Manufacturing method of electrode foil for surface-mounting aluminum electrolytic capacitor

An aluminum electrolytic capacitor, surface mount technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of large leakage current, capacity dispersion, and bending dispersion of the formed foil, so as to meet the requirements of use and improve the use of life and the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

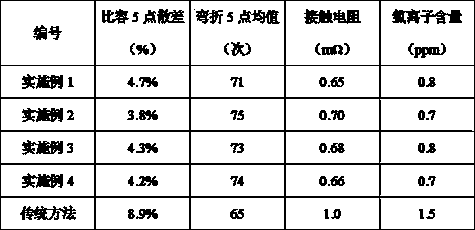

Embodiment 1

[0019] The 91μm thick aluminum foil with a purity of 99.98% is soaked in 0.5% phosphoric acid solution for 1min, and then passed through the current density of 1A / cm 2 The instantaneous high-frequency current is used for surface electrolysis treatment, and the reaction temperature is 50°C; the above-mentioned pretreated aluminum foil is placed in a mixed aqueous solution for a galvanic corrosion, the energization frequency is 80Hz, the reaction temperature is 20°C, and the reaction time is 1min: Then place it in the mixed aqueous solution for chemical corrosion, the reaction temperature is 40°C, and the reaction time is 30s; then place it in the mixed aqueous solution for secondary electrification corrosion, the electrification frequency is 70Hz, the reaction temperature is 20°C, and the reaction time is 2min30s; Then put it in the mixed aqueous solution for three times of electrification corrosion, the electrification frequency is 60Hz, the reaction temperature is 20°C, and th...

Embodiment 2

[0020] Example 2: A 91 μm thick aluminum foil with a purity of 99.98% is soaked in 0.7% phosphoric acid solution for 1 min, and then passed through with a current density of 1.5 A / cm 2 The instantaneous high-frequency current is used for surface electrolysis treatment, and the reaction temperature is 40°C; the above-mentioned pretreated aluminum foil is placed in a mixed aqueous solution for a galvanic corrosion, the energization frequency is 70Hz, the reaction temperature is 30°C, and the reaction time is 1min: Then put it in the mixed aqueous solution for chemical corrosion, the reaction temperature is 50°C, and the reaction time is 30s; then put it in the mixed aqueous solution for secondary electrification corrosion, the electrification frequency is 60Hz, the reaction temperature is 30°C, and the reaction time is 2min30s; Then put it in the mixed aqueous solution for three times of electrification corrosion, the electrification frequency is 50Hz, the reaction temperature is...

Embodiment 3

[0021] Example 3: A 91 μm thick aluminum foil with a purity of 99.98% is soaked in 1% phosphoric acid solution for 1 min, and then passed through with a current density of 1 A / cm 2 The instantaneous high-frequency current is used for surface electrolysis treatment, and the reaction temperature is 30°C; the above-mentioned pretreated aluminum foil is placed in a mixed aqueous solution for a galvanic corrosion, the energization frequency is 60Hz, the reaction temperature is 40°C, and the reaction time is 1min: Then place it in the mixed aqueous solution for chemical corrosion, the reaction temperature is 60°C, and the reaction time is 30s; then place it in the mixed aqueous solution for secondary electrification corrosion, the electrification frequency is 50Hz, the reaction temperature is 40°C, and the reaction time is 2min30s; Then put it in the mixed aqueous solution for three times of electrification corrosion, the electrification frequency is 40Hz, the reaction temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com