Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Improve the workshop environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

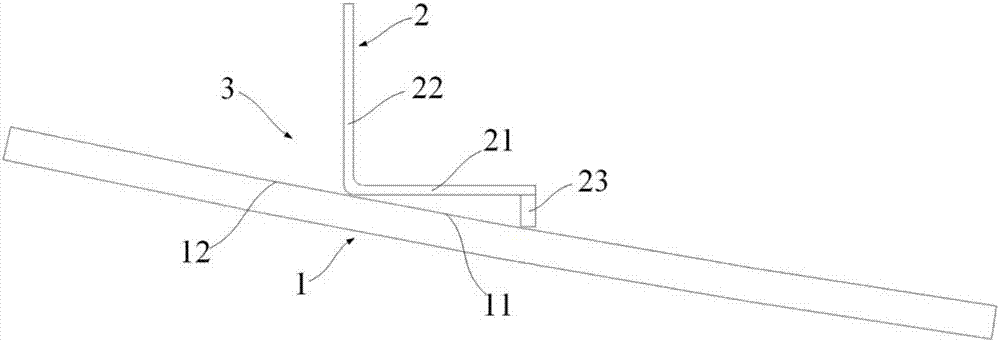

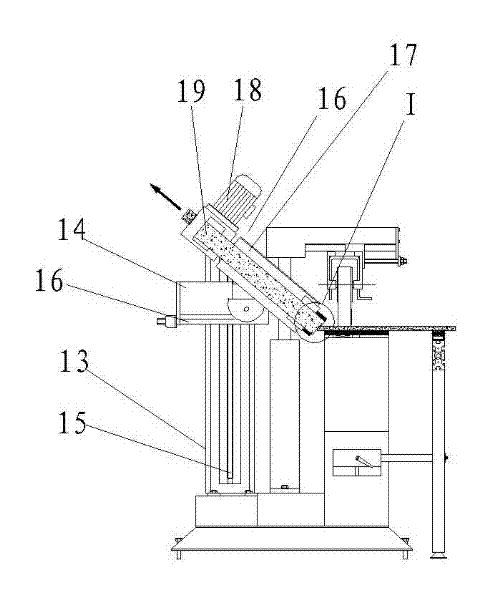

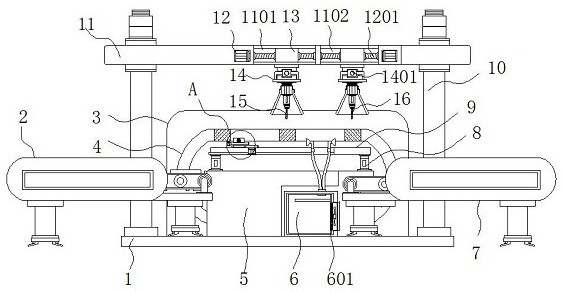

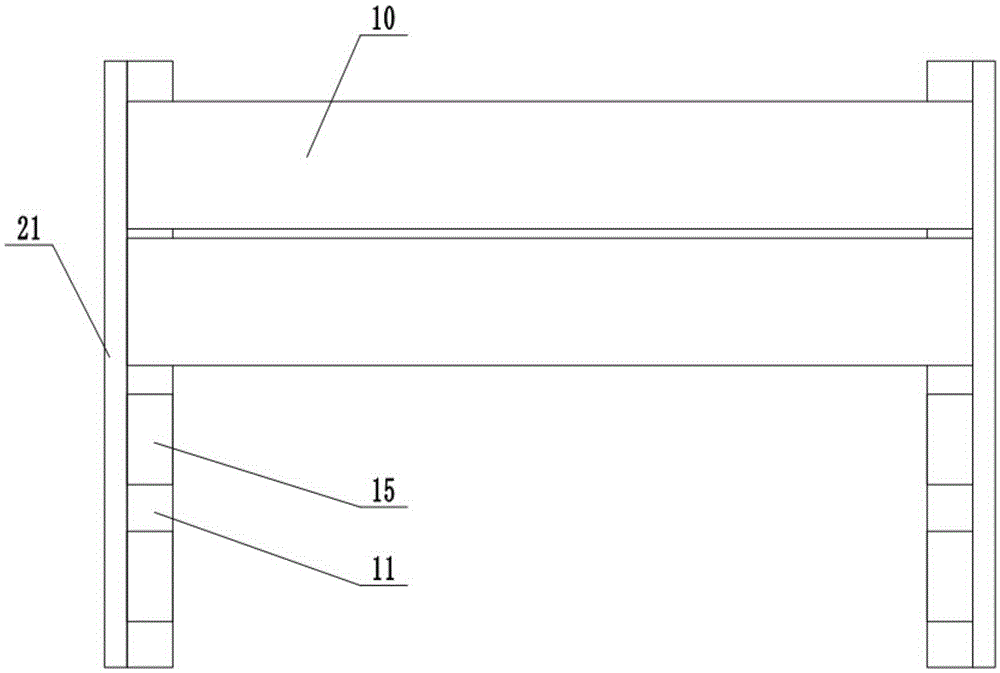

Double-S-curve soft drafting device

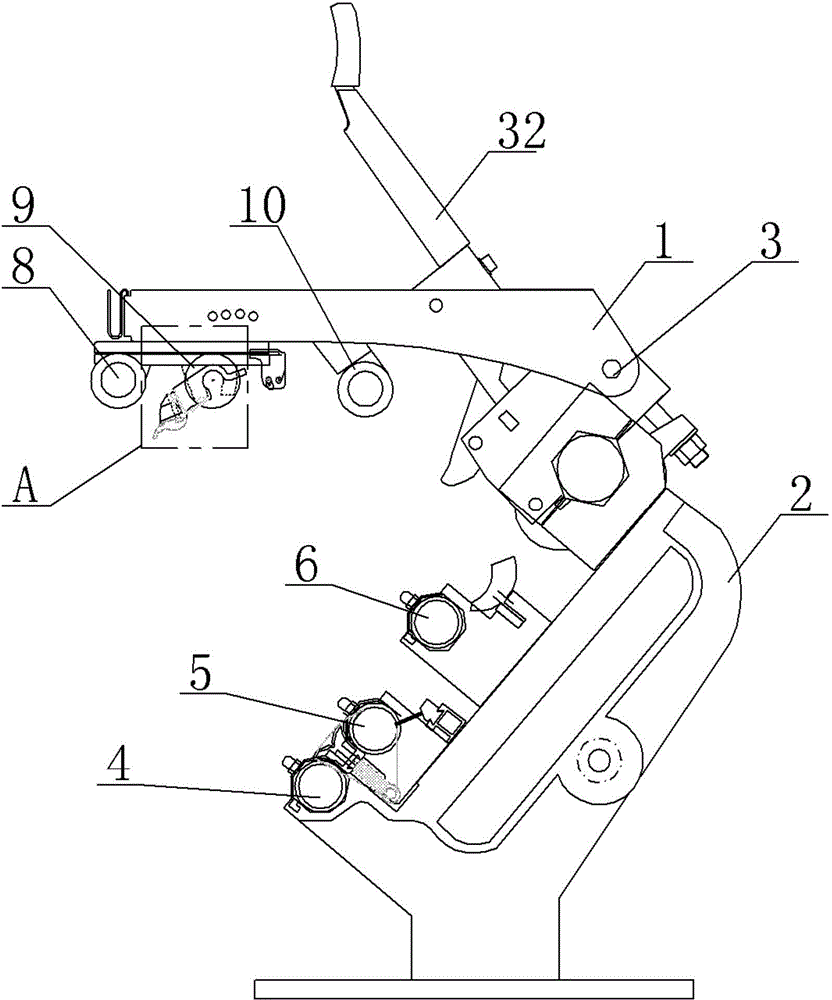

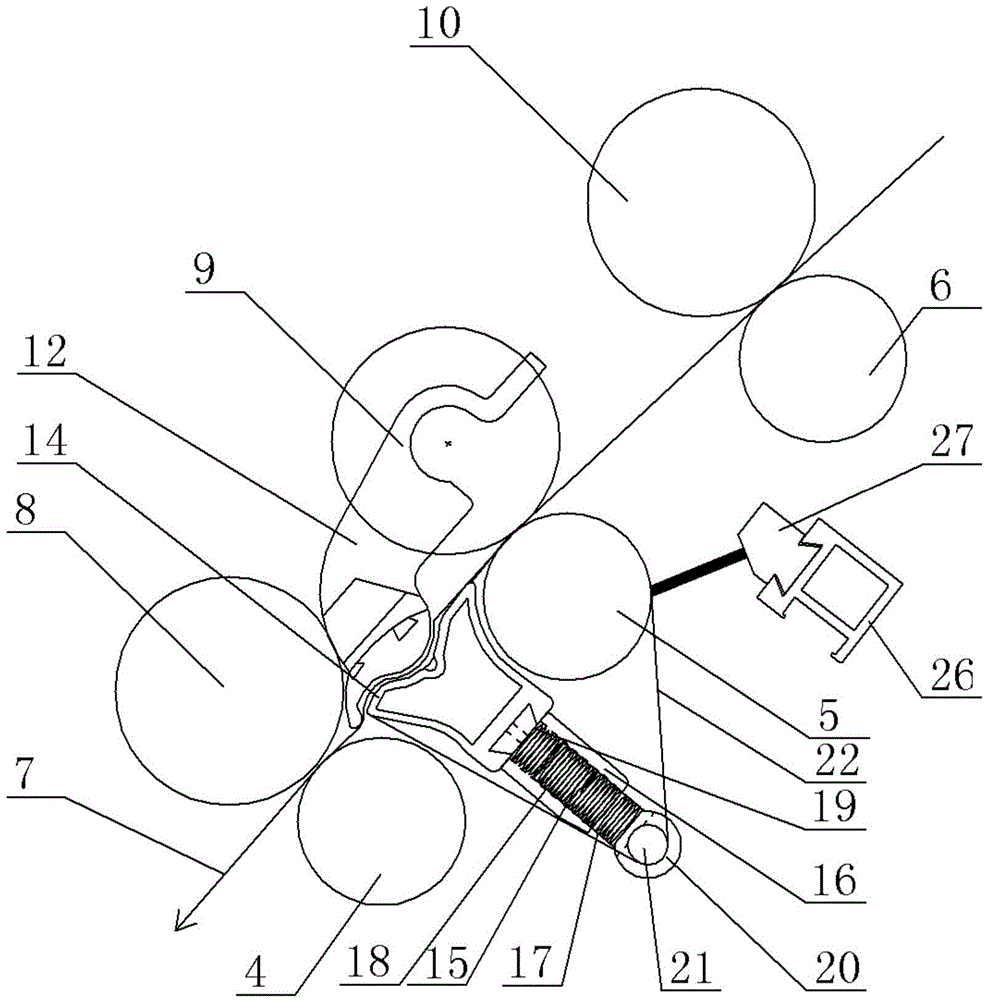

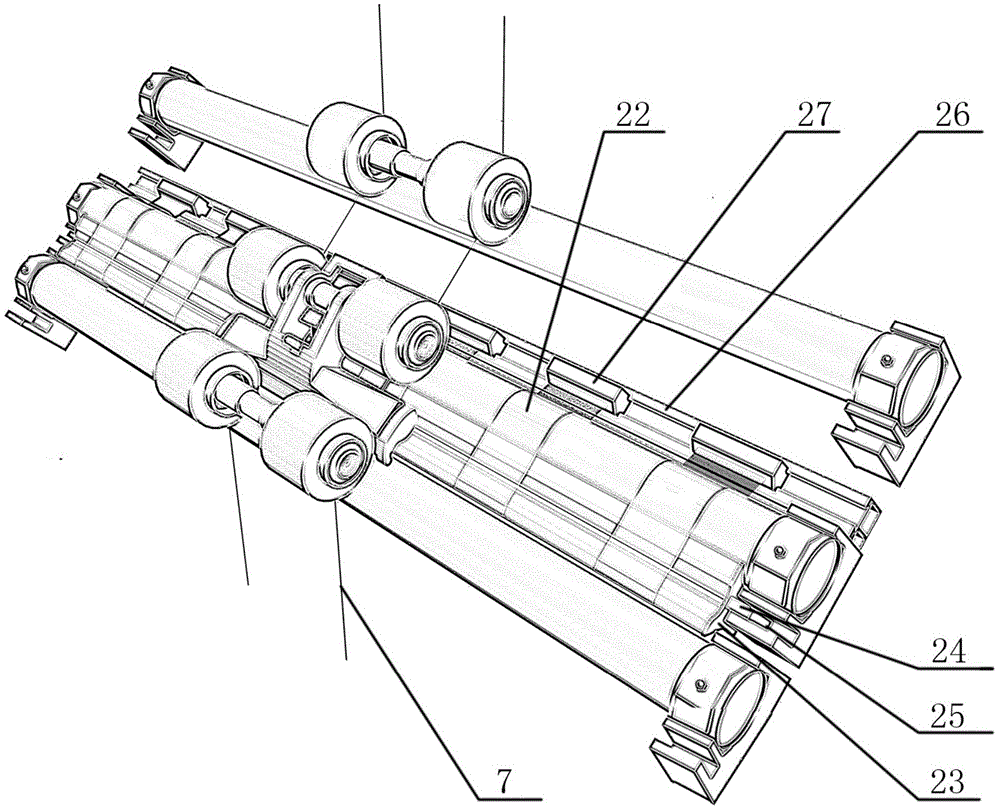

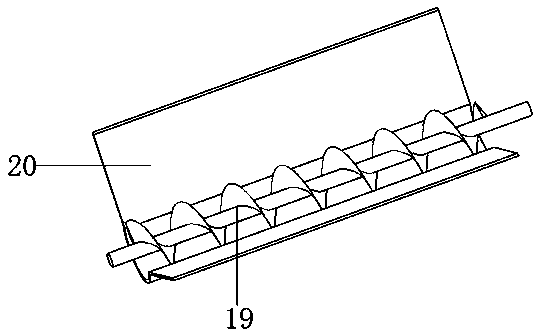

The invention provides a double-S-curve soft drafting device. According to the double-S-curve soft drafting device, the rigid-flex friction force field of a lattice apron and double-S-curve control system mode is utilized to control movement of fiber, the additional friction force field distribution in a main drafting region is more reasonable, and based on the same raw cotton, the yarn forming quality level is obviously superior to that of traditional ring spinning and compact spinning. The double-S-curve soft drafting device comprises an upper support and a lower base. One end of the upper support is connected to one end of the lower base through a rotating shaft. The upper end face of the lower base is sequentially provided with a front roller, a middle roller and a rear roller. The advancing direction of the yarn is set to be the front. The positions, corresponding to the front roller, the middle roller and the rear roller, of the lower end face of the upper support are provided with a front leather roller, a middle leather roller and a rear leather roller. The double-S-curve soft drafting device is characterized in that a center shaft of the middle leather roller is sleeved with a nylon support, the rear portion of the nylon support is arranged on the center shaft of the middle leather roller in a sleeving mode, the front portion of the nylon support is provided an S-curve plate, and the lower end face of the cross section of the S-curve plate is an S-shaped curve surface.

Owner:中科德瑞克科技(东莞)有限公司

Semi-aromatic polyamide resin and preparation method thereof

The invention discloses semi-aromatic polyamide resin and a preparation method thereof. The semi-aromatic polyamide resin comprises, in parts by weight, 20 to 80 parts of aromatic / aliphatic dibasic acid, 20 to 80 parts of aliphatic diamine, 0.05 to 1 part of hindered phenol or hindered amine, 0.01 to 0.06 part of a catalyst, 30 to 160 parts of deionized water, wherein in the aromatic / aliphatic dibasic acid, the mass ratio of the aromatic dibasic acid to the aliphatic dibasic acid is 1:(0-9). A hindered phenol or hindered amine chemical group is connected to the tail end of a polyamide molecular chain through a chemical bond; the loss of the hindered phenol or hindered amine chemical group in a low-temperature environment is reduced; by adding a processing aid in the later-stage modification processing process, the phenomenon of heat stabilizer agglomeration or non-uniform dispersion during the modification does not exist, and the production cost is reduced, so that the product has goodthermal stability at the high temperature for a long time, and the mechanical property and the quality of the product are improved.

Owner:ZHONGLUN PLASTIC IND FUJIAN

Industrial method and polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity

The invention relates to an industrial method and a polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity, comprising the following steps: (1) compounding a flux into an aqueous solution, then mixing with solvent to remove water by refinement and continuously and stably obtaining a solvent system with the water content conforming to the requirement, wherein the weight percentage of the flux in the solvent system is from 6 percent to 15 percent; (2) performing the polycondensation reaction of para-phenylene diamine (PPD) and terephthalyl chloride (TPC) in the mol ratio of 1.01-1 to 1-1.01 in the solvent system prepared in the step (1), and obtaining a polymer after reaction; and (3) obtaining the poly-p-phenylene terephthamide resin in yellow powder after pulverizing, neutralizing, washing and drying the polymer. By utilizing the method, the adverse effects of weather and operation on the polymerized solvent system water is overcome, and continuous, closed and clean production is realized.

Owner:中国平煤神马控股集团有限公司

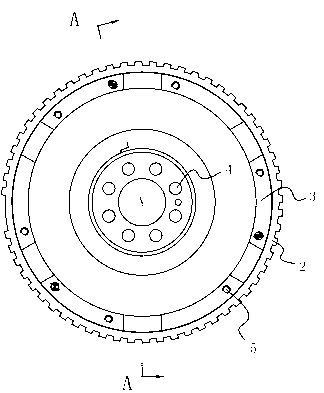

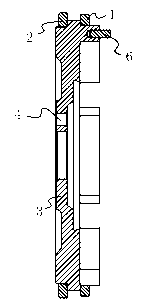

Production process for engine flywheel

The invention discloses a production process for an engine flywheel. The production process is characterized by comprising the following steps: (1) producing a flexible disc; (2) producing a gear ring; (3) machining a mesh gear on an outer side of the gear ring through a gear hobbing machine; (4) hotly pressing and assembling the flexible disc and the gear ring; (5) checking; (6) cleaning; (7) finally checking. Therefore, the quality of a flywheel assembly is greatly improved, production steps are reduced, and the production efficiency is improved.

Owner:WUHU DONGGUANG DAHUA MACHINERY MFG

Production process of flywheel assembly for automobile engine

The invention discloses a production process of a flywheel assembly for an automobile engine. The production process of the flywheel assembly for the automobile engine comprises the following steps: (1) a signal disc is produced; (2) a gear ring is produced; (3) a flywheel body is produced; (4) assembling is conducted in a pressing mode, namely, the signal disc produced in the first step and the gear ring produced in the second step are assembled on the flywheel body produced in the third process, wherein the signal disc is riveted with a connecting disc at first, and then the gear ring is heated for 30-60 minutes under the environmental temperature of 200-300 degrees, is arranged on the flywheel body in a hot pressing mode through a pressing assembling machine after being taken out and is naturally cooled; (5) gravity balancing is adjusted; and (6) cleaning and packaging are conducted. Because the gear ring is heated for 30-60 minutes under the environmental temperature of 200-300 degrees, is arranged on the flywheel body in a hot pressing mode through the pressing assembling machine after being taken out and is naturally cooled, quality of the flywheel assembly is greatly improved, production steps are reduced, and production efficiency is improved.

Owner:QINGDAO JINHUAN AUTOPARTS MFR

High-foaming expendable casting material and preparation method thereof

The invention discloses a high-foaming polystyrene-methacrylic acid-naethylmethacrylate gasified expendable casting material and a preparation method thereof. A functional methacrylic acid monomer is added in the preparation process of the styrene-naethylmethacrylate expendable casting material. The process is as follows: deionized water, a styrene monomer, a methacrylic acid monomer, the naethylmethacrylate monomer, a dispersant and an initiator are mixed, subjected to a suspension polymerization reaction, and prepared into a particle material; the prepared particle material is washed, dried, sieved and stored to obtain a pre-foaming material; the pre-foaming material, a foaming agent, a plasticizer, a surface coating agent and an antistat are placed in a high-pressure kettle to foam and is subjected to temperature keeping, cooling, discharging and washing, as a result, the high-foaming expendable casting material is obtained. According to the high-foaming expendable casting material and the preparation method thereof, the volume of a material in unit mass is greatly increased, the economical benefit of the material is improved, the generation of a cracked gas is reduced, the improvement of an workshop environment is facilitated, and meanwhile pollution to the environment is lowered.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

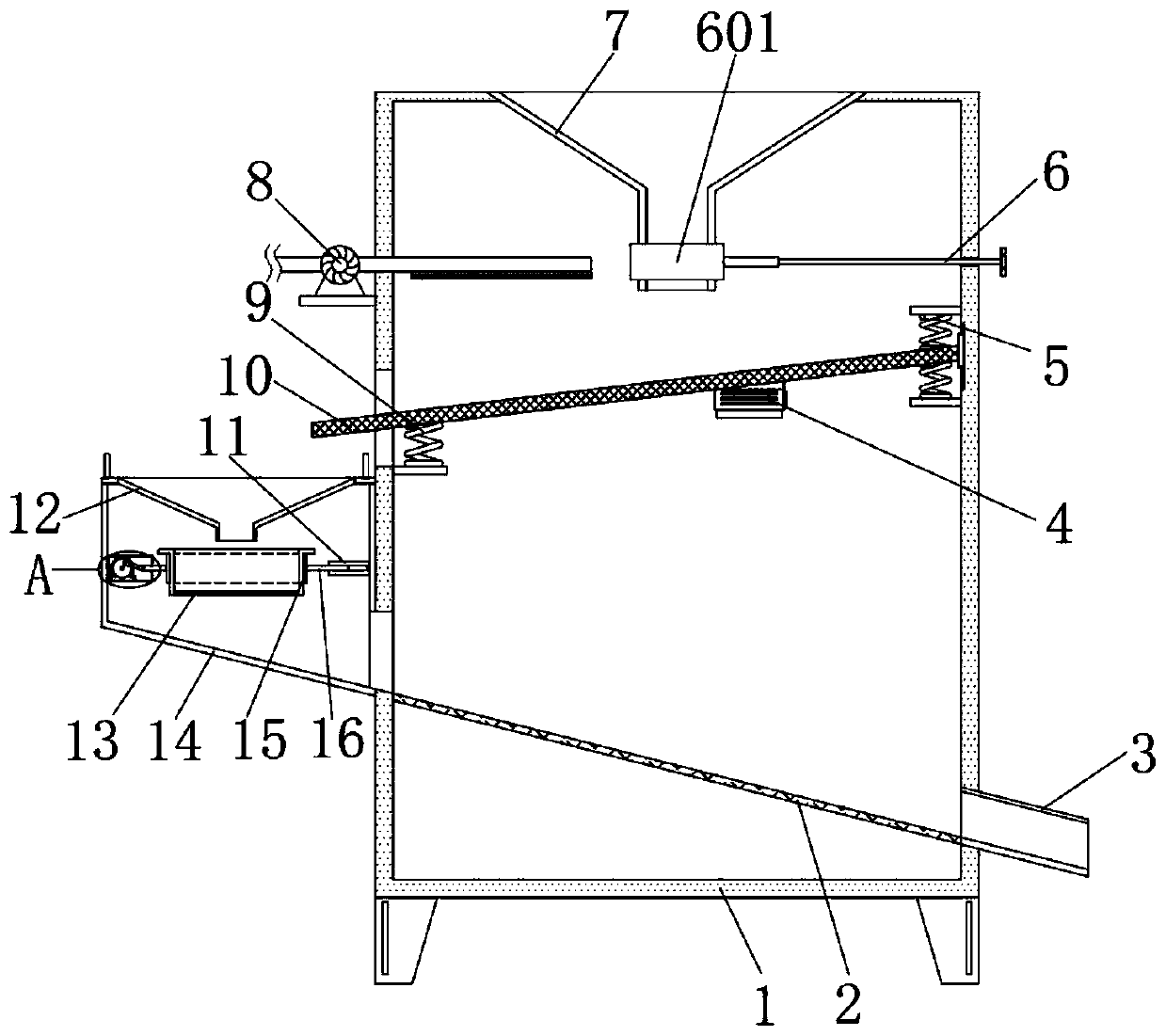

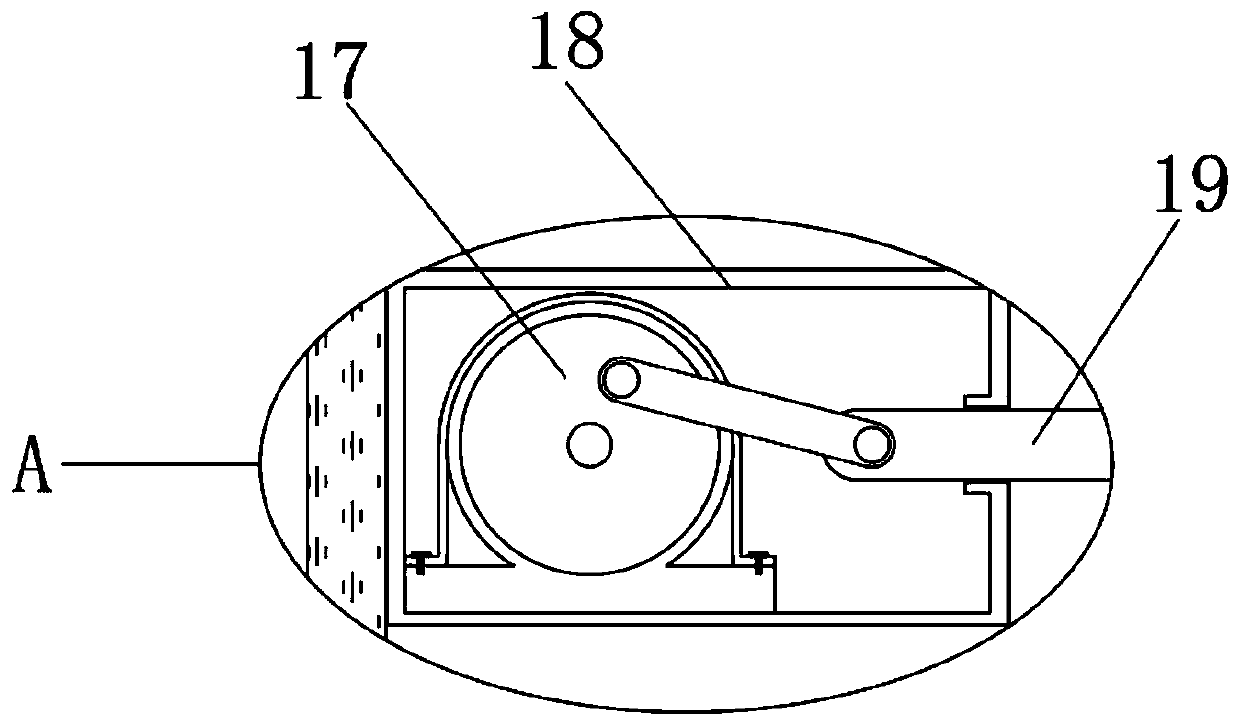

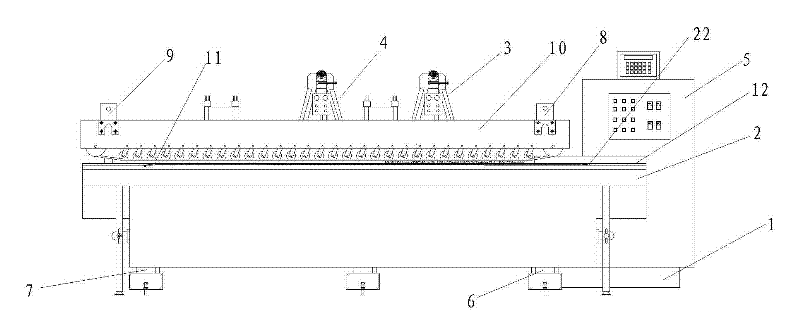

Pebble removing device for flour production

PendingCN110665797AImprove the workshop environmentThe principle is simpleSievingScreeningEngineeringStructural engineering

The invention discloses a pebble removing device for flour production. The pebble removing device comprises a shell and a mounting box, wherein supporting legs are welded to four corners of the bottomand the mounting box is welded to one side of the shell. A receiving hopper and a charging hopper are separately locked and welded to the top ends of the mounting box and the shell, a vibratory screening mechanism and a secondary screening mechanism are separately mounted in the shell and the mounting box, the vibratory screening mechanism comprises a sieve plate, one end of which is slidably connected to the inner wall of the shell, fixed blocks I are welded to two ends of the side, close to the sieve plate, of the shell, a same vibrating spring I is welded to the side, opposite to the sieveplate, of each fixed block I, a material conveying port is formed in one side, close to the other end of the sieve plate, of the shell, and a fixed block II is welded to the inner wall of one side ofthe material conveying port. The pebble removing device can screen wheat effectively by means of the arranged vibratory screening mechanism and secondary screening mechanism, and wheat will fall offfrom the first screening mechanism and the second screening mechanism, so that relatively large impurities such as pebbles can be removed effectively.

Owner:湖北庄品健实业(集团)有限公司

Cleaning method of environment-friendly circuit board printing screens

InactiveCN104527228AImprove working environment and workshop environmentReduce cleaning costsPrinting press partsSodium carbonateEnvironmental resistance

A cleaning method of environment-friendly circuit board printing screens comprises the following steps of step 1, preparing a sodium carbonate solution in a cleaning tank, wherein the mass concentration of the sodium carbonate solution is 1.2 to 4.0%; step 2, scraping the accumulated oil on the surfaces of the screens to be cleaned; step 3, vertically placing the screens to be cleaned into the cleaning tank in the step 1 to be soaked in turn; step 4, brushing the accumulated oil on the surfaces of the screens to be cleaned; step 5, placing the screens to be cleaned into the cleaning tank to be soaked again; step 6, taking out the soaked and cleaned screens and washing the screens through the clear water; step 7, drying. According to the cleaning method of the environment-friendly circuit board printing screens, the environment-friendly effect is achieved, toxic odorous gases cannot be produced in the ink cleaning process through the sodium carbonate solution, and accordingly the damage to bodies of operators cannot be caused, the working environment and the workshop environment can be effectively improved, and the cleaning cost of the screens is reduced and meanwhile the soaking is performed through the same sodium carbonate solution, an additional cleaning tank does not need to be added, and accordingly the input of production materials is saved and the production cost is reduced.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

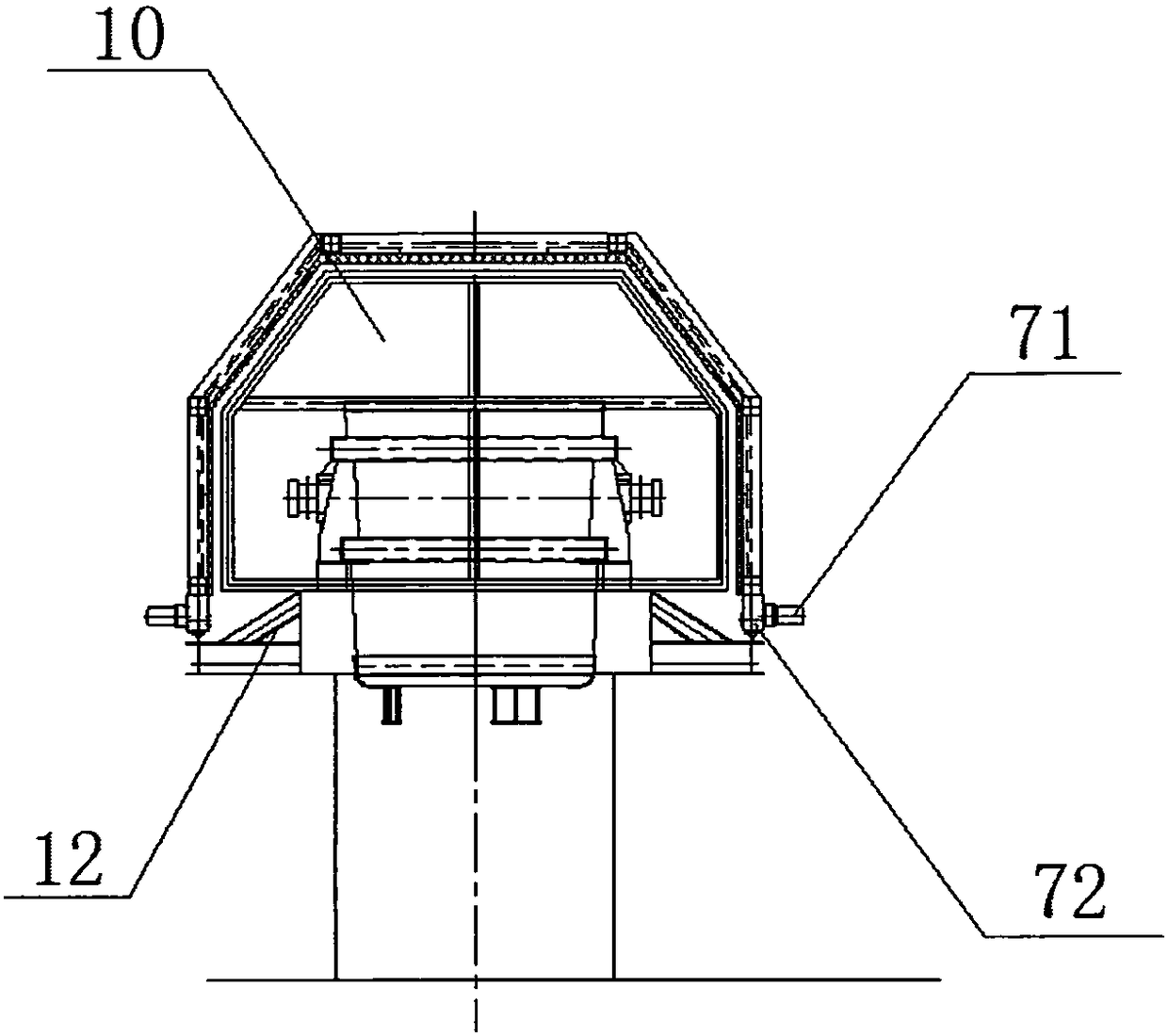

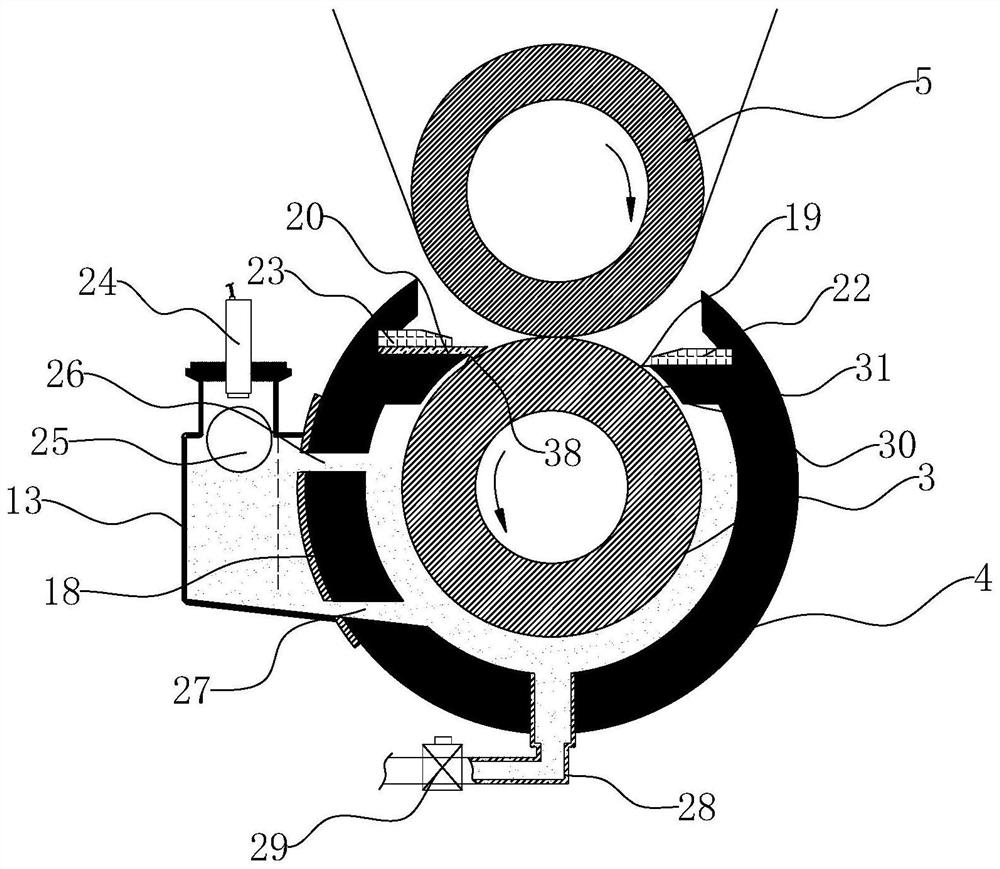

Pouring flue gas dust removal process for continuous casting big ladles

ActiveCN108500224AIncrease capture rateImprove the workshop environmentCasting apparatusFlue gasTuyere

The invention relates to a pouring flue gas dust removal process for continuous casting big ladles. The process comprises the following steps: putting a full pack of steel ladles into a revolving table; rotating the revolving table to a pouring position; moving a movable cover on the upper parts of pouring steel ladles; performing sealing and closure between a fixed cover and the movable cover; beginning to pour the full pack of steel ladles; sucking away flue gas produced in a pouring process by a fan arranged above an operation platform through an air suction hole formed in the fixed cover,and simultaneously, preparing the full pack of steel ladles on a hoisting position; rotating the revolving table to 180 degrees when the pouring is carried out; enabling empty steel ladles to enter into the hoisting position and the full pack of steel lades to enter into the pouring position, and moving the movable cover to the upper part of the pouring position to make room for hoisting; and then repeatedly carrying out the steps. According to the pouring flue gas dust removal process for the continuous casting big ladle disclosed by the invention, through a flue gas collection device with the revolving table for the continuous casting big ladles, dispersion of flue gas is hindered in a process of pouring the big ladles, a flue gas collection ratio is increased, and a workshop environment is improved; and compared with a conventional roofing cover, the pouring flue gas dust removal process disclosed by the invention has the advantages that one-time investment and operation expenses are greatly reduced.

Owner:江苏朗润环保科技有限公司

Dust removal device for welding wire drawing

InactiveCN105363812AQuick and effective extractionImprove the workshop environmentGas treatmentUsing liquid separation agentAtmospheric airEngineering

The invention belongs to the technical field of machining of welding wires and particularly relates to a dust removal device for welding wire drawing. The dust removal device for welding wire drawing comprises a plurality of wire drawing machines which are arranged side by side. A wire wiping machine is arranged at the front end of each wire drawing machine. The dust removal device for welding wire drawing is characterized in that the wire drawing machines and the wire wiping machines are connected with a dust removal main pipe through dust removal branch pipes respectively, a centrifugal fan is arranged at an outlet of the dust removal main pipe, and a water pool is arranged below the outlet of the dust removal main pipe. The dust removal device for welding wire drawing has the beneficial effects that dust generated in the wire drawing process can be rapidly and effectively pumped out, and the workshop environment is purified; since the dust which is pumped out is discharged in water, the dust is prevented from being diffused into the atmosphere, and secondary pollution is avoided; the structure is simple, the dust removal effect is good, the dust removal efficiency is high, and pollution generated in the wire drawing process is almost avoided.

Owner:FARINA JINAN WELDTEC & MACHINERY

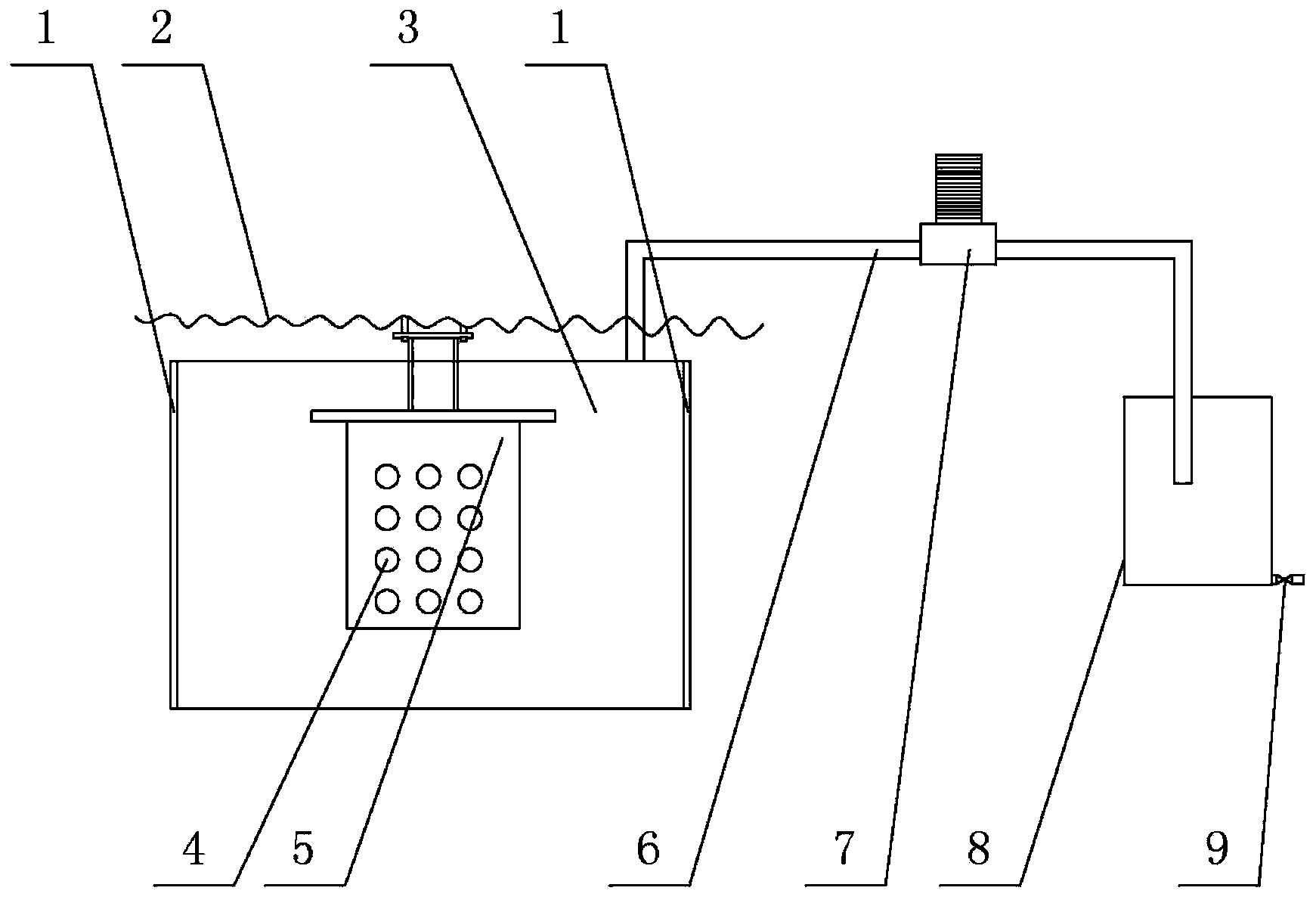

Device for collecting metal dust during electrolytic manganese stripping

ActiveCN103590075AReduce pollutionAchieve recyclingPhotography auxillary processesElectrolysis componentsElectrolysisManganese

The invention relates to a device for collecting metal dust during electrolytic manganese stripping in electrolytic manganese industry, particularly to a device for collecting metal dust produced during electrolytic manganese stripping. The device comprises an electrolytic manganese stripping box for preventing the metal dust from dispersing and flying, a dust collection box for collecting the metal dust, a blower and a pipeline, wherein the electrolytic manganese stripping box is connected with the dust collection box through the pipeline, and the blower is fixedly mounted on the pipeline. The metal dust collecting device has the benefits as follows: the device is simple in structure, dust pollution in stripping process environment is reduced, and recycling of metal resources is achieved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Glitter powder silk-screen printing process

InactiveCN106926597AReduce wasteSolve the separation problemInksOther printing apparatusScreen printingUltraviolet lights

The invention discloses a glitter powder silk-screen printing process. The litter powder silk-screen printing process is characterized by comprising the following steps that S1, a silk-screen printing plate is manufactured; S2, the manufactured silk-screen printing plate and a scraping cutter are installed on a silk-screen printing device, the scraping cutter is a 75-degree scraping cutter, and polishing is carried out to form a circular bead; S3, ultraviolet light polymerization printing ink is added to conduct printing, the scraping cutter is used for forming a silk-screen printing ink layer on a printed material, wherein the ultraviolet light polymerization printing ink is a mixture of crystal oil and glitter powder, the inclining angle of the scraping cutter during printing is 45 degrees to 80 degrees, and the printing pressure is 8 N to 20 N; and S4, ultraviolet light with the wave length being 360 nm to 420 nm is used for irradiating the silk-screen printing ink layer, the silk-screen printing ink layer on the printed material solidifies, and the printing ink printing layer is formed. By means of the printing process, waste of the glitter powder is reduced, the production cost is reduced, and in-batch large-scale production can be formed; and meanwhile, the printing process avoids particle pollution and achieves environmental protection.

Owner:上海东宁丝网印刷有限公司

Method for preparing water-base chain lubricant

ActiveCN101235339AImprove the lubrication effectImprove solubilityLubricant compositionSolubilityWater based

The invention relates to a process for preparing lubricating agent which is used on high-speed conveyer belt production line such as PET bottles, glass bottles, tins and the like, which belongs to the preparation filed of chemical lubricating agent. The components and quality percentages of lubricating agent which are prepared by the process for preparation are that triethanolamine oleate 3-8%, triethanolamine 4-9%, LF-131 2-5%, isothiazolone 1-3%, polymaleic acid 0.5-2%, glucuronidase 4-9%, EDTA-2Na 4-10%, benzotriazole 0.5-2%, sodium dimethyl benzene sulfonate 0.5-2%, H2O 65-75%, the water-base chain lubricating agent has high lubricating property and excellent solubility, which has multinomial excellent properties such as hard water resisting, sterilization, low foaming, non corrosiveness, crack resistance, coagulability resistance and the like, when the lubricating agent is used in lubricating systems, the lubricating system can effectively reduce bottle inversing rate, improve workplace environment and prolong service span of chain mats.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

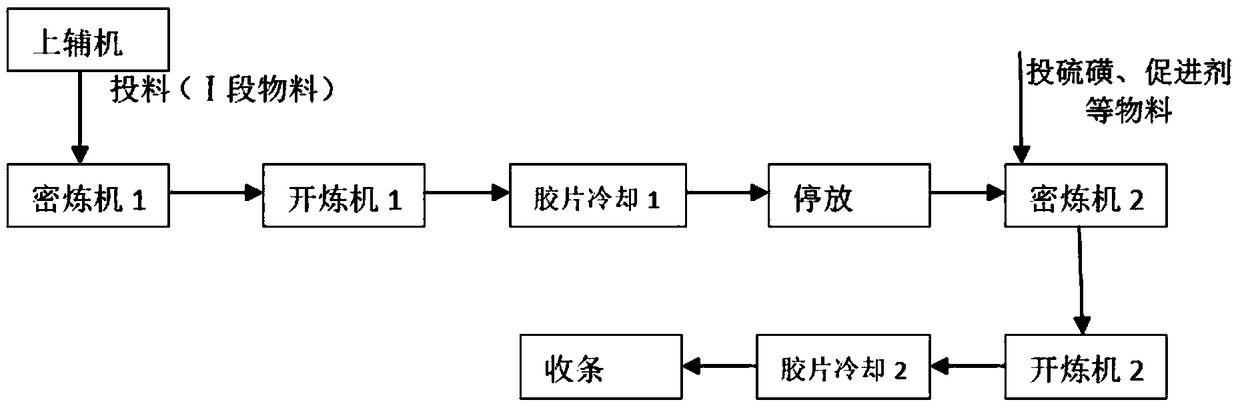

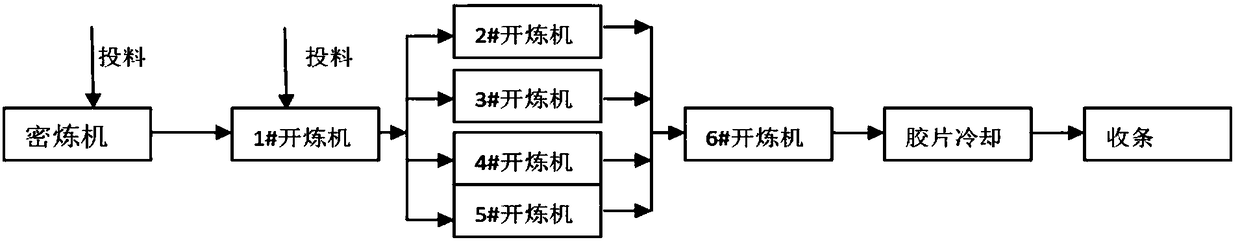

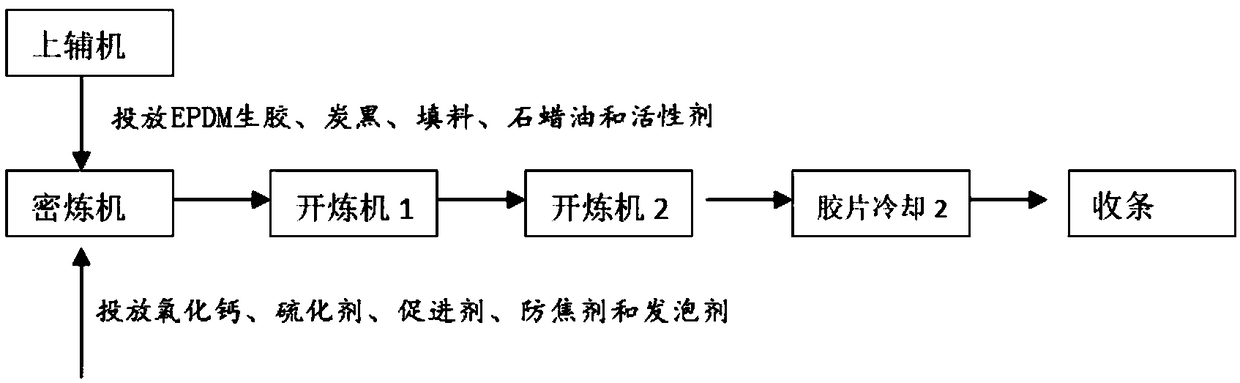

One-step continuously-mixed rubber compound for automobile sealing strips and preparation method thereof

ActiveCN109370065AHigh Mooney viscosityVulcanization stabilityChemical industryPolymer scienceActive agent

The invention discloses a one-step continuously-mixed rubber compound for automobile sealing strips and a preparation method thereof. The rubber compound comprises the following raw materials in partsby weight: 100 parts of EPDM (Ethylene-Propylene-Diene Monomer) raw rubber, 60-200 parts of carbon black, 30-100 parts of filler, 60-120 parts of paraffin oil, 7-12 parts of active agent, 8-12 partsof calcium oxide, 1-2.5 parts of vulcanizing agent, 4.3-10.9 parts of accelerator, 0.6-1 part of anti-scorching agent and 0-4 parts of foaming agent. The rubber compound disclosed by the invention hasthe beneficial effects that the rubber compound is stable in Mooney viscosity and vulcanization performance and good in consistency and when the rubber compound is used for the production of the automobile sealing strips, the obtained product is smooth in surface, few in particles and high in dimensional stability; and the preparation method disclosed by the invention has the beneficial effects of low cost, high efficiency, energy conservation and consumption reduction and has a broad market development prospect in the field of high-end automobile sealing strip preparation.

Owner:ZHEJIANG XIANTONG RUBBER & PLASTIC CO LTD

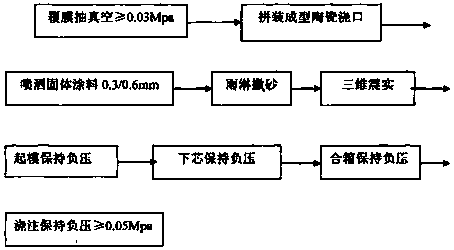

Vacuum seal casting method for wind driven generator ductile iron hub

InactiveCN107855476AGuaranteed compactnessLow gas productionFoundry mouldsFoundry coresWind drivenEnvironmental resistance

The invention provides a vacuum-sealed casting method for a ductile iron hub of a wind power generator, and relates to the technical field of ferrous metal casting. The traditional vacuum-sealed molding (V-method molding) will be used for the molding and casting of ductile iron castings for wind power hubs. Resin sand cores will be used, and the mold cavity will be coated with special solid coatings. The special solid coatings are mainly composed of graphite powder, Composed of quartz powder and zircon powder, the ratio of parts by weight is: graphite powder: quartz powder: zircon powder = 5~7:1:2~5, and the spraying thickness is 0.2~0.6mm. No riser and less cold iron. Solve the problems of low fatigue strength and surface micro-crack defects caused by surface sulfurization of castings in the prior art, and obtain wind power castings with high density that meet the requirements, improve the surface quality and dimensional accuracy of castings, and effectively improve Process yield, energy-saving peak consumption, cost reduction, and improvement of working conditions are conducive to environmental protection and economic efficiency.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

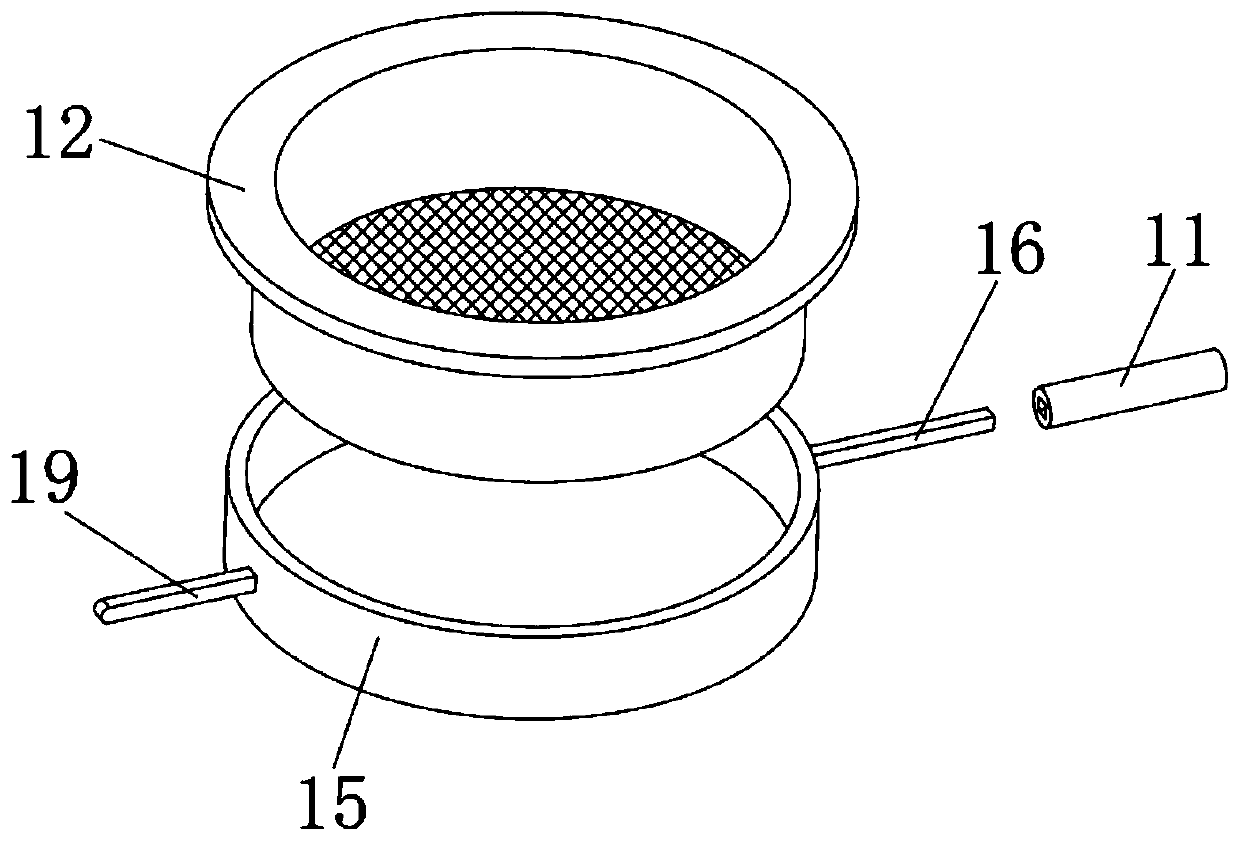

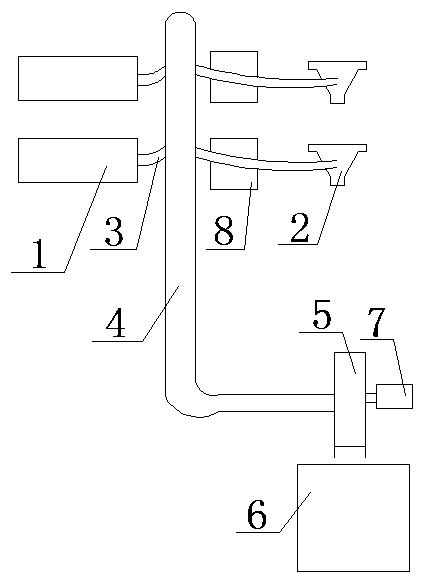

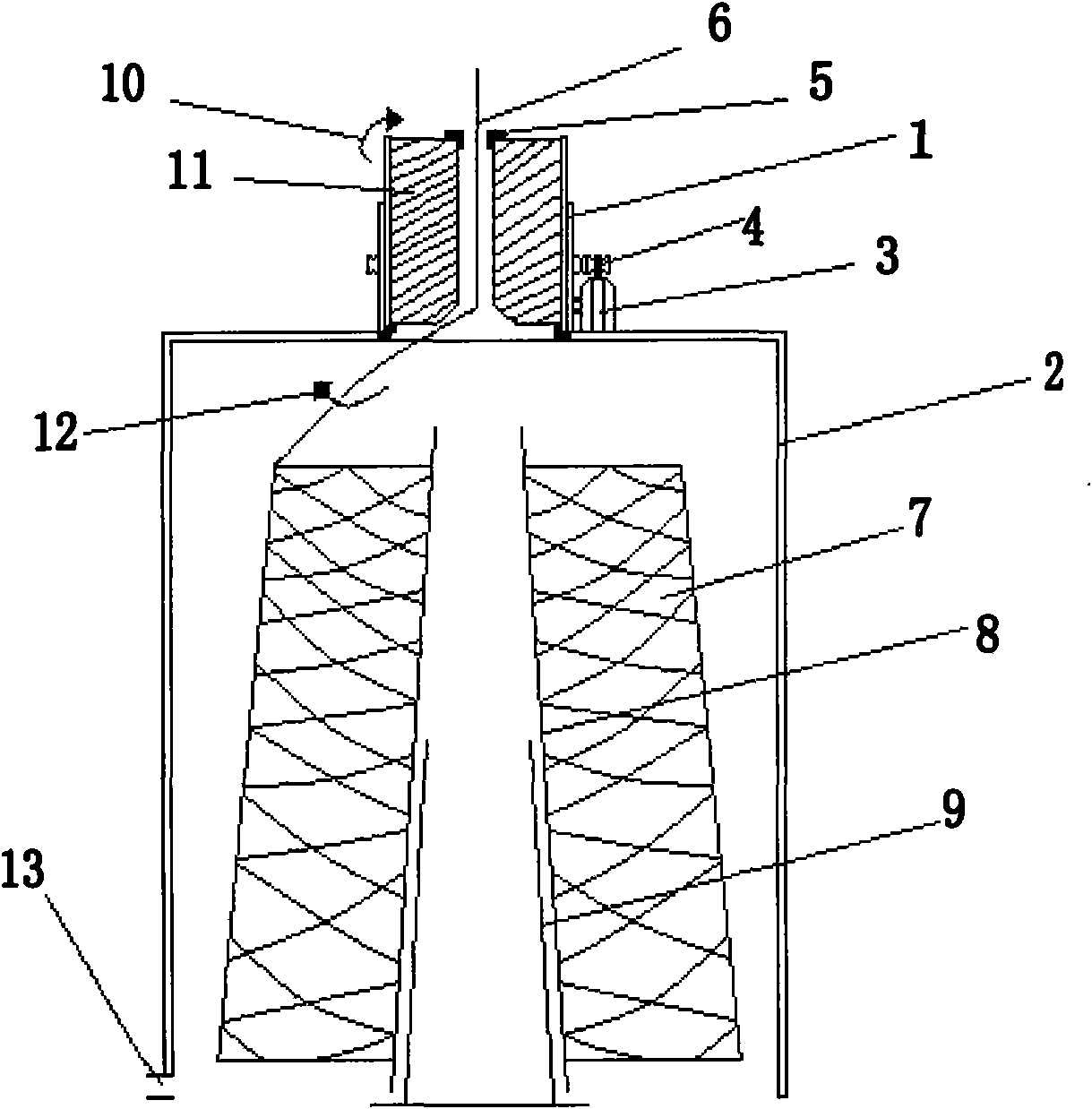

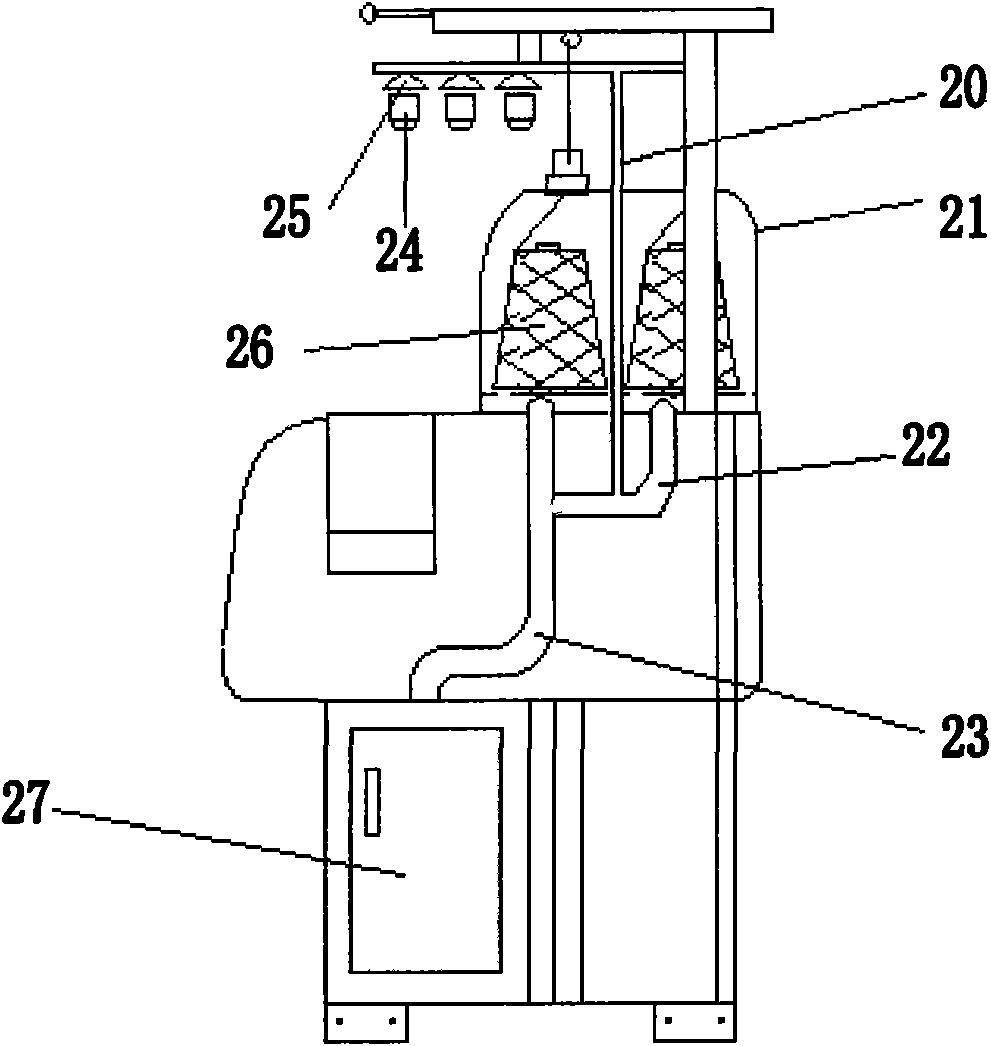

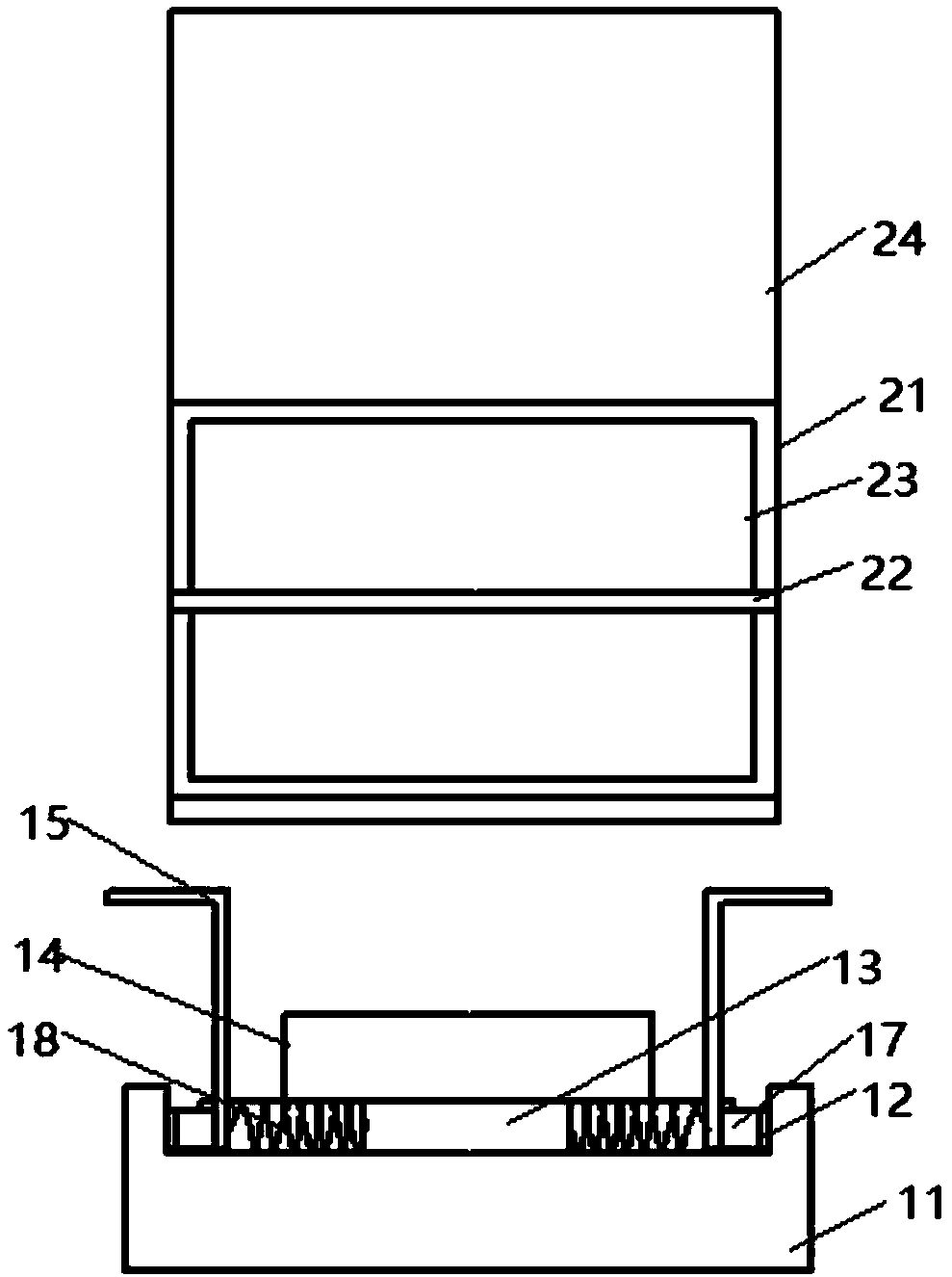

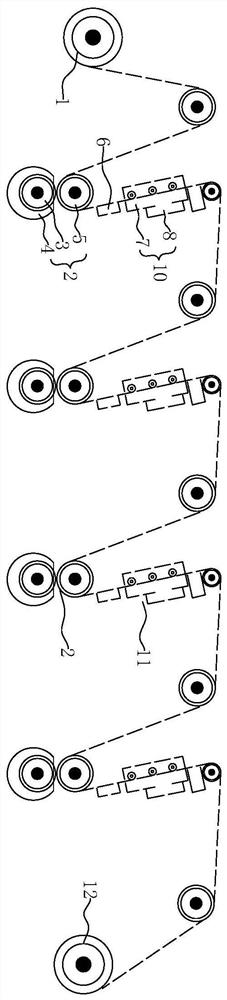

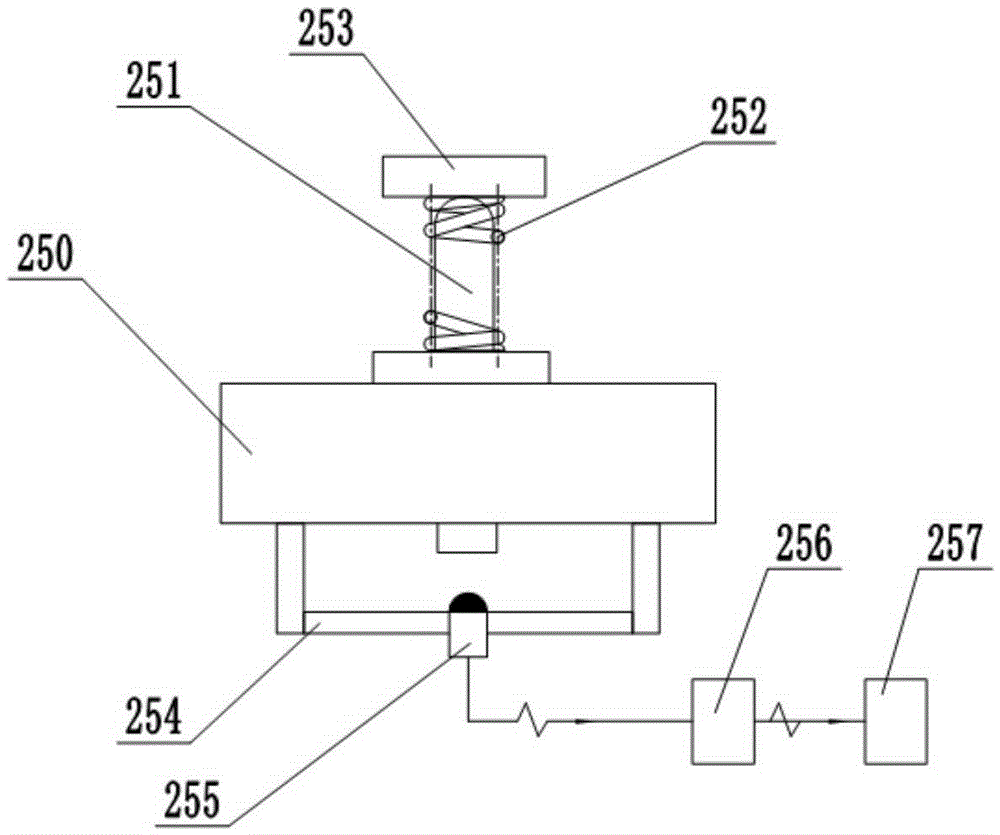

Multi-functional three-dimensional energy-saving and environmentally-friendly lubricating device

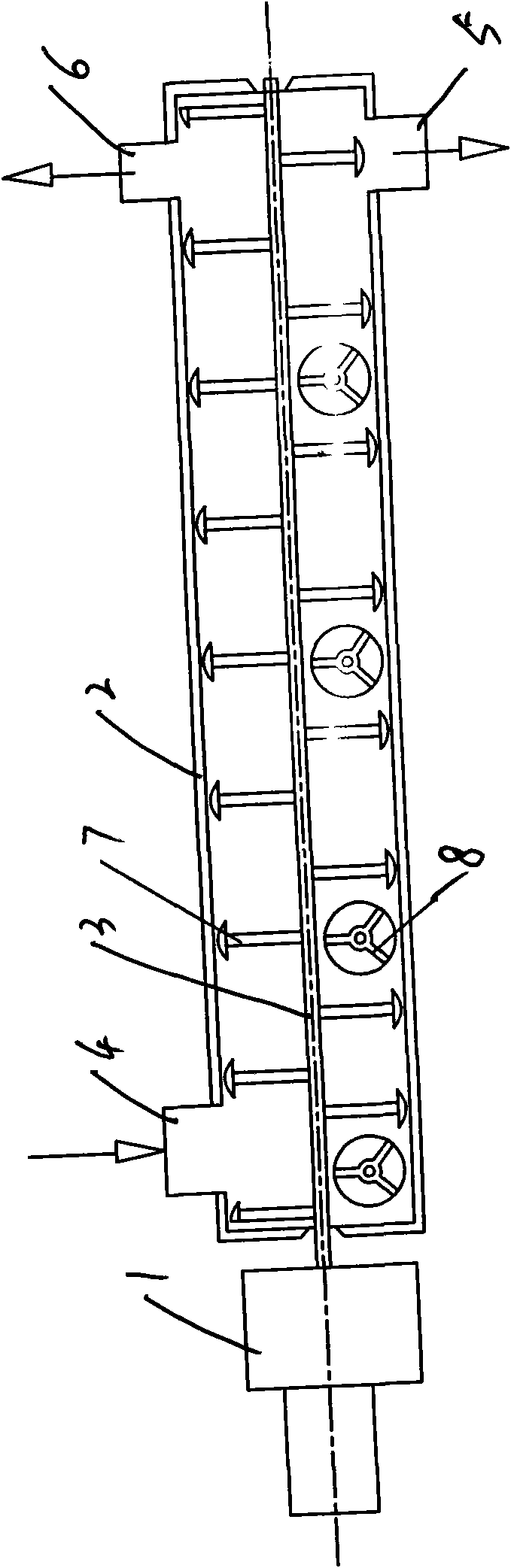

The invention relates to a multi-functional three-dimensional energy-saving and environmentally-friendly lubricating device, which belongs to the field of textile. The aim of the device is fulfilled by the following measures that: a shell of the lubricating device (1) is connected with a gear (4); the gear (4) is connected with a frequency-modulation micromotor (3); the micromotor (3) is connected with a device body (2); the lubricating device (1) is provided with lubricant (11); a positioner (5) is inserted into the central hole at the upper end of the lubricant (11); the lubricating device (10) rotates horizontally and clockwise; yarn (6) is led upward out of the central hole of the lubricant; yarn (12) rotates clockwise; a central yarn tube (8) of a yarn ball (7) is inserted in a central fixing tube (9); a dust-collecting port (13) is connected with a dust-collecting tube (16); 8 to 16 yarn balls (15) are arranged according to requirement; each yarn ball is provided with one lubricating device (14); each device door (19) is connected with another device door; a vacuum cleaner (17) is connected with a collecting bag (18); a trumpet-shaped dust-collecting mouth (25) is connected with a dust-collecting tube (20) to absorb flyings generated by a yarn feeder (24); a yarn ball (26) is connected with a transparent cover (21); and the transparent cover (21) is connected with dust-collecting tubes (22) and (23) to absorb the flyings into the collecting bag of a storage chamber (27). The device is mainly used for reducing the flyings which pollute a workshop. The technical point of the device is energy-saving and environmentally-friendly.

Owner:崔建明

Wood rapid cutting machine

InactiveCN110625697AGood spray cooling treatmentAvoid overall overheatingGuide fencesCircular sawsEngineeringDrive motor

The invention discloses a wood rapid cutting machine. The wood rapid cutting machine comprises a cutting table body. Landing legs are fixedly mounted in the four corners of the bottom of the cutting table body. The cutting table body is rotationally connected with a rotary shaft through a bearing, the rotary shaft is in key connection with a cutting tooth, a drive motor is fixedly mounted on one side of the cutting table body, an output shaft of the drive motor and the rotary shaft are in transmission fit through a belt, an atomizing cooling mechanism is mounted on the side, close to the cutting tooth, of the cutting table body, an adjusting mechanism is mounted at the top end of the cutting table body, and a dust suction mechanism is mounted at the top end of the cutting table body. The atomizing cooling mechanism comprises a water storage box fixedly mounted on one side of the cutting table body, and a water pump communicating with the water storage box is fixedly mounted on one sideof the water storage box. Through the arranged atomizing cooling mechanism, through mutual cooperation of a semiconductor refrigerator, a heat exchange plate, the water pump and an atomizing nozzle,the cutting tooth is well spray-cooled, and the beneficial effect of preventing the cutting tooth from being too hot is achieved.

Owner:ANJI CHENLIN FURNITURE CO LTD

Dustproof device for groove on conveyor belt in tobacco cutting line

ActiveCN102491052AEliminate breeding spacesImprove the workshop environmentTobacco preparationConveyorsRight triangleEngineering

The invention discloses a dustproof device for a groove on a conveyor belt in a tobacco cutting line, which comprises a cassette (2) arranged on the upper side of the groove (1) on the conveyor belt in the tobacco cutting line along the extension direction of the groove (1), wherein the cassette (2) has a triangular cross section; a downward clamping strip (3) is arranged on the entire outer end of the horizontal edge of the cassette (2); the clamping strip (3) is clamped on the outer side of the outer vertical wall of the groove (1); and the upper section of the right-angle edge of the clamping strip (3) is connected with the corresponding face of the inner vertical wall of the groove (1) in a sealed manner. According to the device, the arrangement of the cassette (2) on the upper side of the groove prevents cut tobacco and tobacco ash from falling into the groove, allows the cut tobacco and tobacco ash to fall off from the inclined plane of the cassette and eliminates space for growing tobacco worms, and thus, the workshop environment is improved and the quality safety of the product is ensured; and the cassette can be demounted and mounted freely for use, the dustproof device has the characteristics of unique and attractive shape, low cost and no maintenance and is suitable to be widely used.

Owner:CHINA TOBACCO JIANGXI IND CO LTD +1

Neodymium iron boron magnet chamfering device

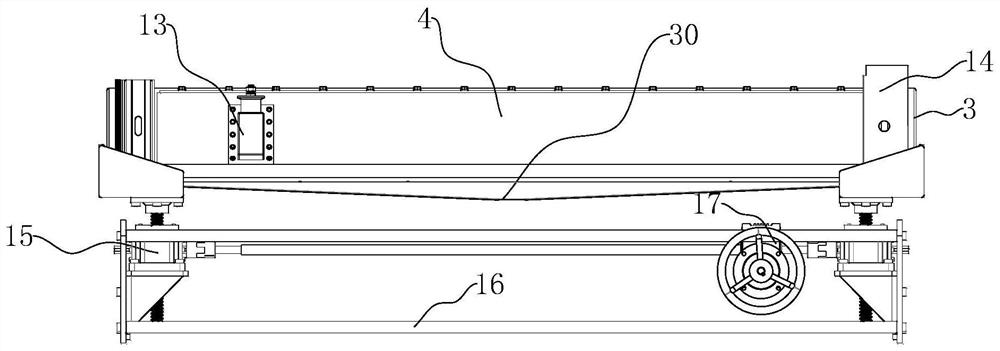

ActiveCN109176202AIncrease widthEasy feedingEdge grinding machinesGrinding carriagesBelt conveyorElectromagnet

The invention discloses a neodymium iron boron magnet chamfering device which comprises a ribbon conveyer. A feeding area, a chamfering area and an unloading area are successively arranged from left to right on a rack on the upper part. Electromagnets are separately arranged on two sides of the racks of the feeding area and the unloading area. Pairs of blind slots are formed in a spaced manner along the length direction of a belt of the ribbon conveyor, and the any pair of blind slots is symmetrically formed along the width direction of the belt; the device also comprises a bump and pairs of adjusting rods, any pair of adjusting rods comprises two integrally formed L-shaped rods, the horizontal rods are above, the free ends of the horizontal rods are arranged outward, an elastic plate strip is connected between the free ends of two adjacent horizontal rods, vertical rods are arranged downward, and permanent magnets attractive to the electromagnets magnetically are arranged on the outersides of the free ends of the vertical rods. The device also comprises pairs of springs, any spring is arranged in each blind slot, one end of the spring is connected to the inner end surface of eachblind slot, and the other end is connected to the inner side of the free end of each vertical rod. The neodymium iron boron magnet chamfering device has the advantages of being convenient to feed anddischarge, good in chamfering quality, high in work efficiency and the like.

Owner:京磁材料科技股份有限公司

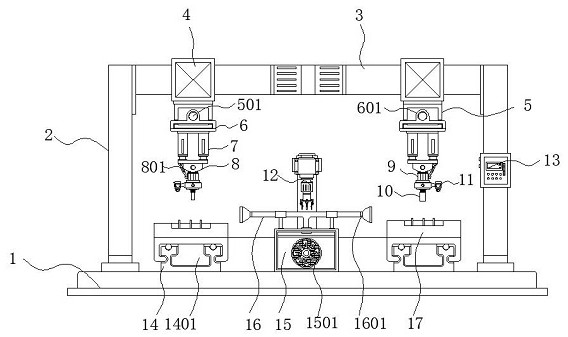

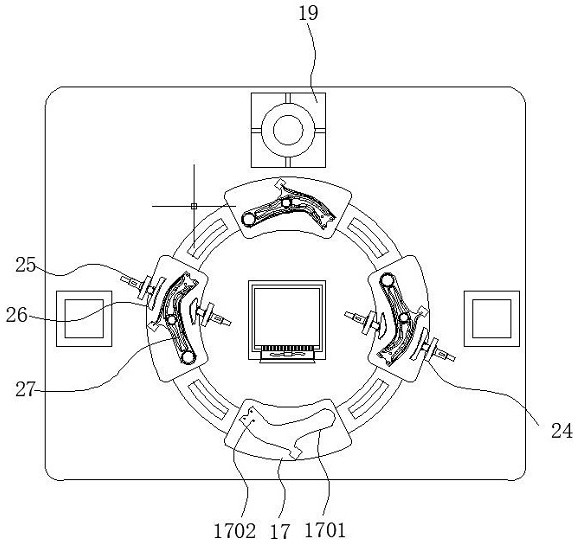

Inner groove grinding device capable of detecting hole diameter of automobile swing arm

InactiveCN112264884ARealize the initial limitEasy to polishGrinding drivesGrinding feed controlStructural engineeringMachining process

The invention discloses an inner groove grinding device capable of detecting the hole diameter of an automobile swing arm. The inner groove grinding device specifically comprises a bottom plate, a detecting mechanism, an annular sliding rail and a movable rail, wherein the annular sliding rail is arranged in the middle of the top of the bottom plate; a scrap collecting box is arranged at the top of the bottom plate at the inner side of the annular sliding rail; sliding blocks are evenly arranged in the annular sliding rail; and workbenches are arranged at the tops of the sliding blocks. According to the inner groove grinding device capable of detecting the hole diameter of the automobile swing arm, a limiting groove, a positioning rod and two clamping plates matched with flangings at the two sides of the swing arm in shape are arranged, the bottom of the swing arm can be embedded into the limiting groove in the machining process, and the positioning rod can be inserted into a fixing hole in the mounting end of a swing arm ball pin, so that the preliminary limiting of the swing arm is achieved; and furthermore, the clamping plates are matched in pairs to clamp the flangings at the two sides of the swing arm, so that grinding is not blocked while clamping is stable, and the machining difficulty is reduced.

Owner:重庆德森诺科技有限公司

Method for manufacturing flanges of wind turbine blade girder mould and wind turbine blade girder mould

The invention provides a method for manufacturing flanges of a wind turbine blade girder mould and the wind turbine blade girder mould. By the method for manufacturing the flanges of the wind turbine blade girder mould, a double-flange wind turbine blade girder mould can be manufactured. After the adoption of double flanges, a double-flange girder is the same with a mould in shape, so that secondary cutting is not needed; after the girder is moulded, the girder can be directly applied to a main mould, so that the turnover time of the girder is shortened, the width of a raw material can be reduced, the using amount of resin is reduced, cutting dust is reduced, the workshop environment is improved, girder turnover is reduced, and risks of girder damage caused by the turnover are reduced.

Owner:上海艾港风电科技发展有限公司

Sealing stock bin

PendingCN112265854AReduce manufacturing costAchieve sealingLiquid surface applicatorsRotary intaglio printing pressMechanical engineeringIndustrial engineering

The invention discloses a sealing stock bin, and relates to the technical field of coating gravure printing. The sealing stock bin comprises a stock bin body with a coating opening in the top and an anilox roller with the two ends rotationally connected with the stock bin body, wherein one side of the anilox roller penetrates the coating opening to extend out of the stock bin body; a scraper bladeconnected with the anilox roller is arranged on one side of the coating opening, and a teflon sealing plate connected with the anilox roller is arranged on the other side of the coating opening; andthe scraper blade, the anilox roller and the teflon sealing plate jointly seal the coating opening. The sealing stock bin is suitable for being used for low-boiling-point solvents, the low-boiling-point solvents such as dichloromethane can be used in the coating industry, the production safety is improved, and the production cost is effectively reduced.

Owner:四川中农能电科技发展有限公司

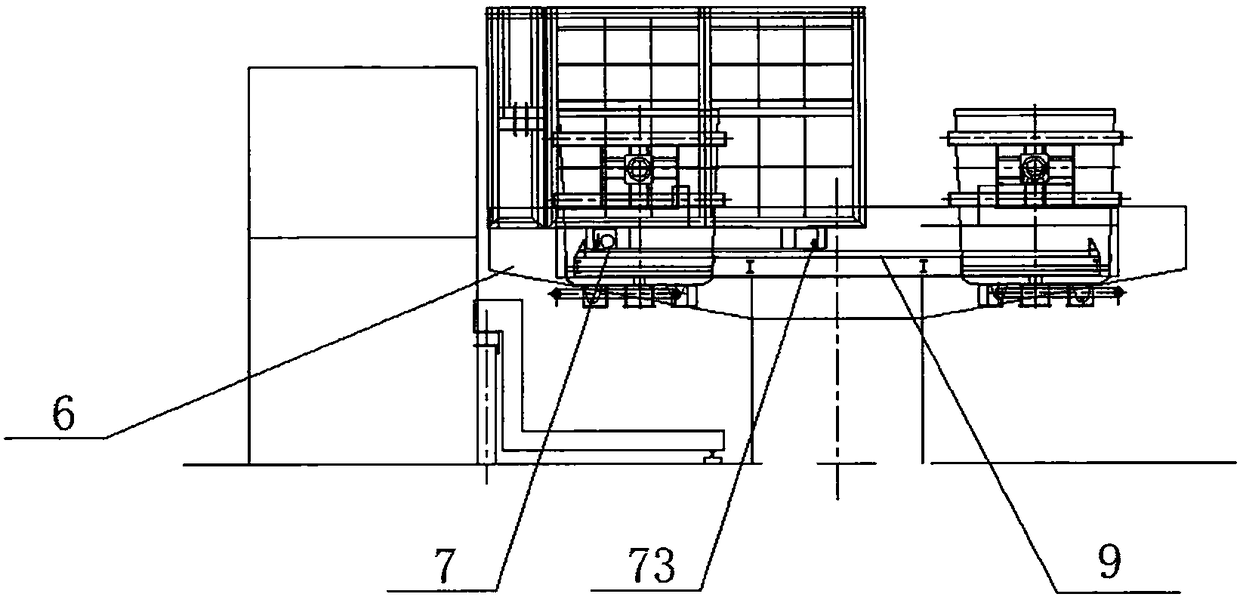

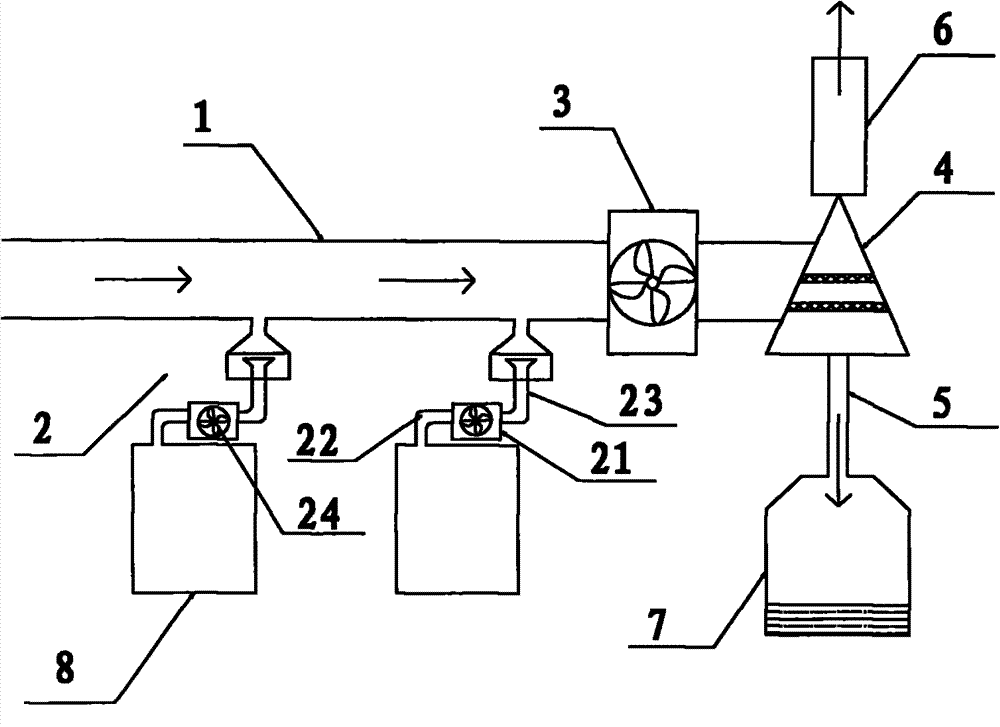

Oil mist recovery system

InactiveCN104511789AImprove the workshop environmentLow costMaintainance and safety accessoriesExhaust gasPollution

The invention discloses an oil mist recovery system. The oil mist recovery system comprises a pipeline, a plurality of oil mist collection devices connected with the pipeline, and an exhaust fan and a filter box which are located at an outlet of the pipeline, wherein the filter box is connected with the exhaust fan, the lower end of the filter box is connected with an oil outlet pipe, and the upper end of the filter box is connected with an exhaust funnel. The oil mist recovery system is mainly used to perform uniform recovery processing and discharging on oil mist discharged by a plurality of machining centers, and not only can improve plant environments, but also can save cost of the pipeline, and furthermore can reduce pollution on the plant environments.

Owner:赵立平

Edge polishing machine for irregular edges

The invention discloses an edge polishing machine for irregular edges. The edge polishing machine comprises a base, a stand, a control electric cabinet and an irregular edge polishing unit, wherein the stand is fixed on the base; two straight columns are arranged at the inner side of the stand and located at two ends of the base; two fixing frames extend forwards and are vertically arranged at the top ends of the straight columns; a lower pressing beam is respectively arranged below the tail ends of the two fixing frames; a trolley belt for transmitting a workpiece is arranged below the lower pressing beam, corresponding to a work platform on the stand; two irregular edge polishing units are arranged at the outer sides of the straight columns and located at the middle part of the base; and each irregular edge polishing unit comprises a lifting frame, a feeding supporting plate and an irregular edge polishing mold group. The edge polishing machine for the irregular edges has the advantages of reasonable design and skillful concept, is capable of polishing irregular edge part profiles of various furniture plates and has wide popularization value.

Owner:DONGGUAN GREVOL FURNITURE

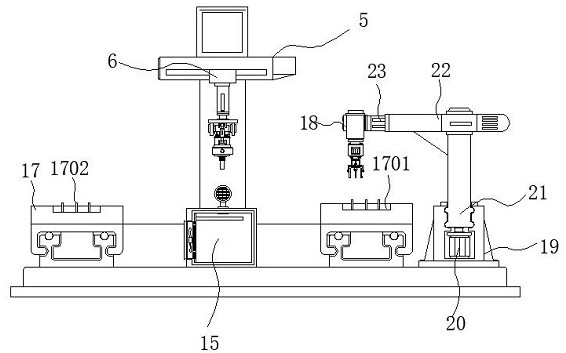

Magnetic isolation ring grinding device with roughness detection function

InactiveCN112123149AWith roughness detection functionGuaranteed sandingGrinding carriagesGrinding drivesEngineeringMagnetic isolation

The invention discloses a magnetic isolation ring grinding device with a roughness detection function. The magnetic isolation ring grinding device specifically comprises a bottom plate, a movable rail, a rotary disc and a magnetic isolation ring, wherein a mechanical table is installed on one side of the top of the bottom plate, a fixing seat is embedded in the top end of the interior of the mechanical table, a control panel is fixed to the middle position of one end of the mechanical table, and a waste chip collecting box is installed at the bottom end of the interior of the mechanical table.According to the magnetic isolation ring grinding device with the roughness detection function, a rotating seat, the movable rail and two telescopic seats are arranged, the tail ends of the two telescopic seats are correspondingly and fixedly provided with a group of grinding mechanisms, grinding heads of one group of grinding mechanisms are suitable for grinding the upper end surface and the side edge of an annular platform, the grinding heads of the other group of grinding mechanisms are suitable for grinding semicircular grooves and through holes of the annular platform, so that the grinding of the end surface, the side edge semicircular grooves and the through holes of the annular platform can be guaranteed through one-time clamping, and the machining efficiency is higher.

Owner:深圳市顺尔通工业设计有限公司

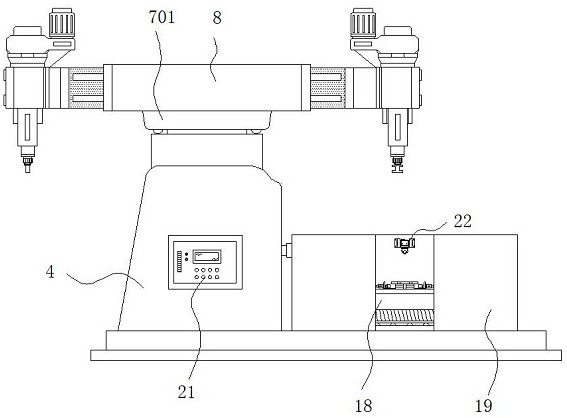

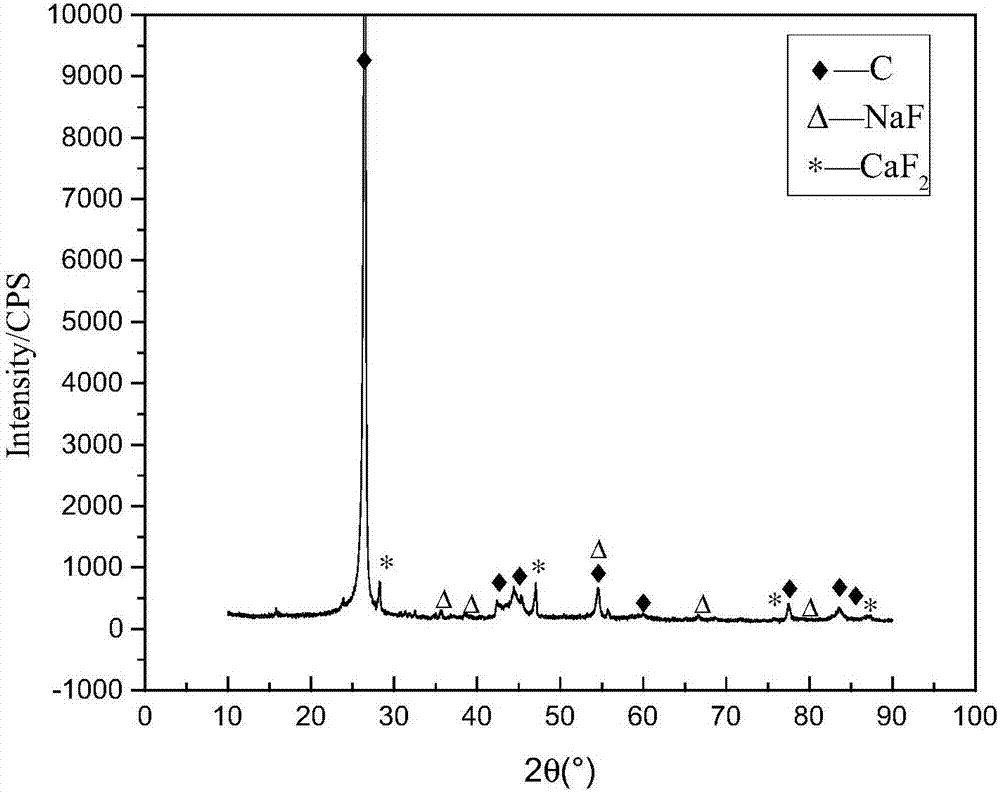

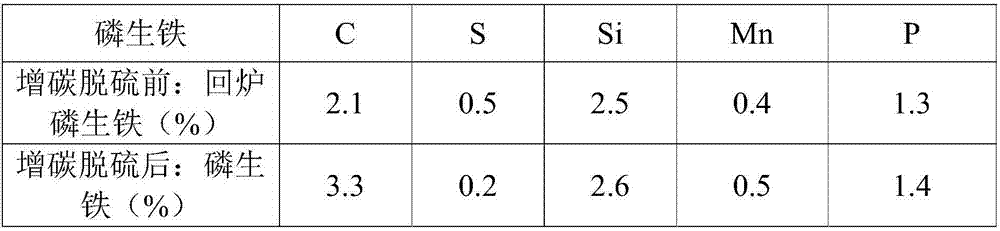

Environment-friendly phosphorous pig iron additive, preparation method of environment-friendly phosphorous pig iron additive and phosphorous pig iron recarburization and desulphurization method

ActiveCN106868246AGood effect of carbon increase and desulfurizationPromote water flowSolid carbonIntermediate frequency

The invention relates to the field of aluminum electrolysis production, in particular to an environment-friendly phosphorous pig iron additive, a preparation method of the environment-friendly phosphorous pig iron additive and a phosphorous pig iron recarburization and desulphurization method. The environment-friendly phosphorous pig iron additive is prepared by pressing 95.5%-98.5% of a carbon material, 1.0%-3.5% of a binder and 0.5%-1% of carbonate by mass percent into a pellet. The carbon material is solid carbon obtained by carrying out vacuum metallurgy treatment on waste cathode carbon blocks. The preparation method is simple, the prepared additive is low in cost, and the recarburization and desulphurization effect on phosphorous pig iron is good. The phosphorous pig iron recarburization and desulphurization method comprises the steps that the additive and a phosphorous pig iron raw material are added into an intermediate frequency furnace in a layered manner, and then smelting is carried out. The method is high in carbon absorptivity and good in desulphurization effect, meanwhile, material flying losses in the phosphorous pig iron recarburization and desulphurization process can be effectively reduced, and the workshop environment can be improved; and the flowability phosphorous pig iron liquid is good, and the obtained phosphorous pig iron meets the requirement of phosphorous pig iron for prebaked anode casting.

Owner:SHANDONG NANSHAN ALUMINUM +1

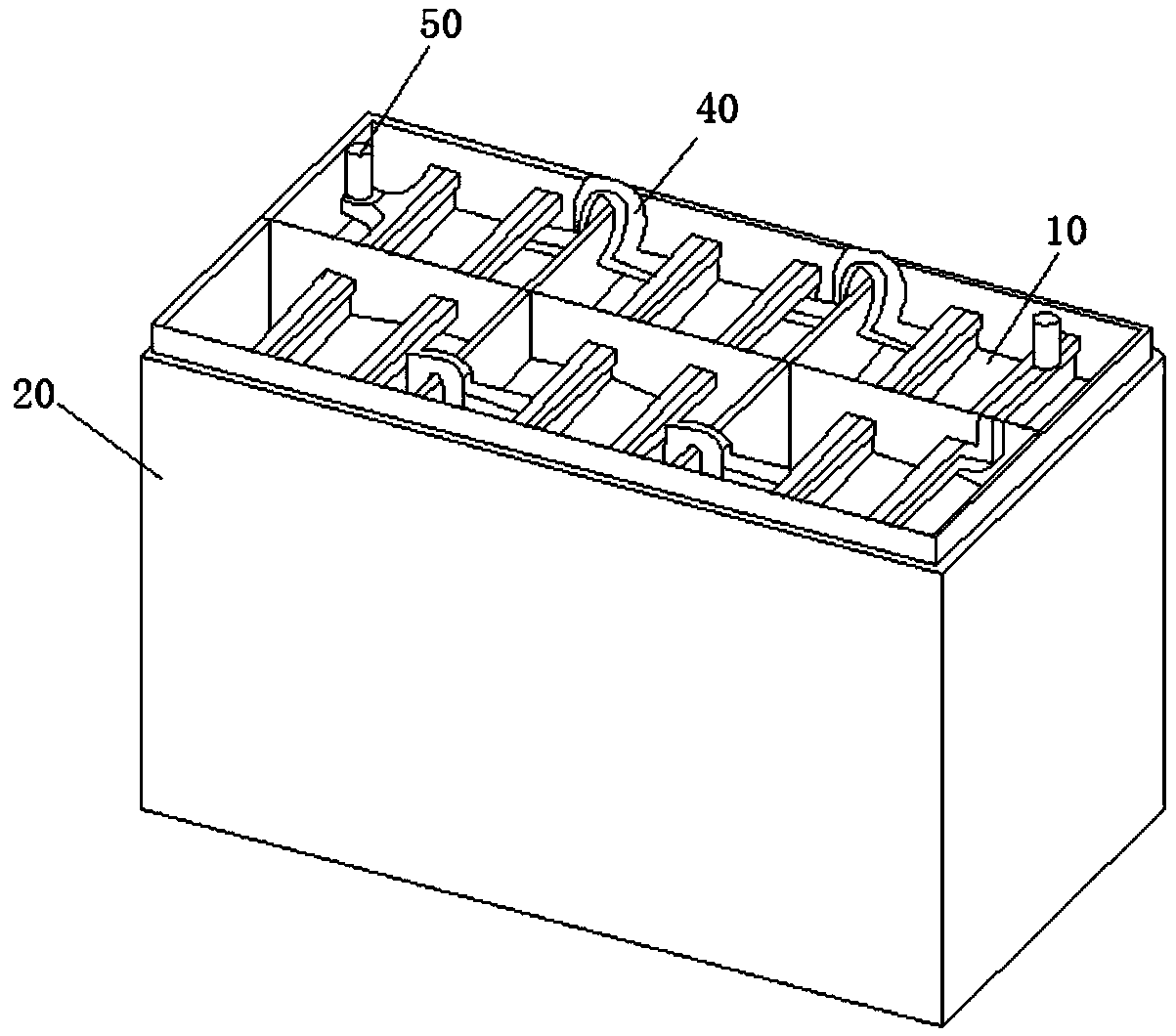

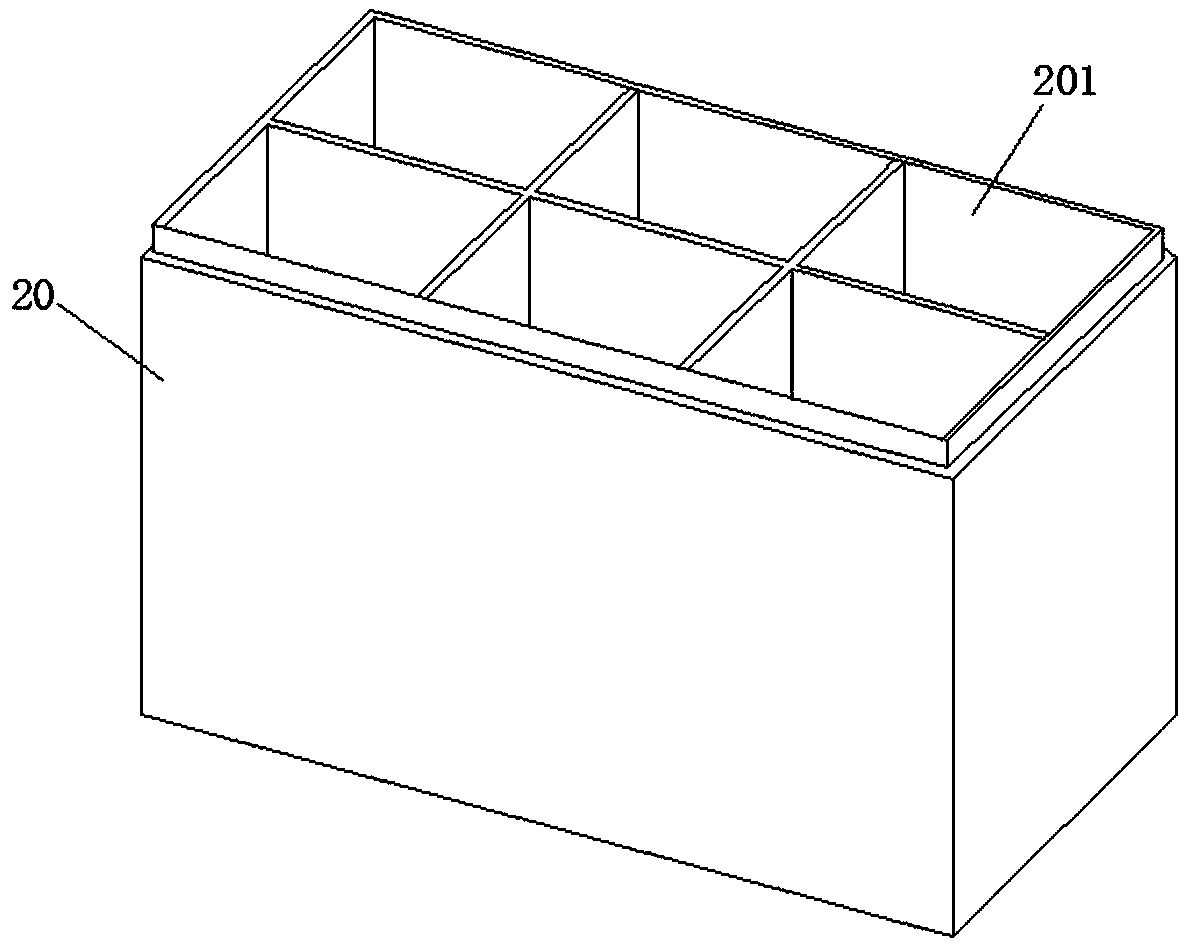

Lead-acid storage battery positive electrode plate processing method and application of lead-acid storage battery

InactiveCN109638226AImprove the workshop environmentNo emissionsFinal product manufactureLead-acid accumulator electrodesBiochemical engineeringMechanical equipment

A lead-acid storage battery positive electrode plate processing method is characterized in that a first AGM separator, a second AGM separator, a positive electrode plate grid and positive electrode fluid lead paste are included; wherein the positive electrode fluid lead paste is attached to the upper surface of the first AGM separator, the positive electrode plate grid is laid on the positive electrode fluid lead paste, a layer of positive electrode fluid lead paste is attached to the upper surface of the positive electrode plate grid, and the second AGM separator is laid on the positive electrode fluid lead paste. The storage battery electrode plate is made into a module structure and then assembled, so that the production efficiency is greatly improved, the limitation that the electrodeplate needs to be independently prepared and then assembled in the traditional changelesslead-acid storage battery machining process is broken through, the electrode plate group is prepared by adopting a 3D printing method, various mechanical equipment is omitted, and the efficiency is obviously improved.

Owner:孟婷婷

Motorcycle accessory milling device capable of carrying out arc detection on parts

InactiveCN113199069AEase of mass productionImprove processing efficiencyMeasurement/indication equipmentsOther manufacturing equipments/toolsMachiningDrill hole

The invention discloses a motorcycle accessory milling device capable of carrying out arc detection on parts. The motorcycle accessory milling device capable of carrying out arc detection on the parts specifically comprises a bottom plate, a conveying mechanism, an installation seat and a detection seat, wherein supporting columns are installed at the four corners of the top of the bottom plate separately, a top plate is fixed to the tops of the supporting columns, and a control panel is fixed to the supporting column at one side of the bottom plate; and a first movable bin is formed in the middle of the interior of the top plate, and a second movable bin is formed in the middle of one side of the interior of the top plate. According to the motorcycle accessory milling device capable of carrying out arc detection on the parts, two side plates are installed, electromagnetic sliding rails are arranged on the two side plates, and sliding blocks slide in the electromagnetic sliding rails; and a clamping seat can be driven to be transferred to a loading station, a detecting station, a milling station, a drilling station and an unloading station, multi-step operation is carried out synchronously and does not interfere with one another, so that higher machining efficiency is achieved; and flow machining is achieved, so that batch production for the part is facilitated.

Owner:长沙市熊亮机电设备有限公司

Preparation method of diatom slow-rebound material

The invention belongs to the technical field of preparation of interior decorations, and particularly relates to a preparation method of a diatom slow rebound material. The method comprises the following steps: selecting 0.3-3 parts by weight of diatomite, 100 parts by weight of polyether polyol, 3-4 parts by weight of water, 0-3 parts by weight of silicone oil, 1-1.7 parts by weight of organosilicon surfactant, 0.2-0.5 part by weight of delayed gel catalyst and 40-50 parts by weight of diphenylmethane diisocyanate; when polyether polyol and diphenylmethane diisocyanate are fused, water and diatom powder are added at the same time, the water serves as a foaming agent for producing polyurethane foam through reaction of the polyether polyol and the diphenylmethane diisocyanate, and a large amount of toxic gas and peculiar smell can overflow in the production process of the polyurethane foam; diatom powder is used as an adsorbent for removing the toxic gas and peculiar smell, so the preparation process is free of peculiar smell, and the prepared product is also free of peculiar smell; and a small amount of diatom powder is blended into the diatom slow-rebound material, so the heat deformation temperature is increased, the bending strength is increased, the decomposition rate is reduced, and the diatom slow-rebound material has non-flammable performance.

Owner:SHENZHEN KAIYUAN CHUANGZHAN IND CO LTD

Counting type lead-out and storage device for drill stems

ActiveCN105382612AReduce impactAvoid collisionMachine tool componentsMeasurement/indication equipmentsEngineeringDrill

The invention relates to a counting type lead-out and storage device for drill stems. The counting type lead-out and storage device for the drill stems comprises a drill stem lead-out device and a storing frame arranged at the rear end of the lead-out device; the lead-out device comprises a supporting frame, a drill stem supporting base is arranged above the supporting frame, an ejecting mechanism is arranged below the drill stem supporting base, and an arc-shaped lead-out plate is installed on the supporting frame; the storing frame comprises supporting plates supporting the two ends of the drill stems, a plurality of drill stem containing grooves are formed in the supporting plates at intervals, and fixing plates are installed on the outer side surfaces of the supporting plates; lifting support blocks are arranged in the drill stem containing grooves respectively and driven by oil cylinders below the supporting plates, and the oil cylinders are fixedly installed on oil cylinder frames; the storing frame further comprises a drill stem lead-in plate which is located at the lead-in end of the supporting plates and is flush with the upper surfaces of the supporting plates, a detecting through hole is formed in the drill stem lead-in plate, a pressure detecting device is installed in the detecting through hole and connected with oil cylinder controllers of the oil cylinders through a pressure signal controller.

Owner:重庆市潼南区龙泉水利开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com