Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232results about How to "Good consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for evaluating consistency of battery pack

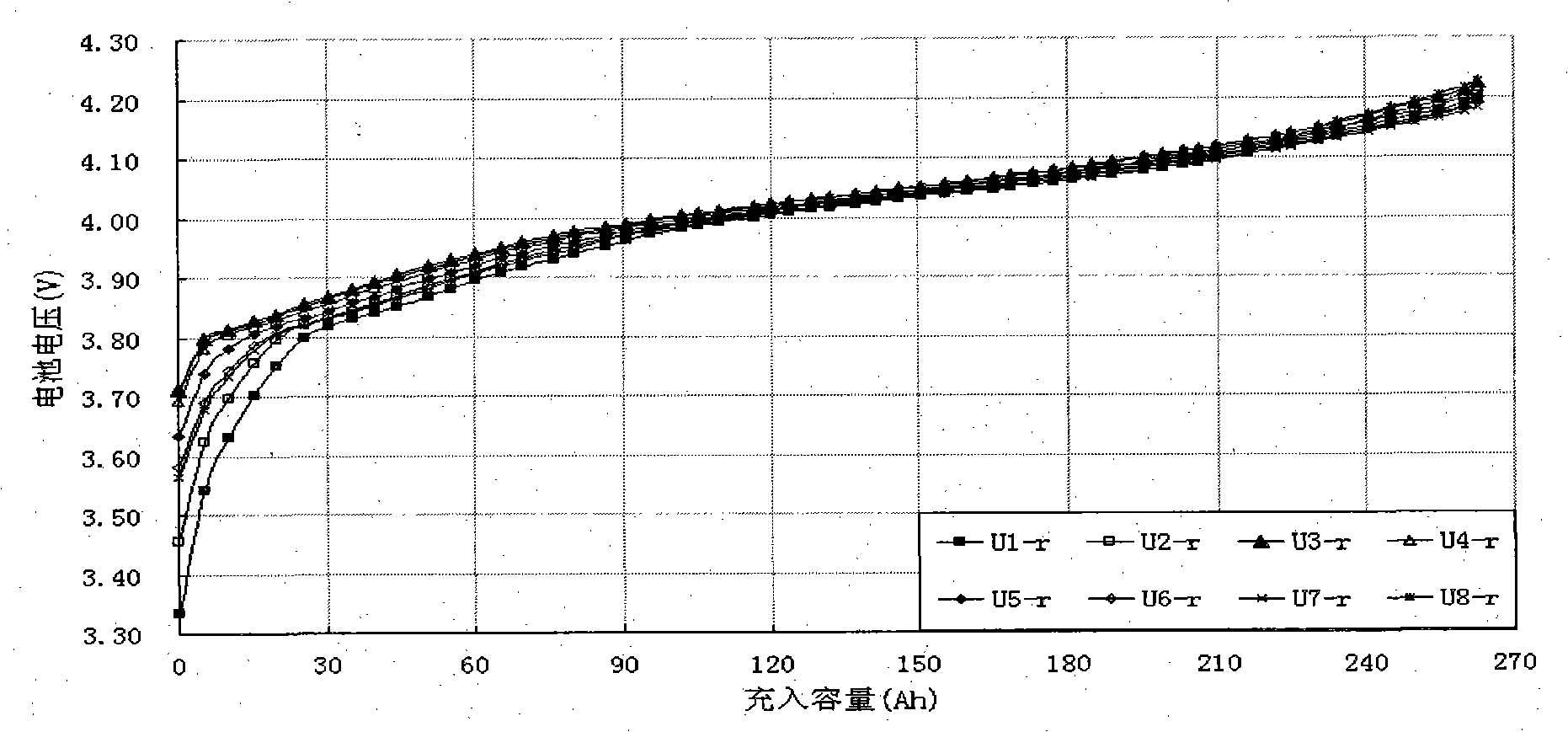

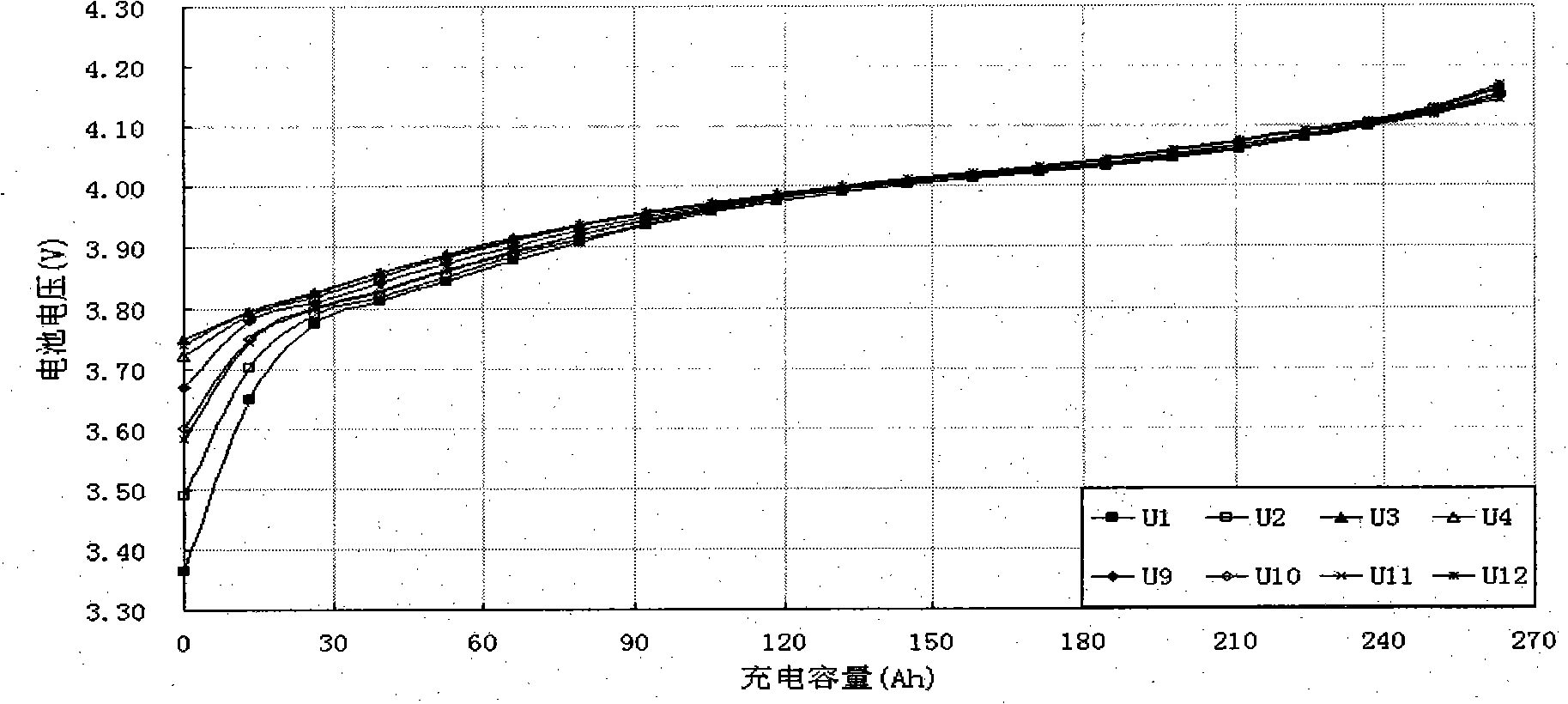

ActiveCN101819259AGood consistencySolve the instability problemElectrical testingState of chargeElectrical battery

The invention relates to the technical field of charging of a battery pack, in particular to a method for evaluating consistency of a rechargeable battery pack. The method comprises the following steps of: charging a battery pack and drawing a battery pack charging curve according to the terminal voltage of the battery pack; calculating direct current internal resistances of all batteries in the battery pack to obtain a charging curve removing ohmic pressure drop; calculating or measuring polarizing voltage to obtain a charging curve removing polarizing voltage influence; singly listing the charging curves of any two batteries; and correcting the two charging curves by adopting the difference of the maximal available capacity of the batteries and the initial state of charge (SOC) to obtain a battery pack charging curve with favorable consistency for finally evaluating the consistency of the battery pack. The corrected battery pack charging curve has favorable consistency; compared with a method for judging the consistency on the basis of singly adopting the outer voltage of the batteries, the difference of performance and a state among the batteries is fixed and is not changed along with the change of charging current and parameters, such as located charge state, and the like, and the problem of no stability brought by a method for evaluating the consistency on the basis of the difference of the applied voltage.

Owner:HUIZHOU EPOWER ELECTRONICS +1

High-performance time-digital converter circuit structure

ActiveCN101043215AGood consistencyHigh timing accuracyAnalogue-digital convertersTime-to-digital convertersImage resolutionBand counts

The invention discloses a high performance time digital converter circuit frame, it includes time-delay chain loop which generates low bit data, counter which generates high bit data and a compensating control source; said time-delay chain loop counts the low bit and transfers to said counter in definite period, said counter accumulates the signal with definite period to be the high bit of the time digital converter; Said compensating control source compensates and controls the voltage signal of said time-delay chain loop; The precision is high; the minimum time distinguishing ratio is the one class buffer transmission delay; the speed of processing is quick, when the counting ends, data is obtained, without additional processing time; the output of flip-latch is connected with high bit counter, it guarantees the correctness of circulation and carry; the compensating control source is introduced to guarantee the consistency of system under the same temperature, voltage, craft; the requirement for every module is not high, so it is easy to realize.

Owner:无锡君谱半导体有限公司

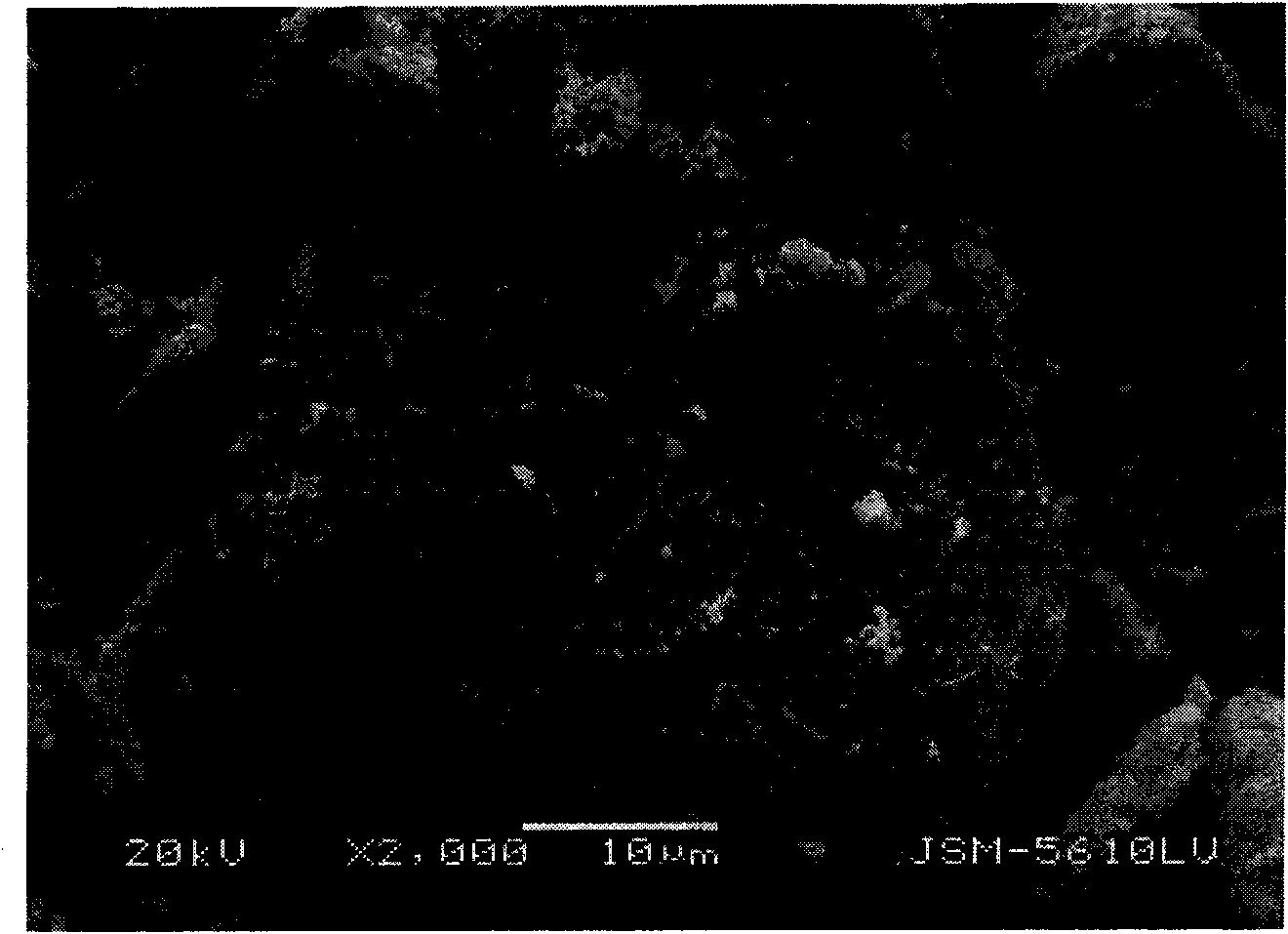

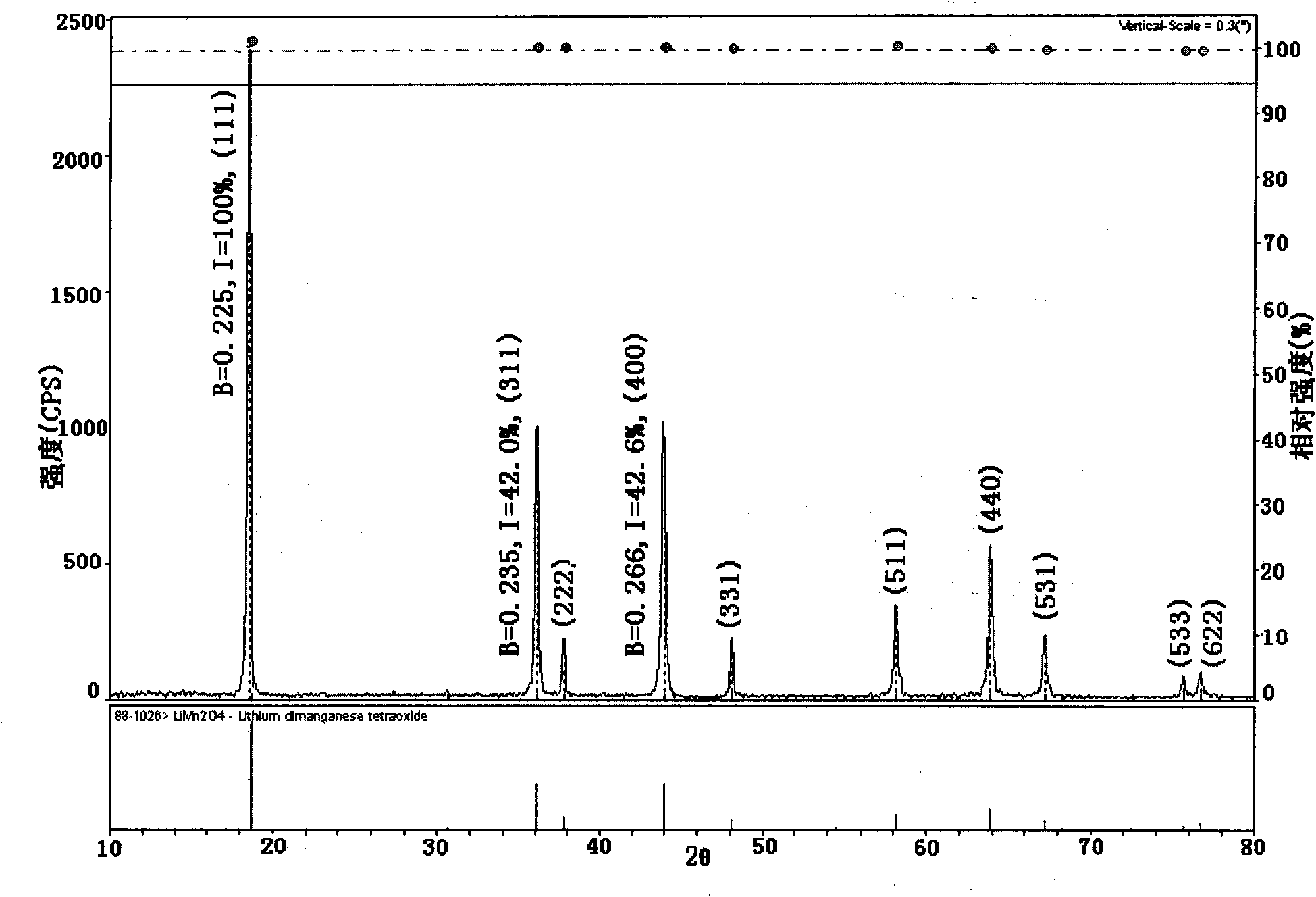

Spinel Li1+xMyMn2-x-yO4, preparation method thereof and lithium-ion secondary battery

InactiveCN101780983ARegular shapeGood consistencyFinal product manufactureLead-acid accumulators constructionLithium ion intercalationCrystallinity

The invention provides a lithium manganese oxide material, i.e. a spinel Li1+xMyMn2-x-yO4, wherein x is less than 0.1 and more than 0, y is less than 0.1 and more than 0, and M is selected from one or a plurality of Mg, Na, Co and Al; the ratio of the 400 crystal face diffraction peak strength I400 to 311 crystal face diffraction peak strength I311 of the Li1+xMyMn2-x-yO4 is 1.05-1.25; the atomic arrangement in crystal of the material is more ordered; the crystallinity degree of the material is higher, and fewer oxygen defects in a crystal lattice exist, thereby being more favourable for the lithium ion intercalation and deintercalation process in the crystal lattice and effectively inhibiting the Jahn-Teller effect to obviously improve the cycle performance of the material; and meanwhile, the invention also provides a preparation method of the material and is simple and easy to realize process. The invention also provides a lithium-ion secondary battery using the material, and the lithium-ion secondary battery has higher specific capacity and cycle performance, especially the high-temperature cycle performance, and satisfies the requirements of the existing battery development.

Owner:BYD CO LTD

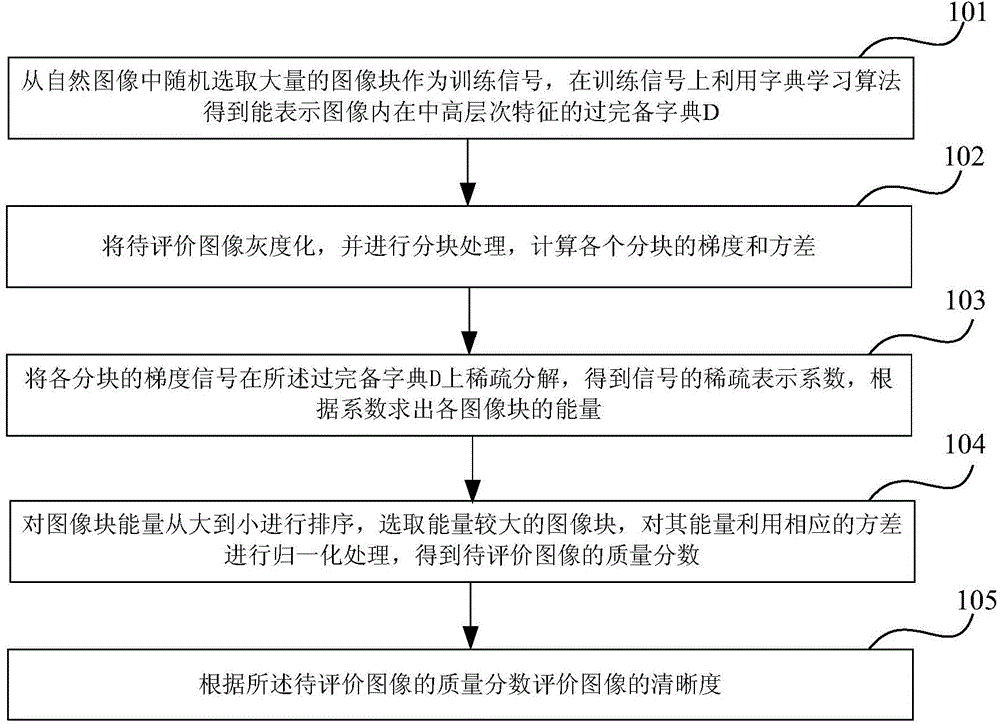

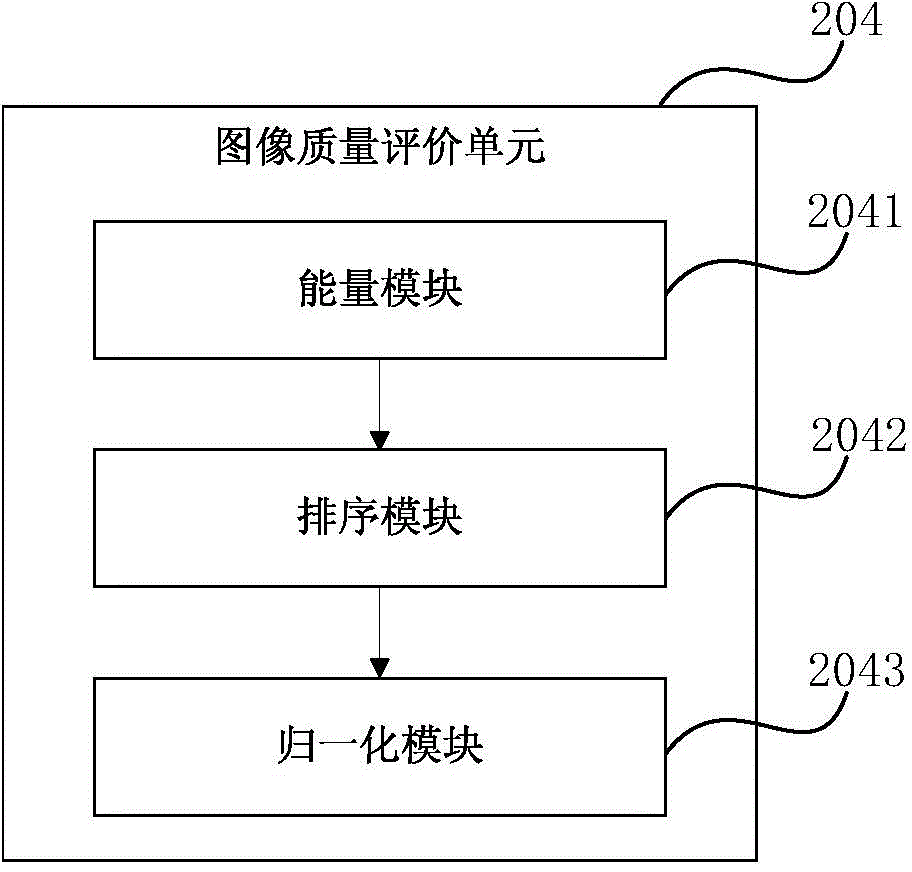

Image definition evaluation method and image definition evaluation device based on sparse representation

InactiveCN104134204AGood consistencyThe evaluation method is accurateImage analysisDecompositionDistinctness of image

The invention relates to an image definition evaluation method and an image definition evaluation device based on sparse representation, and belongs to the image definition evaluation method and the image definition evaluation device. The method comprises the following steps that: color natural images are subjected to graying; a great number of image blocks with the same size are randomly extracted from the color natural images to be used as training signals; an overcomplete dictionary capable of expressing image internal medium-high-layer features can be obtained on the training signals by using a dictionary learning algorithm; images to be evaluated are blocked; the blocking size is identical to that of the training signals; the gradient and the variance of each image block are calculated; on the trained overcomplete dictionary, each image block gradient signal is subjected to sparse decomposition to obtain a sparse representation coefficient of the signal; the energy of each image block is pressed by L2 normal number quadratic sum of each line of elements in a sparse representation coefficient matrix; the energy of the image blocks is subjected to sequencing from great to small; the image blocks with greater energy are selected, the energy of the image blocks is subjected to normalization processing by using the corresponding variance, and the mass fraction of the images to be evaluated is obtained; and the image definition is evaluated according to the mass fraction of the images to be evaluated.

Owner:CHINA UNIV OF MINING & TECH

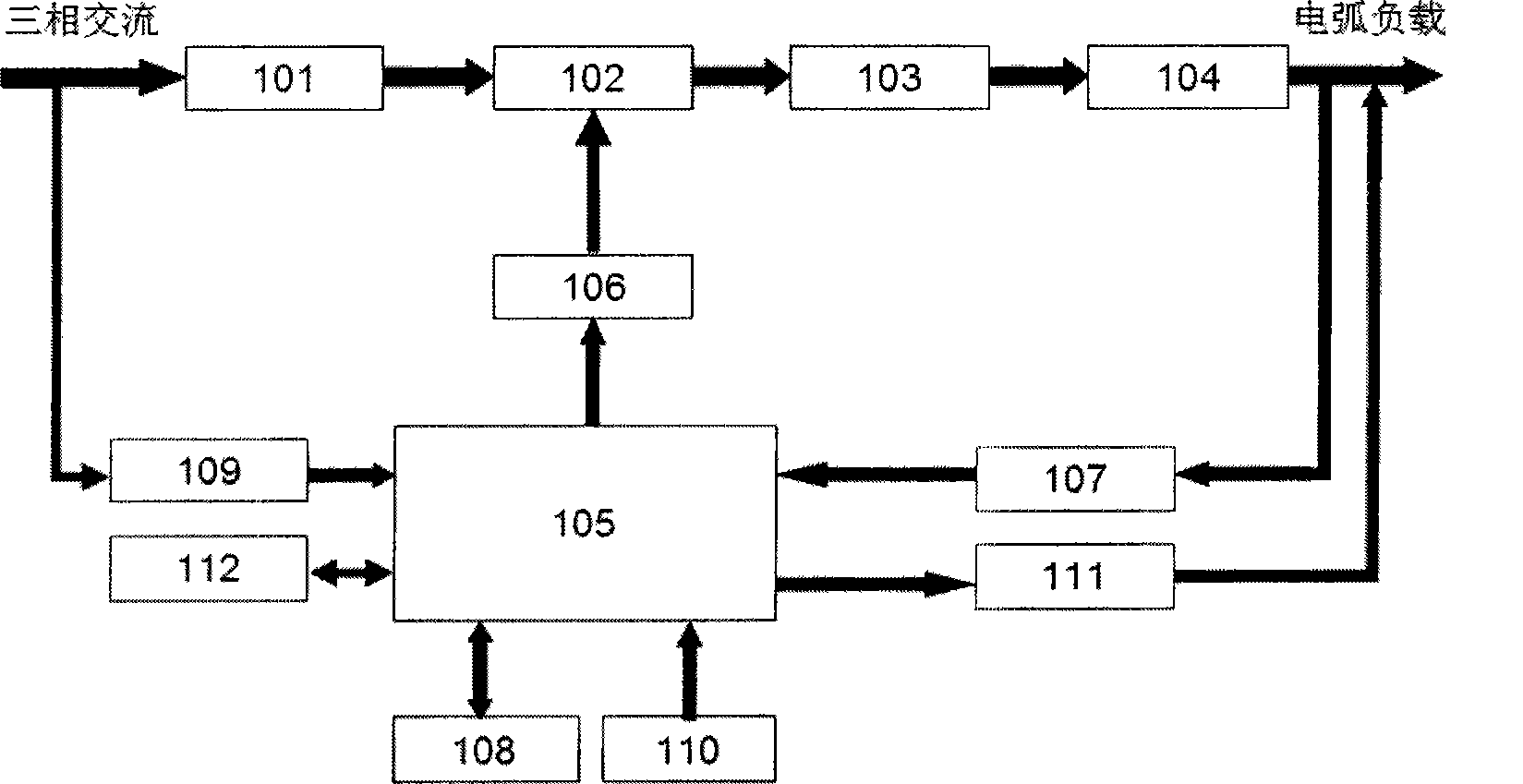

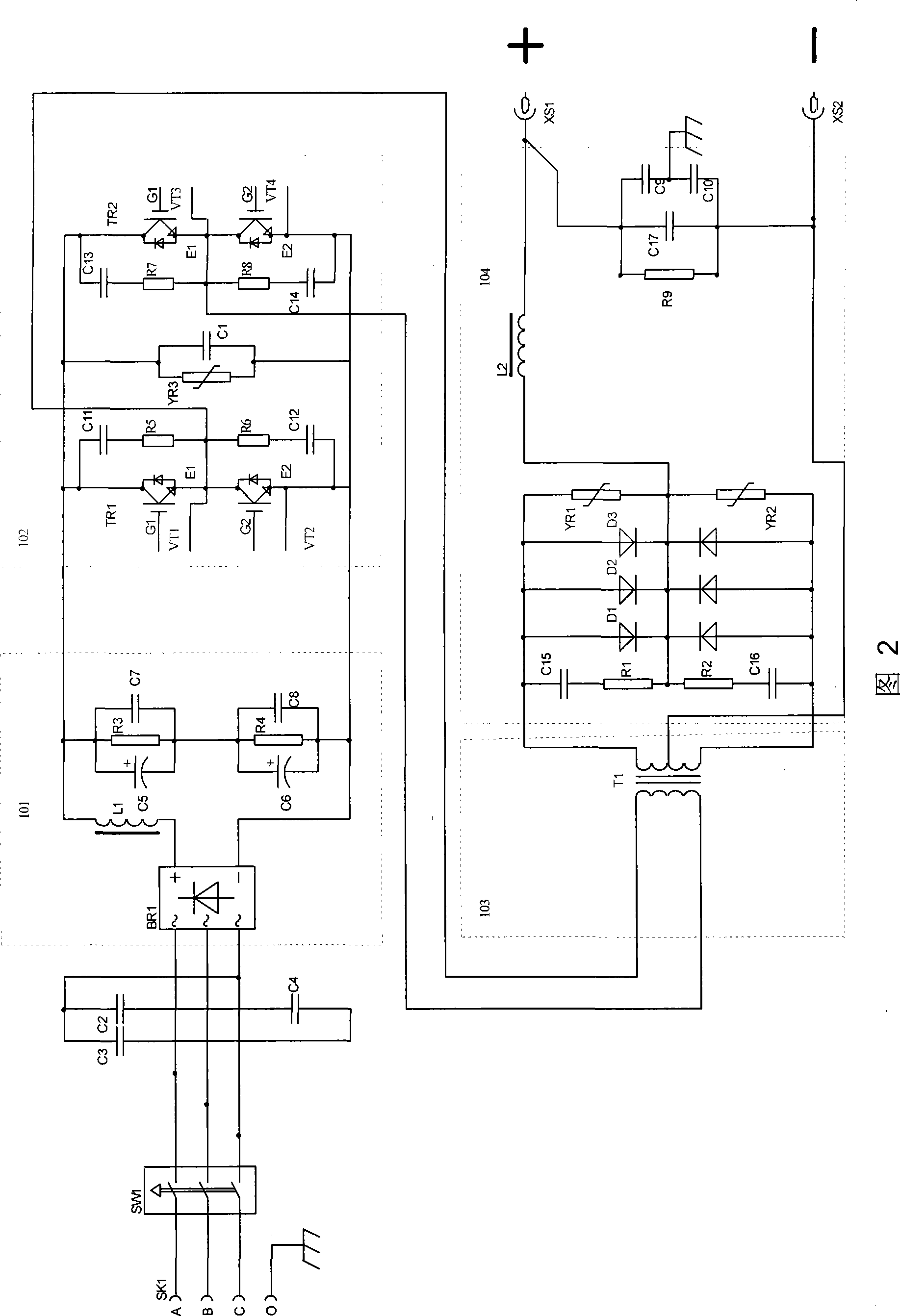

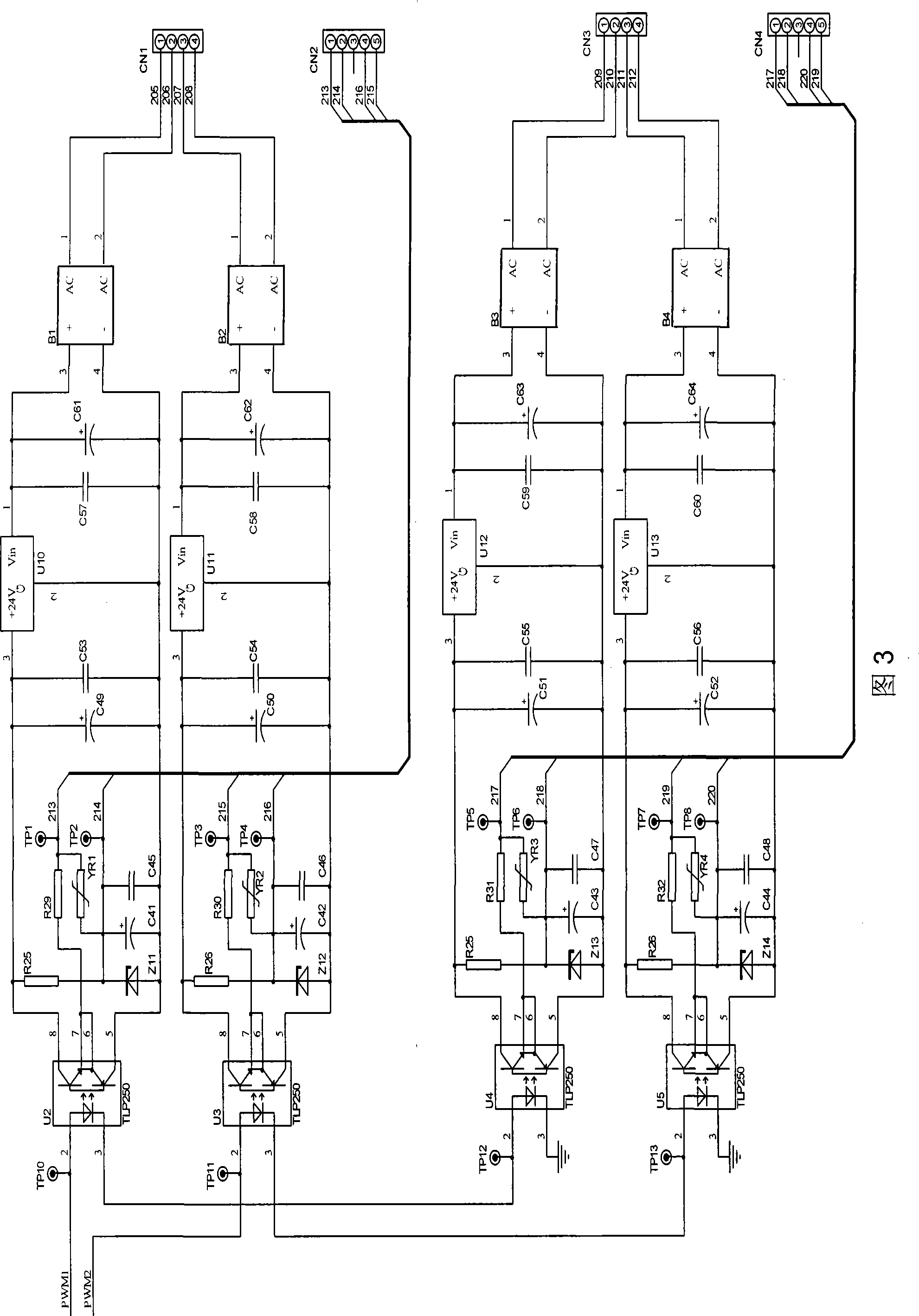

Embedded digitization controlled tube-plate all-position automatic welding inverter

InactiveCN101391336AGood consistencyGuaranteed arc stability and stiffnessArc welding apparatusDc-ac conversion without reversalThree-phaseHigh frequency

The invention is an embedded digital control inverter power source used in tube and plate overall position automatic welding, which comprises a main circuit, a control circuit and a high frequency arc-ignition circuit. The main circuit comprises a rectifying wave filter module, a high frequency inverter module, a power voltage-transforming module and a rectifying smooth module which are connected sequentially. The rectifying wave filter module is connected with a three-phase alternating current (AC) input power, and the rectifying smooth module is connected with a load. The control circuit includes an over-voltage and under-voltage protective testing module, a voltage and current sample testing and feedback module, an ARM microprocessor and a high frequency drive module. The over-voltage and under-voltage protective testing module is respectively connected with the three-phase AC input power and the ARM microprocessor. The voltage and current sample testing and feedback module is respectively connected with the ARM microprocessor and the load. The ARM microprocessor is also connected with the high frequency drive module and the high frequency arc-ignition circuit. The high frequency drive module is also connected with the high frequency inverter module, and the high frequency arc-ignition circuit is also connected with the load. The invention can realize the overall digital control of the tube and plate automatic welding inverter power source.

Owner:GUANGDONG POWER ENG +1

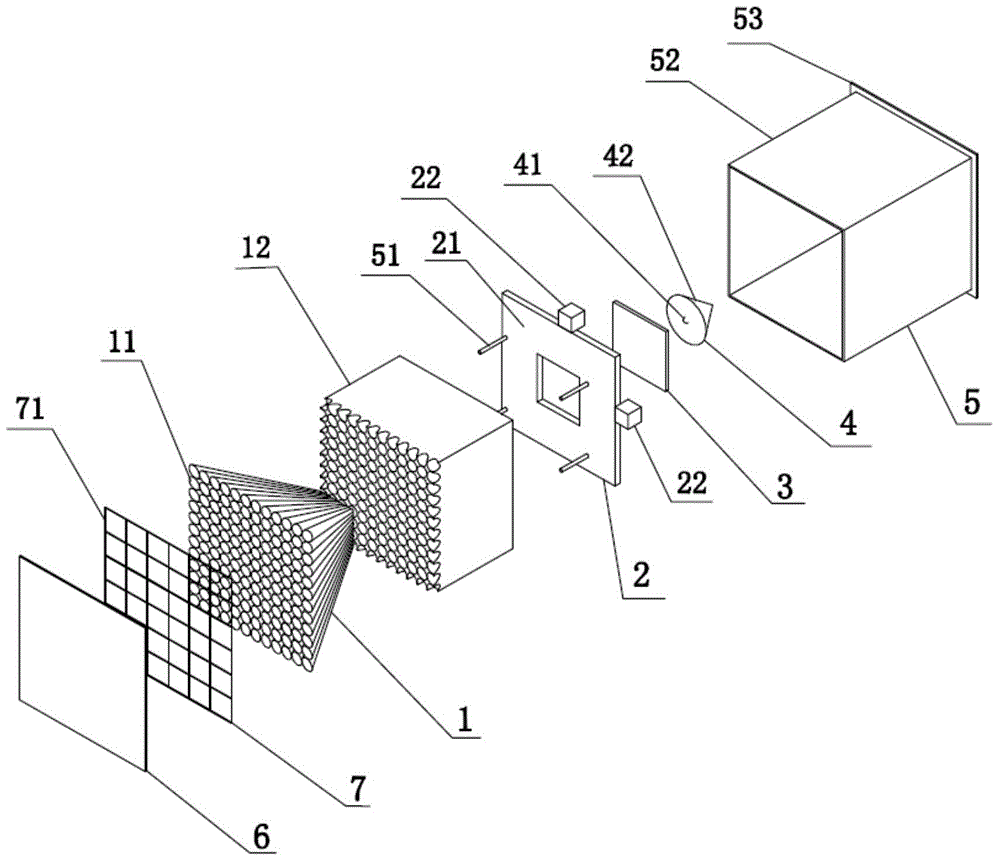

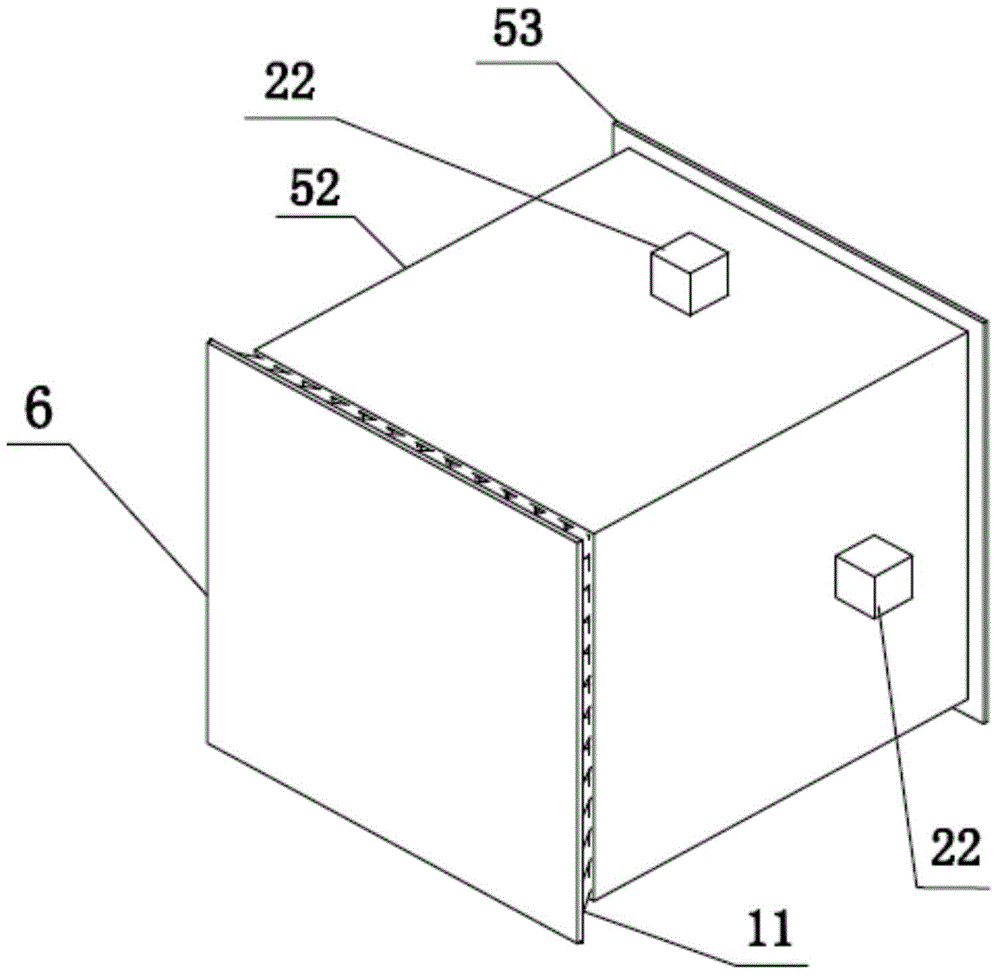

Arbitrary-curved-surface plane seamless spliced high-quality large-screen display device

The invention discloses an arbitrary-curved-surface plane seamless spliced high-quality large-screen display device. The arbitrary-curved-surface plane seamless spliced high-quality large-screen display device is formed by stacking brick-shaped optical-fiber rear-projection display modules, wherein elements of each brick-shaped optical-fiber rear-projection display module include a variable-cross-section optical fiber panel, a signal processing module, a liquid crystal display panel, an LED (light-emitting diode) light source module, a fixing device, a shell, an anti-dazzling frosting coating and a touch sensing plate. The arbitrary-curved-surface plane seamless spliced high-quality large-screen display device has beneficial effects that a seamless spliced high-quality screen with small dot pitch can be produced, a display video picture of an arbitrary curved surface, a special arbitrary shape, and an arbitrary area can be realized; the seamless splicing principle is the primary-pixel splicing principle, pixel points are uniformly and compactly arranged, and the display consistency of the brightness and color is optimal; by adopting the modularized production, the constitutional part is easy to repair and replace; the touch sensing plate can be embedded into the display device, so that precision in positioning can be realized, and the picture quality and the shape of the display device are not affected; the water resistance and collision resistance are relatively good.

Owner:梁岗

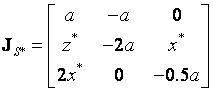

One-parameter robust chaotic signal source

ActiveCN102611388AGood consistencyBroad application prospectsNoise generationAngle demodulationLinear variationAttractor

The invention discloses a one-parameter robust chaotic signal source. The one-parameter robust chaotic signal source comprises an X circuit channel, a Y circuit channel and a Z circuit channel, wherein the X circuit channel comprises a first integration circuit; the Y circuit channel comprises a second integration circuit; the Z circuit channel comprises a third integration circuit; the three integration circuits respectively output three status variables; the gain of a first gain circuit is a; the gain of a second gain circuit is 2a; and the gain of a third gain circuit is 0.5a. The chaotic signal source with linearly adjustable dynamic range, linearly adjustable maximum Lyapunov exponent of a system and chaotic robust stability of the system dynamic property, is realized; with the change of linear adjustment parameters, the dynamic range of a chaotic attractor produced by the chaotic signal source is linearly changed, and the maximum Lyapunov exponent of the system is also linearly changed; and the chaotic signal source has no periodic window and chaotic robustness of behaviors such as intermittency chaos and the like.

Owner:溧阳常大技术转移中心有限公司

Pulsed X-ray generation method and pulsed X-ray generation device

The invention provides a pulsed X-ray generation method and a pulsed X-ray generation device. A feedback signal processing unit of a high-voltage pulse generation system of the pulsed X-ray generation device receives a tube voltage feedback value signal and forms a close loop control circuit with a voltage setting value signal; a feedback signal processing unit of a tube current control system receives a tube current feedback value signal and forms a close loop control circuit with a current setting value signal; a signal generation unit of a control system generates a tube voltage analog value and setting value signal and inputs the signal to the high-voltage pulse generation system, and generates a tube current analog value and setting value signal and inputs the signal to the tube current control system; a feedback signal processing unit of the control system receives the tube voltage and tube current feedback value signals; and a time schedule control unit of the control system controls each unit according to a preset time schedule. The invention has the following advantages: the pulse frequency and the duty ratio are adjustable; each pulsed X-ray has good repeatability and uniformity; and the rising edge and the falling edge of a single pulse are steep.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

Checking instruments and measuring method for detecting vehicle door hinge accuracy

InactiveCN101551223AGood consistencyEasy to measureMechanical clearance measurementsCar doorHinge angle

The present invention discloses checking instruments for detecting vehicle door hinge accuracy, the checking instrument includes horizontally arranged measuring surface, upon which is provided with a plurality of first mounting holes corresponding to first hinge mounting holes of hinge longitudinal mounting surface, the measuring surface is provided with a plurality of second mounting holes corresponding to second hinge mounting holes of the hinge horizontal mounting surface; the first mounting hole is fastening connected with the first hinge mounting hole via fastening screw; also including scribing pin inserted in the first mounting hole for scribing on the upper fastening surface, gap injection gape for measuring gaps among surfaces; measuring block with pre-set scale for measuring gap size between the hinge axis and measuring surface. The vehicle door checking instruments can detect hinge accuracy simply and smartly in imperfect analysis steps of vehicle daily production, therefore, being able to avoid adverse effect caused by hinge accuracy inadequate to the vehicle door mounting in early production.

Owner:GUANGQI HONDA

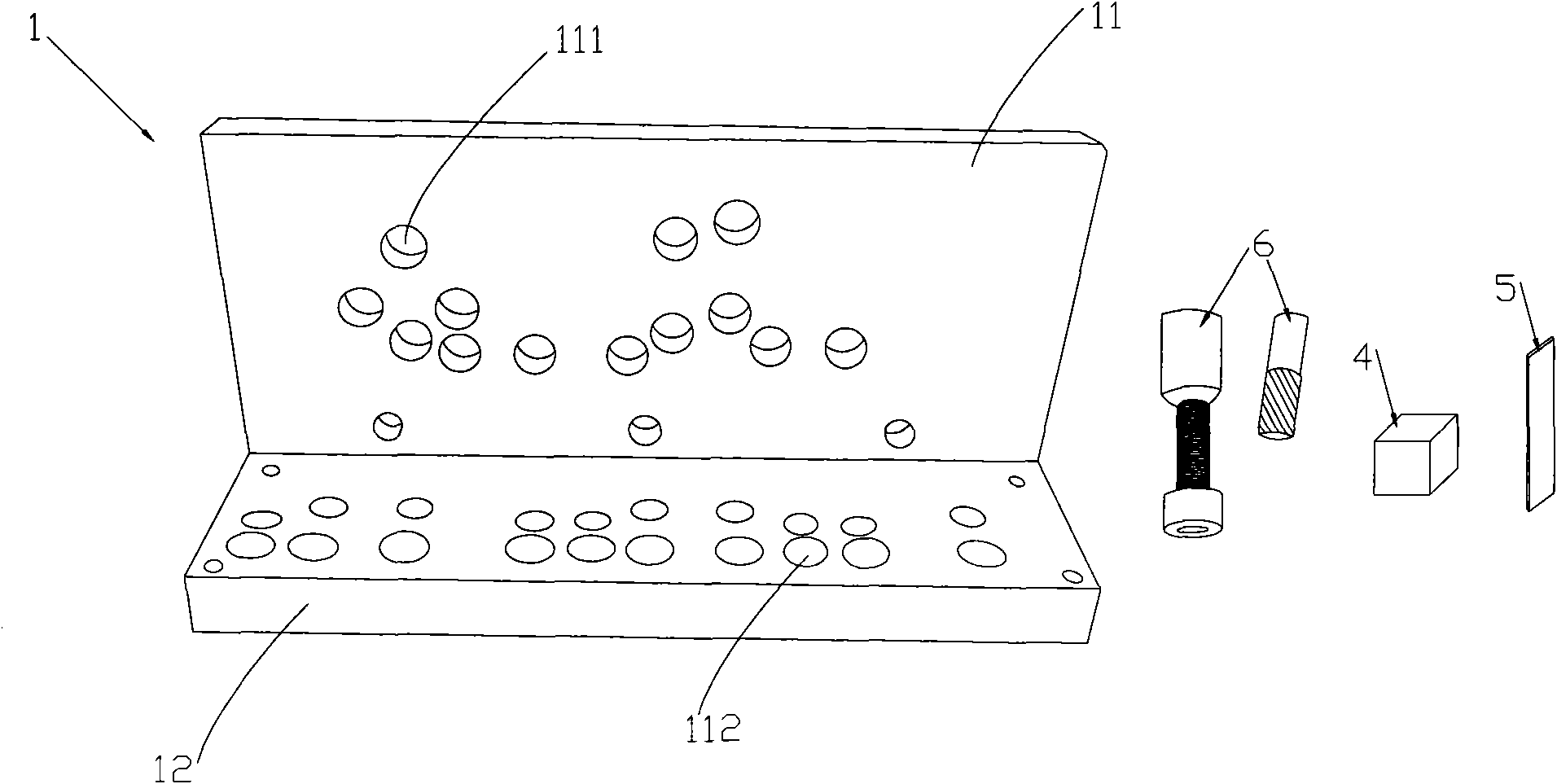

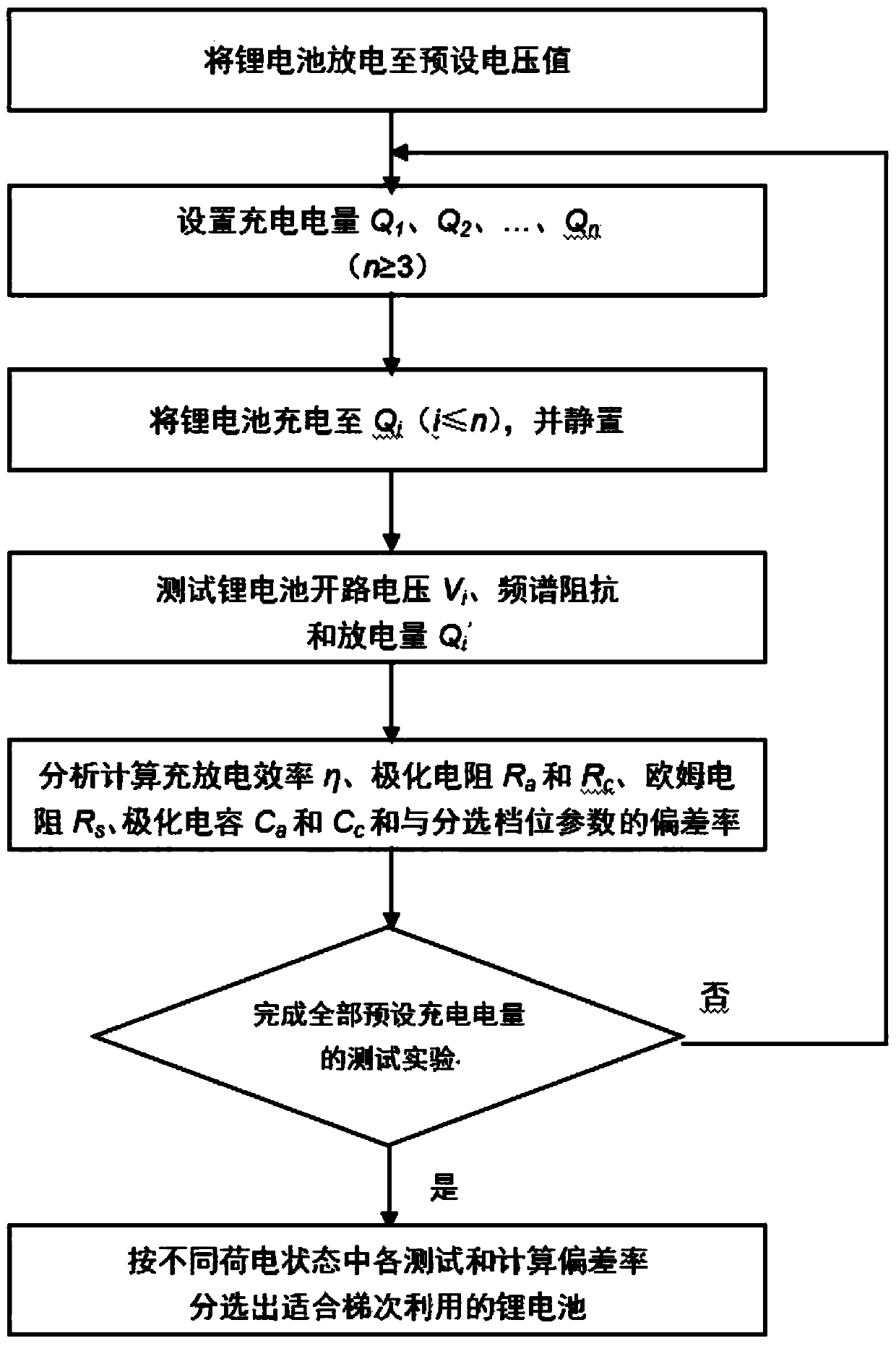

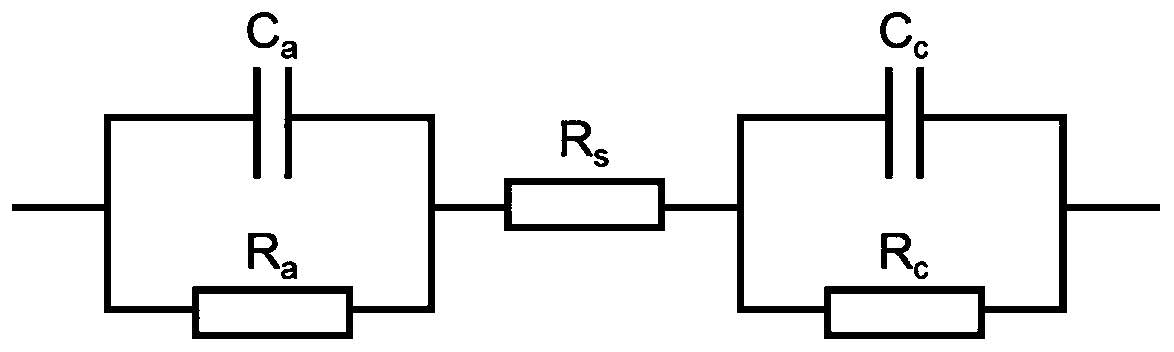

Detecting and sorting method for cascade utilization of lithium batteries

ActiveCN109731808AGood consistencyGuarantees safe and long-term reliable operationElectrical testingOptically investigating flaws/contaminationCapacitanceEngineering

The invention discloses a detecting and sorting method for cascade utilization of lithium batteries. The detecting and sorting method comprises the following steps that the to-be-detected lithium batteries are discharged to a preset voltage value; the n charging amounts are preset, wherein n is an integer which is greater than or equal to 1; according to one of the preset charging amounts, the to-be-detected lithium batteries are charged; after charging is completed, open-circuit voltage testing, frequency spectrum impedance testing and discharge amount testing are conducted on the to-be-detected lithium batteries; tested numerical values are analyzed, a charging-discharging efficiency value and a resistance valve and a capacitance value in a battery equivalent model are extracted, and deviation rates between all the numerical values and sorting gear set parameters are calculated; the steps are repeated until all the preset charging amounts are tested; and the lithium batteries suitable for cascade utilization are sorted according to the obtained deviation rates. The detecting and sorting method has the advantages of accuracy, high efficiency and energy saving, the health states ofthe sorted lithium batteries are fully represented, good consistency is displayed in the actual dynamic operation process of a possible application scenario, and the detecting and sorting method canbe applied to evaluation before cascade utilization of the large-batch lithium batteries.

Owner:JIANGSU TIANHE ENERGY STORAGE CO LTD

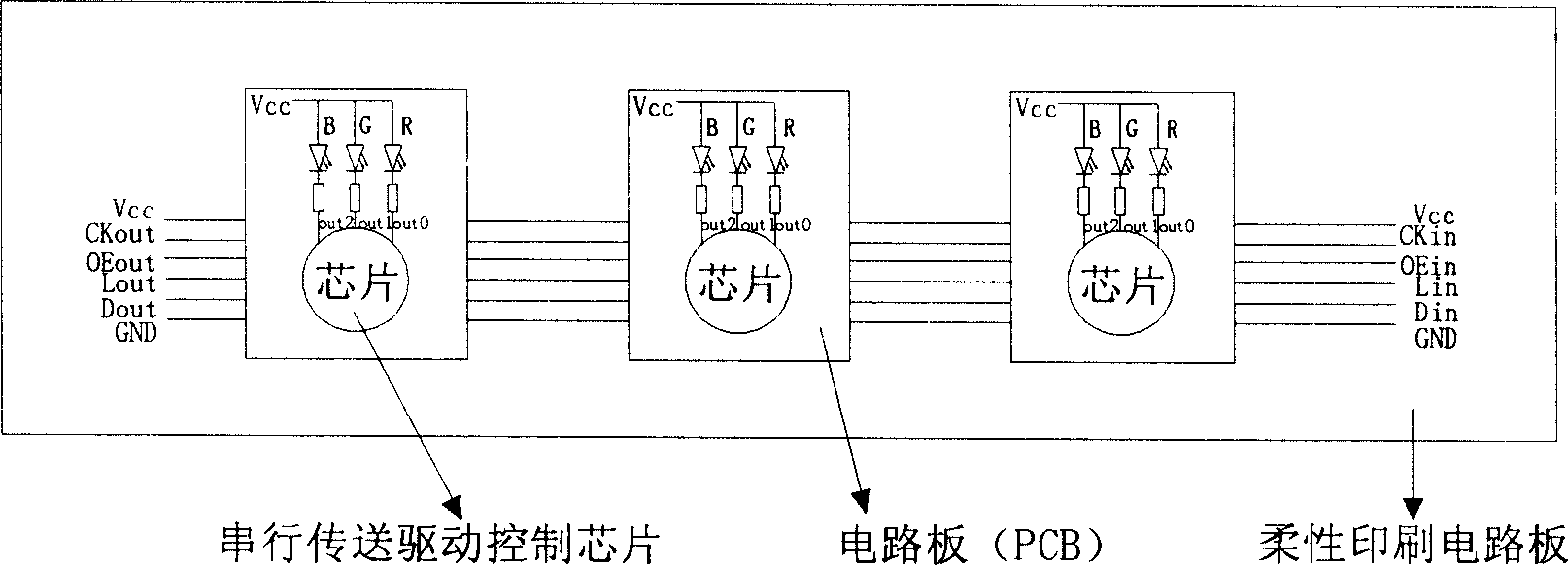

Superminiature full color LED display unit with embedded serial drive control chip

InactiveCN1731482AVarietyImprove clarityStatic indicating devicesIdentification meansElectrical resistance and conductanceLED display

The invention relates to a super small colored LED display unit of embed serial driven control chip in the field of the production and technology of LED display apply. It is characterized in that the super small print circuit plate is formed by a serial transmitting driven control chip, a red LED light, a blue LED light, a green LED light and a plurality of resistances; the super small print circuit can finish any amount of serial connecting. The embed serial transmitting driven control chip provides the RGB brightness independent adjustment to each image element and connects the LED light and the driving part on the super small print circuit plate.

Owner:BEIJING ZHONGQING MICRO ELECTRIC TECH

Impedance test method and device for battery pole piece

ActiveCN102200551AImprove test accuracyGood consistencyResistance/reactance/impedenceElectrical batteryEngineering

The invention relates to the technical field of an impedance test method and an impedance test device, in particular to an impedance test method and an impedance test device for a battery pole piece. The impedance test method for the battery pole piece comprises the following steps of: testing by using an impedance tester, testing an inner resistance of the impedance tester and a total resistanceof an upper pressing head and a lower pressing head, and changing pressure on the pole piece frequently and measuring a resistance of the pole piece for many times. An impedance test device for the battery pole piece comprises a stander and a fixing mechanism, wherein the fixing mechanism comprises a pressurizing mechanism, the upper pressing head, the lower pressing head and a base plate; the upper pressing head comprises a pressing head and an insulation ring; a protrusion is formed at one end of the pressing head; the insulation ring matched with the protrusion is sleeved on the protrusion; a positioning slot matched with the upper pressing head is formed at one end of the lower pressing head; the base plate is fixed on the stander; a sliding slot is formed on the base plate; and the other end, matched with the sliding slot, of the lower pressing head is arranged in the sliding slot. The invention has the advantages of high test precision, high consistency of the test data, simple operation, high reliability and avoiding of interferences of human factors.

Owner:WANXIANG 123 CO LTD

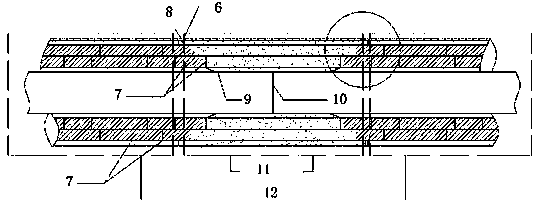

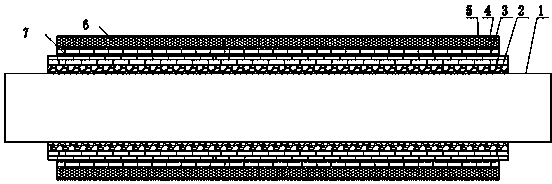

Prefabricated overhead heat insulation pipe

ActiveCN103968190AReduce thermal bridge effectGood consistencyThermal insulationPipe protection by thermal insulationEnvironmentally friendlyEngineering

The invention provides a prefabricated overhead heat insulation pipe. In order to solve the problems that when an overhead pipe delivers hot air at a long distance, heat loss is high, and the construction cycle is long, according to the scheme, the prefabricated overhead heat insulation pipe comprises a working pipe. The prefabricated overhead heat insulation pipe is characterized in that the working pipe is wrapped in an inorganic heat insulation layer, an organic heat insulation layer and an outer protection pipe in sequence, and a protection layer is arranged between the inorganic heat insulation layer and the working pipe; longitudinal joints and transverse joints of the inorganic heat insulation layer, the organic heat insulation layer and the outer protection pipe are all in lap joint in a step shape in a staggered mode; the protection layer is connected in a pressed mode; the lap joint of the inorganic heat insulation layer and the organic heat insulation layer is provided with gaps. According to the measures, compared with a traditional prefabricated overhead heat insulation pipe, the prefabricated overhead heat insulation pipe is lower in heat loss, shorter in construction cycle and more environmentally friendly.

Owner:宁波万里管道有限公司

High productivity spandex fiber process and product

ActiveUS6916896B2Increase spin productivityGood consistencyMonocomponent polyurethanes artificial filamentProduction ratePolymer chemistry

Commercially acceptable spandex can be prepared with greater efficiency, improved consistency and at lower costs from a high-solids content polyurethaneurea polymer solution. The polyurethaneurea is prepared using a combination of 4,4′-MDI and 2,4′-MDI, and an amount of chain extenders and chain terminators such that the polymer solution, prior to spinning, is highly soluble and has an appropriate pre-spun IV and primary amine content.

Owner:THE LYCRA CO LLC

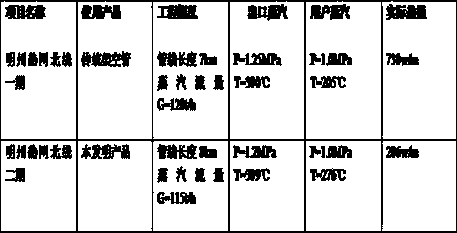

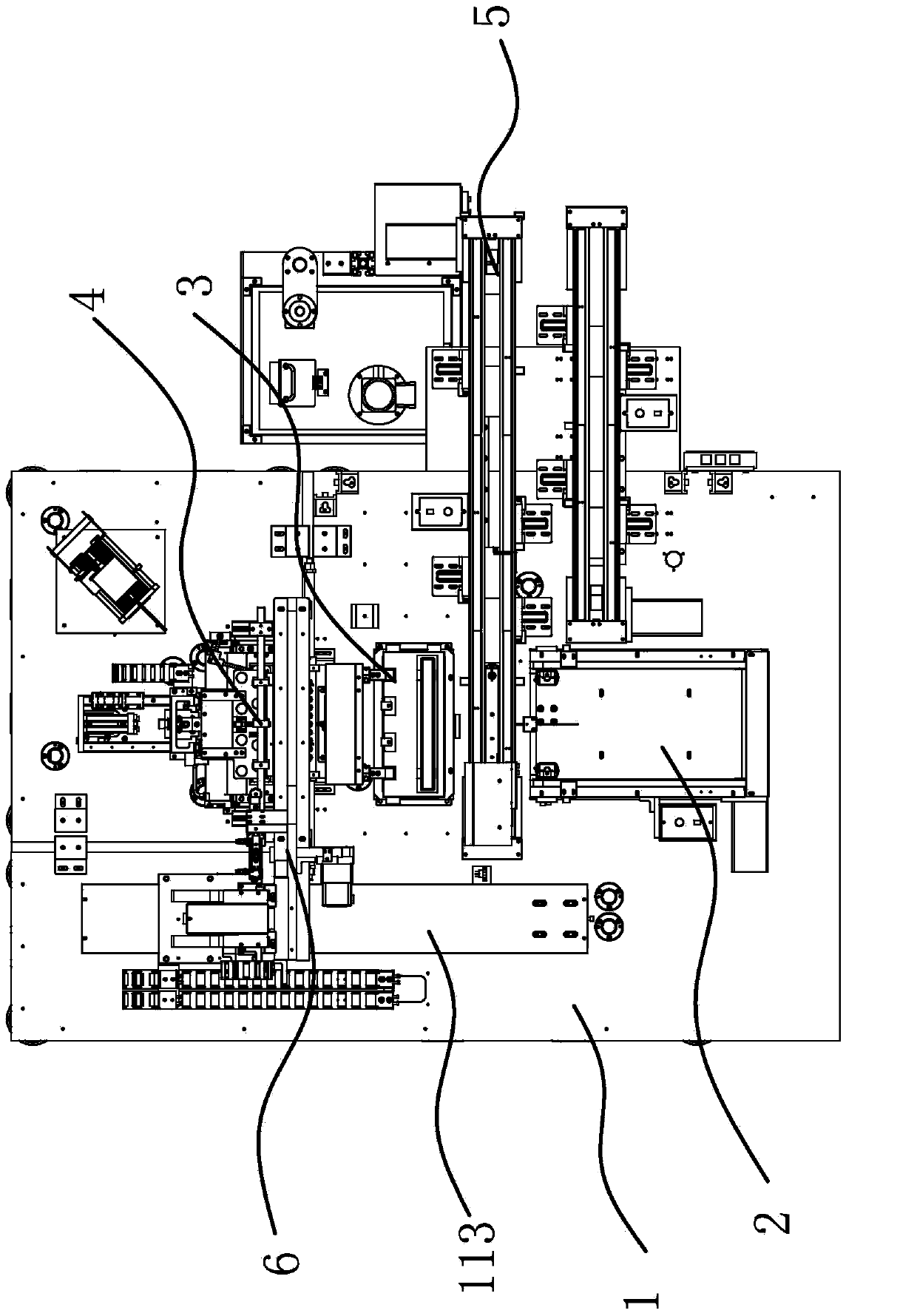

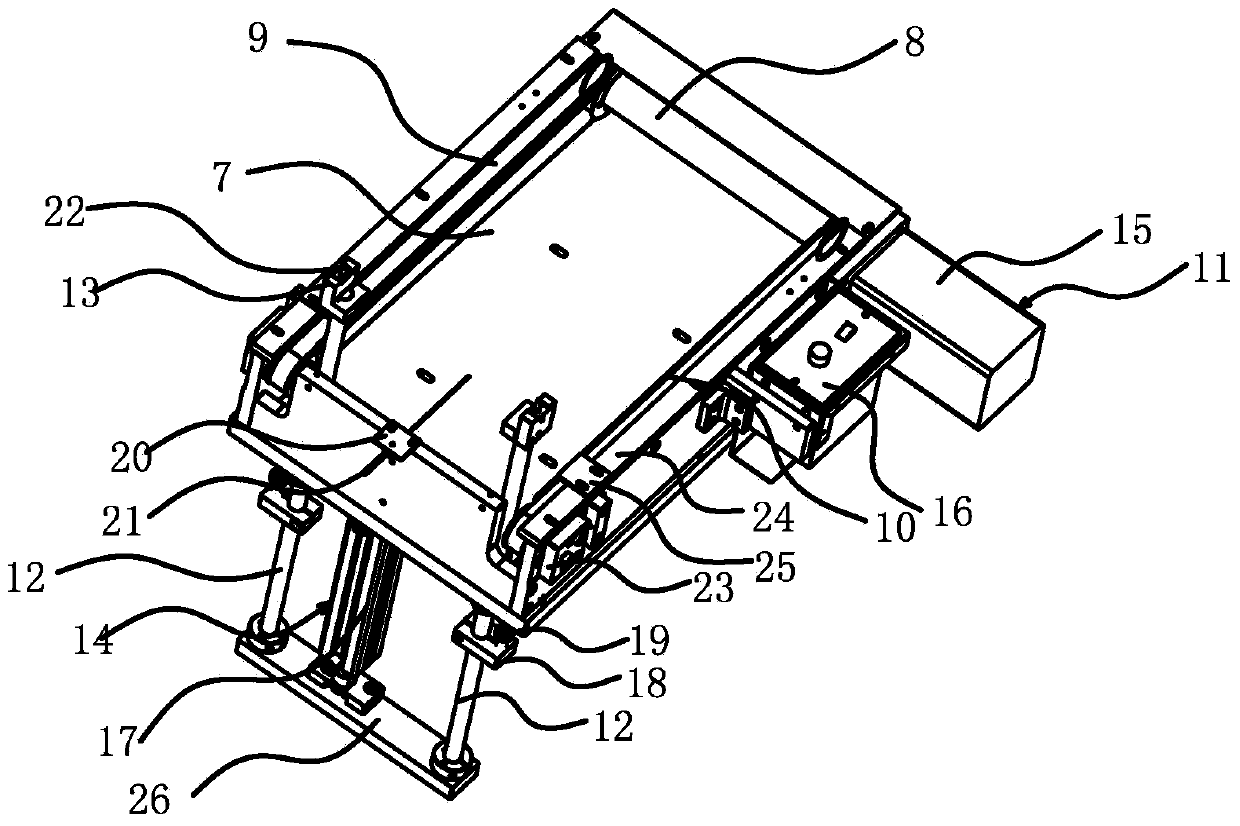

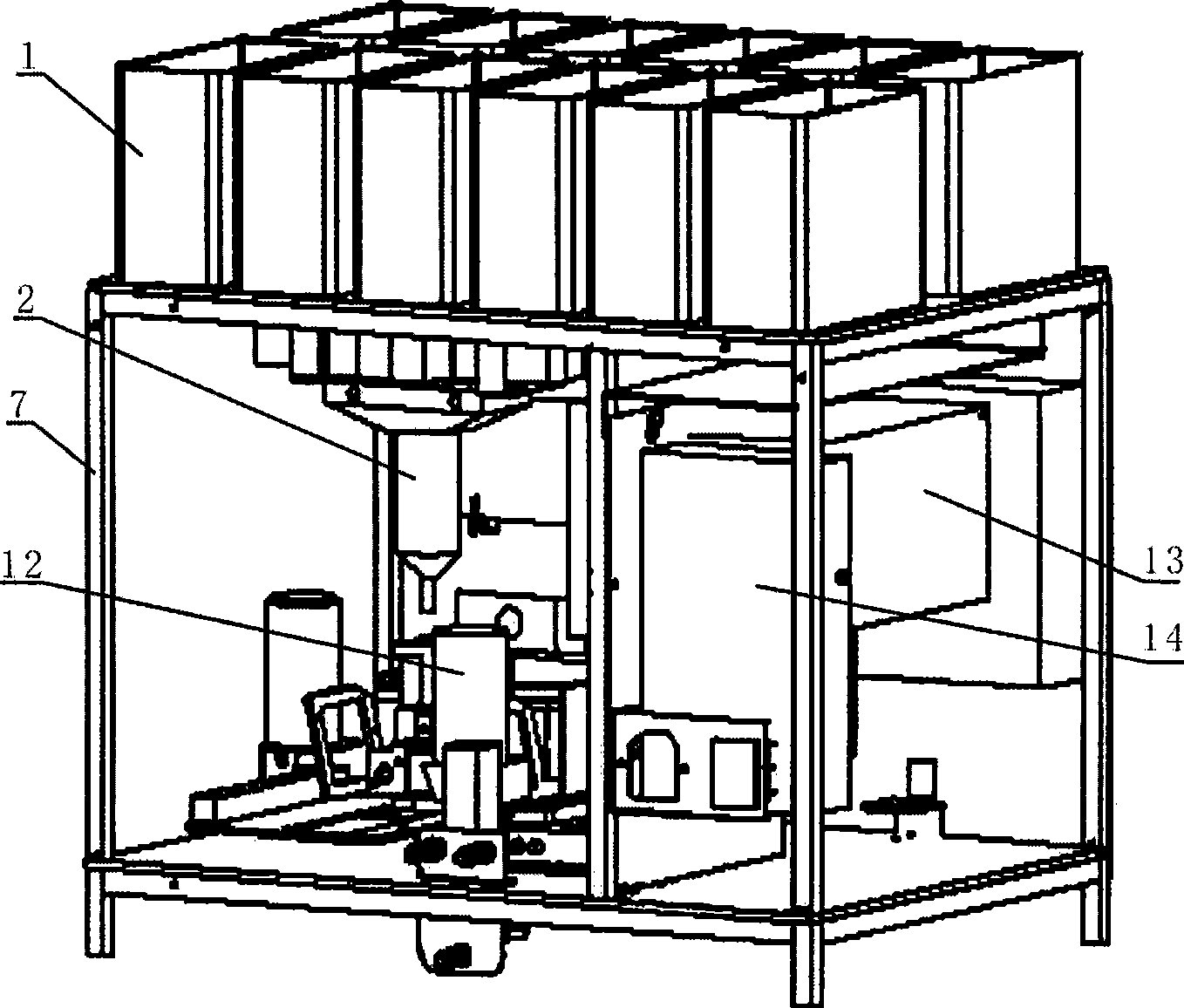

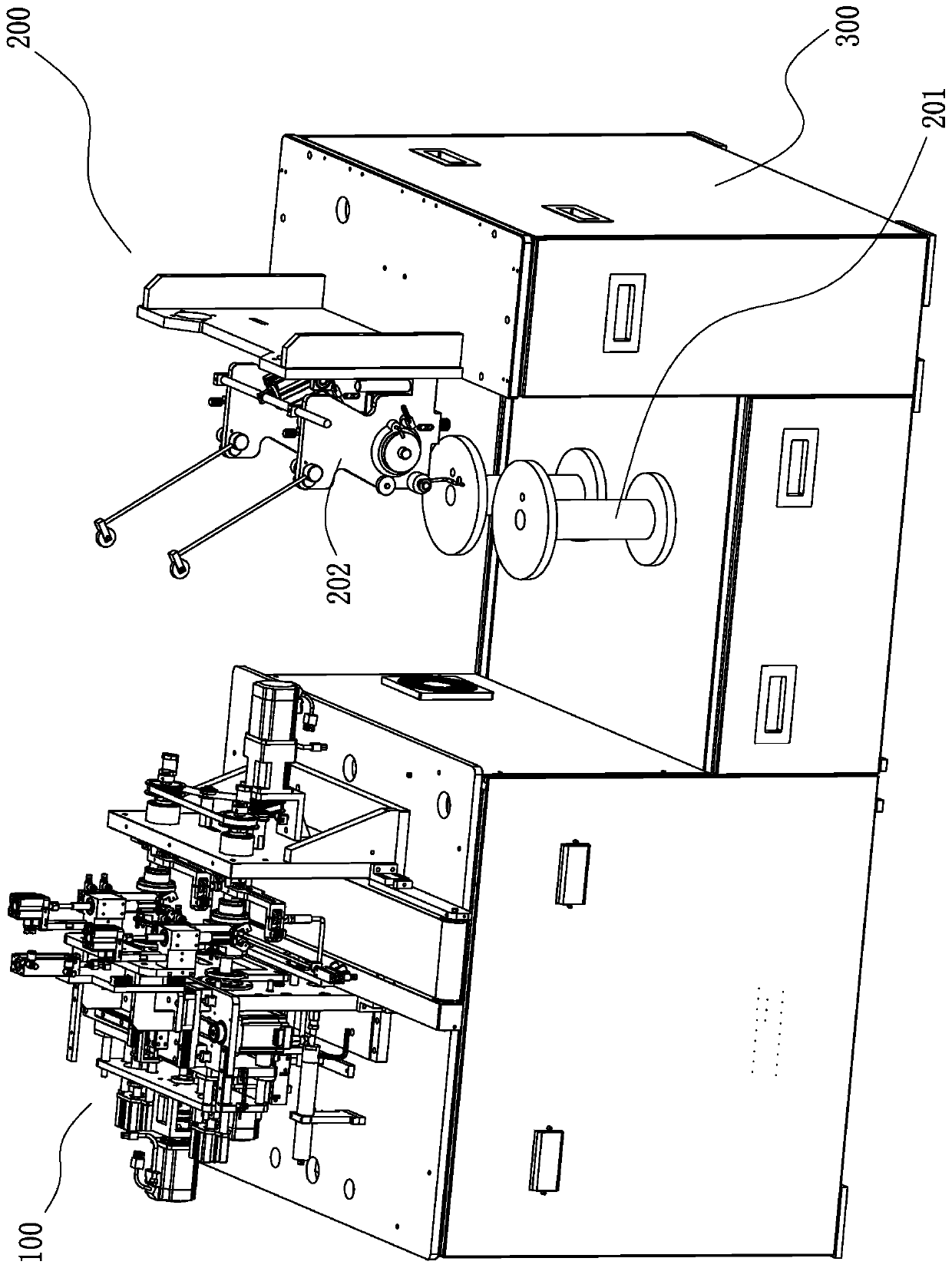

Linear tin soldering machine

ActiveCN103785915AHigh degree of automationGood consistencyWelding/cutting auxillary devicesAuxillary welding devicesSolderingEngineering

The invention provides a linear tin soldering machine and belongs to the technical field of welding equipment. The linear tin soldering machine solves the technical problems of low machining efficiency and the like of a tin soldering machine in the prior art. The tin soldering machine comprises a machine table. A feeding unit capable of conveying a jig to a station to be clamped, a soldering aiding unit and a tin soldering mechanism are sequentially arranged on the machine table, and a conveyer belt combined structure capable of conveying the jig loaded with a tin-soldered workpiece out of the tin soldering machine is arranged between the feeding unit and the soldering aiding unit. A strip-shaped supporting profile is fixed to the machine tool, the feeding unit, the conveyer belt combined structure, the soldering aiding unit and the tin soldering mechanism are sequentially distributed on the same side of the supporting profile in the length direction of the supporting profile, and a mechanical arm mechanism capable of clamping the jig on the feeding unit and conveying the jig to the soldering aiding unit, the tin soldering mechanism and the conveyer belt combined structure is arranged on the supporting profile in a sliding mode in the length direction of the supporting profile. The linear tin soldering machine has the advantages of being high in automation degree, high in tin soldering efficiency and the like.

Owner:TANAC AUTOMATION

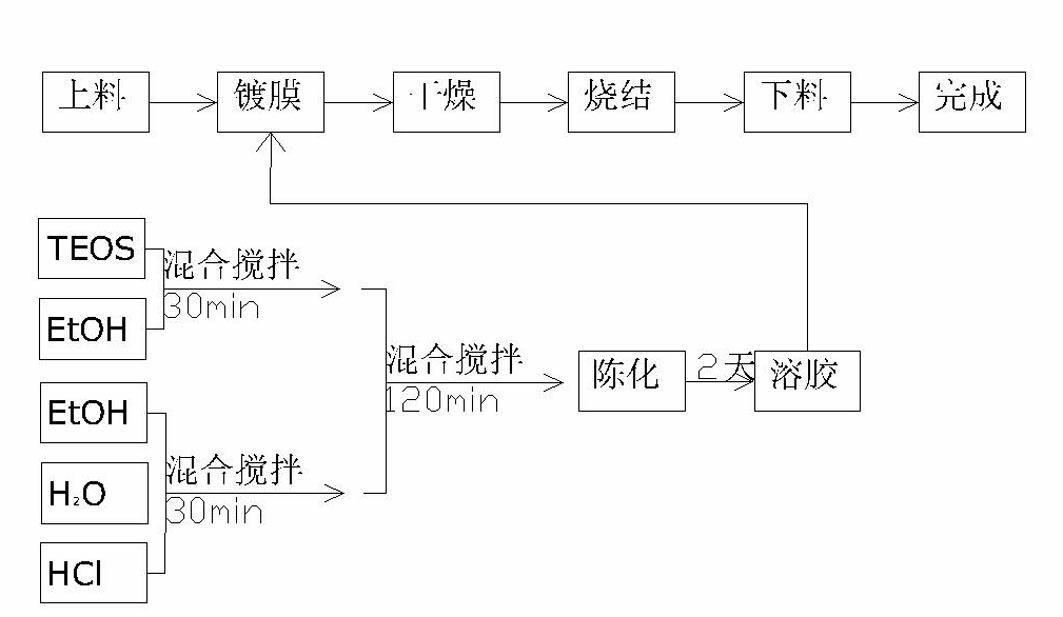

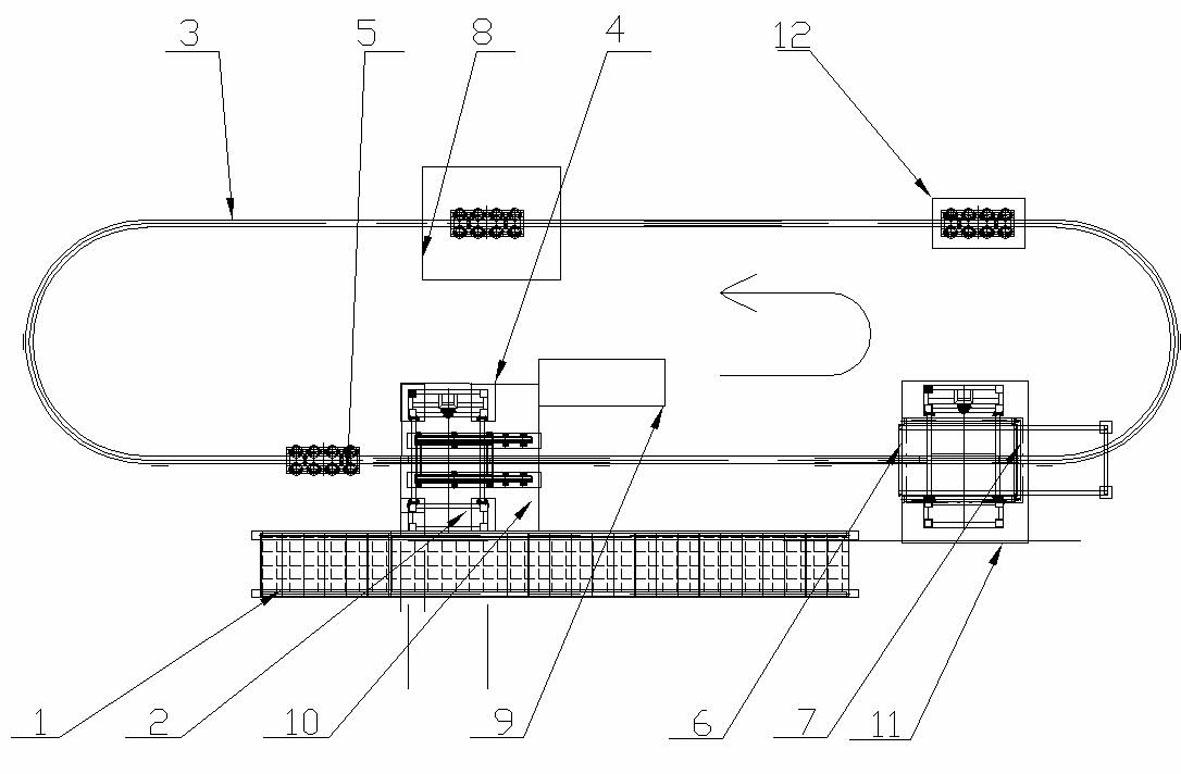

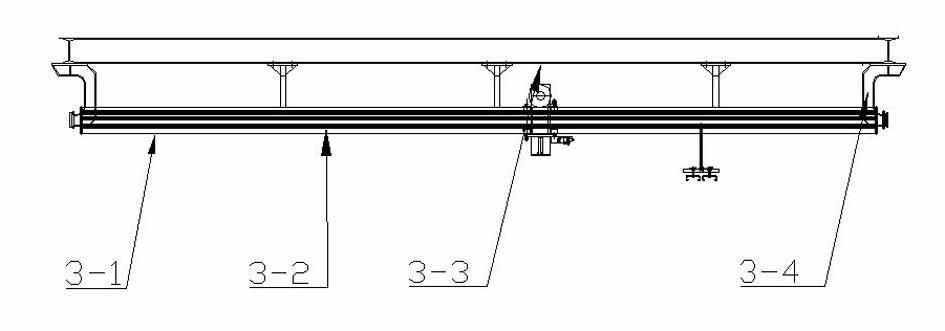

Method for producing anti-reflection coating of cover glass pipe of solar high-temperature heat collecting pipe and production line

The invention discloses a method for producing an anti-reflection coating of a cover glass pipe of a solar high-temperature heat collecting pipe and a production line. The method comprises the following steps of: preparing sol liquid; aging; cleaning, and drying; coating a film; drying; sintering; and cooling. The production line comprises a rail, a self-propelled trolley, a sol tank, a drying device, a sintering furnace, a lifting device and a control device, wherein the rail is provided with an assembly station; the sol tank, the drying device and the sintering furnace are arranged sequentially along the rail with the assembly station at an initial position and are provided with temperature control devices; and the control device is used for controlling the self-propelled trolley to run along the rail and move among the assembly station, the sol tank, the drying device and the sintering furnace. According to the method, the quality of the product is stable, and a solar transmittance ratio of the coating is high.

Owner:SHANDONG LINUO NEW MATERIAL

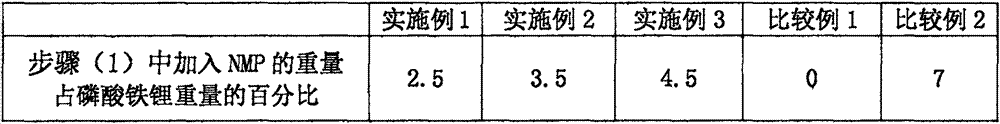

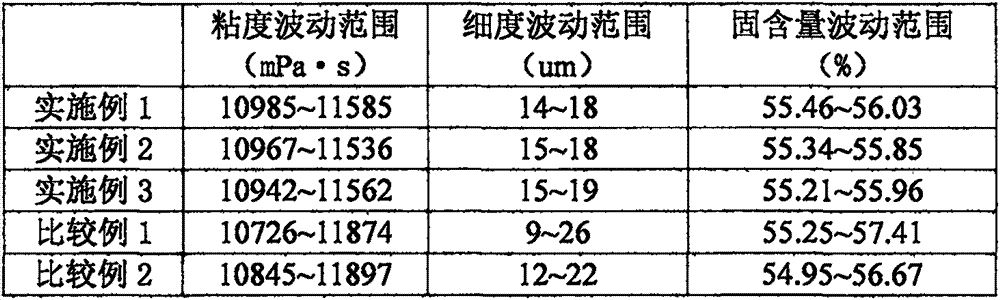

Lithium iron phosphate anode slurry stirring technology

InactiveCN107302078AGood dispersionGood consistencyMaterial nanotechnologyElectrode manufacturing processesSolventCarbon black

The invention relates to a lithium iron phosphate anode slurry stirring technology which comprises the following steps: (1) adding conductive slurry and NMP according to a weight ratio being (6-9) to (1-4) in a stirring tank, wherein the conductive slurry is one or two of graphene slurry and carbon nanotube slurry; (2) adding PVDF in the stirring tank, and stirring for 20-60min; (3) adding lithium iron phosphate and conductive carbon black, dry blending for 80-180min; (4) adding NMP, stirring for 60-150min; (5) carrying out reverse stirring for defoaming; (6) detecting and regulating parameters of slurry, and preparing the slurry, wherein a solvent of the conductive slurry is the NMP, the concentration is 4-10 percent, and the weight of the NMP added in the step (1) is 2-5 percent of that of the lithium iron phosphate. The lithium iron phosphate anode slurry prepared by the stirring technology provided by the invention is good in dispersibility and excellent in consistency.

Owner:江西安驰新能源科技有限公司

Cell tissue dyeing method and dyeing machine

ActiveCN101464236AReduce dosageLow costPreparing sample for investigationTissue stainingControl system

The invention provides a cell tissue staining method which can keep a slide still and control the flow mode of a staining solution, and a staining machine thereof. The staining machine mainly comprises a liquid storage tank, a solenoid valve, a dye vat, a machine frame, a control system, a transition block and a liquid collection device; the liquid storage tank is positioned at the upper part of the machine frame; the dye vat is positioned at the lower part of the machine frame; the liquid collection device and the solenoid valve are positioned between the liquid storage tank and the dye vat; the liquid storage tank is connected with the liquid collection device through the solenoid valve; and the liquid collection device is connected with the dye vat through the transition block. The method is characterized in that the natural liquid level pressure difference of the staining solution serves as a liquid working power source during the entire process of staining; the staining solution in the liquid storage tank flows into the liquid collection device through the solenoid valve; the staining solution in the liquid collection device is heated to the temperature set for staining, and then flows into the dye vat provided by a slide through the transition valve; and the staining process is completed by the slide in the dye vat. Compared with the traditional staining machine which keeps staining solution still and controls the model of slide movement, the invention is advanced and can achieve the effects of enhancing staining effect, improving staining efficiency, saving energy, reducing pollution and saving staining cost.

Owner:WUHAN LANDING INTELLIGENCE MEDICAL CO LTD

Motorboat coating production line

ActiveCN103962270AStable qualityGood consistencyLiquid surface applicatorsCoatingsEngineeringMoisture

The invention relates to a motorboat coating production line. The motorboat coating production line comprises a conveying trolley used for bearing a motorboat, a ground conveying device used for fixing and bearing the conveying trolley, a manual operating area and an automatic operating area. The conveying trolley comprises a frame, idler wheels and a connecting piece. The ground conveying device comprises a fixing piece, a conveying chain and a conveying chain control module. The automatic operating area comprises a moisture drying chamber, a cooling chamber, an electrostatic dust collection chamber, a dust-free paint spray chamber which is provided with a spraying mechanism, a paint make-up chamber, a levelling chamber, a temperature rising chamber, an oil paint solidifying chamber, a strong cold chamber and a temperature control device. The manual operating area comprises a dust-free polishing chamber, a multifunctional processing chamber, an airing and polishing chamber, a paint mixing chamber and a paint make-up chamber. The motorboat coating production line has the advantages of being high in production efficiency, good in product quality consistency, low in maintenance cost, and easy and convenient to operate.

Owner:HUBEI SANJIANG BOATS SCI & TECH +1

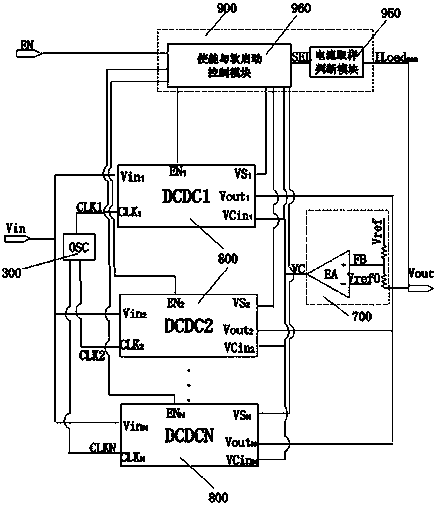

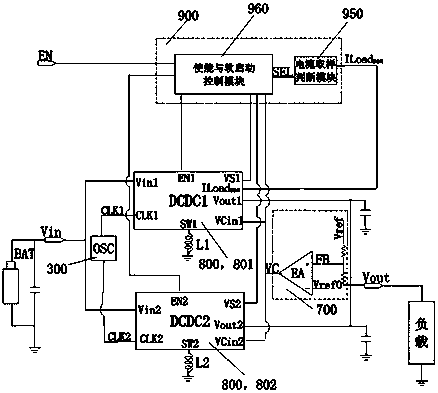

Direct current electric energy conversion method and system with DCDC module automatic conversion function

ActiveCN107659150AGood current balance characteristicsImprove conversion efficiencyPower network operation systems integrationDc-dc conversionControl signalPhase difference

Disclosed is a direct current electric energy conversion method and system with a DCDC module automatic conversion function. The system comprises N DCDC modules arranged in parallel, an output voltagedetection and feedback module and a clock signal module for providing working clock signals; a control module detects a current which is output to an external load, and works out that the number of the DCDC modules which need to be started is Q according to the value of the load current, and outputs enabling and starting control signals to Q DCDC modules; the working clock signals CLKN of the Q DCDC modules are the same in period, and the phase difference of each working clock signal CLKN is equal to 360 degrees / Q; the multiple paths of DCDC modules are connected in parallel, so that a relatively high current can be output and the system power consumption is also lowered; the multiple paths of DCDC modules are arranged on the same chip, so that quite high parameter consistency characteristic and high current balance characteristic in each path are achieved; and by virtue of time-sharing soft start and phase shifting time-sharing control, overcharging can be avoided, the ripple wave ofthe power supply output voltage is lowered, and more stable output characteristic is realized.

Owner:SHENZHEN HOTCHIP TECH

Fault image segmentation method for images scanned from films

InactiveCN101004834AHigh positioning accuracyGood consistencyImage enhancementComputerised tomographsTomographyImage segmentation

A method for dividing tomograph in scanned image of CT film includes confirming resolution of reference tomography, selecting tomograph to be divided, using scale end point of reference tomography as reference point, locking relative position relation of rectangular frame to scale reference point, conforming resolution of the other tomography and carrying out convergent-divergent on the other tomograph as per set ratio, using scale end point of the other tomography as reference to confirm rectangular frame position in the other tomograph and using region surrounded by said frame as tomograph to be divided.

Owner:SICHUAN UNIV

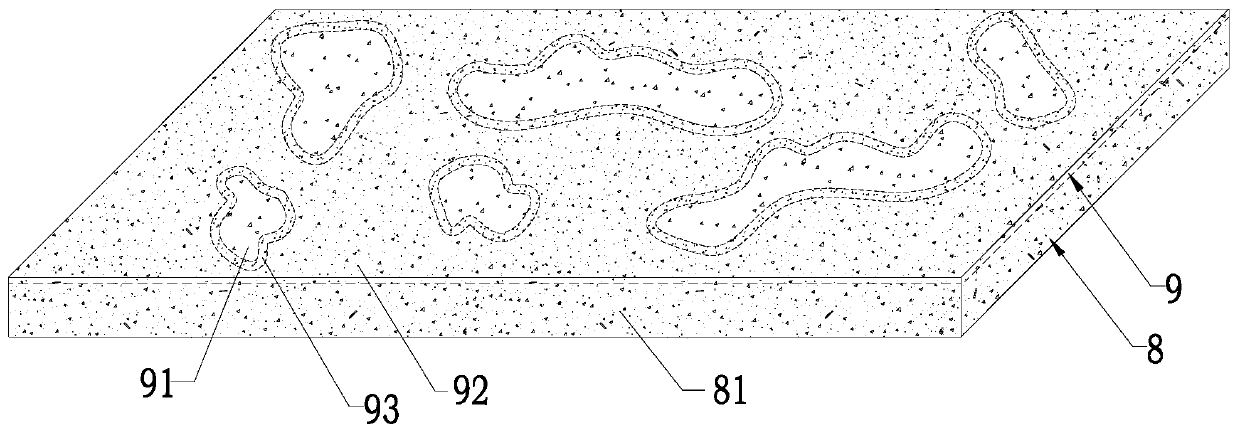

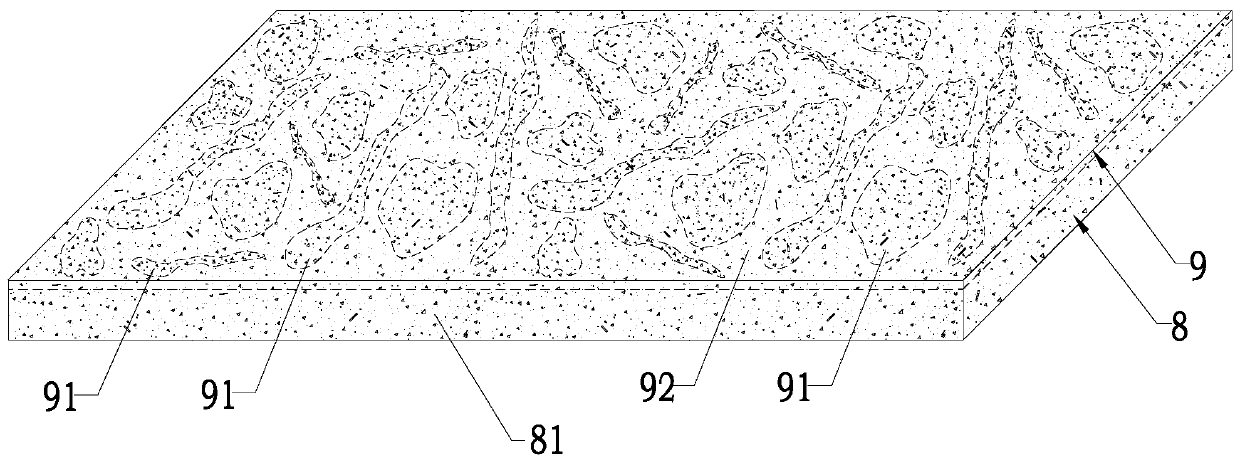

Porcelain plate containing green body texture and manufacturing method of porcelain plate

InactiveCN110103319AGood consistencyMore consistent colorsCovering/liningsFeeding arrangmentsControllabilityGreen body

The invention discloses a porcelain plate containing green body texture and a manufacturing method of the porcelain plate. The porcelain plate comprises a main body layer and a texture layer; the manufacturing method comprises the steps of material preparing, main body layer material distributing, texture layer material distributing, raw material uniform distributing, pressing, drying, sintering,edging or polishing; during texture layer material distributing, texture molding of a green body can be completed fast and efficiently through a carving type roller or a carving belt, or a special-shaped guiding material distributing device provided with a guiding material distributing plate is used, under the action of the guiding material distributing plate, the fluidity is different due to thefact that the particle sizes of flaky materials, granular materials and powdery raw materials are different, so that texture raw materials in a texture color zone form a texture layout with differentand changed accumulation forms. The method is suitable for large plate production, and compared with a traditional material distributing mode, the method has the advantages of being small in occupiedspace, simple in equipment structure and high in controllability.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

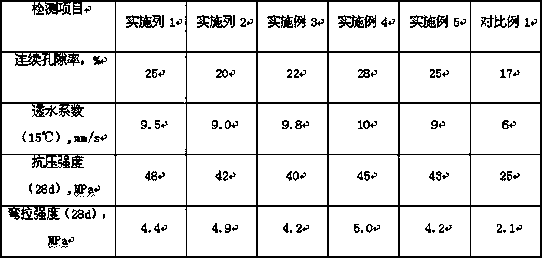

Pervious straw fiber concrete and production method thereof

The invention provides a pervious straw fiber concrete and a production method thereof. The method comprises the following steps: unwinding plant straws into dispersed straw fibers, carrying out alkali liquor steam curing on the straw fibers and silica micro-powder to form silica micro-powder coated modified straw fibers, and uniformly mixing the silica micro-powder coated modified straw fibers with high-calcium fly ash, fine aggregates, a water reducer and water to obtain the pervious straw fiber concrete. Steam oxygen of gaseous oxidation aggregated silica micro-powder makes the gel coated straw fibers have good dispersibility, permeability and thickening property, and the modified fibers formed by the coated straw fibers have a thickening property, so a formed straw fiber network has good water permeability, the adhesion force between a cement mortar and the fine aggregates and between the cement mortar and the straw fibers is enhanced, and the strength of the concrete is greatly improved; and the method effectively recovers agriculture and forestry straws, and realizes the high-value comprehensive utilization of solid wastes.

Owner:青海平兴建设集团有限公司 +1

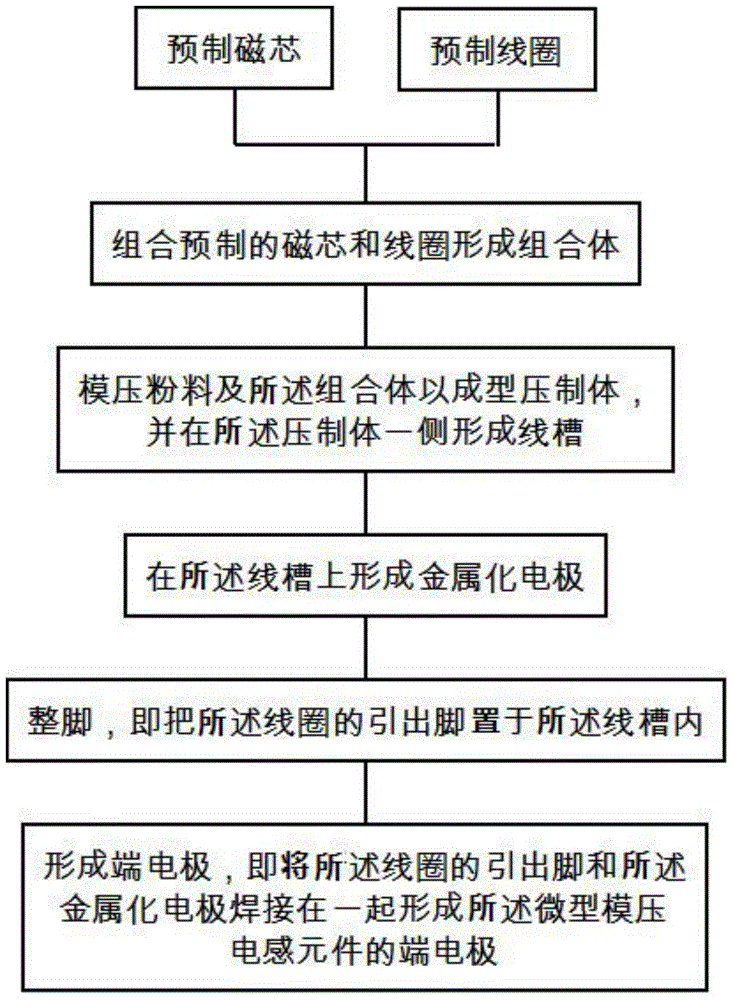

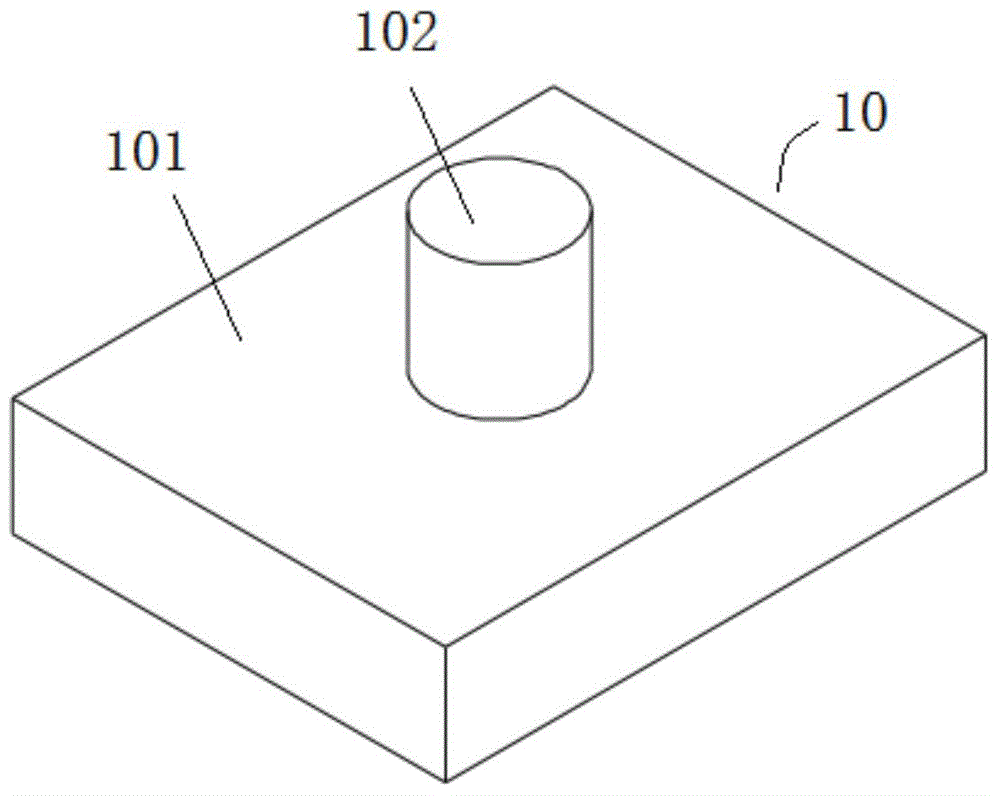

Miniature compression molding inductance element and manufacturing method thereof

ActiveCN104616878AGood consistencyNot easily damagedTransformers/inductances coils/windings/connectionsCoils manufactureMagnetic coreInductor

The invention discloses a miniature compression molding inductance element and a manufacturing method thereof. The manufacturing method of the miniature compression molding inductance element comprises the steps that a magnetic core and a coil are prefabricated; the prefabricated magnetic core and coil are combined into a combined body; powder and the combined body are compressed and molded to form a compression body, and a wire slot is formed in one side of the compression body; a metal electrode is formed on the wire slot; pin arrangement is carried out, in other words, the leading-out pin of the coil is arranged in the wire slot; an end electrode is formed, in other words, the leading-out pin of the coil and the metal electrode are welded together to form the end electrode of the miniature compression molding inductance element. By means of the manufacturing method of the miniature compression molding inductance element, the manufactured inductance element has the better consistency and is not likely to be damaged in the machining process, and the product reliability is higher. In addition, by means of the coil prefabrication technology, product machining is more flexible, the problem that a magnetic core is cracked in the prior art is avoided, and therefore the manufacturing method is more applicable to achieving volume production of thin and miniature power inductance elements.

Owner:东莞华络电子有限公司

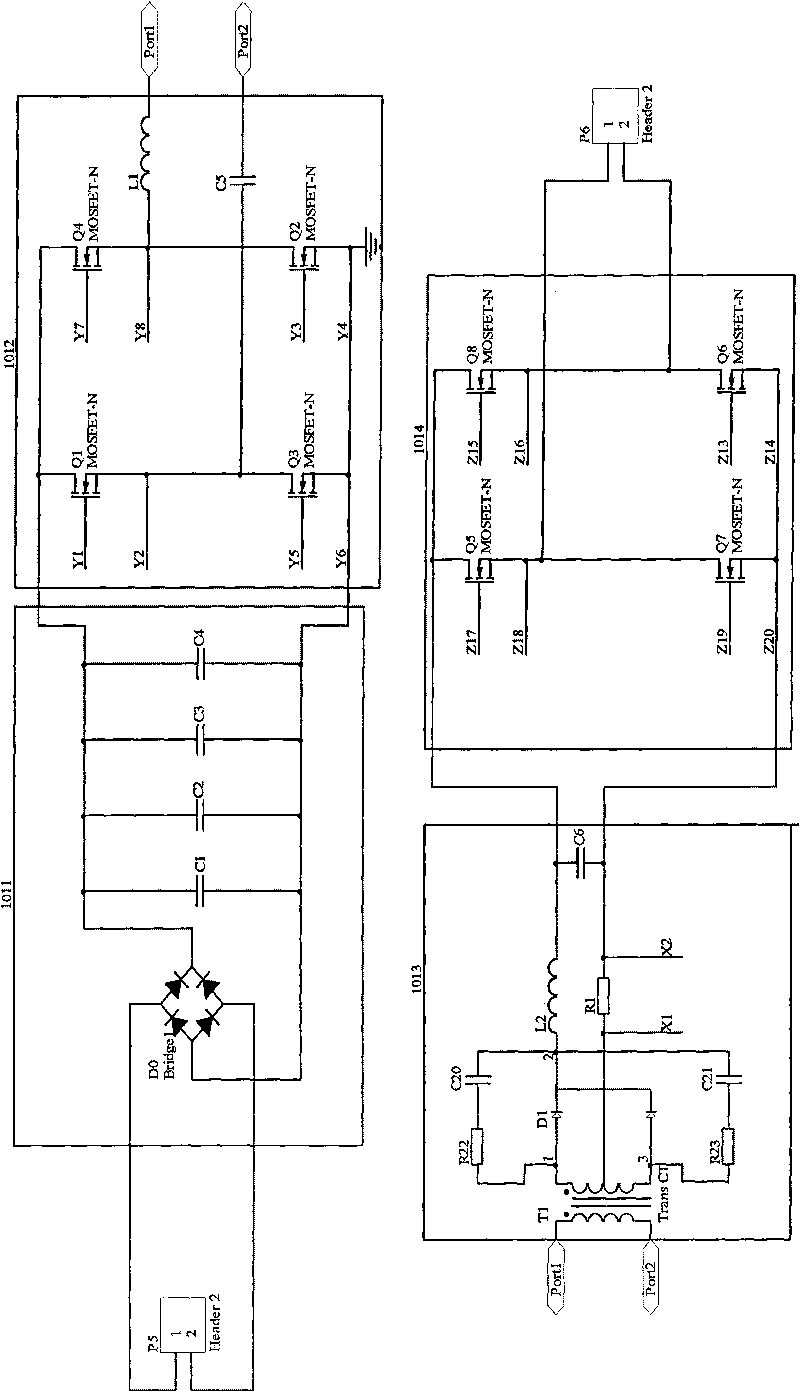

Full-digital dual-inverter alternating magnetic control arc generation device

ActiveCN101698265AGood consistencyImprove power conversion efficiencyArc welding apparatusSingle phaseHigh frequency

The invention discloses a full-digital dual-inverter alternating magnetic control arc generation device, which comprises a magnetic control arc excitation power supply and an excitation coil, wherein the magnetic control arc excitation power supply consists of a dual-inverter main circuit and a full-digital control system; the dual-inverter main circuit is formed by orderly connecting a single-phase rectifying and filtering module, a primary high-frequency inverter module, a transformer rectifier module and a secondary inverter module which access a single-phase alternating current input power supply; the full-digital control system is formed by interconnecting an abnormity detection and protection module, a sampling detection module, an ARM microprocessor system, a primary high-frequency driving module and a secondary driving module; and the excitation coil mainly comprises a carbon steel pipe, a plurality of strands of lacquered wires, a fixed bracket and the like. Full-digital control on the dual-inverter alternating magnetic control arc generation device can be realized, so the device has better consistency, dynamic response performance, good process adaptability, high energy conversion efficiency and strong expandability.

Owner:SOUTH CHINA UNIV OF TECH

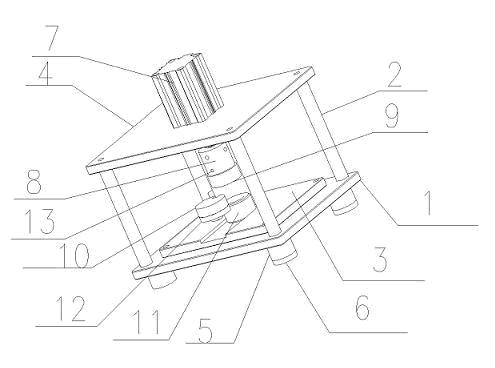

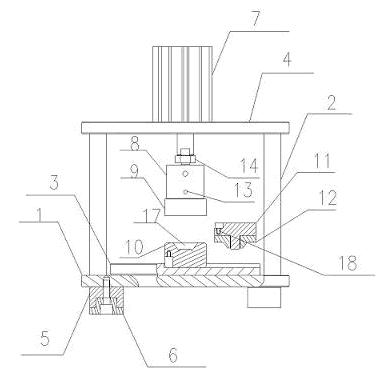

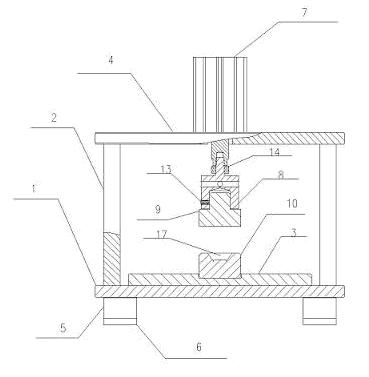

Floating type direct extrusion casting mold and implementing method thereof

The invention discloses a floating type direct extrusion casting mold and an implementing method thereof. A central cone of the mold is embedded in an upper mold; a movable ring is embedded in a lower mold; the movable ring is placed on a movable ring cushion block; the movable ring cushion block is placed on a lower mold base; a movable ring limiting block is fixedly connected to the lower mold base; and a cushion block connecting head is fixedly connected with the movable ring cushion block and matched with a hydraulic cylinder connector by a connector rotating shaft. The upper mold moves downwards, so that an alloy melt is full of a cavity and the alloy melt is extruded; meanwhile, the movable ring and the movable ring cushion block are extruded; the movable ring cushion block rotates under a pressure, so that the movable ring moves downwards along with the upper mold; and excessive alloy melt flows out from an overflow groove. According to the invention, the movable ring is rigidly supported by the movable ring cushion block to rotate along with the movable ring cushion block and the movable ring can stably move downwards, so that the alloy melt uniformly flows out from the overflow groove; therefore, the quality of a cast is guaranteed. The floating type direct extrusion casting mold disclosed by the invention is especially suitable for manufacturing medium and large sized non-ferrous alloy casts by using a plurality of casting methods.

Owner:SOUTH CHINA UNIV OF TECH

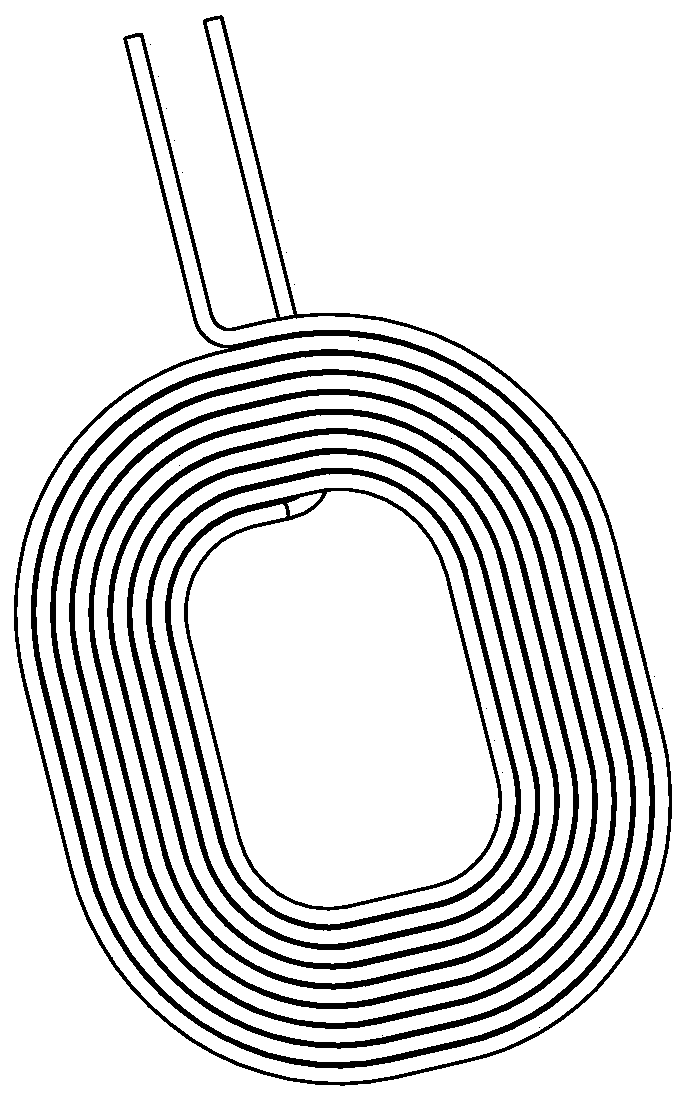

Coil winding machine

The invention discloses a coil winding machine. The coil winding machine comprises a winding machine main body; the winding machine main body comprises a machine frame, a winding jig and a bending andpositioning mechanism; the winding jig comprises a front mold and a winding core; the front mold surface of the front mold is provided with a coil containing groove, an outer ring needle hole and aninner ring needle hole; and the bending and positioning mechanism comprises an outer ring bending needle, an inner ring bending needle and a bending needle telescopic driving device. The inner ring bending needle and the coil containing groove are used for positioning the position where pins of inner rings of coils are bent and shaped; the position where pins of outer rings of the coils are bent is positioned by adopting the outer ring bending needle; and the consistency of the formed coils is good. Furthermore, a coil feeding mechanism, a coil grabbing mechanical arm, a jig rotating driving mechanism and a coil shearing mechanical arm are matched to complete coil winding, so that the production efficiency is high, and waste coils cannot be generated. Moreover, a coil stripping mechanism and a coil conveying line are adopted to complete the discharging of the finished coils, so that the automation degree is high.

Owner:ZHONGSHAN SANLE ELECTRONICS CO LTD

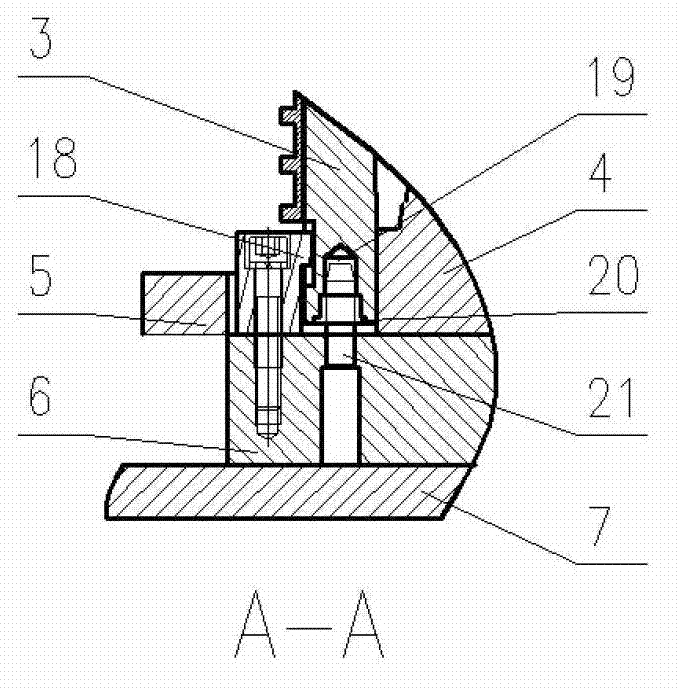

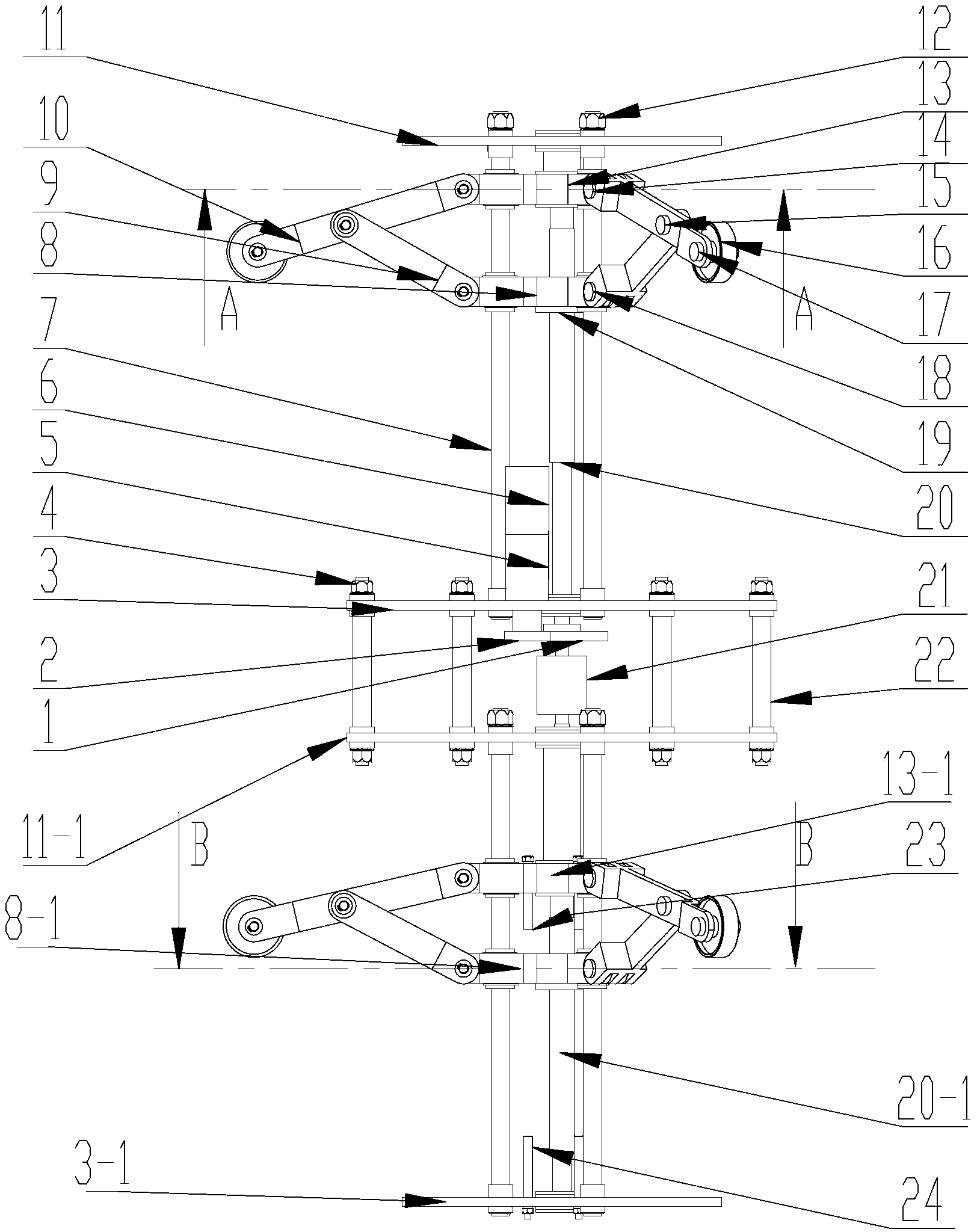

Pipeline inner wall supporting device of limiting double-layer self-adaptive three-point umbrella type

InactiveCN103398264AGood axial orientationGood consistencyPipe elementsSelf adaptiveOffshore drilling

The invention relates to the technical field of devices for removing waste offshore drilling well pipes and drilling platform supporting vertical pipes, in particular to a pipeline inner wall supporting device of a limiting double-layer self-adaptive three-point umbrella type. The pipeline inner wall supporting device is characterized by comprising an upper layer three-point axial guide supporting mechanism and a lower layer three-point guide supporting mechanism. Three-point umbrella type crank block supporting mechanisms are arranged on the three-point axial guide supporting mechanisms, and a driving mechanism is arranged on the upper layer three-point axial guide supporting mechanism. By the adoption of the two layers of self-adaptive three-point umbrella type pipeline inner wall supporting mechanisms, the whole mechanisms have the good axial guide performance and can be stable and reliable in upward sliding inside a pipeline along the pipe wall. Three connecting rod supporting arms drive three supporting connecting rod arms to be unfolded in the radius direction in a self-centering mode, therefore, the requirements for different tightening force and the inner diameter of the inner wall of the pipeline are met, and the corresponding tightening force and the size of the inner diameter of the inner wall of the pipeline can be acquired through a control algorithm. The pipeline inner wall supporting device is convenient to use, safe and high in adaptability.

Owner:NORTH CHINA INST OF AEROSPACE ENG

Manufacturing method of electrode foil for surface-mounting aluminum electrolytic capacitor

The invention discloses a manufacturing method of electrode foil for a surface-mounting aluminum electrolytic capacitor. The method comprises the following steps: soaking aluminum foil in a phosphoricacid solution, and applying transient large current, placing in the mixed aqueous solution to perform repeated power-up corrosion, placing the aluminum foil in the mixed solution containing sulfamicacid and citric acid, soaking in the pure water at 40 DEG C, placing the aluminum foil in an oven, performing thermal treatment at 500 DEG C, applying the required voltage in the formation liquid containing 4%-15% at 70-90 DEG C, and performing formation treatment, and finally drying. The manufacturing method disclosed by the invention has the advantages that the obtained electrode foil residual core is good in consistency, and has the advantages of being high in intensity and low in impedance; and meanwhile, the electrode foil impurity ion content can be effectively controlled to be lower than 1ppm, the electrode foil leakage current is greatly reduced, and the service life is improved. And a use requirement of the surface-mounting aluminum electrolytic capacitor is satisfied.

Owner:NANTONG HAIXING ELECTRONICS +2

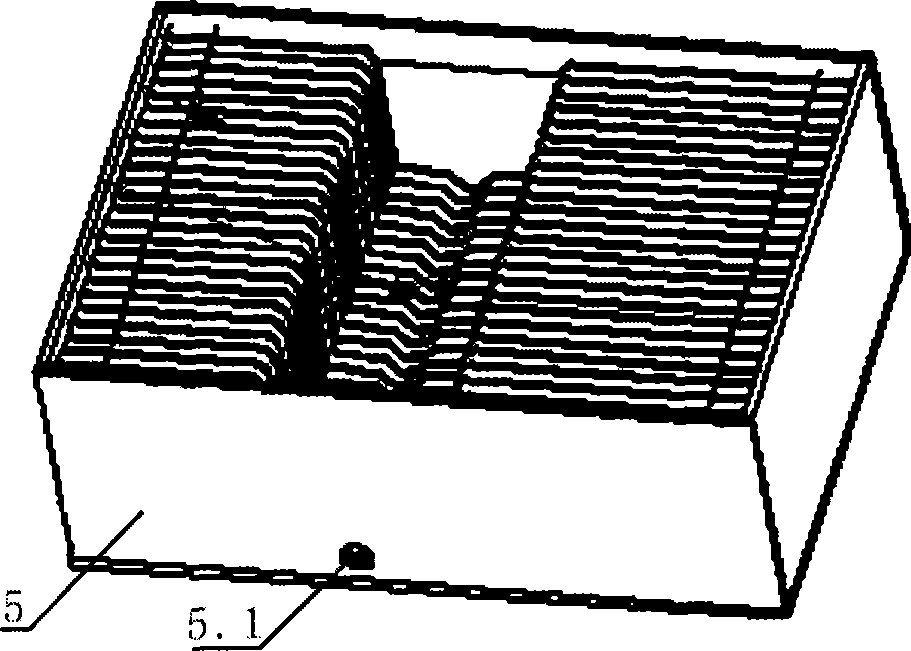

Air ion detection apparatus

InactiveCN103592335AGood consistencyGood shielding effect of interference electromagnetic fieldMaterial analysis by electric/magnetic meansIonAirflow

The invention discloses an air ion detection apparatus, comprising a cylindrical collection pipe (1), an amplifier box (2) accommodating an amplifier (12), a fan seat (3) accommodating a fan (3), an air-flow guiding-out pipe (4) and an ion induction electrode (5) used for capturing air ions, wherein the air inlet of the air-flow guiding-out pipe (4) is hermetically connected with an opening at the side wall of the collection pipe (1), the air outlet of the air-flow guiding-out pipe (4) is connected with the fan seat (3), and the air-flow guiding-out pipe (4) is transversely connected with the sidewall opening near the fixed end of the collection pipe (1) so as to allow air flow in the collection pipe (1) to transversely flow out. The air ion detection apparatus provided by the invention can effectively shield interfering electromagnetic fields, eliminate air-flow rotation effects and ensure no adhesion and accumulation of air impurities on the ion induction electrode, and cleaning-free long-term operation of the air ion detection apparatus is realized.

Owner:北京东创旭新测控技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com