Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Stable heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric circuit module

ActiveUS7206204B2Stable heat resistanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical devices

An electric circuit module comprising: an electric device comprising an electric circuit to serve for passage and interruption of electric current, a packing material packing the electric circuit and a plurality of wiring members to electrically connect the electric circuit with an external circuit; and a heat sink to radiate heat from the electric device. The electric circuit module includes a fixture to fix the heat sink and the electric device together so that a heat radiating surface of the electric device comes into contact with the heat sink. The fixture is formed with a recess to accommodate therein a part of the electric device so that the heat radiating surface of the electric device is exposed from the fixture. When the electric device is fixed to the heat sink by the fixture, the heat radiating surface comes into contact with the heat sink.

Owner:HITACHI IND EQUIP SYST CO LTD

Preparation method of antibacterial type soft polyurethane foaming plastic

InactiveCN103467702AGood antibacterial and bactericidal performanceStable heat resistancePolymer scienceButanediol

The invention discloses a preparation method of an antibacterial type soft polyurethane foaming plastic. The preparation method is characterized by comprising the following technical steps: a, adding metered polyether glycol N330 and 1,4-butanediol, a catalytic amount of dibutyltin dilaurate and tripolycyanamide to a reaction kettle, filling nitrogen or an inert gas into the reaction kettle for protection, heating at 40-60 DEG C, sufficiently stirring for 6-8 hours, and reducing temperature to 25 DEG C; b, adding polyisocyanate, silicone oil, triethylamine, nanometer zinc oxide and a right amount of water to a product obtained from the step a, and stirring at high speed till foaming; c, when a large quantity of white foams appear, immediately injecting the white foams into a mould, aging at 40-60 DEG C for 60-150 minutes, and demoulding to obtain a soft polyurethane foaming plastic product. The obtained polyurethane soft foaming plastic has the advantages of good antibacterial and bactericidal property, stability in heat-resistant property, no bactericide separation, safety, environment protection, simpleness and convenience for production process and suitability for industrialized production.

Owner:NANJING NIANJI REFRIGERATION FOOD

Semi-aromatic polyamide resin and preparation method thereof

The invention discloses semi-aromatic polyamide resin and a preparation method thereof. The semi-aromatic polyamide resin comprises, in parts by weight, 20 to 80 parts of aromatic / aliphatic dibasic acid, 20 to 80 parts of aliphatic diamine, 0.05 to 1 part of hindered phenol or hindered amine, 0.01 to 0.06 part of a catalyst, 30 to 160 parts of deionized water, wherein in the aromatic / aliphatic dibasic acid, the mass ratio of the aromatic dibasic acid to the aliphatic dibasic acid is 1:(0-9). A hindered phenol or hindered amine chemical group is connected to the tail end of a polyamide molecular chain through a chemical bond; the loss of the hindered phenol or hindered amine chemical group in a low-temperature environment is reduced; by adding a processing aid in the later-stage modification processing process, the phenomenon of heat stabilizer agglomeration or non-uniform dispersion during the modification does not exist, and the production cost is reduced, so that the product has goodthermal stability at the high temperature for a long time, and the mechanical property and the quality of the product are improved.

Owner:ZHONGLUN PLASTIC IND FUJIAN

Ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

PendingCN110746683AImprove mechanical propertiesShorten the production cycleLow smoke zero halogenPolymer science

The invention discloses an ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material and a preparation method thereof. The ultraviolet light cross-linked high flame-retardant low-smoke halogen-free polyolefin cable material comprises the following raw material components in parts by mass: 100 parts of a base material, 100-130 parts of a low-smoke halogen-free flame retardant, 5-15 parts of a synergistic flame retardant, 1-3 parts of a cationic initiator, 1-3 parts of a free radical initiator, 1-5 parts of an assistant crosslinking agent, 0.5-1.5 partsof a compound antioxidant, and 1-3 parts of a lubricant. The combination of two different photo-initiation mechanisms is utilized, the crosslinking efficiency is significantly improved, and wire andcable products have shorter production cycle, and more stable heat resistance and mechanical properties. At the same time, the low-smoke halogen-free flame retardant and the flame-retardant synergistare used, so that relatively good flame retardancy can be obtained and the mechanical properties of the material can be improved in the case of a relatively small total amount of the flame retardant.The base material with a specific composition and the lubricant with a specific composition are selected, so that the mechanical properties of the cable material are further improved, the processing performance of the material is improved, and the preparation efficiency is improved.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD

TPU (thermoplastic polyurethane) composite membrane used for fan blades and preparation method for TPU composite membrane

The invention provides a TPU (thermoplastic polyurethane) composite membrane used for fan blades and a preparation method for the TPU composite membrane. The TPU composite membrane is prepared from the following raw materials in parts by weight: 70 to 90 parts of TPU particles, 10 to 25 parts of glass fiber reinforced polybutylene terephthalate, 2 to 10 parts of PVDF (polyvinylidene fluoride), 3 to 8 parts of compatilizer, 1 to 5 parts of pore-foaming agent, 1 to 3 parts of antioxygen and 0.5 to 1 parts of ultraviolet light absorber. The TPU composite membrane provided by the invention is high in strength (the tensile strength can reach 85.1mpa) and high in heat resistance (the maximum vicat softening temperature is 128 DEG C), has good heat insulation property (the minimum heat conductivity coefficient is 0.012w / (m.k)), and is not is easy to separate from adhesive; when the TPU composite membrane is used for the fan blades, the fan blades can be protected to prolong the service life of the fan blades; moreover, the preparation method for the TPU composite membrane is simple.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Traction motor junction box suitable for high voltage class and manufacture method of traction motor junction box

ActiveCN103855849AImprove sealingImprove insulation performanceManufacturing dynamo-electric machinesSupports/enclosures/casingsThree-phaseEngineering

The invention discloses a traction motor junction box suitable for a high voltage class and a manufacture method of the traction motor junction box. The traction motor junction box comprises a box body, a junction box cover plate, a three-phase outgoing line, a three-phase cable wire and pouring sealant, wherein the junction box cover plate covers the box body, both the three-phase outgoing line and the three-phase cable wire enter the box body from the outside and are connected in the box body, and the pouring sealant is poured inside the box body. A three-phase outgoing line outlet through which the three-phase outgoing line passes, a three-phase cable wire outlet through which the three-phase cable wire passes, and a screwing member used for screwing the three-phase cable wire are arranged on the box body. The manufacture method of the junction box comprises the following steps: casting the box body; connecting the three-phase outgoing line with the three-phase cable wire; insulation-wrapping; and pouring and sealing. The junction box disclosed by the invention brings the convenience for sealing and mass production, and is low in cost, reliable in sealing and insulation, and capable of meeting the requirements of high voltage class and small space size during the operation of a traction motor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Preparation method of polysiloxane modified silicon-containing arylacetylene resin

The invention discloses polysiloxane modified silicon-containing arylacetylene resin and a preparation method thereof. The preparation method comprises the following steps: under inert gas shielding, stirring 5-30 parts of ethynyl aniline terminated polysiloxane (SO) and 70-95 parts of silicon-containing arylacetylene resin (PSA) by weight part at 100-140 DEG C to carry out reaction for 0.5-3h to obtain redish brown modified silicon-containing arylacetylene resin. As for the obtained ethynyl aniline terminated polysiloxane modified silicon-containing arylacetylene resin, while excellent heat resistance of the silicon-containing arylacetylene resin is kept, the viscosity of the resin is remarkably lowered, the processing properties and the dielectric properties are improved, the mechanical properties are further improved, and the application range of the silicon-containing arylacetylene resin as an ablation resistant material, a high-temperature resistant wave-transparent material, a ceramic precursor, a structure and function integrated material and the like in the aerospace field, the military field, the electronic field and the like is expanded.

Owner:EAST CHINA UNIV OF SCI & TECH

Insulated structure of induction heating coil

ActiveUS20100243644A1Stable heat resistanceImprove effectCoil arrangementsFurnace typesAluminium oxideSurface cover

It was learned that in an insulation heating coil used for continuously heating a running steel sheet, the conventional insulated structure of the induction heating coil was selected focusing on the heat resistance and insulation ability of the insulation itself and cannot prevent a drop in insulation ability due to entry of fine metal particles (for example, zinc fumes) in the surroundings.Therefore, an insulated structure of induction heating coil preventing the entry of zinc fumes and other fine metal particles, not falling in strength even in a high temperature environment, and able to extend the service life of the induction coil is provided.Specifically, the surface of the induction heating coil is covered with a ceramic cloth made of alumina-silica ceramic long-fibers not containing boron and the surface of that is formed with a heat-resistant insulation layer made of a surface hardening ceramic material containing alumina or alumina-silica fine particles and alumina-silica ceramic short-fibers.

Owner:NIPPON STEEL CORP

Heat-resistant and high thermal conductive adhesive

InactiveUS20110178232A1Improve conductivityIncrease resistanceGroup 4/14 element organic compoundsMaterial nanotechnologyHeat resistanceAdhesive

An object of the present invention is to provide a heat-resistant and high thermal conductive adhesive having excellent mechanical strength, heat resistance, and thermal conductivity. A heat-resistant and high thermal conductive adhesive of the present invention includes: (a) a first component in which a carbon-based filler surface-modified with a first reactive functional group and an adhesive polymer matrix having a second reactive functional group are bonded by an addition condensation reaction of the first reactive functional group and the second reactive functional group; and (b) a second component containing a carbon-based filler surface-modified with a third reactive functional group, wherein the third reactive functional group is a functional group causing an addition condensation reaction with the second reactive functional group by the application of light or heat.

Owner:SHIMANE PREFECTURAL GOVERNMENT MATSUE

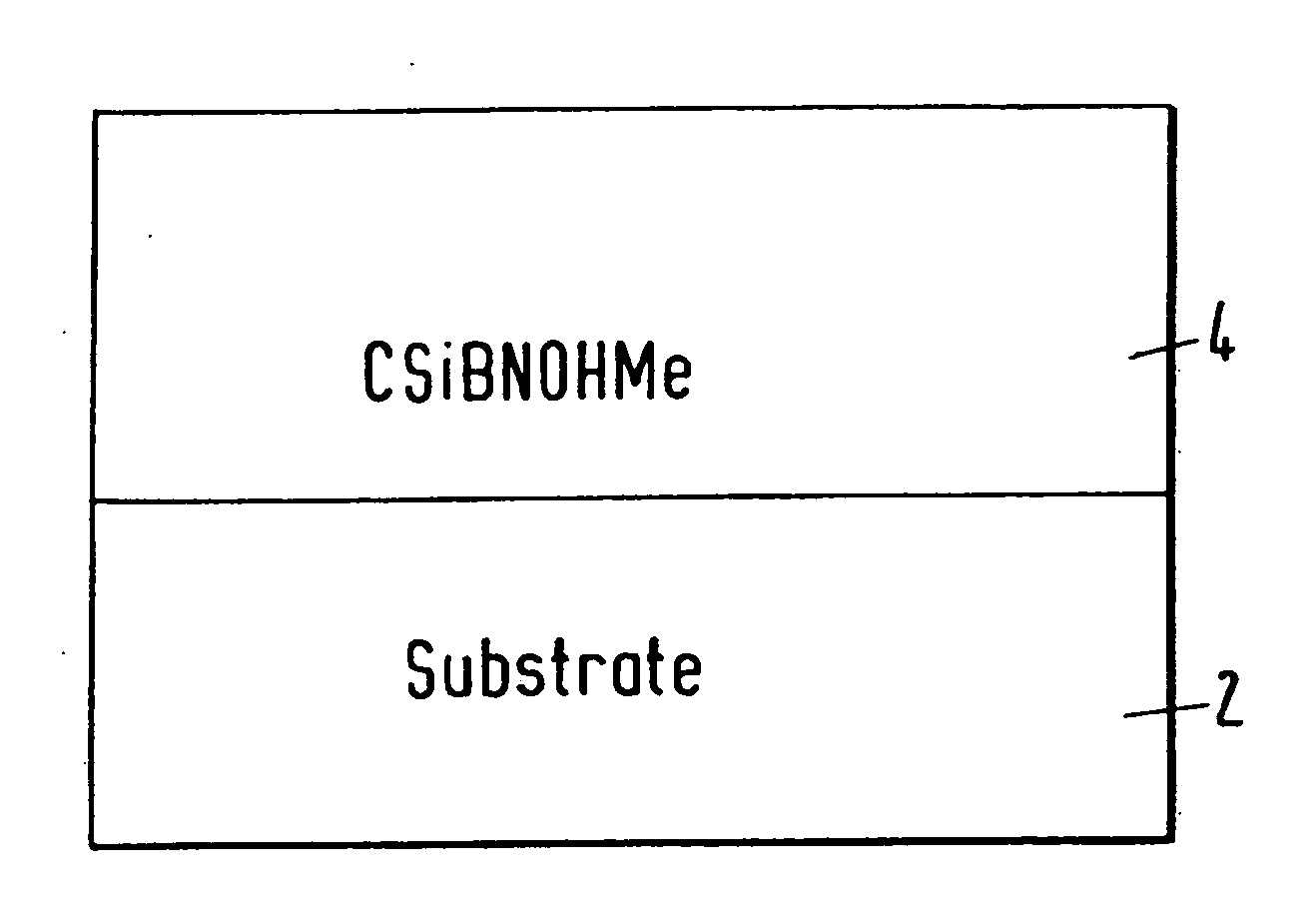

Protective coating, a coated member having a protective coating as well as method for producing a protective coating

ActiveUS20120196137A1Emission reductionReduce friction loss in and transmissionFibre treatmentVacuum evaporation coatingChemical compositionMetal

The invention relates to a protective coating, having the chemical composition CaSibBdNeOgHlMem, wherein Me is at least one metal of the group consisting of {Al, Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Y, Sc, La, Ce, Nd, Pm, Sm, Pr, Mg, Ni, Co, Fe, Mn}, with a+b+d+e+g+l+m=1. According to the invention, the following conditions are satisfied: 0.45≦a≦0.98, 0.01≦b≦0.40, 0.01≦d≦0.30, 0≦e≦0.35, 0≦g≦0.20, 0≦1≦0.35, 0≦m≦0.20. The invention relates also to a coated member having a protective coating, as well as to a method for producing a protective coating, in particular a multilayer film for a member.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

UV-cured flame-retardant waterborne polyurethane adhesive and preparation method thereof

InactiveCN110982476AHigh bonding strengthImprove thermal stabilityPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a UV-cured flame-retardant waterborne polyurethane adhesive and a preparation method thereof. A formula of the UV-cured flame-retardant waterborne polyurethane adhesive is composed of isocyanate, dihydric alcohol, hydroxyethyl acrylate, a reactive diluent, a flame retardant, a photoinitiator, a catalyst, a polymerization inhibitor, an accelerant, triethylamine, a solvent and deionized water. The preparation method comprises the steps: step 1, selecting raw materials; step 2, preparing waterborne polyurethane acrylate; step 3, preparing waterborne flame-retardant polyurethane acrylate; and step 4, mixing and preparing the finished product; according to the invention, the UV curing technology is introduced into the adhesive industry, the curing efficiency is improved,the energy consumption is reduced, and the adhesive is an aqueous system and meets the requirements of the furniture industry on environmental protection and health; meanwhile, the reactive flame retardant is introduced into a polyurethane structure, stable flame retardance and heat resistance are formed, the prepared adhesive is high in bonding strength, the better the thermal stability and flame retardance of a cured film are, the better the storage stability is, and the wide application prospect is achieved.

Owner:SHENZHEN TAIQIANG CHEM

Heat-resistant and highly heat-conductive adhesive agent

InactiveCN102171307AImprove heat resistanceHigh heat resistance High thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesHeat resistanceUltimate tensile strength

Provided is a heat-resistant and highly heat-conductive adhesive agent which has excellent mechanical strength, heat-resistance and heat-conductivity. A heat-resistant and highly heat-conductive adhesive agent comprising (a) a first component wherein a carbon-based filler having been surface-modified with a first reactive functional group and an adhesive polymer matrix having a second reactive functional group are bonded to each other by an addition condensation reaction between the first reactive functional group and the second reactive functional group, and (b) a second component which comprises a carbon-based filler having been surface-modified with a third reactive functional group, wherein the third reactive functional group is a functional group which undergoes an addition condensation reaction with the second reactive functional group by the application of light or heat.

Owner:岛根县

High-performance toughened flame retardant PET (polyethylene terephthalate)/ABS (acrylonitrile-butadiene-styrene) alloy and preparation method

The invention discloses a high-performance toughened flame retardant PET (polyethylene terephthalate) / ABS (acrylonitrile-butadiene-styrene) alloy and a preparation method. The high-performance toughening flame retardant PET / ABS alloy comprises the following components by mass: 20%-70% of PET, 10%-50% of ABS, 5%-25% of a toughening agent, 12%-20% of a flame retardant, 1%-5% of a compatible agent, 0.5%-2% of a lubricant and 0.1%-1% of an antioxidant. The beneficial effect of the high-performance toughening flame retardant PET / ABS alloy is in that: compared with the existing technology, after surface pretreatment of inorganic rigid particles, by interaction and grafting reaction of the pretreated inorganic rigid particles and elastomer, a core-shell structure using the inorganic rigid particles as a core and the elastomer as a shell is formed for synergistic toughening, and the prepared PET / ABS alloy has the significant advantages of high strength, good toughness, high thermal resistance performance, strong environmental stress resistance and the like, and also has good flame retardant property and processing performance.

Owner:QINGDAO XINZHAN PLASTIC

Coating special for metal and production method thereof

InactiveCN108948904AGood light fastnessImprove outdoor aging performanceFireproof paintsAntifouling/underwater paintsMetal coatingGlass fiber

The invention relates to a metal coating, and in particular to a coating special for metal and a production method thereof. The coating special for metal contains the following raw materials in partsby weight: 50-60 parts of acrylic resin, 30-40 parts of polytetrafluoroethylene resin, 10-20 parts of inorganic montmorillonite, 10-20 parts of glass fiber, 20-25 parts of mica powder, 10-15 parts ofaluminium powder, 5-15 parts of ultraviolet shielding agent, 5-8 parts of butyl acetate, 3-5 pars of leveling agent, 2-3 parts of defoaming agent, 1-1.5 parts of dispersing agent, 0.8-1 part of anti-settling agent and 0.5-1 part of thickening agent. The prepared coating special for metal has excellent weatherability, fume resistance and self-cleanness, strong covering capability, good reflecting property for light and heat and strong corrosion protection; the surface of a metal workpiece processed by the coating is smooth, high in glossiness and uniform in color; and the dried paint film is excellent in chemical resistance.

Owner:广西南宁维一防腐科技有限公司

Novel fluororubber vulcanizer and preparation method thereof

ActiveCN104672491APromote generationEasy to prepareOrganic compound preparationCarboxylic acid amides preparationAlkaneNitroalkane

The invention discloses a novel fluororubber vulcanizer which comprises at least one phenolic hydroxyl group and one amino group in the molecular structure. The novel fluororubber vulcanizer can be prepared from the following two preparation methods: one method comprises a step of performing catalytic hydrogenation reduction on a phenolic hydroxyl group and nitroparaffin substituted aromatic hydrocarbon, and the other method comprises a step of reacting phenolic hydroxyl substituted aromatic hydrocarbon carboxylic acid and a multi-amino compound. The novel fluororubber vulcanizer disclosed by the invention is simple in preparation method, gentle in reaction condition and relatively low in raw material cost; when being added with an essential quaternary phosphorus salt accelerant, the novel fluororubber vulcanizer can be used as a special vulcanizer, prepared fluororubber is reliable in heat tearing property, high in strength, good in permanent compression deformation property and stable in heat resistance, a fluororubber composition is relative good in flowability and relatively excellent in processing property, and problems such as scorching of a phenol vulcanization system and poor fluororubber property of an amino vulcanization system can be solved.

Owner:江苏千富之丰科技有限公司

end mill

InactiveCN102294509AStable heat resistanceSave labor and materialsMilling cuttersChatter vibrationMilling cutter

The invention relates to the structural design technology of special end mills for stainless steel and titanium alloys. Its blade adopts unequal helix angle structure. The advantages of the present invention are: 1) Using unequal helix angles, compared with previous products, can effectively suppress high-frequency vibration; 2) Adopting stable and excellent TIALN coating with heat resistance, can process materials with higher hardness; 3) Adding a long-shrinking shank type (outer diameter larger than the shank diameter) saves materials used for end mills; 4) Adopting a curved cutting edge that can suppress the height difference in vertical processing to achieve a good processing surface and improve the acceptance environment of cutting tools.

Owner:江苏万金工具有限公司

Rubber part having a metal fitting and method of producing the same

A rubber part having a metal fitting in which the metal fitting and the rubber part are integrated through an anti-corrosion chemical film formed on a surface of the metal fitting. The anti-corrosion chemical film is a zirconium-based chemical film that is harmless to human body and environment, and is transformable following the squeeze of the metal fitting. The rubber part having a metal fitting is produced by the steps of: degreasing an outer peripheral surface of the metal fitting, subjecting the surface to shot blasting treatment, degreasing the treated surface, and water washing the treated surface; forming a zirconium-based chemical film on the treated surface; water washing and drying an outer peripheral surface of the zirconium-based chemical film; forming an adhesive layer on the outer peripheral surface of the zirconium-based chemical film; and integrating the rubber part on the outer peripheral surface of the adhesive layer.

Owner:SUMITOMO RIKO CO LTD

Graphene viscose/graphene modal blended yarn and preparation method and fabric thereof

ActiveCN109487388AImprove conductivityImprove thermal conductivityWeft knittingWarp knittingYarnGraphene

The invention discloses a graphene viscose / graphene modal blended yarn, which is formed by interweaving graphene viscose spun yarn and graphene modal spun yarn, wherein the graphene viscose spun yarnis formed by spinning graphene viscose composite fiber with the graphene content of 0.5-4wt%, and the graphene modal spun yarn is formed by spinning graphene modal composite fiber with the graphene content of 0.5-4wt%. The invention also discloses a preparation method of the blended yarn and a fabric made of the blended yarn. According to the preparation method of the blended yarn, the graphene isintroduced into the viscose fiber or the modal fiber, the functional characteristics of the graphene are reflected on the viscose fiber and the modal fiber, the viscose fiber and the modal which areexcellent in performance are given good electrical conductivity, thermal conductivity, antibacterial property, anti-ultraviolet function, far-infrared function and the like, and the mechanical properties of the viscose fiber and the modal are improved.

Owner:JIANGYIN XIANGFEI APPAREL

Method for inclusion body protein dilution and dialysis renaturation

ActiveCN109942668AImprove renaturation efficiencyImprove efficiencyPeptide preparation methodsHigh concentrationInclusion bodies

The invention discloses a method for inclusion body protein dilution and dialysis renaturation. A mild degeneration method is adopted for dissolving inclusion body protein, an existing secondary structure in the inclusion body protein is protected against damage so that inclusion body protein renaturation is greatly facilitated; the method integrates dilution and dialysis for performing protein renaturation, the concentration of a degeneration agent is lowered by first-time dilution, protein renaturation is promoted, the concentration of an additive is lowered by second-time dilution, the protein is more easily suitable for the environment of a basic buffer solution, finally, dialysis is performed to remove various additives, and the renaturated protein with the high renaturation efficiency and the high concentration can be obtained.

Owner:安徽环球基因科技有限公司

Rubber part having a metal fitting and method of producing the same

ActiveUS20070235914A1Improve adhesionImprove anti-corrosion performancePortable framesMultiple spring combinationsCompound (substance)Peening

A rubber part having a metal fitting in which the metal fitting and the rubber part are integrated through an anti-corrosion chemical film formed on a surface of the metal fitting. The anti-corrosion chemical film is a zirconium-based chemical film that is harmless to human body and environment, and is transformable following the squeeze of the metal fitting. The rubber part having a metal fitting is produced by the steps of: degreasing an outer peripheral surface of the metal fitting, subjecting the surface to shot blasting treatment, degreasing the treated surface, and water washing the treated surface; forming a zirconium-based chemical film on the treated surface; water washing and drying an outer peripheral surface of the zirconium-based chemical film; forming an adhesive layer on the outer peripheral surface of the zirconium-based chemical film; and integrating the rubber part on the outer peripheral surface of the adhesive layer.

Owner:SUMITOMO RIKO CO LTD

High-compactness anti-fouling marking paint

InactiveCN110079138AReduce porosityImprove compactnessFireproof paintsAntifouling/underwater paintsPorosityCoated surface

The invention discloses a high-compactness anti-fouling marking paint. The high-compactness anti-fouling marking paint comprises primer and finish paint, and is characterized in that the primer and the finish paint are dual-component paints; the primer is colored paint, and the finish paint is varnish; during use, the primer and a curing agent are sprayed to the pavement after being mixed in the volume ratio of 98:2, and then a layer of finish paint is immediately coated and sprayed on the wet primer surface; the finish paint and the primer are in chemical crosslinking reaction to form anti-fouling marking. The paint film is small in porosity and high in compactness; the paint film is covered on the surface of the coating, the adhesion and corrosion to the coating by the dust, the oil contamination and fine particulate matters and like pollutants is prevented and reduced, and the coating anti-fouling performance is greatly improved; the finish paint and the primer are bounded through the chemical crosslinking reaction, two coatings are firmly adhered to form the marking coating heat resistance stability; the coating cannot become tacky and soft after encountering the heat, therebyeffectively preventing the pollutant from adhering or embedding into the coating to form the pollution. The high-compactness anti-fouling marking paint disclosed by the invention is suitable for the urban road marking and the lane edge marking of the highway.

Owner:南宁华之邦交通设施材料有限公司

Composite film production technology

InactiveCN107351512AShorter lead timesEasy to operate and constructLaminationLamination apparatusEnvironmental resistanceCooking & baking

The invention discloses a composite film production process, comprising: 1) coating a polyurethane adhesive on one side surface of a PET film, the coating amount is 4-5g / m2, and smoothing; 2) coating the polyurethane adhesive The PET film of the mixture is sent to an oven, and after heating in the oven from 60-80°C, it is compounded with aluminum foil under the action of cold wind to obtain a PET-aluminum foil film; 3) The PET-aluminum foil film is cured at 55-60°C6 ‑10h; 4) preheating the cured PET‑aluminum foil film to 140‑160 °C; and 5) bonding the preheated PET‑aluminum foil film to a polymer film to obtain a composite film. This production process abandons the traditional way of using two-component adhesives for gluing. It has short curing time, high peel strength, greatly shortens the process cycle, and makes the process more environmentally friendly. The obtained composite film has good heat resistance and aging resistance, and can be applied to the surface of heat insulation materials.

Owner:广盟环保新材料(广州)有限公司

Novel insulated special cable and preparation method thereof

InactiveCN103779003AImprove corrosion resistanceImprove insulation performanceInsulated cablesInsulated conductorsXylyleneElectrical conductor

The invention discloses a novel PPEK insulated special cable. The novel PPEK insulated special cable comprises a conductor (1), the conductor (1) is plated with nickel, and a PPEK insulation layer (2) covers the nickel-plated conductor (1). A fireproof layer (3) wraps the PPEK insulation layer (2). A wear resistant layer (4) is braided outside the fireproof layer (3). The conductor of the cable is made of nickel-plated copper wires, and the insulation layer is made of polyetherketone resin. Being prepared through high-temperature melting and extruding at 350 DEG C, the novel PPEK insulated special cable has the following characteristics: the heat resistance is stable, and the conductor works at 260 DEG C for a long term; the radiation resistance is not lower than 10<8>Gy; the insulation property is good, the volume resistivity is 10<16> Omega CM, and the electric breakdown strength is 43Kv / mm; the tensile strength is not lower than 106Pma; the flame retardancy is excellent, and the oxygen index is 33; the cable is resistant to hydrolysis, can safely work in 100-DEG C water vapor for a long term, and is moisture-proof and mould-proof; the cable has excellent chemical stability and is resistant to gasoline, acetone, ethanol, xylene and sea water; and the cable is light in specific gravity, the specific gravity of the cable is 1.32 and is 65% of that of fluorine resin, and the cable is non-toxic.

Owner:河南中录科技有限公司

Method for preparing konjac sipunculid worm jelly

InactiveCN102302148AGood gelInsufficient improvementFood preparationRefrigerated temperatureRefrigeration

The invention relates to method for preparing konjac sipunculid worm jelly, which comprises the steps of: preparing materials; preparing a flavoring material bag; preparing a konjac liquid; boiling a sipunculid worm soup; and preparing sipunculid worm jelly. According to the method for preparing the konjac sipunculid provided by the invention, the sipunculid is taken as the main raw material, and added konjac fine powder and k-carrageeenen have the advantages of good gelation, heat resistance, stability and the like, so that the prepared sipunculid worm jelly has stable heat resistance and high resilience and is nutritious and healthy, and the defects of the traditional sipunculid worm jelly in storage and mouthfeel are greatly improved. Generally, the sipunculid worm jelly is suitable to be refrigerated at a temperature of 0 to minus 4 DED C and is directly eaten after being taken out of a refrigerator; and the keeping time for refrigeration is generally not longer than 1 week.

Owner:FUJIAN AGRI & FORESTRY UNIV

Heat-resistant polypropylene plastic film and preparation method thereof

The invention discloses a heat-resistant polypropylene plastic film, comprising the following materials according parts by weight: 0.1-0.2 part of 1-glycerol stearate, 0.1-0.3 part of alkenyl succinic anhydride, 0.1-0.16 part of ricinoleic acid, 2-3 parts of tris(nonylphenyl) phosphite, 210-300 parts of polypropylene, 7-9 parts of montmorillonite powder, 1-2 parts of lanthanum chloride, 5-6 parts of polyvinyl alcohol, 2-3 parts of sodium carbonate, 0.7-1 part of aluminum dihydrogen phosphate, 2-3 parts of calcium petroleum sulfonate, 0.4-1 part of sodium dodecyl sulfate, 3-5 parts of bisphenol A phosphite, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 0.6-1 part of diacetone acrylamide, and 1-2 parts of hydroxyethyl cellulose. In the invention, limestone is treated using hydroxyethyl cellulose and mixed with aluminum dihydrogen phosphate solution, thus improving viscosity of a mixture system and improving the strength of bonding of the limestone with heat-resistant additives, the calcium stearate and the zinc stearate. The invention also adds bisphenol A phosphite, tris(nonylphenyl) phosphite and the like, further improving heat resistance stability of a plastic film product.

Owner:SUZHOU ZIJIN PLASTIC

High-temperature-resistant metal plate adopting inorganic coating and preparation method thereof

InactiveCN112625469AStable heat resistanceGood weather resistanceFireproof paintsWeather resistancePhysical chemistry

The invention discloses a high-temperature-resistant metal plate adopting an inorganic coating, which comprises a metal base material and the inorganic coating coated on the base material, wherein the inorganic coating comprises the following components by mass: 25-45 parts of nano silicon dioxide sol, 25-45 parts of organosilane, 5-15 parts of functional filler, 5-15 parts of water, 10-20 parts of inorganic pigment, 0.1-3 parts of a functional assistant and 0.1-2 parts of a thickener. The product has stable heat resistance, high weather resistance, high chemical resistance, high wear resistance and high hardness, and the product reaches A1-grade fireproof performance.

Owner:舾蒙新材料科技(上海)有限公司

Alkyl-substituted disiloxane and preparation method thereof

InactiveCN102731559AOptimal Control StructureThe reaction process is simpleGroup 4/14 element organic compoundsDisiloxaneDistillation

The invention discloses alkyl-substituted disiloxane shown by a chemical formula (I), and a preparation method thereof. The preparation method of the compound comprises the steps that: raw materials are adopted according to a molar ratio of magnesium to bromoalkane to silicon tetrachloride of 3-3.5:3-3.3:1; magnesium is added into a reaction vessel; bromoalkane-tetrahydrofuran or an anhydrous diethyl ether solution and a silicon tetrachloride-ligroin solution are added under the protection of nitrogen gas; the mixture is subjected to a reaction for 2-6h under a temperature of 20-60 DEG C; an ammonium chloride solution or dilute hydrochloric acid is mixed into the mixture for stopping the reaction; an organic phase is separated from an aqueous phase; the aqueous phase is extracted by using an organic solvent, and the organic phases are combined; the mixture is washed by using deionized water, and is dried by using a drying agent; the material is subjected to pump-filtration; the filtrate is subjected to distillation concentration, and is dehydrated for 3-4h under a temperature of 160-260 DEG C; the material is then subjected to silica gel column chromatography, such that the alkyl-substituted disiloxane is obtained. The alkyl-substituted disiloxane provided by the invention has good thermal stability, good oxidation resistance, and high flash point. The compound is suitable to be used in hydraulic oil, diffusion pump oil, and heat conduction oil.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing intermetallic aluminum-erbium or aluminum-lithium-erbium alloy by fused salt electrolysis

The invention provides a method for preparing intermetallic aluminum-erbium or aluminum-lithium-erbium alloy by fused salt electrolysis, which is implemented in a way that: in an electrolytic furnace, metallic aluminum is use as a cathode, a graphite rod is used as an anode, and Ag / AgCl is used as a reference electrode; a mixture, which comprises 48.9 wt% of KCl, 48.9% of LiCl and 2.20% of ErCl3,is used as an electrolyte system; electrolysis is carried out at 520 DEG C; and by controlling the cathode potential at -1.4--2.1V, erbium precipitates on the solid-state aluminum cathode and diffuses to the inside of the aluminum cathode to form the aluminum-erbium alloy containing Al3Er, Al2Er and Al2Er3, or aluminum-lithium-erbium alloy containing Al-Li and Al3Er. By controlling the cathode potential, the formed strengthened phase Al3Er has high melting point and stable heat resistance, and can obviously enhance the strength of the aluminum-erbium or aluminum-lithium-erbium alloy. The invention overcomes the actual state that the composition of the aluminum-erbium or aluminum-lithium-erbium alloy prepared by the fused salt electrolysis process can not be controlled.

Owner:HARBIN ENG UNIV

Preparation method of insulating and high-temperature resistant battery outer packaging film

InactiveCN109910420AHigh bond strengthEnhanced microscopic space structure strengthNon-macromolecular adhesive additivesLaminationFilter cakeMethyl acrylate

The invention relates to a preparation method of an insulating and high-temperature resistant battery outer packaging film, and belongs to the technical field of packaging film preparation. The preparation method comprises the following steps: preparing a mixed solid product from straw and soybean as raw materials, mixing the mixed solid product with water and citric acid, adding copper powder toprepare a modified liquid, filtering the modified liquid to obtain a filter cake, mixing the filter cake with methyl acrylate, and applying the mixture to a nylon film for hot pressing to obtain the insulating and high-temperature resistant battery outer packaging film. Amino and carboxyl extracted from the soybean are utilized to form complex adsorption on aluminum ions and other chemical bond force adsorption to be more strongly adsorbed in fiber molecules, copper ions are subjected to reaction with oxygen to generate copper oxide which is mixed in carbon fibers, and aluminum oxide generatedfrom elementary aluminum by oxidation covers the fibers. Therefore, insulation performance and high-temperature resistance of the packaging film are improved, and the packaging film has broad application prospect.

Owner:谭凤香

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com