Full-digital dual-inverter alternating magnetic control arc generation device

A fully digital, arc generation technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of small pulse duty ratio and pulse frequency adjustment range, difficult adjustment of magnetic control parameters, and continuous adjustment. Achieve the effect of simple and convenient circuit design, easy precision modulation, and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

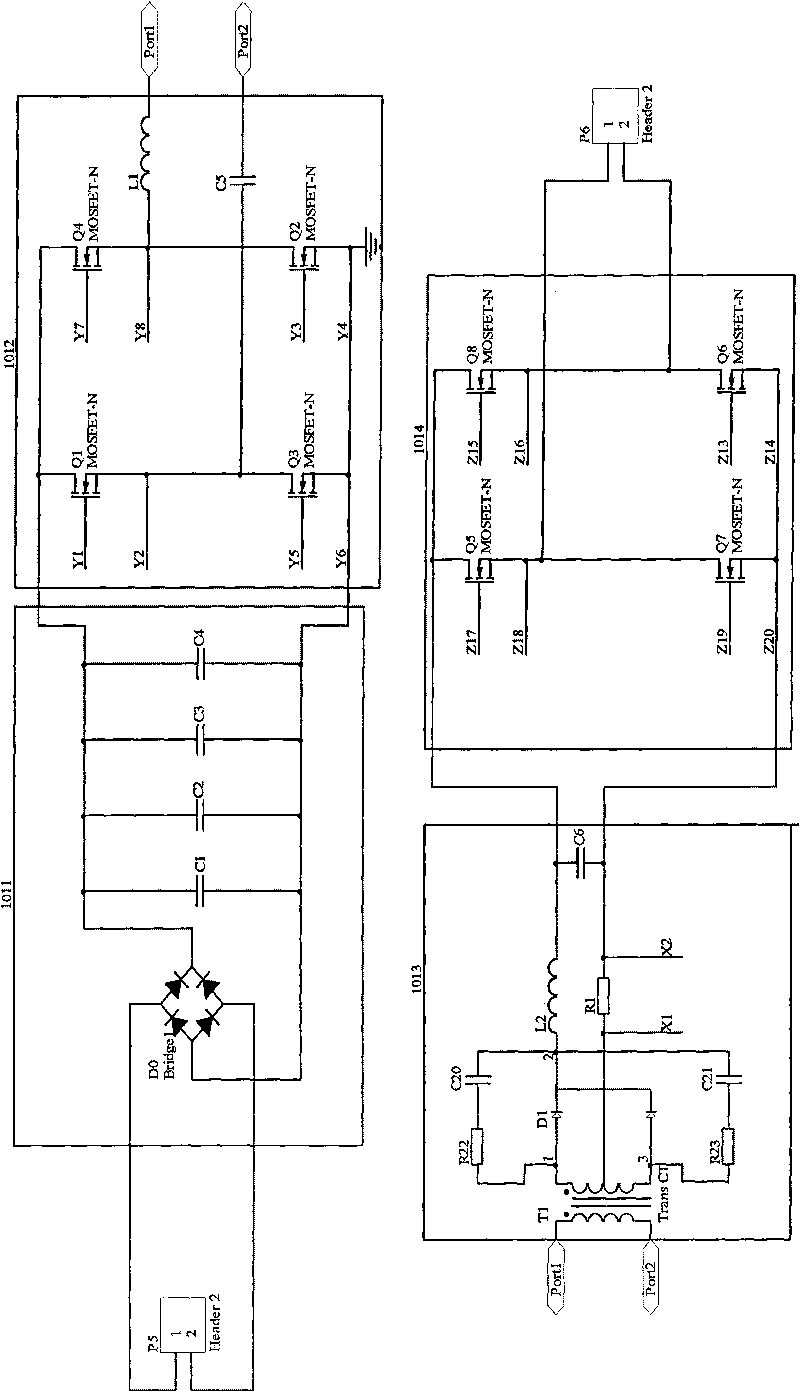

[0031] Such as figure 1 As shown, the all-digital double-inversion alternating magnetron arc generating device of the present invention includes two major parts of a magnetron arc excitation power supply 100 and an excitation coil 200; The digital control system 102 is composed of a single-phase AC input power supply as the input of the double inverter main circuit 101 , and the output of the double inverter main circuit 101 is directly connected to the excitation coil 200 . The excitation coil 200 adopts the existing excitation coil 200, which mainly includes carbon steel pipes, multi-strand enameled wires and fixed brackets. fixed.

[0032] Such as figure 2 As shown, the dual-inverter main circuit 101 of the all-digital double-inverter alternating magnetron arc gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com