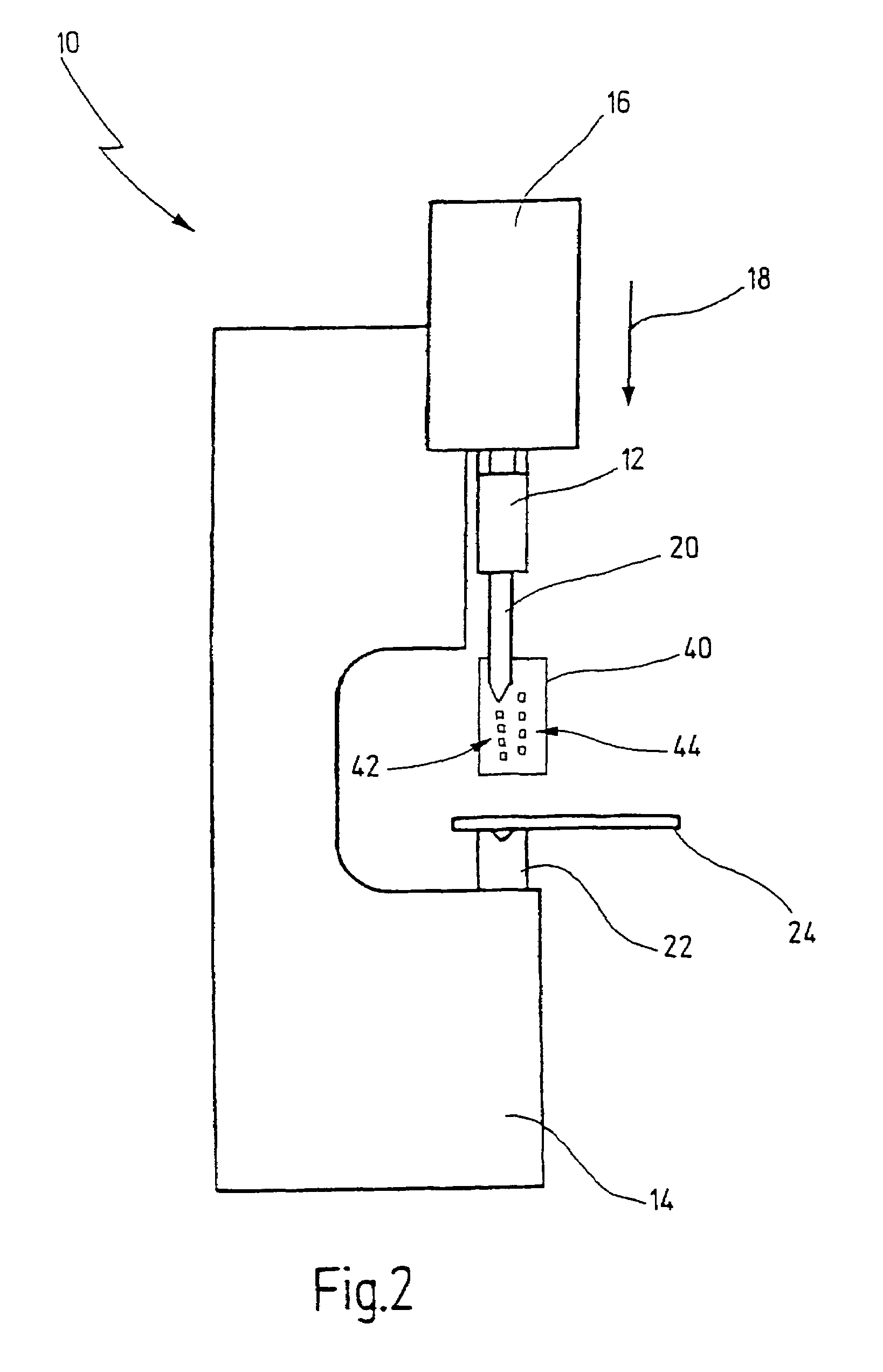

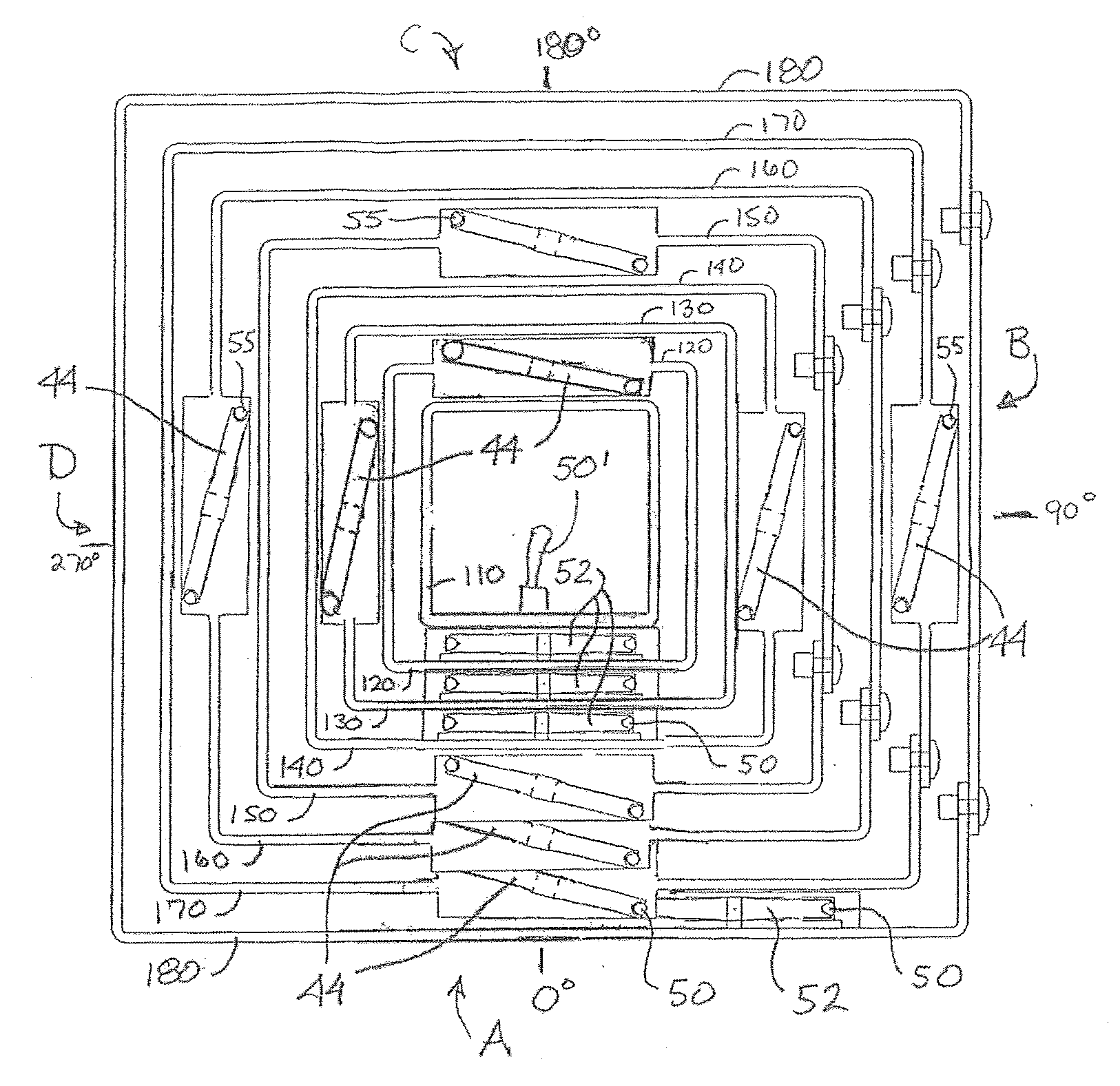

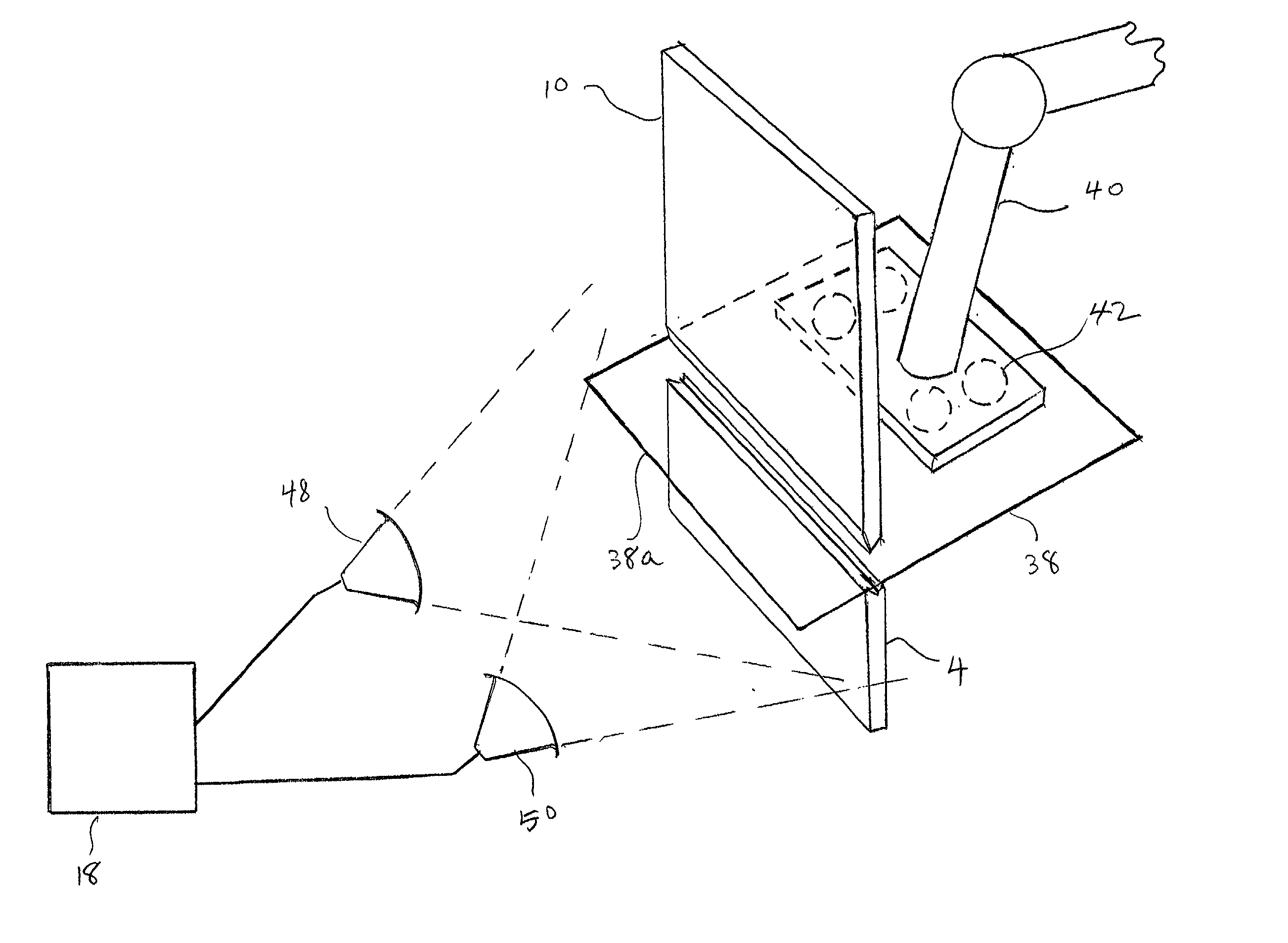

Press brake worksheet positioning system

InactiveUS6644080B2Precise positioningCompensation deviationMetal-working feeding devicesShaping safety devicesPositioning systemPress brake

To improve the speed with which a worksheet is positioned in a press brake, and to further eliminate the need for conventional moving back gauge systems, the present invention replaces the conventional back gauge mechanical system with sensors that non-contactedly determine the positioning of the worksheet, with reference to the bending tools. The thus sensed worksheet position is compared with the desired worksheet location preprogrammed into the CNC controller. Any deviation between the sensed, or the actual worksheet position, with the desired worksheet position for each bend of the worksheet is compensated by further moving the worksheet, until there no longer is any discrepancy between the actual and the preprogrammed desired locations.

Owner:FINN POWER INT

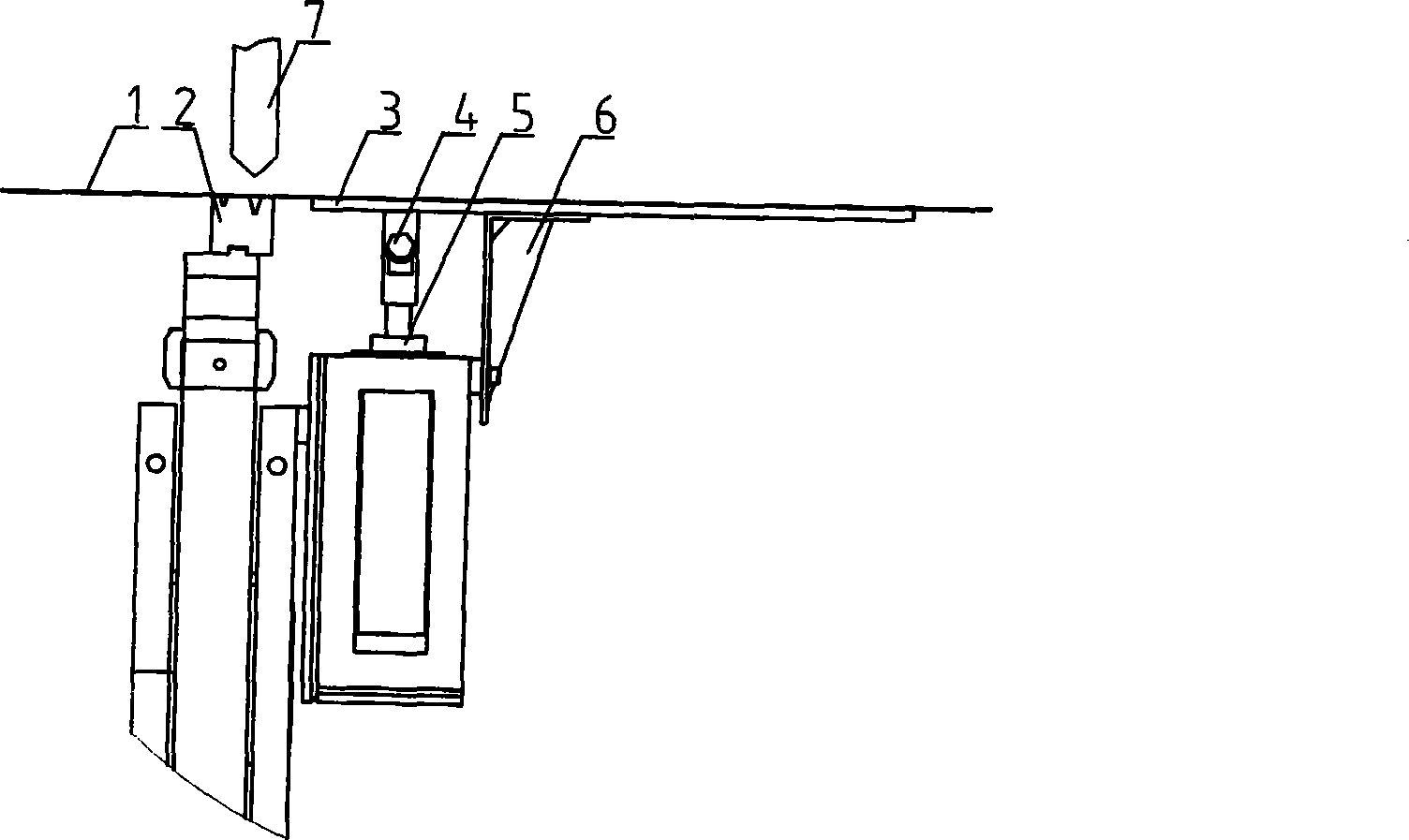

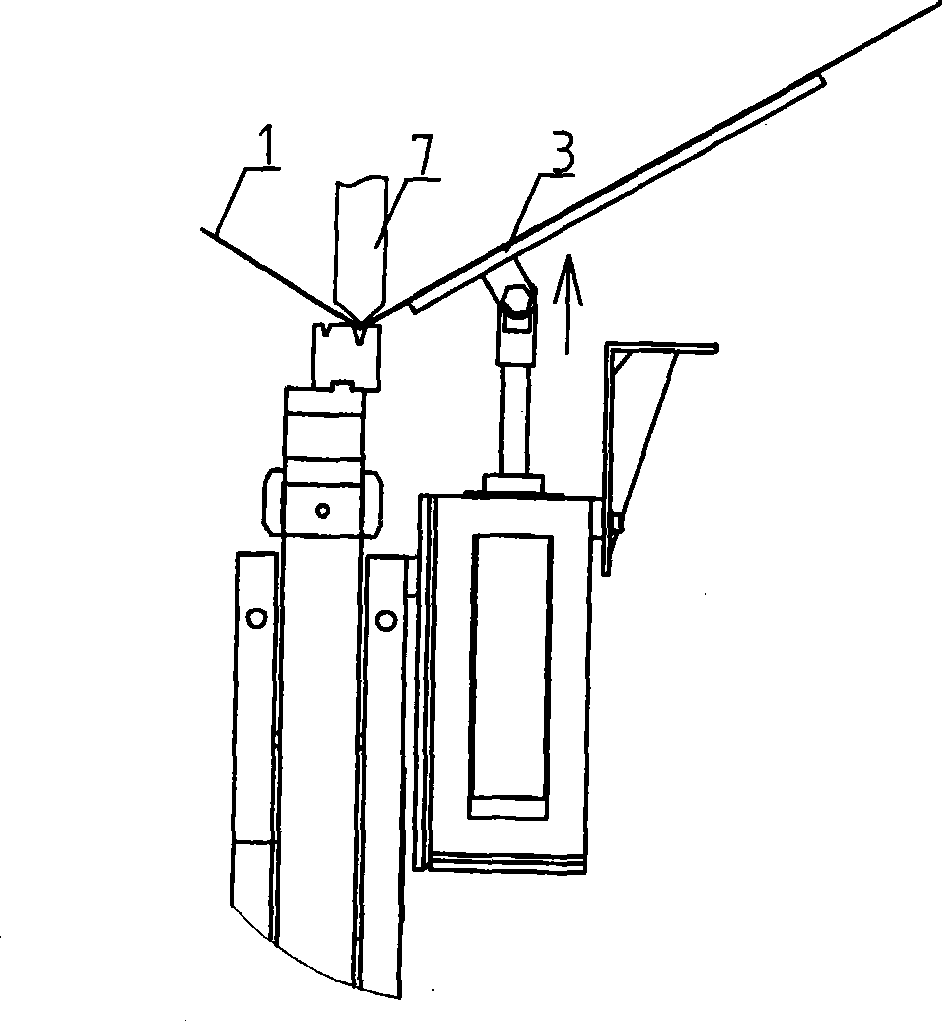

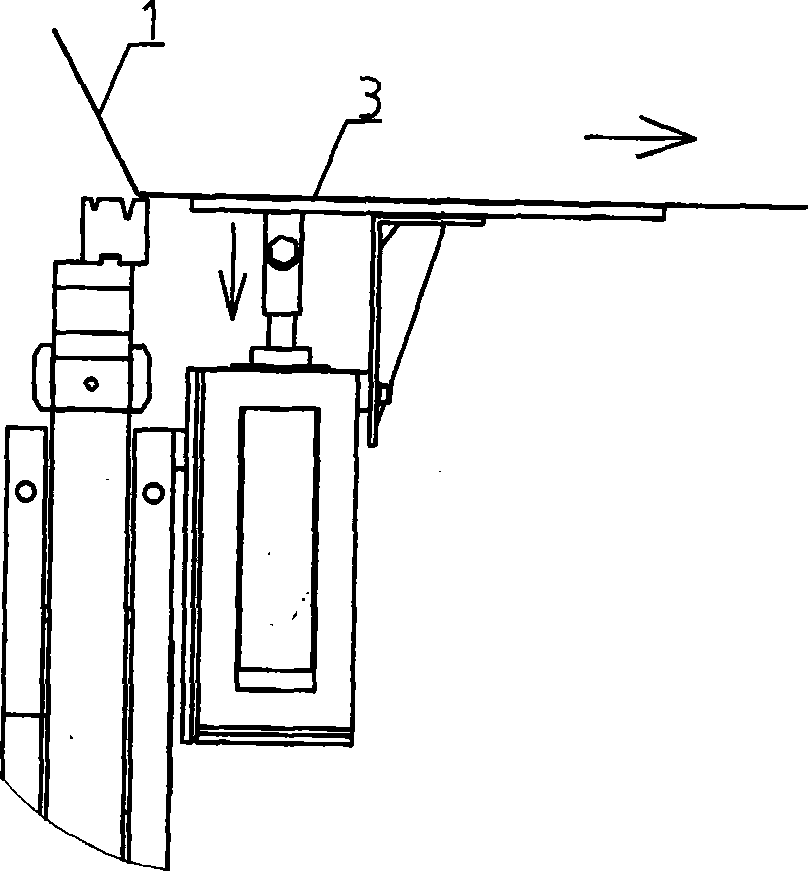

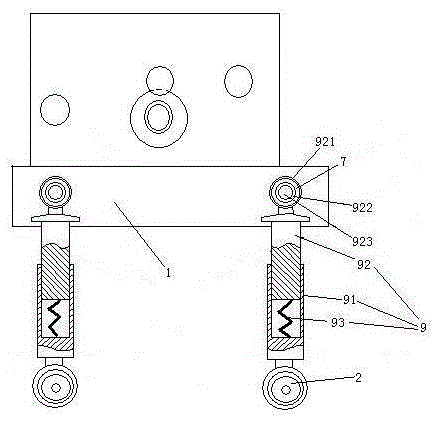

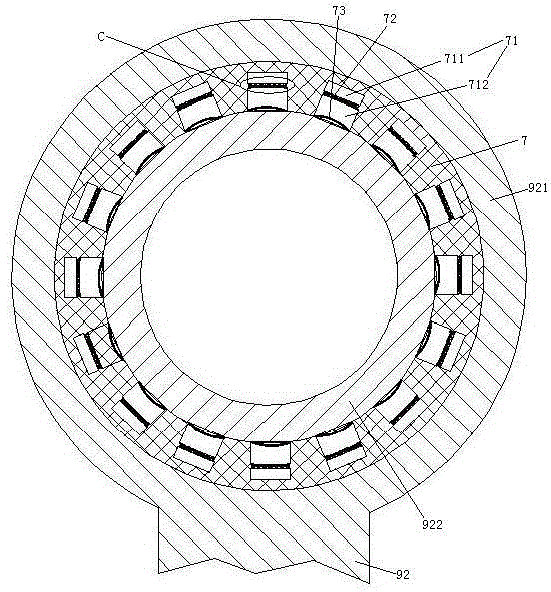

Sheet follow-up supporting device of bending machine

ActiveCN101462132AAvoidance of impactStable supportMetal-working feeding devicesPositioning devicesControl systemEngineering

The invention discloses a plate follow-up supporting device for a bending machine, and relates to a plate supporting device for a bending machine. The device is connected with a control system of the bending machine, arranged at the position of a lower die on a workbench of the bending machine which faces a discharge opening, and consists of at least two cylinders distributed on the lower side of the discharge opening and retainer plates hinged with the top of cylinder piston rods; the cylinders are fixedly connected to the lower part of the outer side of the discharge opening of the workbench of the bending machine; hinge seats are arranged on the bottom surfaces of the retainer plates; the tops of the cylinder piston rods are connected with the hinge seats on the bottom surfaces of the retainer plates by hinge shafts; and the movement of the cylinders is controlled by the control system according to time sequence of the bending movement. The device ensures that the plate drops quite slowly, and prevents collision between the plate and the workbench.

Owner:江苏扬力数控机床有限公司

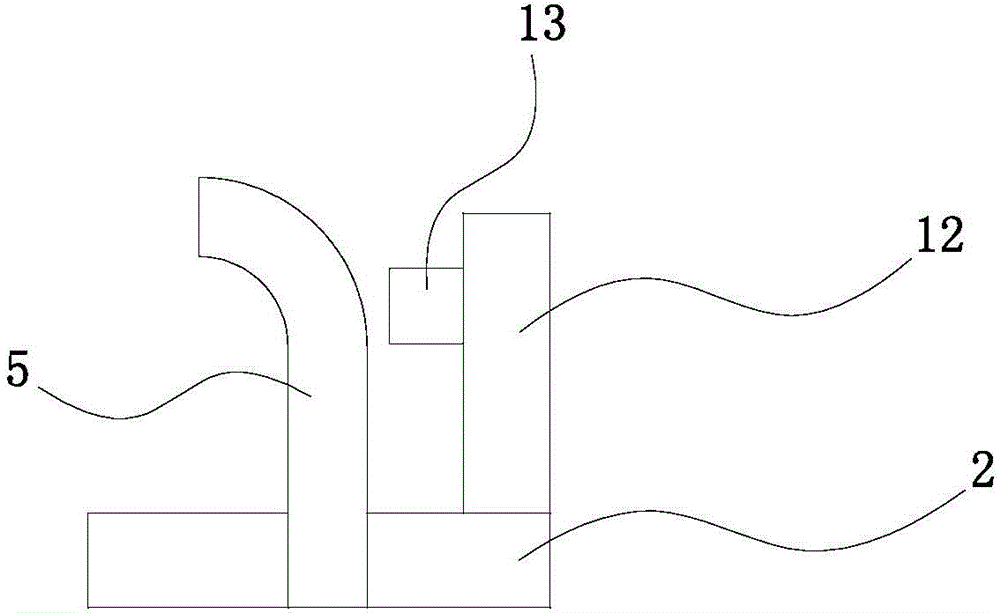

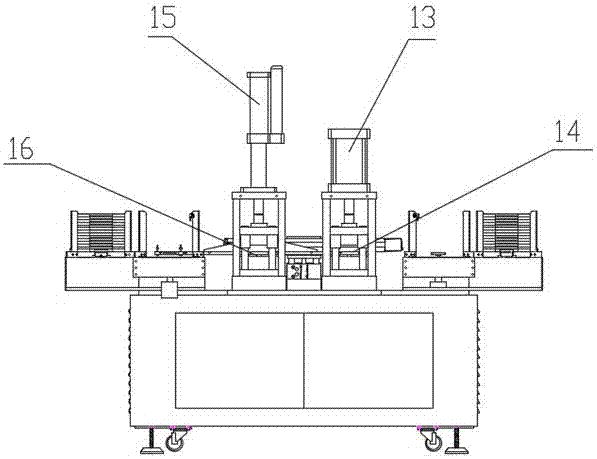

Pin bending machine

The invention relates to the technical field of electronic element machining equipment, in particular to a pin bending machine. The pin bending machine comprises a frame, and a bending device, a pin cutting device, a carrying device and a controller arranged on the frame. The pin bending machine is characterized in that the bending device and the pin cutting device are arranged in the frame side by side; the carrying device comprises a lifting cylinder vertically arranged in the frame, and a first linear slide rail horizontally mounted on a slide block of the lifting cylinder; a carrying arm is fixedly mounted on the first linear slide rail; four sucking nozzles are arranged on the carrying at equal intervals; the sucking nozzles are connected with a vacuum pump through pipelines; the gaps of an automatic feeding device, the bending device, the pin cutting device and an automatic collecting device are just equal to the gaps of the sucking nozzles; working planes for placing network transformers in the automatic feeding device, the bending device, the pin cutting device and the automatic collecting device are the same in heights; and the carrying device can synchronously finish the work of taking from a taking point to the bending device, carrying of the network transformers from the bending device to the pin cutting device and carrying from the pin cutting device to a collecting point under the control of the controller.

Owner:LEIYANG YAXIANG ELECTRONICS TECH

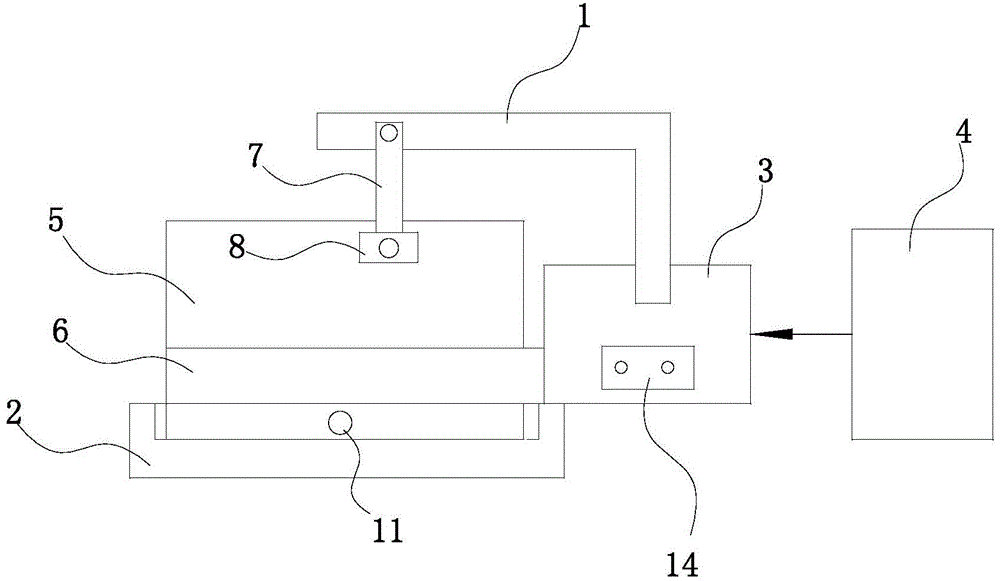

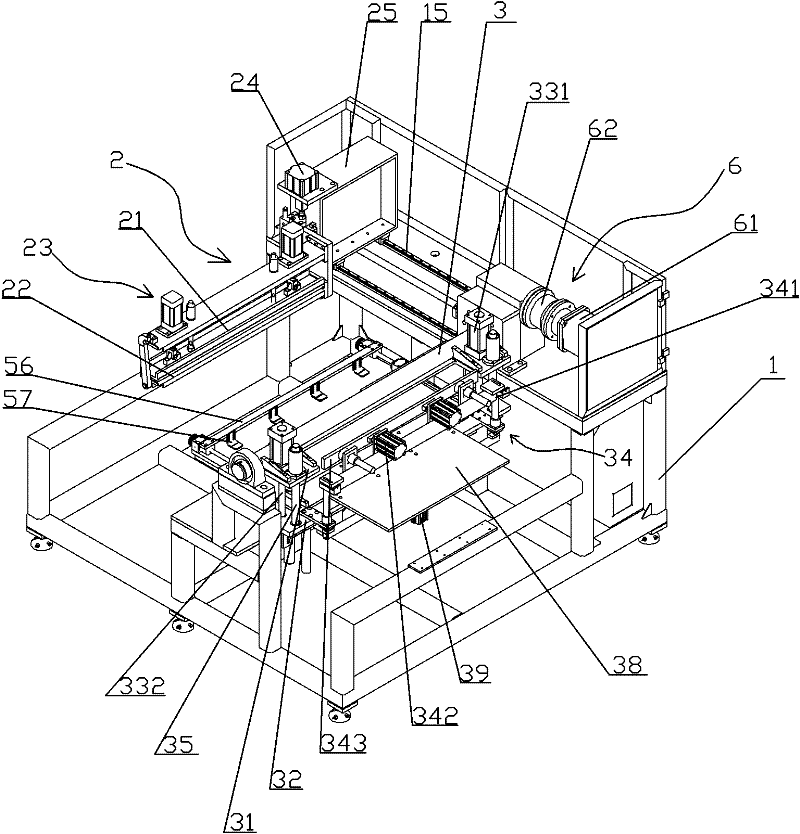

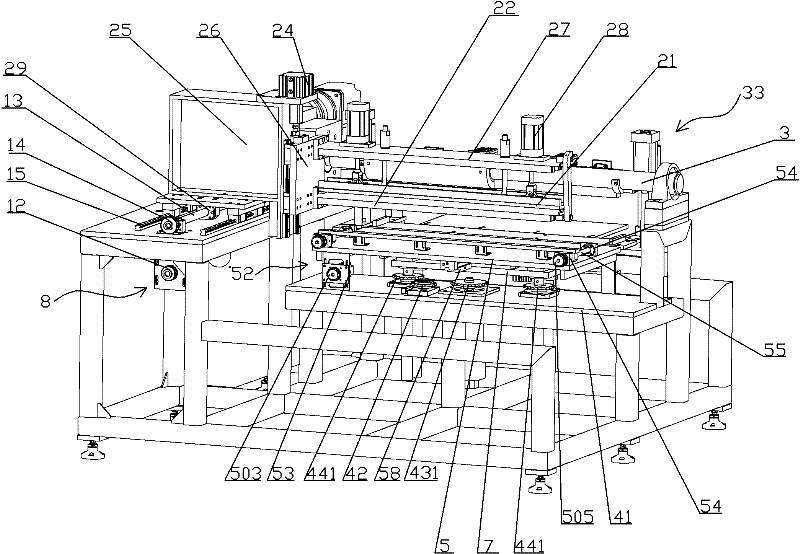

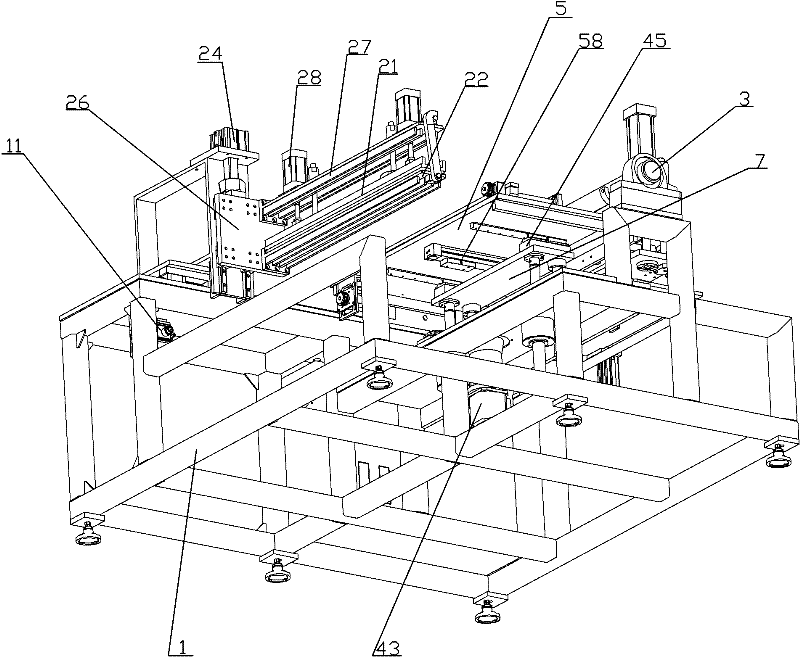

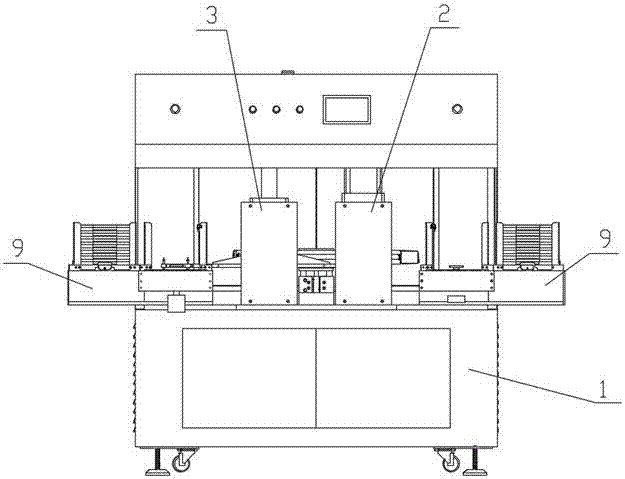

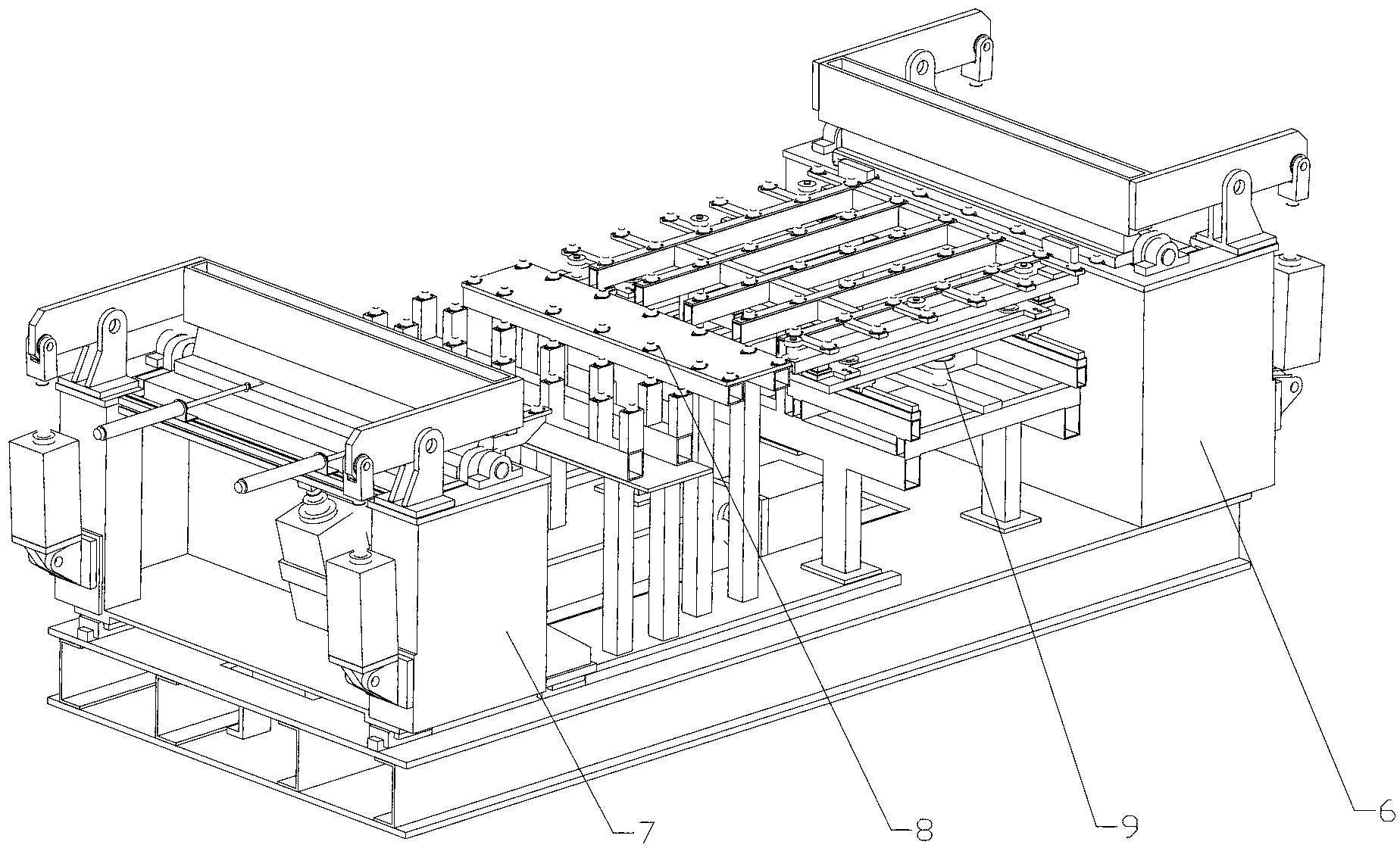

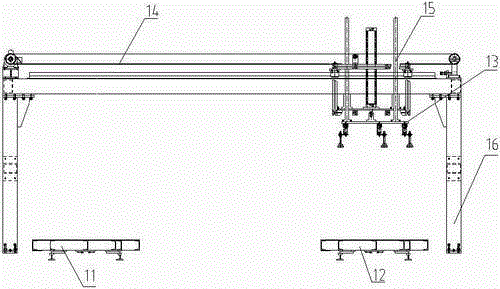

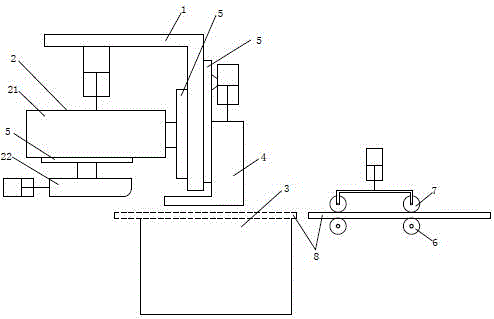

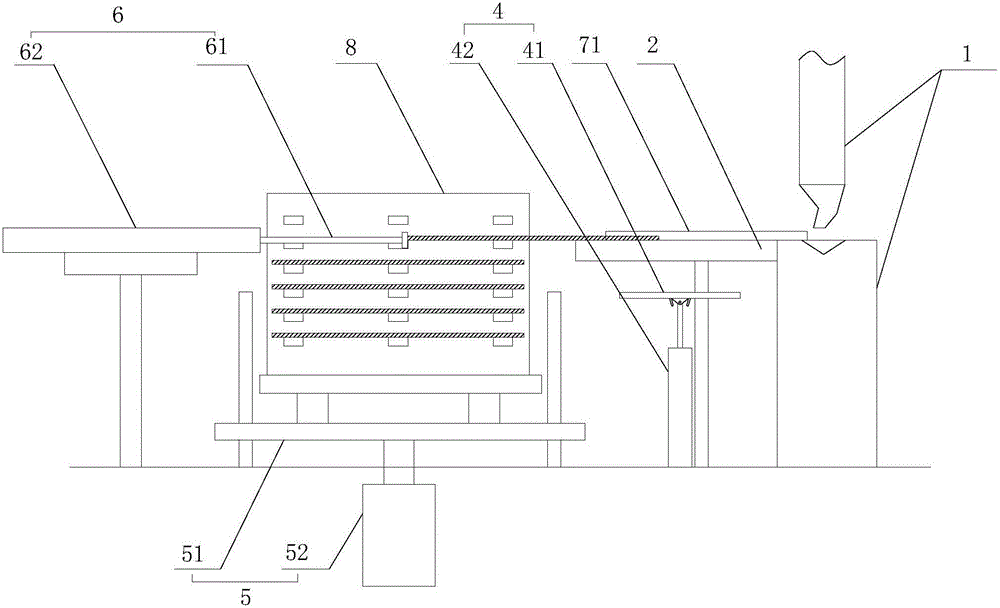

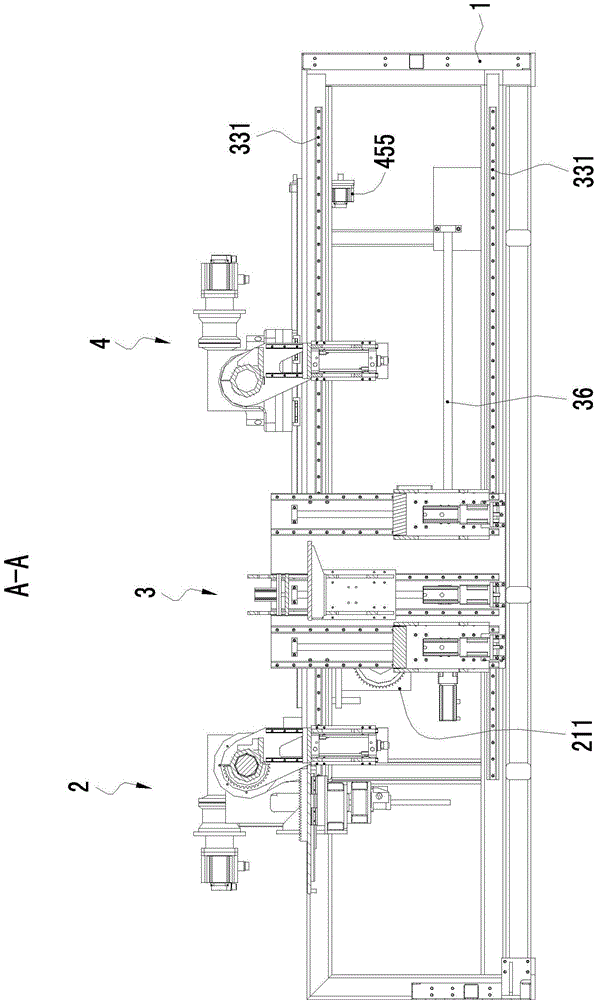

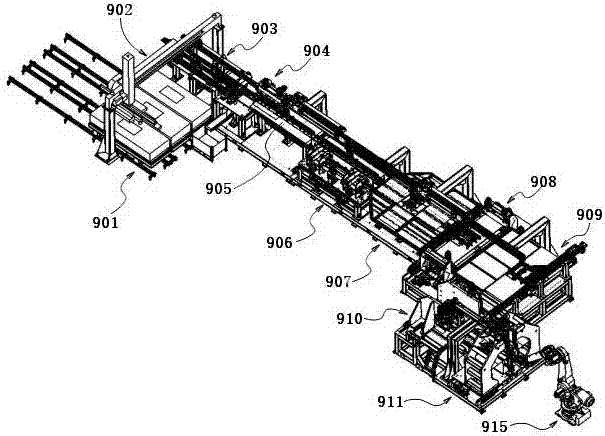

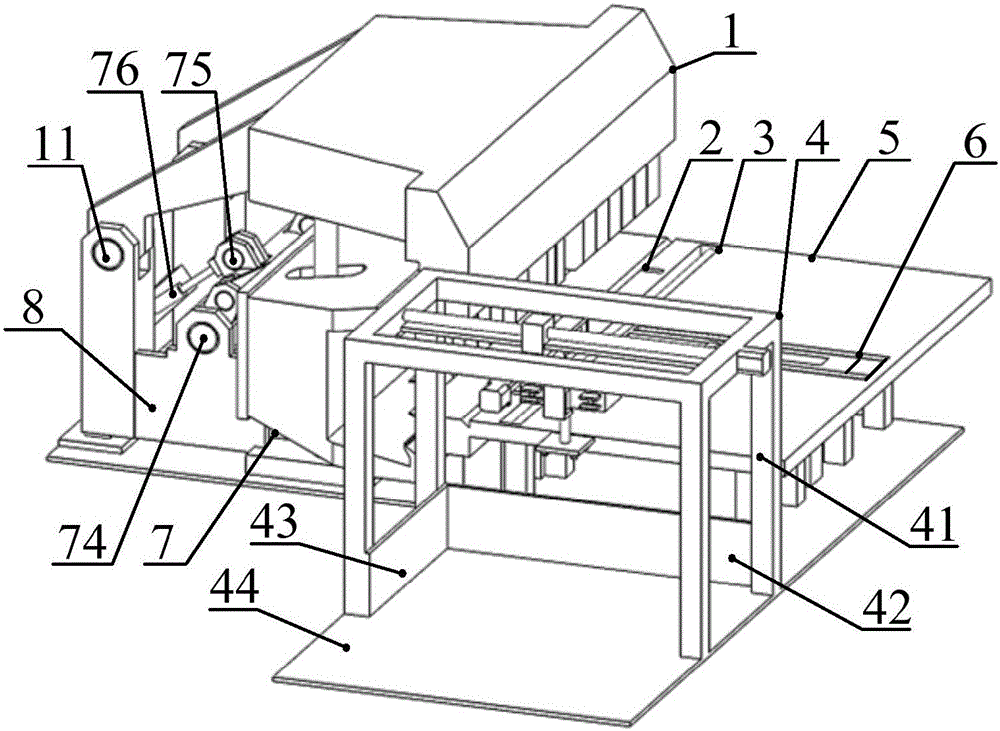

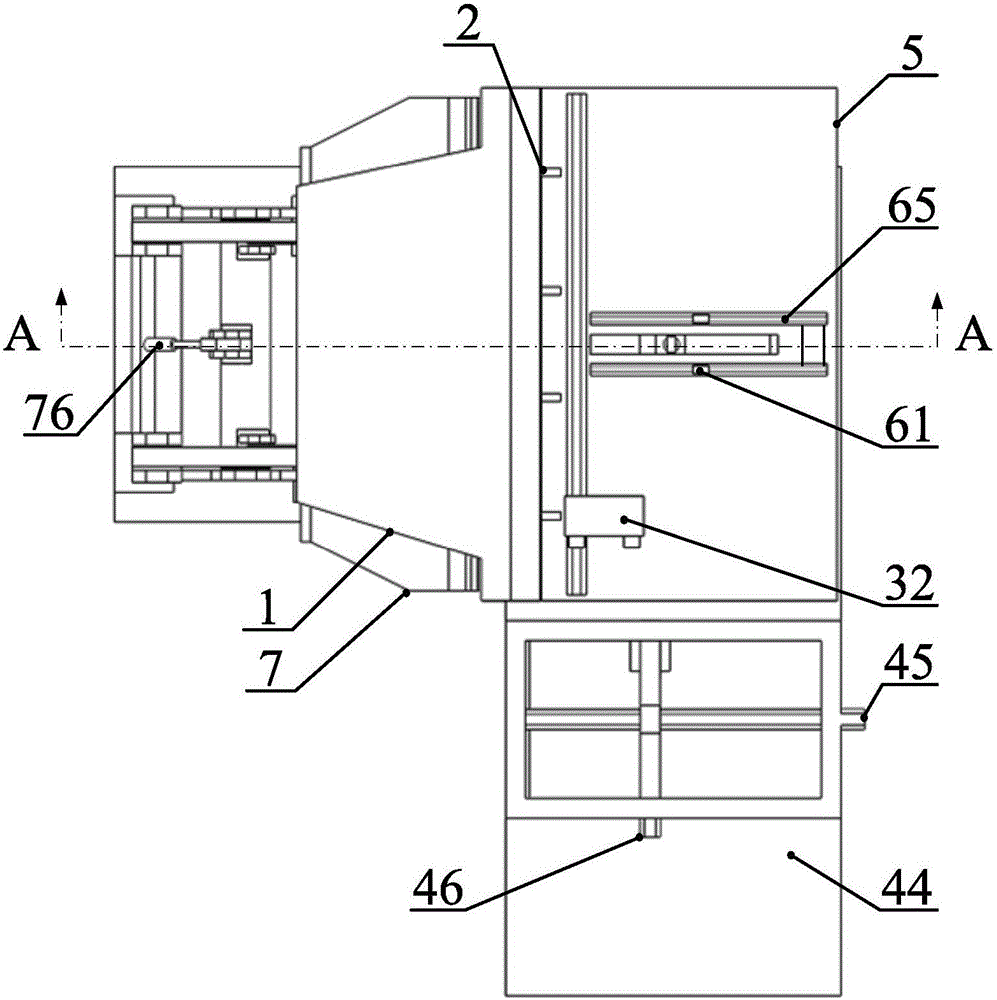

Four-side bending system

ActiveCN102909244AImprove combination efficiencyEasy to arrange for productionMaterial transferPress brake

The invention relates to a four-side bending system comprising a first bending unit, a second bending unit and a material transferring device, wherein the first bending unit is used for completing the bending work of a group of opposite sides of a material to be bent; the second bending unit is used for completing the bending work of the other group of opposite sides of the material to be bent; and the material transferring device is used for shifting the material according to the process. The first bending unit comprises a first static bending machine, a first movable bending machine, a first working table and a first positioning part, wherein the first static bending machine and the first movable bending machine are oppositely placed on a main frame; and the working table and the positioning part are placed between the first static bending machine and the first movable bending machine. The second bending unit comprises a second static bending machine, a second movable bending machine, a second working table and a second positioning part, wherein the second static bending machine and the second movable bending machine are oppositely placed on the main frame; and the second working table and the second positioning part are placed between the second static bending machine and the second movable bending machine. The four-side bending system is relatively high in production efficiency, relatively low in manufacture cost and simple to maintain and is suitable for various productions.

Owner:YINDU KITCHEN EQUIP

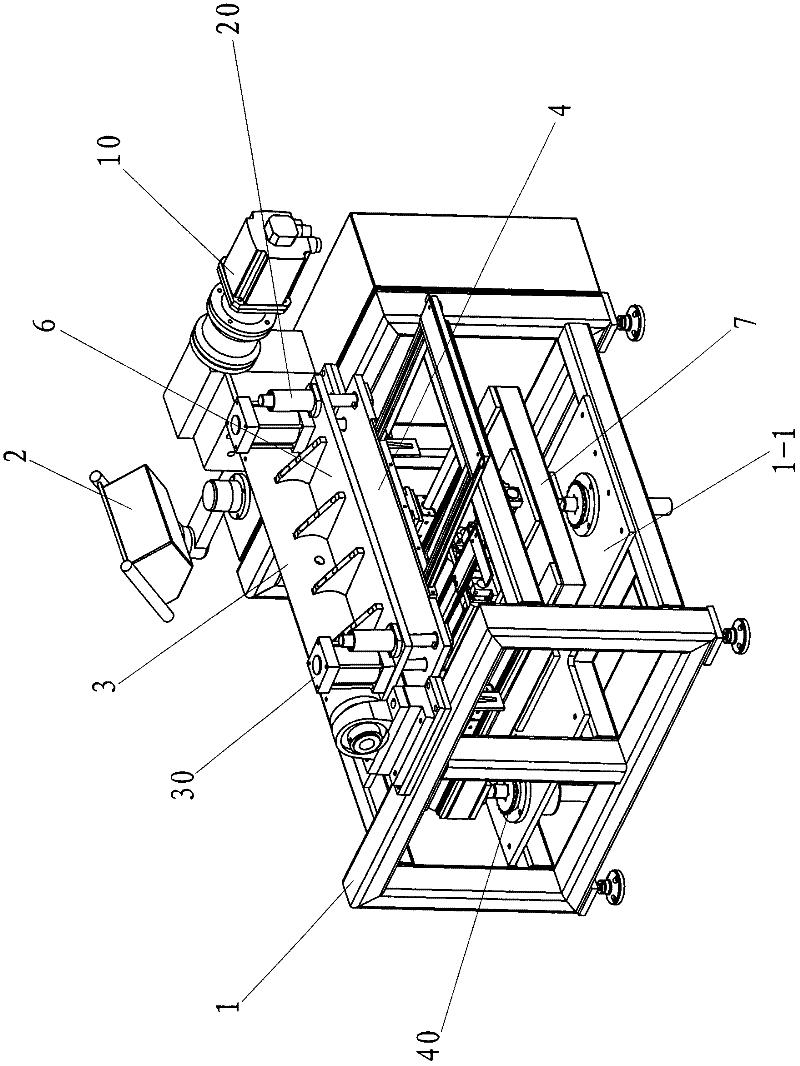

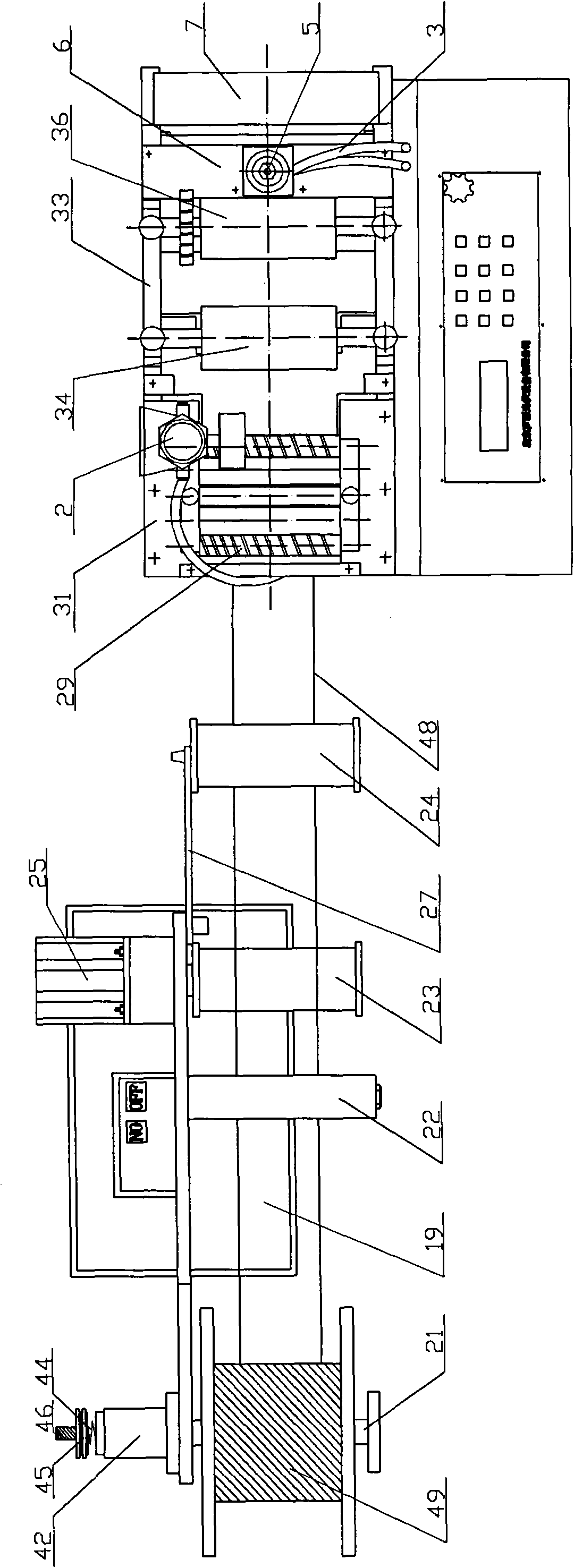

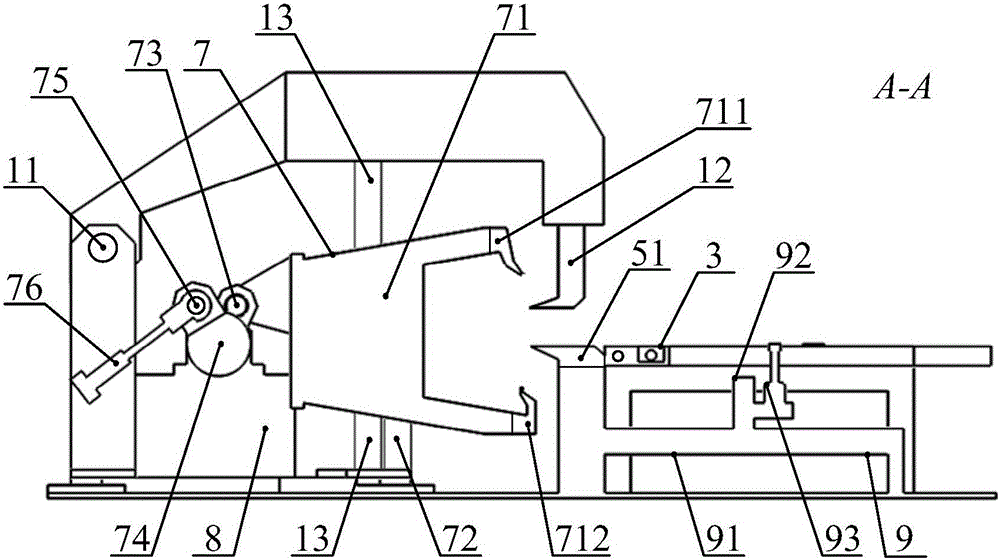

Bending machine

The invention relates to a part of bending and forming equipment of a heat exchanger, in particular to a bending machine capable of bending the heat exchanger, in particular to the bending machine capable of adopting a layered bending and forming process on a multi-layer heat exchanger. The bending machine comprises a machine frame, a controller, a rotary roller, a rotary roller driving mechanism, a lower pressing plate and a follower plate, wherein an upper pressing plate is arranged on the rotary roller; the lower pressing plate is parallel to the upper pressing plate; a horizontal lifting platform is arranged in the machine frame; a follower plate guiding mechanism, a follower plate driving mechanism and a clutch device are arranged on the lifting platform; the follower plate can longitudinally feed and can longitudinally follow; and the height of the follower plate can be adjusted. The bending machine has the following advantages that: because of servo bending, the precision is high; the height and the longitudinal position of the follower plate are adjusted and controlled through a servo, so the follower plate is automatically lifted and is automatically, horizontally and longitudinally moved and the positioning is precise; because of layered bending, a force applied to the heat exchanger is reduced and a fin is prevented from collapsing and being crushed; and the whole machine has a simple structure and a reasonable layout, is easy to manufacture and is convenient to operate.

Owner:OMS MASCH CO LTD

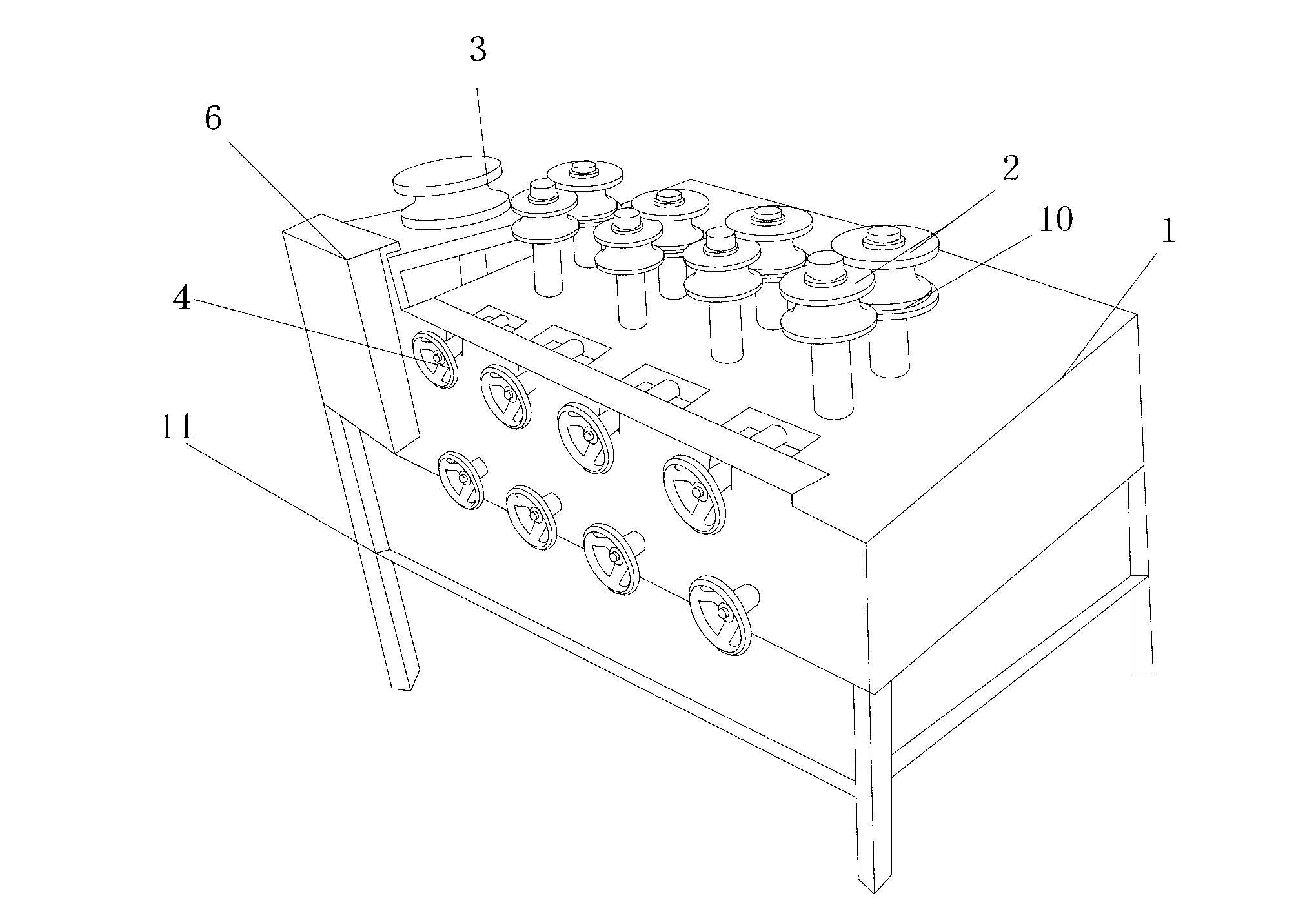

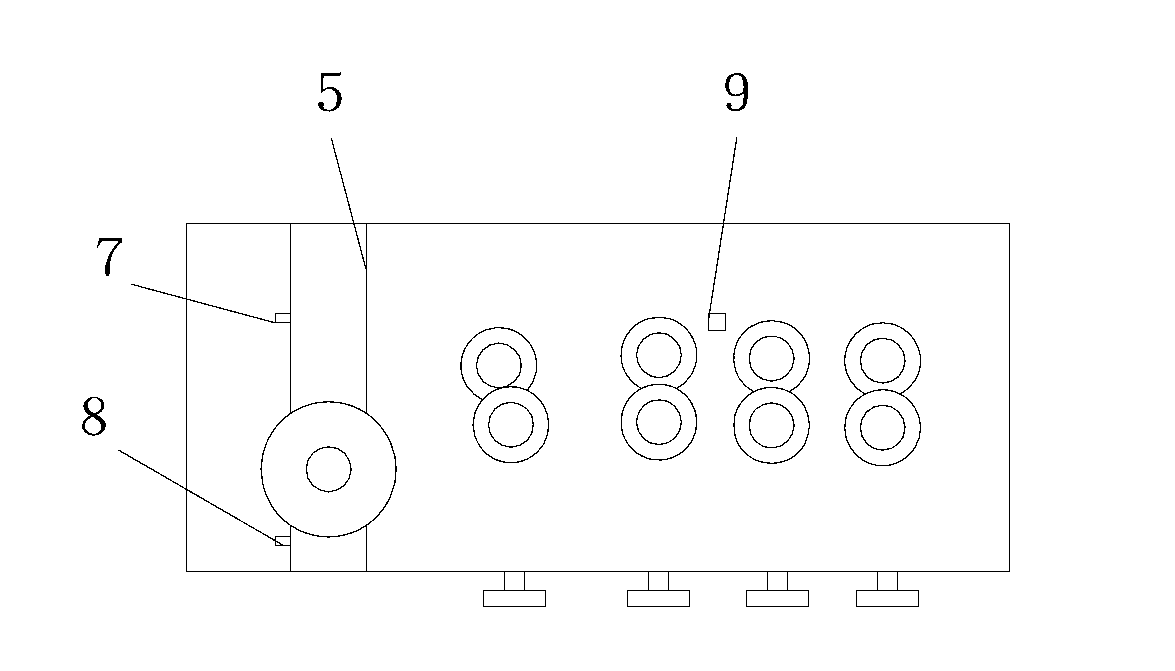

Multi-angle bender

The invention relates to the technical field of pipe benders, in particular to a multi-angle bender which comprises a bench, press rolls, a bending roll and a PLC (programmable logic controller). The press rolls are sequentially disposed at the top of the bench. Adjusting wheels for adjusting transverse movement of the press rolls are arranged on one side wall of the bench. The bending roll is in sliding connection with a guide on the bench. The bending roll is driven to move on the guide by a step motor disposed on one side of the bench. A first position sensor and a second position sensor are arranged on one side of the guide. An output end of the PLC is connected with a signal end of the step motor. A third sensor is arranged between two adjacent pairs of press rolls. The multi-angle bender is simple in structure and low in manufacturing cost. The motor controls the position of the bending roll on the guide to obtain required bending angles. Different bent angles can be made at different positions on one steel pipe by the multi-angle bender, and work efficiency is increased.

Owner:TIANJIN KAICHUANG TUODA METAL STRUCTURE

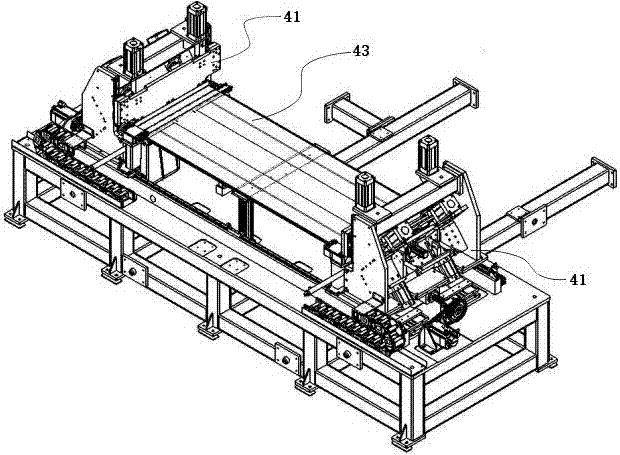

Automatic bending production line for kitchen cabinet sheet metal parts

ActiveCN105127253AImprove machining accuracyVersatility in sizeMetal-working feeding devicesPositioning devicesProduction lineShape change

The invention discloses an automatic bending production line for kitchen cabinet sheet metal parts. The automatic bending production line is composed of an automatic feeding machine, an automatic positioning machine, a side face edge rolling machine, a lower side bending machine, an upper side bending machine, a four-corner flanging machine, a lower end bending machine, an upper end bending machine, a first conveying machine, a second conveying machine and a control system; the automatic feeding machine, the automatic positioning machine, the side face edge rolling machine, the lower side bending machine, the upper side bending machine, the four-corner flanging machine and the lower end bending machine are horizontally arranged in the same axis, and the lower end bending machine and the upper end bending machine are arranged to be perpendicular to the automatic feeding machine, the automatic positioning machine, the side face edge rolling machine, the lower side bending machine, the upper side bending machine, the four-corner flanging machine and the lower end bending machine. Compared with the prior art, the automatic bending production line has the advantages that the automation functions of various bending technologies are achieved, automatic flexible regulation can be performed according to the size and shape changes, the machining precision and the machining speed are high, the stability is good, the problems that manual bending of the kitchen cabinet sheet metal parts is low in efficiency and poor in reliability are solved, and automatic bending of the kitchen cabinet sheet metal parts is achieved.

Owner:ANHUI KECHANG MACHINERY MFG

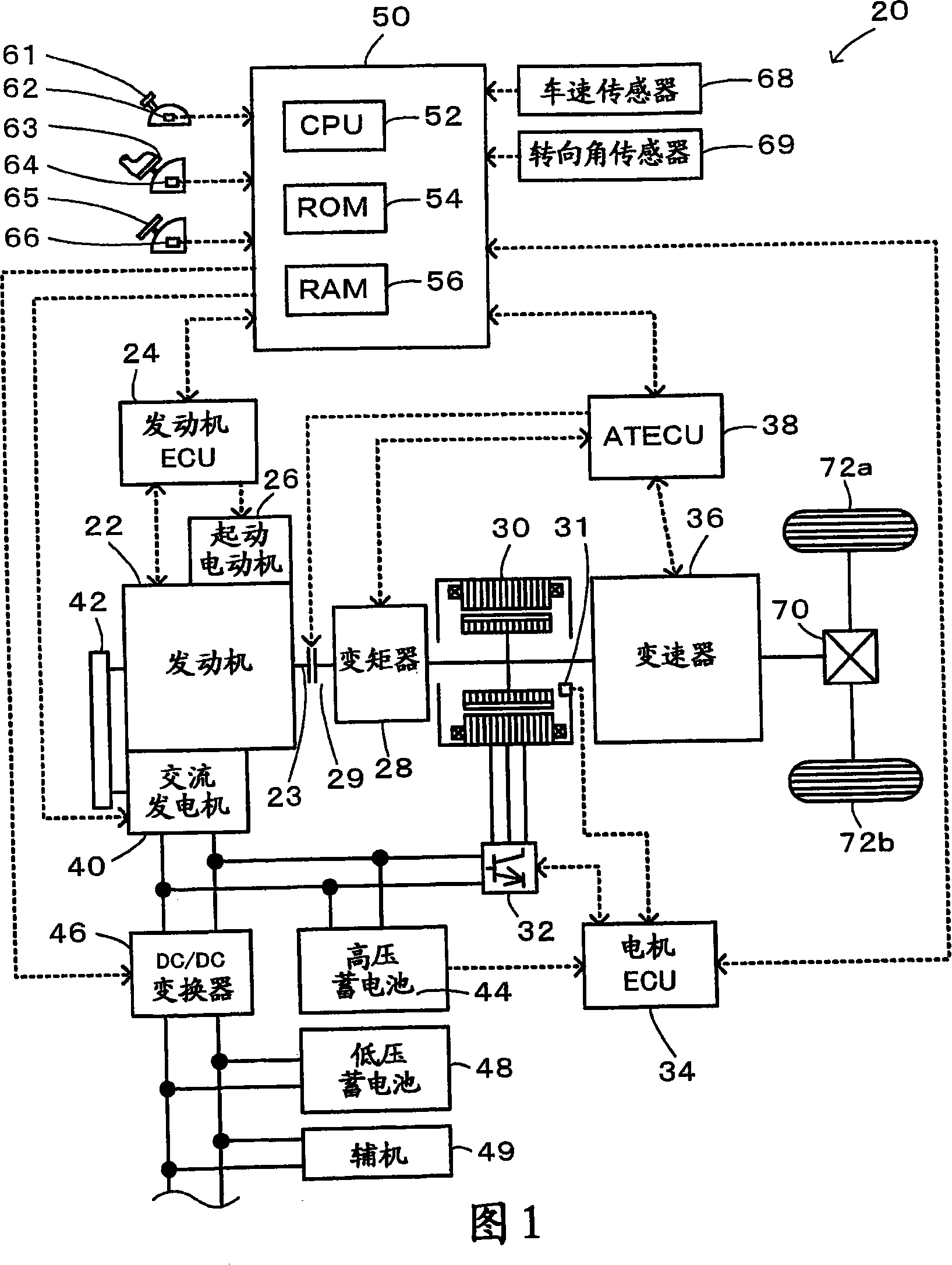

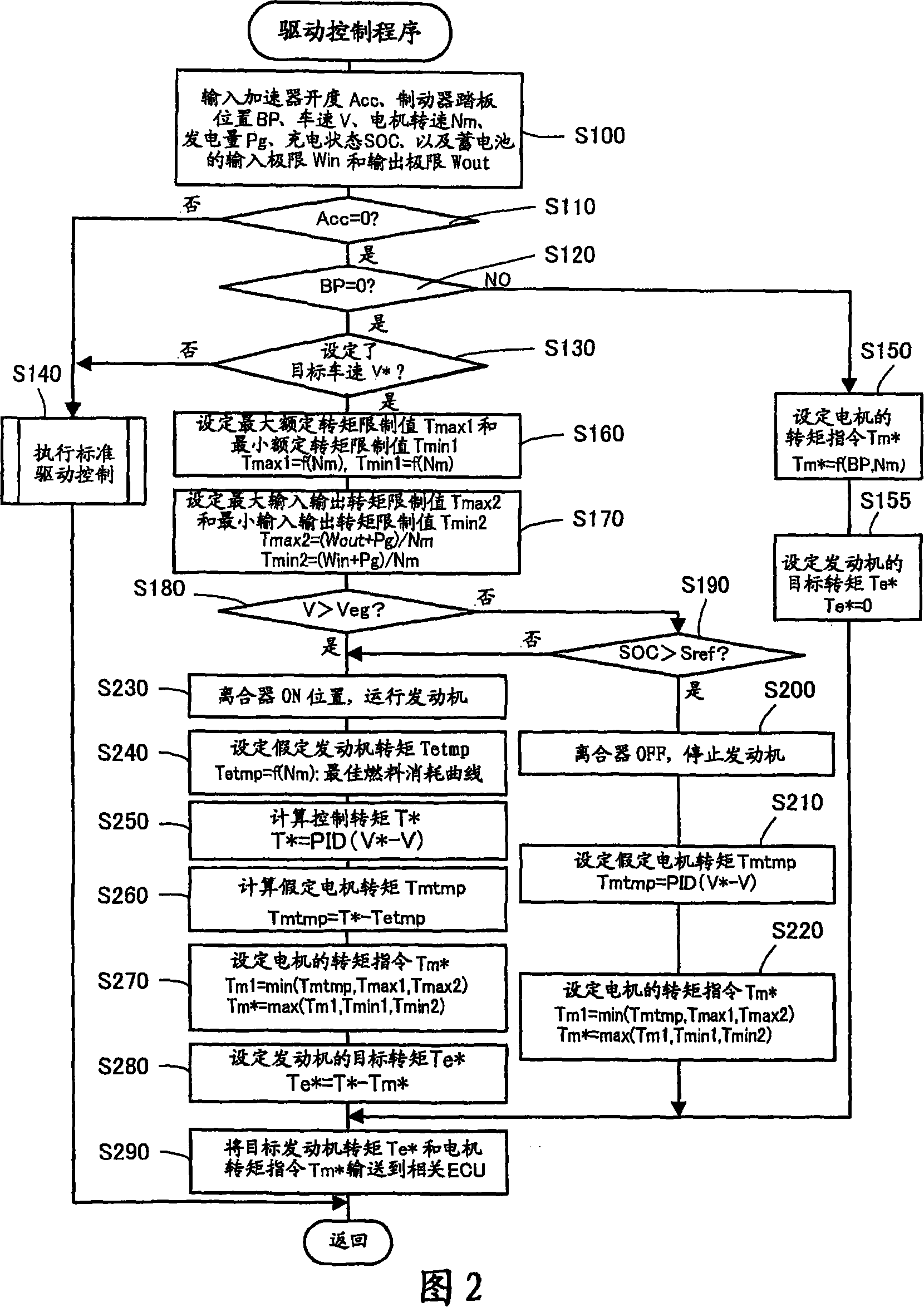

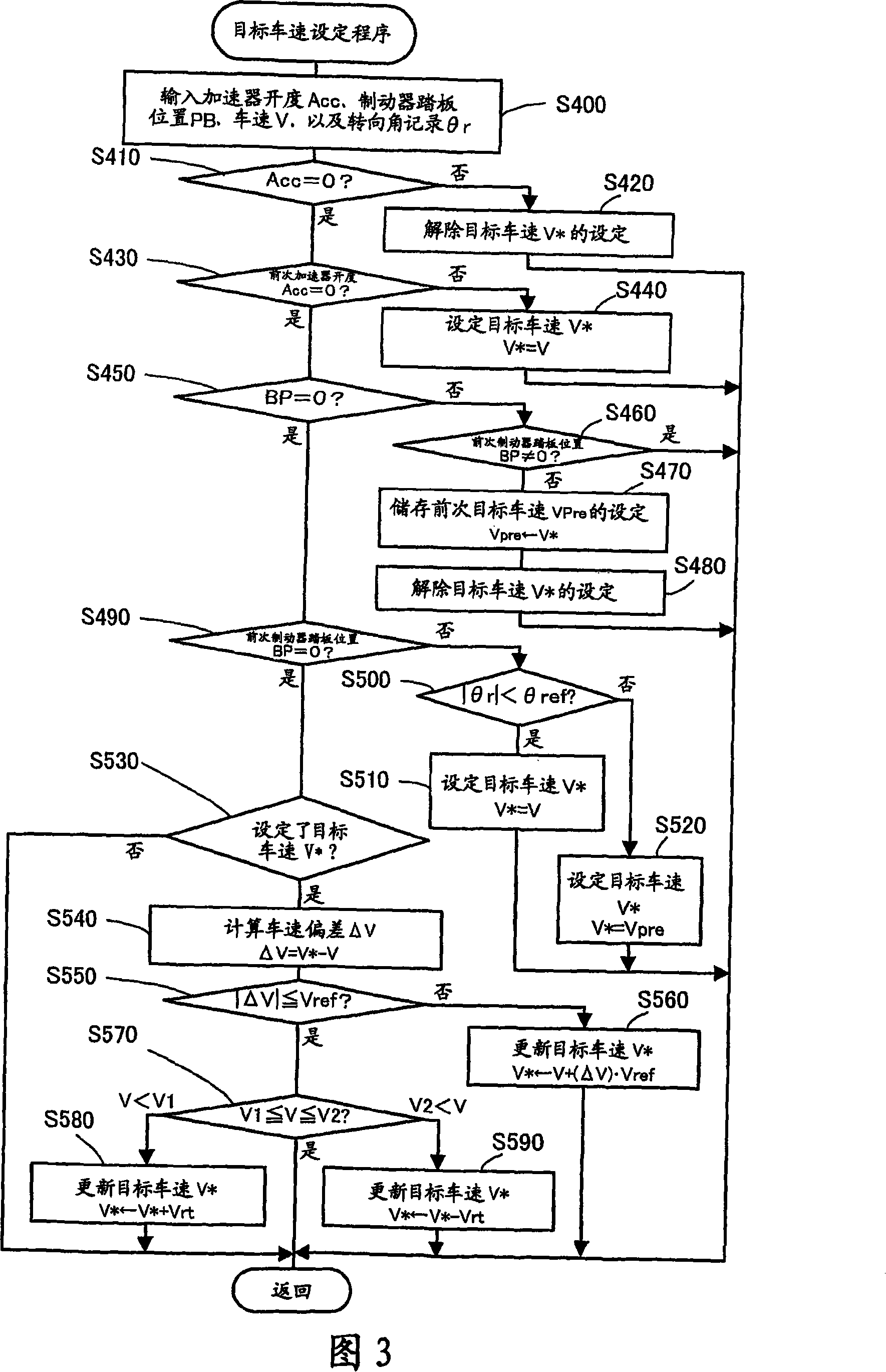

Vehicle and control method of vehicle

InactiveCN101115638AEasy to startThe accelerator operates properlyVehicle fittingsEngine controllersSteering wheelControl store

In the vehicle of the present invention, when the driver releases the depressed accelerator pedal, the drive control sets the vehicle speed V at that time as the target vehicle speed V* (step S440). The engine and the motor for outputting driving force are controlled to drive the vehicle at the target vehicle speed V*. When the driver steps on the relaxed brake pedal, the drive control stores the target vehicle speed V* set before the driver depresses the brake pedal as the previous target vehicle speed Vpre and cancels the setting of the target vehicle speed V* (steps S470 and S480 ). In response to the driver's subsequent release of the brake pedal, the drive control sets the vehicle speed V at this time as the target vehicle speed V* (step S510) and resumes constant speed (cruising) driving. When the driver turns the steering wheel to or beyond a predetermined degree for left or right turn, the driving control sets the previous target vehicle speed Vpre to the target vehicle speed V* (step S520) and restarts the constant speed driving. This arrangement ensures easy and quick start of constant speed (cruising) driving and enables constant speed (cruising) driving according to changes in the driving state.

Owner:TOYOTA JIDOSHA KK

Safety apparatus for a machine, in particular for a press brake

Owner:PILZ (COMPANY)

Bending machine used for bending plates

ActiveCN105013887ARealize automatic feedingRealize the defect that the bending is not in placeMetal-working feeding devicesPositioning devicesEngineeringMachining

The invention discloses a bending machine used for bending plates and belongs to the technical field of machining. The bending machine comprises a rack, an upper bending part, a lower bending part and a feeding mechanism. The lower bending part is fixedly arranged, and the upper bending part is arranged in a vertical sliding mode. A material pressing plate is correspondingly arranged above the lower bending part. The material pressing plate is arranged in a vertical sliding mode. The upper bending part comprises an ejecting block and a sliding pressing plate. The ejecting block is arranged in a vertical sliding mode. The sliding pressing plate is located on the lower surface of the ejecting block and is arranged in a reciprocating sliding mode in the feeding direction. The sliding pressing plate is provided with a sliding driving device in a matched mode. A round corner is arranged on the side, matched with the lower bending part, of the sliding pressing plate. A bending gap is reserved between the sliding pressing plate and the lower bending part. The feeding mechanism comprises driving rollers and driven rollers located above the driving rollers, and the driven rollers are connected with a lifting driving device. The bending machine ensures the bending precision and is capable of improving efficiency, simple, practical and obvious in effect.

Owner:CHANGSHA CITY WANZHENG LORRY CARRIAGE

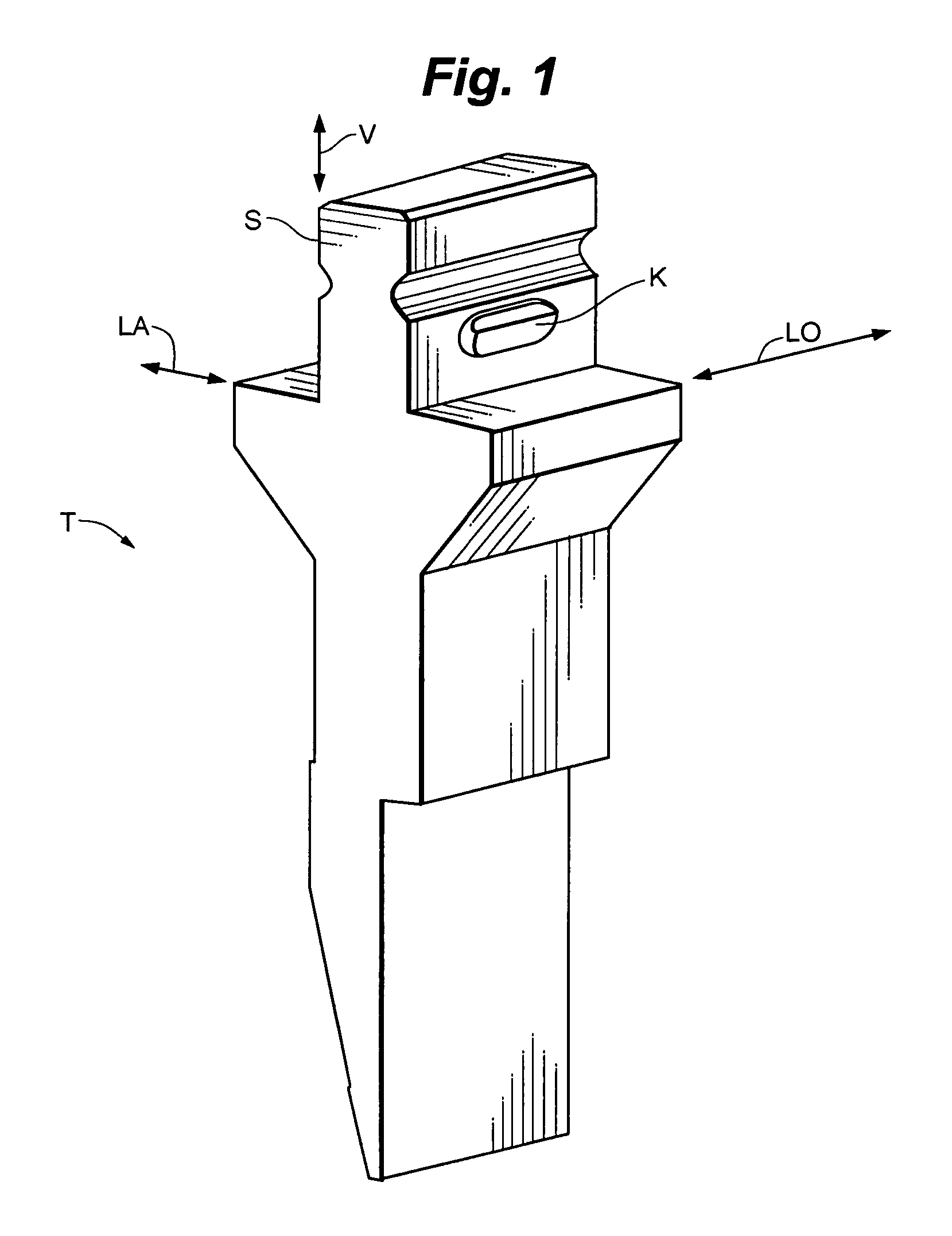

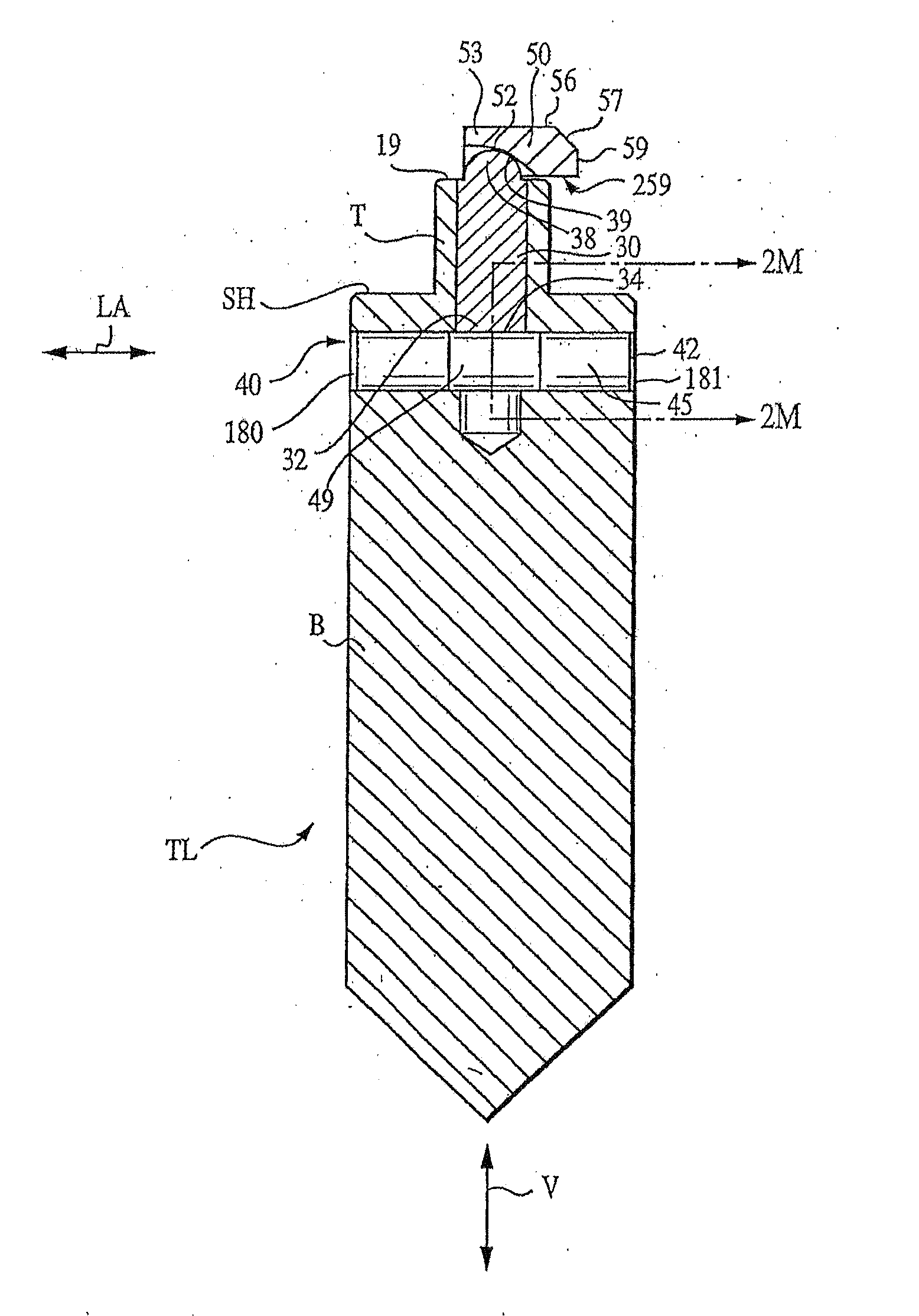

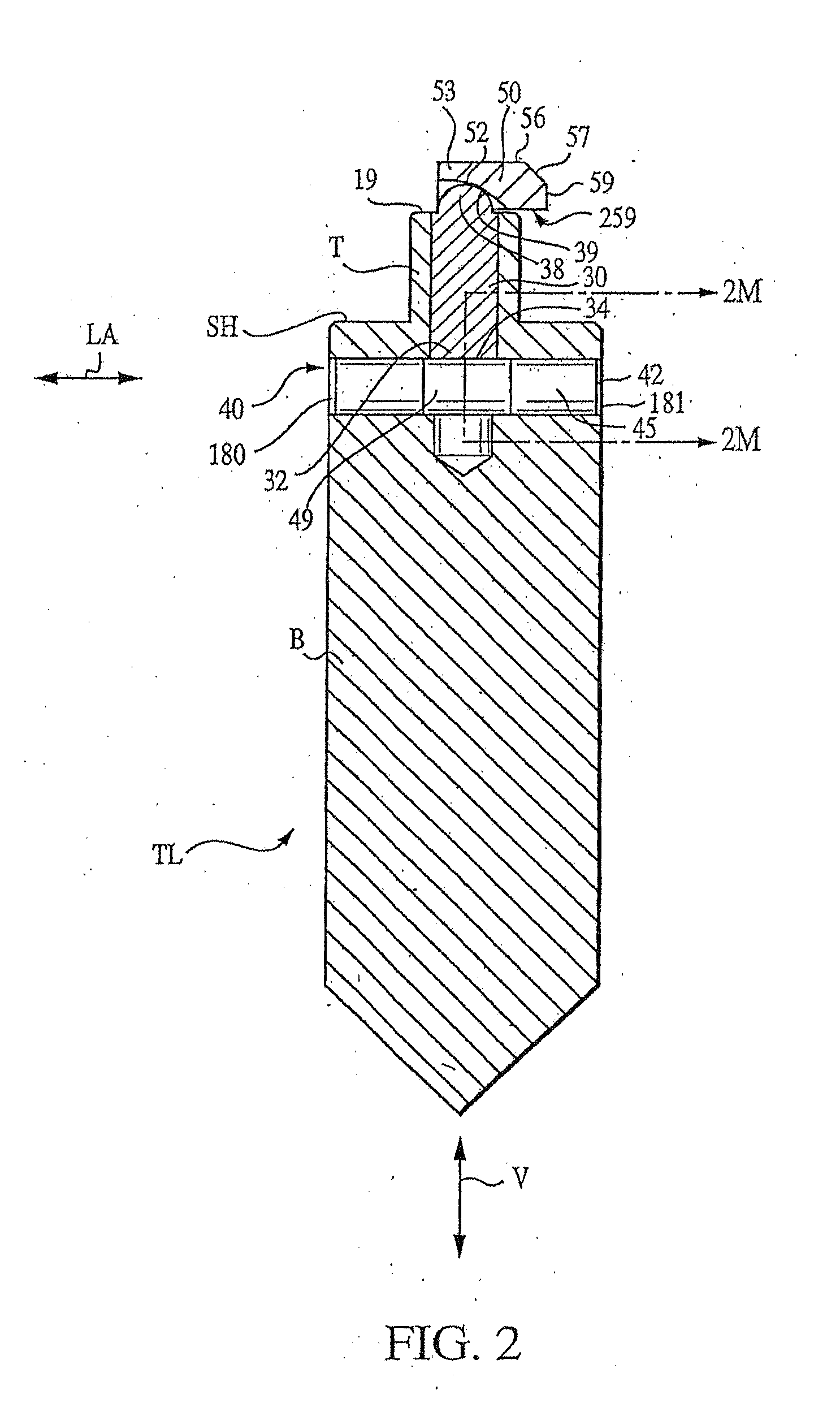

Press Brake Tool Safety Key Assemblies

The invention provides a press brake tool having a retractable safety key. In some embodiments, the tool includes a lock that can positively lock the safety key in an extended position. Different lock assemblies of this nature are provided. Also provided is a combination including a press brake tool and a tool holder. In some embodiments, the invention provides a press brake tool having a retractable safety key with an engagement portion having a tapered leading region (adapted to facilitate mounting the tool in a recess of a tool holder) and a tapered trailing region (adapted to facilitate dismounting the tool from the recess of the tool holder). Methods of use are also provided.

Owner:WILSON TOOL INT

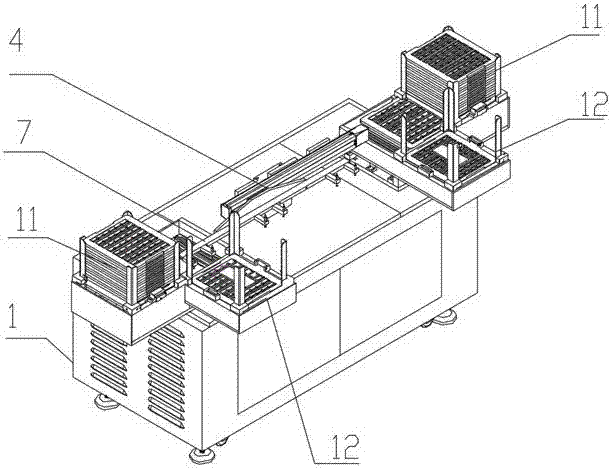

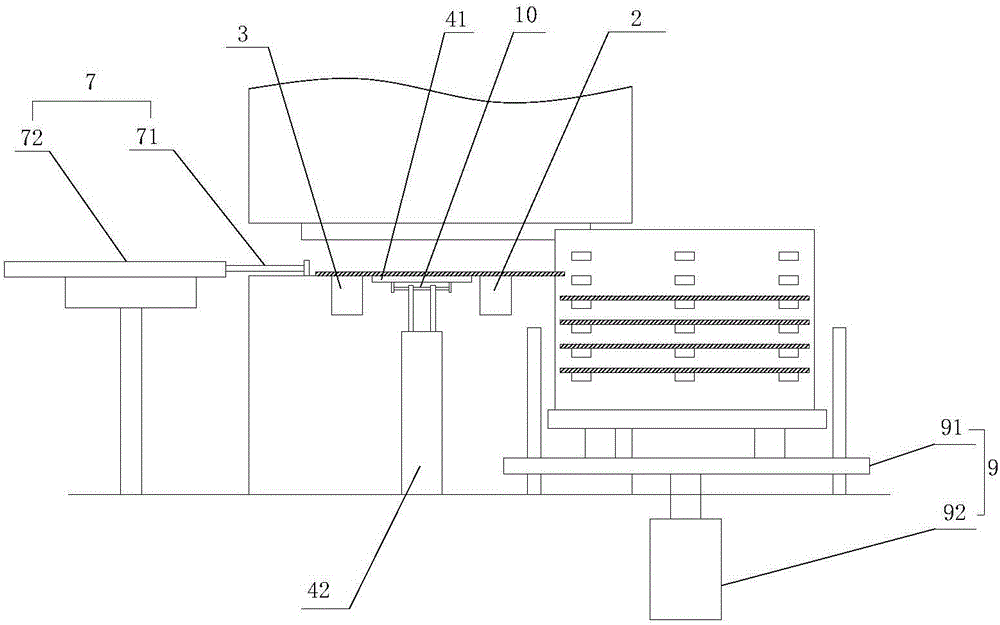

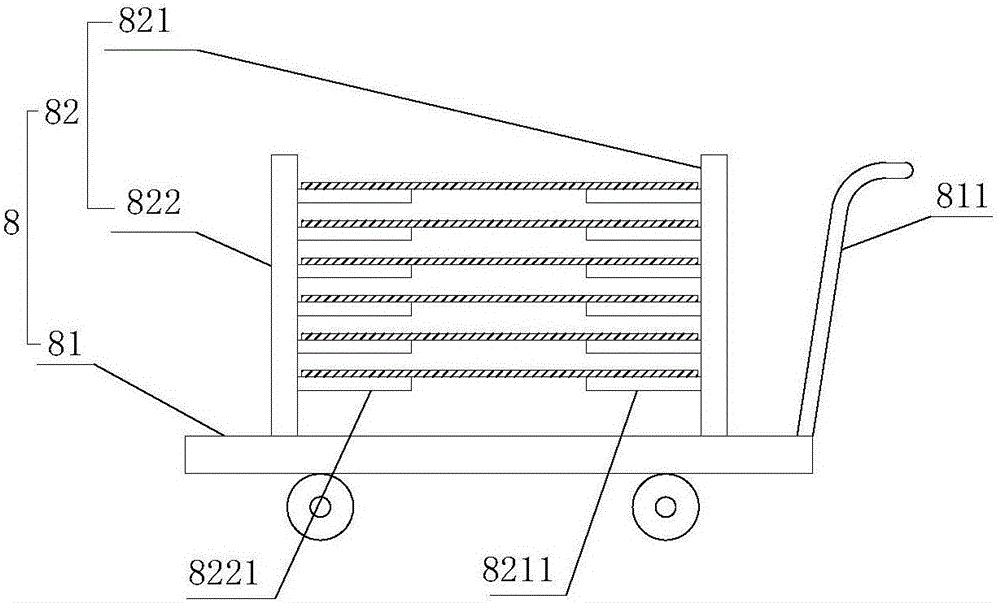

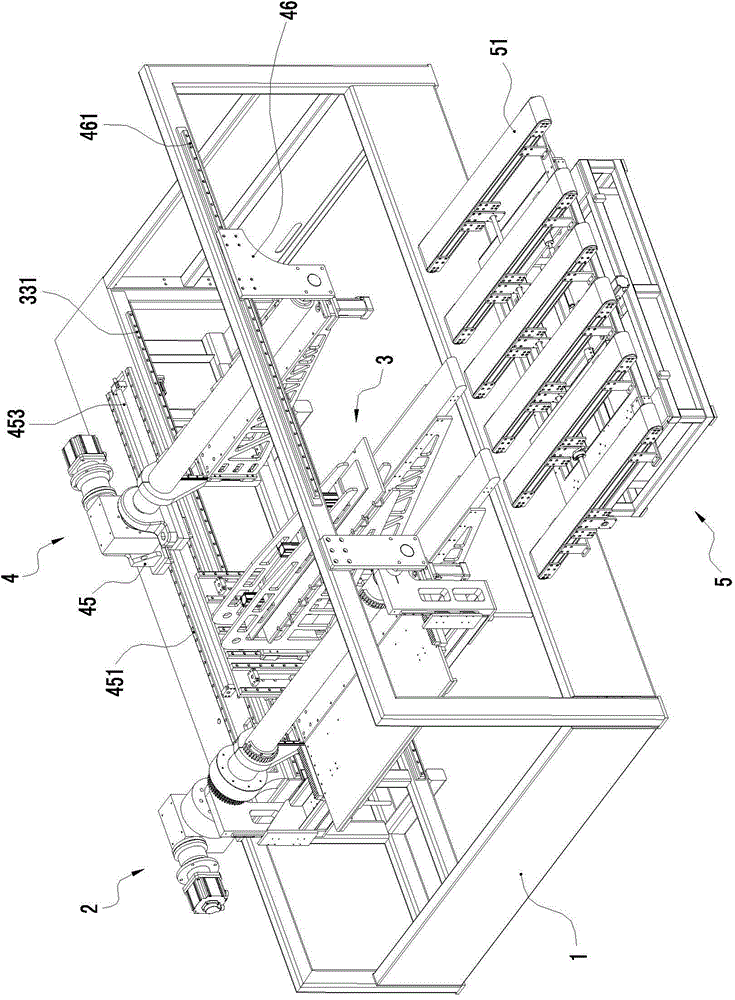

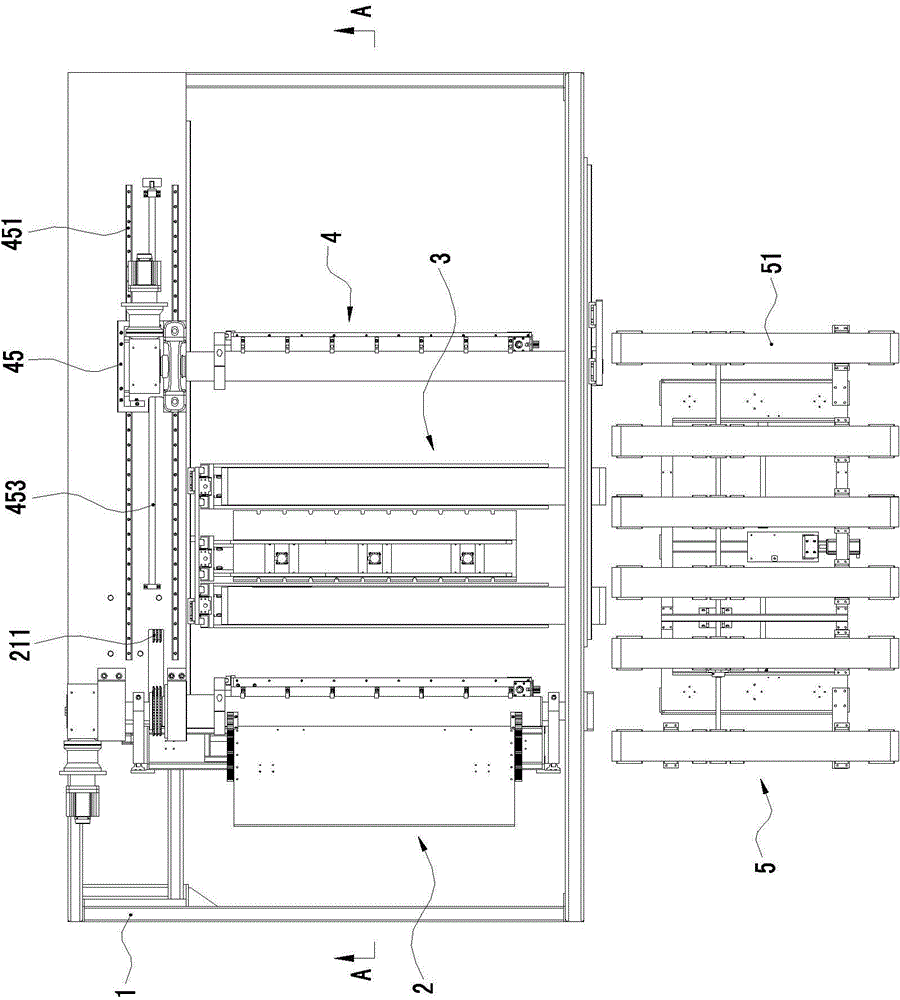

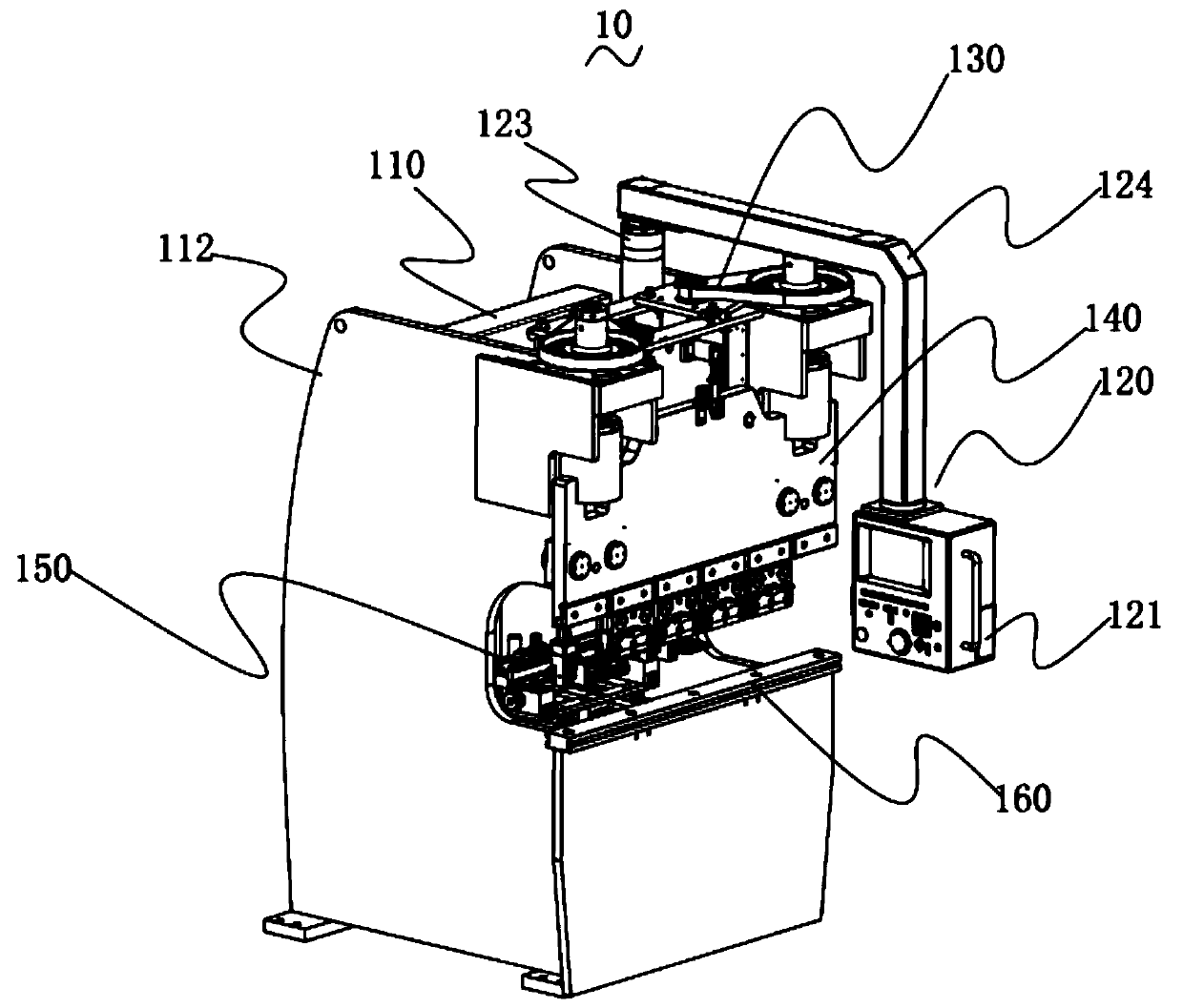

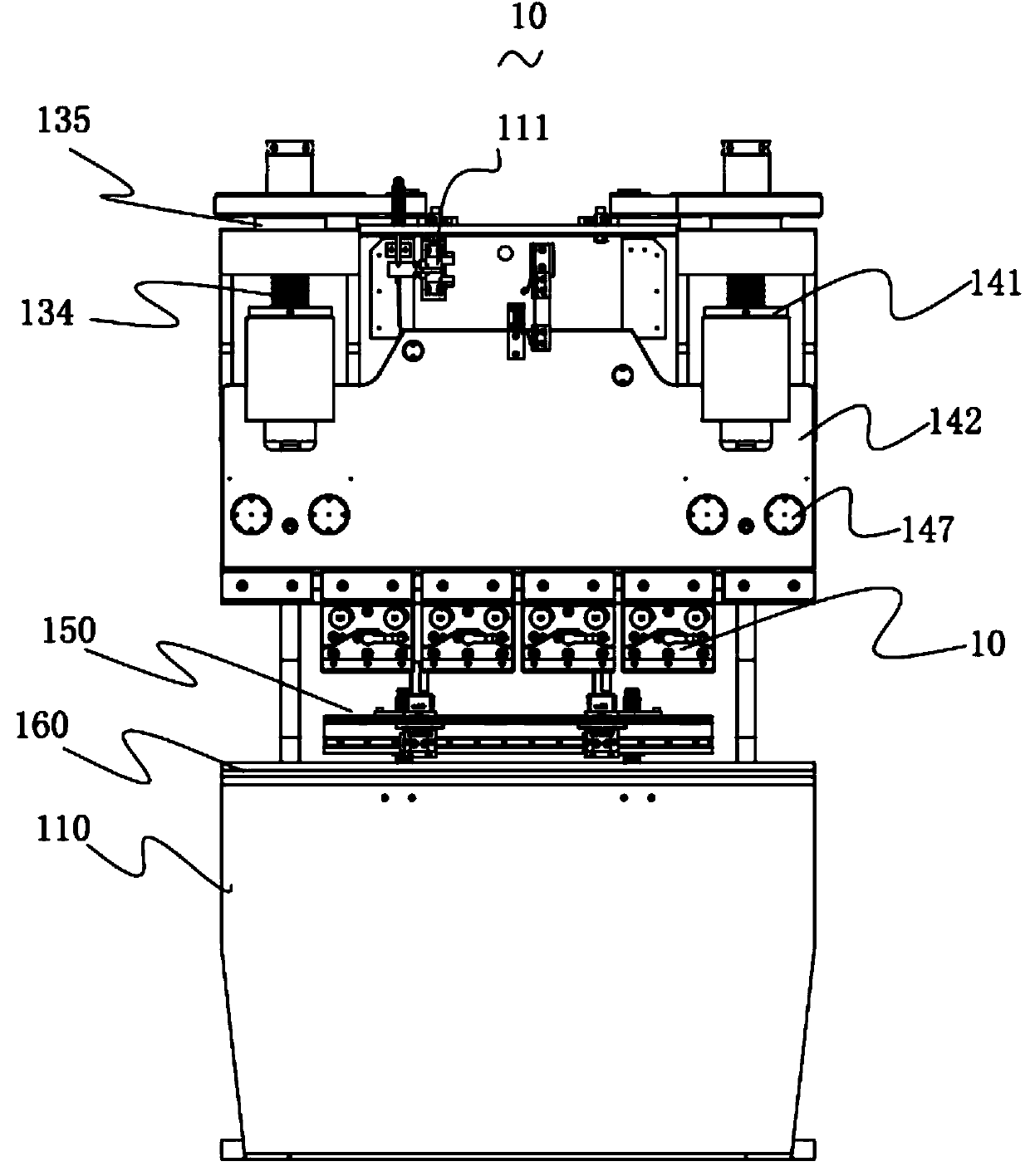

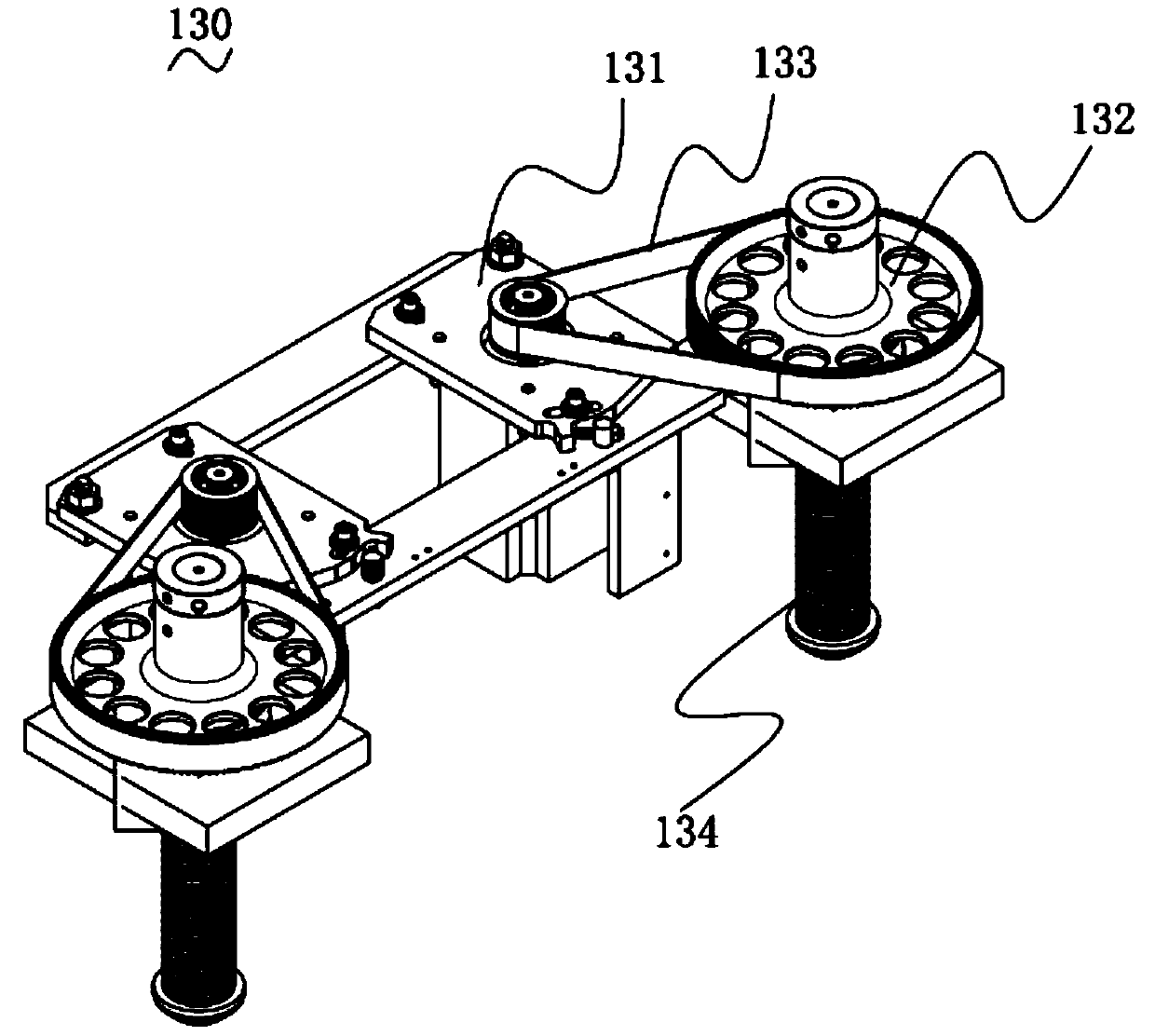

Automatic bending device of elevator door plates

ActiveCN106077334AFully automatedIncrease productivityMetal-working feeding devicesPositioning devicesEngineeringAutomation

The invention discloses an automatic bending device of elevator door plates. The automatic bending device of the elevator door plates comprises a bending machine, a first supporting roller, a second supporting roller, a feeding mechanism, a conveying mechanism, a first pushing mechanism, a second pushing mechanism and a frame, wherein the first supporting roller and the second supporting roller are matched to support the plates; the plates are arranged and placed on the frame layer by layer; the conveying mechanism is used for driving the frame and the plates to move up and down together; the first pushing mechanism is used for pushing the plates on the frame in the conveying mechanism towards the bending machine; the bending machine is used for bending the plates; the feeding mechanism is used for pushing the plates upwards in the bending process; and the second pushing mechanism is used for pushing the bent plates out. The automatic bending device of the elevator door plates realizes automation of bending of the plates, and effectively improves production efficiency.

Owner:安徽省恒胜机电工程股份有限公司

Bending machine

ActiveCN104646460AReduce the number of repositioning workpiecesEasy to achieve U-shapeMetal-working feeding devicesStripping-off devicesEngineeringRapid prototyping

Owner:OMS MASCH CO LTD

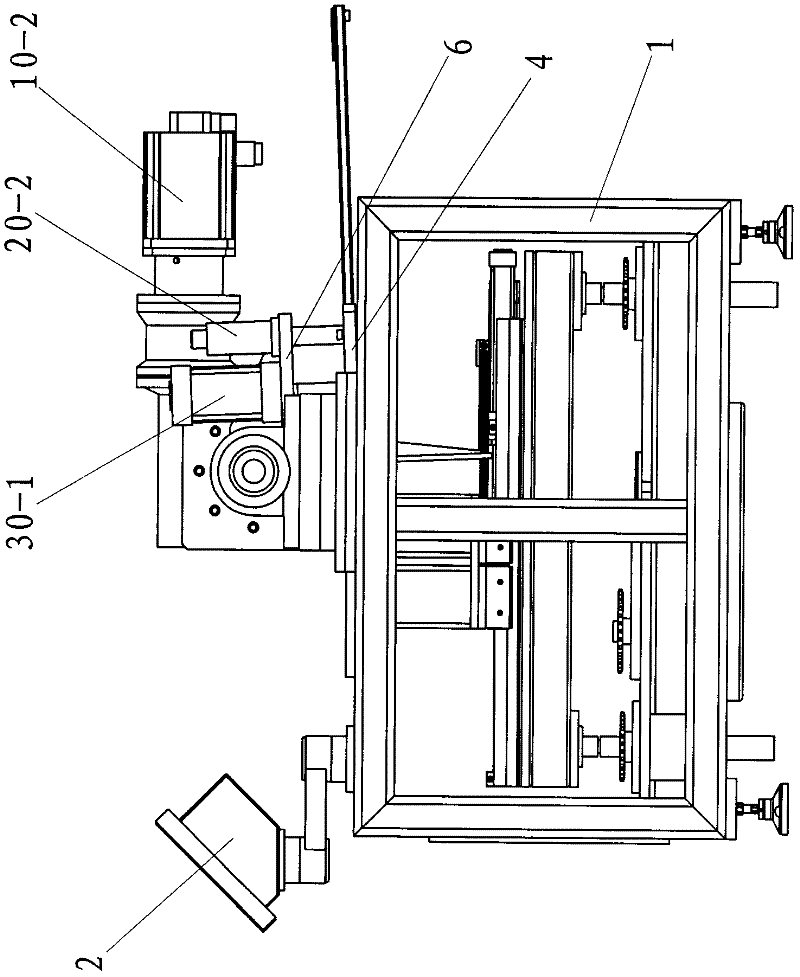

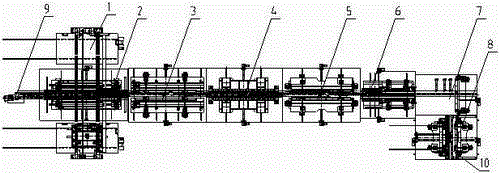

Numerical control full-servo bending machine

ActiveCN104209379AHigh precisionImprove stabilityMetal-working feeding devicesPress ramNumerical controlMotor drive

The invention relates to a numerical control full-servo bending machine, which comprises a machine frame, a numerical control device, a transmission device, a sliding device, a back material retaining device and a worktable, wherein the transmission device, the sliding device, the back material retaining device and the worktable are arranged on the machine frame, the transmission device is connected with the sliding device, the worktable is arranged opposite to the sliding device, the back material retaining device is arranged at one side of the worktable, and the numerical control device is fixedly arranged on the machine frame, and is respectively connected with the transmission device and the back material retaining device. The numerical control full-servo bending machine has the advantages that the servo motor drives a screw rod to rotate, so when the transmission device performs transmission, the action precision and stability are improved; the sliding device consists of an X-shaped guide rail and a V-shaped slide block which are matched, so the contact surface of the guide rail and the slide block is increased, a higher position precision can be guaranteed under the condition of larger force bearing, and condition of rail deviation does not easily occur; the action of the back material retaining device is controlled by the numerical control device, so the manual operation is reduced, and the action precision and working efficiency are improved According to the numerical control full-servo bending machine the working precision is improved, and the product quality and stability are further improved.

Owner:DONGGUAN ZEWEI HARDWARE PROD

Steel pipe bending machine

The invention relates to a steel pipe processing device. A steel pipe bending machine comprises a frame, wherein a bending roller, a driving roller, a limiting roller and a motor for driving the driving roller are arranged on the frame; a resistance increasing layer is arranged on the surface of the driving roller; the resistance increasing layer is formed by vulcanizing 20% of steel particles and 80% of rubber together; the particle size of the steel particles is smaller than 1mm. The steel pipe bending machine is high in traction force during feeding; the problem of low traction force caused by high possibility of slippage of the driving wheel of the steel pipe bending machine in the prior art during driving can be solved.

Owner:ZHEJIANG HUXIN STAINLESS STEEL MFG

Full-automatic welding strip cutting bender

InactiveCN101837392AControl the feeding speedControl cutting speedMetal working apparatusElectric machineryPulp and paper industry

The invention relates to a full-automatic welding strip cutting bender, which is characterized by comprising an emptying mechanism, a levelling mechanism, a bending mechanism, a cutting mechanism and a box body, wherein one end of the oil-water separator of the bending mechanism is connected with a gas resource, and the other end of the oil-water separator is connected with a cylinder by a pipeline; the cylinder is fixed on a cylinder frame; the cylinder shaft of the cylinder is connected with a bending path frame; the cylinder frame is fixed on a fixed mount on the discharge end of the box body; the lower cutter of the cutting mechanism is fixed on the lower end of the fixed mount; the upper cutter is fixed on an upper cutter frame capable of moving up and down; a motor is connected with one of two eccentric sprockets with same eccentricity, and the eccentric sprockets are fixed on an eccentric shaft by a chain; two eccentric sprockets are fixedly connected with two ends on the bottom of the upper cutter frame via a link block; a small eccentric wheel with a photosenser is fixed in the middle of the eccentric shaft between two eccentric sprockets; and a photo-groove is arranged near the position below the small eccentric wheel. The invention improves production efficiency, lowers labour cost and improves product quality.

Owner:启东市罗源光伏设备有限公司

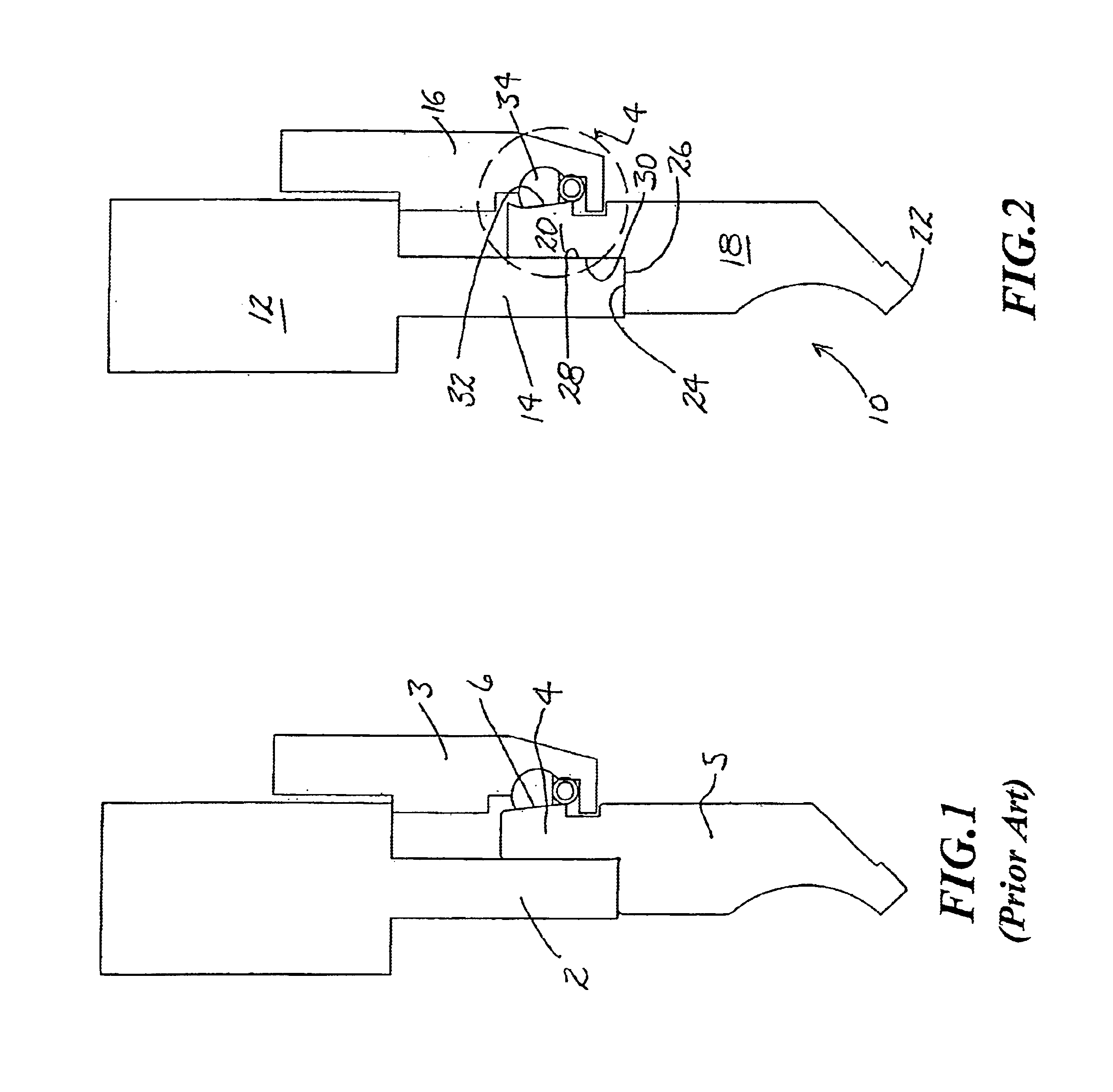

Press brake tool having lockable safety key

ActiveUS7004008B2Facilitates upward advancementFacilitates downward removalShaping toolsEngineeringPress brake

A press brake tool that is adapted to be mounted in a tool holder. The tool has a lockable safety key that is moveable between an extended position and a retracted position. The press brake tool has a lock that is operatively coupled to the safety key and is movable between a locked position wherein the safety key is locked in the extended position and an unlocked position wherein the safety key is permitted to move between the extended position and the retracted position. Also provided is a press brake tool having a particularly advantageous, longitudinally-elongated safety key.

Owner:WILSON TOOL INT

Production line of square coaming of freezer liner

The invention discloses a production line of square coaming of a freezer liner. The production line comprises a plate bin, a charging platform, a die cutting unit, a first transition platform, a long edge folding machine, a 90 DEG steering platform, a flanging machine with two ends in different directions, a second transition platform, a first bending machine and a second bending and riveting machine. A first sucker manipulator is arranged between the plate bin and the charging platform. Gripper manipulators are arranged among the charging platform, the die cutting unit and the first transition platform. First duplex sucker manipulators are arranged among the first transition platform, the long edge folding machine and the 90 DEG steering platform. Second duplex sucker manipulators are arranged among the 90 DEG steering platform, the flanging machine with the two ends in different directions and the second transition platform. A second sucker manipulator is arranged between the second transition platform and the first bending machine. A third sucker manipulator is arranged between the first bending machine and the second bending and riveting machine. Plates are bent to U-shaped coaming by the first bending machine. The U-shaped coaming is bent to the square coaming and riveted by the second bending and riveting machine.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

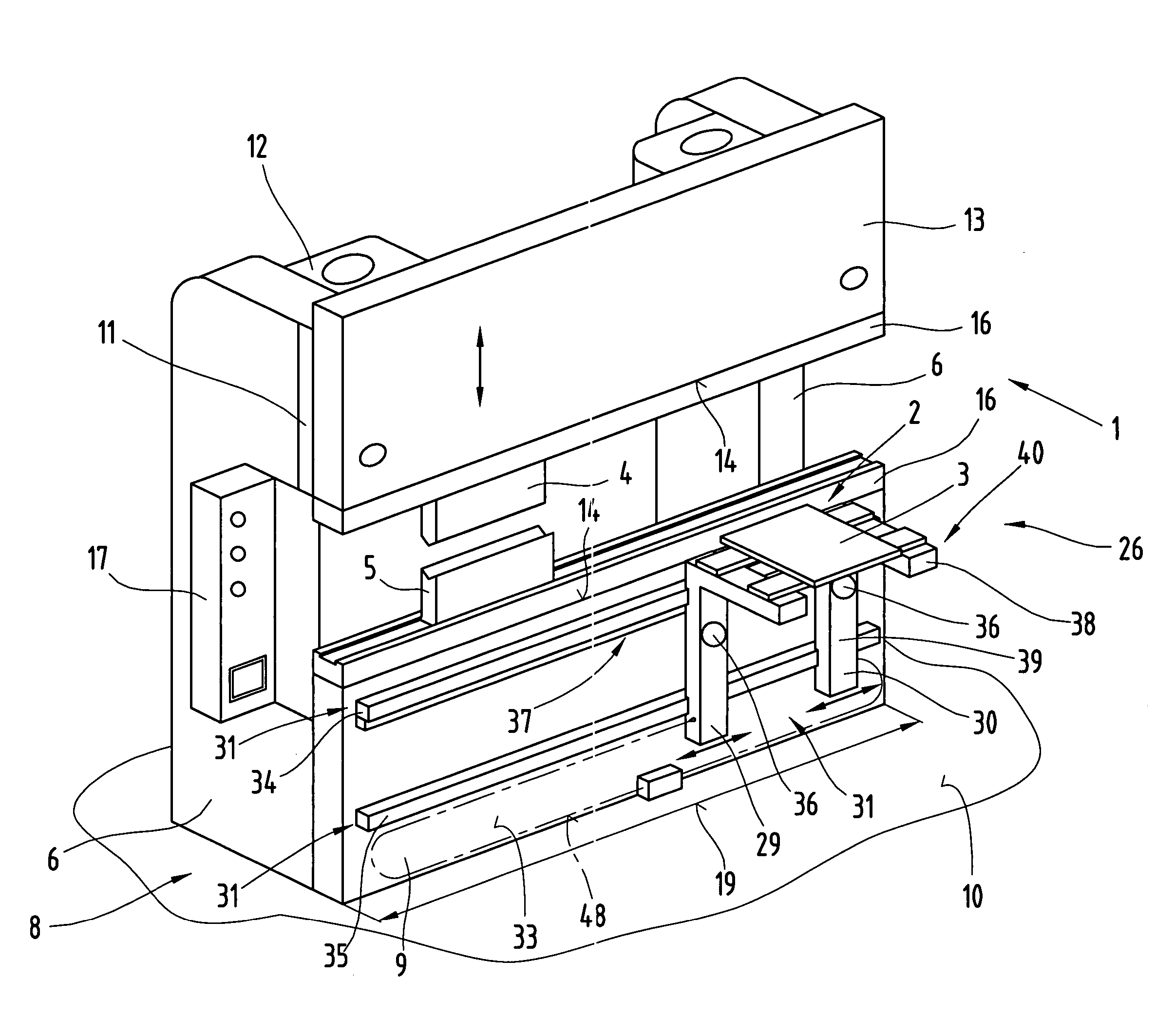

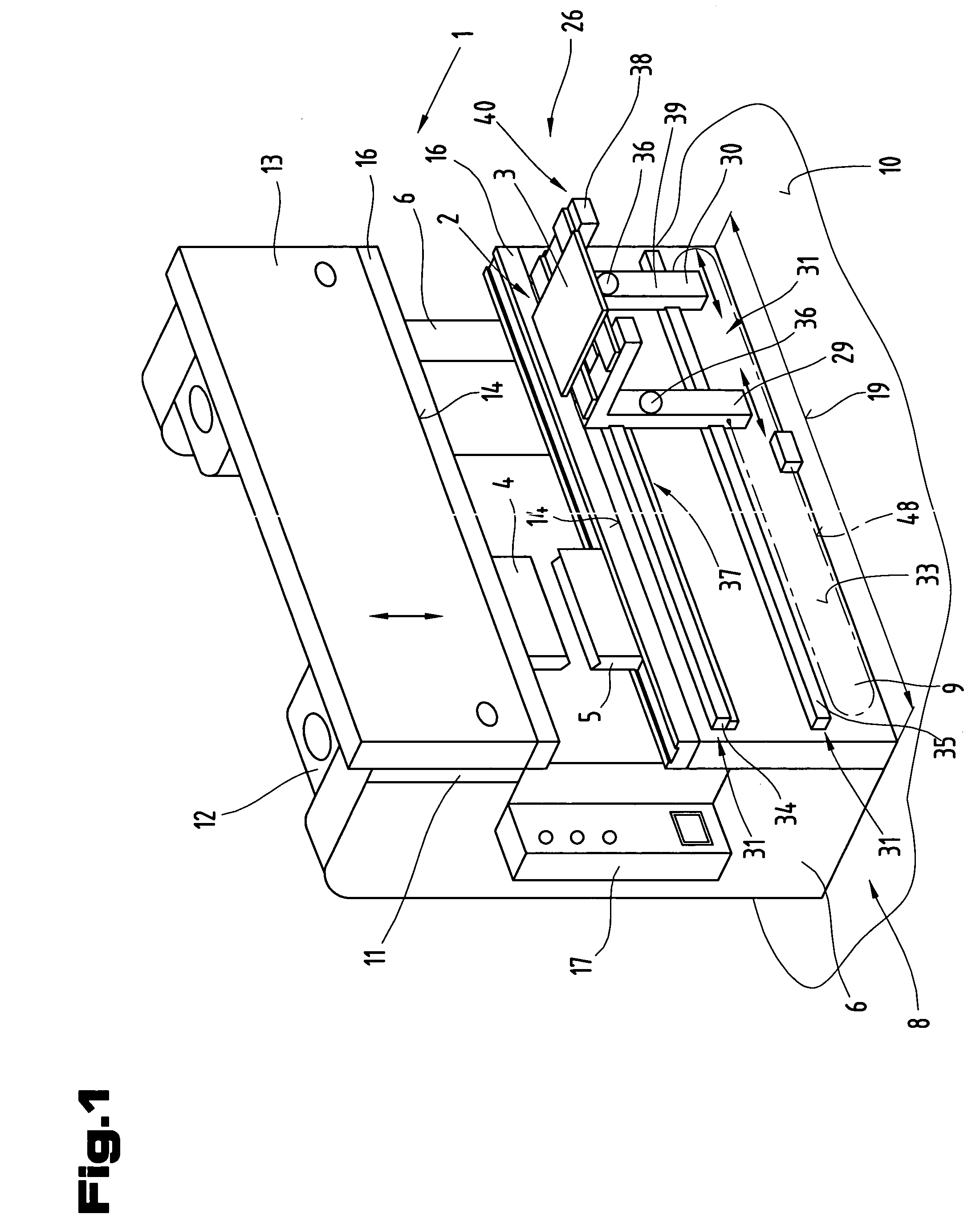

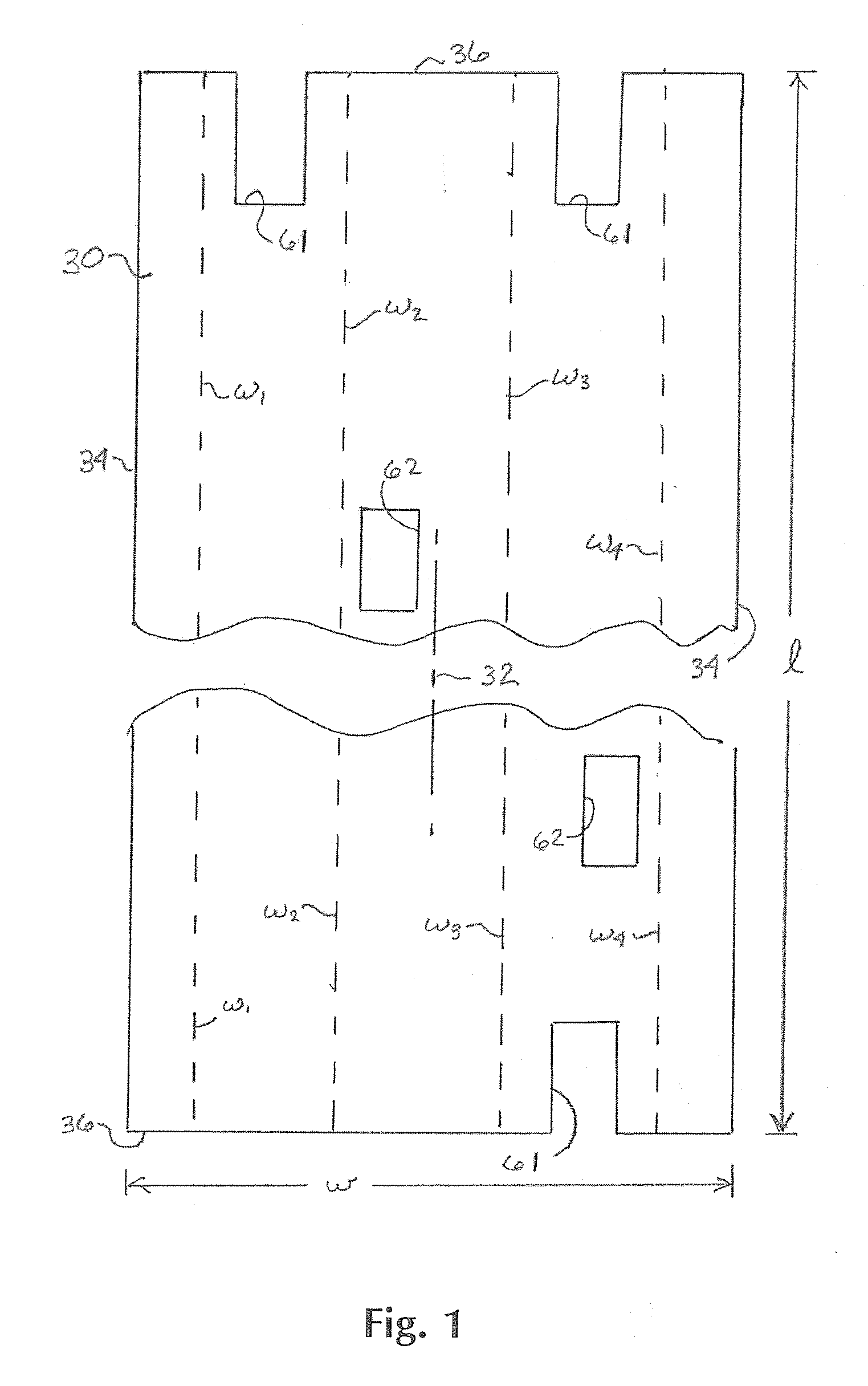

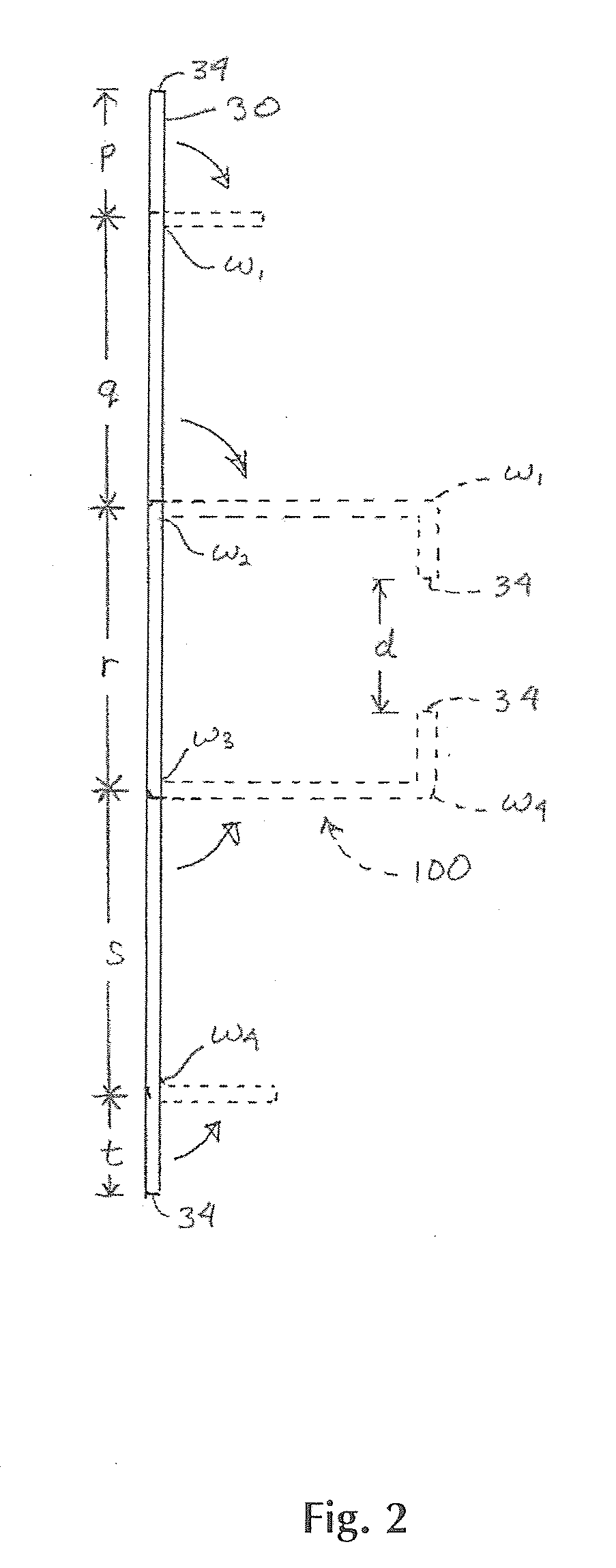

Metal sheet folding device with depositing/positioning device

ActiveUS20060179913A1Shorten the time spanSave free timeMetal-working feeding devicesShaping safety devicesEngineeringMetal sheet

A metal sheet folding device, particularly a folding press, comprising a table beam stationarily arranged on a machine frame, and a press beam arranged on the machine frame in guide arrangements with a driving device. The press beam is adjustable in relation to the table beam. Furthermore, provision is made for a sheet depositing / positioning device for at least one metal sheet plate or at least one workpiece for intermediately positioning the latter for carrying out a gripping operation with the gripping device of a handling system. The device is supported on the machine frame preferably on the table beam and adjustable in a linear guide arrangement in the direction of the longitudinal expanse of the table beam over at least part of the length.

Owner:TRUMPF MASCHEN AUSTRIA

Telescoping tower and method of manufacture

InactiveUS20080236060A1High dimensional accuracyReduce manufacturing costTowersCranesAcute angleMetal sheet

A mast section for a telescoping tower system is made by aligning press brake tools along the length of the metal sheet at spaced width locations and forming the corners of the tube. After forming of the last corner, an opening remains along the length of the tube. The press brake male tool axis is offset sufficiently to permit the tool to apply forming force to the last corner of the tube through the opening, and is sized to remove the tool from the opening. At least three mast sections are nested to form the tower system. Pulleys for a cable extension system are mounted near the upper and lower ends of a wall of an intermediate mast section, with one of the pulleys being oriented at an acute angle to the mast section wall to permit routing of the cable.

Owner:BATTAGLIA VINCENT P

Plate bending method for intelligent numerical control bending machine

ActiveCN106077168ARealize automatic crawlingNo human intervention requiredMetal-working feeding devicesPositioning devicesAutomatic controlEngineering

The invention discloses a plate bending method for an intelligent numerical control bending machine and belongs to the technical field of bending machines. The machine comprises a rack, a worktable, a bending device and a base. The rack and the bending device are arranged on the base. The machine further comprises a material blocking device, a discharging device, a feeding device, a positioning device, a material conveying device and a numerical control system. A machined piece is conveyed to the worktable through the feeding device and clamped by the discharging device to move on the worktable, and the machined piece can be positioned in the X-axis direction. The material blocking device and the positioning device are matched to position the machined piece in the Y-axis direction. The material conveying device conveys the machined piece to a machining station for bending machining and controls the machined piece to rotate to be subjected to multi-edge bending, and the machined piece is pushed to get away from the worktable through the discharging device after machining is completed; and the numerical control system is used for completing automatic control over the whole bending process. The intelligent numerical control bending machine is high in work efficiency and automation degree, full-automatic multi-edge forward and reverse bending can be achieved on the machined piece, use is convenient, and the labor force can be sufficiently liberated.

Owner:JIANGSU HAIJIAN

Press brake worksheet positioning system

InactiveUS20020092333A1Precise positioningCompensation deviationMetal-working feeding devicesShaping safety devicesEngineeringPositioning system

To improve the speed with which a worksheet is positioned in a press brake, and to further eliminate the need for conventional moving back gauge systems, the present invention replaces the conventional back gauge mechanical system with sensors that non-contactedly determine the positioning of the worksheet, with reference to the bending tools. The thus sensed worksheet position is compared with the desired worksheet location preprogrammed into the CNC controller. Any deviation between the sensed, or the actual worksheet position, with the desired worksheet position for each bend of the worksheet is compensated by further moving the worksheet, until there no longer is any discrepancy between the actual and the preprogrammed desired locations.

Owner:FINN POWER INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com