Continuous polymerization reaction device for producing poly-p-phenylene benzo dioxazole

A technology of benzobisoxazole and polymerization reaction, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of high viscosity of PBO polymer, low polymer molecular weight and difficulty in stirring and other problems, to achieve the effect of increasing molecular weight, short production cycle and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

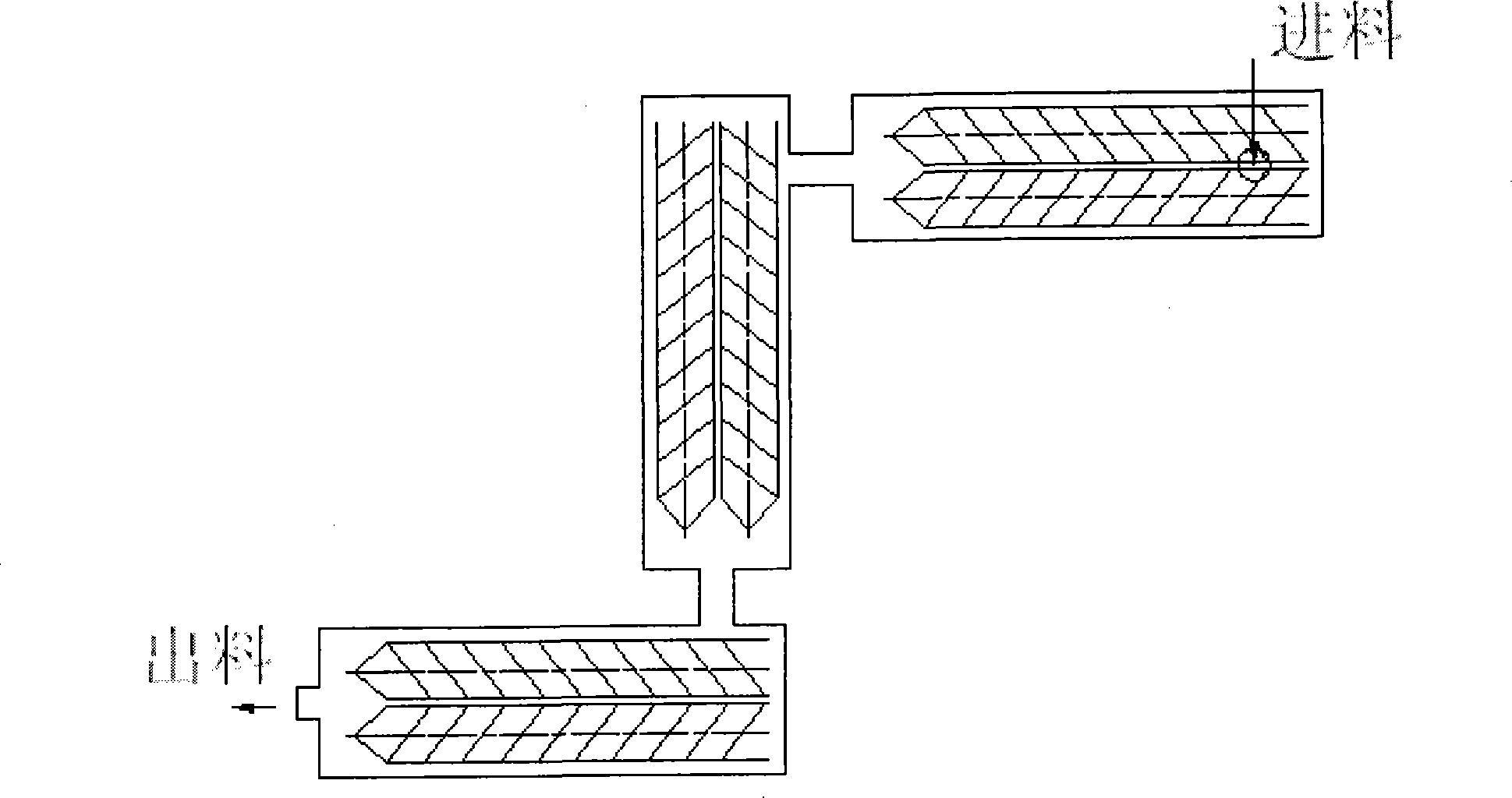

[0009] Specific implementation mode one: (see figure 1 , figure 2 ) The continuous polymerization reaction device of the present embodiment is made up of prepolymerization kettle and screw extruder unit, and the discharge port of prepolymerization kettle is connected with the feed inlet of screw extruder unit, and screw extruder unit is composed of two to ten It is composed of end-to-end screw extruders, in which the material of the screw, barrel, feed port and discharge port of the screw extruder should be acid-resistant, corrosion-resistant, or treated with acid-resistant and corrosion-resistant materials; The working temperature is 20-300°C, the extrusion pressure of the screw extruder is 0.1-30MPa, the screw diameter D=20mm-200mm, the screw length-to-diameter ratio L / D=10-60 (screw length / screw diameter, for conical For a twin-screw extruder, the screw diameter refers to the diameter of the largest screw diameter), the screw speed is 1-1000r / min, and the vacuum degree in...

specific Embodiment approach 2

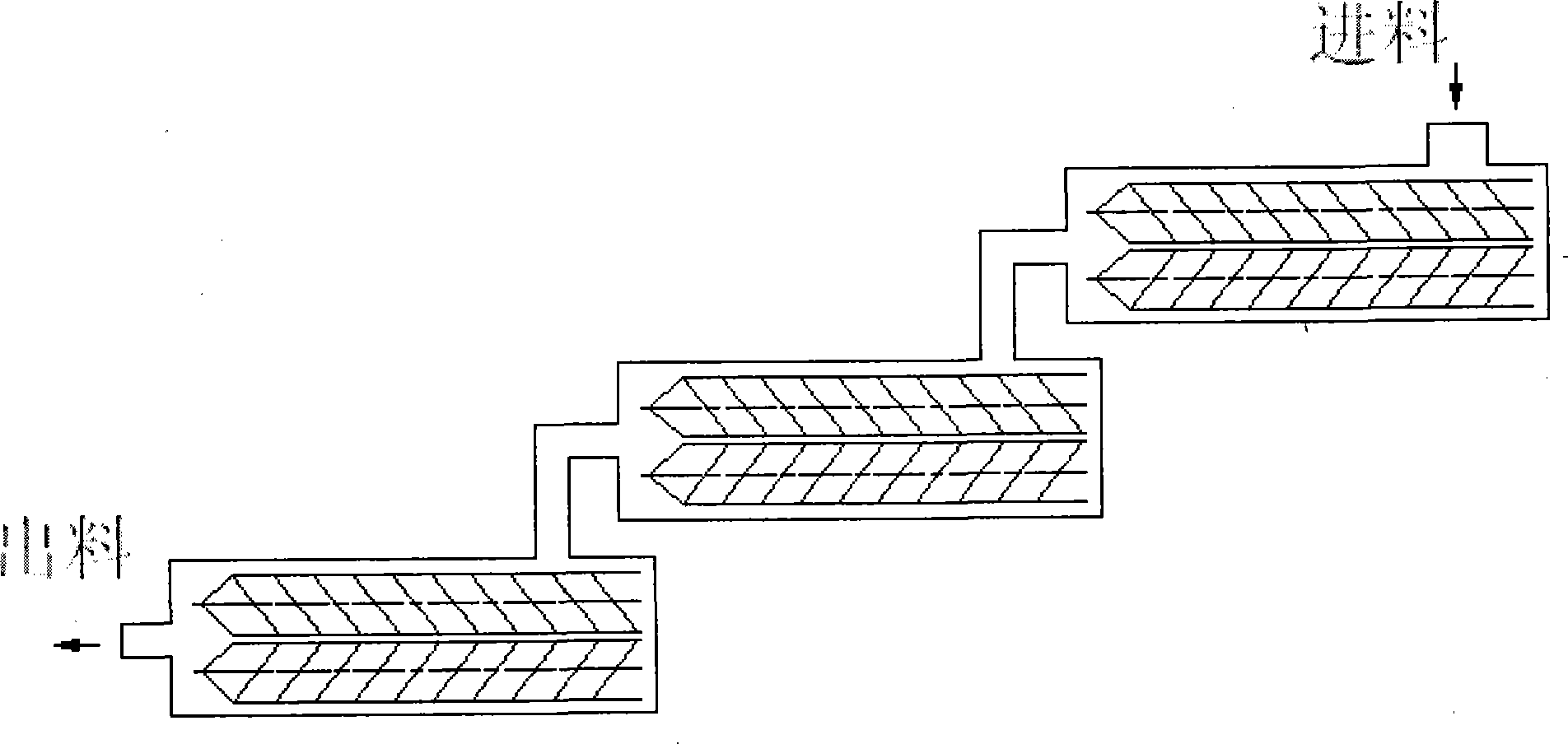

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that: the connection mode of the screw extruder unit is a plane series combination or a ladder combination. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the plane series combined type is to place the screw extruders on the same horizontal plane, and the included angle between the screw axes of two adjacent screw extruders is 0°~180°. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com