Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

217results about How to "Control the feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

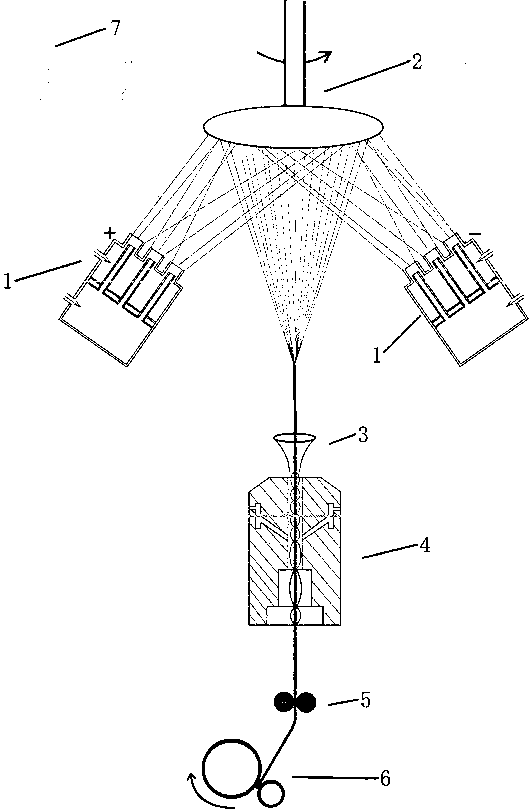

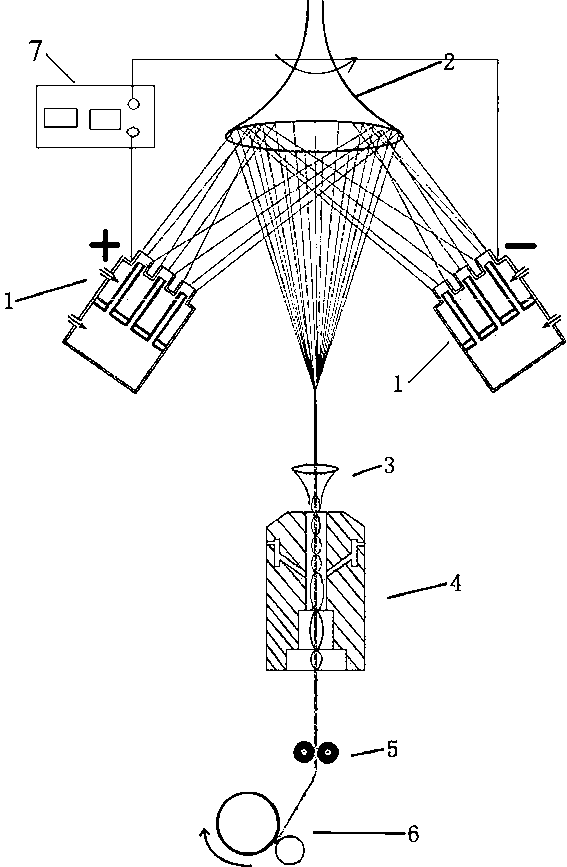

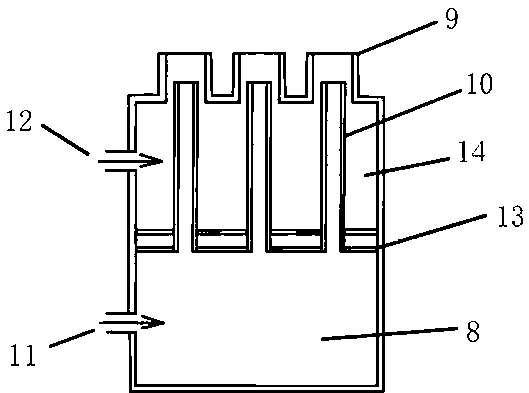

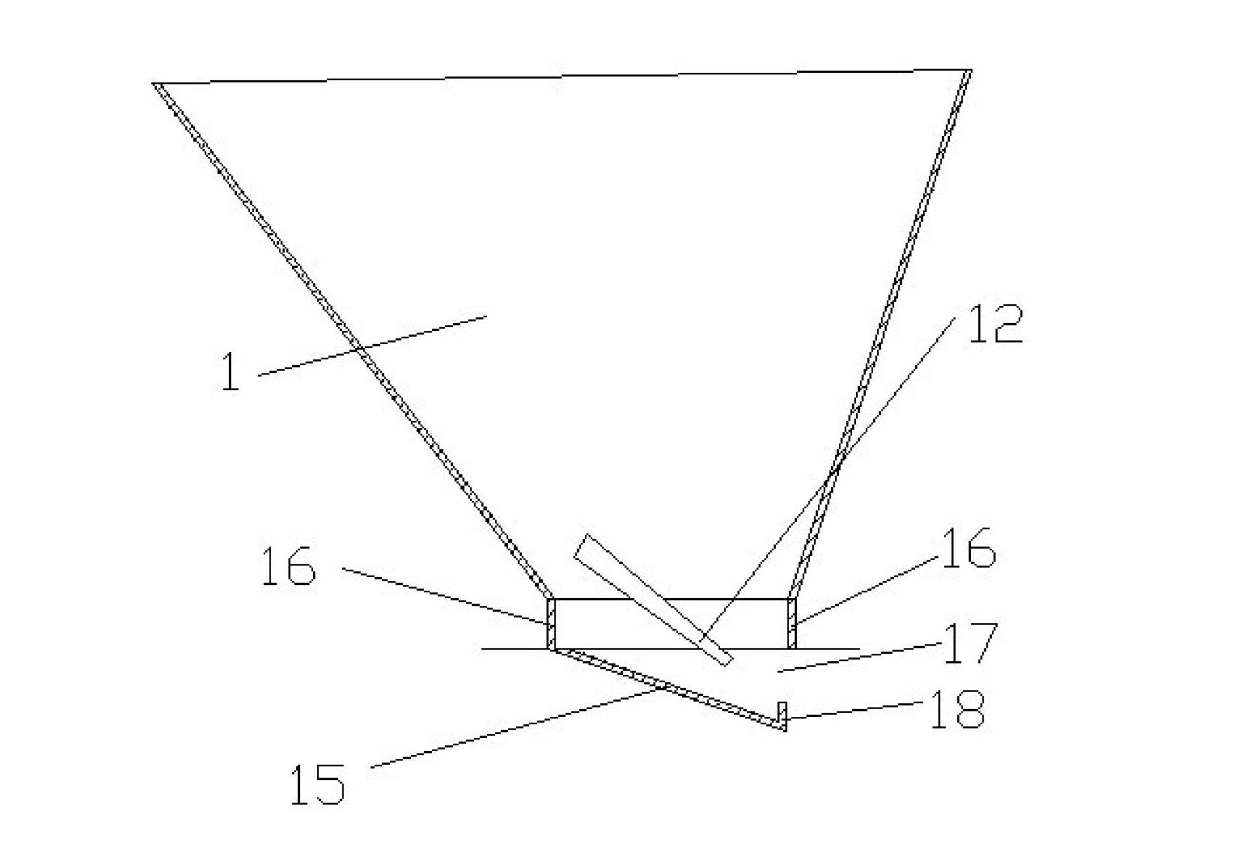

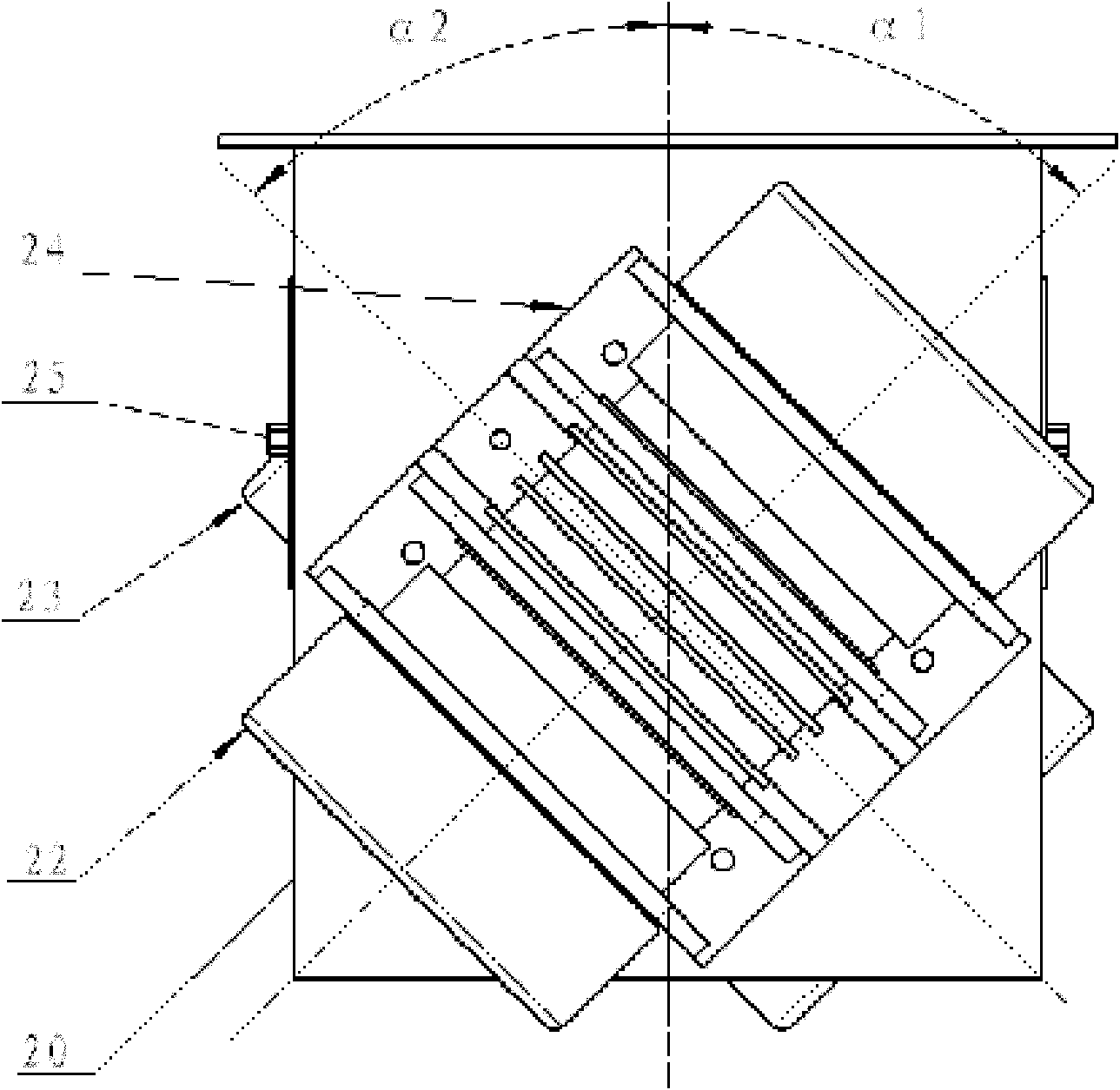

Jet yarn spinning device for electrostatic spun nano fiber and preparing method

InactiveCN102703998AIncrease productionReduce volatilitySpinnerette packsFilament/thread formingYarnNanofiber

The invention discloses a jet yarn spinning device for an electrostatic spun nano fiber, which includes a collecting device, wherein two thread jetting devices are arranged on the two sides of the collecting device and connected with a high-voltage electrostatic generator; a buncher is arranged below the collecting device; the two thread jetting devices are arranged between the collecting device and the buncher and symmetrically and oppositely arranged along the axis; a jet nozzle twister is arranged below the buncher; a delivery roller is arranged below the jet nozzle twister; a winding mechanism is arranged below the delivery roller; and the collecting device, the buncher, the jet nozzle twister and the delivery roller are arranged along the same axis from top to bottom. The electrostatic spun nano fiber spinning device integrates thread jetting, collecting, drawing, twisting and winding, and can continuously prepare the electrostatic spun nano fiber yarns. The nano fiber spinning method has simple process, high yarn yield, is suitable for multiple polymer yarn solutions, and realizes the continuous and scaled preparation of the nano fiber yarns.

Owner:ZHONGYUAN ENGINEERING COLLEGE

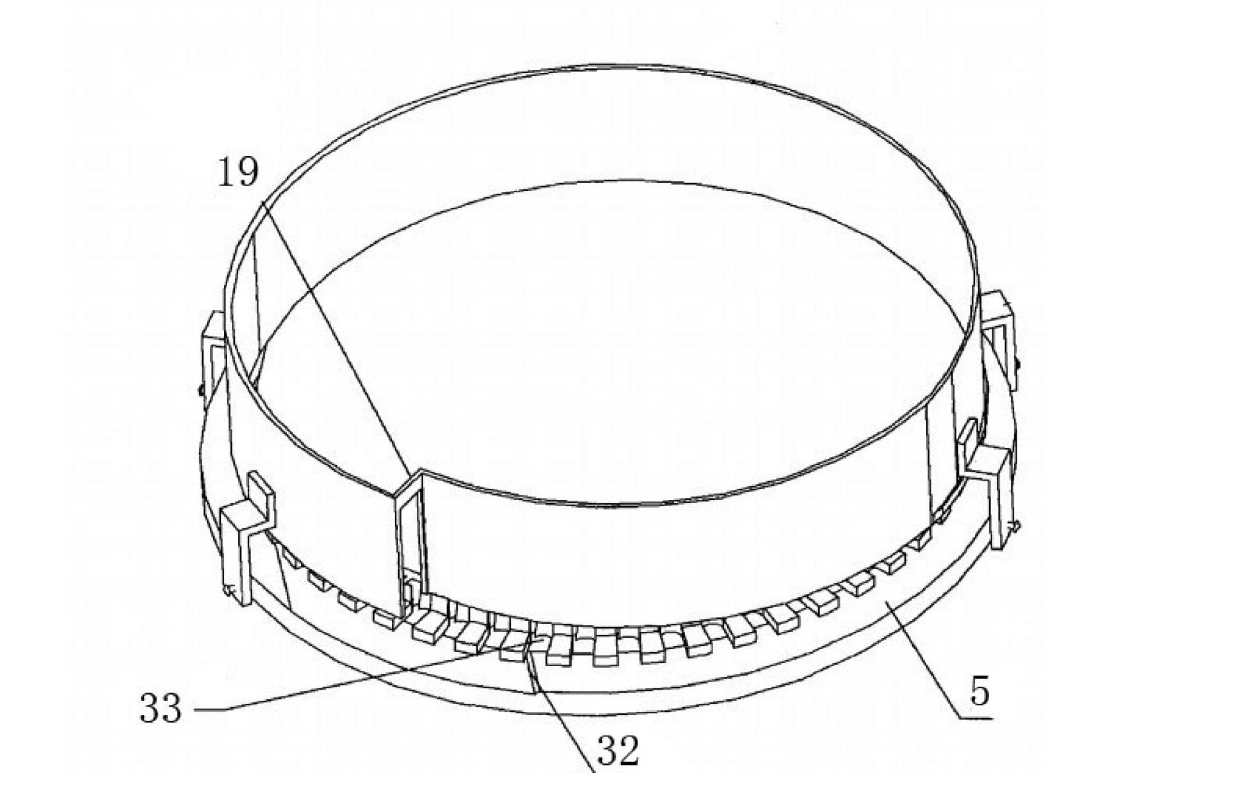

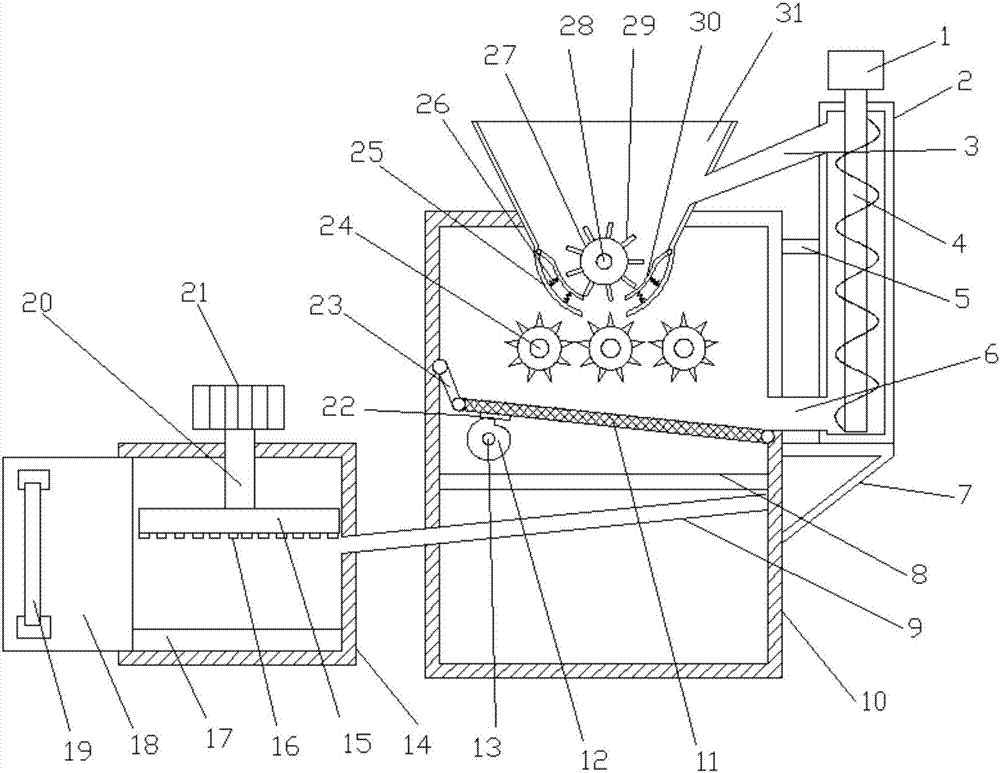

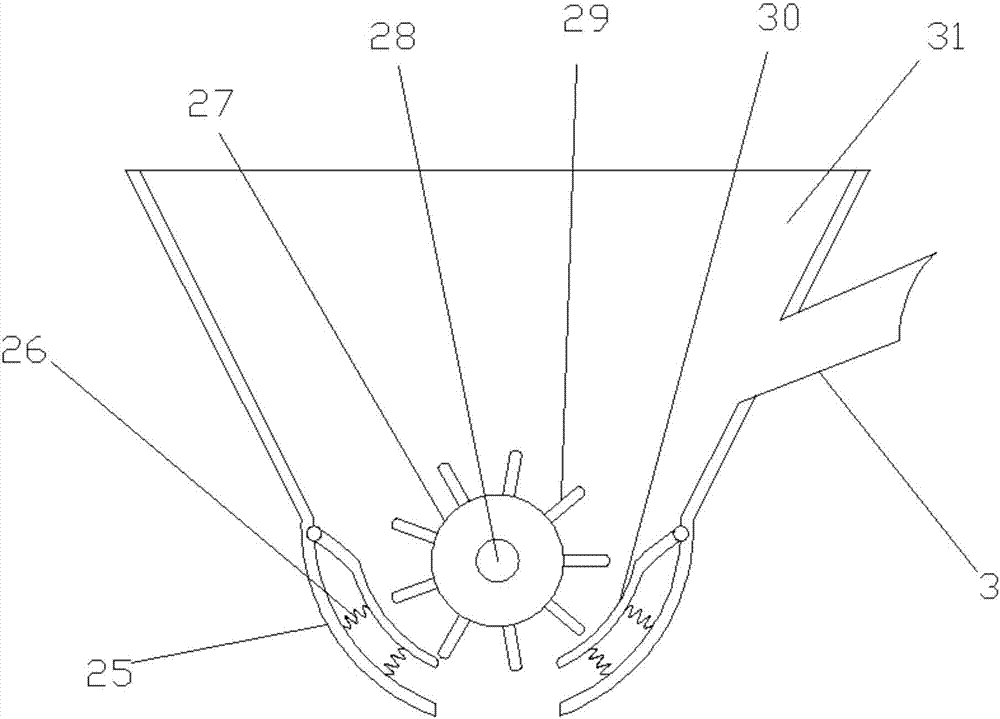

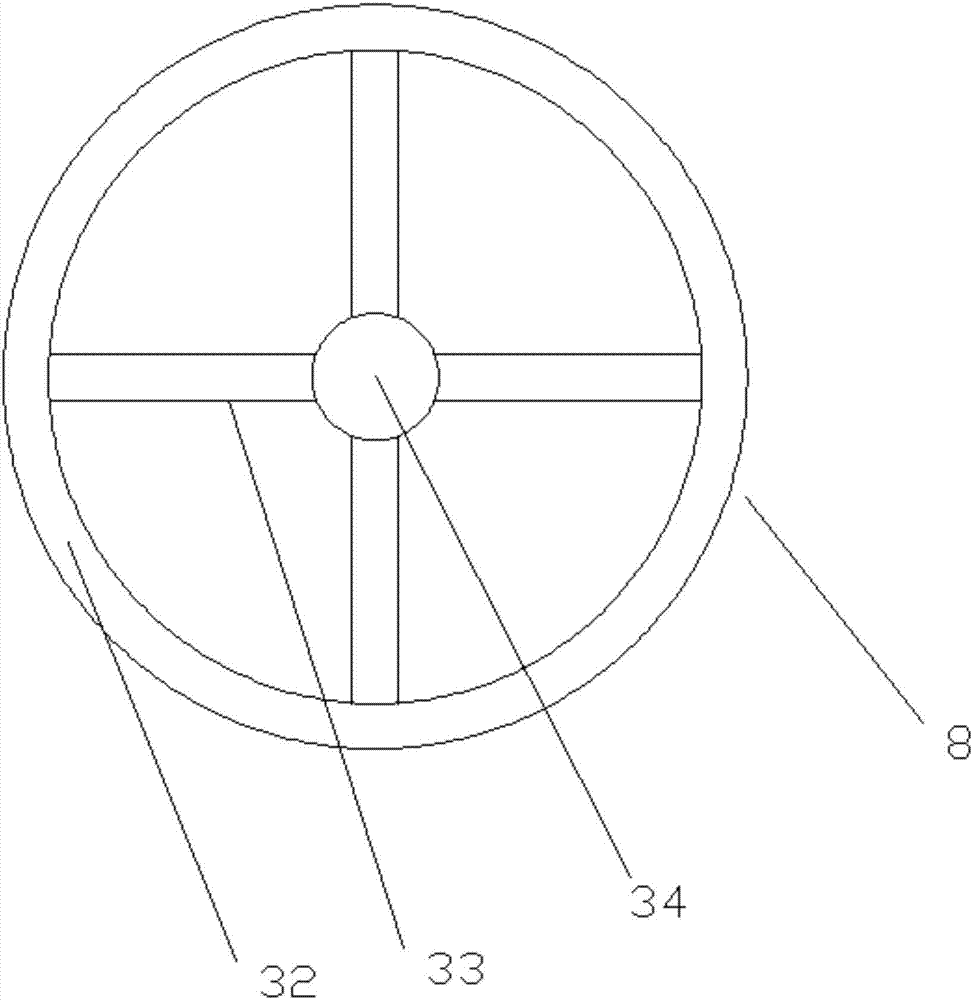

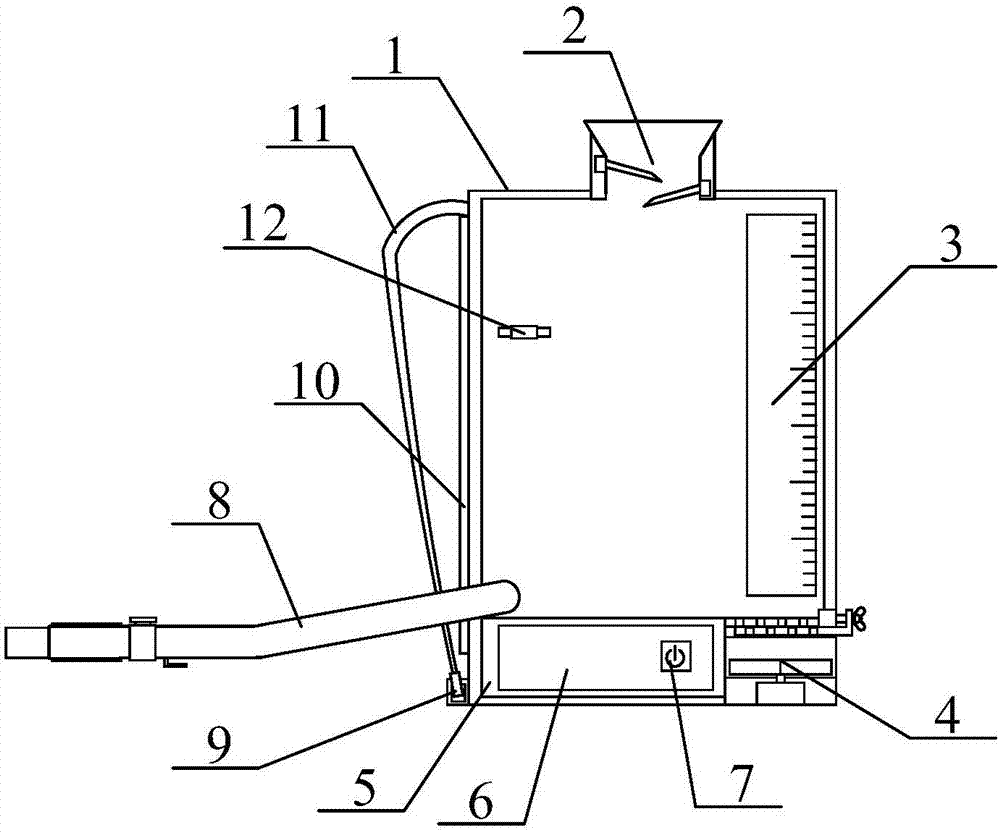

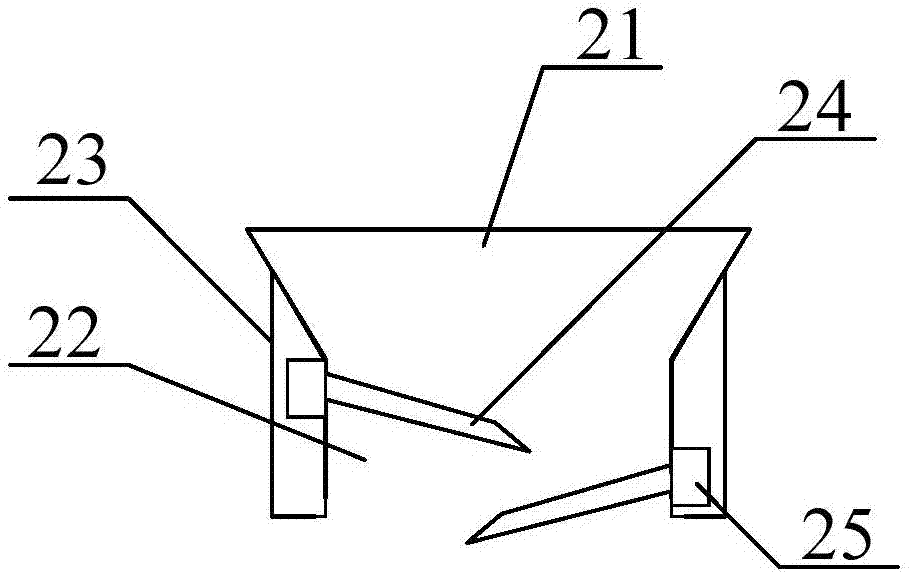

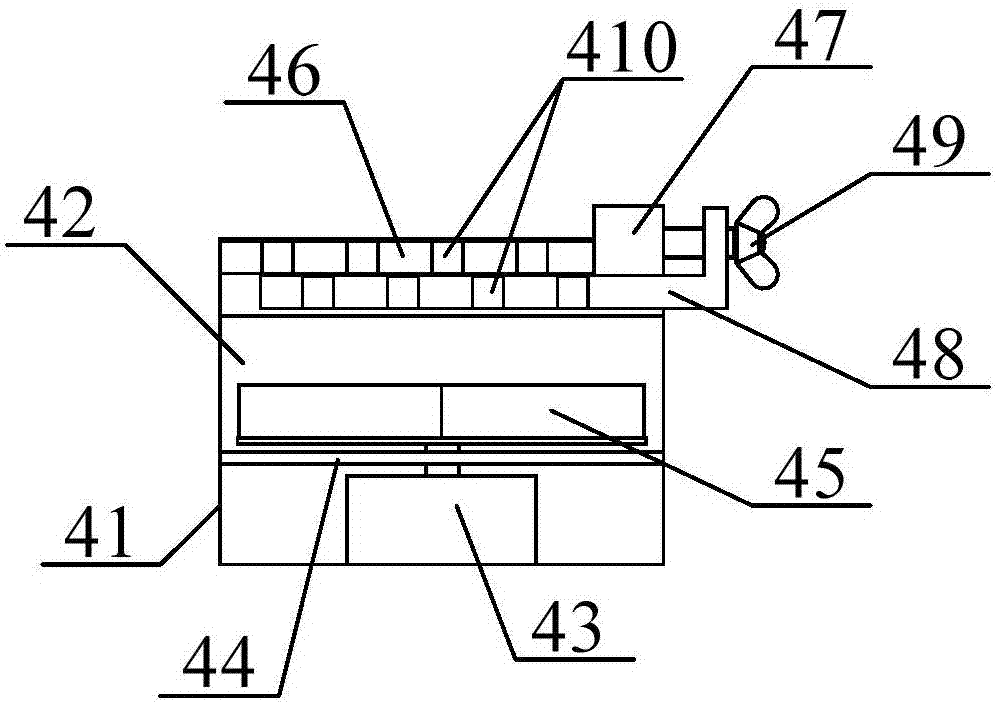

Rejection type intelligent capsule inspection machine

ActiveCN102680491AImprove efficiencySimple mechanical structureMaterial analysis by optical meansSortingControl systemEngineering

The invention relates to a machine, in particular to an electromechanical rejection type intelligent capsule inspection machine. The rejection type intelligent capsule inspection machine comprises a feeding mechanism, an electronic detection system, a conveying mechanism, a rejector, a discharger, a blowing and suction mechanism and a master control system, the master control system is electrically connected with the feeding mechanism, the electronic detection system, the conveying mechanism, the rejector, the discharger and the blowing and suction mechanism, the feeding mechanism is arranged at the initial end of the conveying mechanism, and the discharger is arranged at the tail end of the conveying mechanism. A feeding outlet, a sidewall, a blowing nozzle and a sensing probe of the rejection type intelligent capsule inspection machine can cooperate to control the discharge speed in order to prevent an excessive quantity of materials from being stored in a storage box to affect feeding; a plurality of cameras jointly work to shoot the different parts of each capsule, thus preventing the phenomenon of missing and increasing the accuracy of detection; an air nozzle of the rejector can blow rejects out of a conveyer belt, the structure is simple, the speed is high, and the rejector is convenient and cannot damage capsules.

Owner:XINCHANG HANGDA MACHINERY MFG

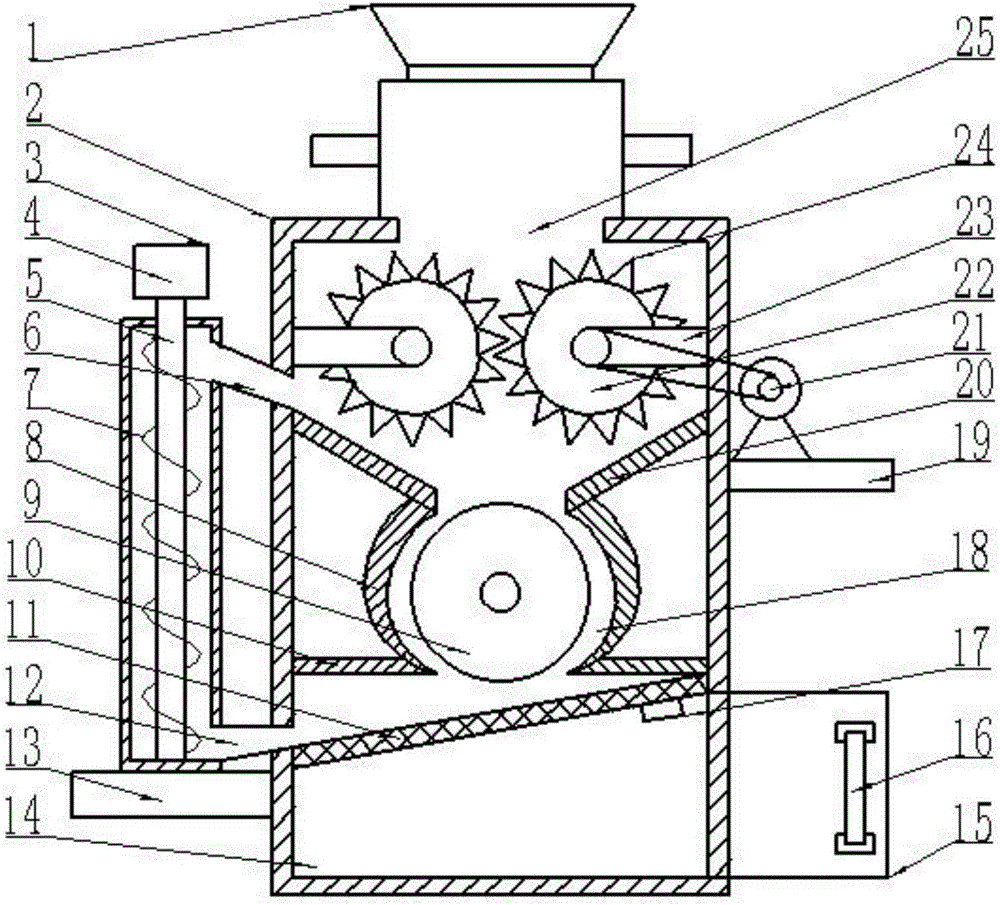

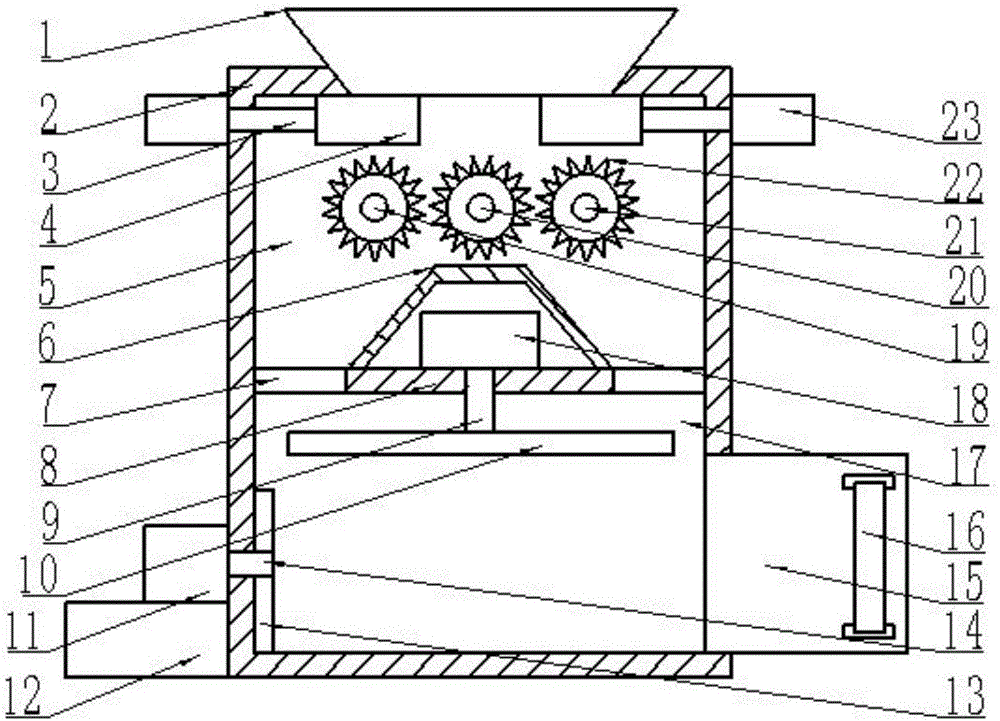

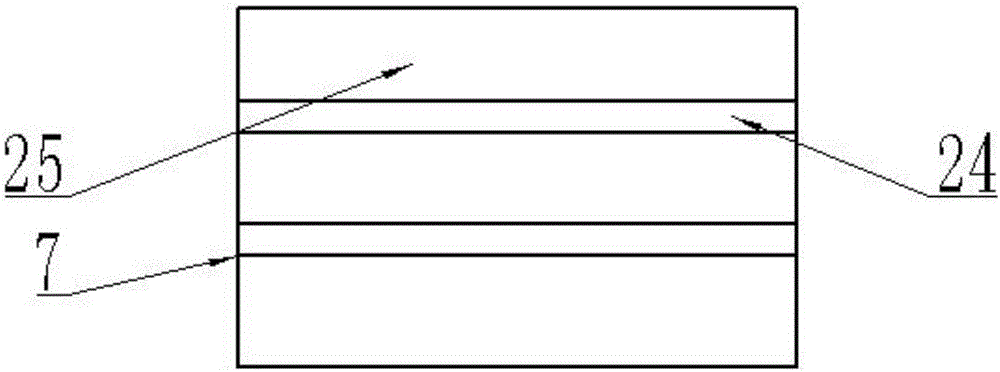

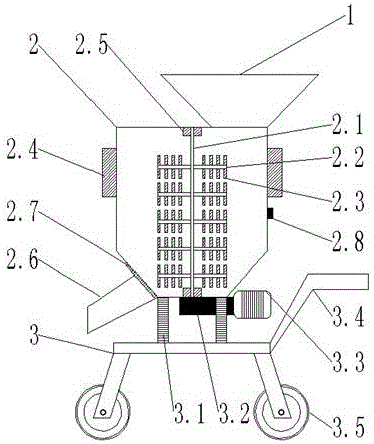

Efficient bone smashing and grinding device for food processing

InactiveCN107413498ASpeed up the fallPrevent overflowSievingScreeningMechanical engineeringFood processing

The invention discloses an efficient bone smashing and grinding device for food processing. The efficient bone smashing and grinding device comprises a smashing box and a grinding box. The smashing box is provided with a material control device, a circulation feeding device, a smashing device, a screen cloth, a screen cloth vibrating mechanism, an iron removing plate and a discharging plate. The material control device comprises a discharging hopper. The discharging hopper is arranged at the upper end of the smashing box. An arc-shaped volute is arranged at the bottom end of the discharging hopper. The bottom end of the volute is provided with an opening and further communicates with the smashing box. A material distributing rotary table is sleeved with the volute. The material distributing rotary table is arranged on a material distributing rotating shaft in the middle of the volute in a sleeving mode. The two ends of the material distributing rotating shaft are arranged on bearings on the corresponding side walls of the volute in a sleeved mode separately. A plurality of material distributing plates are evenly and symmetrically arranged on the material distributing rotary table. According to the efficient bone smashing and grinding device for food processing, feeding is stable, the sealing property is good, circulation smashing is achieved, grinding can be facilitated, working efficiency is high, the screen cloth and the screen cloth vibrating mechanism are ingeniously arranged and thus screening efficiency is high.

Owner:汪云霞

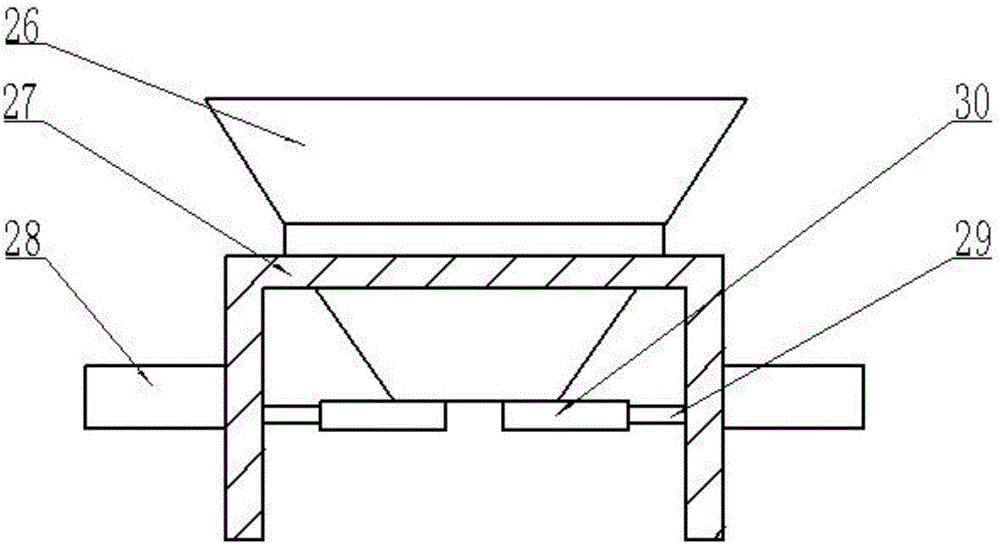

Corn pulverization device with thorough pulverization function

The invention provides a corn pulverization device with a thorough pulverization function. The corn pulverization device comprises a material control device and a box. The material control device comprises a feed hopper and a rack and is fixed to the upper end of the box. The rack is provided with cylinders, telescopic shafts and material blocking blocks. The box is provided with a sieve, a holding plate, a material storage bin, a grinding bin, a motor base and supporting rods. The holding plate is fixed to the left end of the box in a welded mode and provided with a cyclic device which comprises a first drive motor, a discharge pipe and a feed pipe. The material storage bin is arranged at the lower end of the sieve and provided with a door. The grinding bin is arranged at the upper end of the sieve and provided with grinding frames, a grinding roller, lower supporting plates and upper supporting plates. The motor base is fixed to the right end of the box in a welded mode and provided with a second drive motor. The corn pulverization device is capable of conducting cyclical pulverizing, thorough in pulverization and high in efficiency; material control is facilitated, damage to the corn pulverization device is avoided, and particles can be screened.

Owner:河南常青藤信息科技有限公司

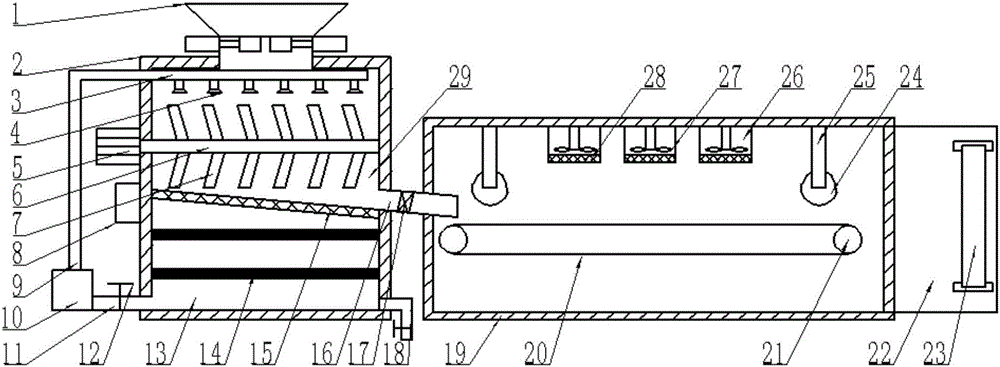

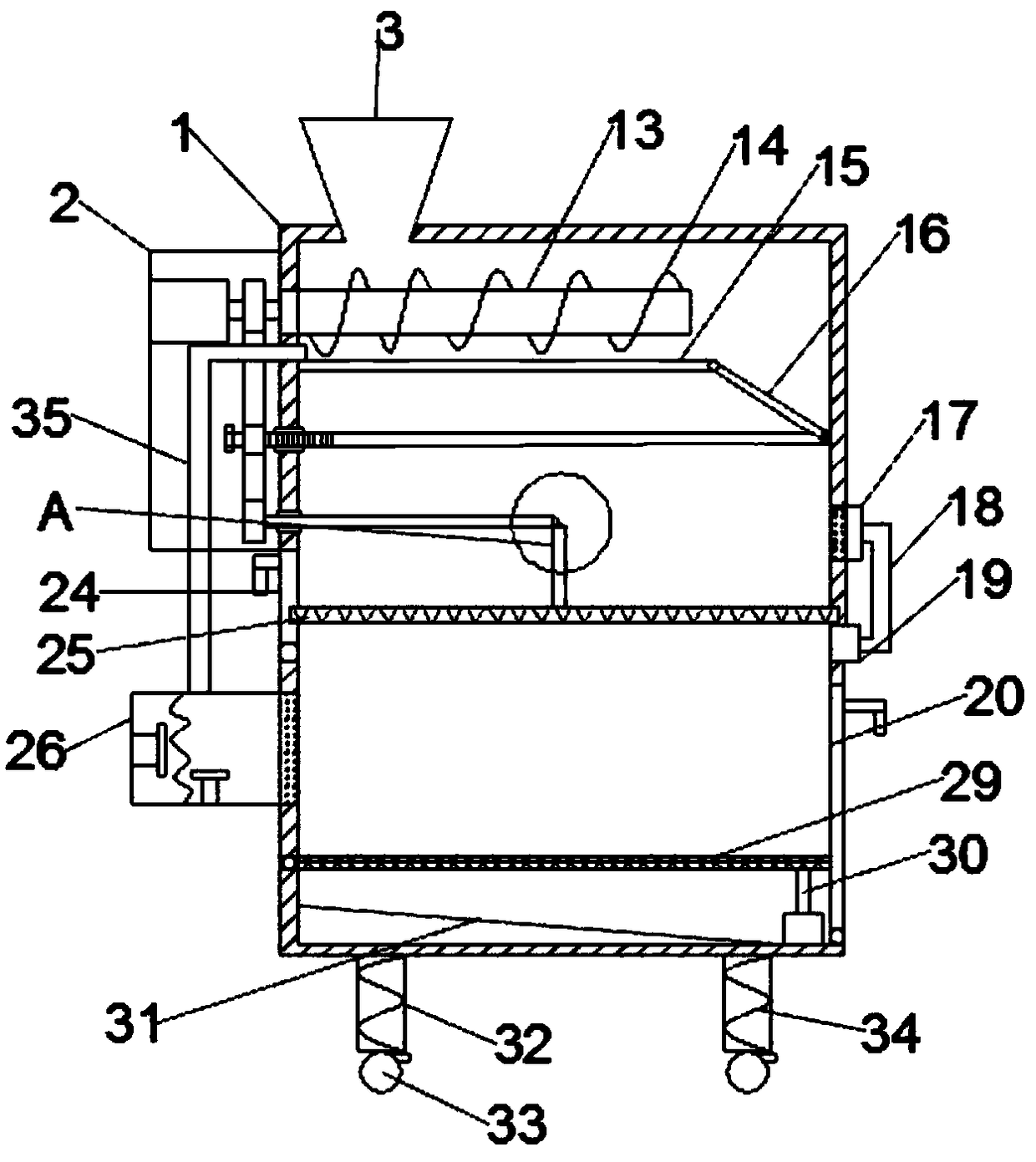

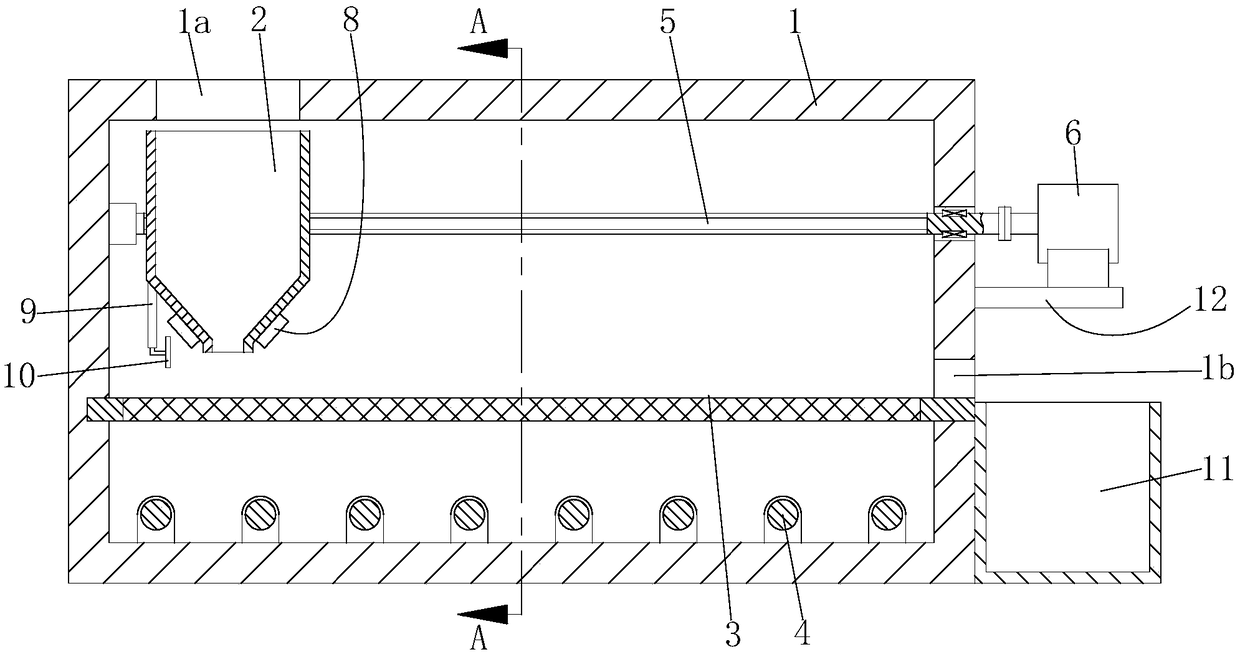

Water-saving traditional Chinese medicine cleaning and drying device

InactiveCN106623198AFast cleaningSave waterDrying gas arrangementsDrying machines with progressive movementsDrive motorWater pipe

The invention provides a water-saving traditional Chinese medicine cleaning and drying device, which comprises a material control device, a cleaning box and a drying box. The material control device comprises air cylinders, a feed hopper, stopping plates and telescopic shafts; the cleaning box comprises a cyclic cleaning device, a cleaning cavity and a sewage tank; the cyclic cleaning device comprises a cyclic water pipe, a cyclic pump and a water discharging pipe; the cleaning cavity comprises a water inlet pipe, a drive motor, a rotary shaft and a water filter plate; a vibrator and a material discharging pipe are arranged on the outer end of the cleaning cavity; filter layers and a drainage pipe are arranged in the sewage tank; the drying box is arranged on the right end of the cleaning box and is connected with the cleaning box through the material discharging pipe; a conveyor belt, conveyor rollers, a box door, fixing rods and air blowers are arranged in the drying box; the conveyor belt is connected with the conveyor rollers; a plurality of air blowers are arranged and are uniformly distributed between the fixing rods; and a fan and a filter screen are arranged in each air blower. The water-saving traditional Chinese medicine cleaning and drying device provided by the invention integrates cleaning and drying into a whole, is high in efficiency and fast in speed, can recycle a water resource, and can control the blanking speed.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

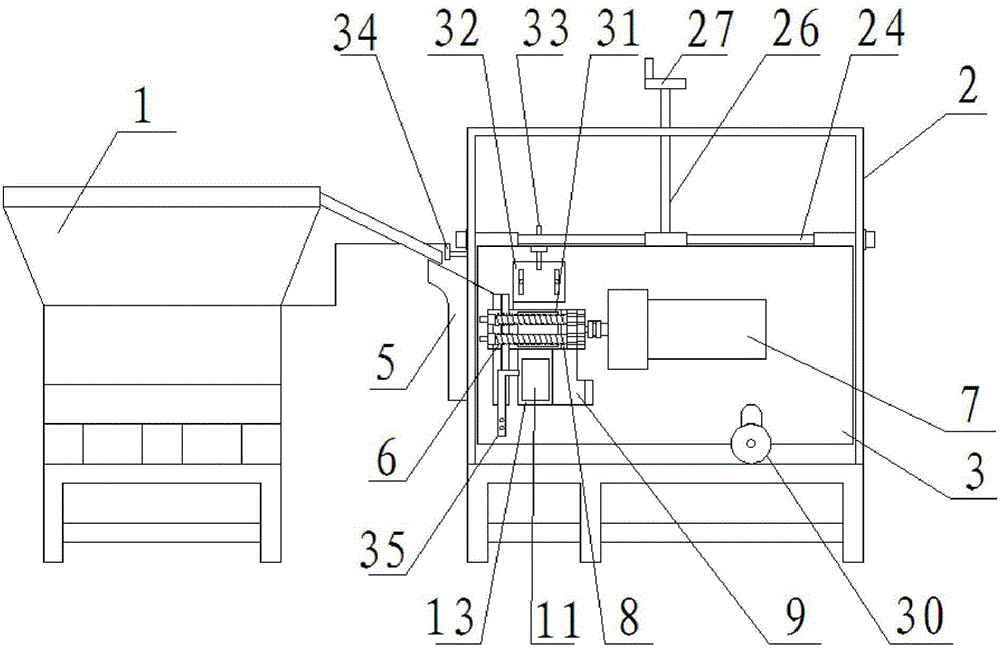

Full-automatic welding strip cutting bender

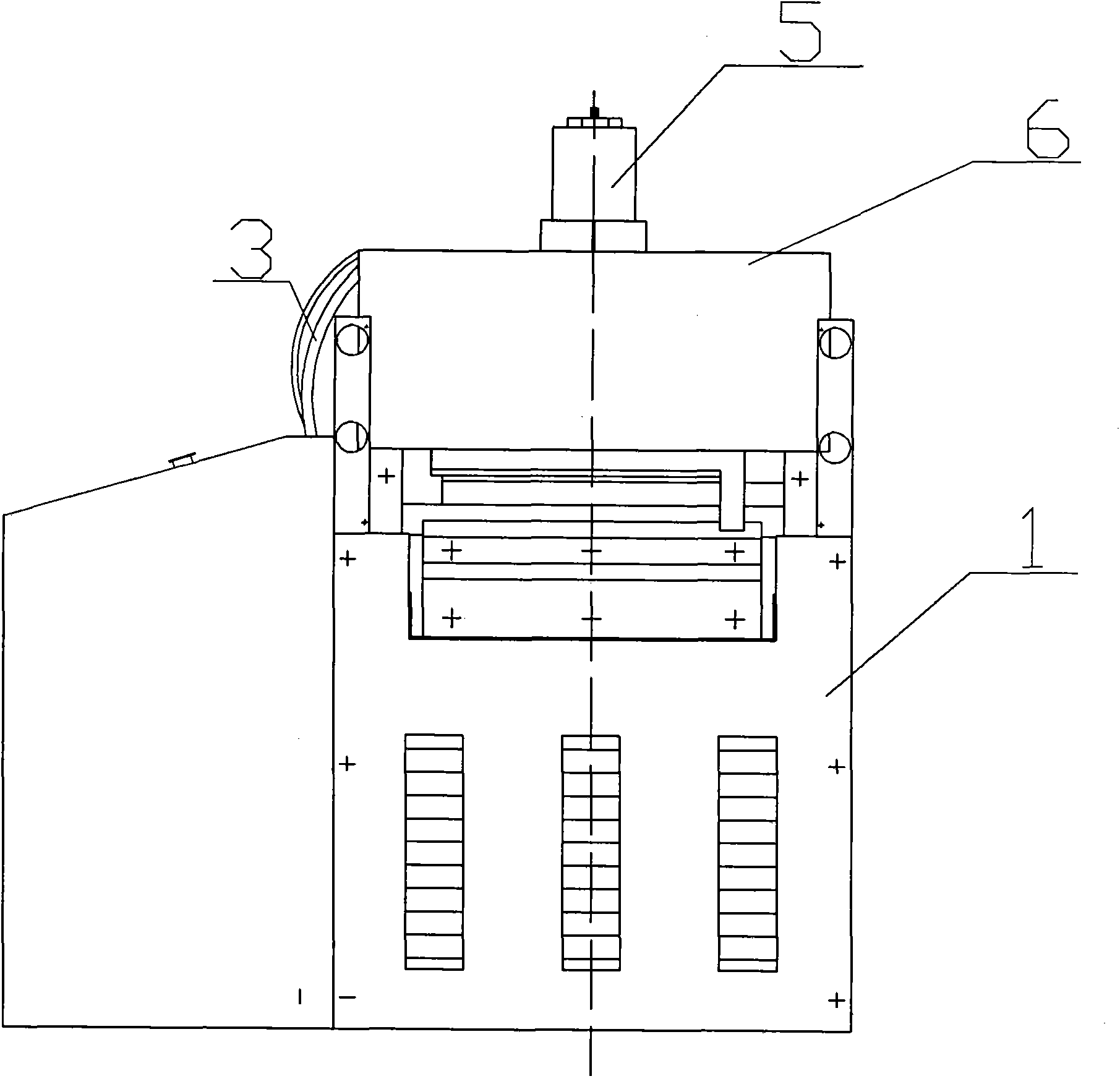

InactiveCN101837392AControl the feeding speedControl cutting speedMetal working apparatusElectric machineryPulp and paper industry

The invention relates to a full-automatic welding strip cutting bender, which is characterized by comprising an emptying mechanism, a levelling mechanism, a bending mechanism, a cutting mechanism and a box body, wherein one end of the oil-water separator of the bending mechanism is connected with a gas resource, and the other end of the oil-water separator is connected with a cylinder by a pipeline; the cylinder is fixed on a cylinder frame; the cylinder shaft of the cylinder is connected with a bending path frame; the cylinder frame is fixed on a fixed mount on the discharge end of the box body; the lower cutter of the cutting mechanism is fixed on the lower end of the fixed mount; the upper cutter is fixed on an upper cutter frame capable of moving up and down; a motor is connected with one of two eccentric sprockets with same eccentricity, and the eccentric sprockets are fixed on an eccentric shaft by a chain; two eccentric sprockets are fixedly connected with two ends on the bottom of the upper cutter frame via a link block; a small eccentric wheel with a photosenser is fixed in the middle of the eccentric shaft between two eccentric sprockets; and a photo-groove is arranged near the position below the small eccentric wheel. The invention improves production efficiency, lowers labour cost and improves product quality.

Owner:启东市罗源光伏设备有限公司

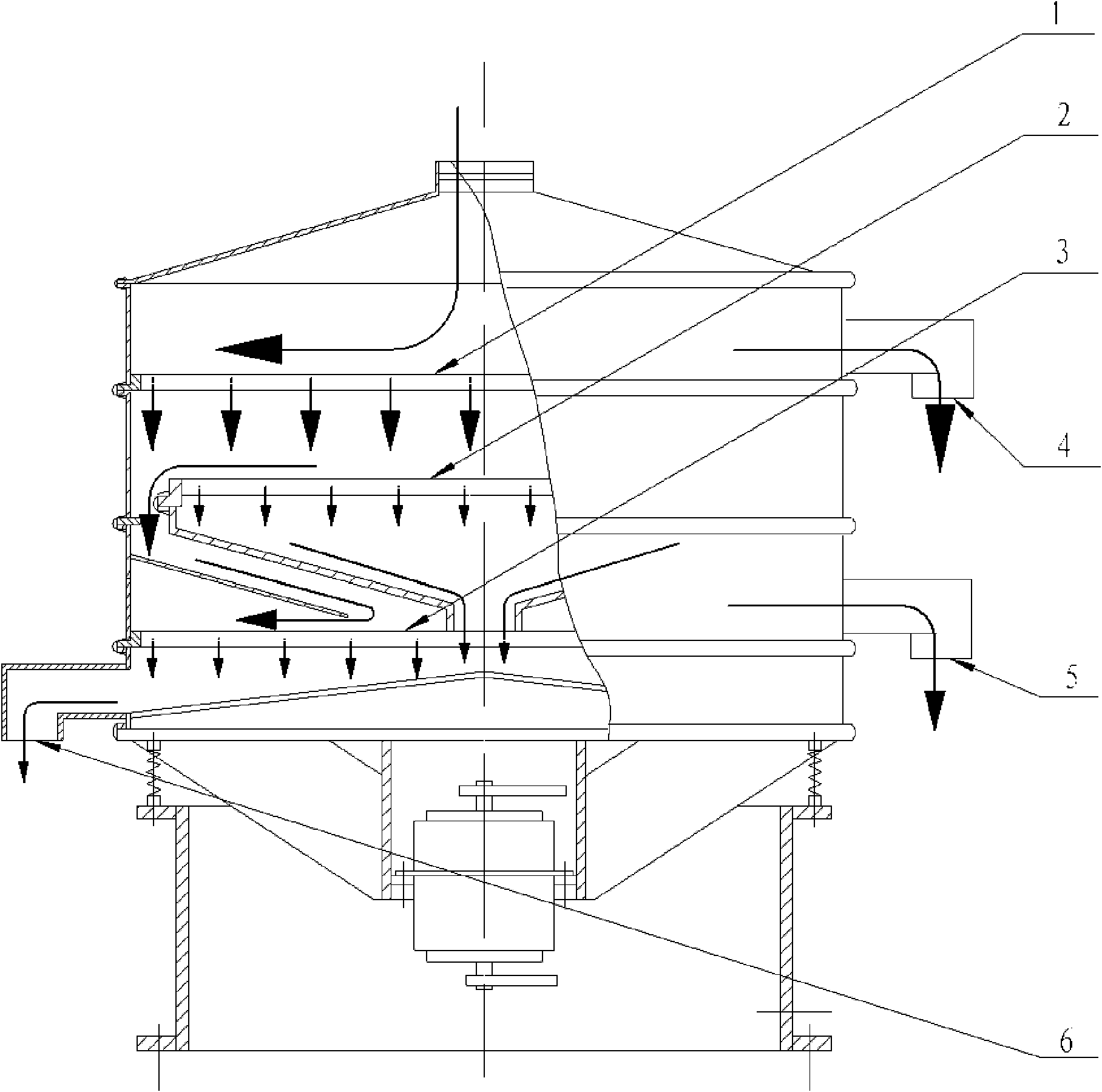

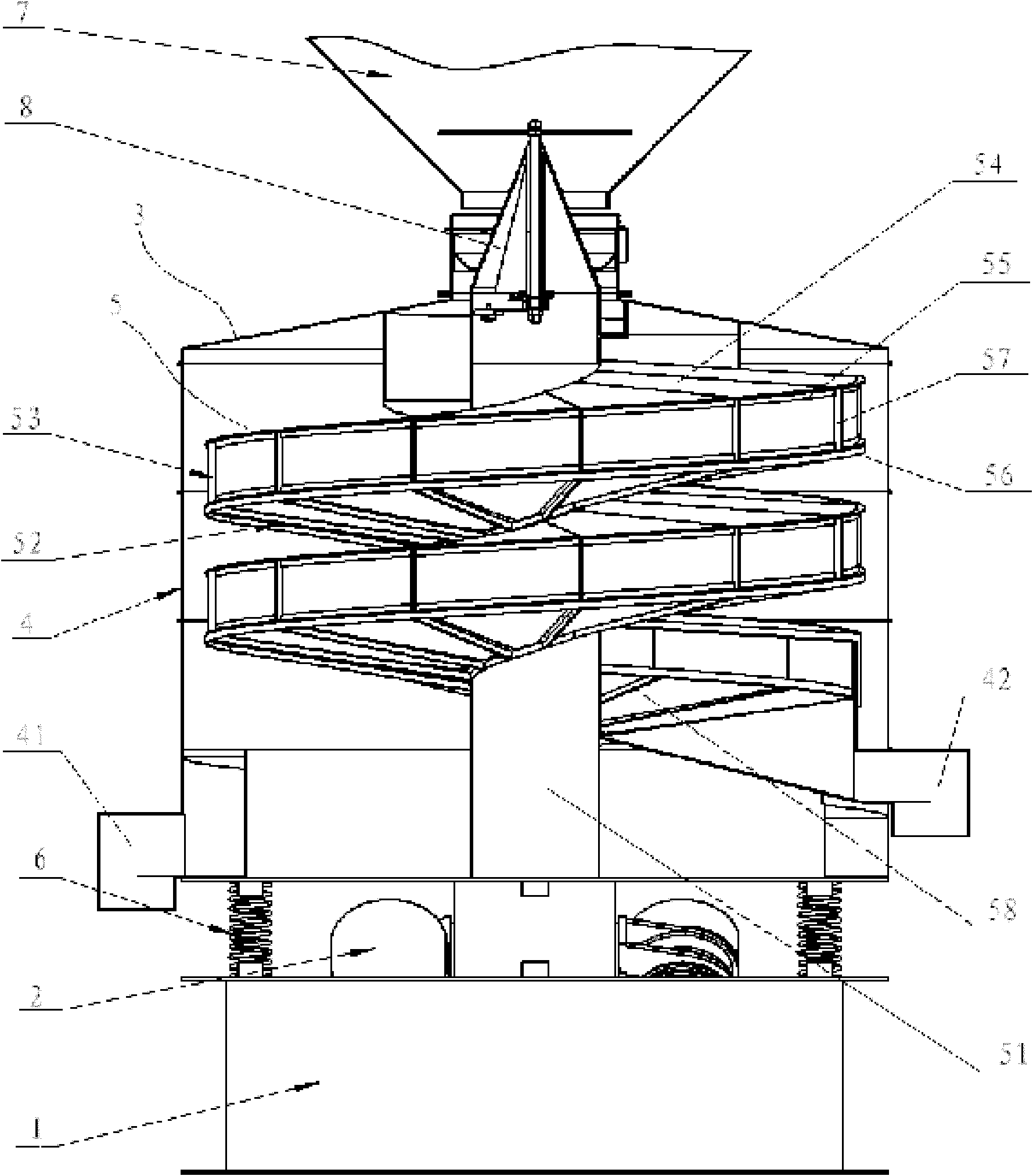

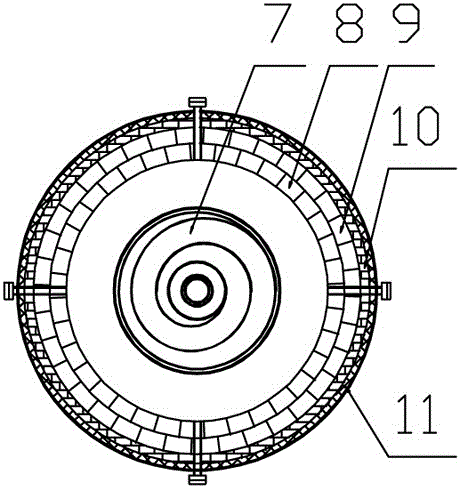

Vertical spiral vibrating screen

InactiveCN102371246AImproved resistance to fatigue vibrationIncrease the range of motionSievingScreeningEngineeringFine powder

The invention discloses a vertical spiral vibrating screen capable of greatly increasing the area of a screen and lengthening the movement stroke of powder. The vertical spiral vibrating screen comprises a base, a screen arranged on the base through a plurality of supporting springs, a vibrating device connected with the lower end of the screen and positioned in the base, a bin arranged at the upper end of the screen and a feeding valve arranged in the bin. The screen comprises a shell, a middle upright post and a screen net. The shell is a cylinder provided with a cover plate and a bottom plate, and the lower part of the shell is provided with a fine powder feeding hole and a coarse powder feeding hole; the middle upright post is vertical to the center of the shell; and the screen net comprises a bottom screen net, a lateral screen net and a top plate, wherein the inner edge of the bottom screen net is fixed on the middle upright post and is downwards spiral around the middle upright post, the lateral screen net is arranged coaxial with the middle upright post and is downwards spiral around the middle upright post, the lower end of the lateral screen net is connected with the outer edge of the bottom screen net, and the inner edge of the top plate is fixed on the middle upright post and is downwards spiral around the middle upright post.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

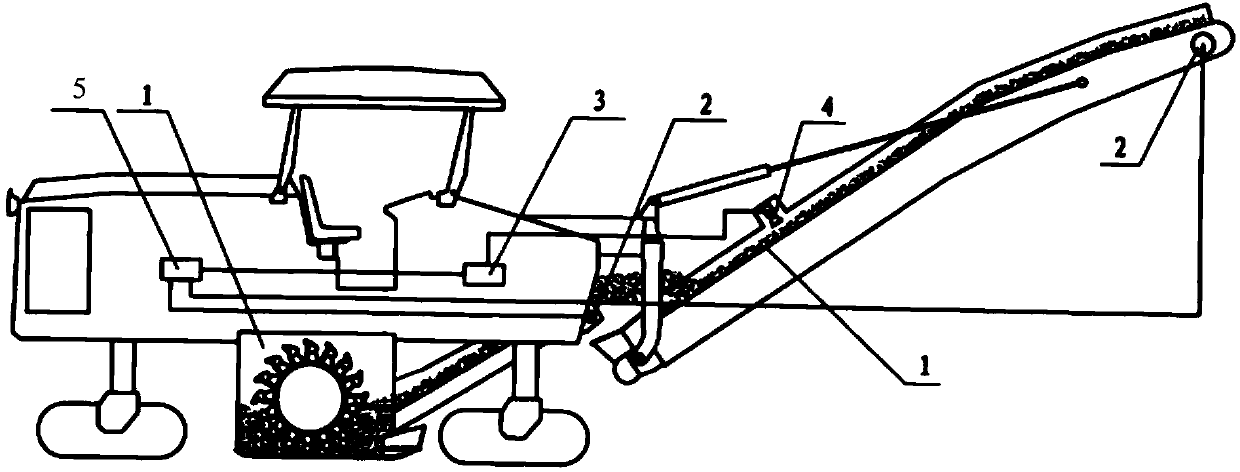

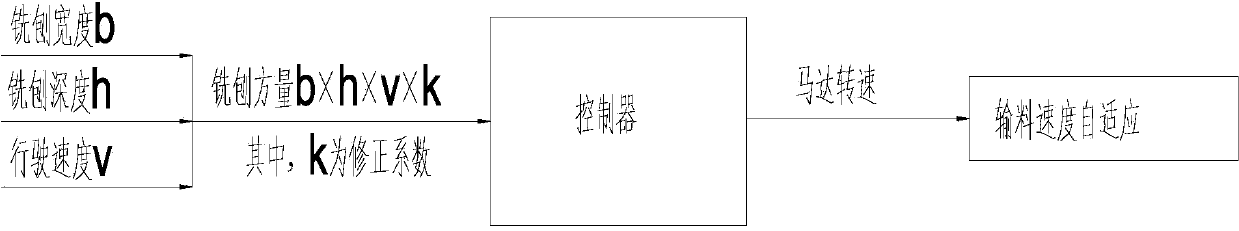

Milling machine and control system thereof

ActiveCN103741575AEasy to operateAccurate calculationRoads maintainenceControl systemControl engineering

The invention provides a control system of a milling machine. The control system is used on the milling machine and comprises a controller and detection devices, wherein the controller is electrically connected with the detection devices; the controller can be used for controlling the running speed of the milling machine; the pavement milling width of the milling machine can be input or selected in the controller; the detection devices comprise a first detection device and a second detection device, wherein the first detection device is used for detecting the milling depth of the milling machine, and the second detection device is used for detecting the running speed of the milling machine; the controller can control the material delivery speed of the milling machine according to the milling material quantity of the milling machine. The control system with the structure can accurately calculate the milling material capacity of the milling machine in real time and can adjust the material delivery speed of the milling machine according to the milling material quantity and enable the delivery speed to be higher when the milling material quantity is larger. On the other side, the invention also provides the milling machine comprising the control system of the milling machine.

Owner:HUNAN SANY ZHONGYI MASCH CO LTD

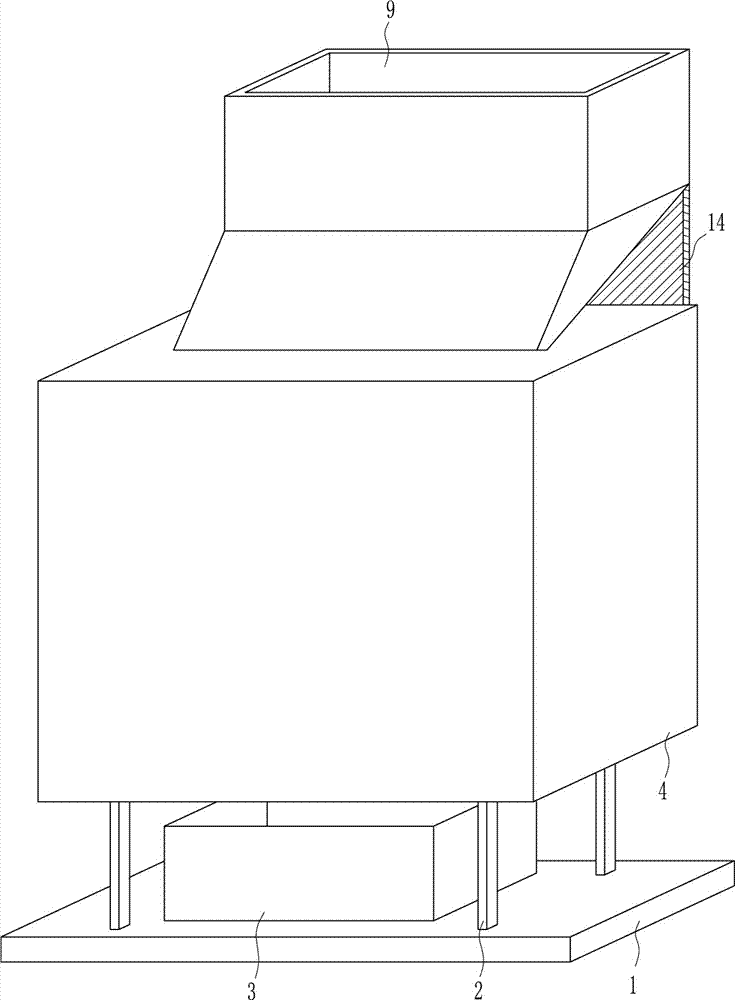

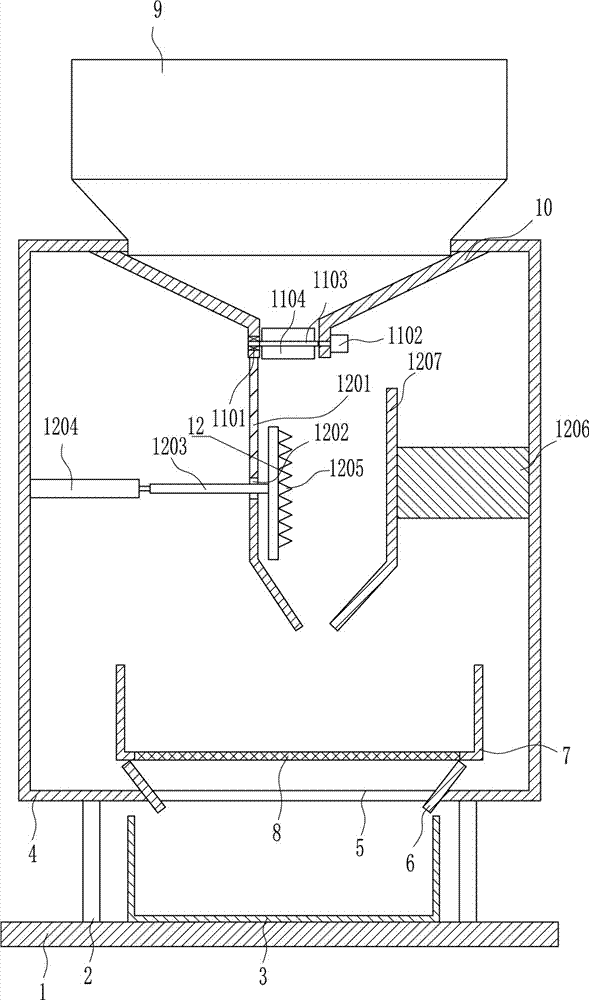

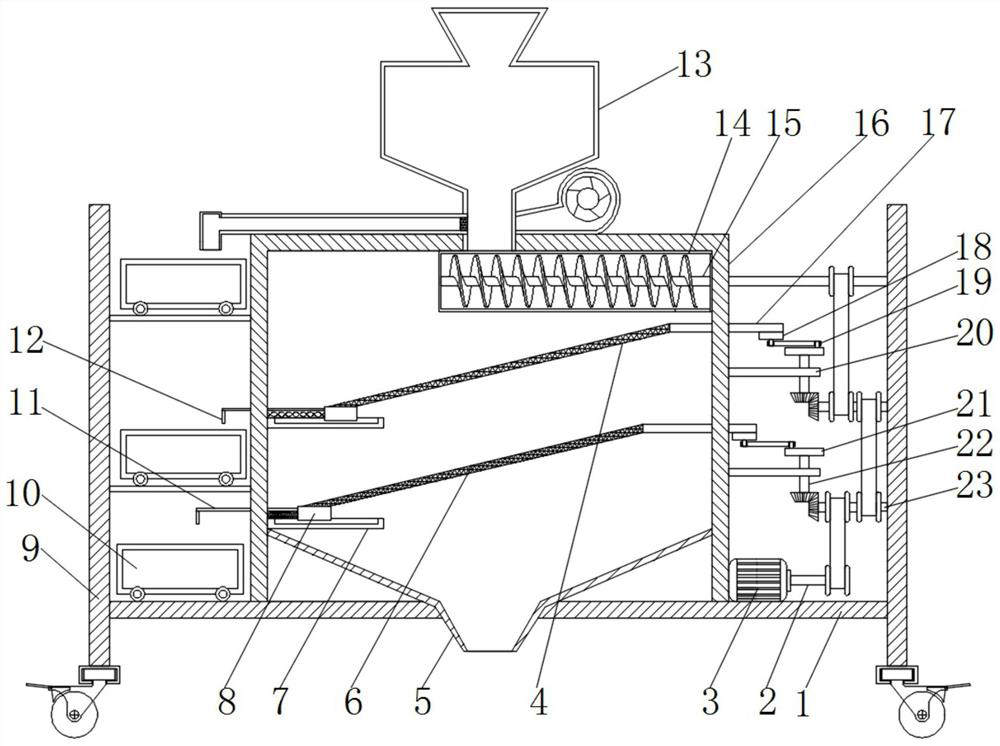

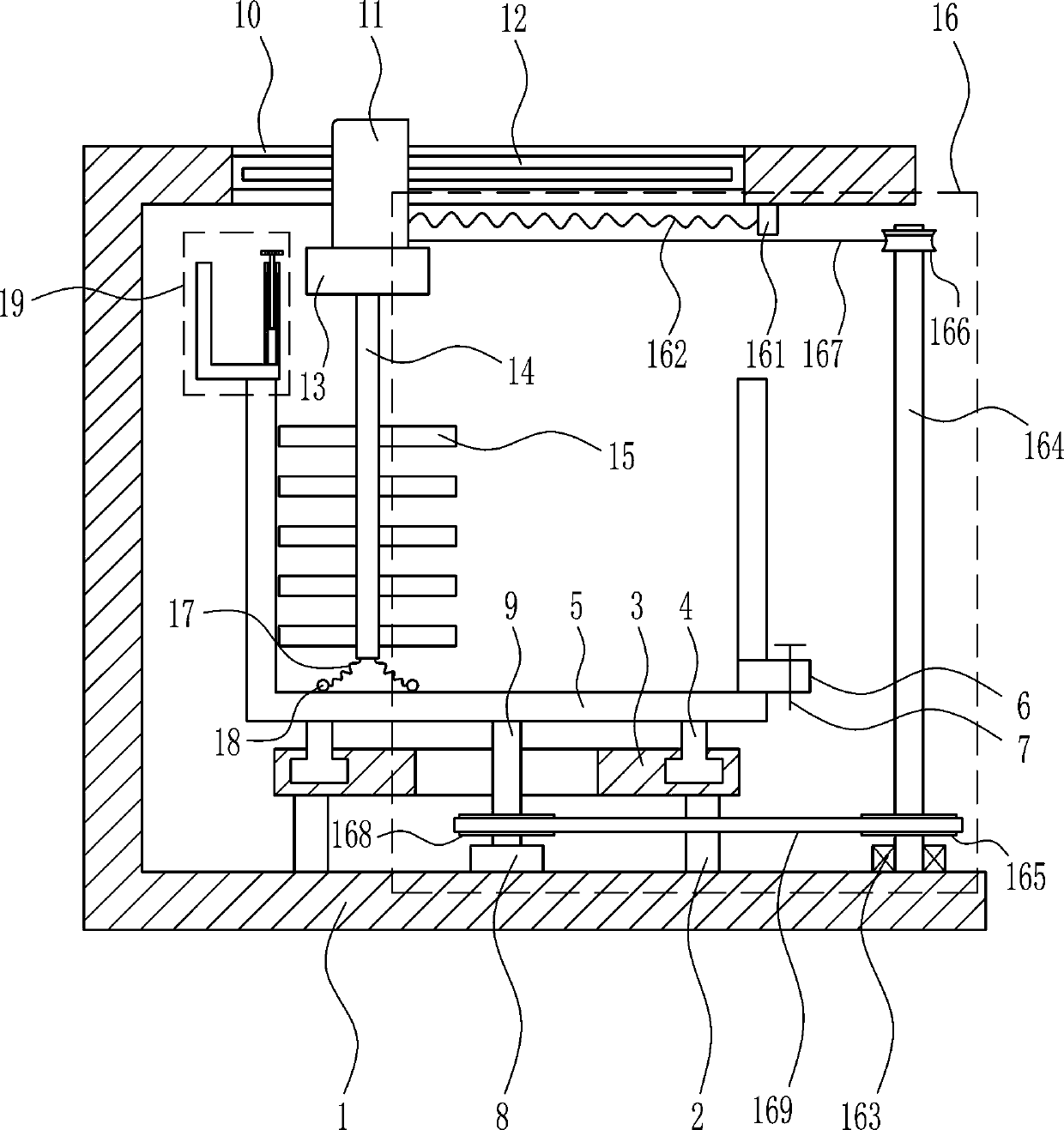

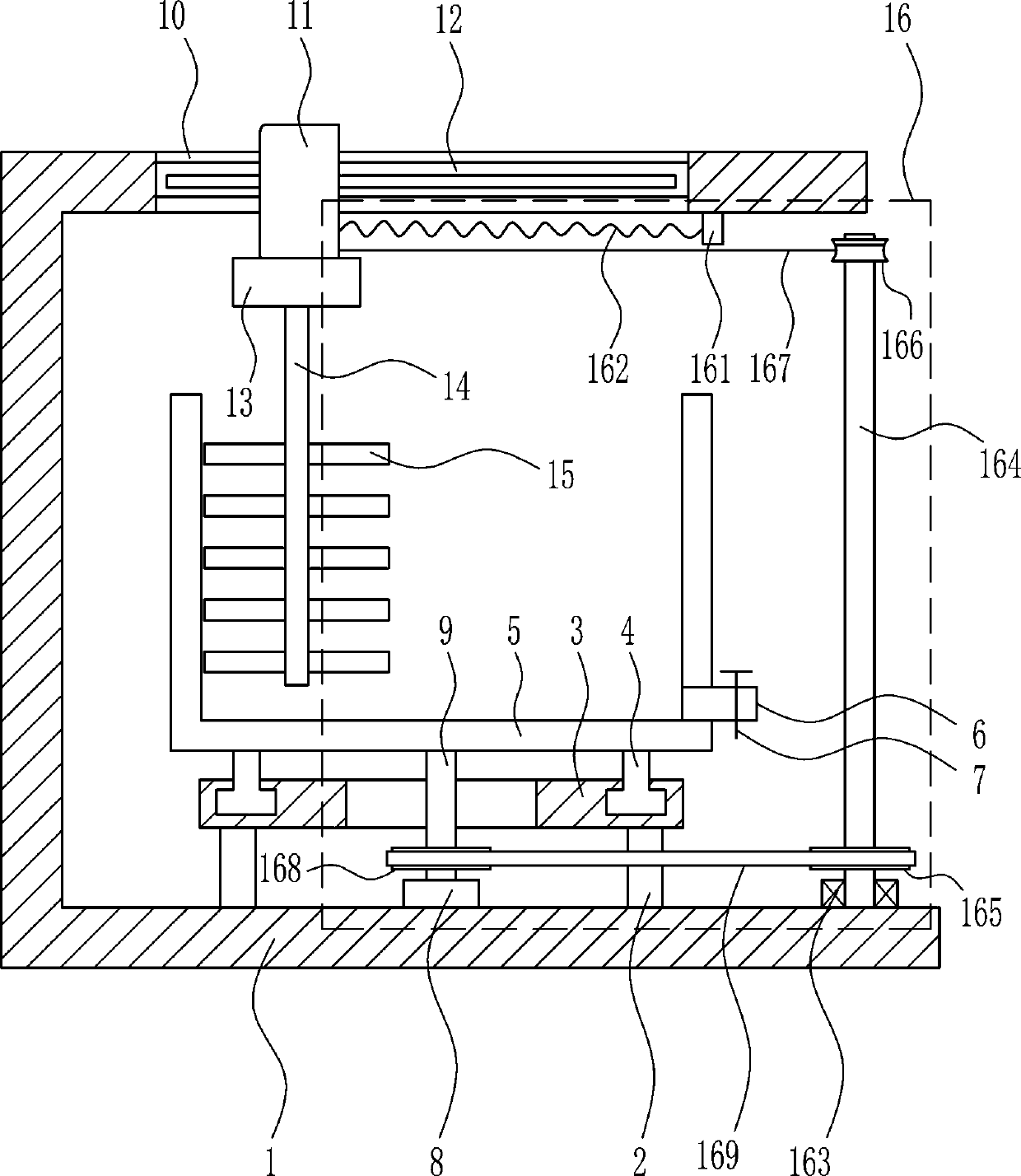

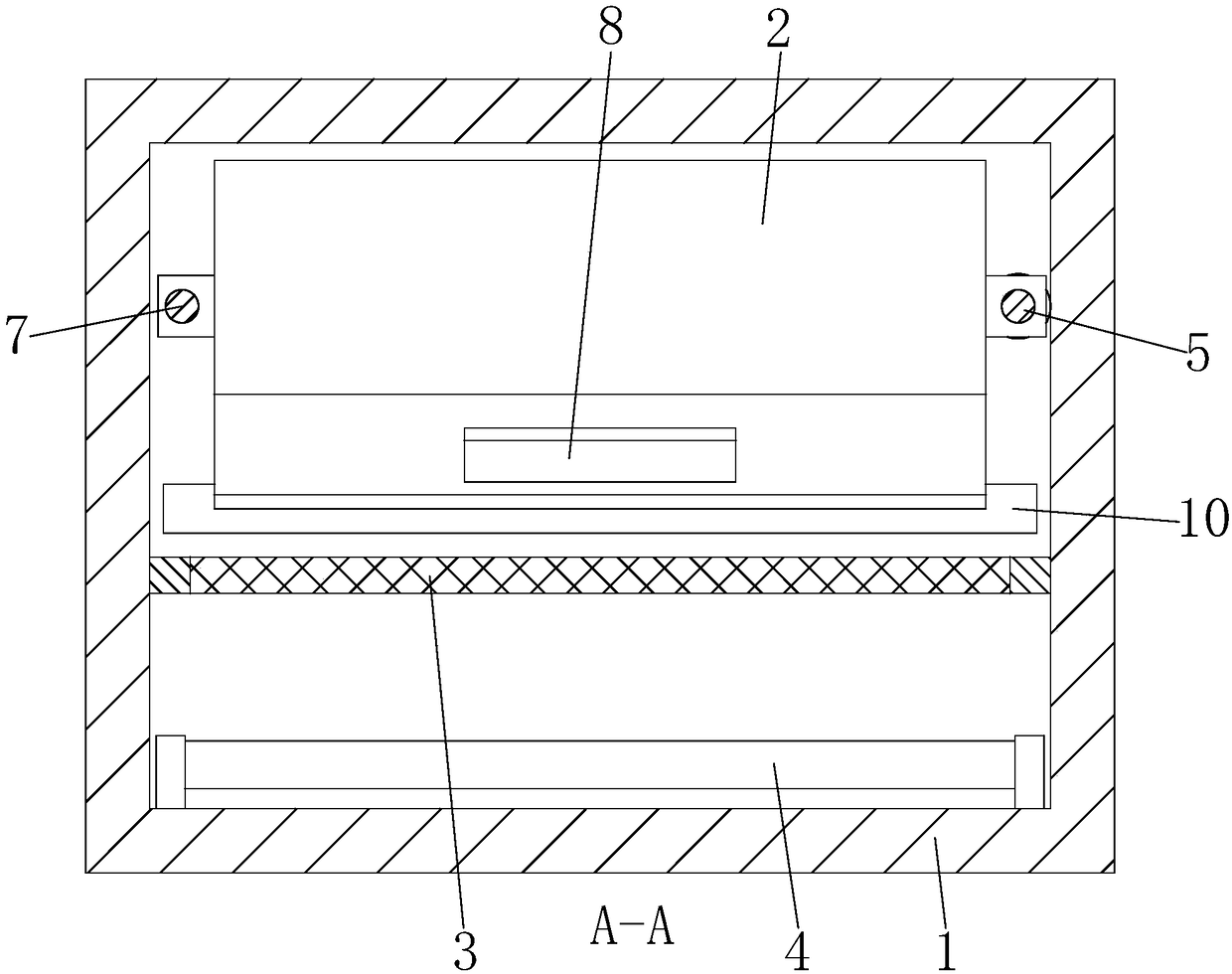

Medicinal material secondary crushing device with material control function

InactiveCN106513151AAvoid wastingControl the feeding speedPharmaceutical product form changeGrain treatmentsEngineeringDrive motor

The invention provides a medicinal material secondary crushing device with a material control function. The medicinal material secondary crushing device comprises a box body and a box door, wherein a material control device, a primary crushing chamber and a secondary crushing chamber are arranged on the box body; the material control device comprises a feed hopper, first telescopic shafts, baffle plates and first cylinders; a crushing device and a motor cover are arranged inside the primary crushing chamber; the crushing device comprises a left driven roller, a drive roller and a right driven roller; discharge plates, a partition, a rolling device and a material pushing device are arranged inside the secondary crushing chamber; the rolling device comprises a driving motor, a rolling shaft and a pressing plate; the driving motor is placed on the partition; the rolling shaft is arranged at the lower end of the driving motor; the material pushing device comprises a second cylinder, a second telescopic rod and a pushing plate; a placing plate is arranged at the lower end of the second cylinder; the second cylinder is placed on the placing plate; the second telescopic rod penetrates through the left end wall of the box body; and the second telescopic rod is connected with the pushing plate. According to the medicinal material secondary crushing device, the crushing is thorough, residues can be avoided, and the discharge speed can be controlled.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

Drying and screening device for agricultural cereals

PendingCN108787413AAvoid wasting heatSimple structureSievingScreeningAgricultural engineeringLeft wall

The invention discloses a drying and screening device for agricultural cereals. The drying and screening device for agricultural cereals comprises a main body, a power box and a heating box. The rightend of the left wall of the power box is fixedly connected to the left end of a motor, the right end of an output shaft of the motor is fixedly connected to a sleeve, the right end of the output shaft of the motor is fixedly connected to a first transmission wheel on the right side of the sleeve, the first transmission wheel is connected to a second transmission wheel and a third conveyor belt through a conveyor belt, separately, the second transmission wheel is arranged at the left end of a first rotating rod, the right end of the first rotating rod s connected to one end of a hinge plate, spiral blades are arranged on the sleeve, the sleeve is arranged in the supporting plate, the left end of the supporting plate is fixedly connected to the inner surface of the left wall of the main body, and the third conveyor belt is fixedly connected to the right end of a second rotating rod. The drying and screening device for agricultural cereals disclosed by the invention is energy-saving, candry agricultural cereals for three times simultaneously, is high in drying efficiency, can adjust the discharging speed of agricultural crops, and is high in practicality and suitable for being popularized.

Owner:兰州集智信息技术有限公司

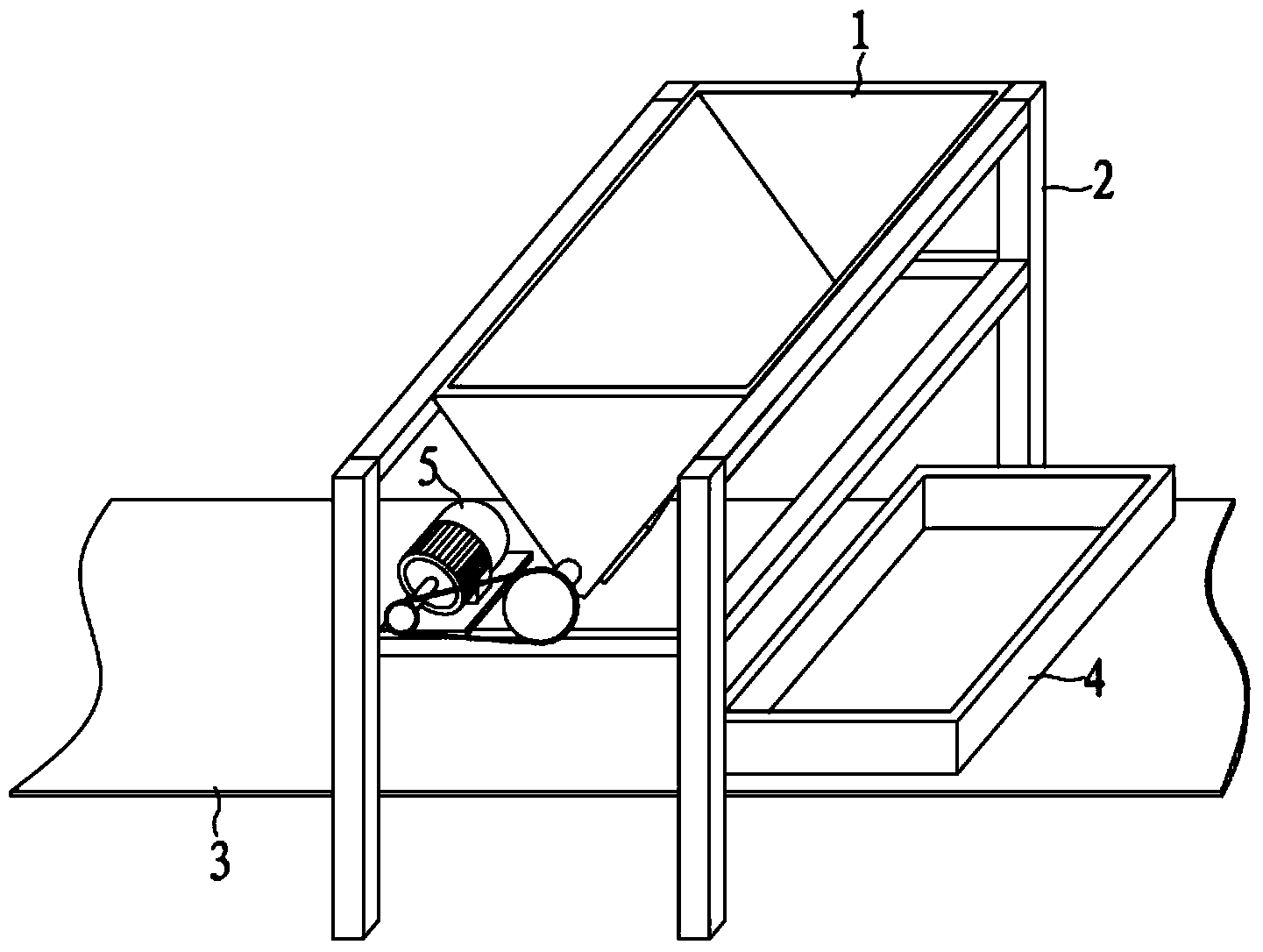

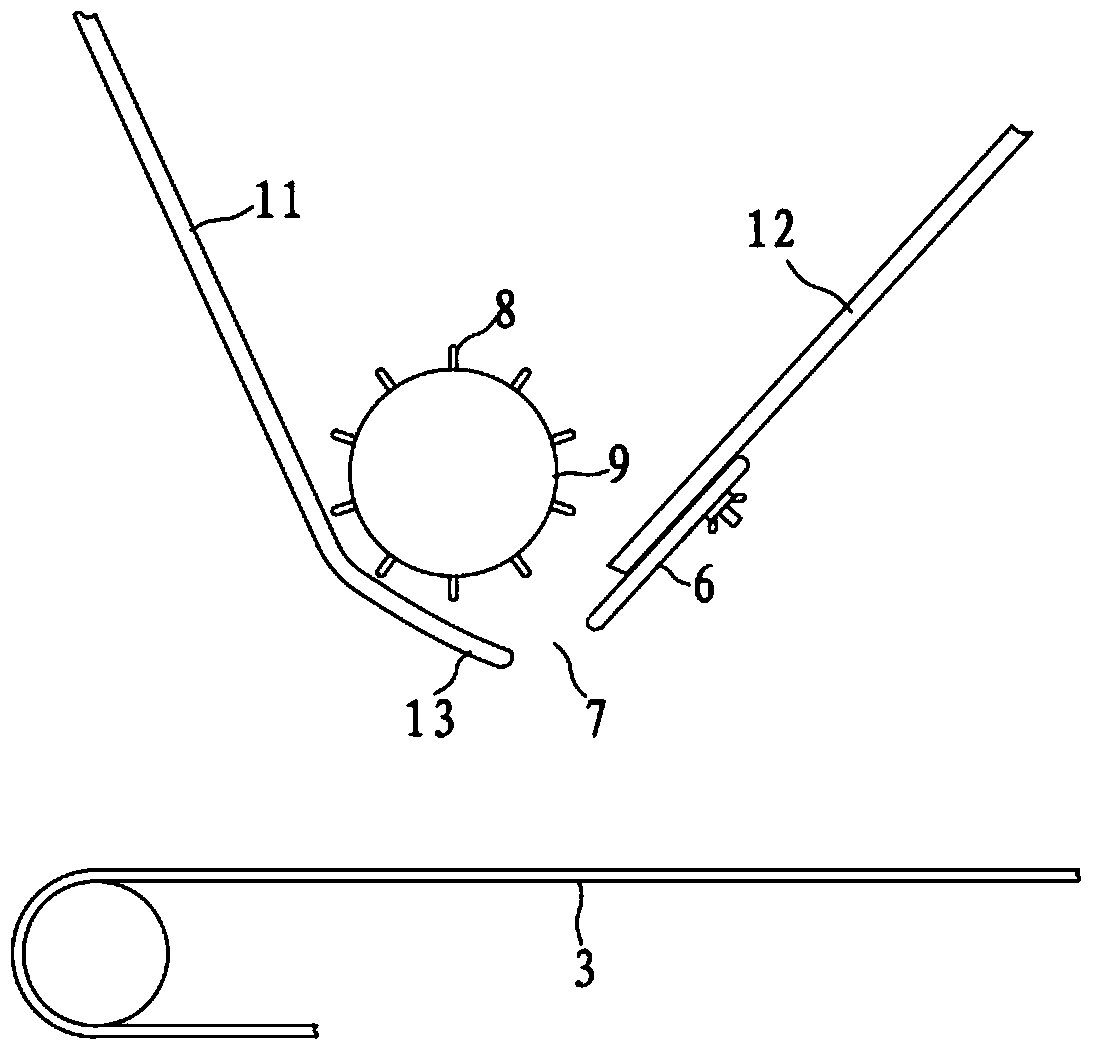

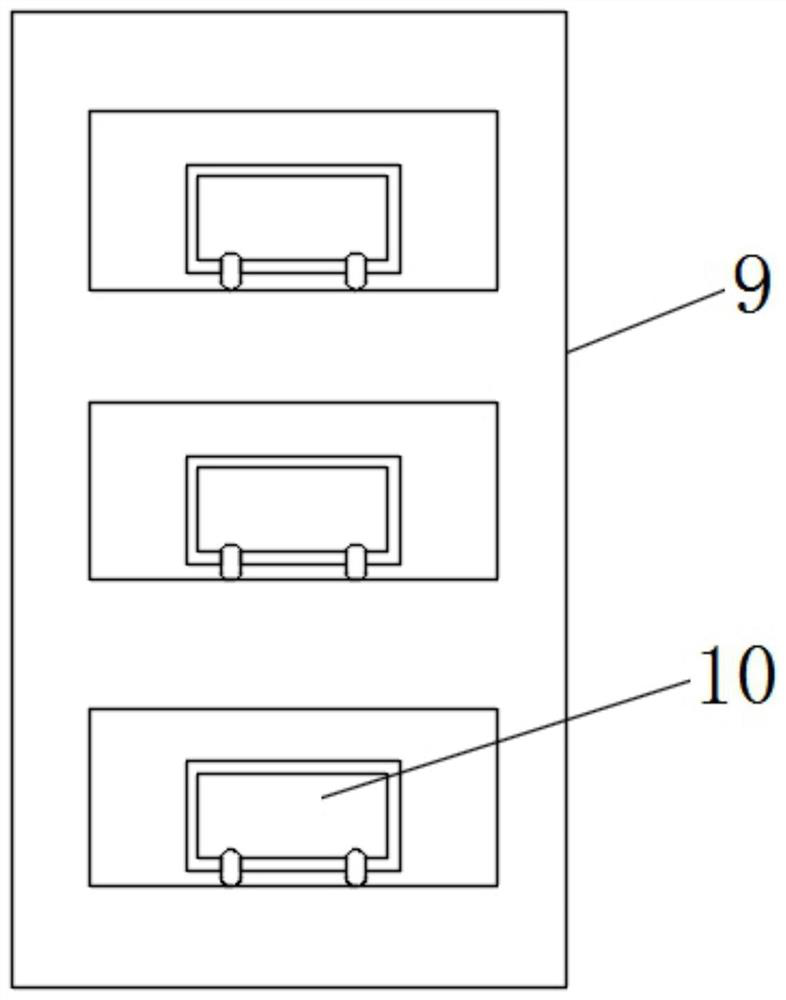

Mushroom cultivation charging mulcher

The invention discloses a mushroom cultivation charging mulcher which comprises a support, a feeding hopper and a conveying belt. The feeding hopper is mounted on the support, a feeding opening is formed in the bottom of the feeding hopper, and the conveying belt is placed below the feeding hopper and is used for conveying cultivation beds. The feeding hopper is provided with a first side plate and a second side plate which tilt relatively, the bottom of the first side plate is provided with a stopping part which extends to the second side plate in a curved mode, and the feeding opening is formed between the stopping part and the bottom edge of the second side plate. A roller which is arranged at the position, close to the feeding opening, in the feeding hopper in a rotatable matching mode, the roller presses close to the first side plate, and material dialing teeth are distributed on the peripheral face of the roller. The mushroom cultivation charging mulcher is simple in structure, low in manufacturing cost and convenient to popularize, the feeding opening which is obliquely arranged is used, the roller with the material dialing teeth is mounted on the side edge of the feeding hopper, caking and bridging of materials are prevented, the falling materials are distributed more evenly, the feeding opening with the adjustable size is arranged to be used for controlling the feeding speed, and the demand for charging of the cultivation beds is met.

Owner:HANGZHOU ACAD OF AGRI SCI

Pebble removing device for flour production

PendingCN110665797AImprove the workshop environmentThe principle is simpleSievingScreeningEngineeringStructural engineering

The invention discloses a pebble removing device for flour production. The pebble removing device comprises a shell and a mounting box, wherein supporting legs are welded to four corners of the bottomand the mounting box is welded to one side of the shell. A receiving hopper and a charging hopper are separately locked and welded to the top ends of the mounting box and the shell, a vibratory screening mechanism and a secondary screening mechanism are separately mounted in the shell and the mounting box, the vibratory screening mechanism comprises a sieve plate, one end of which is slidably connected to the inner wall of the shell, fixed blocks I are welded to two ends of the side, close to the sieve plate, of the shell, a same vibrating spring I is welded to the side, opposite to the sieveplate, of each fixed block I, a material conveying port is formed in one side, close to the other end of the sieve plate, of the shell, and a fixed block II is welded to the inner wall of one side ofthe material conveying port. The pebble removing device can screen wheat effectively by means of the arranged vibratory screening mechanism and secondary screening mechanism, and wheat will fall offfrom the first screening mechanism and the second screening mechanism, so that relatively large impurities such as pebbles can be removed effectively.

Owner:湖北庄品健实业(集团)有限公司

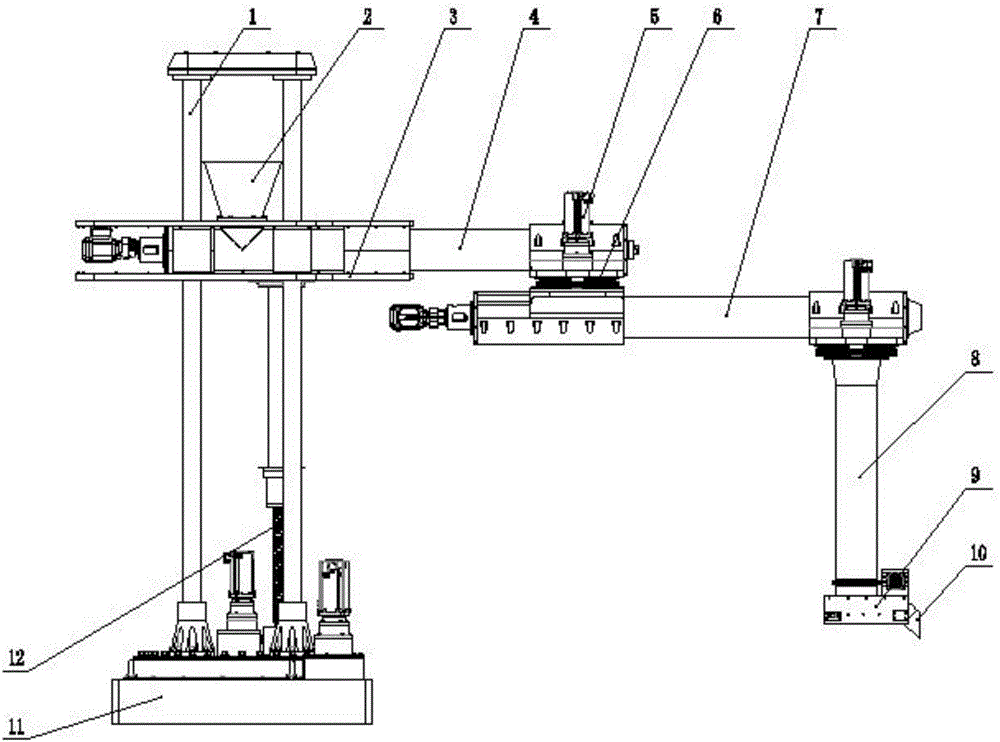

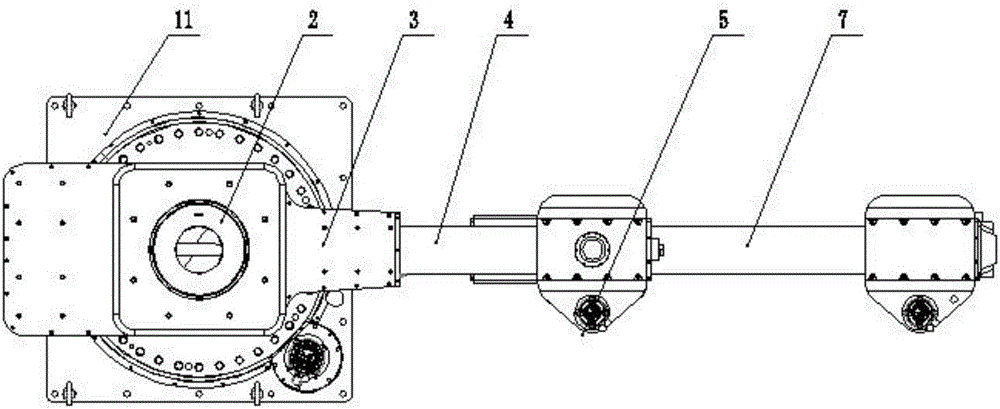

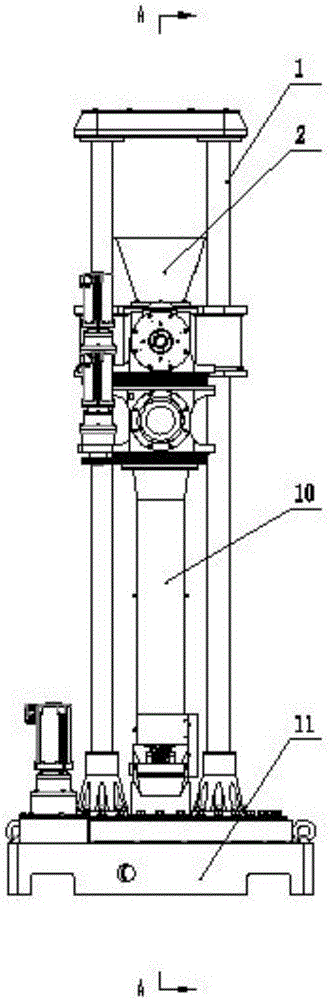

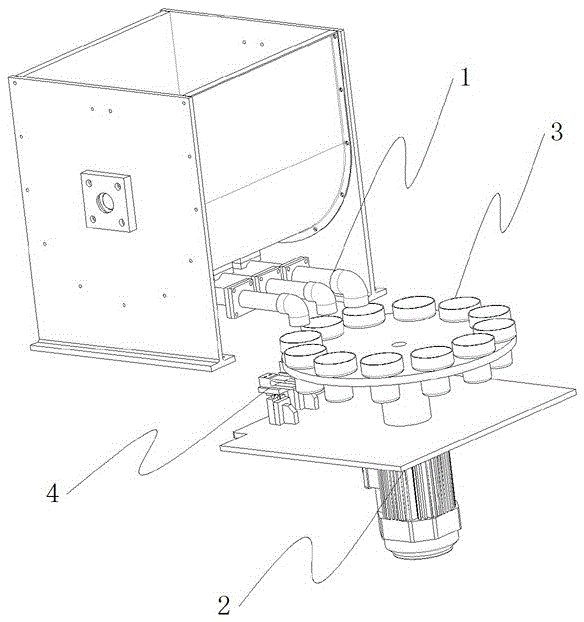

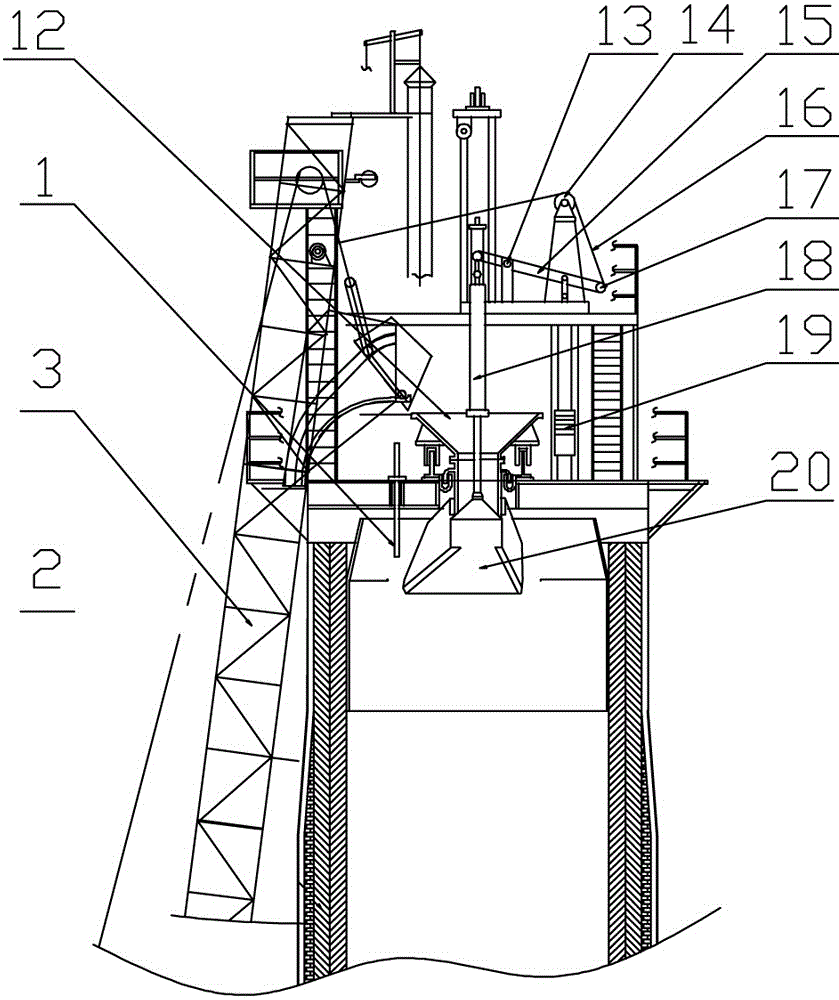

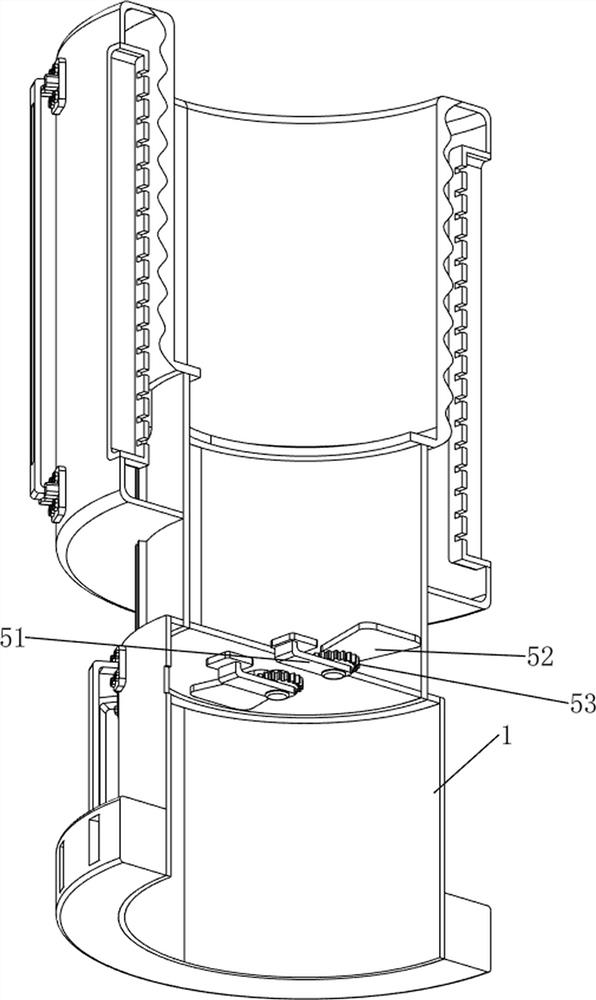

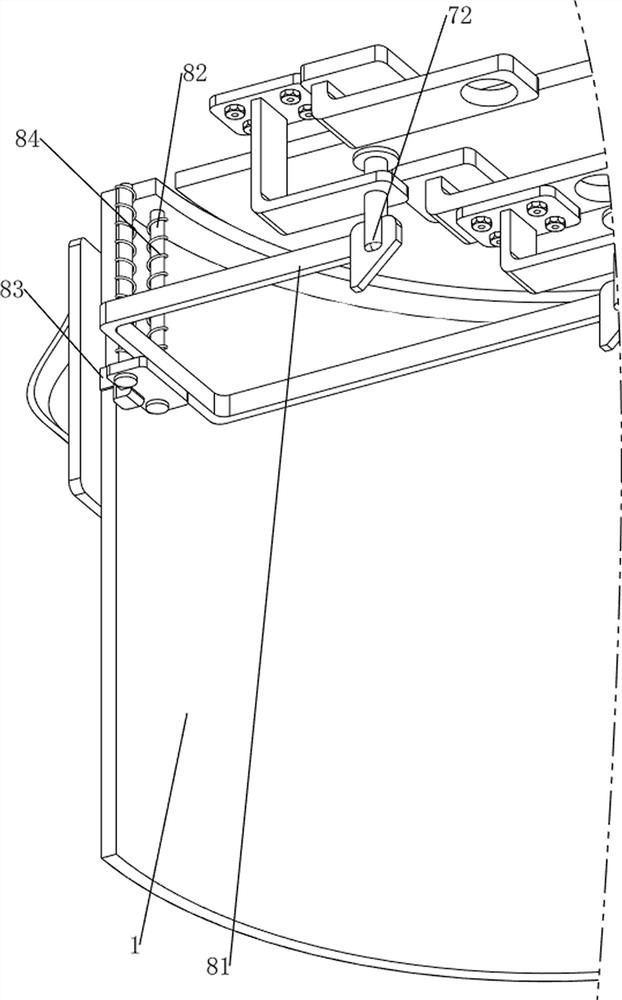

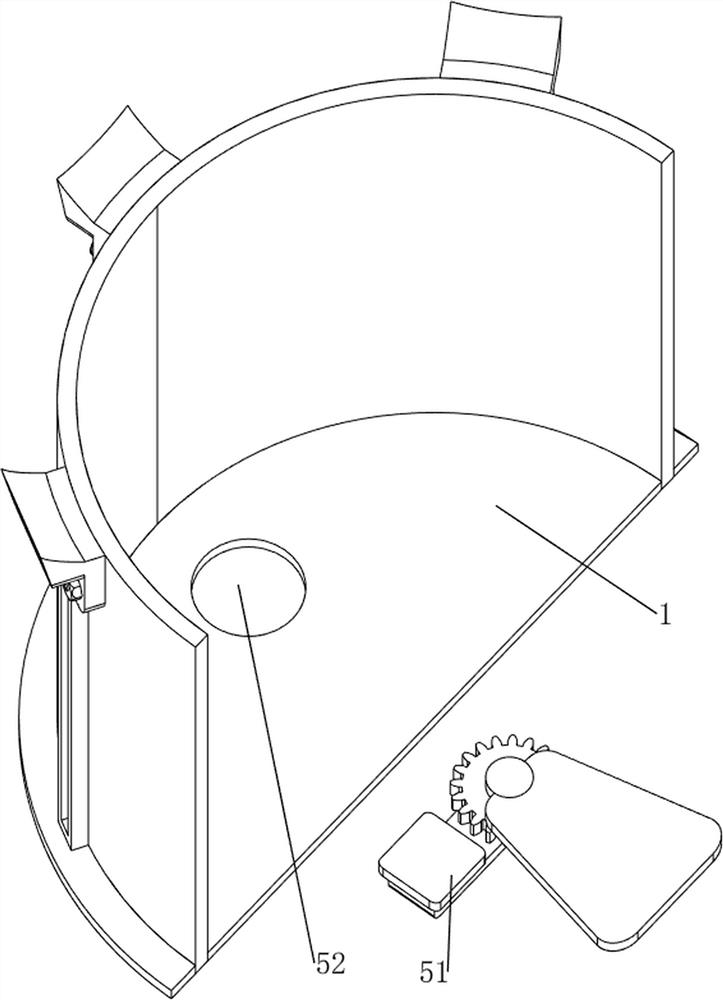

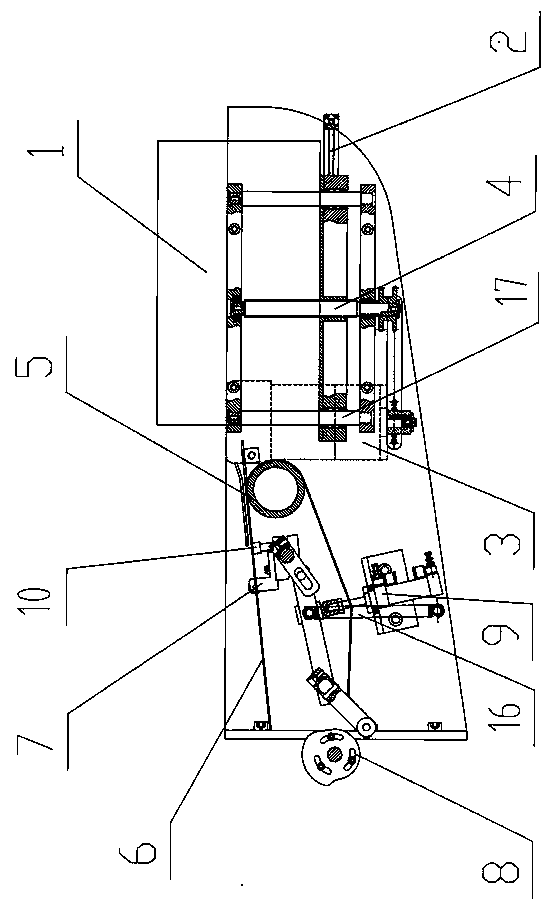

Intelligent grain loading robot for flexible spreading

InactiveCN105923410ACompact structureControl the feeding speedAlcoholic beverage preparationPackagingDistillationEngineering

The invention relates to an intelligent grain loading robot for flexible spreading. The robot comprises a base, a vertical frame, a lifting frame, a first-grade feeding arm, a second-grade feeding arm, a vertical feeding arm and a buffer feeding arm; the vertical frame is vertically mounted at the upper end of the base; the first-grade feeding arm is mounted on the vertical frame in a horizontal cantilever form; one end of the second-grade feeding arm is horizontally and rotationally mounted at a cantilever end of the first-grade feeding arm; the upper end of the vertical feeding arm is closed and mounted below the other end of the second-grade feeding arm; the vertical feeding arm is a hollow cylindrical structure; one end of the buffer feeding arm is mounted at the lower end of the vertical feeding arm; and a spreading outlet is mounted in the other end of the buffer feeding arm. The robot is provided with a flexible feeding end bearing platform, and the bearing platform is controllable in height, so that fermented grains are gently spread in a grain barrel, the spread fermented grains are kept loose, and the later distillation processing effect is improved; and the bearing platform can rotate for spreading operation without dead angle in the grain barrel.

Owner:天津津晟浩科技有限公司

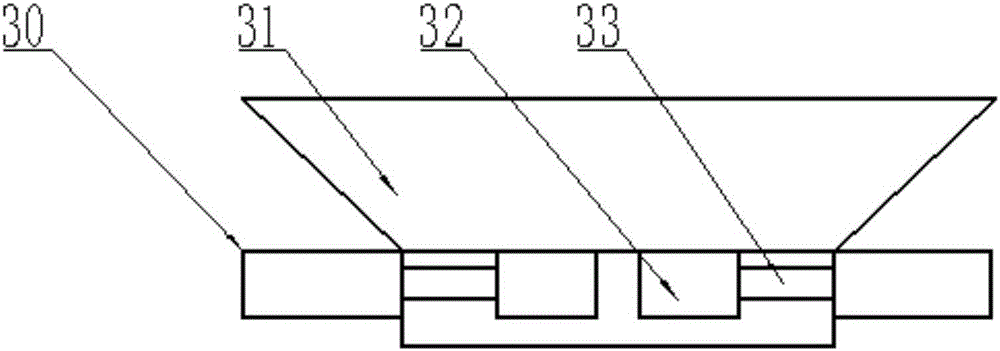

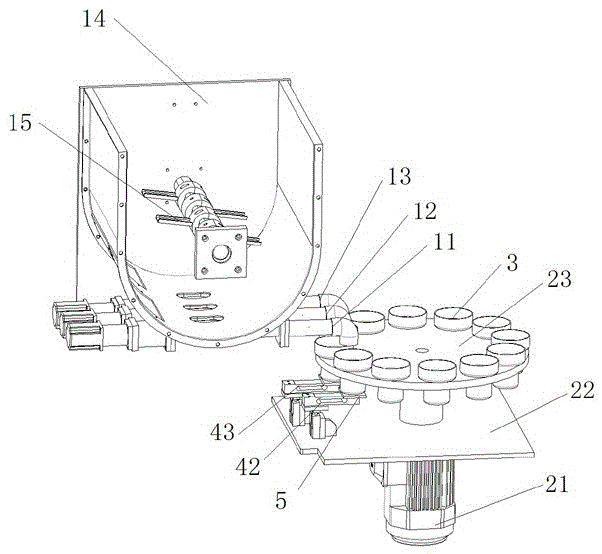

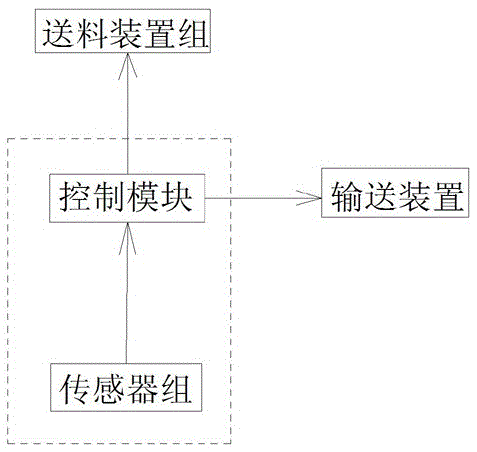

Multi-station weighing machine and method

ActiveCN105466533AShorten weighing timeFast weighingSpecial purpose weighing apparatusEngineeringMechanical engineering

The invention discloses a multi-station weighing machine and method. The multi-station weighing machine is provided with a feeding device group, a conveying device, a material weighing container group and a control system. The feeding device group is provided with at least two feeding devices, and each feeding device is provided with a material inlet and a material outlet. The conveying device is provided with a plurality of conveying stations which are successively arranged in the arranging direction of the material outlet. The material weighing container group is composed of a plurality of material weighing containers, and each material weighing container is correspondingly installed on one conveying station. The control system is provided with a control module and a sensor group electrically connected with the control module, and the control module is electrically connected with the feeding device group and the conveying device. The multi-station weighing machine has the advantages that the weighing speed is high, the weighing precision is high, material overflow is prevented, the size is small, the cost is low, the operation is easy, the structure is simple, the maintenance is simple, etc.

Owner:ZHUHAI HUALI FRICTION MATERIAL

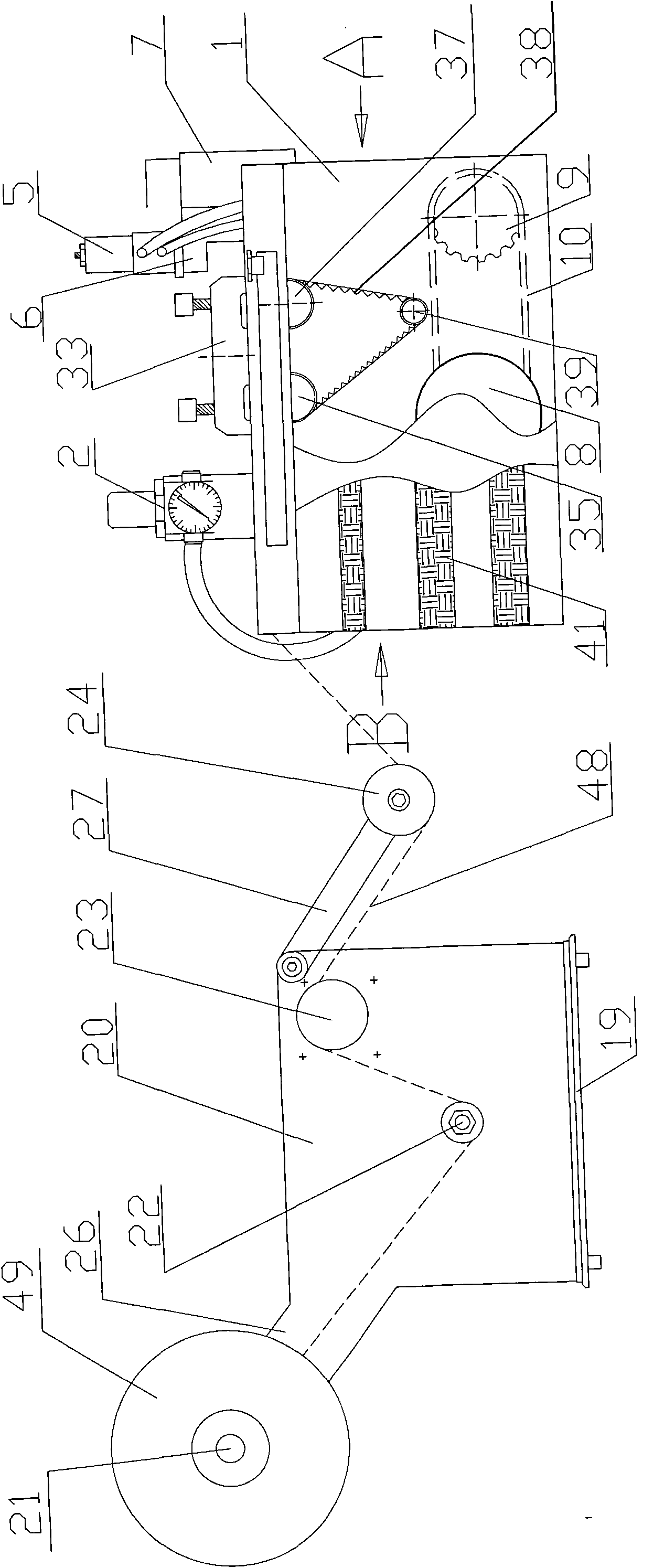

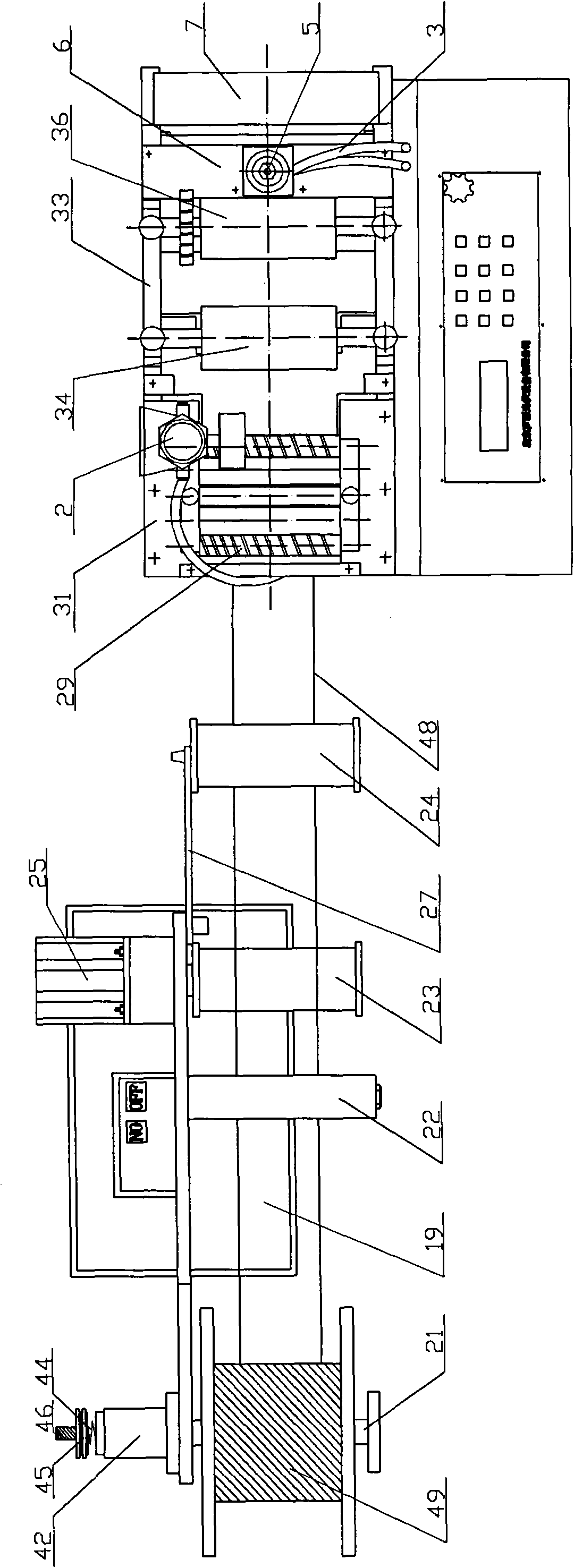

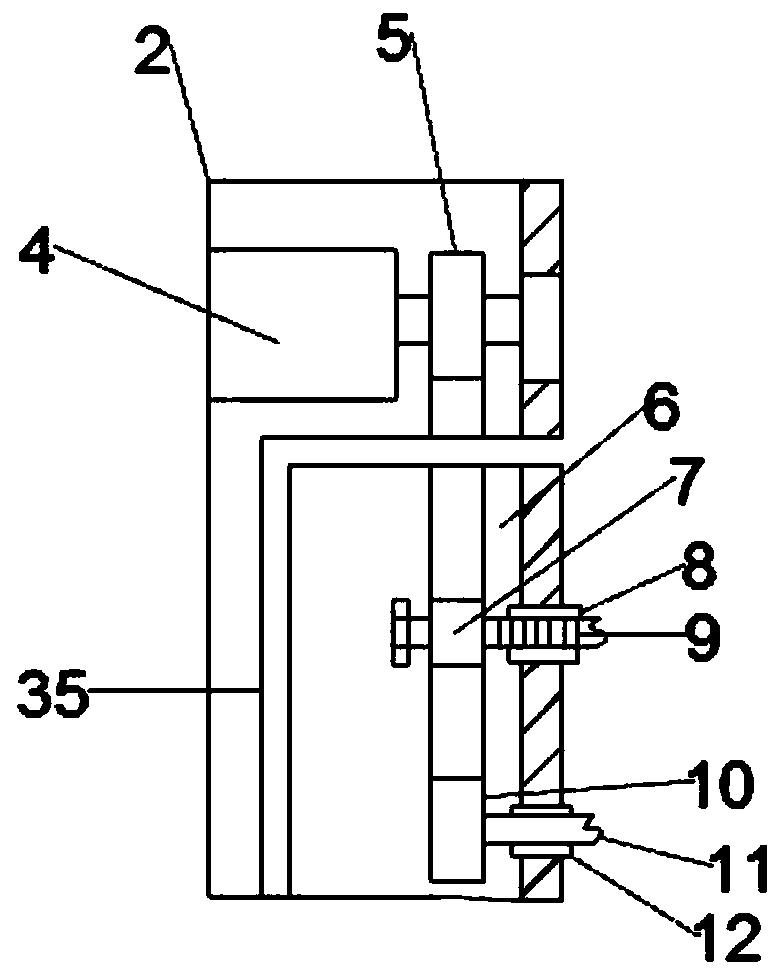

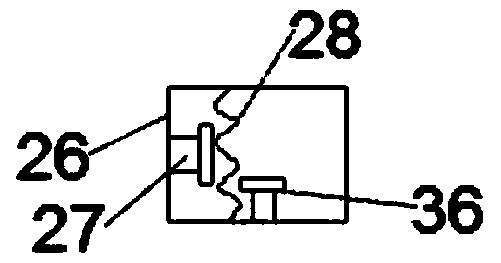

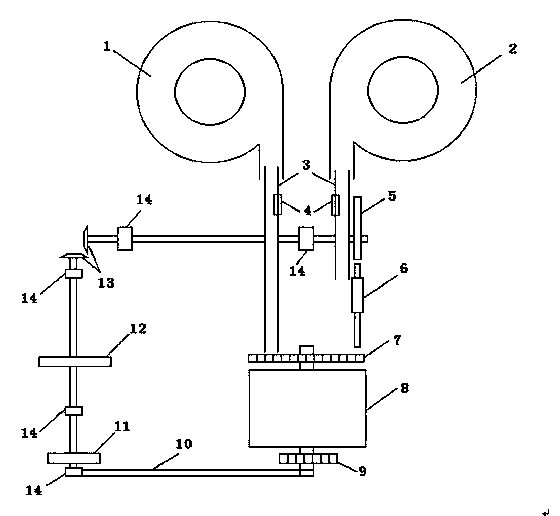

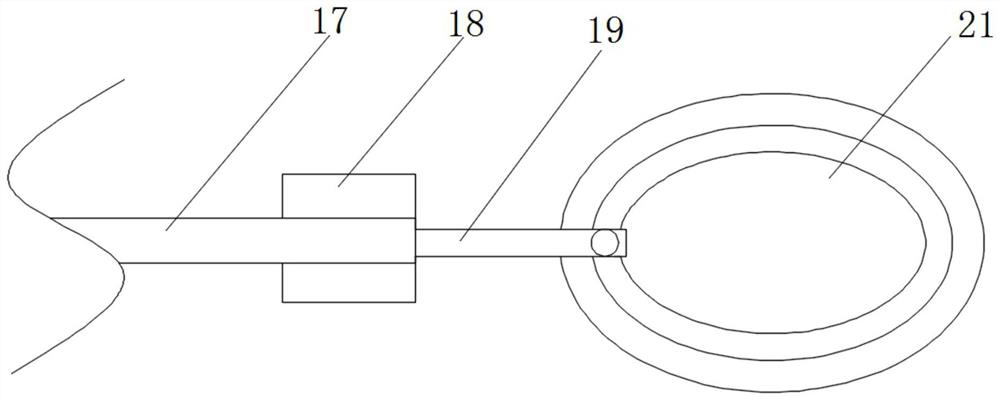

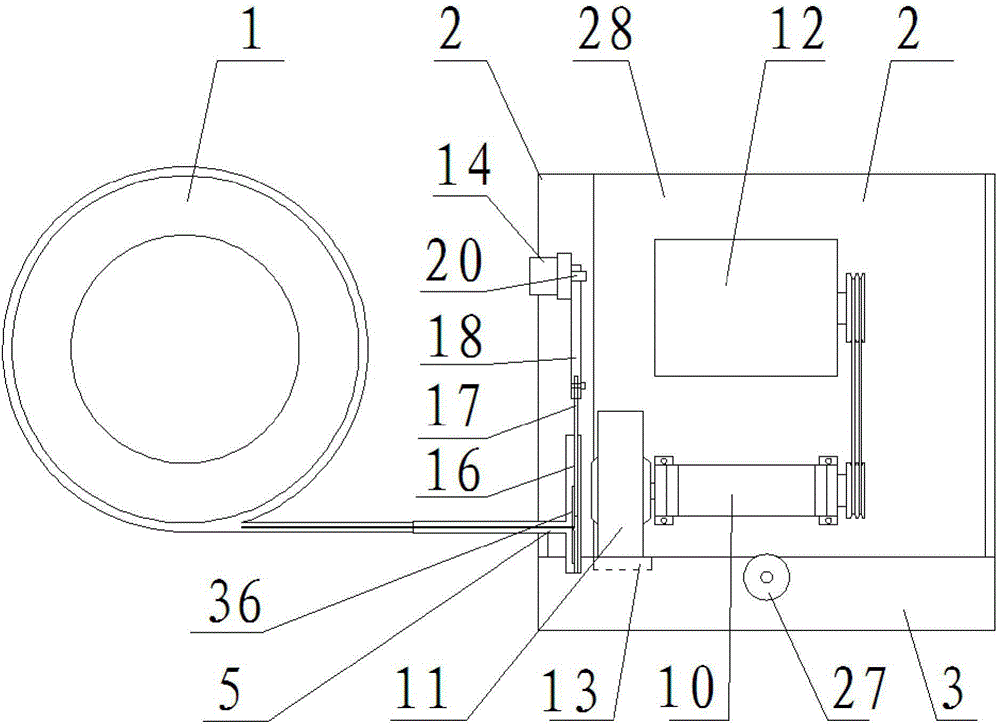

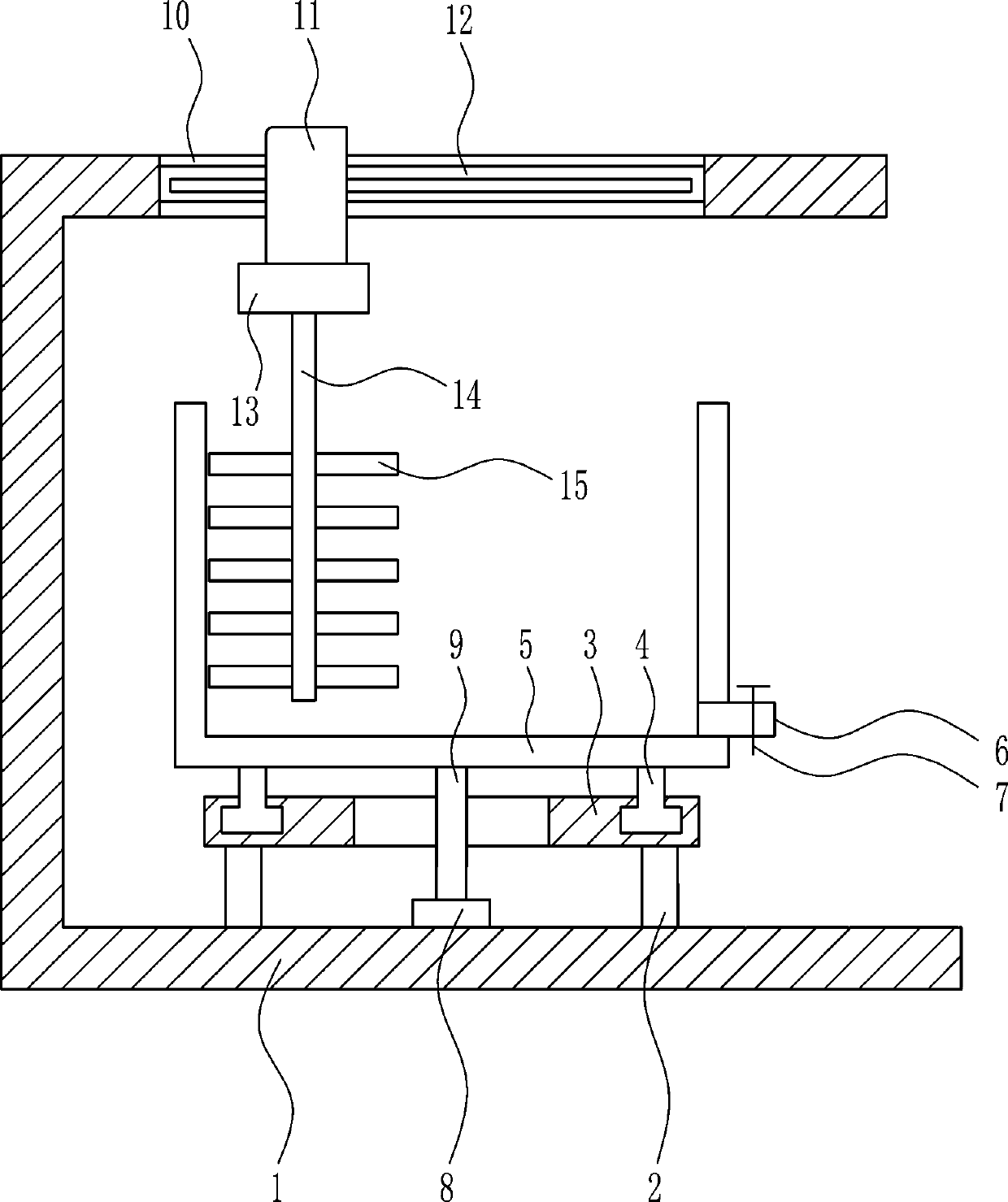

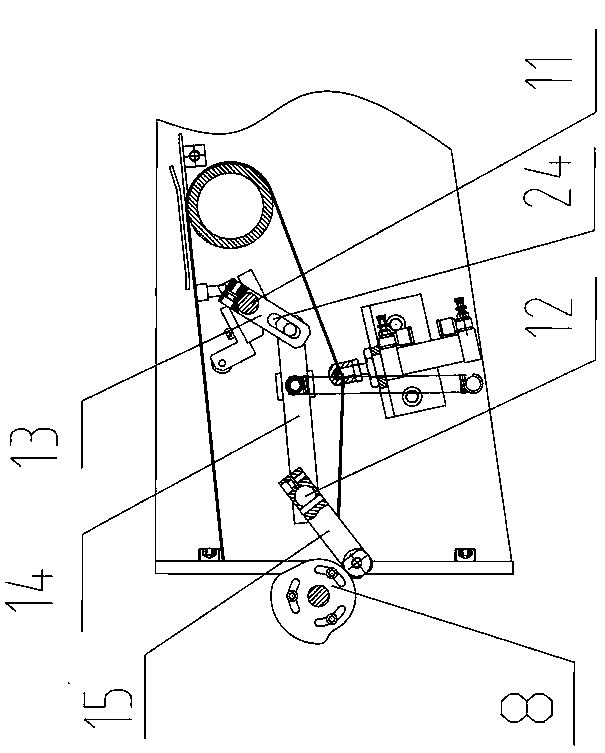

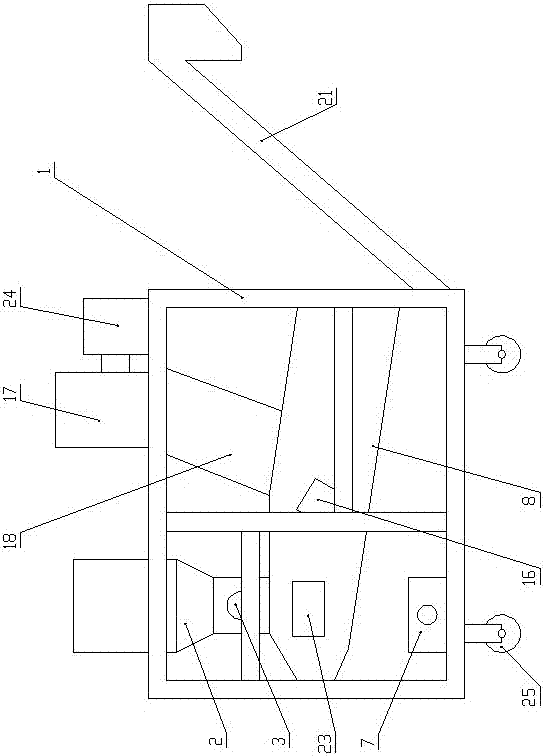

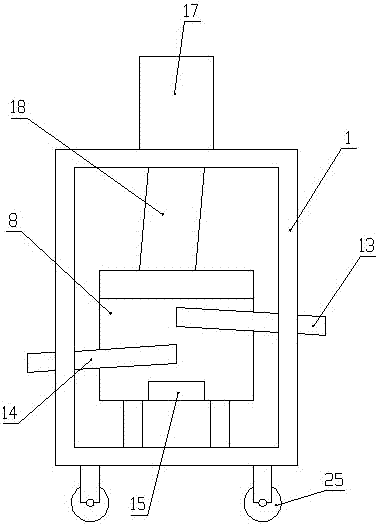

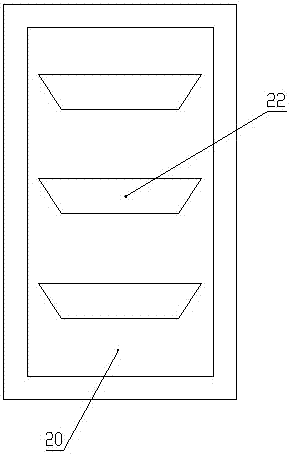

Full-automatic pipe clamp and nail assembling machine

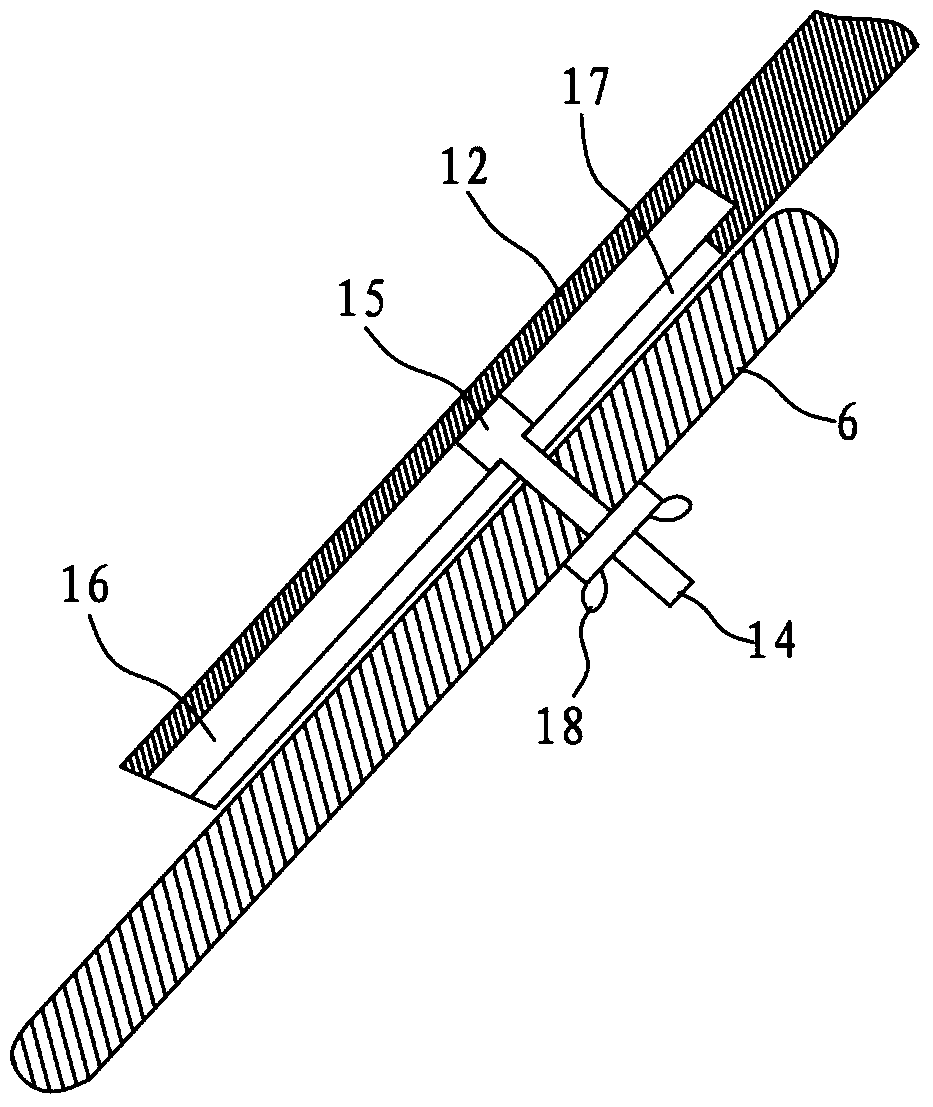

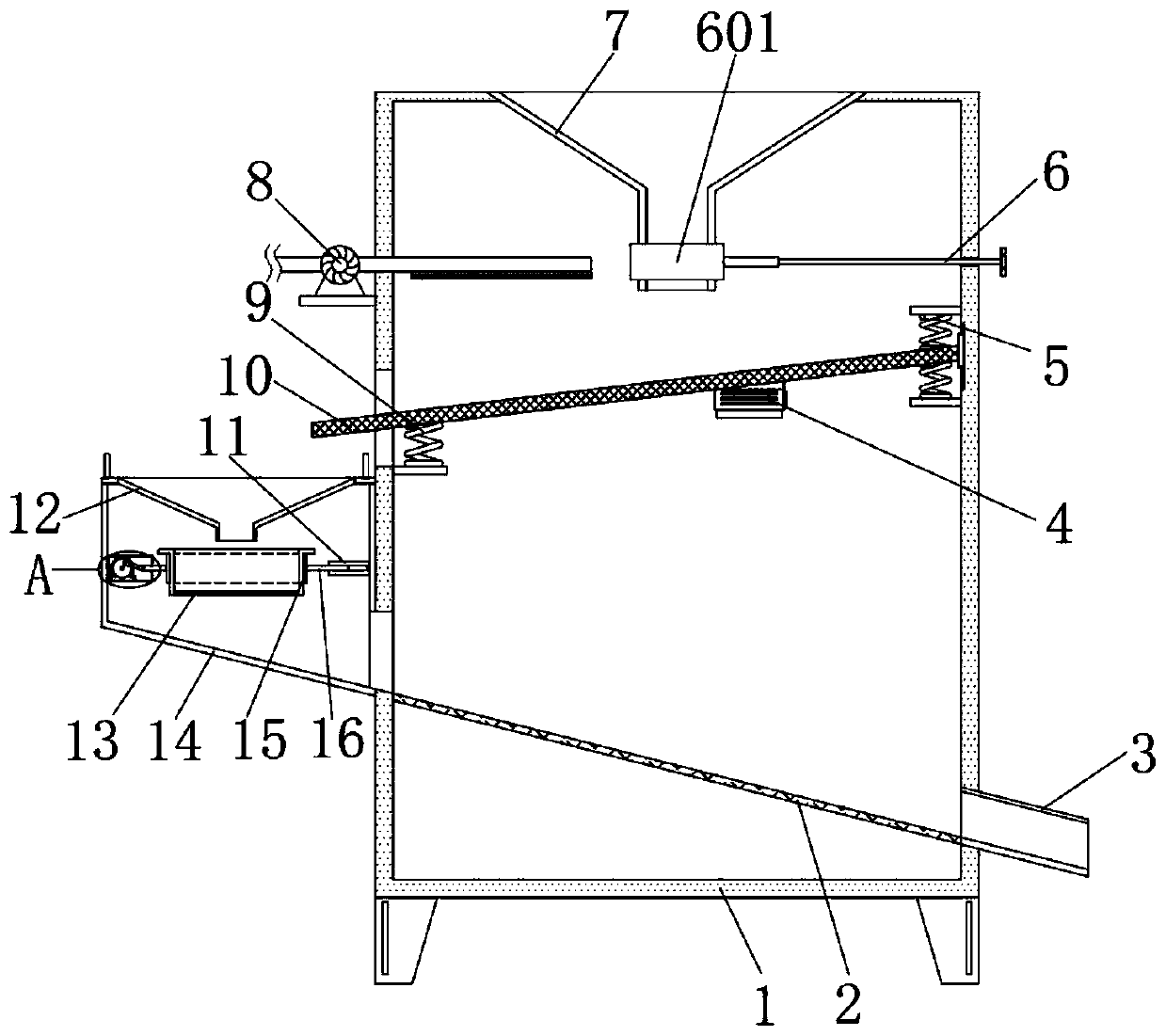

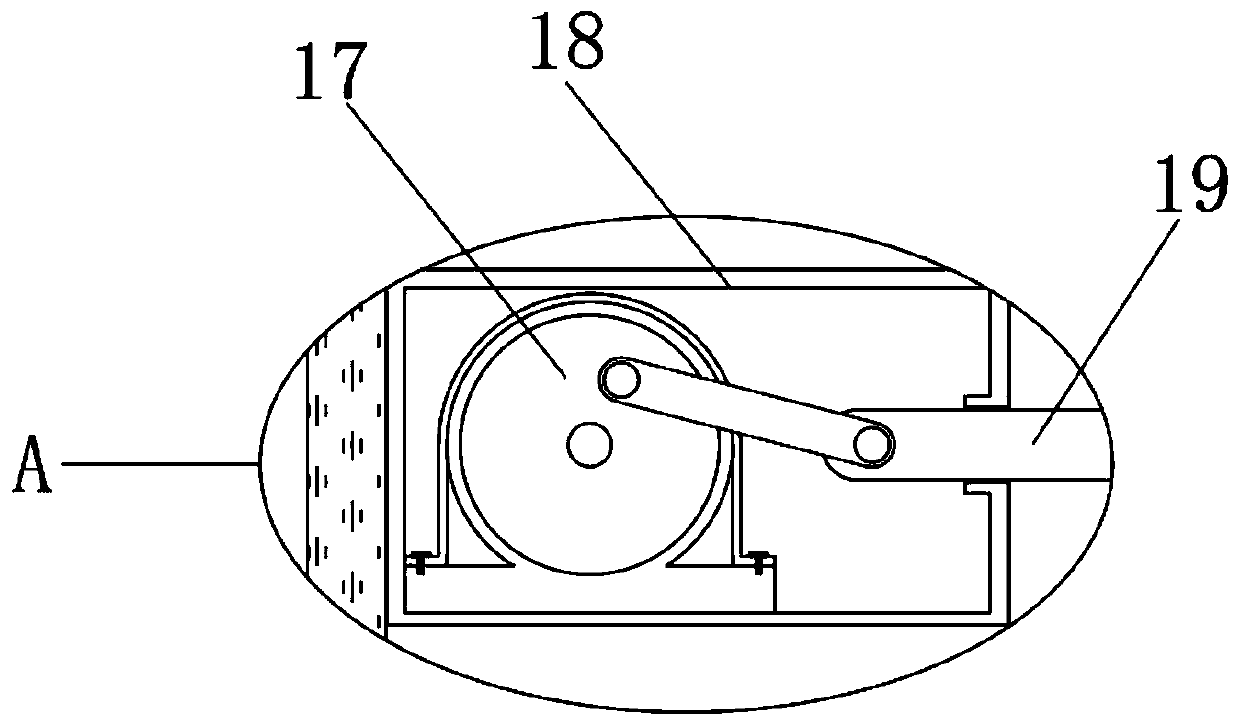

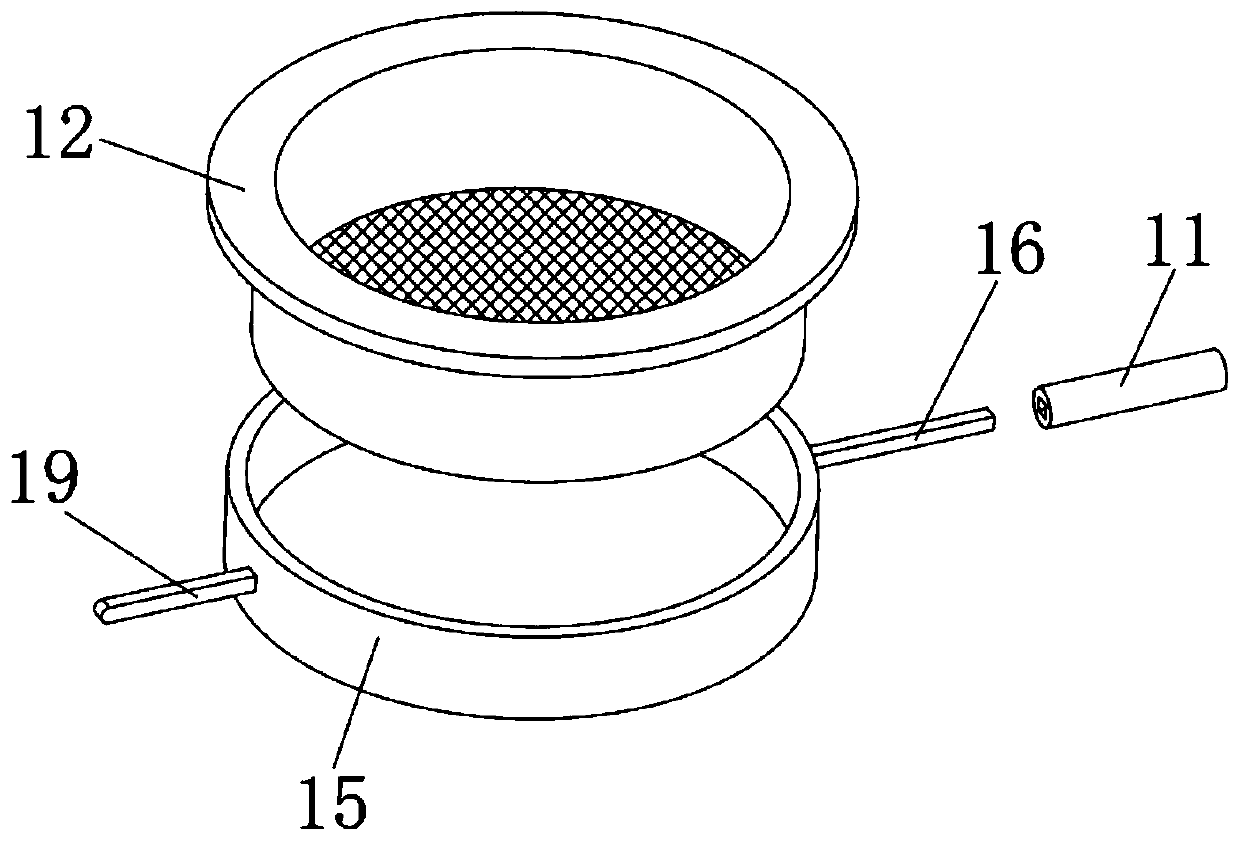

InactiveCN103722352AControl the feeding speedPrevent feed rateMetal working apparatusTransmission beltInductor

The invention relates to a full-automatic pipe clamp and nail assembling machine and belongs to the technical field of machines. The full-automatic pipe clamp and nail assembling machine comprises a nail disc (1), a pipe clamp disc (2), material channels (3), inductors (4), an eccentric wheel (5), a pipe clamp material receiving die (6), a poking disc (7), a main shaft frame (8), a ratchet wheel (9), a connecting rod (10), an adjusting disc (11), a transmission belt wheel (12), bevel gears (13) and bearing pedestals (14). The full-automatic pipe clamp and nail assembling machine is provided with two vibration discs which are the nail disc (1) and the pipe clamp disc (2) respectively. Nails and plastic pipe clamps enter the two material channels (3) respectively through the nail disc (1) and the pipe clamp disc (2), the two inductors (4) are arranged above the two material channels (3) respectively, and the nails are conveyed along the material channels (3) and arranged on the poking disc (7) side by side. The full-automatic pipe clamp and nail assembling machine is used for automatically assembling the plastic pipe clamps and the nails and high in working efficiency and automation degree and easy and convenient to operate.

Owner:TIANJIN LONGYIDA MACHINERY MFG

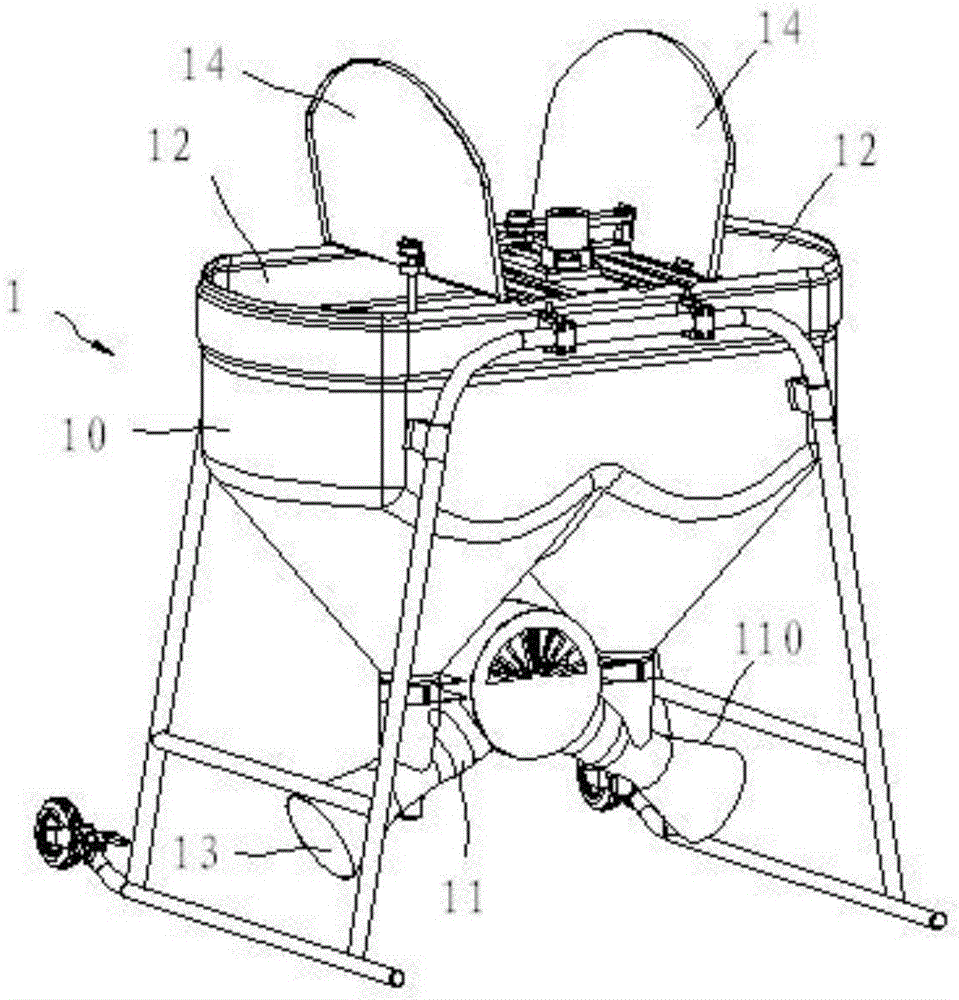

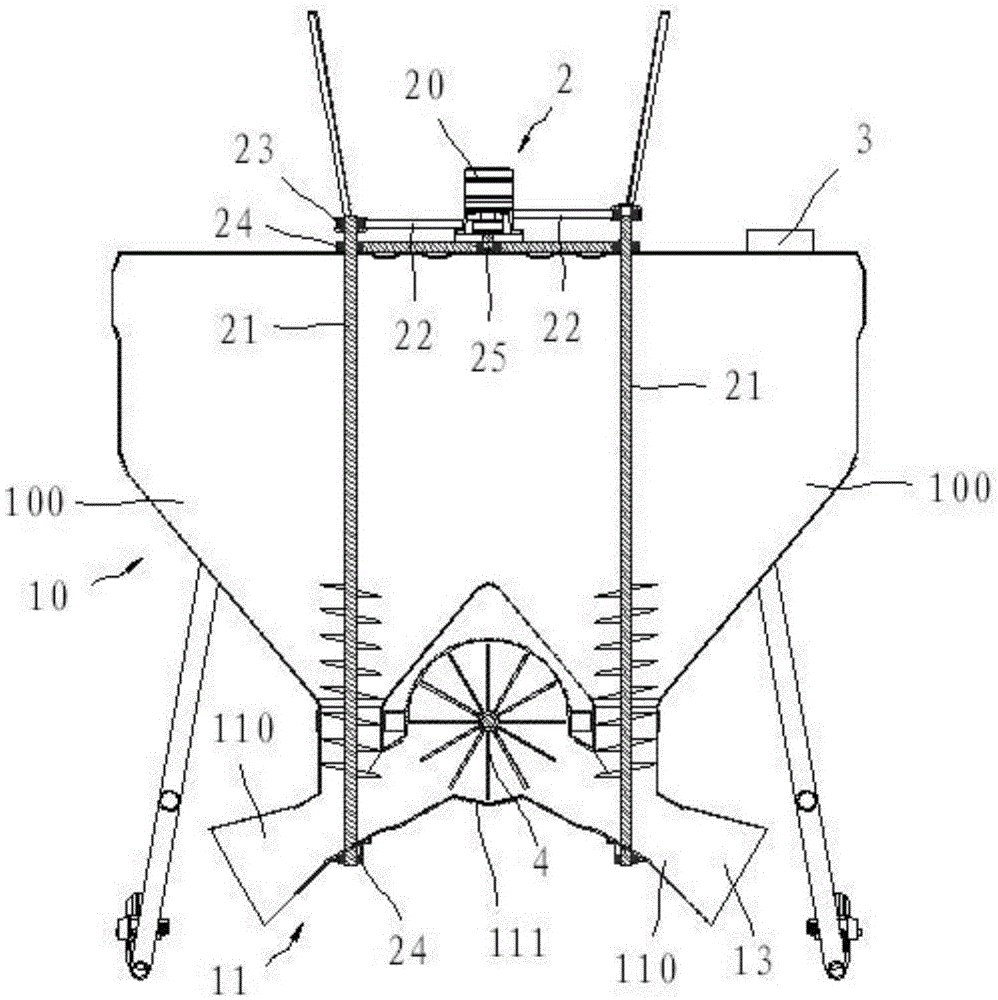

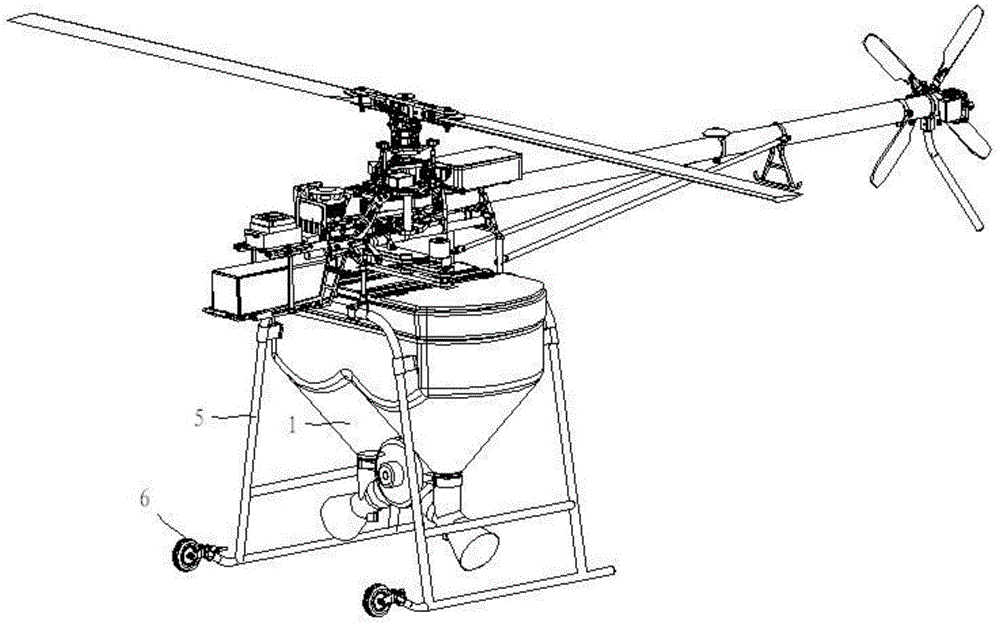

Dusting device and flying dusting device

PendingCN106628184AControl the feeding speedThe control unit controls the feeding speedAircraft componentsLaunching weaponsEngineeringMechanical engineering

The invention discloses a dusting device and a flying dusting device. The dusting device comprises a material cylinder, a material feeding mechanism and a control unit. The material cylinder comprises a primary material tank and a secondary material tank which communicate with each other. The material feeding mechanism comprises at least one screw shaft which is used for conveying the material in the primary material tank to the secondary material tank, and one motor which is coupled with the screw shaft. The control unit controls the material feeding speed of the screw shaft through the motor. At least one material discharge hole is formed in the secondary material tank. A fan is installed in the secondary material tank for blowing the material in the secondary material tank out of the material discharge hole. The dusting device has the advantages that the control unit is used for controlling the rotation speed of the rotation shaft, thus being capable of controlling the material feeding speed of the screw shaft, and attaining the predicted requirement, and the motor can drive two or more screw shafts to feed the material simultaneously, thus enhancing the dusting uniformity to attain the goal of uniform dusting.

Owner:SHENZHEN HI TECH NEW AGRI TECH CO LTD

High-efficient crushing device for petroleum coke

ActiveCN106861875AControl the feeding speedFast cutting speedGrain treatmentsElectric machineryPetroleum

The invention relates to a crushing device for petroleum coke, in particular to a high-efficient crushing device for petroleum coke. The invention aims to solve the technical problem of providing the high-efficient crushing device for the petroleum coke which is simple for operation, good in crushing effect and convenient for use. For solving the above technical problem, the invention provides the high-efficient crushing device for the petroleum coke which comprises a bottom plate, first support rods, a collection frame, a crushing box, a support plate, a crushing frame, a screen plate, a first crushing device, a first discharging hopper, a second discharging hopper and the like, wherein four corners of the top of the bottom plate are all vertically connected with the first support rods in a bolt connection mode; the collection frame is arranged on the top of the bottom plate among the four first support rods; the petroleum coke is crushed by the first crushing device, a second crushing device and third crushing teeth; and crushing of the petroleum coke can be realized by only starting a first motor, a second motor and a cylinder manually.

Owner:弘润石化(潍坊)有限责任公司

Agricultural crop seed selection and screening device

InactiveCN113102230AControl the feeding speedUniform feedingSievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses an agricultural crop seed selection and screening device, and relates to the technical field of agricultural instruments. Aiming at the problems that manual selection is mostly adopted for seed screening, time and labor are wasted, the efficiency is low, selected seeds cannot be uniform in particle, and when an existing screening device is used for screening, due to non-uniform and uncontrollable species discharging, the screening effect and efficiency are non-ideal, the following scheme is currently provided. According to the following scheme, side plates are welded to the two ends of a bottom plate, two third rotating shafts are rotationally connected to the left side of the side plate on the right side, a second box body is welded to the top of the bottom plate, a first box body is welded to the right side of the inner wall of the top of the second box body, and the inner wall of the left side of the first box body is rotationally connected with a conveying disc. According to the device, the discharging speed of seeds can be controlled by adding the conveying disc, discharging is uniform, seeds with different sizes can be screened by adding two screens with meshes with different sizes, and the device is convenient to use, high in practicability and convenient to popularize.

Owner:郑金聪

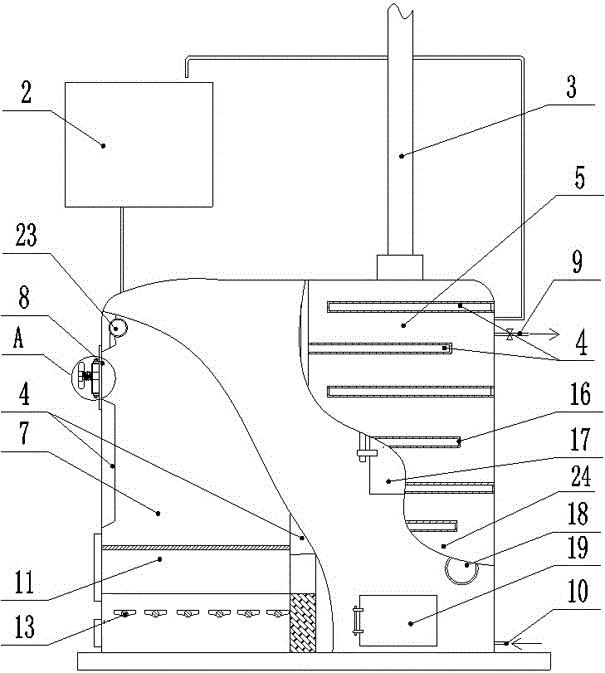

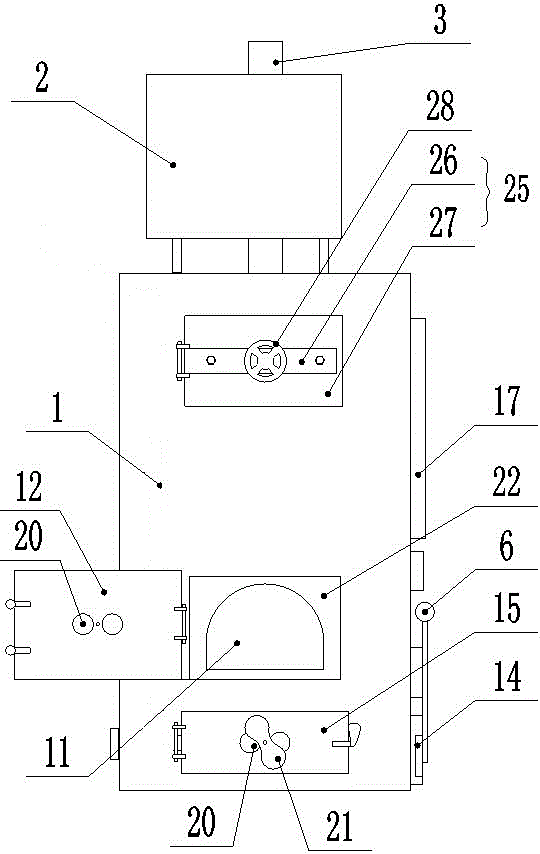

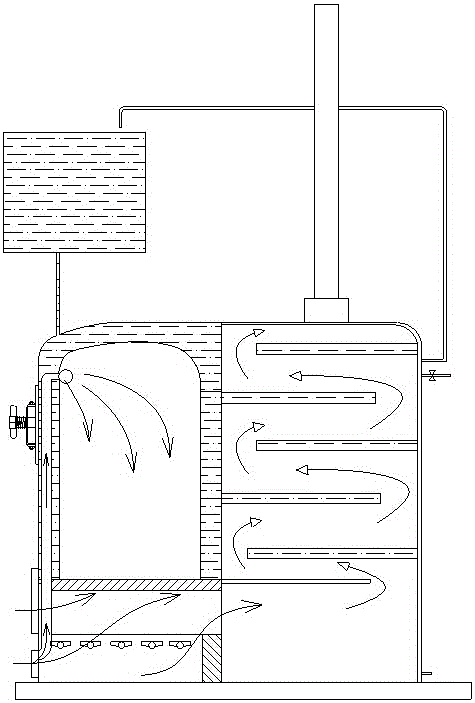

Normal-pressure smoke-free environment-friendly combustion furnace

ActiveCN106322439ABurn fullyControl the feeding speedLighting and heating apparatusStove/ranges for heating waterCombustion chamberEngineering

The invention discloses a normal-pressure smoke-free environment-friendly combustion furnace and relates to the technical field of combustion furnaces. The combustion furnace comprises a furnace body and a water jacket, wherein the water jacket is arranged inside the furnace body and is communicated with a water tank; a rotary smoke flue connected with a chimney is arranged at the upper part of the back of the furnace body; a feeding opening communicated with a dry distillation chamber is formed in the upper part of the side wall of the furnace body; a water discharging opening and a water returning opening are formed in the back of the furnace body; a combustion kiln is arranged at the lower part of the dry distillation chamber; the combustion kiln is horizontal; the longitudinal section of the combustion kiln is arched; one end of the combustion kiln is fixed at the front of the furnace body; a kiln door is formed in an open end; the other end of the combustion kiln is fixed in the middle of the furnace body; gaps are formed between two sides of the combustion kiln and the inner wall of the dry distillation chamber; the back of the combustion kiln is communicated with a secondary combustion chamber; a furnace grate is arranged under the combustion kiln; a furnace dust cleaning mechanism connected with the furnace grate is arranged on the outer side of the furnace body; a main dust cleaning door with an air inlet is arranged under the furnace grate. According to the normal-pressure smoke-free environment-friendly combustion furnace, the fuel can be dispersed in the dry distillation chamber and the furnace grate by virtue of the combustion kiln; through the adoption of the combustion kiln and the secondary combustion chamber, the fuel can be fully combusted; through the adoption of the S-shaped rotary smoke flue, the dust emission is reduced; the purposes of saving energy, avoiding smoke and protecting environment can be achieved.

Owner:SHIJIAZHUANG CHUNYAN HEATING EQUIP

Full-automatic nail polishing machine

ActiveCN104440466AAvoid harmEasy to operateEdge grinding machinesGrinding feedersEngineeringDistributor

The invention relates to a full-automatic nail polishing machine which comprises a vibration disc feeder, a horizontal nail polishing machine tool body and a vertical nail polishing machine tool body, wherein a front panel is arranged on the vertical nail polishing machine tool body; an automatic nail arranging distributor, a transmission screw rod and a transmission motor are fixed on the front panel; the automatic nail arranging distributor is connected with a discharging port of the vibration disc feeder; a discharging port of the automatic nail arranging distributor is propped against the outer thread at one end of the transmission screw rod; a discharging port is formed in the other end of the transmission screw rod; a grinding wheel and a grinding wheel transmission motor are fixed on the horizontal nail polishing machine tool body; a polishing port is formed in the vertical nail polishing machine tool body and below the transmission screw rod; the polishing surface of the grinding wheel extends into the polishing port. The full-automatic nail polishing machine is convenient to operate, and during the operation, the nails to be polished are put in the vibration disc feeder and then starting is carried out on the polishing machine, so that the labor intensity of manual emptying and polishing is decreased, the polishing efficiency is improved, the harm from the dust to the operators is avoided, the approximately same length and shape of the polished nails are realized, and the polishing quality is improved.

Owner:山东佰盛能源科技有限公司

Concrete stirrer

InactiveCN106626065AReduce the presence of air bubblesEnsure mixing qualityDischarging apparatusMixing operation control apparatusCouplingPulp and paper industry

Owner:唐健发 +1

An experiment device used for preparing environment-friendly spray coating

InactiveCN107913638AQuality improvementGood control over mixing speedRotating receptacle mixersTransportation and packagingSpray coatingEngineering

The invention relates to an experiment device, particularly an experiment device used for preparing environment-friendly spray coating. A technical problem to be solved is to provide an experiment device which is used for preparing environment-friendly spray coating and which is capable of controlling a raw material ratio well and slowly adding raw materials. To solve the problem, the experiment device is provided and includes a mounting rack, supporting bars, an annular slide rail, first slide blocks, a frame, a first material discharging pipe, and the like. The supporting bars are disposed at the inner bottom of the mounting rack in a bilaterally symmetrical manner. Tops of the supporting bars are connected to the annular slide rail. The inside of the annular slide rail is provided withthe first slide blocks in a slide connection manner. Tops of the first slide blocks are connected to the frame. The device achieves effects of controlling a raw material ratio well and slowly adding raw materials. A first motor rotates clockwise to drive the frame to rotate clockwise, and a second motor rotates anticlockwise to drive stirring bars to rotate anticlockwise, thus making a raw material mixing speed higher.

Owner:李四英

Uniform heating drying device for down processing,

InactiveCN109059460AIncrease production lossIncrease production costDrying machines with non-progressive movementsDrying solid materialsElectric machineryDrive motor

The invention relates to the technical field of down processing auxiliary devices, in particular to a uniform heating drying device for down processing. The device comprises a drying box, a feeding port is formed in the upper part of the drying box, a uniform material falling mechanism is arranged below the feeding port, the uniform material falling mechanism is connected with a driving motor, anda material pushing mechanism is arranged on the uniform material falling mechanism; and a drying net is arranged below the uniform material falling mechanism, a plurality of electric heating pipes are arranged below the drying net and located at the bottom of the drying box, a discharging port is formed in the side wall of the drying box on the side edge of the drying net, and a collecting box isarranged below the discharging hole. According to the uniform heating drying device, the problems that an existing drying device adopts a boiler to provide hot steam for drying, the drying temperature cannot be adjusted, the heating of the down is caused not to be uniform due to the fact that the spreading thickness of the down is difficult to master, the down is easily damaged, the quality of the down is influenced, and the production loss and the production cost are increased are solved.

Owner:安徽万利达羽绒制品有限公司

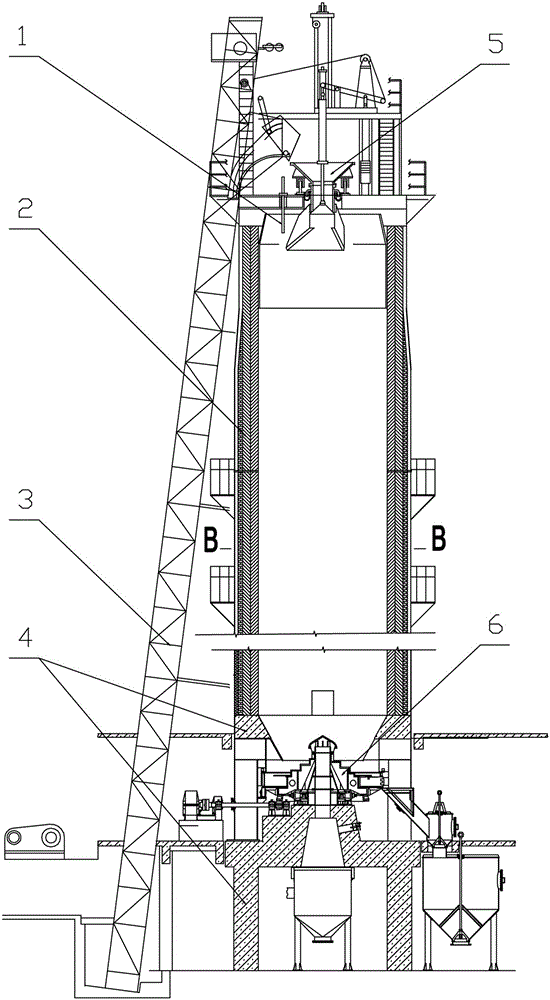

Energy-saving environment-friendly lime shaft kiln

The invention relates to an energy-saving environment-friendly lime shaft kiln with a kiln body. A feeding device is arranged on the outer side of the kiln body, a distributing device is positioned at the top of the kiln body, and a heat-resistant concrete supporting table is poured on the lower portion of the kiln body. A discharging device is arranged at the bottom of the kiln body and located at the middle of the heat-resistant concrete supporting table. The discharging device comprises a spiral cone ash-discharging tower, and a cap is installed at the top of the spiral cone ash-discharging tower, a kiln air inlet channel is arranged at the center of the spiral cone ash-discharging tower, and an external structure of the spiral cone ash-discharging tower is a spiral step structure. A round of secondary supporting plate is arranged on a bottommost layer spiral step of the spiral step structure in a butt joint mode and comprises an upper layer small supporting plate and a lower layer large supporting plate. A surrounding plate is arranged on the periphery of the large supporting plate, a baffle is slantly arranged between the lower layer large supporting plate and the upper layer small supporting plate, an ash receiving tank is arranged on the lower portion of the large supporting plate in a butt joint mode, a material receiving pipe is arranged on the lower portion of a discharging port of the ash receiving tank, and two bin type discharging devices are positioned at the lower end of the material receiving pipe. The energy-saving environment-friendly lime shaft kiln is environmentally friendly, saves energy and is low in underfiring rate, the working conditions in the kiln are stable, and the yield is high.

Owner:HUANGSHI LANTIAN ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP

Quantitative filling frame for constructional engineering

ActiveCN113445750ARealize automatic dischargeSave human effortBuilding material handlingCement mixing apparatusClassical mechanicsStructural engineering

The invention relates to a filling frame, in particular to a quantitative filling frame for constructional engineering. The invention provides a quantitative filling frame capable of controlling blanking, automatically stirring and clamping for constructional engineering. The quantitative filling frame for constructional engineering comprises a connecting barrel, a charging barrel, a discharging mechanism and a stirring intermittent cutting mechanism, wherein the charging barrel for containing concrete is arranged on the upper side of the inner part of the connecting barrel, the discharging mechanism is arranged on the lower side of the charging barrel, and the stirring intermittent cutting mechanism is connected between the connecting barrel and the discharging mechanism. According to the quantitative filling frame for constructional engineering, the stirring intermittent cutting mechanism drives a sliding material blocking plate to move upwards, so that a first spring is compressed, then the stirred concrete falls into the lower side of the connecting barrel from the charging barrel, automatic discharging is achieved, and manpower is saved.

Owner:新疆西泉建设工程有限公司

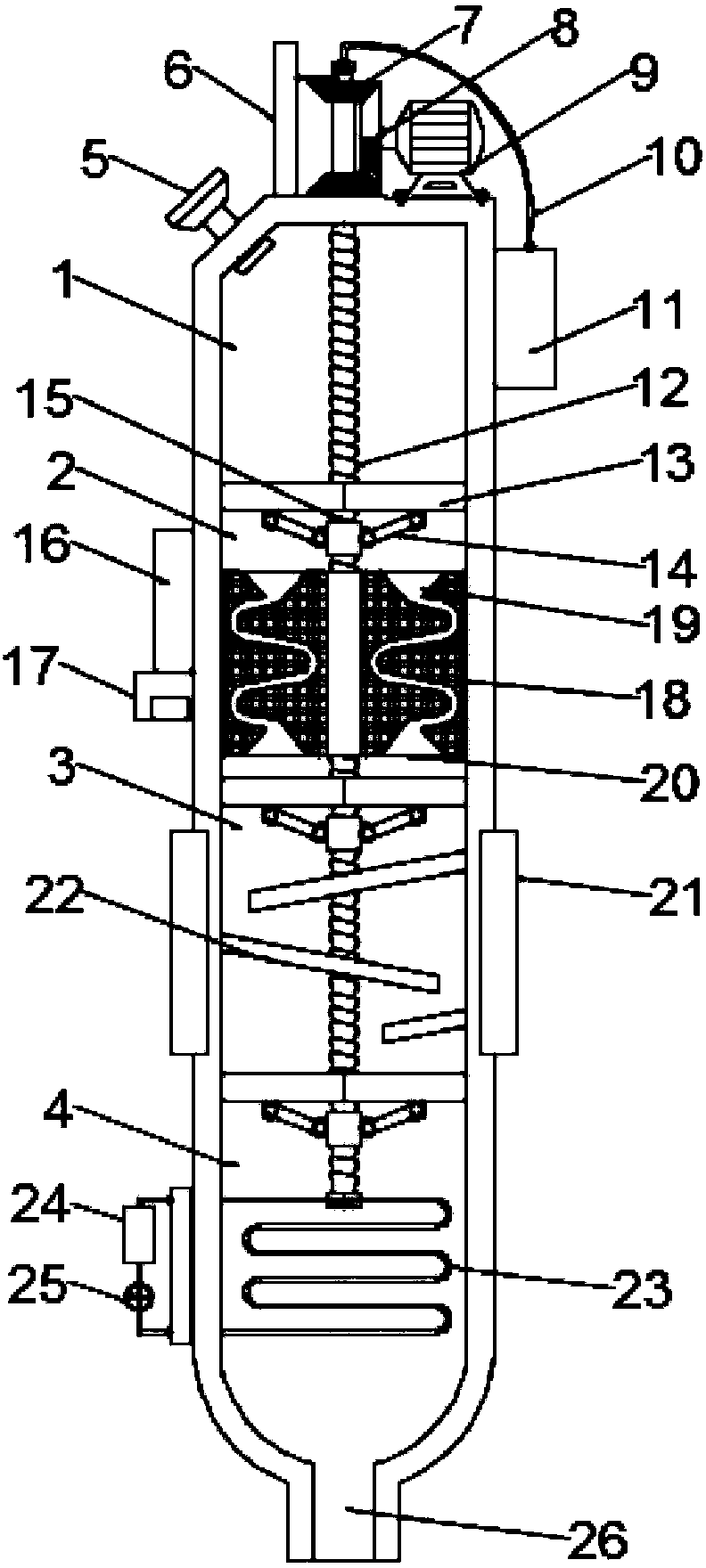

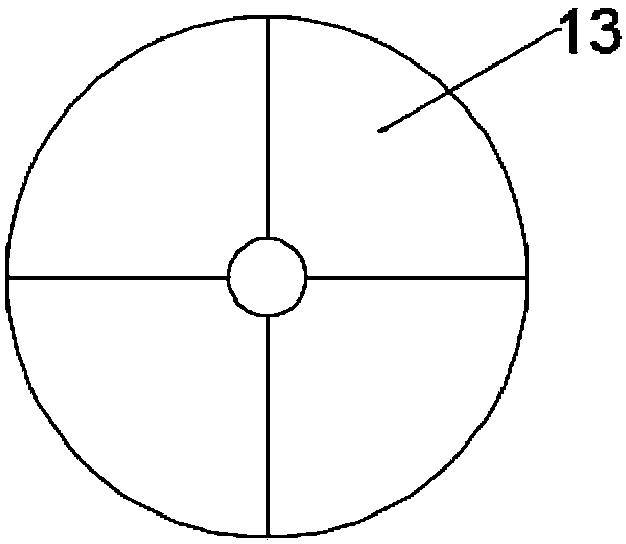

Adjustable chemical reaction synthesis tower

InactiveCN108435110AInnovative designHigh synthesis efficiencyChemical/physical/physico-chemical processesFeed devicesCushioningBevel gear

The invention discloses an adjustable chemical reaction synthesis tower. The adjustable chemical reaction synthesis tower includes a synthesis tower body; a preheating cavity, a heating cavity, a cushioning cavity and a cooling cavity are formed in the inner side of the synthesis tower body sequentially from top to bottom, every two adjacent cavities are separated by a baffle, and the inner side of the synthesis tower body is provided with a threaded rod. The synthesis tower is novel in design, when a motor rotates, an incomplete bevel gear is driven to rotate, when the incomplete bevel gear rotates, reciprocating positive and negative rotation motion of the threaded rod is achieved through intermittent meshing of the incomplete bevel gear and two bevel gears, when the threaded rod rotates, a threaded sleeve is driven to conduct reciprocating up-and-down movement, therefore, reciprocating opening and closing of the baffles are achieved, then the effect of controlling the feeding speedis played, and meanwhile, by controlling the rotational speed of the motor, the opening and closing speed of the baffles can be controlled; the arranged preheating cavity can preheat chemical raw materials, therefore, the subsequent synthesis efficiency is improved, the arranged cushioning cavity can effectively prevent influence caused by the chemical raw materials which suddenly enter a cold environment from a hot temperature state, and the practicability of the adjustable chemical reaction synthesis tower is high.

Owner:肇庆创奇者新能源科技有限公司

Improved fertilizing apparatus for agricultural plantation

InactiveCN107873204AImprove playbackSpread fertilizer over a large areaFertiliser distributersAgricultural engineeringMaterial distribution

The invention discloses an improved fertilizing apparatus for agricultural plantation. The fertilizing apparatus comprises a material box, a vibration feed device, an observation window, a material dispersing device, a battery framework, a battery, a power supply switch, a material distribution pipe structure, a fixing buckle, a sponge pad, straps, and a suspension loop. The vibration feed deviceis installed in the middle-upper part of the material box. The material dispersing device is embedded in the right-lower part of the material box. The battery framework is embedded in the left-lower part of the material box. The battery is installed in the battery framework. Baffle plates are crossly distributed so that fertilizers can be conveniently dispersed in a material distribution frame, alarge-scale fertilizing effect is realized; a vibration screen is arranged in a feed pipe and is connected to a vibration motor so that blocks in fertilizers can be broken to prevent a discharge pipefrom being obstructed; the observation window is arranged on the right side of the front surface of the material box, people can conveniently observe the materials in the material box, and the fertilizing apparatus is very convenient.

Owner:ZHANGJIAGANG DAXIN LIQUN FARMER SPECIALIZED COOP

Crushing machine capable of achieving sufficient smashing

The invention provides a crushing machine capable of achieving sufficient smashing. Firstly, a material pressing assembly is arranged, therefore, in the material cutting process, a material pressing effect can be well achieved, and a preliminary cutting effect also can be well achieved; secondly, an adjusting air cylinder in a feeding assembly is arranged, therefore, the size of a feeding port canbe well adjusted, the effect of controlling the feeding speed is achieved, and the feeding port can be closed at the crucial moment; thirdly, vibration motors in a material screening assembly are arranged, therefore, vibration of a screen mesh is well achieved, and then crushed material screening is convenient; fourthly, the screen mesh is arranged in sliding rails, therefore, materials which arenot sufficiently crushed can be crushed for the second time, and then the crushing quality is guaranteed; and lastly, a first camera and a second camera are arranged, therefore, the effect of well monitoring the interior can be achieved, the problems of the screen mesh and material cutting can be found in time, and then the next-step work can be conveniently conducted.

Owner:洛阳宏润塑业有限公司

Paper feeding mechanism of paperboard pasting machine

ActiveCN103662887ASimple structureGood synchronizationRegistering devicesArticle feedersPaperboardEngineering

The invention relates to a paper feeding mechanism of a paperboard pasting machine. The paper feeding mechanism comprises a frame. At least two conveying belts driven by a power source are arranged on the frame and are separated from each other. Conveying outlets of the conveying belts face a main unit of the paperboard pasting machine. Retainers capable of moving up and down are arranged in the space between the conveying belts, and up and down movement routes of the retainers pass through conveying planes of the conveying belts. The retainers are connected with transmission control devices for driving the same to move up and down. The transmission control devices are arranged below the conveying planes of the conveying belts. The conveying belts and the transmission control devices cooperate with the main unit of the paperboard pasting machine in working, and paper on the conveying belts is prevented from moving by up and down movements of the retainers. As the up and down movements of the retainers are controlled by the transmission control devices which cooperate with the main unit of the paperboard pasting machine in working, released paper on the conveying belts continue to move into the main unit to reach a working station rightly. The paper feeding mechanism has the advantages of convenience and flexibility and high stability in paper feeding.

Owner:温州旭弘机械有限公司

Peanut cleaning and screening machine

PendingCN107321621AControl the feeding amountControl the feeding speedSievingGas current separationElectric machineryStructural engineering

A peanut cleaning and screening machine comprises a machine frame. The upper portion of the machine frame is provided with a feeding hopper and a winnowing device, the middle of the machine frame is provided with a vibration screening device, and a conveying device located at an outlet of the vibration screening device is arranged on the machine frame; and a discharging mechanism is arranged at an outlet of the feeding hopper and comprises a stirring rotating barrel, the outer surface of the stirring rotating barrel is provided with stirring baffles, and the outer edge of each stirring baffle is provided with a fur layer. The vibration screening device comprises a shell, a first screen plate and a second screen plate are arranged in the shell in a spaced mode in the vertical direction, springs are connected between the edge of the first screen plate and the edge of the second screen plate, the rear end of the shell is provided with a first impurity discharging opening, a material discharging opening and a second impurity discharging opening, and the side portion of the shell is provided with a vibration motor. The winnowing device comprises a self-suction fan arranged on the machine frame. The peanut cleaning and screening machine is reliable in working, convenient and fast to operate, good in screening effect, high in working efficiency and capable of effectively removing impurities in peanut materials.

Owner:正阳县豫丰机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com