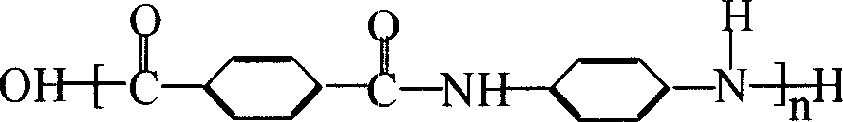

Method for continuously preparing poly p phenylene diamine terephthalamide resin

A technology of poly-p-phenylene terephthalamide and p-phenylene diamine, which is applied in the field of continuous preparation of poly-p-phenylene terephthalamide resin, and can solve the problem of harsh operating environment, easy blockage, and difficult molar ratio and other problems, to achieve the effect of good solubility, good fiber color and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 100Kg of anhydrous N-methylpyrrolidone (NMP) into a 150L jacketed stainless steel reaction kettle, add 6Kg of anhydrous calcium chloride (CaCl) activated by high temperature 2 ), after completely dissolving, add 4.32Kg p-phenylenediamine (PPDA), make it dissolve fully, and make NMP-CaCl 2 - PPDA solution, cooled to 0°C for later use. The NMP-CaCl 2 -PPDA solution and terephthaloyl chloride (TPC) powder are added at a speed of 1838.67g / min and 135.33g / min to be Φ65, the aspect ratio is 60, and the rotating speed is in the twin-screw reaction extruder of 200rpm. The third section of the screw extruder passes dry liquid ammonia at a speed of 22.67g / min to neutralize the hydrogen chloride gas generated by the reaction, and controls the temperature inside the twin-screw extruder to 60°C for about 20 minutes to extrude The polycondensation product in the form of light yellow corn powder was left to stand for 2 hours. After removing the solvent, it was crushed, washed wi...

Embodiment 2

[0032] Add 100Kg of anhydrous N,N-dimethylacetamide into a 150L jacketed stainless steel reaction kettle, add 6Kg of anhydrous lithium chloride activated by high temperature, and after completely dissolving, add 4.32Kg of p-phenylenediamine (PPDA) , make it fully dissolved, make a solution, and cool to -20°C for later use. The prepared solution and terephthaloyl chloride (TPC) powder are added at a rate of 1838.67g / min and 135.33g / min by using a liquid metering feeding system and a high-precision loss-in-weight continuous metering electronic scale, respectively. 35, rotating speed is in the twin-screw reaction extruder of 200rpm, add polyvinylpyrrolidone (PVP) with the speed of 10g / min in the sixth section of twin-screw extruder, control the temperature in the twin-screw extruder to be 75 ℃, about 15 minutes, you can extrude the polycondensation product of light yellow corn flour, let it stand for 2 hours, remove the solvent, grind, wash and dry to obtain light yellow poly-p-p...

Embodiment 3

[0034]Add 100Kg of anhydrous hexamethyl triamine phosphate into a 150L jacketed stainless steel reaction kettle, add 6Kg of anhydrous magnesium chloride activated by high temperature, after completely dissolving, add 4.32Kg of p-phenylenediamine (PPDA) to fully dissolve , dubbed into a solution, cooled to -15 ℃ for later use. The prepared solution and terephthaloyl chloride (TPC) powder are added at a rate of 1838.67g / min and 135.33g / min by using a liquid metering feeding system and a high-precision loss-in-weight continuous metering electronic scale, respectively. 50, rotating speed is in the twin-screw reaction extruder of 200rpm, adds polyvinylpyrrolidone (PVP) with the speed of 10g / min in the sixth section of twin-screw extruder, and the temperature in the control twin-screw extruder is 30 ℃, about 25 minutes, the light yellow corn flour-like polycondensation product can be extruded, stand for 2 hours, after removing the solvent, pulverize, wash with water, and dry to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inherent viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com