Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248 results about "Poly(p-phenylene)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(p-phenylene) (PPP) is made of repeating p-phenylene units, which act as the precursor to a conducting polymer of the rigid-rod polymer family. The synthesis of PPP has proven challenging, but has been accomplished through excess polycondensation with the Suzuki coupling method.

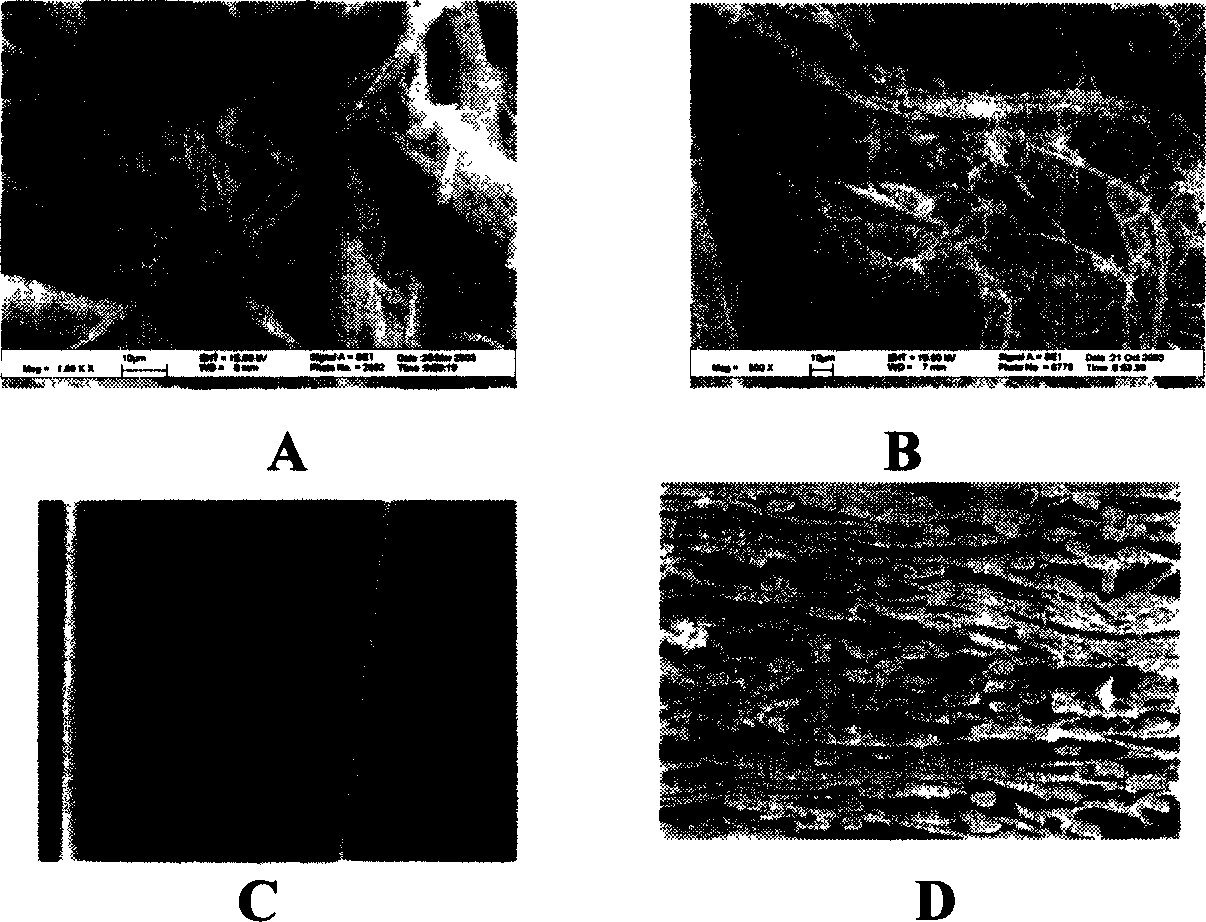

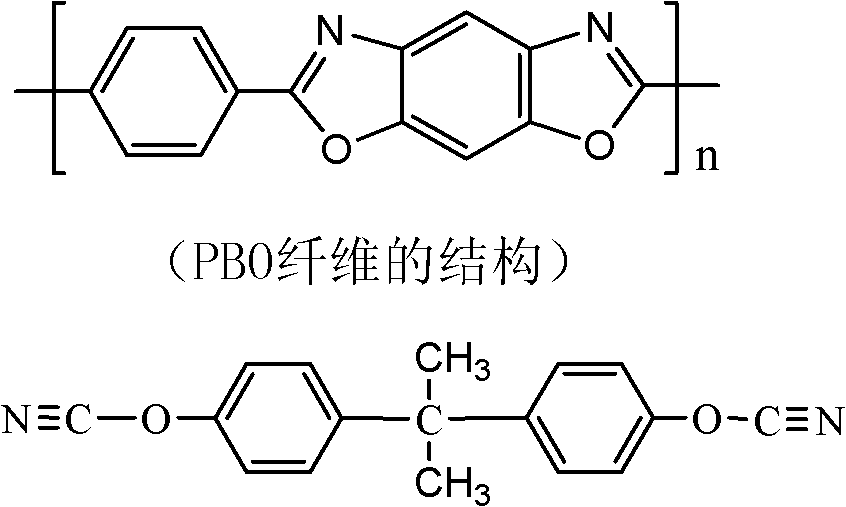

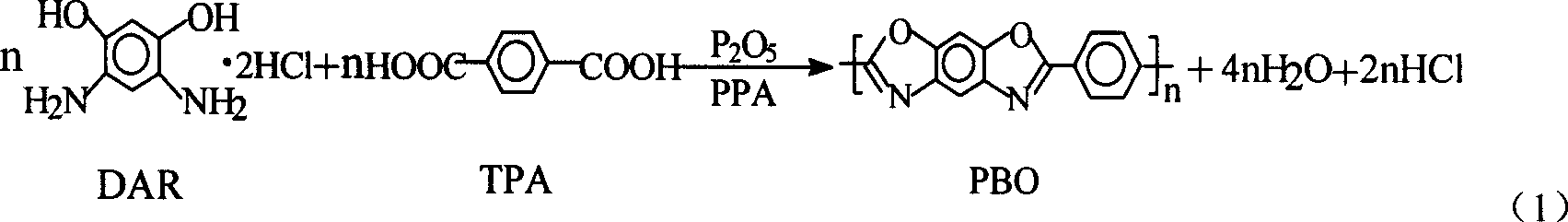

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

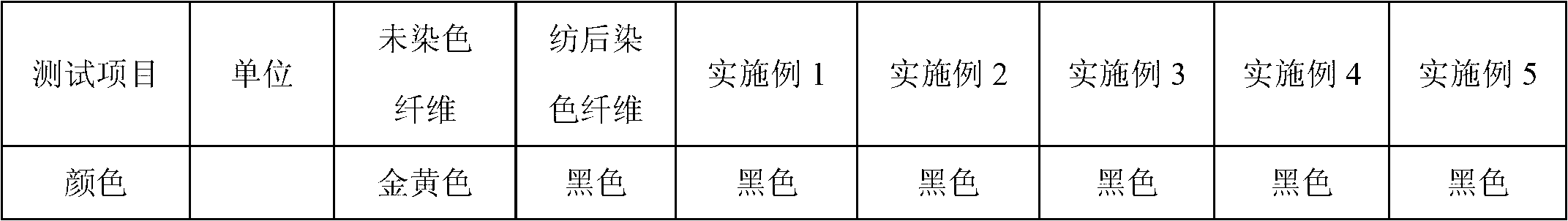

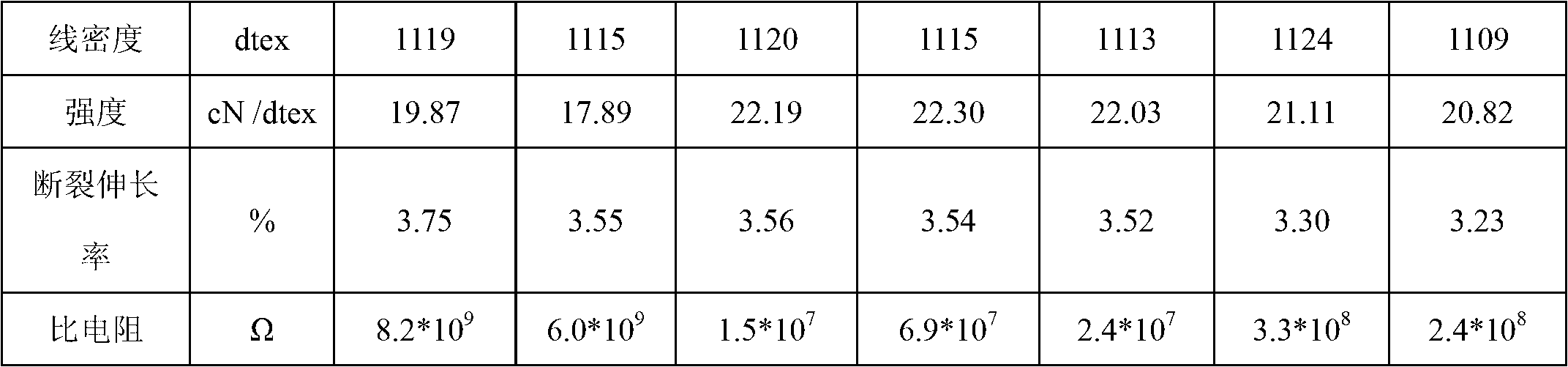

High-temperature high-pressure swelling dyeing method

InactiveCN101191306ASolving Dyeing PuzzlesIncrease profitSucessive textile treatmentsDyeing processPolymer scienceCrystallinity

The invention relates to a high temperature high pressure bulking dyeing method which comprises dyeing and after treatment. By adoption of the dyeing method of the invention, fibers or textile fabrics like aramid fibers, polysulfonamide fibers, polyphenylene sulfides, polybenzimidazole, poly-p-phenylene benzobisoxazole fibers, phenol formaldehyde resins, fibrilia and so on which have high crystallinity and high orientation degree or high glass transformation temperature can be dyed, and fibers after dyeing have the advantages of evenness, bright colors, high dyefastness, improvement of light fastness and little impact on physical properties.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

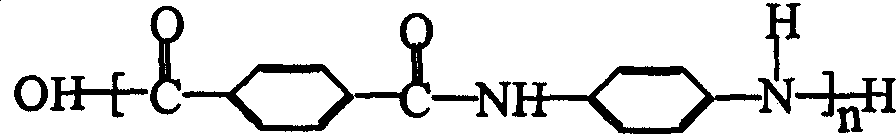

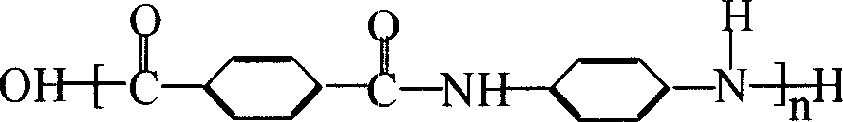

Semi-continuous preparation method of poly p-phenylene terephthalamide resin

The invention discloses a semi-continuous preparation method of poly p-phenylene terephthalamide resin which comprises the steps of, proceeding pre-polycondensation to p-phenylene diamine and part of the paraphthaloyl chloride into the dissolvent architecture of solvent and assisting solvent, charging in pre-polymerization member and the remaining paraphthaloyl chloride powder into double bolt extrusion machine, letting in dried liquid ammonia to neutralize the hydrogen chloride gas produced in the reaction, and charging macromolecular addictive polyvinylpyrrolidone into the double bolt extrusion machine to obtain the polymer.

Owner:DONGHUA UNIV +1

Amide aramid fiber paper, preparation method and application

ActiveCN1563570AHigh tensile strengthEasy to tearSynthetic cellulose/non-cellulose material pulp/paperFibrilTransformer

This invention provides a method for preparing PPTA amide paper including the following steps; adding 20-90% PPTA short fibers, 0-40% PPTA fibril chemical fibers, 1-80% PPTA pulp cakes and scattering aids to scatter them to get sizing materials to be formed on net to be de watered, squeezed and dried to be formed by thermal pressure. The proportion of said components is weight percentage. The paper can be used in structure materials, insulation materials of transformers or motors cellular, heat isolation, flame resistance, filtration and electronic materials.

Owner:SOUTH CHINA UNIV OF TECH

Nano inorganic powder coated high molecular fiber and its preparing method

The present invention relates to a high-molecular fiber composite material covered with nano inorganic powder body and its preparation method. It is made up by using at least one chemical fiber selected from poly-p-phenylene benzodioxazole fiber, aramid fiber and ultrahigh-molecular polyethylene fiber as matrix, using at least one nano inorganic powder body selected from nano titanium dioxide, nano silicone oxide, nano magnesium oxide, nano zinc oxide, nano aluminum oxide, nano zirconium oxide, nano nickel oxide and nano cobalt oxide as intermediate covering body and adopting impregnation coating process.

Owner:UNIV OF SCI & TECH BEIJING

Method for continuously preparing poly p phenylene diamine terephthalamide resin

The present invention discloses a method for continuously preparing poly(p-phenylene terephthalamide) resin, said method includes the following steps: (1). after the p-benzenediol powder is completely dissolved in the solvent containing cosolvent, adding P-benzenediol solid and terephthaloyl powder into extruder according to the ratio of 1:1-1.01; (2). feeding the solvent contaiing P-benzenediol and cosolvent into extruder adopting low-temperature medium cooling, its temperature is -20-5 deg.C, the residence time of reaction system in reactor is 2-25 min, polycondensation temp. is 30-90 deg.C, after the reaction is completed, extruding the above-mentioned material; and (3). making the extruded polymer body undergo the processes of standing still, washing, dewatering and drying so as to obtain light yellow polymer body powder.

Owner:DONGHUA UNIV

Method for improving mechanical properties of aramid fiber in supercritical fluid through stretching orientation

The invention relates to a method for improving mechanical properties of an aramid fiber in a supercritical fluid through stretching orientation. A supercritical carbon dioxide fluid is utilized for partially destroying interaction of a PPTA (poly-p-phenylene terephthamide) molecular chain in the aramid fiber under the action of certain tension, and the molecular chain is further oriented, so that the aramid fiber with good properties is obtained. The method for improving the mechanical properties of the aramid fiber in the supercritical fluid through stretching orientation mainly comprises the following steps: ensuring that the aramide fiber maintains certain tension in a closed container, introducing CO2 into the container at a certain temperature, so that the internal space of the closed container is in a supercritical CO2 state, carrying out swelling reaction for a period of time, and slowly releasing pressure, thus the highly stretching-oriented aramid fiber is obtained. The method for improving the mechanical properties of the aramid fiber in the supercritical fluid through stretching orientation guarantees that the aramid fiber is in a stretched state in a reaction process, so that orientation degree and crystallinity of a molecular chain are increased while stretching tension is changed, crystal particles are largened, and crystals are more and more complete.

Owner:DONGHUA UNIV +1

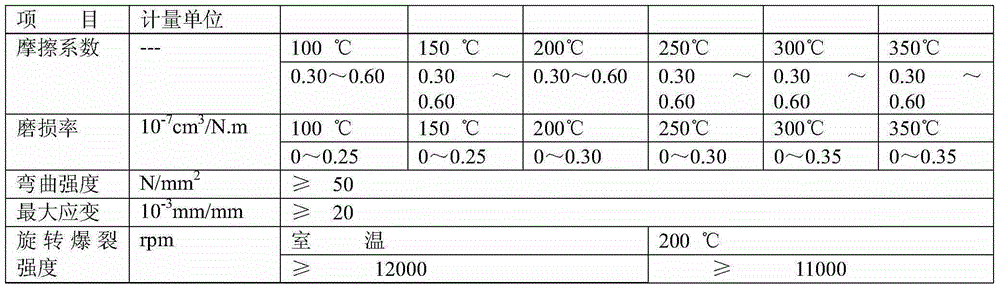

Poly-p-phenylene terephthamide composite fiber dry clutch facing and preparation method thereof

ActiveCN105114498AImprove mechanical propertiesLow production costOther chemical processesFriction liningBursting strengthFiber

The invention relates to the field of friction materials in automobile transmission structures, and discloses a poly-p-phenylene terephthamide composite fiber dry clutch facing which is prepared from the following substances: 30-70 parts of composite fibers, 15-40 parts of adhesive, 2-10 parts of rubber compound ingredients, 5-20 parts of a friction performance modifying agent, and 5-20 parts of fillers. The invention further discloses a preparation method of the poly-p-phenylene terephthamide composite fiber dry clutch facing. The preparation method comprises the following steps of (1) fiber compounding; (2) steeping and drying; (3) friction coil preparing; (4) hot press molding; (5) vulcanization heat treatment; (6) coarse grinding machining; (7) spot facing; (8) fine grinding machining; and (9) printing and marking, and packing. The poly-p-phenylene terephthamide composite fiber dry clutch facing prepared according to the preparation method has higher rotating burst strength, higher bending strength, a maximum strain value and excellent friction and wear performance and high temperature resistance. The preparation method of the poly-p-phenylene terephthamide composite fiber dry clutch facing is low in production cost, and can save 3-8 percent of raw materials effectively.

Owner:杭州科瑞特摩擦材料有限公司 +1

Continuous production device for poly-p-phenylene terephthamide resin

ActiveCN102838744AReduce continuous metering errorsQuality improvementContinuous measurementPolymer science

The invention provides a continuous production device for a poly-p-phenylene terephthamide resin, which belongs to the field of high molecular materials and relates to a high molecular material manufacturing technology. The continuous production device is characterized by comprising a p-phenylenediamine melt and solvent mixing and cooling device, a pre-polycondensation double-screw reactor, a combined second-order polycondensation double-screw reactor and a water washing device. After the continuous production device provided by the invention is used, the p-phenylenediamine and paraphthaloyl chloride are both fed as melts, so that continuous measurement errors are reduced and degrees of influences of flow fluctuation and solvent concentration on the mol ratio of the p-phenylenediamine and the paraphthaloyl chloride are reduced; and the obtained poly-p-phenylene terephthamide resin has the advantages of stable mass, narrow molecular weight distribution and low ash content and is suitable for industrially and continuously preparing the poly-p-phenylene terephthamide resin on a large-scale.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

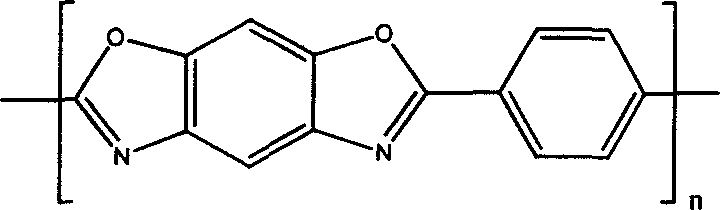

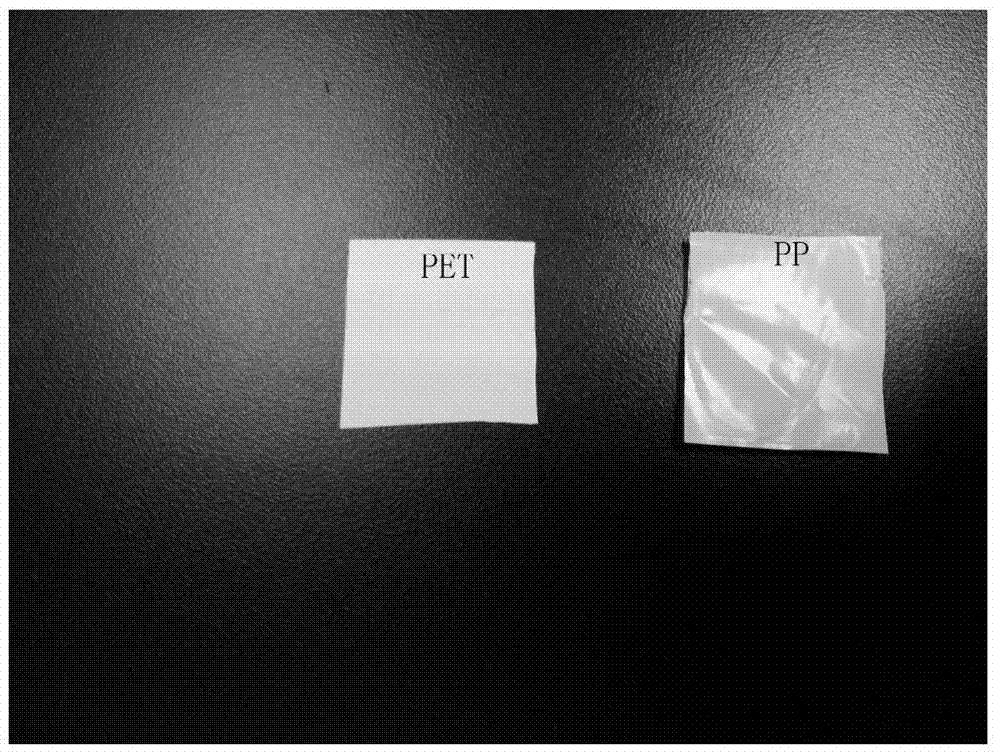

Preparation of poly-p-phenylene benzodioxazole fibers

InactiveCN1644772AEasy to transportPrevent moisture absorptionMonocomponent synthetic polymer artificial filamentFiberPolymer science

A process for preparing poly-p-phenylene benzdioxazole (PBO) fibres includes such steps as prepolymerizing by adding part (90-99%) of terephthalic acid to obtain low-viscosity prepolymer, mixing the rest of terephthalic acid with polyphosphoric acid (PPA) to obtain slurry, mixing it with prepolymer and polycondensating in a dual-screw extruder, and liquid-crystal spinning.

Owner:DONGHUA UNIV

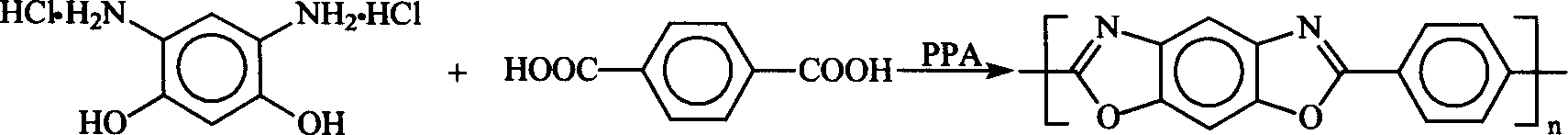

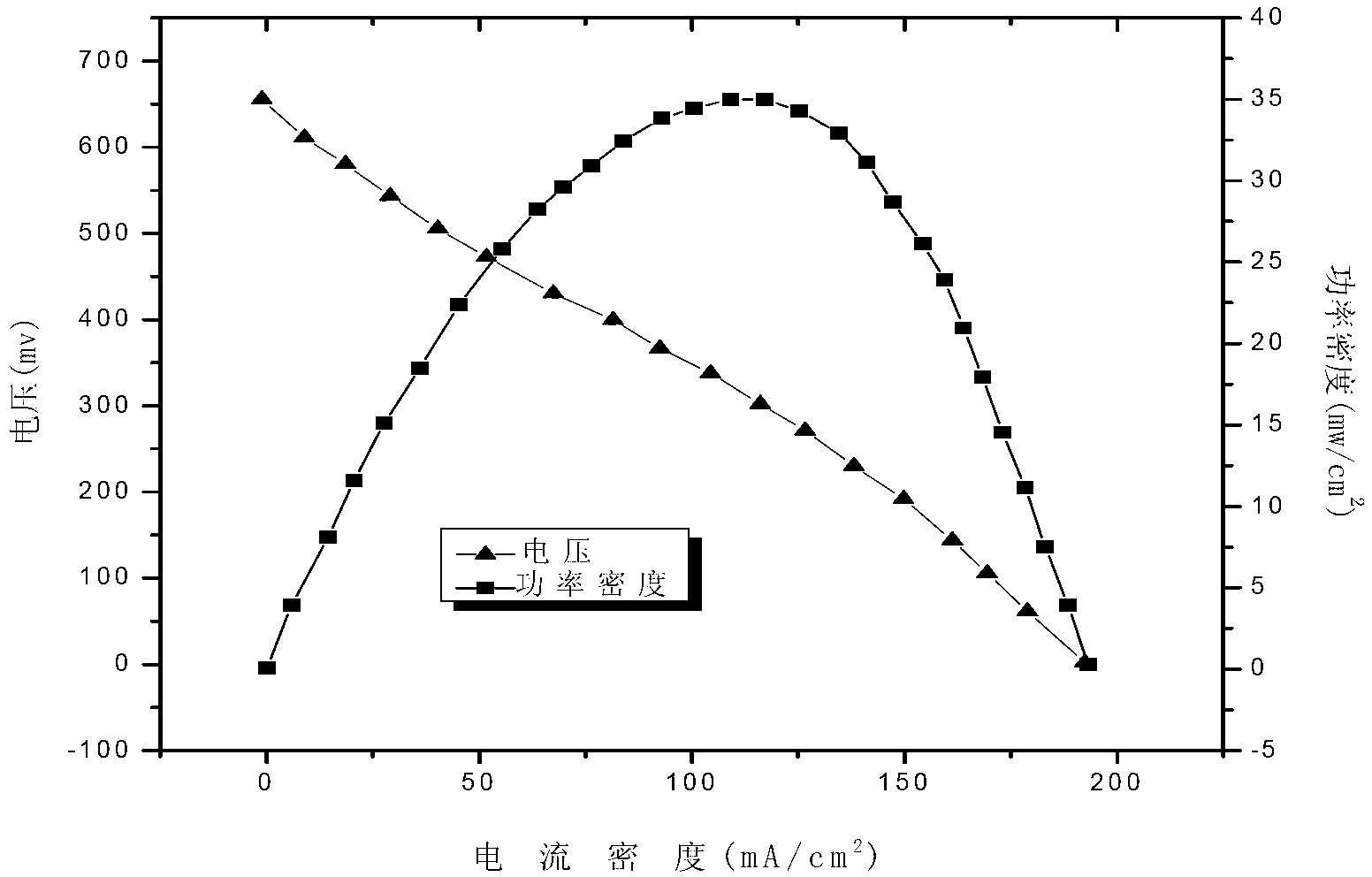

Proton exchange membrane and preparation method thereof

ActiveCN103236557AOmit separabilityOmit solubilityFinal product manufactureSolid electrolyte fuel cellsProtonPhosphoric acid

The invention relates to a proton exchange membrane and preparation method thereof, and the proton exchange membrane is a Poly-p-phenylene ben-zobisthiazole and polyphosphoric acid blend membrane (PBO / PPA), and the method for preparing the Poly-p-phenylene ben-zobisthiazole and polyphosphoric acid blend membrane (PBO / PPA) as a proton exchange membrane comprises: (1) polymerizing and obtaining a PBO / PPA slurry; (2) preparing the PBO / PPA slurry into a PBO / PPA proton exchange membrane; (3) controlling the thickness of the membrane by controlling the concentration of the polymer solution and the compacting temperature and pressure; (4) carrying out a proton conductivity test directly after the membrane is taken out and the membrane is used as a proton exchange membrane is assembled in the H2 / O2 fuel monocell for investigating power generation performance. The invention selects an appropriate film forming technology according to the characteristic of the PBO rigid molecular chain, and has the advantages of simple preparation technology and easy control, and the obtained proton exchange membrane has a higher proton conductivity under high temperature with excellent power generation property.

Owner:DONGHUA UNIV

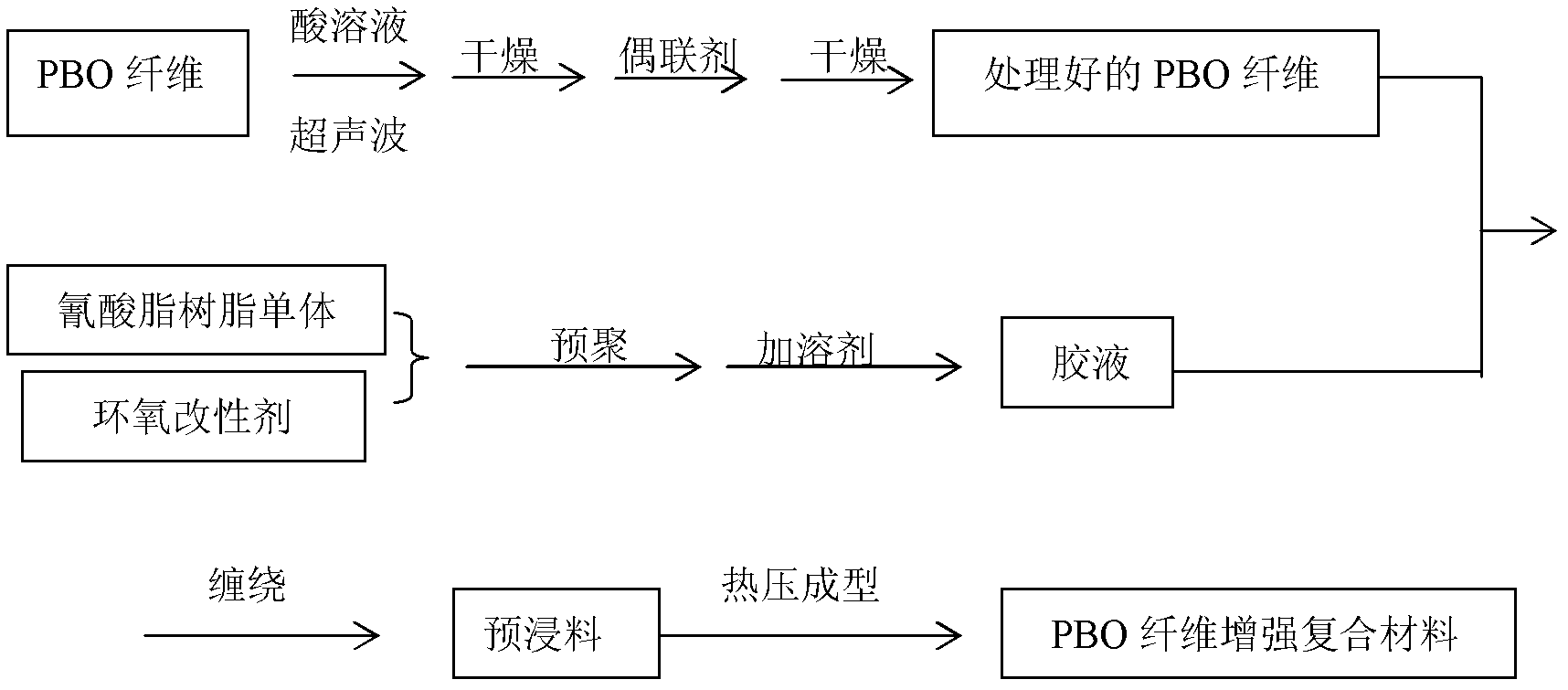

High-performance wave-transmitting composite material based on PBO (poly-p-phenylene benzobisthiazole) fiber and preparation method thereof

The invention discloses a high-performance wave transmitting composite material based on PBO (poly-p-phenylene benzobisthiazole) fiber and a preparation method of the composite material. The preparation method comprises the steps of: preparing epoxy-modified cyanate resin prepolymer from PBO fiber as a reinforcing material and modified bisphenol A type cyanate resin as a substrate through a heating fusion method, wherein the used cyanate resin contains an epoxy modifier; and adding an organic solvent to prepare liquid glue, immersing and winding treated PBO fiber, obtaining a prepreg after solvent is volatilized, paving the prepreg in a mold, and preparing the PBO fiber-reinforced cyanate composite material by a high-temperature pressure molding method. The high-performance wave transmitting composite material has the advantages of high strength, high modulus, low density, excellent high-temperature resistance and dielectric properties, excellent molding process property and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

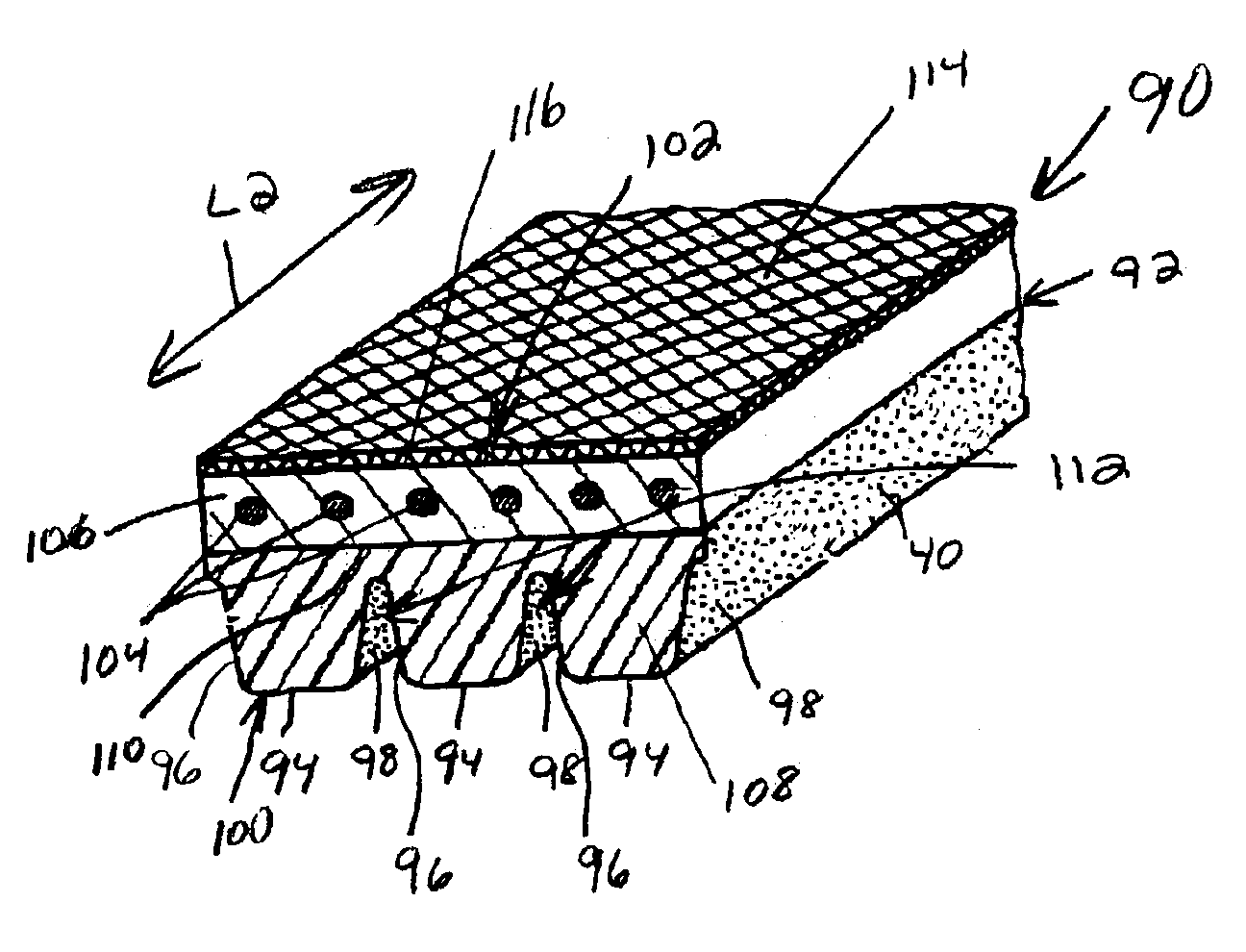

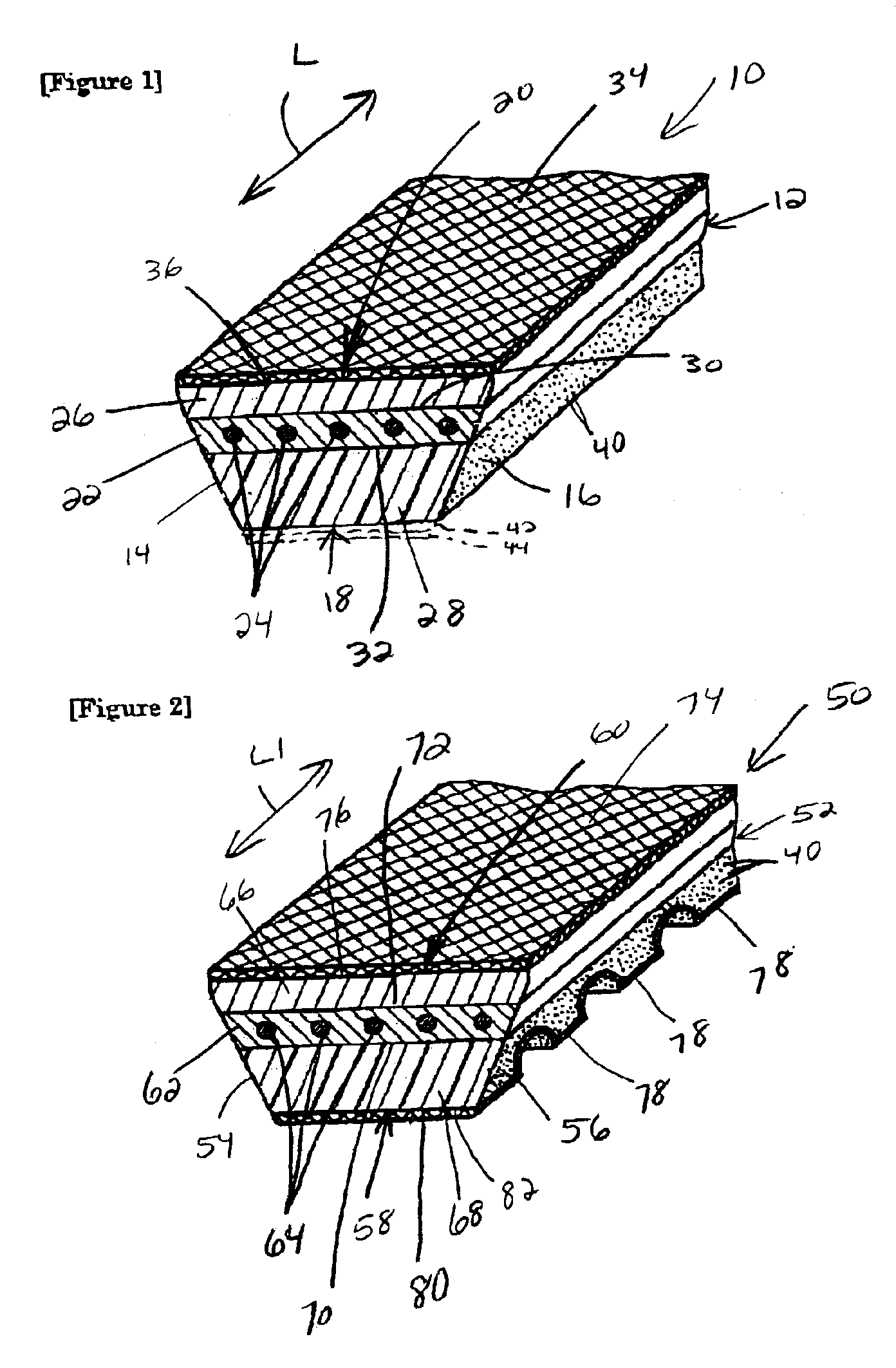

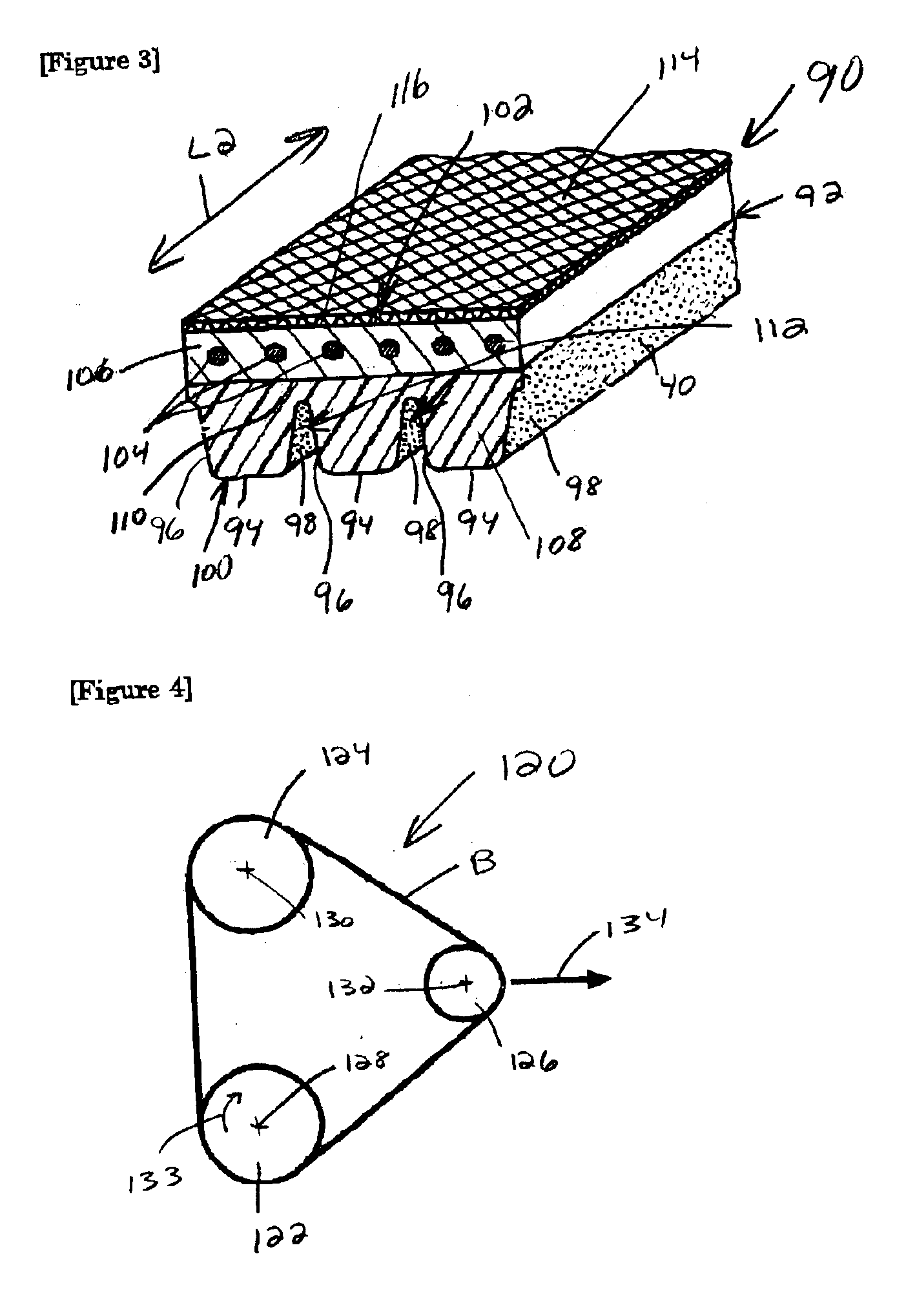

Power transmission belt

A power transmission belt having a body with a length, a width, an inside, and an outside. The body includes a rubber composition. The body further has a plurality of short fibers in the rubber composition. The plurality of short fibers may include a plurality of poly-p-phenylene benzobisoxazole fibers.

Owner:MITSUBOSHI BELTING LTD

Continuous large-scale production method for p-aramid nanofiber dispersion liquid

ActiveCN106750265AThe polymerization process went wellForm evenlyMonocomponent polyamides artificial filamentNanofiberChloride

The invention relates to a continuous large-scale production method for p-aramid nanofiber dispersion liquid, and belongs to the technical field of novel polymer materials. A proper aid is added in a process of generating poly-p-phenylene terephthamide (PPTA) through a reaction of p-phenylenediamine and paraphthaloyl chloride, so that the PPTA can directly generate nanofiber instead of random particles under control. Double screws are taken as a main reactor of PPTA polymerization, and an aid damaging molecular molecular aggregation of the PPTA is added into a PPTA polymerization system, so that successful proceeding of a PPTA polymerization process can be ensured on the one hand, interaction between the aid and the PPTA can be accelerated under the strong shear stirring action of a screw element on the other hand, and uniform nanofiber is formed instead of random particles by the PPTA. Moreover, a dispersing process of the nanofiber is finished directly in the screws under the shearing action of the double screws. The method is simple in equipment and is urgent in production links, major reaction and dispersion processes are finished in the double screws, and the production stability and continuity are enhanced greatly.

Owner:山东聚芳新材料股份有限公司

P-aramid nanofiber solution and preparation method thereof

The invention relates to a novel method for preparing a p-aramid nanofiber solution, belongs to the field of macromolecules and also belongs to the field of nano-materials. According to the solution, p-aramid nanofibers have the diameter of 20-50nm and the length of about 10 microns. The method comprises the steps: purging a dry three-mouthed bottle with nitrogen gas for 10 minutes under the protection of nitrogen gas, adding a deprotonation reagent (sodium hydride or potassium hydride or lithium hydride) and anhydrous dimethyl sulfoxide under the protection of nitrogen gas, mechanically stirring, heating to the temperature of 70 DEG C within 20 minutes, continuously reacting for 40 minutes, and then, cooling to the temperature of 30 DEG C; and then, slowly adding poly-p-phenylene terephthalamide staple fibers, and reacting for 6-72 hours at the temperature of 30 DEG C, thereby obtaining an orange-red solution containing the p-aramid nanofibers, wherein the weight percent of the p-aramid nanofibers is 0.05-3.6%. The method disclosed by the invention is simple and is strong in operability, and a feasible method is provided for the low-cost and large-scale preparation of p-aramid nanofiber materials.

Owner:LUDONG UNIVERSITY

Preparation of high viscosity Poly(p-phenyleneterephthalamide) resin

The invention discloses a method for preparing poly p-phenylene terephtha-lamide resin with high viscosity. Firstly, para-phenylene diamine is fully dissolved and added into a prereactor, then paraphthaloyl chloride is added into the prereactor for prepolycondensation, then a prepolymer is added into a double screw extruder, a pyridine acid absorbent and a remained paraphthaloyl chloride low-temperature solution are respectively and synchronously added for a final polycondensation reaction through a liquid metering pump, and the extrusion is performed; and a polymer is kept stand, washed, dehydrated and dried. The inherent viscosity of the poly p-phenylene terephtha-lamide resin prepared by the method is between 6.5 and 9.5dl / g, the resin has good spinnability, and the spun fiber has good color and luster, high strength, and stable performance.

Owner:SINOPEC YIZHENG CHEM FIBER

Preparation method of black p-aramid fiber

ActiveCN102839444AHigh strengthEvenly dispersedPigment addition to spinning solutionMonocomponent polyamides artificial filamentCarbon nanotubeUltimate tensile strength

The invention relates to a preparation method of black p-aramid fiber. The black p-aramid fiber obtained by the preparation method has high fiber strength and is fadeless. The preparation method comprises the following steps of: (1) dispersing multi-walled carbon nanotubes in concentrated sulfuric acid to obtain carbon nanotube dispersion, wherein the weight ratio of the multi-walled carbon nanotubes to concentrated sulfuric acid is 1:(100-500), the average wall number of the multi-walled carbon nanotubes is 2-6, the average diameter of the multi-walled carbon nanotubes is 1-20nm, and the average length of the multi-walled carbon nanotubes is 0.5-20mu m; and (2) dissolving poly-p-phenylene terephthamide to the carbon nanotube dispersion to obtain a spinning stock solution, filtering and debubbling the spinning stock solution, spinning by a dry-jet wet spinning method, washing with base, washing with water, drying and carrying out heat treatment to obtain the black p-aramid fiber, wherein the weight ratio of poly-p-phenylene terephthamide to the carbon nanotube dispersion is 1:(3.9-4.1), and the intrinsic viscosity of poly-p-phenylene terephthamide is 6-8dL / g<3>.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

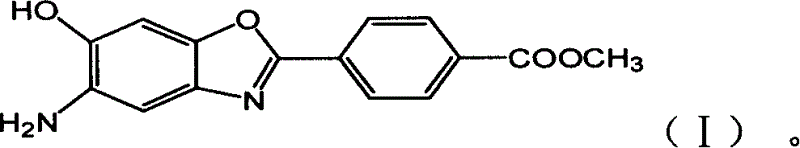

AB type poly(p-phenyl) benzdioxan monomer and its preparation and use

A 5- amino-6-hydroxy-2-MAB and its production are disclosed. The production is carried out by: (1) R1-R2, green synthesizing 4-amino-6-ANR.HCL by resorcinol; (2) R3: preparing AB monomer precursor 5-nitro-6-hydroxy-2-NHAB, and refining purifying; (3) R4: catalyst hydrogenating reducing NHBA nitro group, and obtaining high-purity AB PBO monomer. It achieves simple process, short polymeric time and normal polymeric apparatus.

Owner:ZHEJIANG UNIV OF TECH

Brake pad made of composite material

InactiveCN106009495AImprove high temperature resistanceImprove heat stabilityFriction liningActuatorsCarbon fibersSisal fiber

The invention discloses a brake pad made of a composite material. The brake pad comprises a steel sheet and a friction block, and the friction block is prepared from boron-modified phenolic resin, organic silicone-modified phenolic resin, barium phenolic resin, phenylacetylene phenolic resin, epoxy-terminated liquid reaction type nitrile rubber, butadiene rubber, molybdenum disulfide, sisal fiber, bamboo carbon fiber, aluminum fiber, molybdenum fiber, poly-p-phenylene benzodioxazole fiber, zinc oxide crystal whiskers, montmorillonite, vermiculite, nanometer aluminum oxide, cerium oxide, zirconium boride, aluminum silicate hollow spheres, graphene oxide, copper powder, carbon nano tubes, nano carbon black, butadiene styrene rubber powder, ammonium molybdate and octaphenyl silsesquioxane. The brake pad made of the composite material is high in high temperature resistance, excellent in heat stability, high in abrasion resistance and long in service life.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

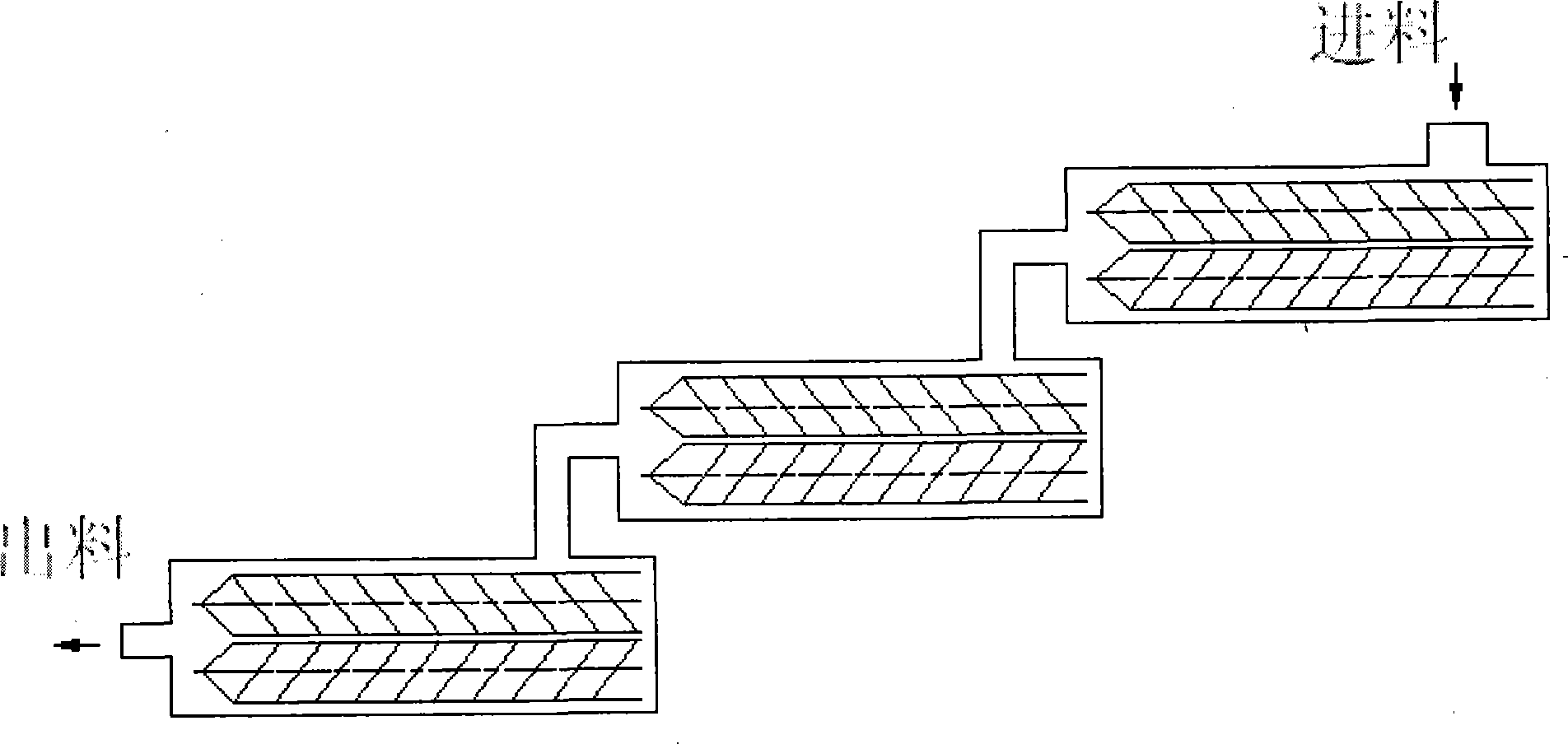

Continuous polymerization method of high-viscosity poly-p-phenylene terephthamide

The invention provides a continuous polymerization method of high-viscosity poly-p-phenylene terephthamide. Based on the design of the polymerization formula, and the design and use of a novel mixing device and a hydrogen chloride discharge device matched with the design of the polymerization formula, continuity of the PPTA (poly-p-phenylene terephthamide) polymerization is guaranteed, and the molecular weight of the obtained PPTA is high. The method is characterized by comprising the following steps of: preparing materials, namely dissolving hydrotropy salt and PPD (p-Phenylenediamine) at a low temperature; keeping the TPC (paraphthaloyl chloride) in molten state; mixing, by combination of a Venturi jet mixer and a dynamic or static mixer, ensuring even mixing of the TCP and the PPD solution; and polymerization, finishing the polymerization of the PPD and the TPC by a double-screw reactor, and eliminating the hydrogen chloride released by some reaction. The continuous polymerization method has the advantages of improving the stability of the PPD and TCP reaction, ensuring the continuity and the stability of the production, and facilitating the high-efficiency separation of the hydrogen chloride; by the continuous polymerization method provided by the invention, polymerization production of high-viscosity PPTA can be realized steadily and continuously.

Owner:AFCHINA CORP CO LTD +1

Industrial method and polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity

The invention relates to an industrial method and a polycondensation reactor for continuously preparing poly-p-phenylene terephthamide resin with high viscosity, comprising the following steps: (1) compounding a flux into an aqueous solution, then mixing with solvent to remove water by refinement and continuously and stably obtaining a solvent system with the water content conforming to the requirement, wherein the weight percentage of the flux in the solvent system is from 6 percent to 15 percent; (2) performing the polycondensation reaction of para-phenylene diamine (PPD) and terephthalyl chloride (TPC) in the mol ratio of 1.01-1 to 1-1.01 in the solvent system prepared in the step (1), and obtaining a polymer after reaction; and (3) obtaining the poly-p-phenylene terephthamide resin in yellow powder after pulverizing, neutralizing, washing and drying the polymer. By utilizing the method, the adverse effects of weather and operation on the polymerized solvent system water is overcome, and continuous, closed and clean production is realized.

Owner:中国平煤神马控股集团有限公司

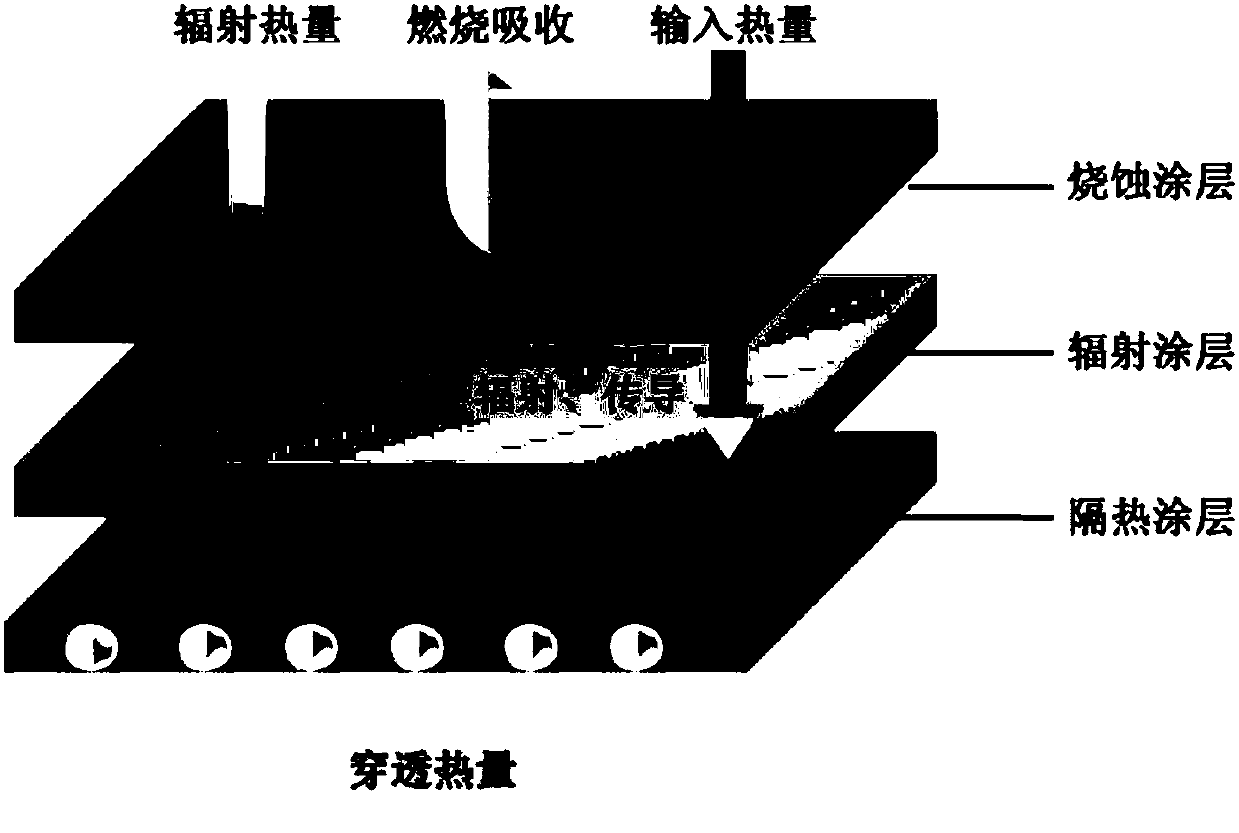

Silicone rubber-based heat-insulating coating and preparation method thereof

ActiveCN107760194AImprove mechanical propertiesEnhanced interface bindingCoatingsSpecial surfacesFiberRocket

The invention provides a silicone rubber-based heat-insulating coating and a preparation method thereof. The silicone rubber-based heat-insulating coating comprises heat-insulating coating, radiationcoating and ablation coating, wherein the heat-insulating coating is arranged on the surface of a substrate; the radiation coating is arranged between the heat-insulating coating and the ablation coating; the heat-insulating coating, the radiation coating and the ablation coating are silicone rubber-based coating; the radiation coating performing an in-situ ceramization reaction through heat penetrating through the ablation coating; poly-p-phenylene benzobisoxazole fiber is distributed in the ablation coating. The preparation method comprises the steps of preparing the ablation coating, the radiation coating and the heat-insulating coating. Compared with the prior art, the silicone rubber-based heat-insulating coating has the beneficial effects as follows: through use of the poly-p-phenylene benzobisoxazole fiber, the mechanical properties of the ablation coating are improved; through the in-situ ceramization reaction, the high-radiation coating is prepared, and the defects of low mechanical properties and heat-insulating performance of the silicone rubber-based heat-insulating coating are successfully overcome; the silicone rubber-based heat-insulating coating has a wide application prospect in the field of heat protection of structural surfaces of rocket-carrying and missile weapons and the like.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

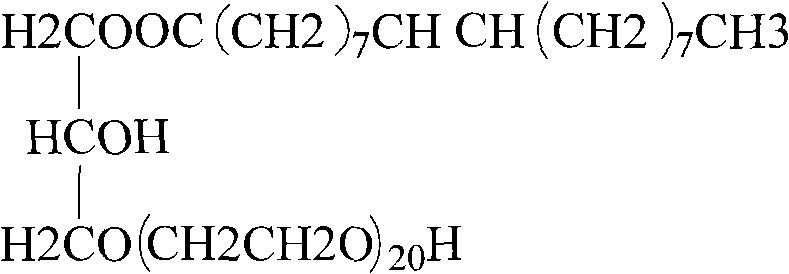

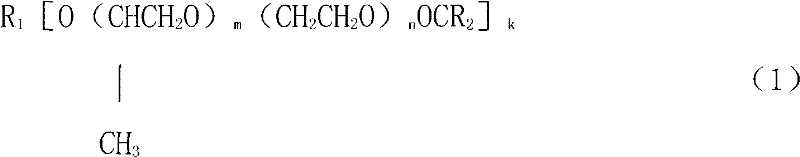

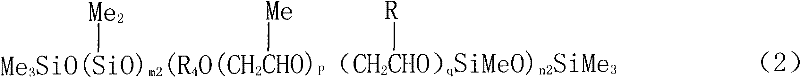

Filament oil agent for poly-p-phenylene telephthalamide

The invention discloses a filament oil agent for poly-p-phenylene telephthalamide, aiming to solve the problems, such as poor heat resistance, smoothness, adaptability and the like of the oil agent in the prior art. The filament oil agent for the poly-p-phenylene telephthalamide, provided by the invention, comprises the following components: (a) 3-60wt% polyol fatty acid ester, (b) 2-40wt% polyoxyethylene polyol fatty acid ester, (c) 5-40wt% fatty alcohol ethylene oxide-propylene oxide polyether fatty acid ester, (d) 1-20wt% polyoxyethylene alkyl phosphonate, (e) 5-30wt% long-chain fatty alcohol and fatty acid ester, (f) 1-20wt% adhesion property improver and (g) 0.1-5wt% polyether modified silicone oil. The oil agent has the advantages of good smoothness, heat resistance, antistatic property, dyeing uniformity and post processing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for purifying N-methyl pyrrolidone

InactiveCN102993078AEfficient removalMeeting high-purity demandsOrganic chemistryInorganic saltsDistillation

The invention relates to a method for purifying N-methyl pyrrolidone. The method comprises the steps of (1) washing poly-p-phenylene terephthamide polymers obtained after the polycondensation through deionized water repeatedly to obtain washing liquor containing the N-methyl pyrrolidone (NMP), adding antalkali into the washing liquor to perform neutralizing treatment, and regulating PH of the solution to 6-7; (2) performing extraction separation on the washing liquor to obtain solution with an NMP-extraction agent system on the lower layer and a water-inorganic salt system on the upper layer, and performing secondary extraction on the water-inorganic salt system on the upper layer; and (3) adding an organic solution with an isocyanic acid functional group into a crude product of the NMP, and performing filtering and distillation to obtain the high-purity NMP. By means of the method, the purity of the finally-obtained NMP solvent is remarkably improved, processing procedures are simplified, accordingly, working efficiency is improved, and operability is strong. Furthermore, the purity of the NMP solvent obtained by means of purifying is higher than 99.8%, and the water content of the NMP solvent is smaller than 0.01%.

Owner:DONGHUA UNIV +1

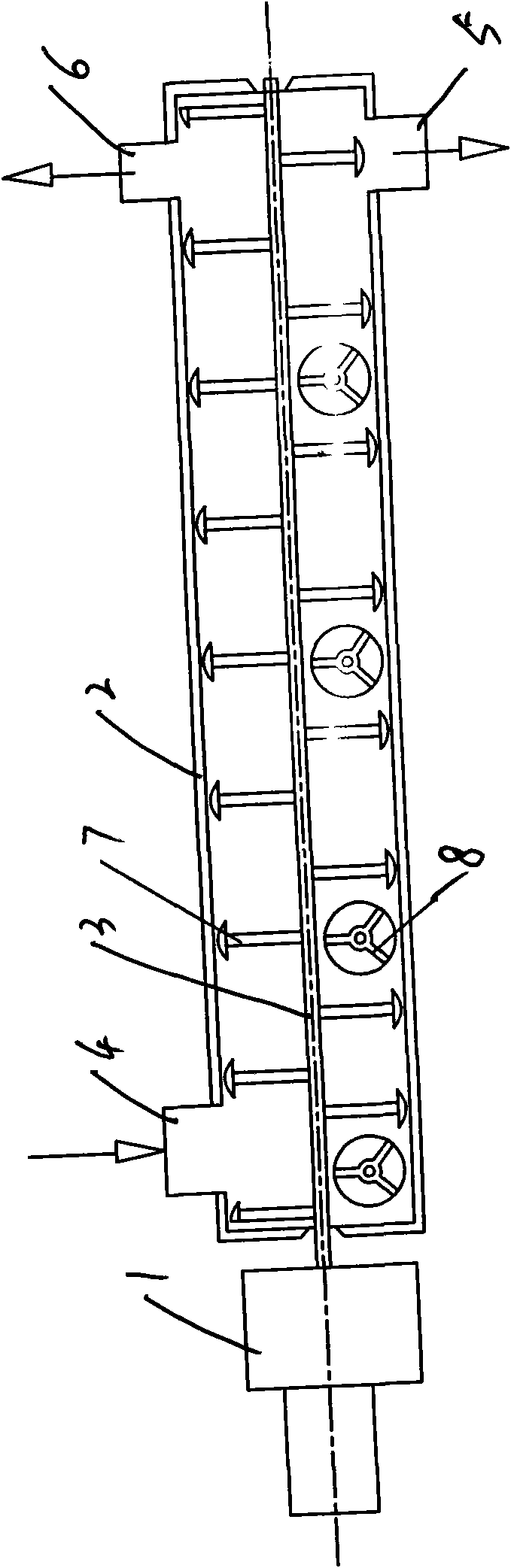

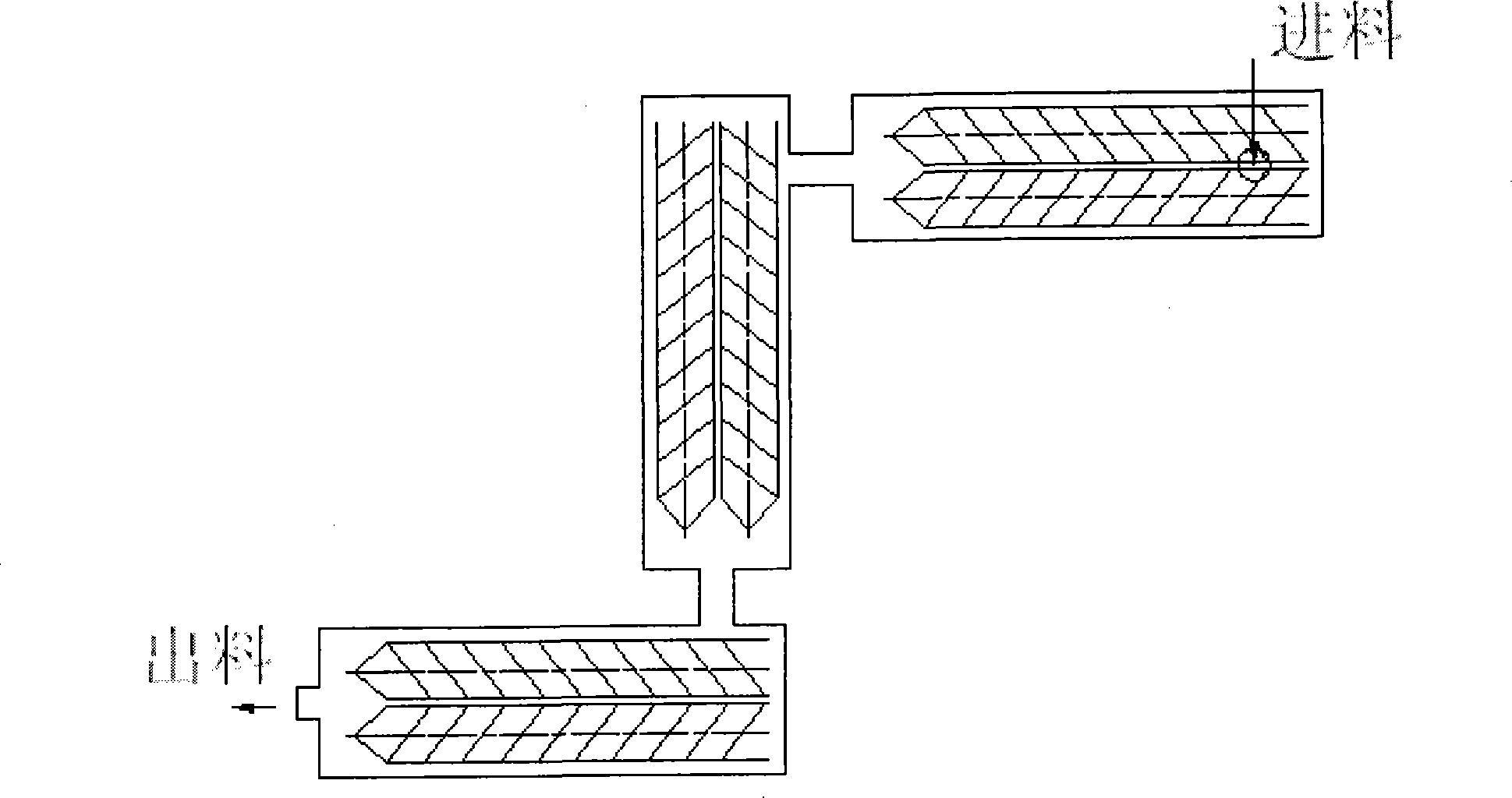

Continuous polymerization reaction device for producing poly-p-phenylene benzo dioxazole

ActiveCN101245143AWell mixedHigh molecular weightMonocomponent synthetic polymer artificial filamentWorking temperatureDiameter ratio

The invention discloses a continuous polymerization device which prepares PBO, which relates to a continuous polymerization device. The invention brings about solutions to the stirring problems caused by the high viscosity of PBO polymer and to the low molecular weight problems existed in the polymer which is prepared by current manufacturing process. The discharge hole of the pre-polymerization reactor of the invention is communicated with the charging hole of screw extruder unit which consists of 2-10 full-bay screw extruders which are connected by in-line platform combination or staging pack; wherein the screw, screw barrel, the charging hole, the discharge hole are acid-resisting and corrosion-resisting; the working temperature for screw is 20-300 DEG C, the extrusion pressure for the screw extruder is 0.1-30 MPa, the diameter D for the screw is 20-200 mm, the length-diameter ratio L / D for the screw is 10-60, the rotation speed is 1-1000r / min, and the vacuum degree in the screw is minus 0.1 MPa. The continuous polymerization device has the advantages of improved molecular weight, quick reaction speed, short manufacturing cycle, uniform material mixture and full reaction, which can realize continuous operation and is conductive to commercial process.

Owner:HARBIN INST OF TECH

Preparation method of poly-p-phenylene terephthamide resin

The invention relates to a preparation method of poly-p-phenylene terephthamide resin. The preparation method is characterized by comprising the following steps: (1) preparing a p-phenylenediamine solution; (2) preparing paraphthaloyl chloride molten mass; (3) subjecting the p-phenylenediamine solution and the paraphthaloyl chloride molten mass to a pre-polymerization reaction; (4) carrying out a condensation reaction to prepare the poly-p-phenylene terephthamide resin. The prepared poly-p-phenylene terephthamide resin powder has the advantages of high polymerization degree, uniform particle, narrow molecular weight distribution, and small repose angle. During the whole technology process, the paraphthaloyl chloride is added in a molten state, so the metering is relatively simple, the precision is high, the production stability is higher, and the production period is longer. Moreover a mixer and a pre-reactor are adopted, the thermal energy generated by the reactions can be effectively distributed to the mixer, the pre-reactor, and a double-screw reactor, thus the thermal transmission problem is solved, and the polymerization process is controllable.

Owner:SINOPEC YIZHENG CHEM FIBER +1

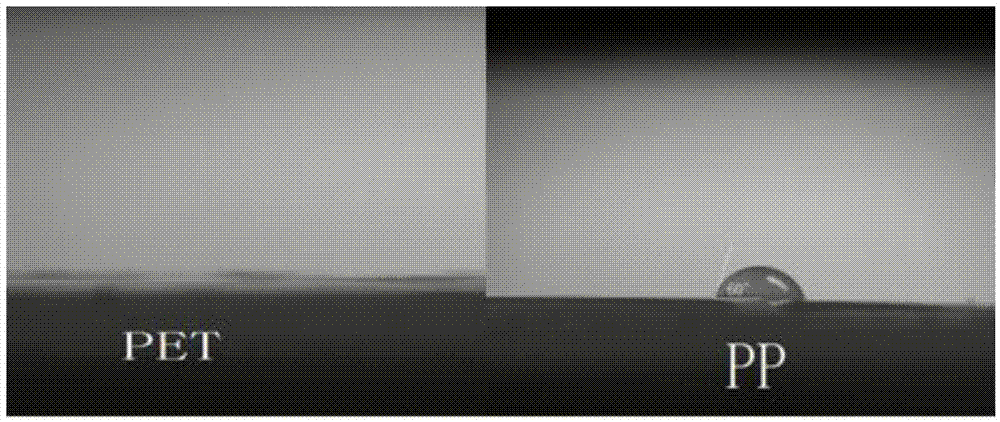

Lithium battery

InactiveCN106920910ASolve problems such as poor infiltrationImprove securityLi-accumulatorsCell component detailsCellulosePhosphonium salt

The invention discloses a lithium battery. The lithium battery comprises a cellulose non-woven fabric diaphragm and an electrolyte, wherein the electrolyte contains an ionic liquid solvent; the cellulose non-woven fabric battery diaphragm is selected from one or more of polypropylene fiber, polyacrylonitrile fiber, formalized polyvinyl alcohol fiber, polyethyleneterephthalate, polyethylene glycol terephthalate, nylon and poly-p-phenylene terephthamide. The ionic liquid solvent is preferably selected from aliphatic quaternary ammonium salt, quaternary phosphonium salt, pyrrole salt, pyrrolidone salt, imidazolium salt and piperidine salt. Meanwhile, the invention provides the high-safety cellulose non-woven fabric diaphragm and the ionic liquid solvent, and the problem that the wettability of the ionic liquid solvent with a traditional polyolefin diaphragm is low is also solved, so that the charge and discharge performance of the power battery is improved, and the safety of the lithium battery is doubled and improved.

Owner:OPTIMUM BATTERY CO LTD

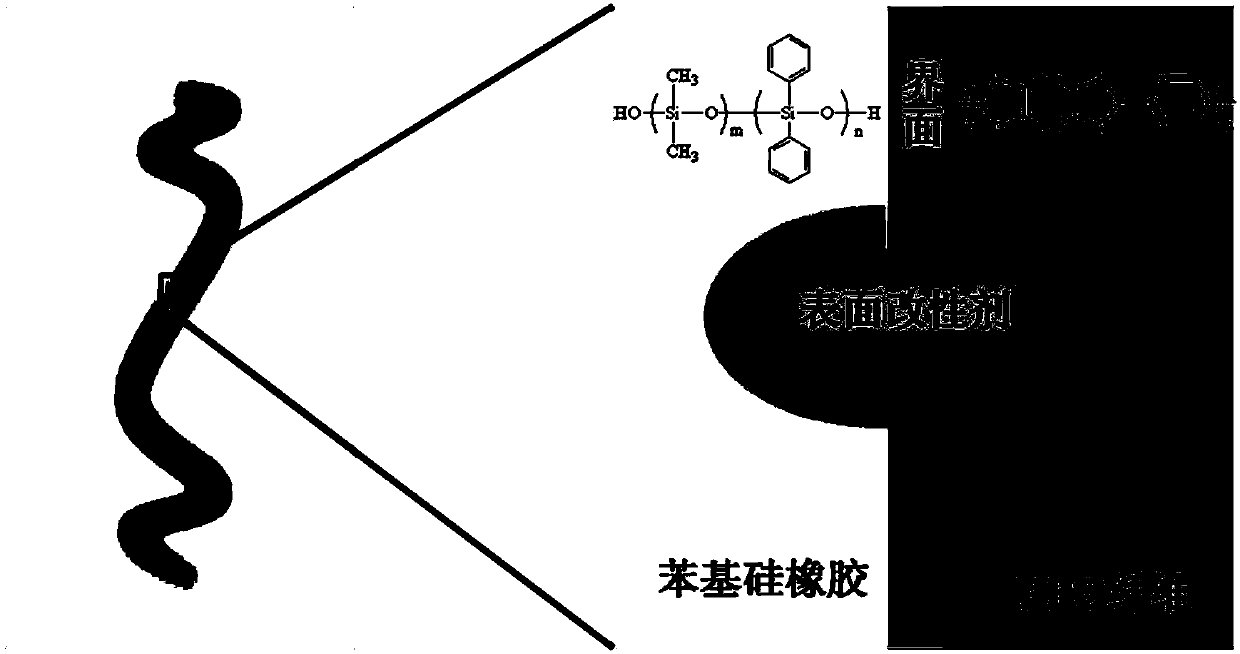

Preparation method for poly-p-phenylene-benzo-dioxazole fibre/epoxy resin composite material

InactiveCN101319084ASolve the problem of poor interface binding forceImprove mechanical propertiesFirming agentRare earth

The invention relates to a method for preparing a poly (p-phenylene-benzobisoxazole) fiber / epoxide resin composite material. The surface modification treatment is performed on the poly (p-phenylene-benzobisoxazole) fiber by using a rare-earth modifying agent, a firming agent is added into the epoxide resin to prepare an epoxy colloid, the treated poly (p-phenylene-benzobisoxazole) fiber is immersed into the epoxy colloid to prepare a prepreg compound, the content of the prepreg compound in the epoxy colloid is controlled to between 35 and 45 percent, and then the composite material is prepared by using the wet method filament winding process. The winding process is performed on a digital control fiber winder, and the prepreg compound is wound on a flat core model to certain thickness and is subjected to solidifying, demoulding, finishing and forming, wherein, the rare-earth modifying agent comprises lanthanum chloride, ethanol, ethylenediamine tetracetic acid, ammonium chloride, nitric acid and carbamide. The method has simple technique and low cost, and does not pollute the environment. The composite material prepared by the technique has good mechanical property.

Owner:SHANGHAI JIAO TONG UNIV

Positive electrode material and battery

InactiveCN106328950AImprove conductivityImprove stabilityCell electrodesFinal product manufactureInternal resistancePolypyrrole

The invention discloses a positive electrode material. The positive electrode material comprises a positive electrode active material and a conductive agent, wherein the positive electrode active material can realize deintercalation-intercalation of first metal ions in a reversible manner; the conductive agent comprises a conductive polymer; the conductive polymer is selected from at least one kind of polyacetylene, polyphenylene sulfide, polyquinoline, poly-phenylene vinylene, poly-p-phenylene, polypyrrole, polyaniline, polythiophene and poly-3, 4-ethylenedioxythiophene-polystyrolsulfon acid; and the conductive agent accounts for 6-15% of the positive electrode material based on mass percentage. The invention also discloses a battery, wherein the battery comprises a positive electrode, a negative electrode and an electrolyte; and the positive electrode comprises the positive electrode material. According to the positive electrode material, the conductive polymer is used as the positive electrode conductive agent; and the conductive polymer has high stability and conductivity, so that the internal resistance of the battery is lowered while the service life of the battery is prolonged.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

Strong-strength aramid 1414 filament/flame-retardant cotton fiber blended fabric and production method for same

InactiveCN103388223AHigh breaking strengthImprove flame retardant performanceLiquid/gas/vapor removalWoven fabricsMoisture permeabilityEngineering

The invention relates to a strong-strength aramid 1414 filament / flame-retardant cotton fiber blended fabric and a production method for the same. The production method mainly comprises the following steps of (1) impregnating cotton yarns into flame-retardant liquid for wetting, and drying the cotton yarns to produce flame-retardant cotton; (2) combining and twisting poly-p-phenylene terephthamide fiber filaments and the flame-retardant cotton obtained by flame-retardant treatment to form yarns, wherein the degree of twist is ranged from 280T / M to 350T / M, a direction of twist is Z, and the weight ratio of the poly-p-phenylene terephthamide fiber filaments to the flame-retardant cotton is 2:3; and (3) weaving twisted strong-strength aramid 1414 filament / flame-retardant cotton fiber blended yarns as warps and wefts, wherein the density of the warps is 200 to 250 per 10cm, and the density of the wefts is 180 to 220 per 10cm. The produced strong-strength aramid 1414 filament / flame-retardant cotton fiber blended fabric has the characteristics of strong strength, flame retardance, high temperature resistance, high air permeability and moisture permeability, weak static electricity, high wearability and the like.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com