Full-automatic welding strip cutting bender

A fully automatic, bending machine technology, applied in metal processing, etc., can solve the problems of defective products in the length specification of the welding strip, low production cost of work efficiency, and difficult counting of the number of welding strips, etc., to achieve novel appearance design, Reduce labor intensity, friendly interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

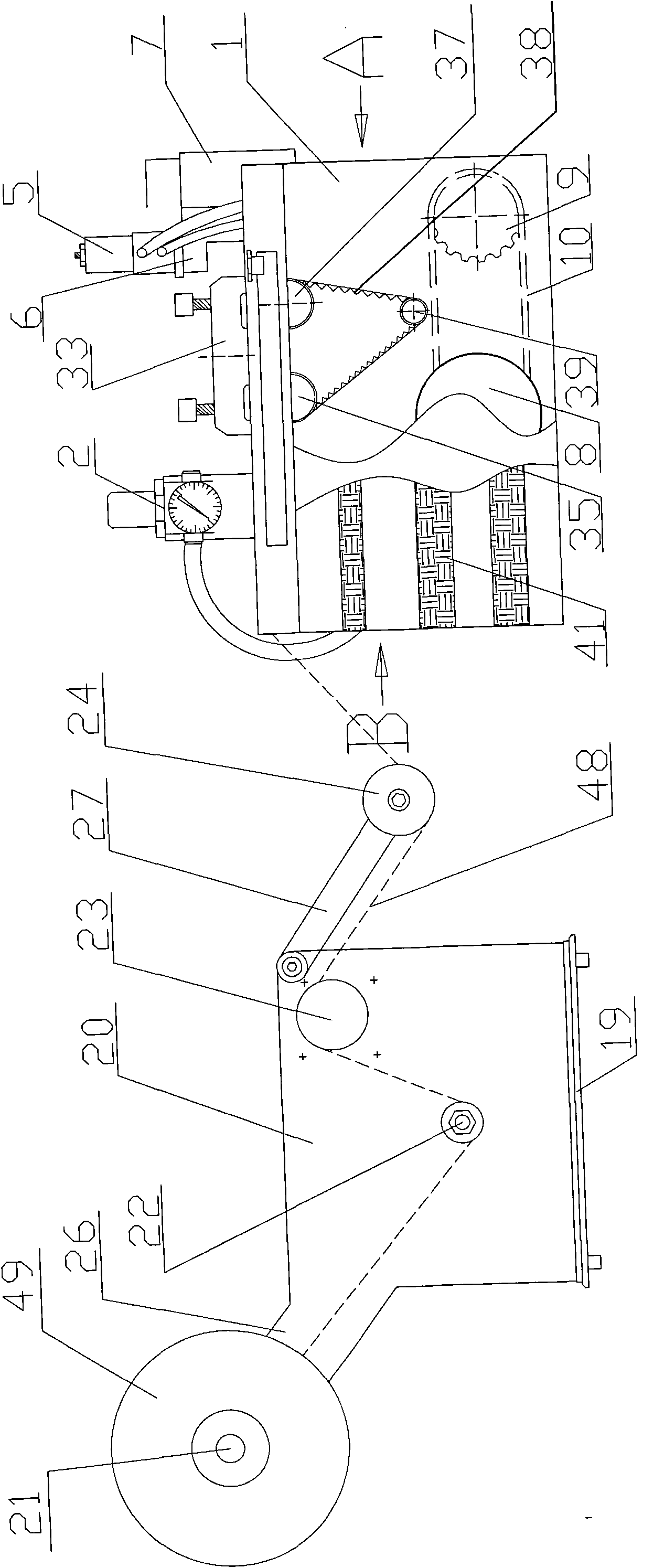

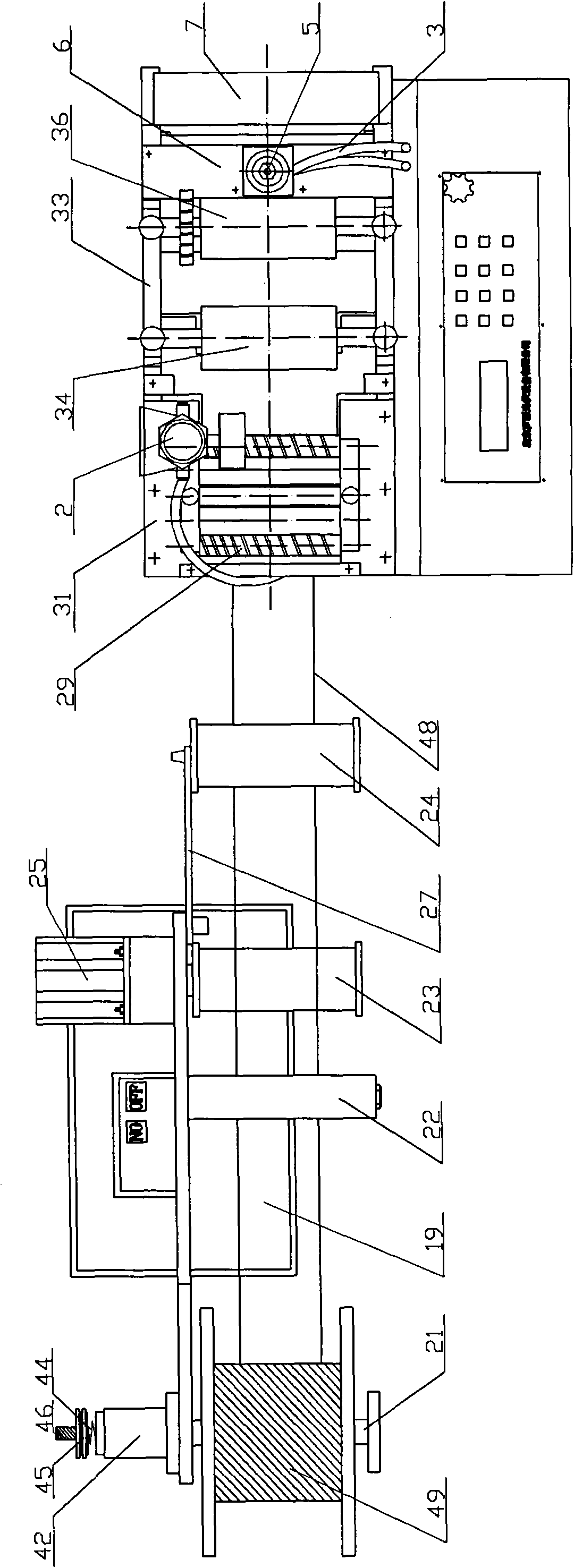

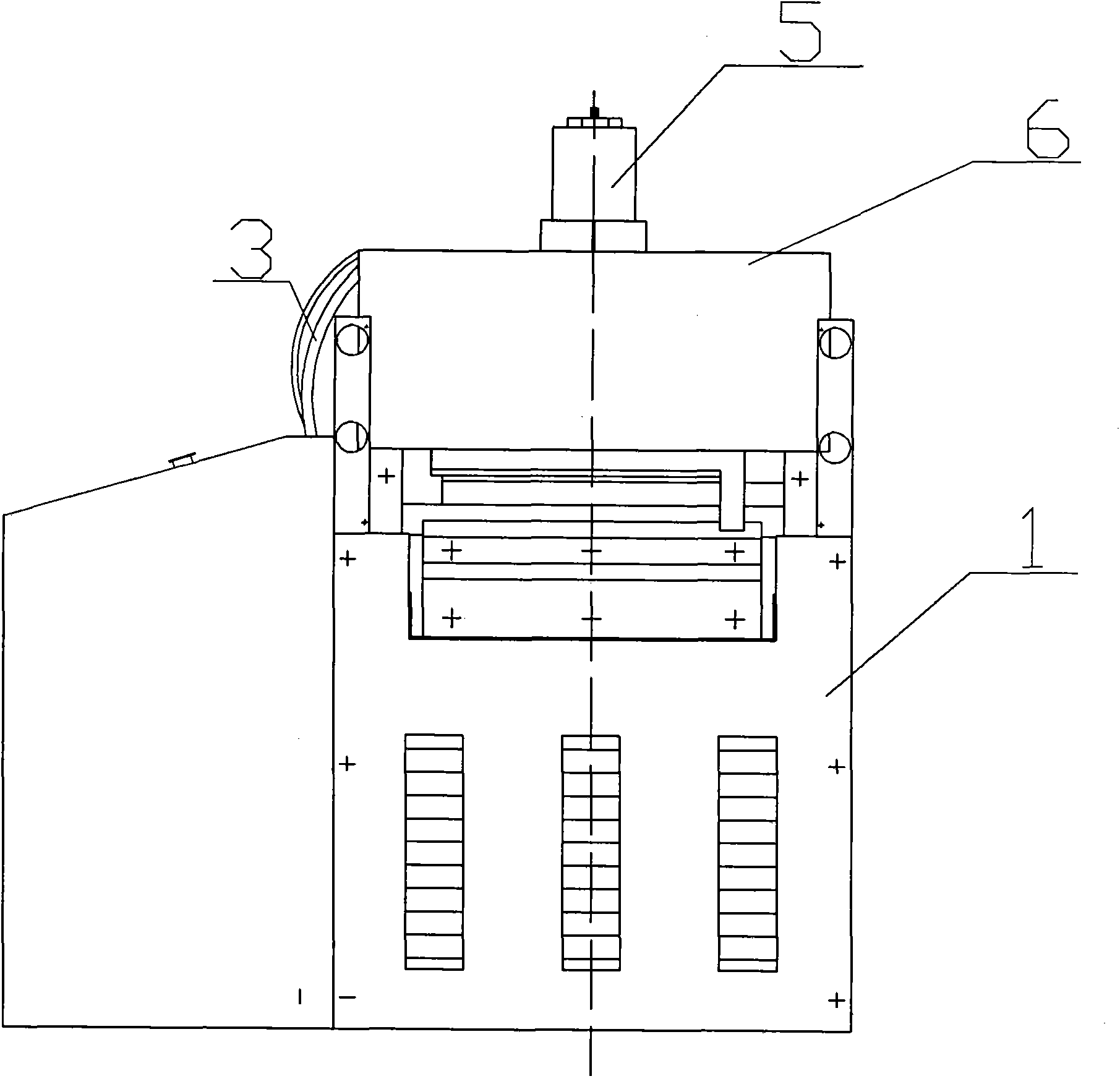

[0033] like Figures 1 to 7 As shown, the fully automatic welding strip cutting and bending machine of the present invention includes a feeding mechanism, a leveling mechanism, a bending mechanism, a cutting mechanism and a box body 1,

[0034] The bending mechanism includes an oil-water separator 2 fixed on the side of the box body 1, a pipeline 3, a bending frame 4, a cylinder 5 and a cylinder frame 6, one end of the oil-water separator 2 is connected to the air source, and the other end of the oil-water separator 2 passes through the pipeline 3 is connected with the cylinder 5, the cylinder 5 is fixed on the cylinder frame 6, the cylinder shaft 47 of the cylinder 5 is connected with the bending track frame 4, and the cylinder frame 6 is fixed on the fixed frame 7 at the discharge end of the casing 1.

[0035] The cutting mechanism includes a motor 8, an eccentric sprocket 9, a chain 10, an eccentric shaft 11, a lower cutter 12 and an upper cutter 13, the lower cutter 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com