Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

329 results about "Anhydrous magnesium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It can be prepared by heating hydrated magnesium chloride crystals in a current of dry hydrogen chloride or by heating magnesium ammonium chloride.Anhydrous magnesium chloride crystallizes from magnesium chloride hexahydrate as leaflets. It is electrically conductive.

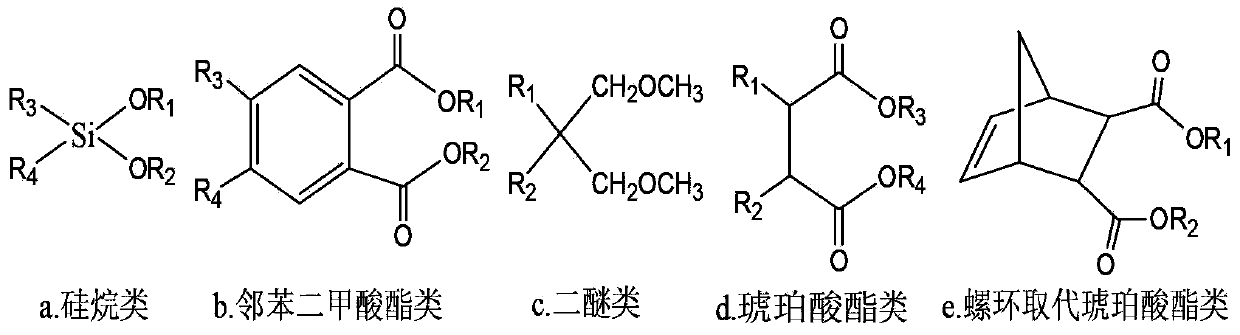

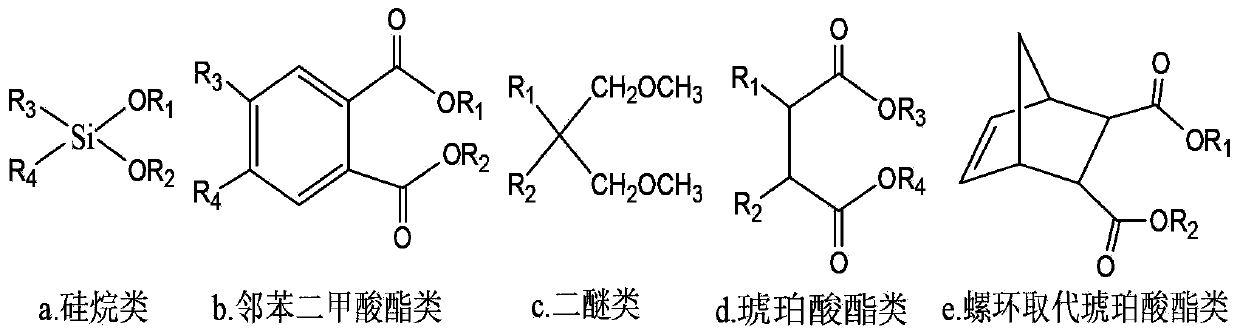

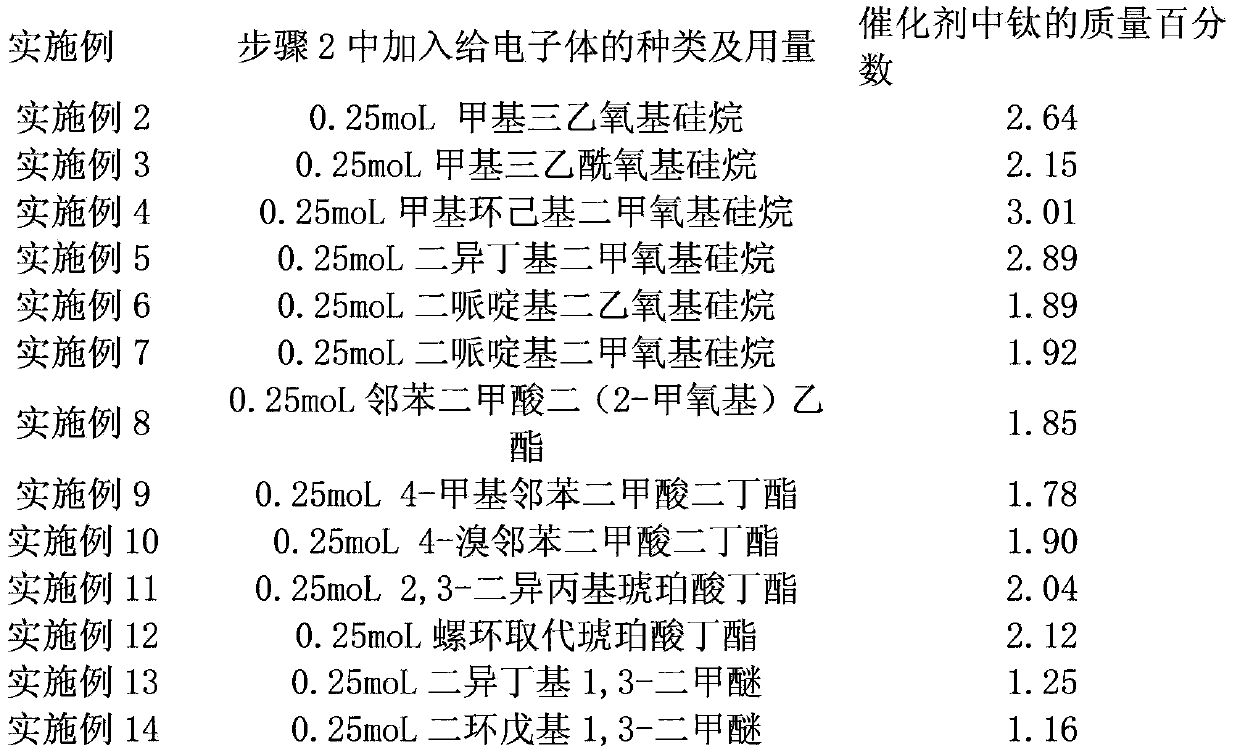

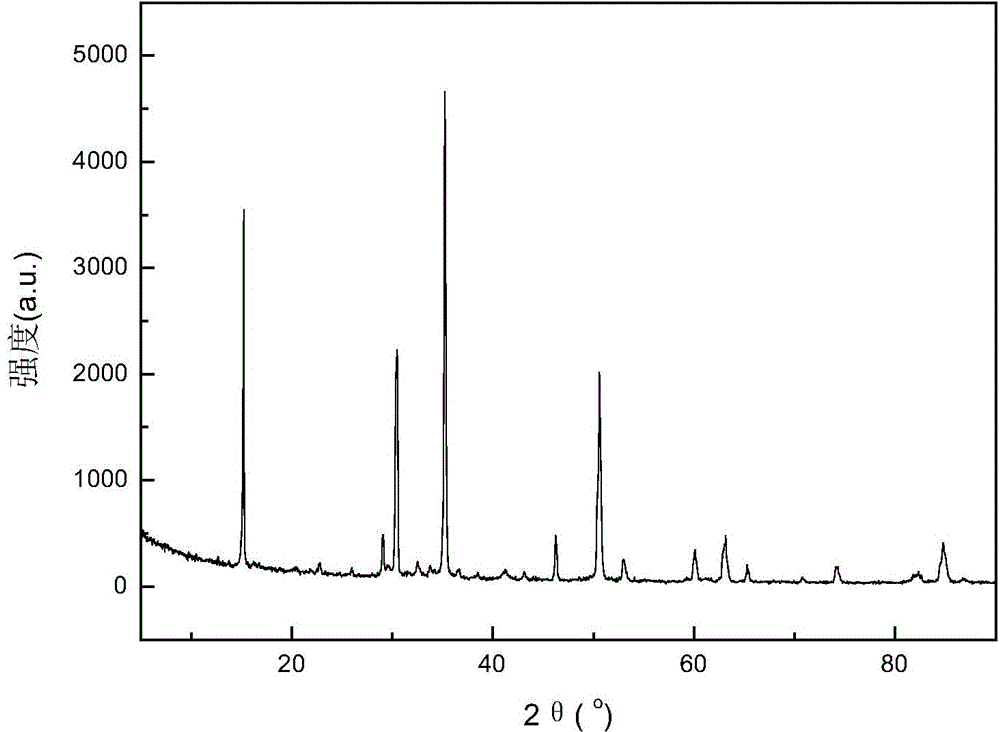

Process for preparing olefin polymerization ball type catalytic component and carrier

The spherical catalyst carrier is prepared with alcoholated magnesium chloride containing double-ether compound in emulsifying pelletizer. Liquid titanium halide compound is carried onto the spherical catalyst carrier to form spherical solid catalyst component in the presence of electron donor. In the X-ray diffraction spectrogram, the spherical solid catalyst component has diffraction peak in 13.3 deg of 2theta angle, strongest diffraction peak in 26.5 deg of 2theta angle and no characteristic diffraction peak of alpha-anhydrous MgCl2 in 15 deg of 2theta angle. The catalyst of the presentinvention has very high activity and may be used to produce polymer with good form, high apparent density and less fine powder. The catalyst is used in homopolymerization and copolymerization of olefin and suitable for various polymerization process.

Owner:YINGKOU XIANGYANG CATALYST

Process for preparing MgC12-ol-organic complexing agent as spherical carrier of catalyst

A spherical MgCl2-alcohol-organic complexing agent composition as the carrier of catalyst is prepared through sublimation reaction of anhydrous MgCl2 on alcohol to obtain a molten mixture, adding organic complexing agent, low speed stirring in the mixture of methylsilica oil and atoleine, quick cooling, washing and drying.

Owner:ZHEJIANG UNIV

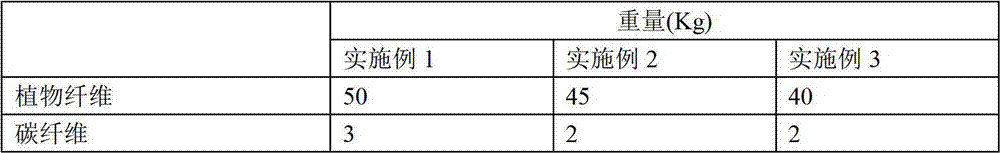

Preparation method of wear-resistant wood/plastic material

The invention provides a preparation method of wear-resistant wood / plastic material, falling into the technical field of material processing. The material comprises the following materials by weight: 40-50 parts of plant fiber, 2-3 parts of carbon fiber, 5-10 parts of glass fiber, 5-10 parts of ceramic fiber, 1-5 parts of polyacrylonitrile-based carbon fiber, 3-5 parts of aluminum silicate fiber, 5-10 parts of cellulose, 10-15 parts of polystyrene, 10-15 parts of polypropylene, 5-8 parts of polyethylene, 2-6 parts of poly(butylene succinate), 10-15 parts of natural rubber, 10-15 parts of PVC resin, 5-8 parts of ethylene-acrylic acid copolymer, 1-2 parts of calcium carbonate, 2-3 parts of alumina, parts of silica 3-4, 1-3 parts of talc powder, 1-3 parts of diatomite, 1-2 parts of anhydrous magnesium chloride, 1-4 parts of magnesium sulfate, 2-3 parts of calcium stearate, 1-2 parts of a coupling agent, 1-2 parts of sodium phosphite, 2-3 parts of polyester wax and 4-8 parts of paraffin.

Owner:苏州大豪塑料制品有限公司

Inorganic fire-resistant foam filling material for door core board

The invention relates to an inorganic fire-resistant foam filling material for a door core board. The filling material is mainly prepared by foaming slurry by a foaming agent, wherein the slurry comprises the following components in part by mass: 15 to 25 parts of anhydrous magnesium chloride, 5 to 15 parts of magnesium sulfate, 0.5 to 0.8 parts of carbon fibre, 0.2 to 0.3 parts of fire-resistant bamboo stick, 5 to 10 parts of kaoline, 3 to 6 parts of soot, 45 to 55 parts of light magnesium oxide, 1.5 to 2.5 parts of closed-cell perlite and 25 to 35 parts of water; and the foaming agent comprises the following raw materials in part by mass: 1.5 to 2.5 parts of animal protein foaming agent, 1 to 2 parts of K12 foaming agent and 25 to 30 parts of water. The frame material in the foam material of the invention has the characteristics of uniform distribution, high foaming efficiency, stable foaming structure, dense holes and good sound insulation effect; and the foamed material has the characteristics of high fire-resistance rating, strong fire resistance without toxicity or side effect, and safe use, and is worthy of popularizing and using.

Owner:ZHOUSHAN SHENGMU THERMAL PRESERVATION BUILDING MATERIAL RES & DEV CO LTD

Magnesium oxide board and preparation method thereof

The invention discloses a magnesium oxide board which is prepared by extruding a reinforced material and slurry into a sheet through forming equipment, wherein the reinforced material is composed of a non-woven fabric and a fiberglass mesh or other reinforced materials; the slurry comprises the following components in parts by mass: 100 parts of magnesium oxide with the magnesium content of at least 85% and the activity degree of at least 62%, 80-90 parts of anhydrous magnesium chloride water solution with the concentration of 10-40 baume degrees, 10-15 parts of lightweight filler A, 15-20 parts of lightweight filler B, 1-5 parts of silicon dioxide and 1-10 parts of foaming agent; the particle size of magnesium oxide is 250-400 meshes; preferably, the lightweight filler A is one or more selected from perlite, polyphenyl granules, gangue and vermiculite, and the lightweight filler B is one or more selected from wood flour, straw, rice husk and bamboo fiber; more preferably, the lightweight filler A is hole-closed perlite, and the lightweight filler B is straw sawdust of 80-100 meshes. The invention also discloses a preparation method of the magnesium oxide board. The magnesium oxide board prepared according to the invention is high in strength, not easy to get damp, strong in fire resistance and free of cracks after being fired at high temperature; in addition, the preparation method of the magnesium oxide board disclosed by the invention is short in time.

Owner:SHANGHAI HUIZHUO BUILDING DECORATIVE MATERIAL

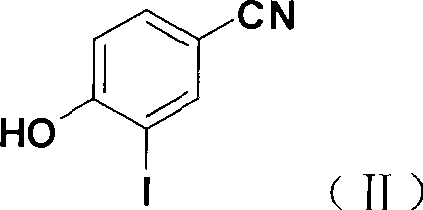

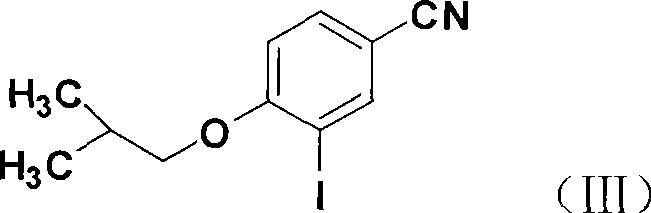

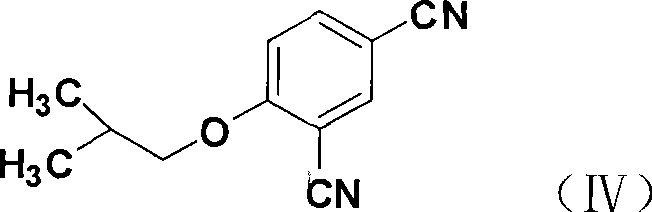

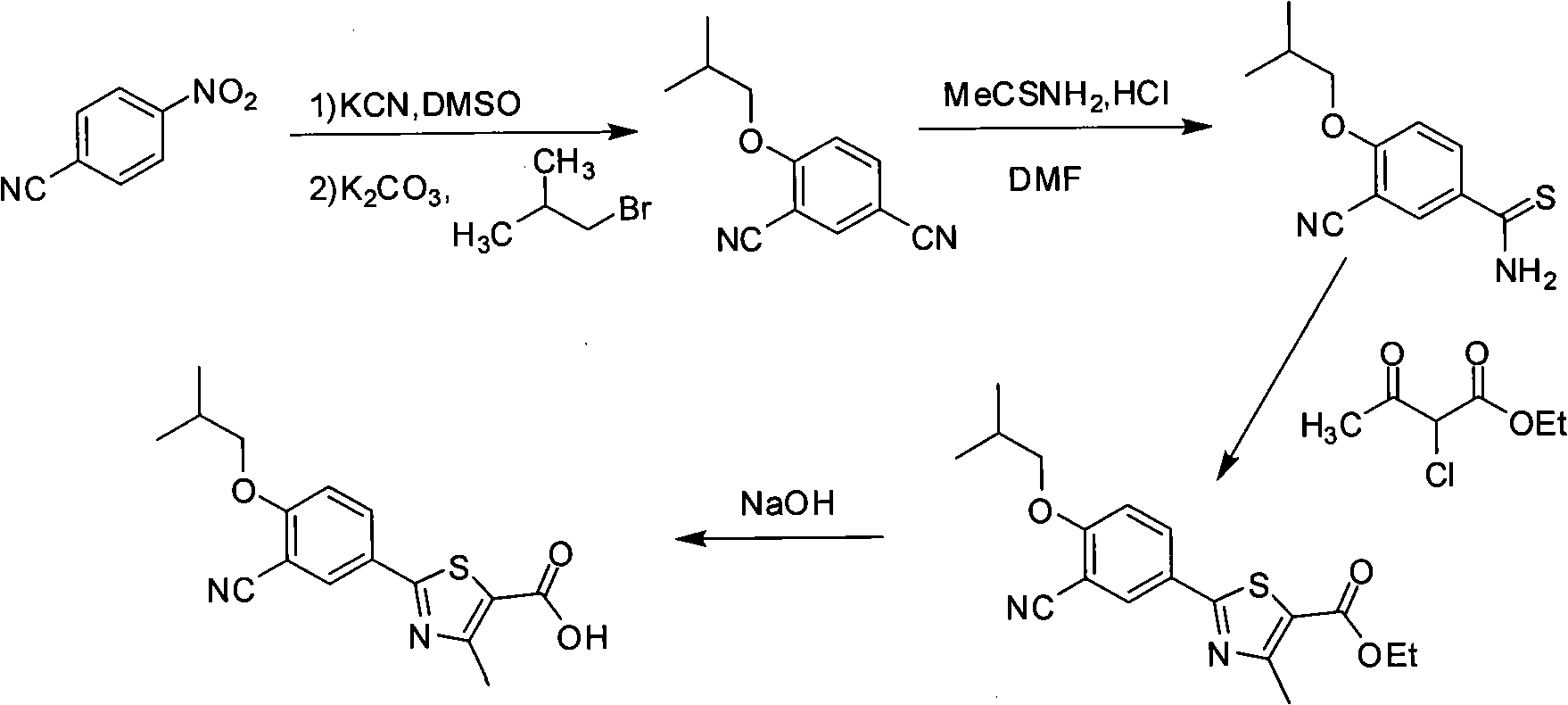

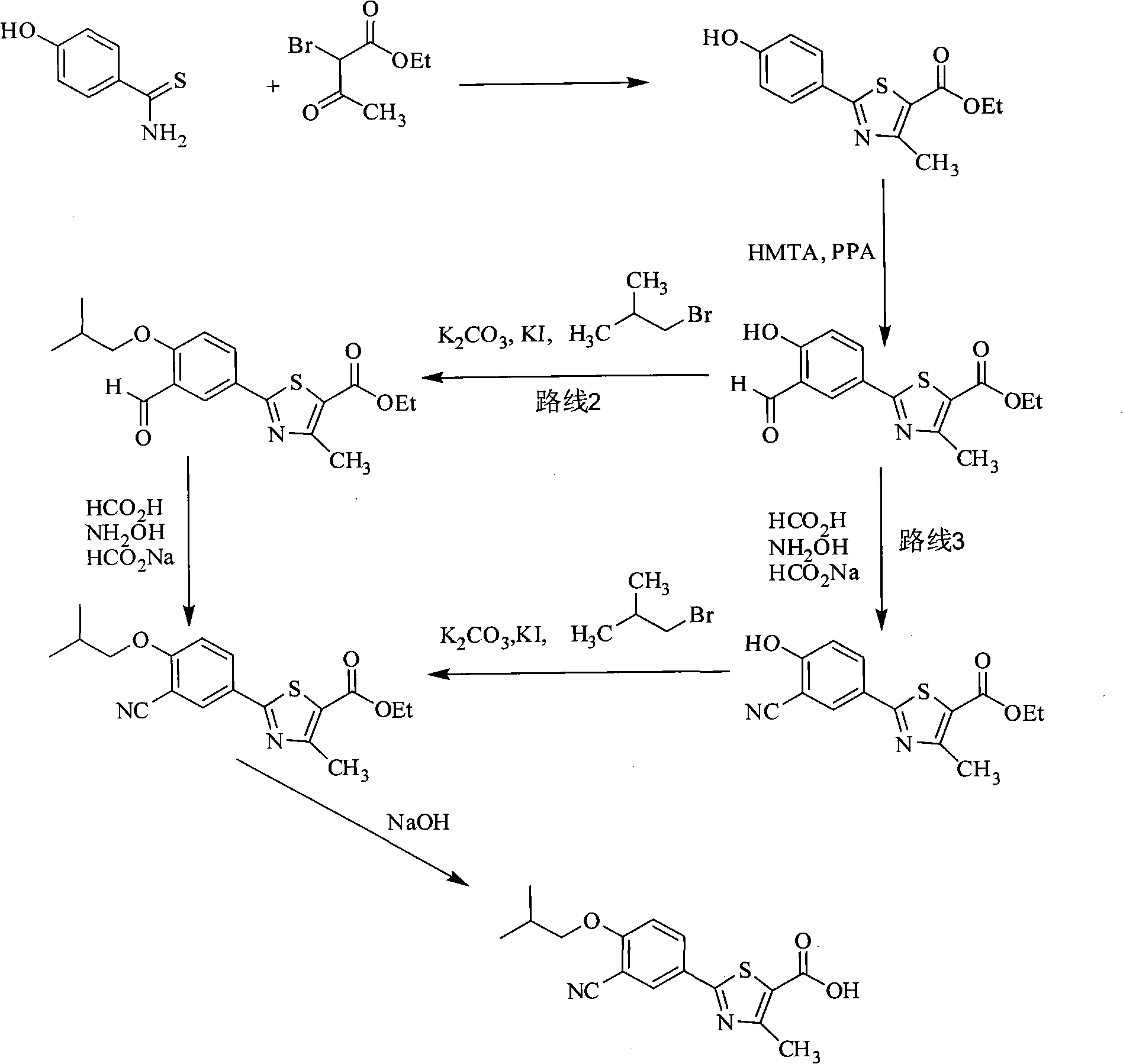

Method for synthesizing 2-(3-cyano-4- isobutoxy phenyl)-4-methyl-carboxylate

ActiveCN101497589ARaw materials are easy to getSimple and fast operationOrganic chemistrySkeletal disorderBenzeneSodium bisulfide

The invention belongs to the technical field of medicine, and relates to a method for synthesizing 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method comprises that: 4-hydroxyl cyanobenzene is used as a raw material, and subjected to iodination, hydrocarbylation and cyanation to obtain an intermediate of 4-isobutoxy-1,3-benzene dinitrile, the intermediate reacts with sodium bisulfide and anhydrous magnesium chloride to obtain a key intermediate of 3-cyano-4-isobutoxy phenyl thioformamide, and the 3-cyano group-4-isobutoxy phenyl thioformamide is subjected to cyclization and hydrolysis reaction to obtain the 2-(3-cyano-4-isobutoxy phenyl)-4-methyl-5-thiazole formic acid. The method has the advantages of easily obtained materials, simple and convenient operation, high yield, low cost and suitability for industrialized production.

Owner:SHENYANG PHARMA UNIVERSITY +1

Molten salt electrolyte composition for preparing magnesium-rare earth alloy by using water-containing chloride to electrolyze

The invention relates to a molten salt electrolyte composition for preparing magnesium-rare earth alloy by using water-containing chloride to electrolyze, wherein the molten salt electrolyte is formed by mixing potassium chloride, anhydrous magnesium chloride, anhydrous rare earth chloride according to the weight ratio of 1: 0.05: 0.50-1: 0.50: 0.05. When the magnesium-rare earth alloy is prepared by using water-containing chloride as raw material to electrolyze, the preparation cost can be effectively reduced, and simultaneously the rare earth content with relatively wider range can be obtained under the condition that water-containing chloride is used as electrolysis raw material to electrolyze.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

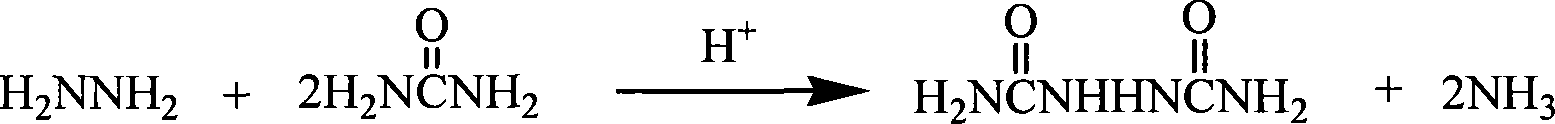

Method for recovery utilization of mother solution hydrochloric acid for ADC foaming agent production

ActiveCN101219974AAvoid degradationHigh yieldChlorine/hydrogen-chloride purificationOrganic chemistryBiureaHydrazine compound

The invention relates to a recycling and reusing method for producing an ADC foaming agent mother liquor hydrochloride, which includes the following steps: A) a hydrazine hydrate and a urea liquor carry out a concentration reaction by pumping a hydrogen chloride gas in or adding a sulfate; the hydrogen chloride gas is pumped in to control and maintain the pH value as 4 to 6 to generate a biurea and an ammonium salt; and a biurea solid and a corresponding ammonium salt mother liquor can be acquired after separation; B) the biurea is made into a suspension liquid of 10 to 40 percent and a sodium bromide which accounts for 0.2 to 1.0 percent of the amount of the biurea is added as a catalyzer to oxidize and generate the ADC foaming agent by pumping in an chlorine-oxygen, and then the ADC foaming agent and hydrochloride mother liquor can be gotten after separation; C) the separated hydrochloride mother liquor is added with an anhydrous magnesium chloride or a dihydrate magnesium chloride accounting for 20 to 40 percent of the amount of hydrochloride mother liquor feed rate, and then heated to distill a hydrogen chloride gas under the state of stirring; D) the distilled hydrogen chloride gas is returned to the biurea concentration technique to be used as the raw materials for neutralization . The beneficial effects of the invention are that the invention can save 60 percent of the amount of the acid used in the concentration process, make full use of the resources, reduce the production cost, decrease the discharging of the pollutions and has significant economic benefits.

Owner:HANGZHOU HI TECH FINE CHEM

Desiccant composition

InactiveCN101549243AGood hygroscopicityHigh moisture absorptionDispersed particle separationTime rangeDesiccant

The invention discloses a desiccant composition, including 55-90% (weight) easy deliquescence salt and 10-45% (weight) potato modified starch, wherein, the easy deliquescence salt is anhydrous calcium chloride, anhydrous magnesium chloride or mixture of them. The invention provided desiccant has a large water absorbing capacity and excellent moisture sorption effect in a long time; and immobile after absorbing water and holds a certain tractable gel shape, convenient use, no-mould after absorbing water and good stability. The invention provided desiccant has low production cost, easy industrial production, meanwhile has advantages of wide materials sources, innocuity, degradable and wide applicability.

Owner:HANGZHOU HOMESONG PACKGING MATERIAL

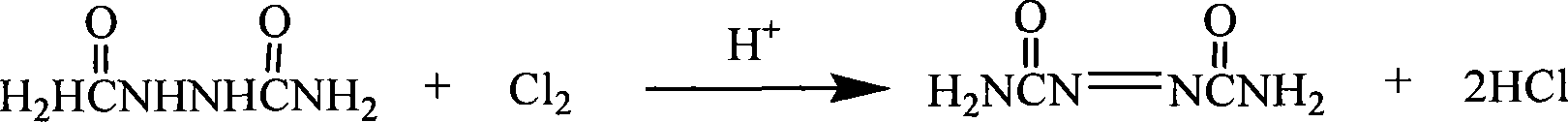

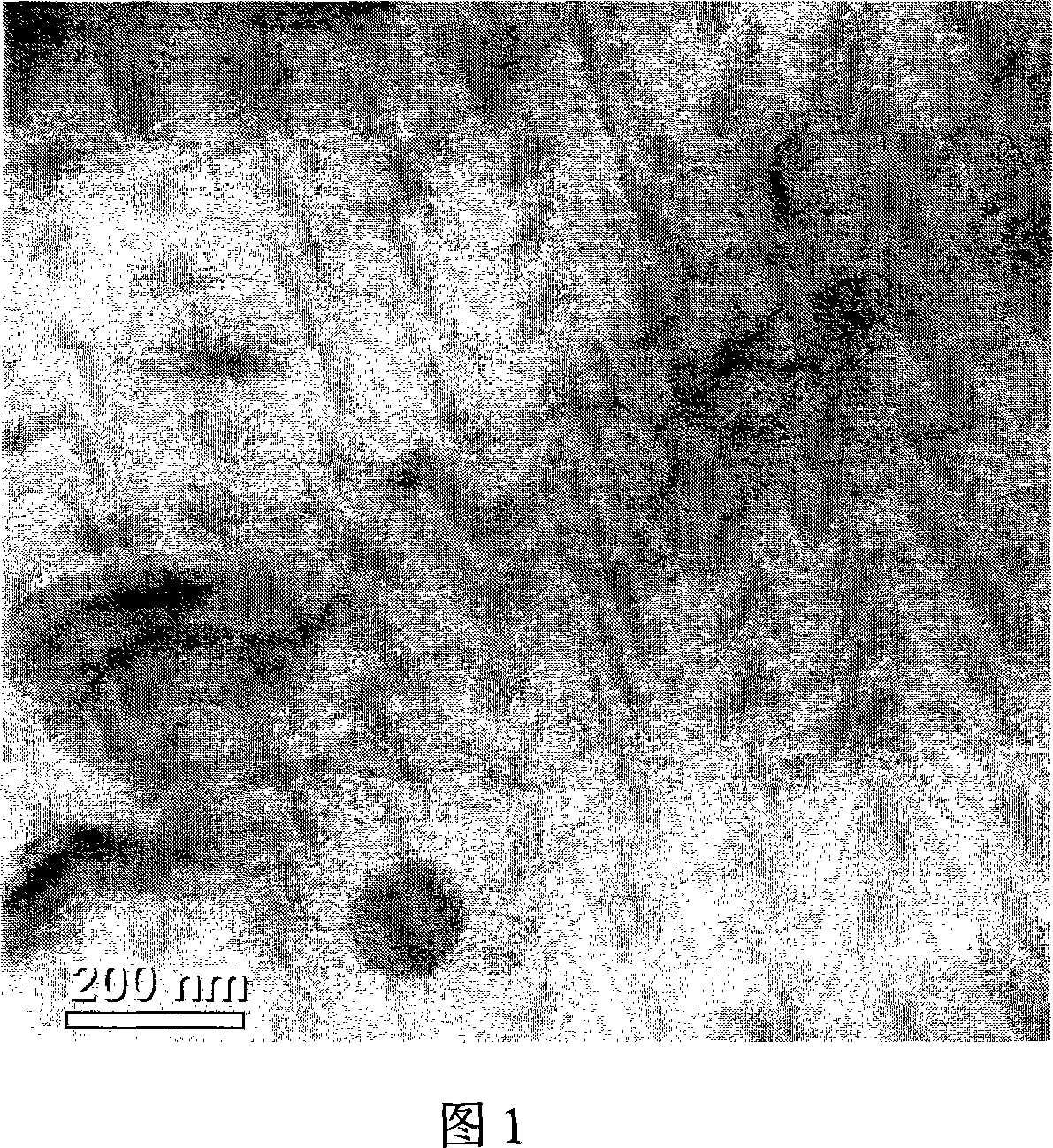

Preparation and application of zinc ion fluorescence probe based on Schiff base

InactiveCN106966924ALow detection limitHigh sensitivityCarboxylic acid nitrile preparationOrganic compound preparationFluorescenceHydrazine compound

The invention relates to preparation and application of a zinc ion fluorescence probe based on Schiff base. A zinc ion fluorescence probe compound has the structure shown by a formula I. The preparation method comprises the steps that 2-aminobenzoic acid (methyl anthranilate) and hydrazine hydrate are subjected to heating reflux in ethyl alcohol to obtain a white solid II, cyanophenyl phenol, anhydrous magnesium chloride and paraformaldehyde are subjected to heating reflux in a triethylamine-containing acetonitrile solution to obtain a white solid III, the white solid II and the white solid III are subjected to heating reflux in ethyl alcohol to a yellow solid I. The probe compound has very good selectivity and sensitivity on zinc ions, is low in detection limit and can be applied to determination of the content of zinc ions in a water body.

Owner:UNIV OF JINAN

Montmorillonite//MgCl2 composite carrier load alpha-2 imine nickel catalyst, and method for preparing polythene/montmorillonite composite material

Owner:SUN YAT SEN UNIV

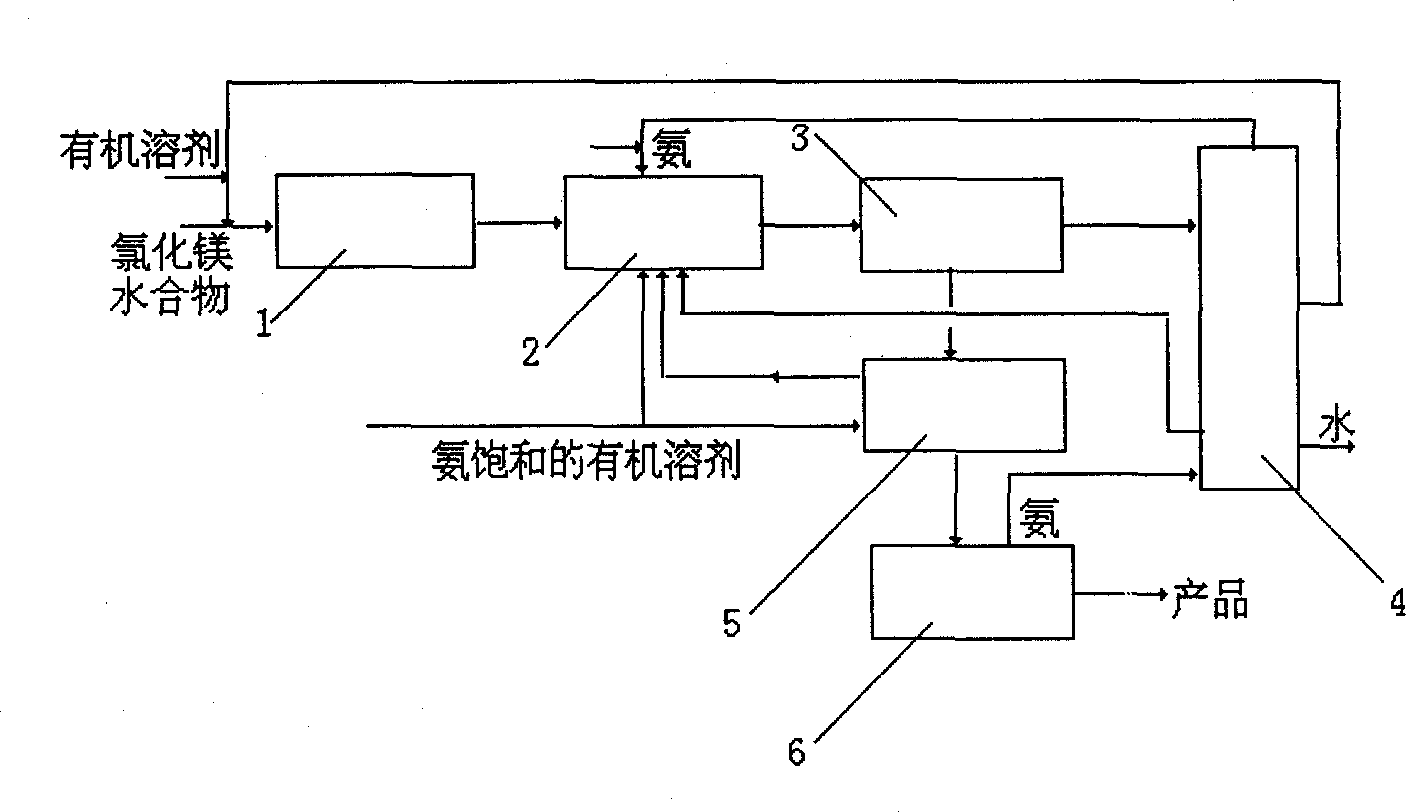

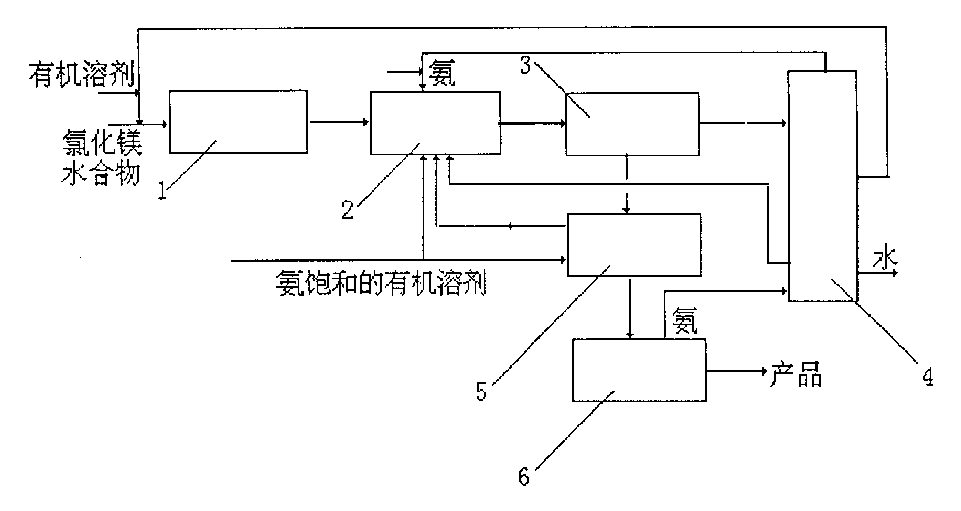

Methodf or preparing anhydrous magnesium chloride

InactiveCN1333183AIncrease sedimentation rateReduce generationMagnesium chloridesAmmonia preparation/separationOrganic solventChloride

The method for preparing anhydrous magnesium chloride includes the following steps: 1. preparation of organic hydrated magnesium chloride; 2. reaction, crystallization and coupling reaction to prepare anhydrous magnesium chloride complex; 3. solid-liquid separation and washing; 4. crystallizing mother liquor and circular utilization of precipitant; and 5. heat treatment of complex intermediate product to obtain the anhydrous magnesium chloride. Said invention adopts mixed organic solvent to prepare hydrated magnesium chloride solution, can reduce production of alkoxide in the course of crystallization, and can return the washing liquor containing saturated hexamine magnesium chloride into crystallization reaction procedure, and can raise rate of deposition of magnesium chloride and utilization rate of ammonia, and can reduce the running load of recovery tower. Said invention also adopts the reaction cold-crystallization process, and is favorable for implementing industrial production.

Owner:青海盐湖镁业有限公司

Modified Ti-Mg catalyst as well as preparation method and application thereof

ActiveCN102107145AEasy to makeRaw materials are easy to getOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorActive component

The invention relates to a modified Ti-Mg catalyst as well as a preparation method and application thereof. The catalyst takes porous silica gel and anhydrous magnesium chloride as carriers, titanium-containing transition metal as an active component and an electron donor compound as a modifier. The modified Ti-Mg catalyst contains, based on the weight percentage, 1.2% to 7.9% of Ti, 4.0% to 12.6% of Mg:, 0.2% to 8.6% of the electron donor compound: and the balance of the carriers. A polyethylene product produced by using the catalyst has the characteristics that the molecular weight distribution range is increased to the range from 5.2 to 13.2 and the molecular weight distribution range is controllable, so that the processing property of resin is greatly improved and the application range of the product is broadened.

Owner:PETROCHINA CO LTD +1

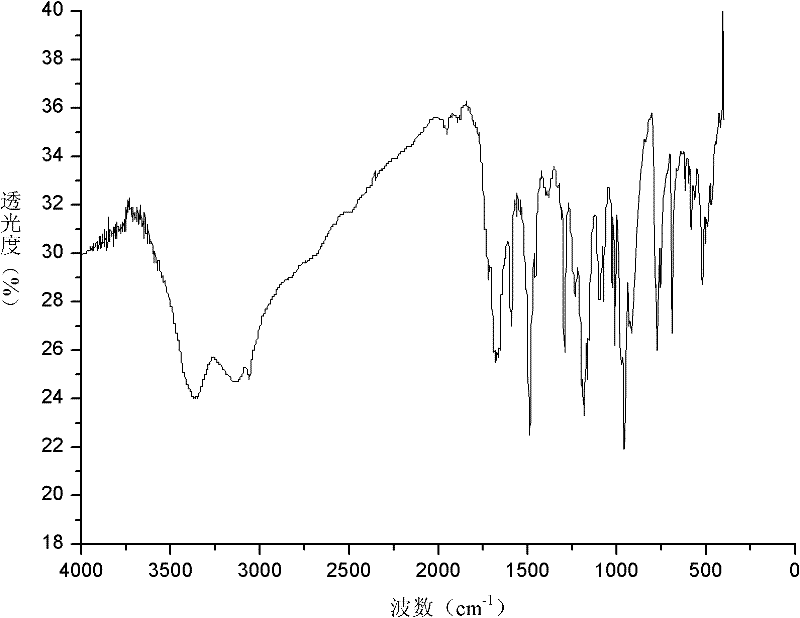

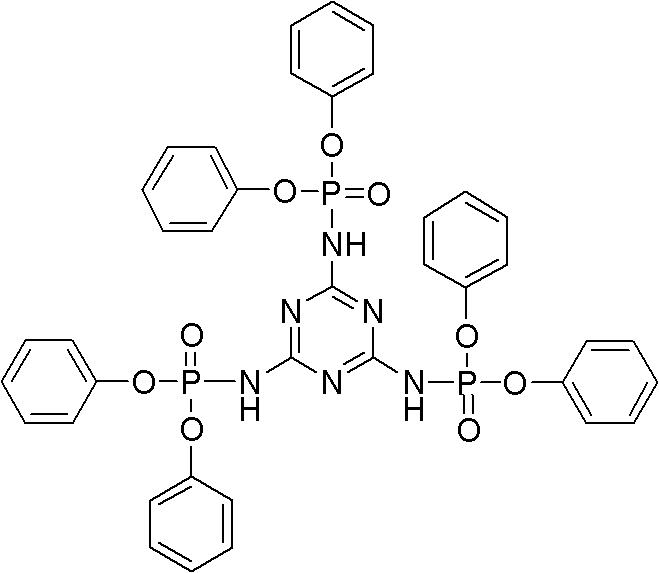

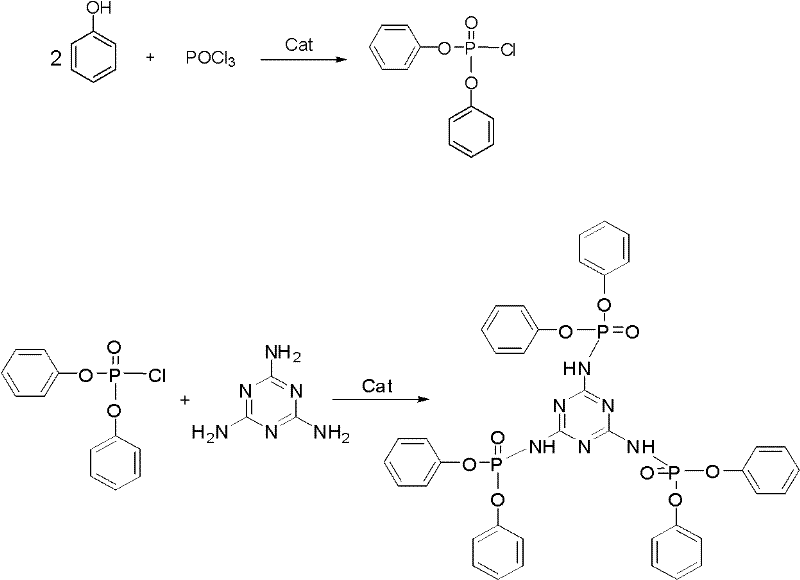

Hexaphenyl phosphate ester melamine salt fire retardant and method for preparing same

InactiveCN102190814ALess physical and chemical propertiesLittle impact on physical and chemical propertiesGroup 5/15 element organic compoundsFiltrationPhosphate

The invention relates to a hexaphenyl phosphate ester melamine salt fire retardant and a method for preparing the same. Based on the molar ratio, the reaction ratio of diphenyl phosphorus oxychloride to melamine is (3.0-3.6):1.0, and the diphenyl phosphorus oxychloride comprises components of phenol, phosphorus oxychloride and anhydrous magnesium chloride in a ratio of (2.0-2.5):(1.0-1.4):(0.01-0.03). The preparation method comprises the following steps of: adding phosphorus oxychloride, anhydrous magnesium chloride and phenol respectively, performing continuous stirring reflux during reaction, and performing vacuum distillation after the reaction to obtain diphenyl phosphorus oxychloride; and adding the diphenyl phosphorus oxychloride and melamine, performing stirring reflux, and after the reaction, cooling the obtained product in an ice bath, and performing suction filtration, water washing and drying on the product to obtain the hexaphenyl phosphate ester melamine salt. The hexaphenyl phosphate ester melamine salt fire retardant prepared by the method has the advantages of low toxicity, less smoke, harmlessness, high efficiency, environmental friendliness and the like and leads the development trend of intumescent fire retardants in the future.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Magnesium oxychloride and magnesium oxysulfate compound cement foam fire door core board and preparation method thereof

The invention provides a magnesium oxychloride and magnesium oxysulfate compound cement foam fire door core board and a preparation method thereof. The core board comprises the following raw materials: magnesium oxide, an anhydrous magnesium chloride solution, a magnesium sulfate solution, desulfurization gypsum, superfine carbon fiber, superfine micro-silica, a cationic polyacrylamide solution, ferrous sulfate and an efficient foaming agent, between which the ratio is 100:60:66.6:2:0.8:0.5:0.5:0.5:0.5. The method comprises the following steps: uniformly mixing the anhydrous magnesium chloride solution and the magnesium sulfate solution, adding the anhydrous magnesium chloride solution and the magnesium sulfate solution into a stirring machine, adding the cationic polyacrylamide solution and a ferrous sulfate solution into the stirring machine, and adding superfine carbon fiber, lightly calcined magnesium oxide, desulfurization gypsum, superfine microsilica and a foaming solution in sequence while performing stirring; pushing a stack of moulds, in which foaming slurry is poured, into a curing stove, curing the moulds for 8-10h, and then performing demoulding; and after demoulding, performing moisture preservation and temperature control curing and water control curing respectively until the moisture content is less than or equal to 10%. The core board provided by the invention is environmentally friendly and light, has high-strength and favorable high temperature resistance and meets the national requirements for fire prevention and safety.

Owner:海城市大德广消防门业材料有限公司

Heat-preservation fireproof board and preparation method thereof

ActiveCN103951369AGood heat insulationHigh ignition pointSolid waste managementSilicon dioxideFire prevention

A heat-preservation fireproof board is prepared by the following raw materials: 80-100 parts by weight of magnesium oxide, 2-3 parts by weight of dimethyl silicone oil, 4-6 parts by weight of aluminum nitride powder, 20-30 parts by weight of anhydrous magnesium chloride, 3-5 parts by weight of hollow glass beads, 8-12 parts by weight of tetrapod-shaped zinc oxide whiskers, 3-6 parts by weight of aerosil, 3-5 parts by weight of polyvinyl acetate emulsion, 20-30 parts by weight of refractory materials, 3-6 parts by weight of rock wool, 3-5 parts by weight of methylisothiazolinone, 2-4 parts by weight of ferriferrous oxide, 5-8 parts by weight of methyl sodium silicate, 1-2 parts by weight of sodium dodecyl benzene sulfonate, and 130-150 parts by weight of water. By virtue of adding the multiple types of refractory materials, the board can be high in burning point and good in flame retardation effect; and with the addition of the fly ash hollow beads, the board can be good in heat insulation effect and fine in fireproof effect. In brief, the board of the invention is a novel inorganic heat-preservation and heat-insulation building material integrating characteristics of heat preservation, heat insulation, high strength, fire prevention, water proofing, sound absorption, sound insulation, and decoration.

Owner:安徽颐鑫节能材料有限公司

Method for preparing anhydrous magnesium chloride from bischofite

The invention relates to a method for preparing anhydrous magnesium chloride from bischofite, which uses the bischofite as a raw material for preparing the anhydrous magnesium chloride. The method comprises the following technical processes: (1) firstly, drying the bischofite for dewatering most crystallization water; (2) dissolving the dried magnesium chloride in glycol for preparing a glycol solution of the magnesium chloride and using a vacuum distillation method for dewatering water in the glycol solution of the magnesium chloride; (3) reacting the dewatered glycol solution of the magnesium chloride with ammonia for crystallizing so as to generate magnesium chloride hexammoniate crystals; (4) washing, filtering and drying for obtaining the magnesium chloride hexammoniate crystals; and (5) heating, decomposing and deaminating the dried magnesium chloride hexammoniate crystals for preparing the anhydrous magnesium chloride. In each process, ammonia gas, detergent and a crystallization mother liquor are recycled. The process has the characteristics of convenient operation, easy large-scale production, low energy consumption, low product cost and no pollution to environment and the prepared anhydrous magnesium chloride can be used as a raw material for producing magnesium metal by an electrolysis method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

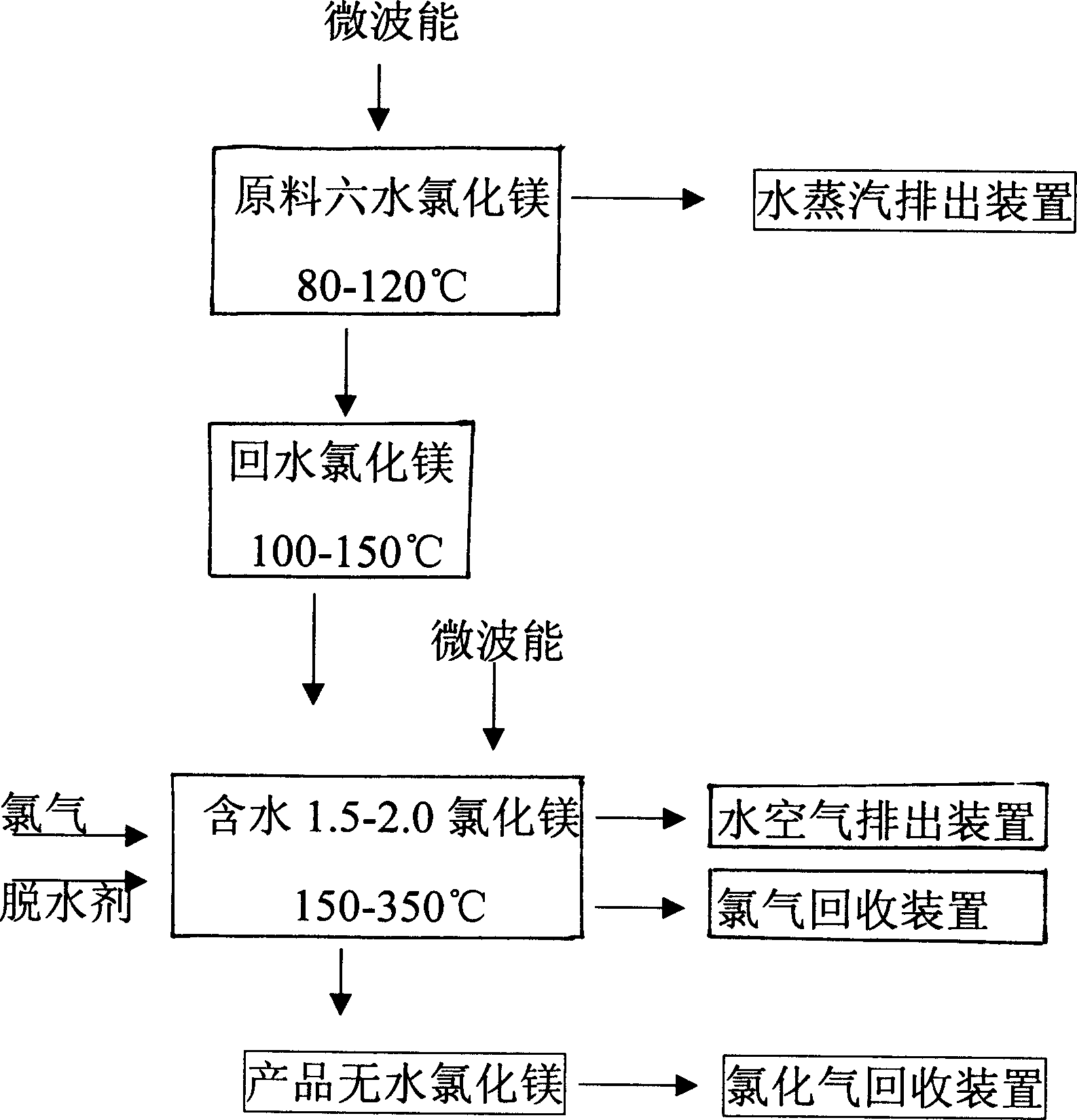

Process for producing anhydrous magnesium chloride by microwave energy

InactiveCN1613770AImprove heating efficiencyShorten heating timeMagnesium chloridesPhysical chemistryChloride

Anhydrous magnesium chloride production by microwave energy is disclosed. It is carried out by dehydrating hexhydrated magnesium chloride to obtain magnesium chloride with 1.5-2.0 water content in the first microwave heater, dehydrating hexhydrated magnesium chloride to obtain tetrahydrated magnesium chloride at temperature 100-120deg.C, dehydrating tetrahydrated magnesium chloride to obtain magnesium chloride with 1.5-2.0 water content at temperature 100-150deg.C, and realizing magnesium chloride with 1.5-2.0 water content to obtain anhydrous magnesium chloride at temperature 150-350deg.C. It achieves low dehydrating temperature and short time.

Owner:陈瑜

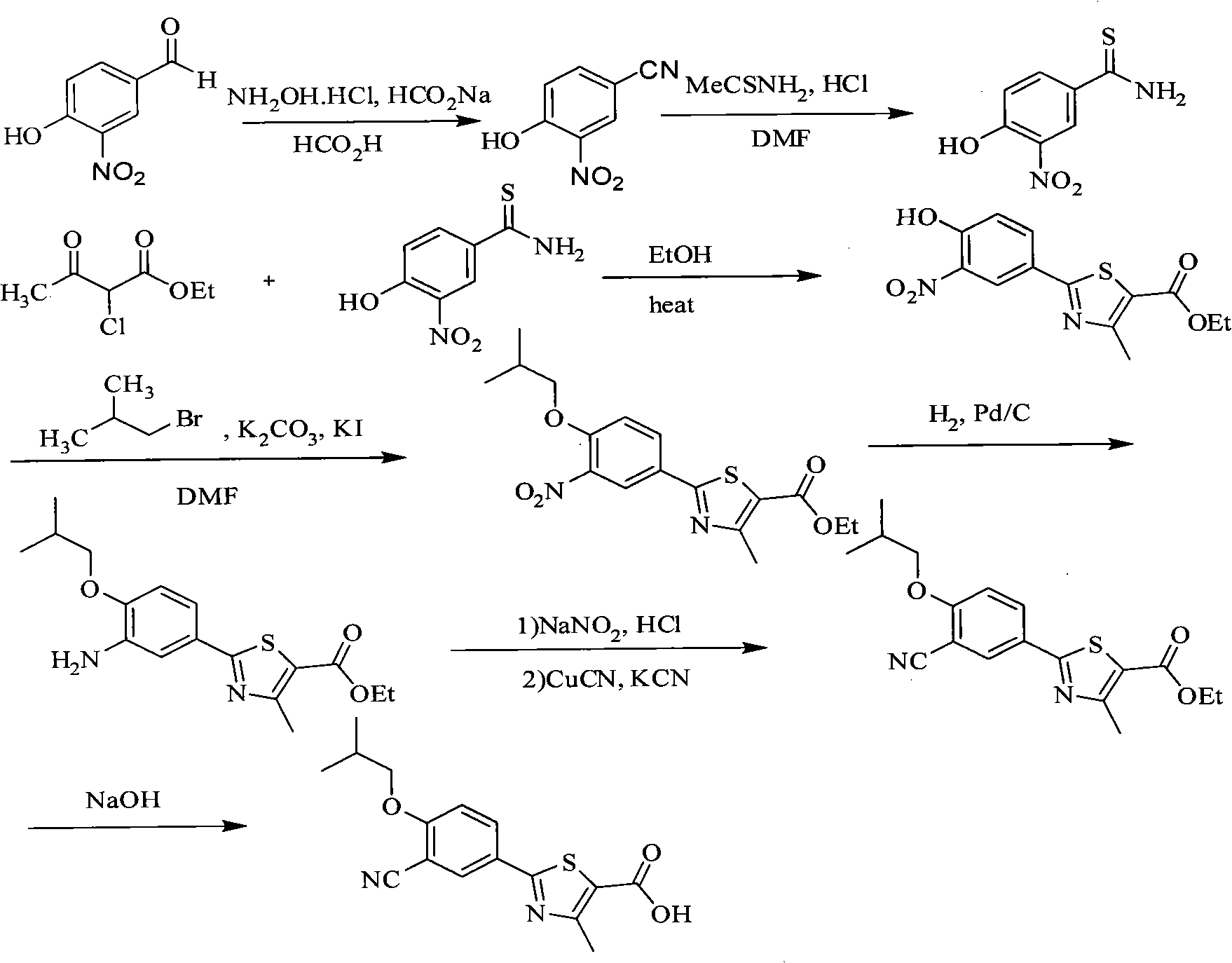

Synthesis method of 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid

InactiveCN101863854ARaw materials are easy to getSimple and fast operationOrganic chemistryFormylation reactionSynthesis methods

The invention belongs to the technical field of medicine, relating to a synthesis method of 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid. The synthesis method is characterized by comprising the following steps of: brominating to obtain 3-bromine-4-hydroxyl cyanobenzene by using 4-hydroxyl cyanobenzene as a raw material, alkylating by using bromo-isobutane to obtain 3-bromine-4-isobutoxy cyanobenzene, and cyaniding with cuprous cyanide to obtain 4-isobutoxy-1,3-benzene dinitrile; carrying out a formylation reaction with sodium bisulfide to prepare 3-cyan-4-isobutoxyphenylthioformamide in the presence of anhydrous magnesium chloride, and cyclizing with 2-chloroacetoacetic acid ethyl ester to prepare 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole ethyl formate; and finally, hydrolyzing to prepare the 2-(3-cyan-4-isobutoxy) phenyl-4-methyl-5-thiazole formic acid. The method has the characteristics of easy raw material obtaining, simple and convenient operation, higher yield, lower cost and higher final product purity (the HPLC, High Performance Liquid Chromatography purity is not lower than 99.9 percent) and is suitable for industrial production.

Owner:SHENYANG PHARMA UNIVERSITY

Method for preparing metal magnesium by silicothermic process

InactiveCN101698907AAvoiding the Difficulties of Preparing Anhydrous Magnesium ChlorideLow equipment requirementsPotassiumPidgeon process

The invention provides a new method for preparing metal magnesium by a silicothermic process and by using bischofite from the seawater salt making or salt lake brine salt and potassium chloride making as a raw material. The method comprises the steps of: reacting lime and solution of magnesium chloride to generate a calcium-magnesium mixed hydroxide; calcining the calcium-magnesium mixed hydroxide to obtain a calcium-magnesium mixed oxide; finely grinding the mixture of calcium-magnesium mixed oxide, silicon iron and fluorite in a ball mill, pressing the ground mixture into a walnut shape or a sheet shape on a forming press, and reducing the walnut-shape or sheet-shape mixture under vacuum in a magnesium smelting reduction pot to obtain the magnesium crystalline; and finally refining the magnesium crystalline, casting the refined magnesium crystalline into ingot, and performing surface treatment to obtain a magnesium metal ingot. The method overcomes the defect that a great amount of carbon dioxide greenhouse gas is exhausted in the Pidgeon process for calcining dolomite, avoids the problem of preparing anhydrous magnesium chloride by an electrolytic process, overcomes the defect that the direct calcining of bischofite gives corrosive and toxichydrogen chloride gas, has low requirements on equipment and is clean, environmentally-friendly and safe in production. The method can also be applied to the field of alkaline waste liquor treatment and comprehensive utilization.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for preparing low-sodium carnallite, sodium chloride and magnesium chloride from refined magnesium slag

InactiveCN102424916AReduce pollutionAvoid pollutionProcess efficiency improvementPhysical chemistryCarnallite

The invention relates to a chemical extraction method, in particular to a method for preparing low-sodium carnallite, sodium chloride and magnesium chloride from refined magnesium slag. The method comprises the following steps of: crushing; screening; dissolving; filtering; adjusting the molar ratio of K<+> to Mg<2+> in the filtrate; evaporating, concentrating, settling, filtering and drying the filtrate to obtain a sodium chloride crystal; cooling and crystallizing the filtrate after the sodium chloride is separated to obtain low-sodium carnallite and brine; putting the filter residue into a reaction kettle; adding a full amount of hydrochloric acid for full reaction according to the contents of magnesium oxides and alkaline matters in the filter residue; after reacting, filtering, and cooling, dehydrating and drying the filtrate to obtain anhydrous magnesium chloride; adding a full amount of hydrochloric acid for full reaction according to the contents of magnesium oxides and alkaline matters in the filter residue; and after reacting, filtering, and cooling, dehydrating and drying the filtrate to obtain anhydrous magnesium chloride. The method provided by the invention has the characteristics of reasonable process route, environmental friendliness and the like and can realize cyclic and efficient utilization of the three wastes as well as cyclic utilization of water, and the utilization ratio can reach 85%.

Owner:SHIZUSN KAIRUI MAGNESIUM CHEM

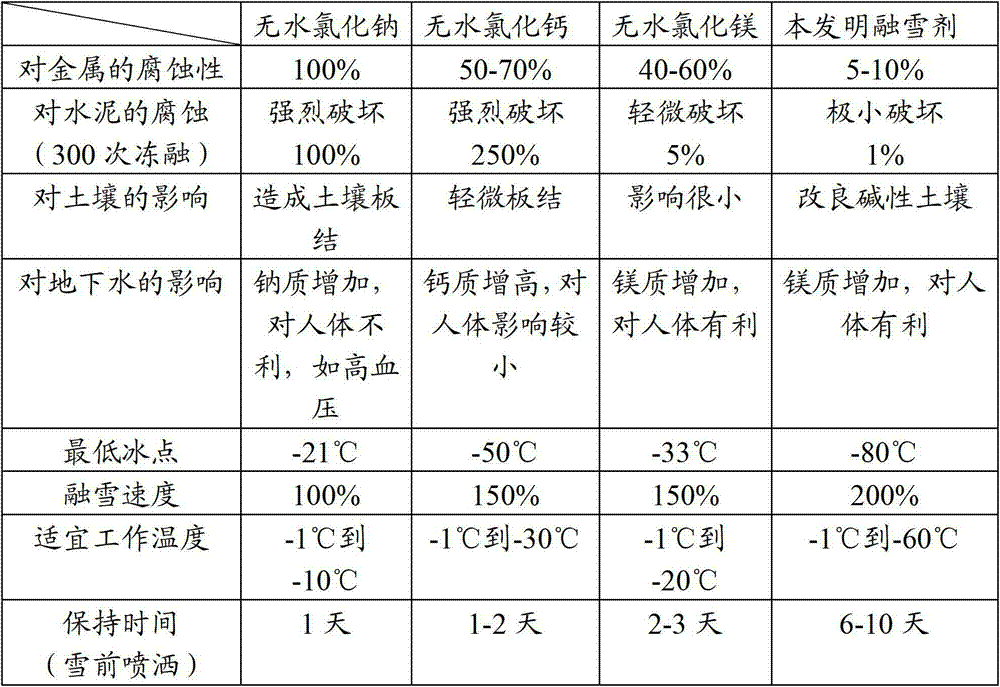

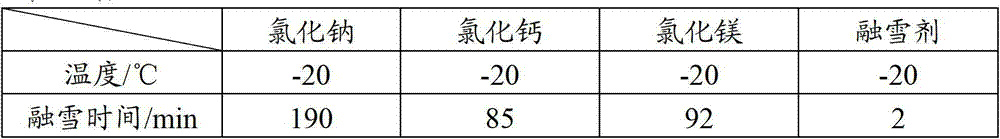

Inorganic-organic compound environment-friendly snow-melting agent

The invention discloses an inorganic-organic compound environment-friendly snow-melting agent. The inorganic-organic compound environment friendly snow-melting agent comprises the following components in parts by weight: 10-20 parts of anhydrous magnesium chloride or / and anhydrous calcium chloride, 10-20 parts of anhydrous sodium acetate or / and anhydrous potassium acetate and 0.1-5.0 parts of zinc sulphate. After the snow-melting agent disclosed by the invention is dissolved in water or snow, a freezing point of the snow-melting agent is below 0 DEG C, the freezing point of the anhydrous magnesium chloride after being dissolved in the water is minus 33 DEG C, and magnesium in underground water is increased, so as to be beneficial to human body; the freezing point of the anhydrous calcium chloride after being dissolved in the water is about minus 20 DEG C, and calcium in the underground water is increased, so that influence to human body is less; and the freezing point of acetic acid is about minus 30 DEG C; and a solidifying point of saline water is lower than that of the water, so that an ice cake is hardly formed after salt is dissolved in snow water. According to the inorganic-organic compound environment friendly snow-melting agent, the zinc sulphate forms a protective film on carbon steel, so that chloride ions can not corrode a metal bridge or a concrete pavement.

Owner:JIANGSU XINSHENG ENVIRONMENTAL PROTECTION TECH DEV

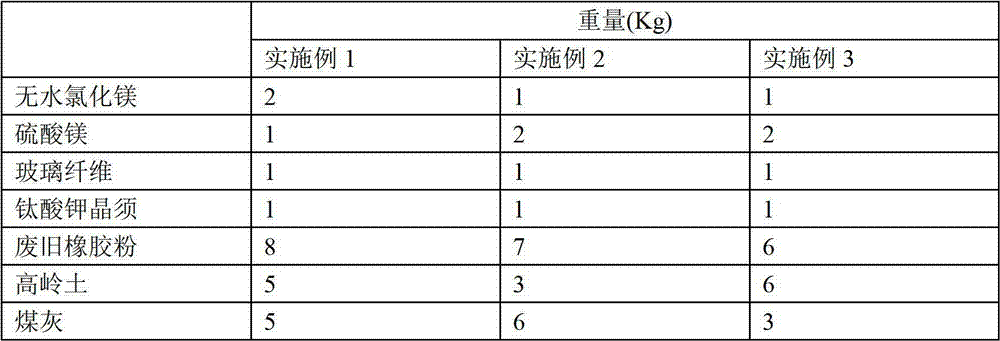

Filling material for sandwiched building plate

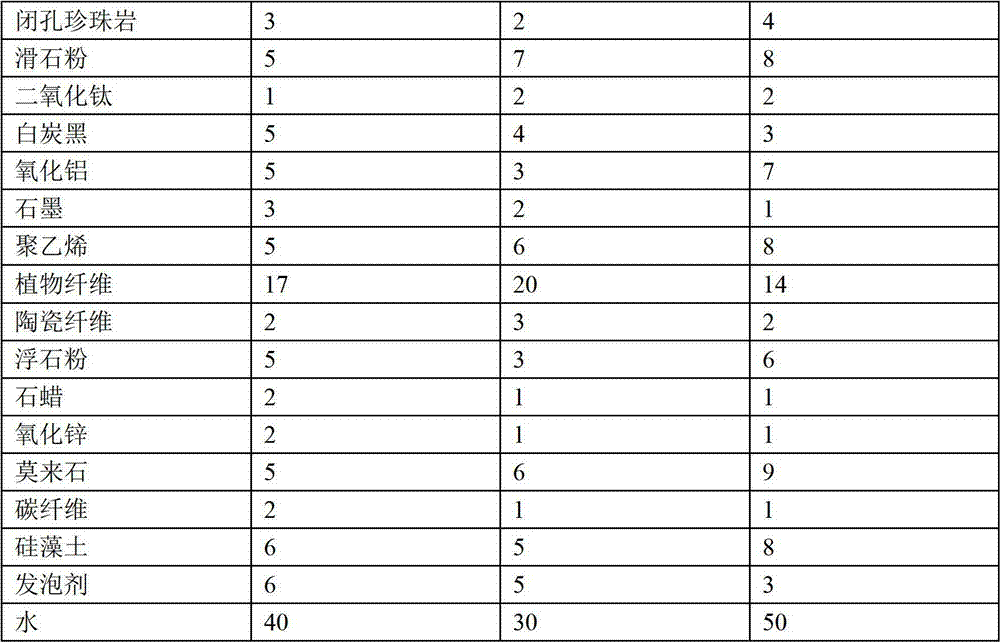

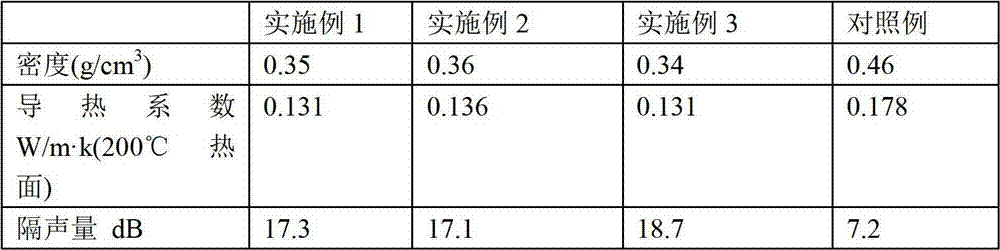

The invention provides a filling material for a sandwiched building plate, which belongs to the technical field of building materials. The filling material is prepared from the following raw materials by weight: 1 to 2 parts of anhydrous magnesium chloride, 1 to 2 parts of magnesium sulfate, 1 part of glass fiber, 1 part of potassium titanate whisker, 5 to 8 parts of waste rubber powder, 3 to 6 parts of kaolin, 3 to 6 parts of coal ash, 2 to 4 parts of closed-cell perlite, 5 to 8 parts of talcum powder, 1 to 2 parts of titanium dioxide, 3 to 5 parts of white carbon black, 3 to 7 parts of alumina, 1 to 3 parts of graphite, 5 to 8 parts of polyethylene, 14 to 20 parts of vegetable fiber, 2 to 4 parts of ceramic fiber, 3 to 6 parts of pumice sand, 1 to 2 parts of paraffin, 1 to 2 parts of zinc oxide, 5 to 9 parts of mullite, 1 to 2 parts of carbon fiber, 5 to 8 parts of diatomite, 3 to 6 parts of a foaming agent and 30 to 50 parts of water. The filling material for a sandwiched building plate provided by the invention has sound insulation and thermal insulation effects and is applicable to building plates.

Owner:苏州市德莱尔建材科技有限公司

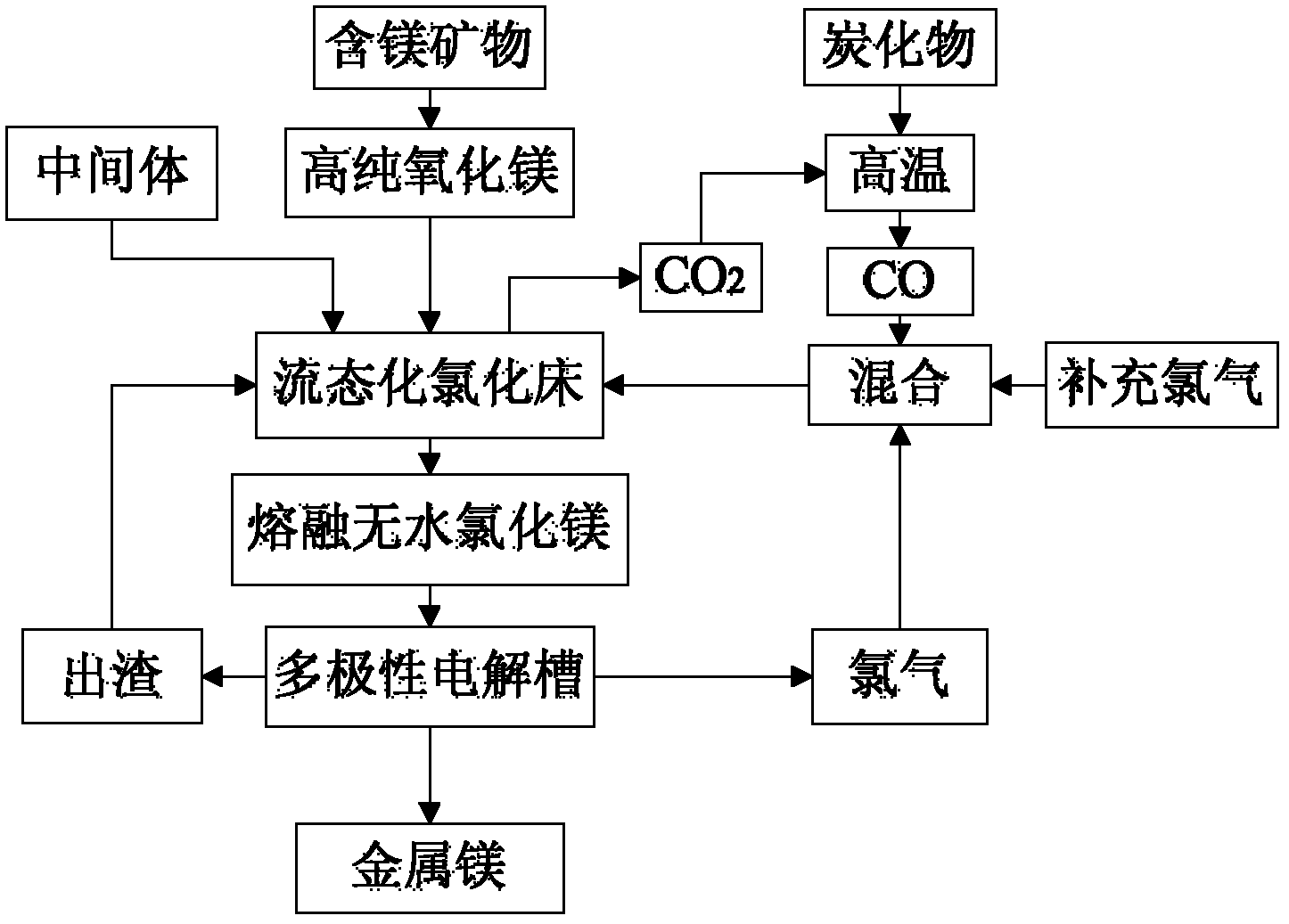

Preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by preparation method

The invention belongs to the field of metal material, and relates to a preparation method of metal magnesium by magnesium-containing mineral and equipment adopted by the preparation method. The method comprises the following steps of: converting useful components in magnesium-containing mineral into high-activity magnesium oxide, and under the effects of high temperature and a catalytic midbody, enabling the high-activity magnesium oxide to have chlorination reaction with chlorine and carbon monoxide, so that molten magnesium chloride anhydrous is generated; and mixing the molten magnesium chloride anhydrous with the other molten inorganic salt according to a certain proportion to be taken as electrolyte, and leading the electrolyte into a multi-polarity electrolytic cell to electrolyze, so that the metal magnesium is prepared. The technology adopts the fluidzed chlorination bed and the multi-polarity electrolytic cell of the novel equipment, and adds the midbody of catalytic reaction in the process of chlorination, so that the preparation method is more high-efficiency and energy-saving compared with the conventional method. The waste gas and the waste residue generated in the whole process are treated to be reused, so that the preparation method and the equipment are environment-friendly.

Owner:UNIV OF SCI & TECH BEIJING

Gas phase fluidized bed process LLDPE catalyst, preparation and application thereof

The invention relates to a catalyst for preparation of LLDPE by a gas phase fluidized bed process, preparation and application thereof. The catalyst takes porous silica gel and anhydrous magnesium chloride as the carrier, adopts a titanium-containing transition metal loaded on the porous silica gel-magnesium chloride composite carrier as active components, and employs an electron donor compound as a modifier. In terms of the total mass of the catalyst, the load components include: 1.00-5.00% of Ti, 15.20-32.35% of Cl, 1.35-6.52% of Mg, 0.10-5.78% of the electron donor, and the balance silica gel. The catalyst is used for a gas phase polyethylene process, solves the problems of low activity, poor copolymerization ability and high product ash content in general catalysts, and can be used for production of polyethylene resin with different melt indexes, especially for production of ethylene / 1-hexene copolymerization new products with high added value, thereby enhancing the product performance, improving the processability of resin, and broadening the application fields of the products.

Owner:PETROCHINA CO LTD

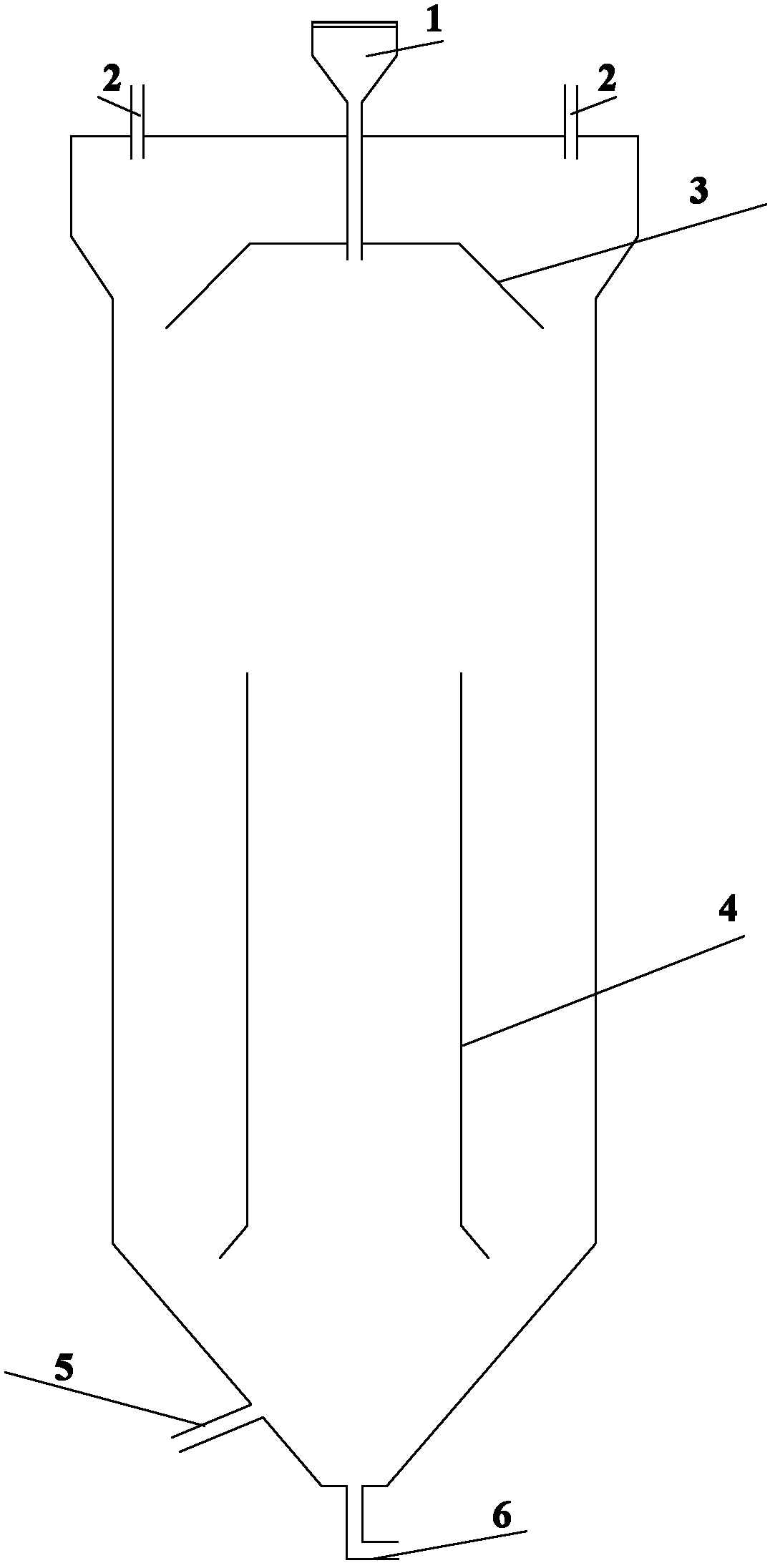

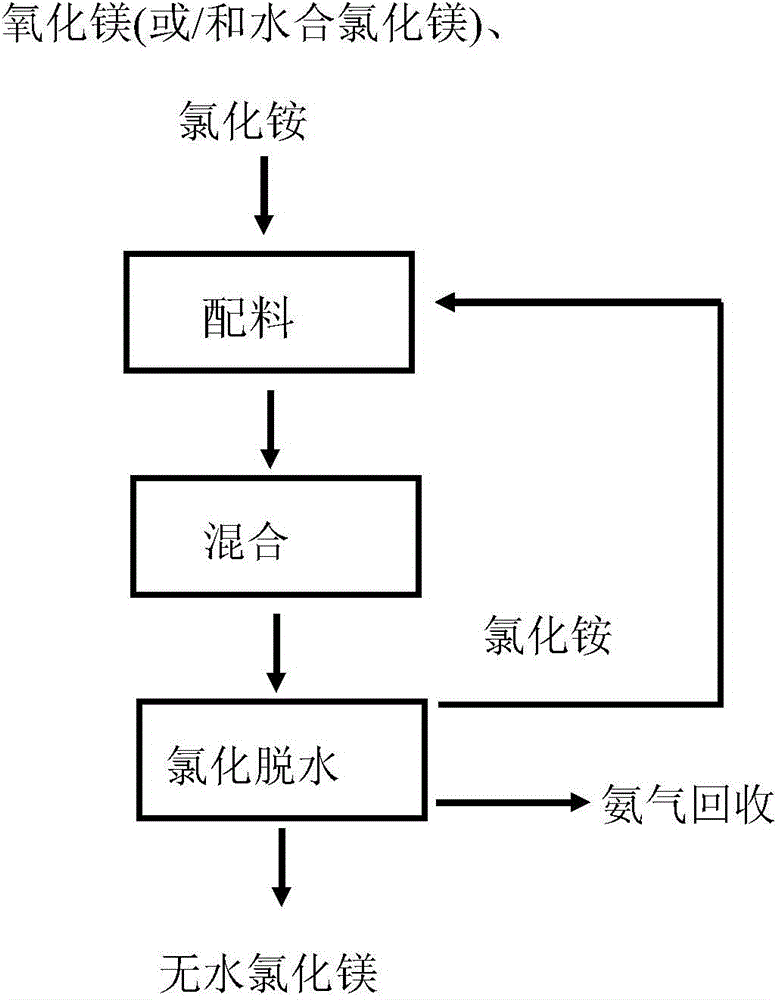

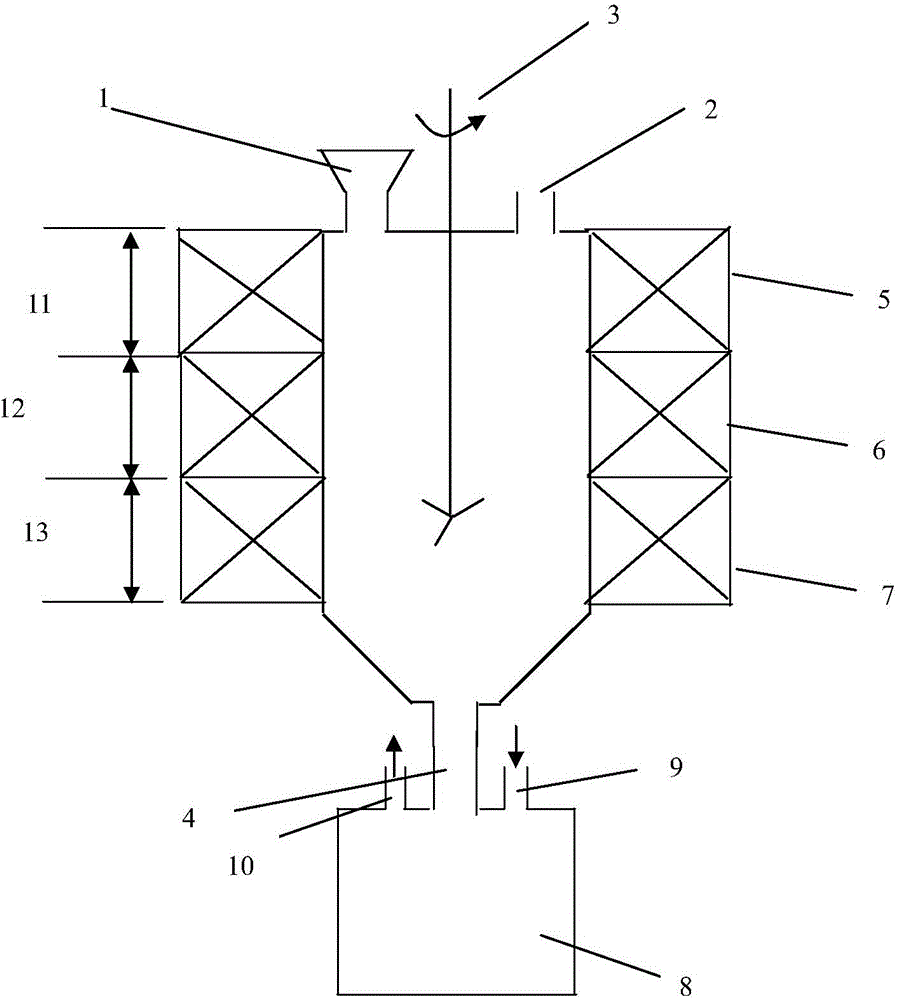

Method and device for preparing anhydrous magnesium chloride

The invention relates to a device for preparing anhydrous magnesium chloride and a preparation method which uses the device. The device is a chlorination dehydration furnace and comprises a storage cabin, wherein the upper part of the storage cabin is a preheating zone; the middle part of the storage cabin is a double salt forming zone; the bottom of the storage cabin is an ammonium removing zone; the storage cabin is connected with an outlet and has certain sealing property. The preparation method comprises the following steps: uniformly mixing magnesium oxide and / or hydrated magnesium chloride and ammonium chloride, adding the mixture into the chlorination dehydration furnace, and heating, thereby preparing anhydrous magnesium chloride; and repeating the above operation steps when the anhydrous magnesium chloride is discharged out, thereby achieving continuous production. A method for preparing anhydrous magnesium chloride by using the rich magnesite and magnesium chloride hexahydrate resources in China is provided by the invention, continuous production of anhydrous magnesium chloride is achieved, the production efficiency is improved, the production cost is lowered, and the cost of environment protection is lowered; the prepared anhydrous magnesium chloride is high in purity, the content of the main impurity magnesium oxide in the anhydrous magnesium chloride can be controlled to be 0.5% or even less than 0.1%, and the anhydrous magnesium chloride can be used for preparing magnesium metal in an electrolysis manner and has very good industrial and commercial prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite ethephon preparation used for spraying and accelerating maturation of vegetables and fruits

InactiveCN102027990APromote absorptionReduce surface tensionBiocidePlant growth regulatorsEthephonGibberellin

The invention relates to a composite ethephon preparation used for spraying and accelerating maturation of vegetables and fruits, which comprises the following raw materials in parts by weight: 50-90 parts of ethephon, 1-20 parts of extending agent, 0-20 parts of synergist and 4-25 parts of stabilizing agent, wherein the ethephon is solid pure ethephon; the extending agent is one or a mixture of ethyoxyl modified polytrisiloxane powder, lauryl sodium sulfate, saponin and sodium dodecyl benzene sulfonate; the synergist is one or a mixture of glucose, gibberellins, naphthylacetic acid and urea; and the stabilizing agent is one or a mixture of anhydrous magnesium sulfate, anhydrous magnesium chloride and anhydrous potassium sulfate. The invention has the advantages of stable product, long shelf life, uniform spraying, strong seepage force, small consumption, rapid plant absorption and strong action.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

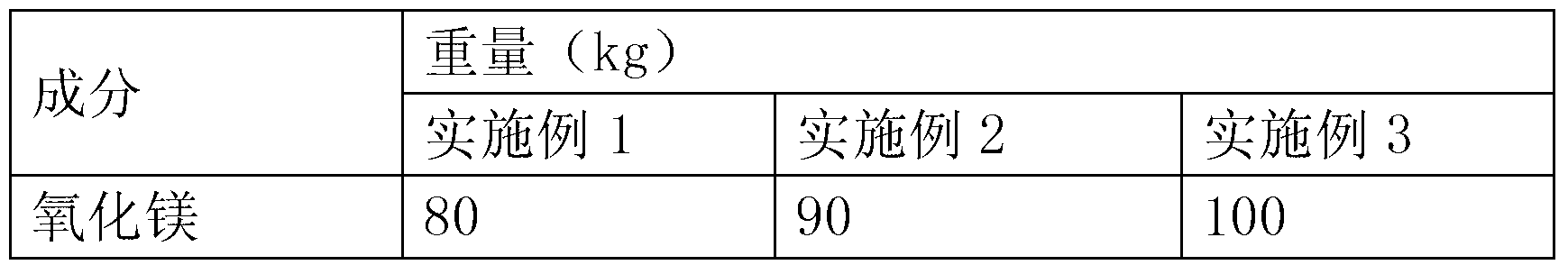

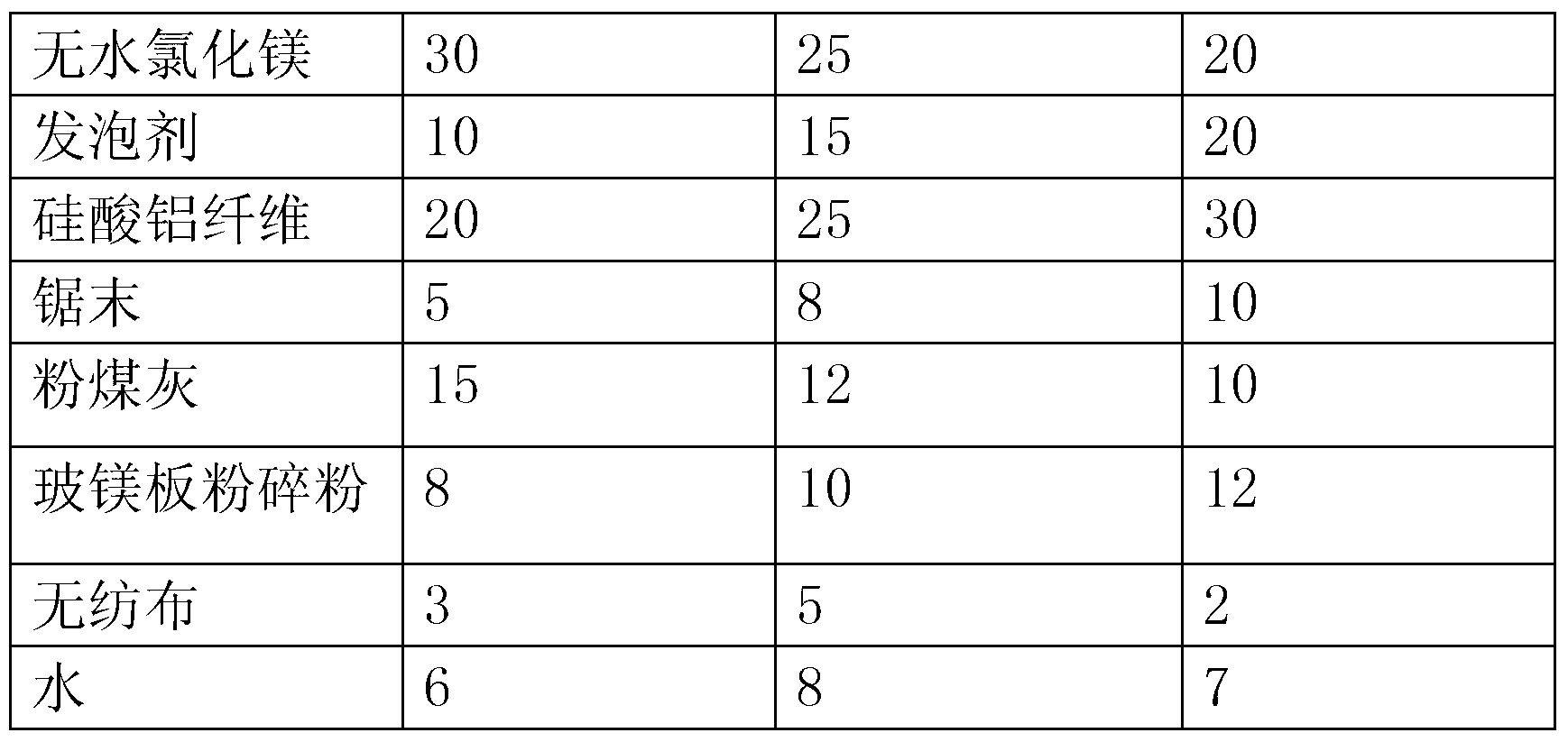

Magnesium oxide plate and manufacturing process thereof

InactiveCN103319198AImprove flame retardant performanceLong fire resistanceCeramicwareFiberAluminum silicate

The invention discloses a magnesium oxide plate and a manufacturing process thereof. The magnesium oxide plate disclosed by the invention is characterized by being prepared through mixing the following mixed raw materials in parts by weight: 80-100 parts of magnesium oxide, 20-30 parts of anhydrous magnesium chloride, 10-20 parts of foaming agent, 20-30 parts of aluminum silicate fiber, 5-10 parts of saw dust, 10-15 parts of coal ash, 8-12 parts of glass magnesium board disintegrated powder, 1.5-5 parts of non-woven fabric, and 6-8 parts of water. The magnesium oxide plate is manufactured by adding the raw materials in the parts by weight into mixing equipment and uniformly mixing the raw materials to prepare a base stock, introducing the base stock into a mold, extruding the base stock by using extrusion equipment, then molding the extruded base stock, and air-drying the molded plate. The magnesium oxide plate disclosed by the invention meets AQ1 grade safety and performance requirements; inspection according to GB24-2006 standards proves that the burning performance of the magnesium oxide plate meets A1 grade requirements; the magnesium oxide plate is smooth in surface, good in water resistance, can be applied to exterior wall decoration, and greatly expands the application space of a glass fiber and magnesium fire-proof plate.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

Fireproof door core board material, fireproof door core board and manufacturing methods thereof

The invention provides a fireproof door core board material, a fireproof door core board and manufacturing methods thereof. The fireproof door core board comprises the following components by mass fraction: 15%-25% of expanded perlite, 17%-23% of magnesium oxide, 18%-22% of anhydrous magnesium chloride, 12%-18% of water, 5%-10% of urea-formaldehyde glue, 3%-7% of talcum powder, 4%-7% of a polyester adhesive, 2%-4% of white alum, 0.8%-1.2% of a foaming agent, 0.8%-1.4% of an anti-crack fiber, 0.5%-1.4% of potassium permanganate and 0.6%-1.5% of ferrous sulfate. The fire resistance of the fireproof door core board manufactured by the fireproof door core board material provided by the invention is relatively high; and in addition, the fireproof door core board manufactured by the fireproof door core board material provided by the invention also has excellent humidity resistance and corrosion resistance, good heat-insulating property, light weight and good sound absorption performance. The manufacturing method of the fireproof door core board is free of exhaust gas emission in the process, and accords with the requirements of development of environmental development.

Owner:CHANGCHUN JINTAIHE FIREPROOF MATERIAL CO LTD

Glass magnesium fireproof board

InactiveCN102503351AIncrease the use of spaceImprove waterproof performanceUltimate tensile strengthFly ash

The invention discloses a glass magnesium fireproof board, comprising a base material, a skeleton material and a coating material. The glass magnesium fireproof board is characterized in that: the base material comprises the following components in mass: 100 Kg of magnesium oxide, 27 Kg of anhydrous magnesium chloride, 113 Kg of water, 0.6 Kg of peregal modifier, 20 Kg of fly ash and 53-57 Kg of sawdust; and a skeleton layer is made of glass fabrics and non-woven fabrics. The coating material comprises the components in mass: 10 Kg of the magnesium oxide, 2.7 Kg of the anhydrous magnesium chloride, 9-11 Kg of the water and 35 Kg of crushed glass magnesium board powder. According to the invention, by adding fly ash into the glass magnesium fireproof board, the strength of the glass magnesium fireproof board is improved while the waterproof performance is increased. Meanwhile, a coating material layer is increased and the layer is more smooth, so that the product can be used for decorating outer walls, the use space of the glass magnesium fireproof board is greatly expanded, and the aim that the glass magnesium fireproof board has the advantages of good waterproof performance, high strength and suitability to outer wall decoration is completely achieved.

Owner:仪陇县民信高分子材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com