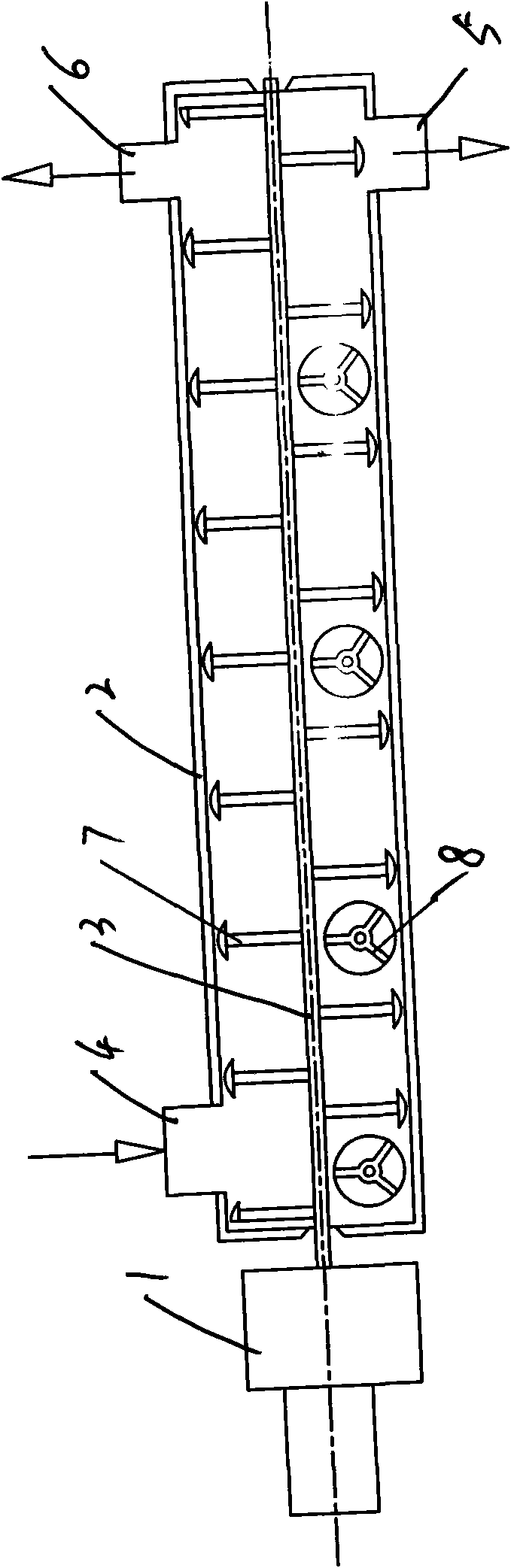

Industrial method and polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity

A technology of poly-p-phenylene terephthalamide and terephthaloyl chloride, which is applied in the field of continuous preparation of high-viscosity poly-p-phenylene terephthalamide resin, can solve the problem of low viscosity and environmental protection Unfavorable solvent recovery and other problems, to achieve the effect of purifying the workshop environment, simplifying the recovery process and equipment requirements, and increasing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The industrial method for continuously preparing high-viscosity poly-p-phenylene terephthalamide resin of the present invention comprises the following steps: adding 650L of pure water in the dissolving kettle, adding 800Kg calcium chloride dihydrate, 25Kg aluminum chloride, dissolving in Prepare an aqueous solution of about 40% calcium chloride in water. After settling and filtering, take 730Kg of calcium chloride / water solution and mix it with 3500Kg of 10% water-containing NMP to obtain NMP / calcium chloride aqueous solution; preheat it to 120°C with a pump The water-containing solvent is sent into the vacuum rectification tower (feeding in the tower) at a speed of 600kg / h, and the temperature of the tower bottom is 100°C, and the pressure of the tower bottom is rectification to remove water under the condition of -50kpa, and the refined solvent system , after inspection, the calcium chloride content is 8.4%, the water content is 85PPm, the temperature is about 50°C, a...

Embodiment 2

[0034] The industrial method for continuously preparing high-viscosity poly-p-phenylene terephthalamide resin of the present invention comprises the following steps: adding 650L of pure water in the dissolving kettle, adding 800Kg calcium chloride dihydrate, 25Kg aluminum chloride, dissolving in Prepare about 40% calcium chloride aqueous solution in water; after settling and filtering, take 830Kg of additive aqueous solution and mix with 3500Kg of 5% water-containing NMP to obtain NMP / calcium chloride aqueous solution. The speed of the solvent 1000kg / h is sent into the vacuum distillation tower (feeding in the tower), and the temperature of the tower bottom is controlled at 200°C, and the pressure of the tower bottom is controlled at -90kpa to rectify and remove water. The refined solvent system is passed through Inspection, calcium chloride content is 10%, water content is 100PPm, at 3.5m 3 Add 2600.0L of solvent to the p-phenylenediamine dissolution kettle, stir and cool dow...

Embodiment 3

[0036] The industrial method for continuously preparing high-viscosity poly-p-phenylene terephthalamide resin of the present invention comprises the following steps: adding 650L of pure water in the dissolving kettle, adding 800Kg calcium chloride dihydrate, 25Kg aluminum chloride, dissolving in Prepare about 40% calcium chloride aqueous solution in water; after settling and filtering, take 675Kg of additive aqueous solution and mix with 3500Kg of 5% water-containing NMP to obtain NMP / calcium chloride aqueous solution. The speed of the solvent 1000kg / h is sent into the vacuum distillation tower (feeding in the tower), and the temperature of the tower bottom is controlled at 200°C, and the pressure of the tower bottom is controlled at -90kpa to rectify and remove water. The refined solvent system is passed through Inspection, the refined solvent system has a calcium chloride content of 7.5%, a water content of 150PPm, a temperature of about 50°C, and a temperature of 3.5m 3 Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com