Water outlet switching valve and combined shower

A technology for switching valves and water outlets, applied to valve details, multi-way valves, valve devices, etc., can solve the problems of complex valve core structure, high processing cost, cumbersome process steps, etc., and achieve simple structure, low production cost and excellent process The effect of requiring simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

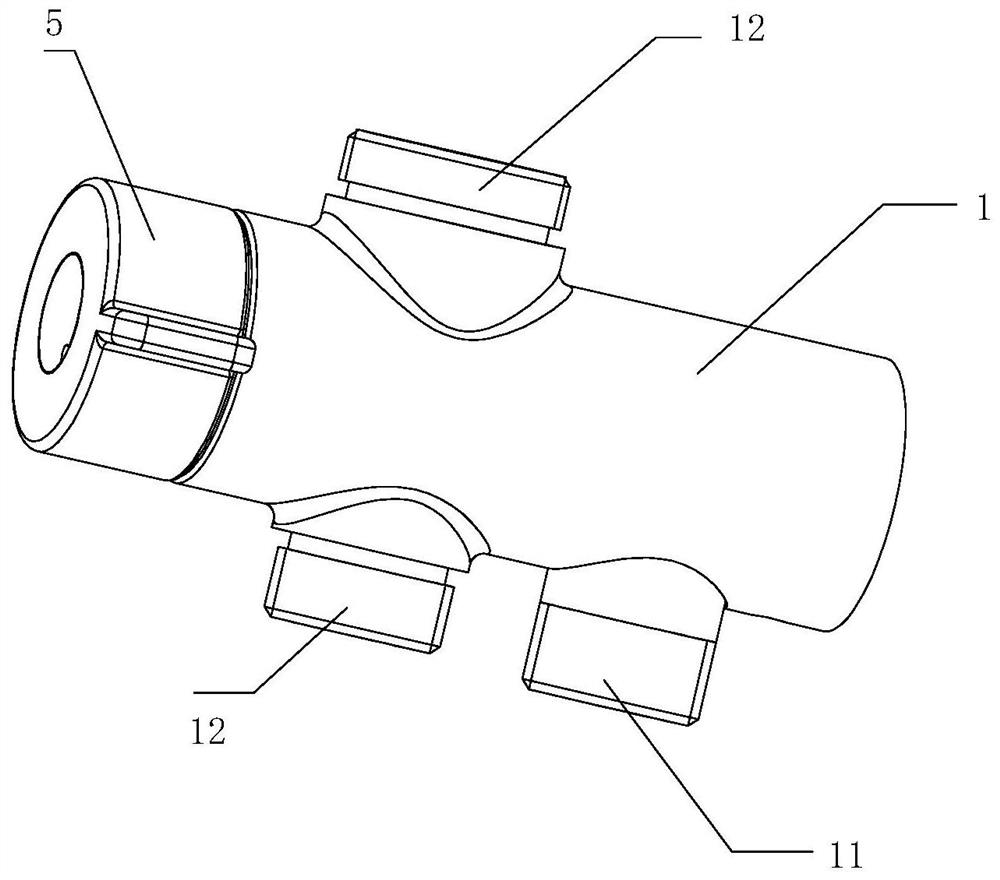

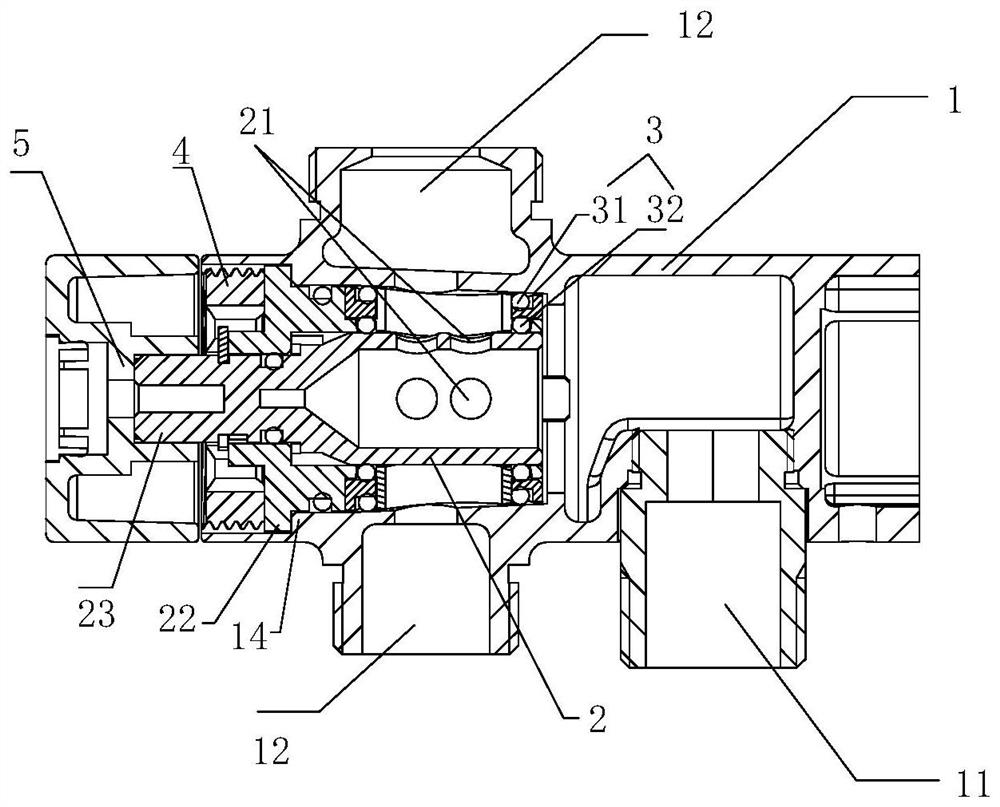

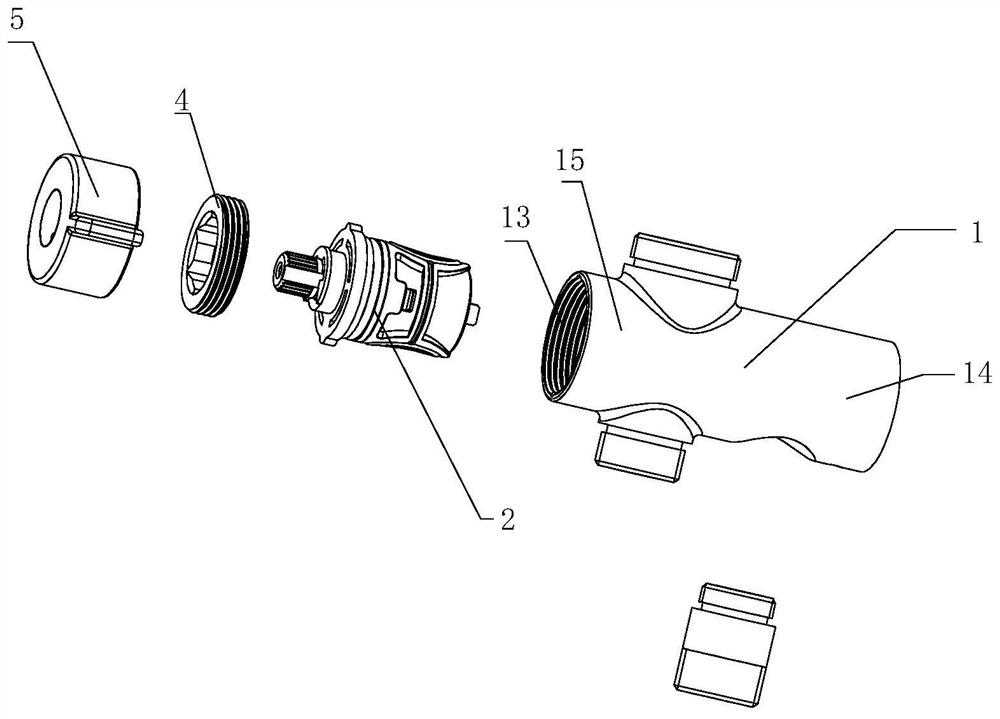

[0033] refer to Figure 1-Figure 5 , a water outlet switching valve, comprising: a casing 1 and a valve core 2;

[0034] The housing 1 has a water inlet 11 and two water outlets 12, the housing 1 includes a first end 15 and a second end 14, the second end 14 is connected to the wall, and the first end 15 is arranged on The other end of the shell 1 away from the wall is provided with an installation opening 13 at the first end 15, and the installation opening 13 is used to install the valve core 2; the number of water outlets 12 can be freely adjusted according to the number of water outlet terminals, if The water outlet switching valve is used in a combination shower. In order to supply water to the head shower and the hand shower, the number of water outlets 12 can be set to two.

[0035] The valve core 2 is placed in the housing 1 from the installation opening 13, and the outer wall of the valve core 2 and the inner wall of the housing 1 are sealed and connected at the oute...

Embodiment 2

[0044] refer to Figure 6-Figure 10 , this embodiment provides a water outlet switching valve, including: a valve core 6 and a valve core seat 7;

[0045] The valve core seat 7 has a water inlet hole 71 and at least two water outlet holes 72, and an installation opening 73 for installing the valve core 6; the number of water outlet holes 72 can be freely adjusted according to the number of water outlet terminals, if The water outlet switching valve is used in a combination shower. In order to supply water to the head shower and the hand shower, the number of water outlet holes 72 can be set to two.

[0046] The valve core 6 is placed in the valve core seat 7 from the installation opening 73, and the outer wall of the valve core 6 and the inner wall of the valve core seat 7 are sealed and connected at the outer periphery of the water outlet hole 72 through a seal 8, The water outlet hole 72 can only communicate with the valve core 6 located within the projected area of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com