Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Increase extrusion area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

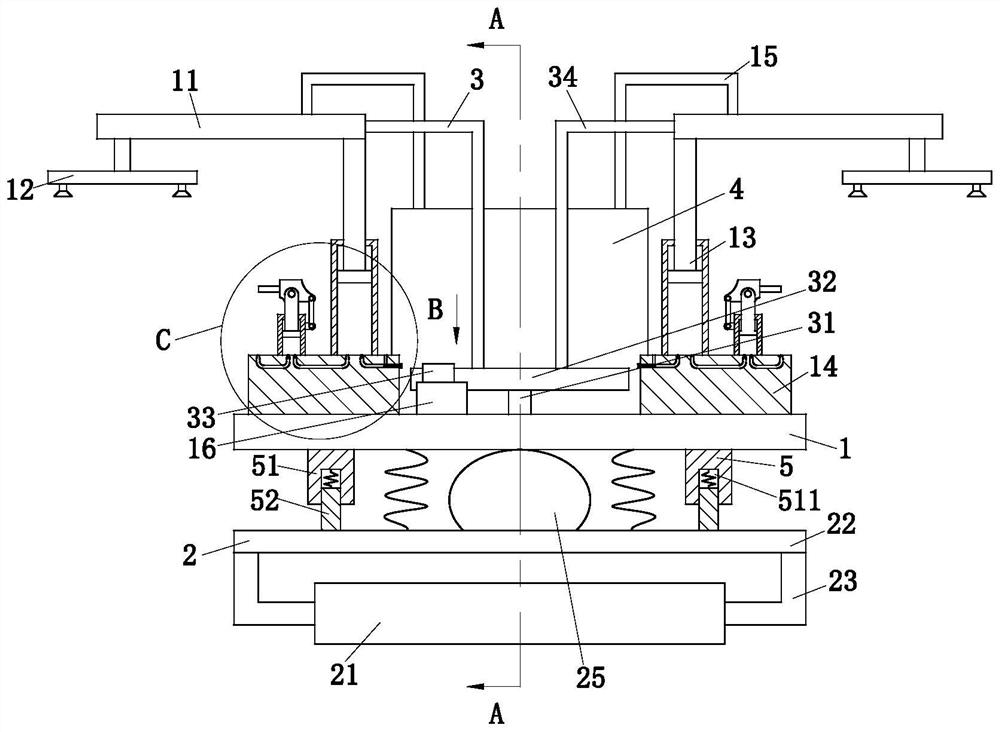

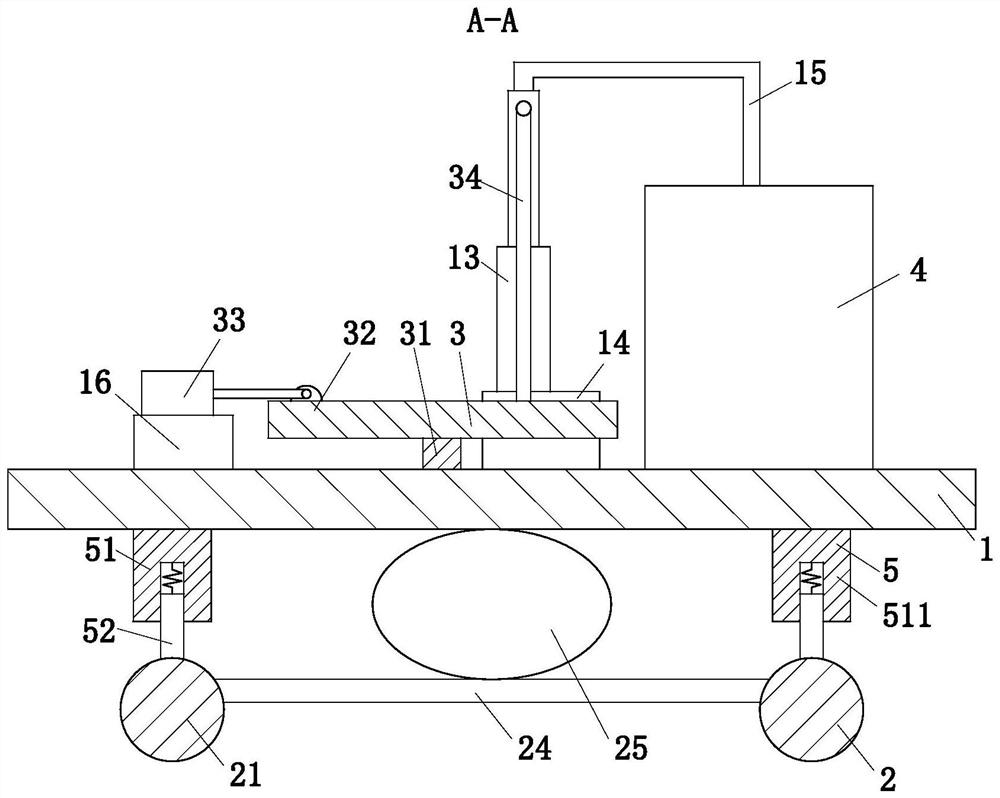

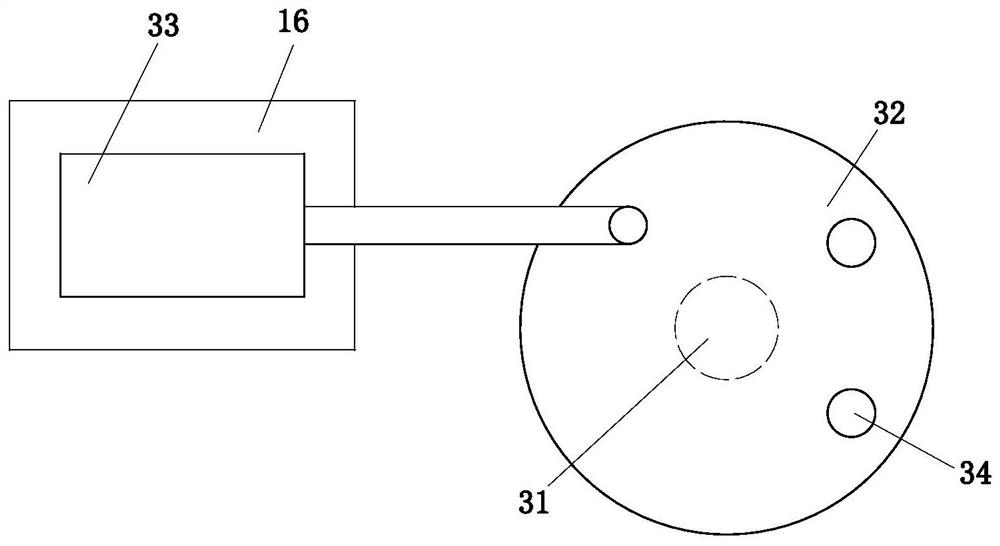

Floating type direct extrusion casting mold and implementing method thereof

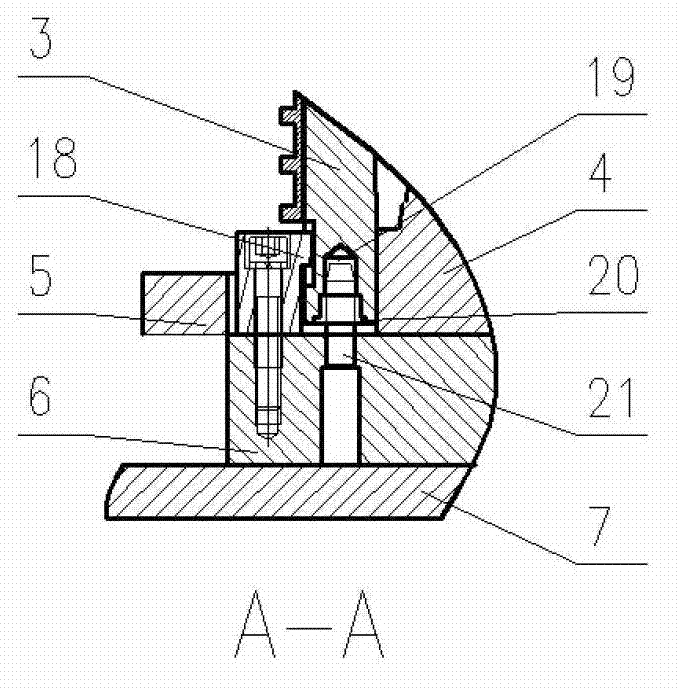

The invention discloses a floating type direct extrusion casting mold and an implementing method thereof. A central cone of the mold is embedded in an upper mold; a movable ring is embedded in a lower mold; the movable ring is placed on a movable ring cushion block; the movable ring cushion block is placed on a lower mold base; a movable ring limiting block is fixedly connected to the lower mold base; and a cushion block connecting head is fixedly connected with the movable ring cushion block and matched with a hydraulic cylinder connector by a connector rotating shaft. The upper mold moves downwards, so that an alloy melt is full of a cavity and the alloy melt is extruded; meanwhile, the movable ring and the movable ring cushion block are extruded; the movable ring cushion block rotates under a pressure, so that the movable ring moves downwards along with the upper mold; and excessive alloy melt flows out from an overflow groove. According to the invention, the movable ring is rigidly supported by the movable ring cushion block to rotate along with the movable ring cushion block and the movable ring can stably move downwards, so that the alloy melt uniformly flows out from the overflow groove; therefore, the quality of a cast is guaranteed. The floating type direct extrusion casting mold disclosed by the invention is especially suitable for manufacturing medium and large sized non-ferrous alloy casts by using a plurality of casting methods.

Owner:SOUTH CHINA UNIV OF TECH

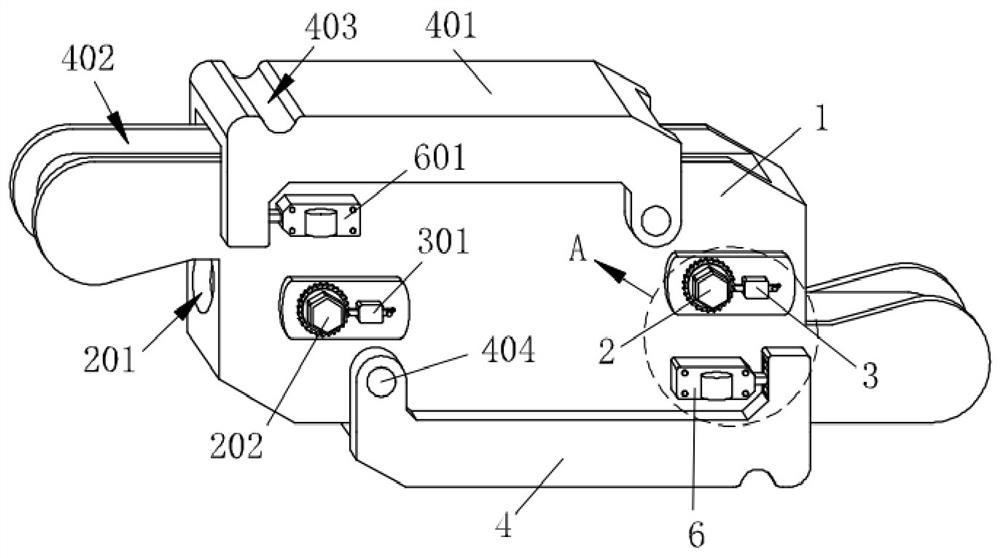

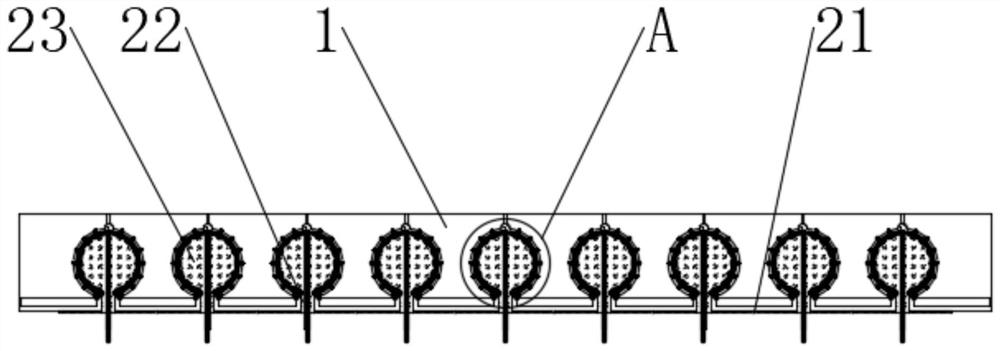

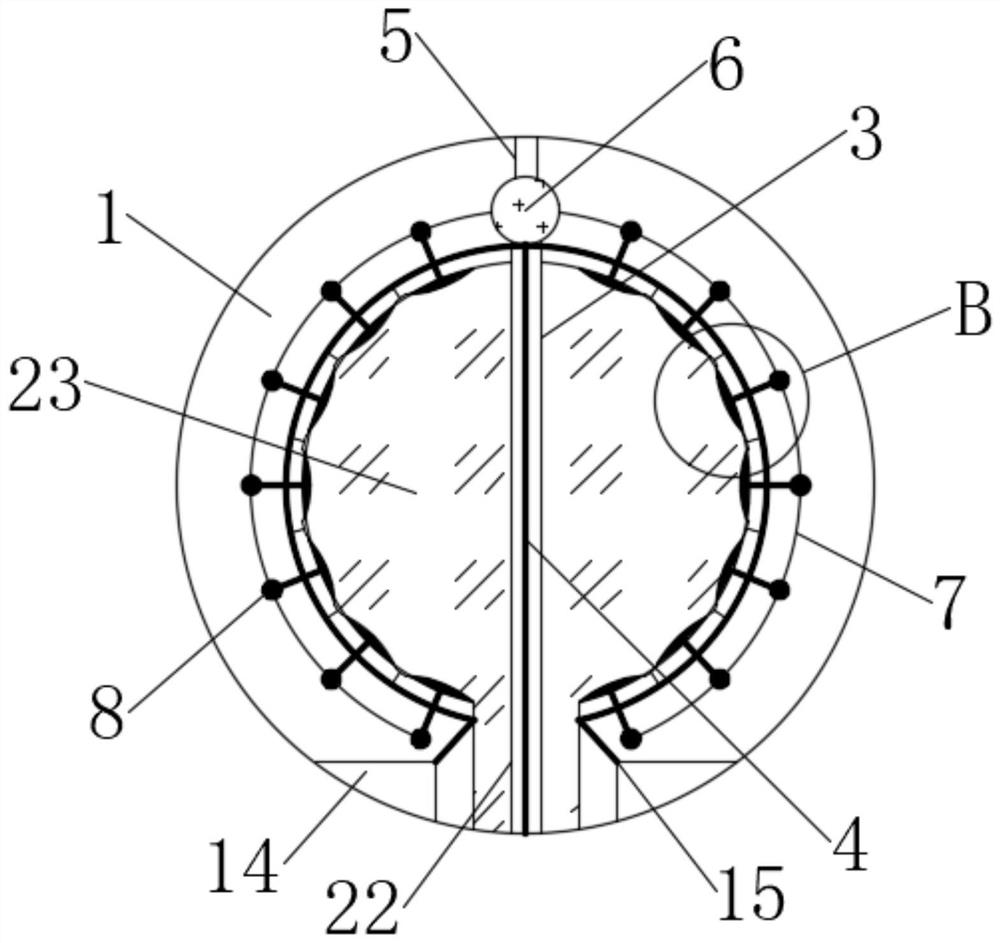

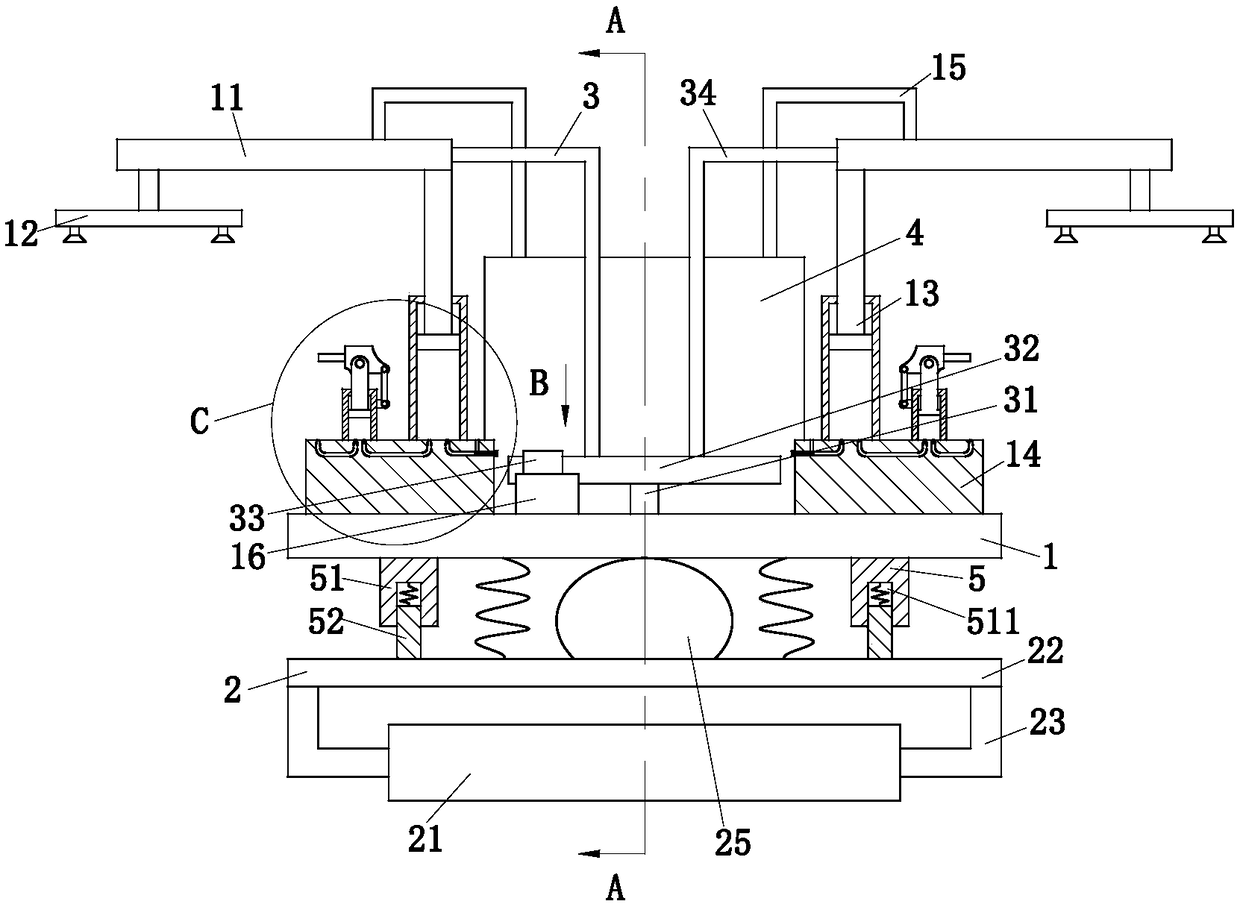

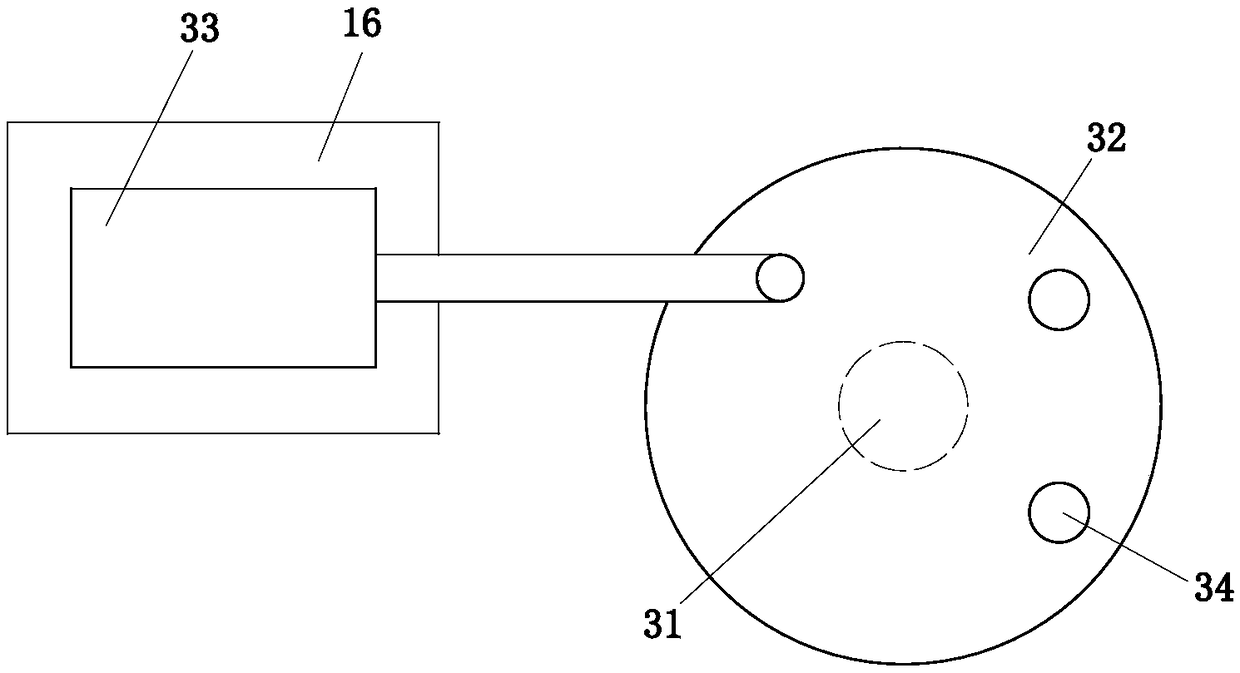

Deforming contact type fabric fluff removal device

ActiveCN111648111AImprove adhesionAccelerate sinkingMechanical cleaningPressure cleaningEngineeringHot melt

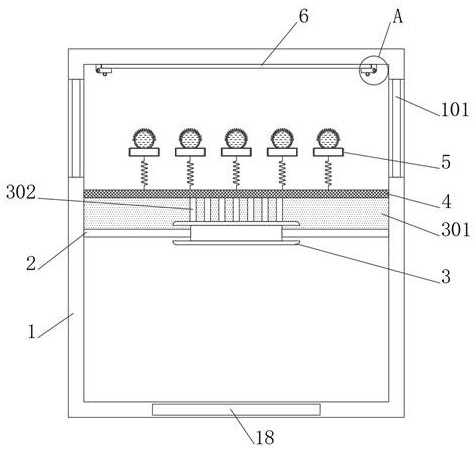

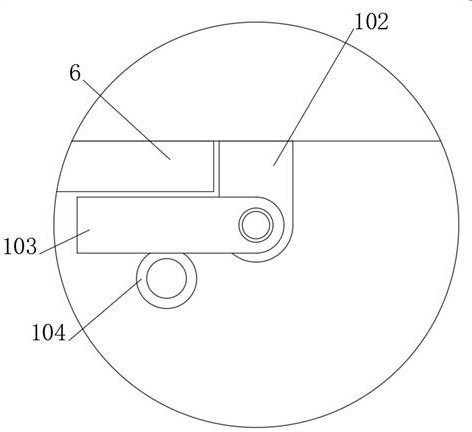

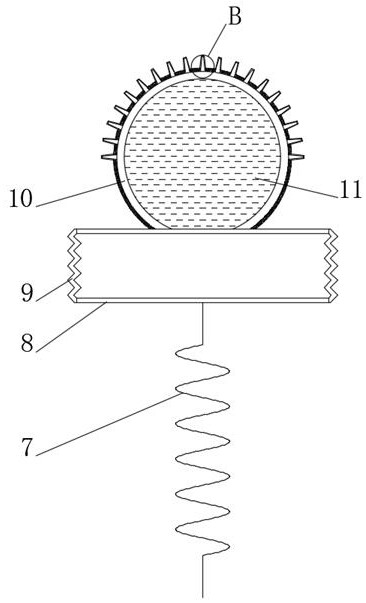

The invention discloses a deforming contact type fabric fluff removal device, and belongs to the technical field of clothing processing. A semiconductor refrigeration sheet is heated to 60 DEG C and the heat is transferred to a fluff collecting device. With the expansion of a lifting air bag, the lifting air bag can be promoted to move up until the fluff collecting device comes to contact with fabric. Meanwhile, by intermittently starting and turning off an electromagnet, the fluff collecting device can repeatedly move up and down between a bearing filter screen and the fabric and collect fluff adhering to the surface of the fabric with the help of collecting bore spines and hot melt adhesive layers at the outer ends of fluff collecting balls. When the fluff collecting balls come into contact with the fabric, the fluff collecting balls can squeeze the fabric until the fluff collecting balls become flat balls, and the collection efficiency of the fluff adhering to the surface of the fabric is increased. Meanwhile, traction particles are released, so that the fluff adhering with the traction particles can be adsorbed downward and collected. Moreover, the antistatic property of the fabric can be improved through an antistatic powder layer, and the possibility of the fluff adhering to the fabric again can be reduced.

Owner:SHANDONG TAROKO WEAVING & DYEING IND

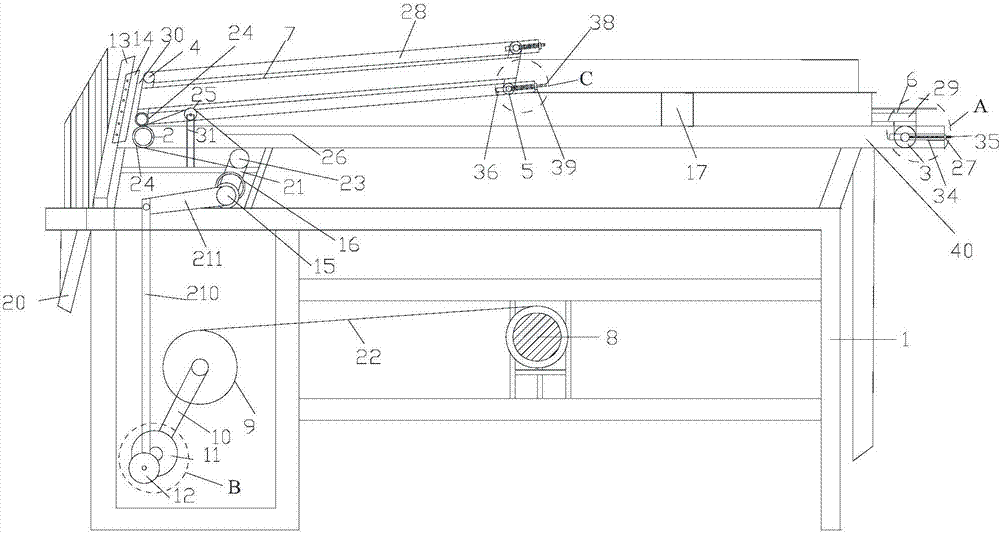

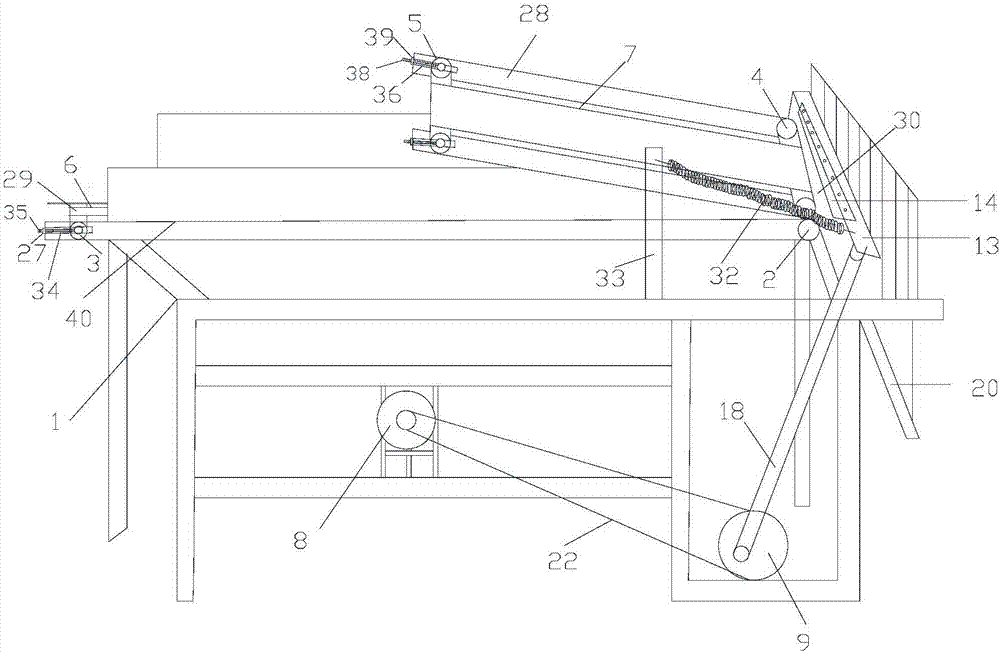

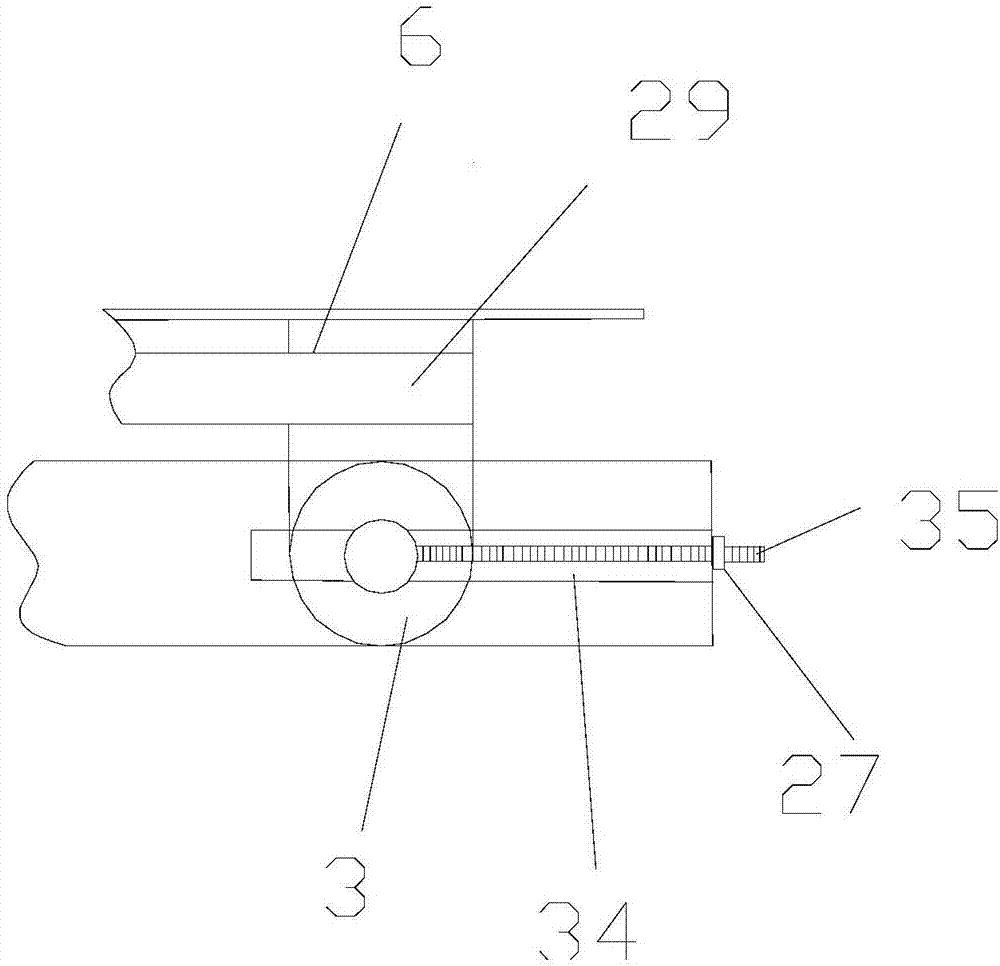

Automatic mulberry leaf cutting machine

The invention provides an automatic mulberry cutting machine, comprising a frame, a belt conveying mechanism, a cutting device and a driving device, the belt conveying mechanism, the cutting device and the driving device are all mounted on the frame, and the driving device includes a power source, a transmission wheel, Connecting rod, crank, adjusting bolt, transmission shaft and ratchet mechanism, the power source is installed on the frame and connected with the transmission wheel and the cutting device to drive the transmission wheel to rotate and drive the cutting device to cut mulberry leaves. There is an adjusting slideway extending radially along the drive wheel, the adjusting bolt is threaded through one end of the connecting rod to be screwed with the adjusting slideway, the end of the connecting rod away from the adjusting bolt is rotationally connected with one end of the crank, the pawl of the ratchet mechanism is connected to the crank Connection, the ratchet of the ratchet mechanism is coaxially fixed with the transmission wheel, the transmission shaft is rotatably installed on the frame and connected with the belt conveying mechanism, and the adjusting bolt can move along the adjusting slideway when it is in a loose state to adjust the belt conveying mechanism. transfer speed.

Owner:玉林市蚕业技术推广站

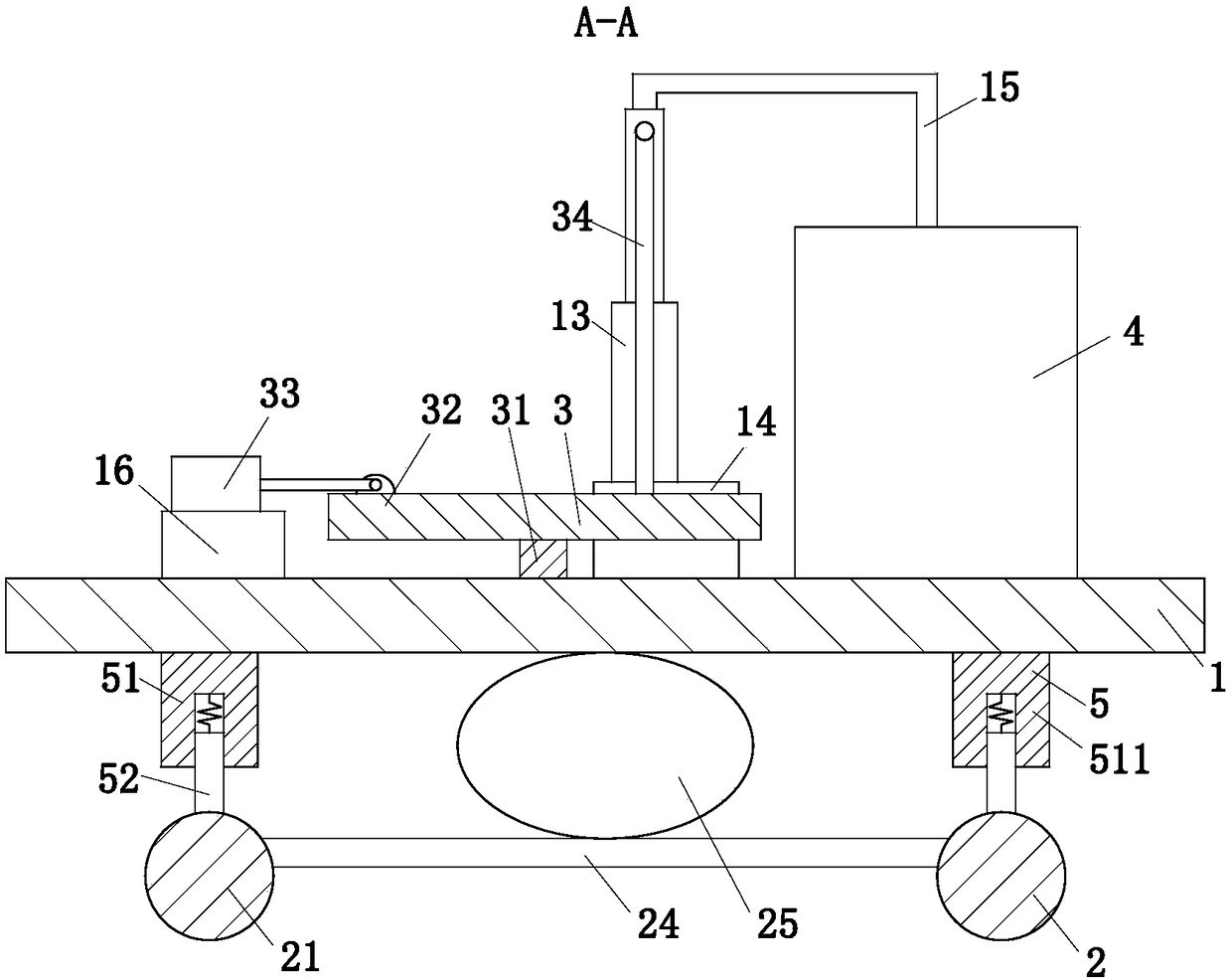

Efficient cart for spinning

InactiveCN108483078ARealize windingRealize transportationWebs handlingWrinkle skinMechanical engineering

The invention discloses an efficient cart for spinning. The efficient cart for spinning comprises a carrying plate, a water tank and handheld frames. The handheld frames are symmetrically arranged onone side of the carrying plate and fixedly connected with the carrying plate. The water tank is arranged at the bottom of the carrying plate and fixedly connected with the carrying plate through screws. A mounting base is arranged on the top surface of the carrying plate and welded to the carrying plate, and a cloth winding shaft, a first roller shaft and a second roller shaft are mounted on the surface of the mounting base. According to the efficient cart for spinning, a cart carrying mode is adopted, winding equipment is carried, gauze conveying can be achieved through belt brake wheels, cloth conveying can be achieved, the number of subsequent production steps can be further reduced, the pressure on workers is greatly relieved, and meanwhile production efficiency is enhanced. The efficient cart for spinning further has the functions of thermal ironing and water spraying, and thus wrinkles, protrusions and concave faces of the surface of gauze can be smoothened.

Owner:JIANGSU CHENFEI SPORTS GOODS CO LTD

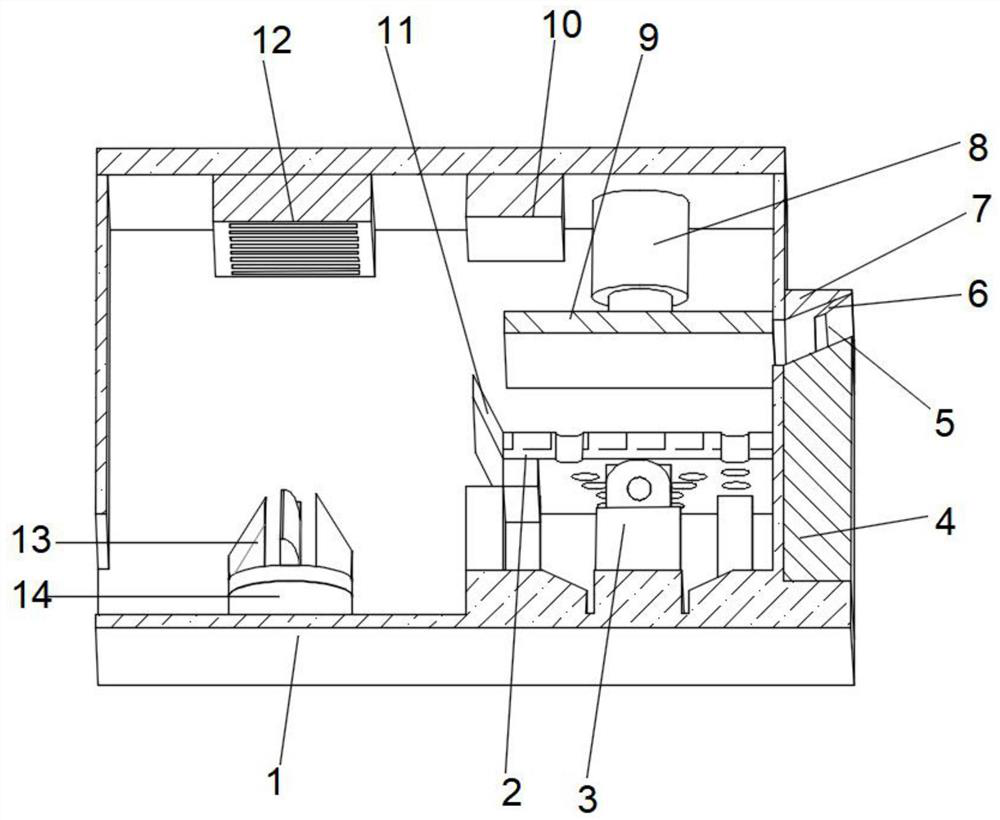

Water absorption device for waste gas treatment

InactiveCN113350956ARealize the collectionReduce water permeabilityGas treatmentDispersed particle separationWaste gasDisposal Technique

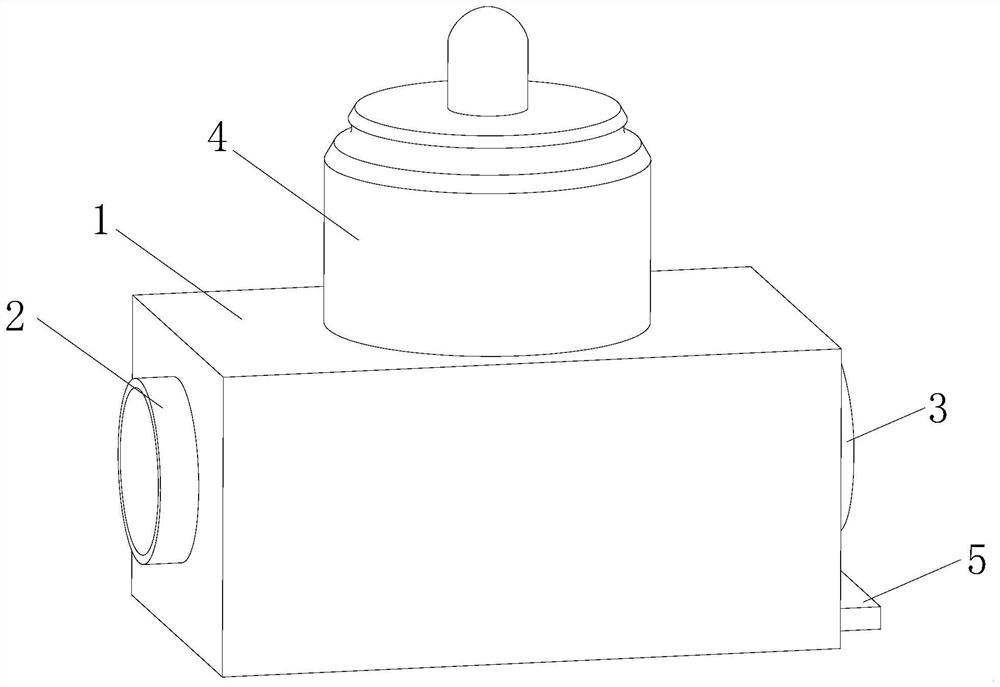

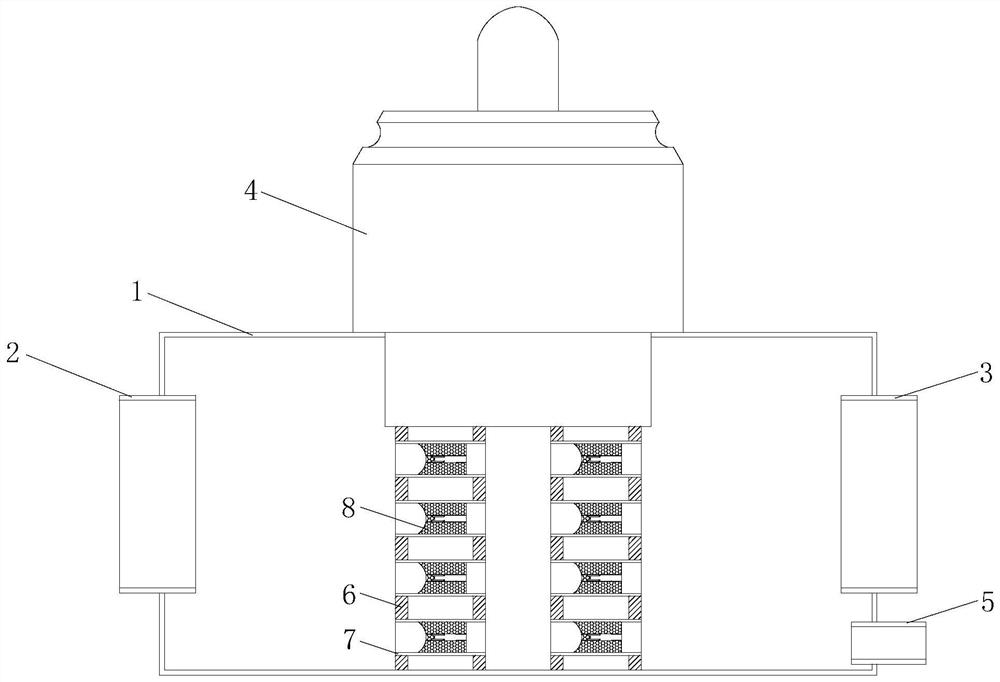

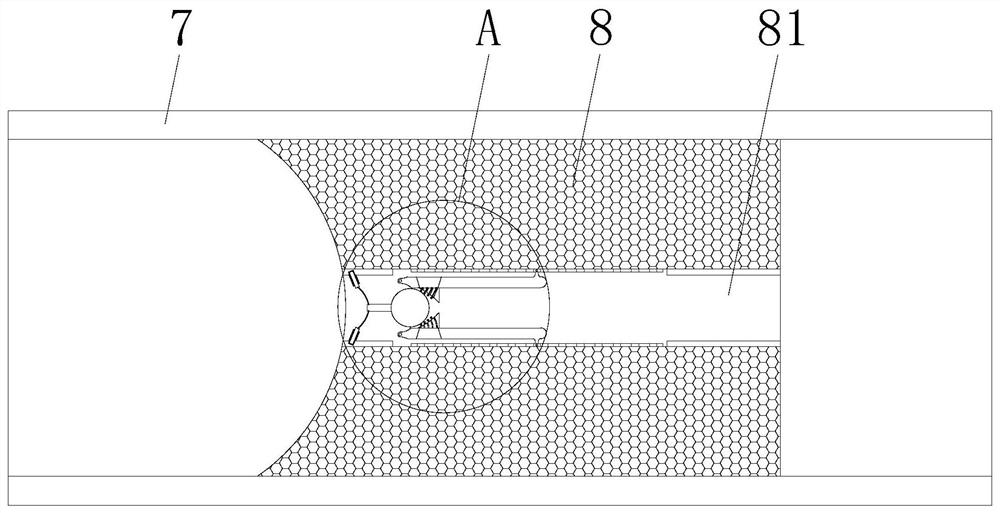

The invention discloses a water absorption device for waste gas treatment, which relates to the technical field of waste gas treatment. The water absorption device for waste gas treatment comprises a device body, a gas inlet channel and a gas outlet channel are formed in the left side and the right side of the device body respectively, a cooling device is fixedly installed at the top of the device body, a freezing element located in the cooling device is located in the device body, and a drainage channel is formed in the bottom of the right side of the device body. According to the water absorption device for waste gas treatment, waste gas can be cooled through the cooling device, vaporous water in the waste gas is cooled and liquefied, and the liquefied water is sucked into the absorption sponge, so that the vaporous water in the waste gas is collected, and the water permeability of the absorption sponge is reduced along with the increase of water absorbed by the absorption sponge; and the auxiliary drainage mechanism can extrude the absorption sponge, so that water absorbed in the absorption sponge is drained, and automatic cleaning of the water in the absorption sponge is achieved.

Owner:孙佳佳

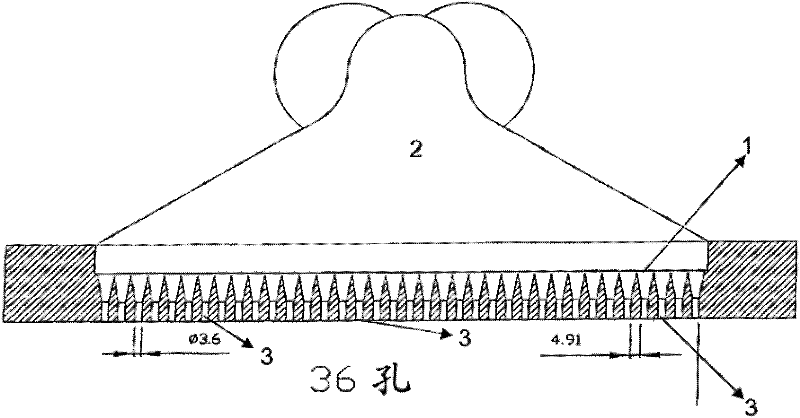

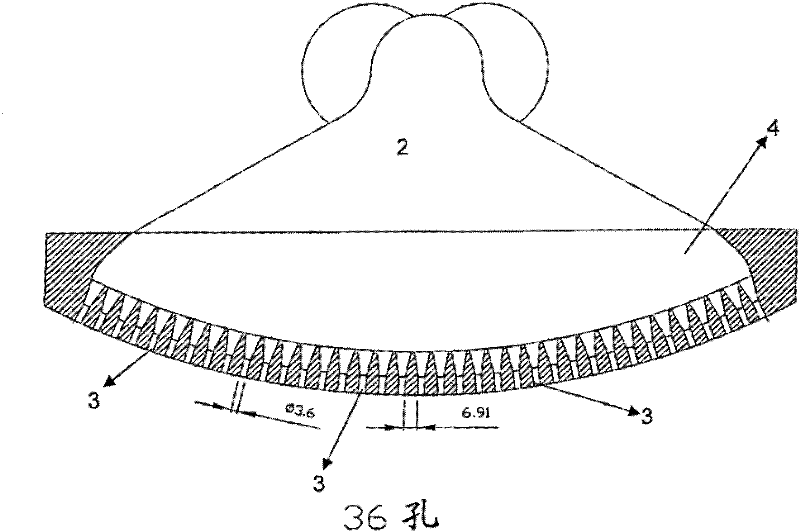

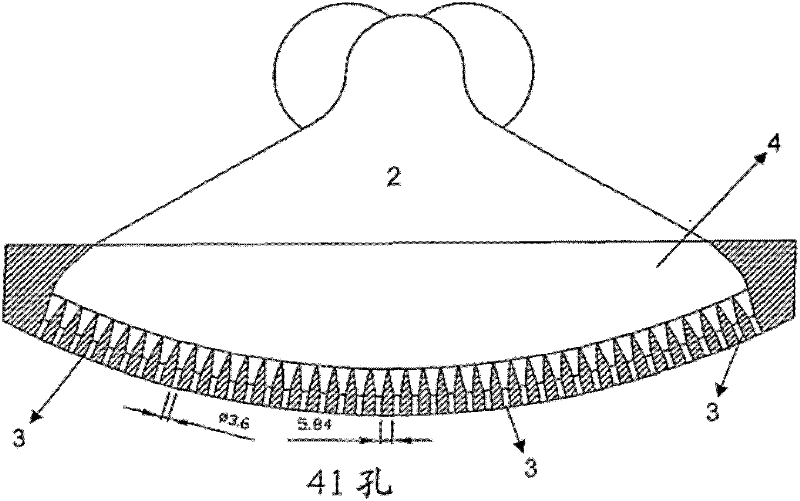

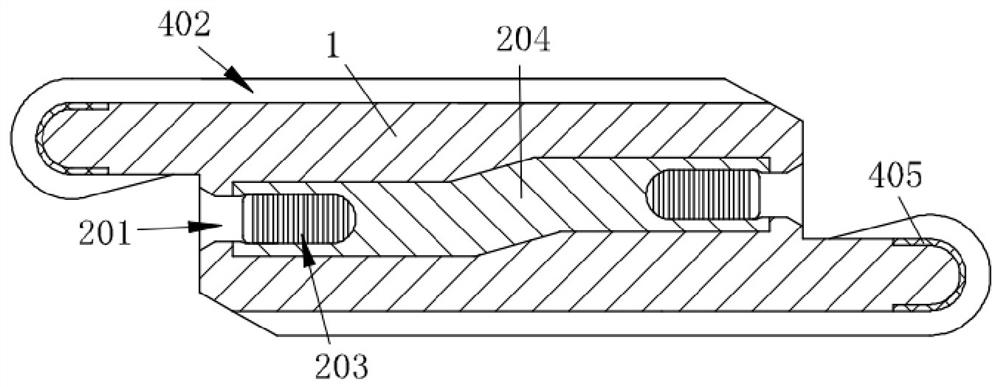

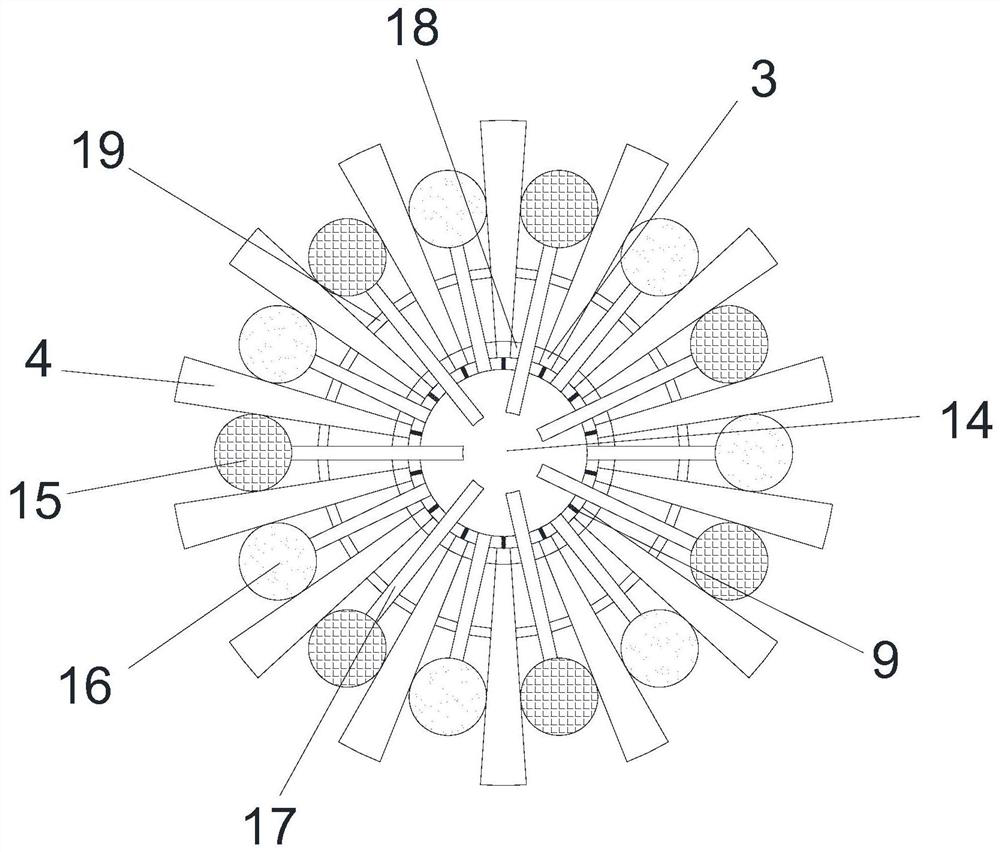

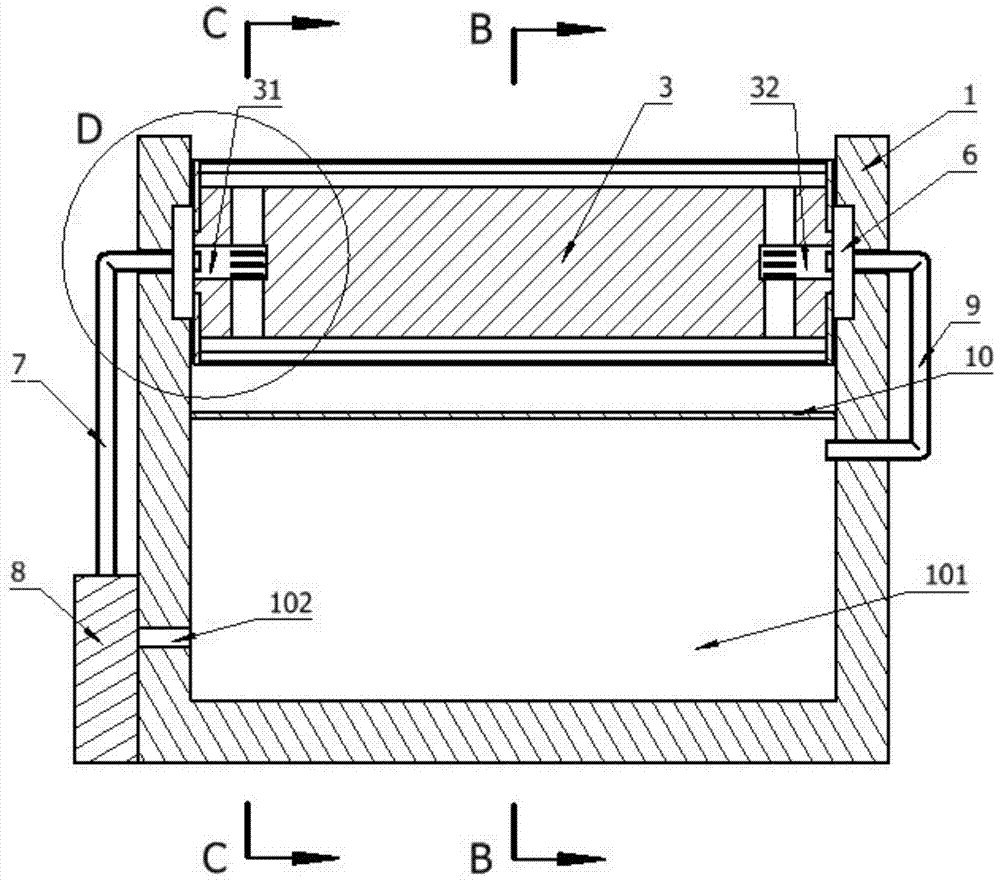

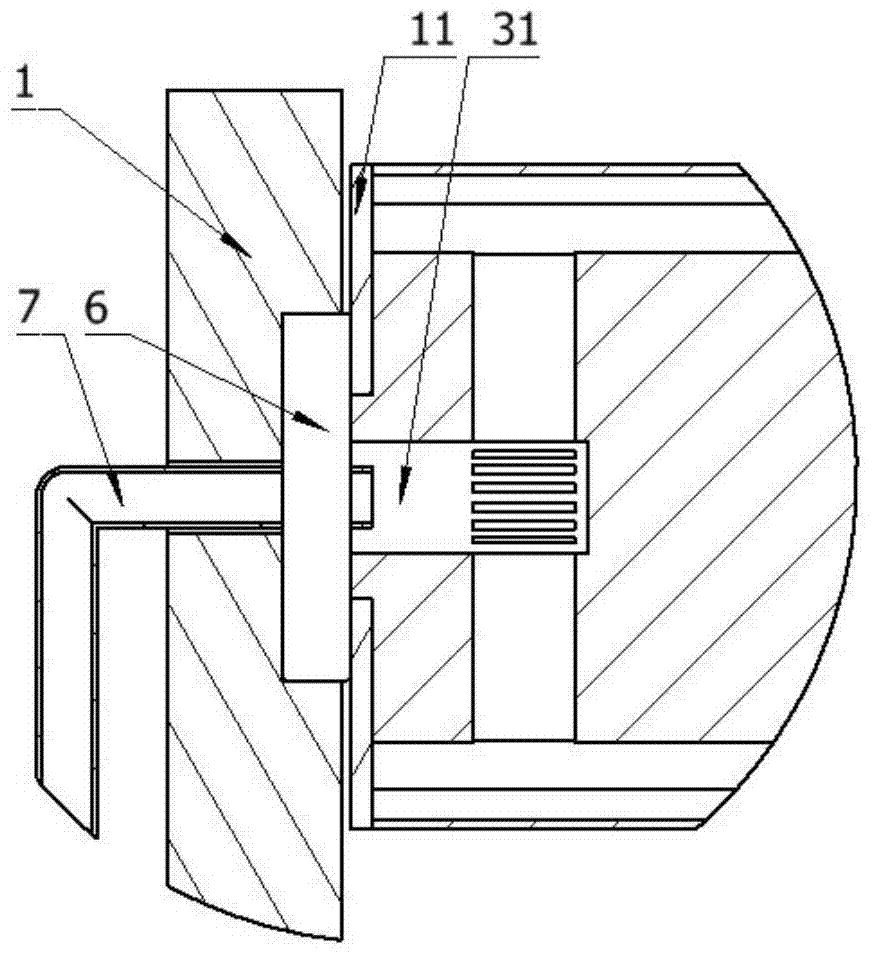

Nozzle plate having nozzles disposed convexly and the use of the same

ActiveCN102414008AIncrease the number ofIncrease extrusion areaSpinnerette packsConvex sideEngineering

The invention relates to a concave-convex nozzle plate (4) having an arrangement of the nozzles (3) on the convex side. Said nozzle plate and an extrusion device (2) equipped therewith is suitable for extruding plastic melts in strand granulation.

Owner:AKRO PLASTIC

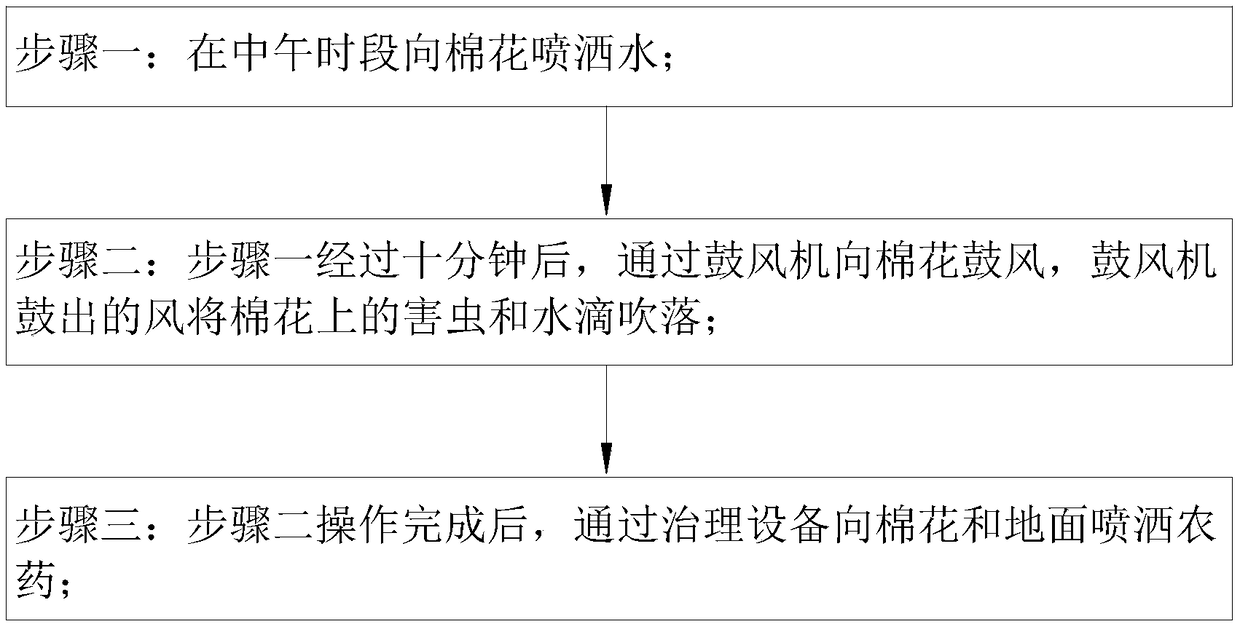

Method for preventing and treating diseases and pests of cotton

ActiveCN109122178ASpray evenlyAvoid harmCotton cultivationHorticulture methodsDiseaseTreatment effect

The invention belongs to the technical field of agricultural production, and specifically provides a method for preventing and treating diseases and pests of cotton. The method adopts a treatment device which comprises a vehicle body, water supply pipes and spraying assemblies and also comprises a driving unit, a swinging unit, an air cylinder No. 1, first fixed blocks No. 1, a second fixed blockNo. 2, a water tank and hoses, wherein the driving unit is used for movement of the vehicle body; and the swinging unit is used for uniform spraying of the spraying assemblies. According to the invention, through mutual cooperation of the driving unit and the swinging unit, a pesticide solution is uniformly sprayed to agricultural and forestry crops according to actual situations, and the agricultural and forestry crops are avoided from being damaged by the diseases and the pests, so the prevention and treatment effects on agricultural and forestry diseases and pests are improved; meanwhile, by utilization of a power source of an agricultural and forestry disease and pest treatment device, the utilization rate of resources is improved, and external power equipment is reduced at the same time, so the manufacturing cost of the agricultural and forestry disease and pest treatment device is reduced.

Owner:真木农业设备(安徽)有限公司

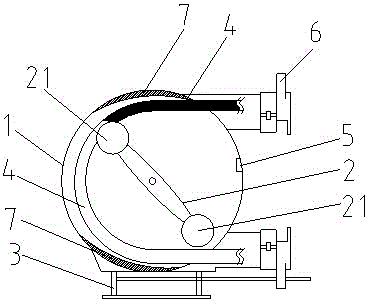

Flexible pipe pump

PendingCN104832405AFound damageEasy maintenancePositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

Disclosed in the invention is a flexible pipe pump comprising a pump shell, a rotor body, a base, and a flexible pipe. The flexible pipe and the rotor body are arranged inside the pump shell; and the pump shell is arranged at the base. The cross section of the rotor body is in an elliptic shape; compression rollers are respectively arranged at the two ends of the rotor body; and the compression rollers can exert rotation extrusion on the flexible pipe with rotation of the rotor body. Fluid adsorbed by the flexible pipe pump is only in contact with the flexible pipe and various fluid materials with different viscosities, densities, corrosion degrees, and corrosivities can be conveyed. Besides, a flexible pipe fracture detection apparatus is also installed in the pump shell, so that the damage of the flexible pipe in the pump shell can be found instantly and thus repairing can be carried out conveniently. With the side compression rollers, deformation recovering of the flexible pipe can be realized conveniently. Because the compression rollers and the rotor body are made from self-lubrication materials, no lubrication is needed. And a pulsation damper is arranged at the pump shell, thereby eliminating the pulse caused by pump movement and hammering during pump starting.

Owner:SHANGHAI KT PUMP IND MFG CO LTD

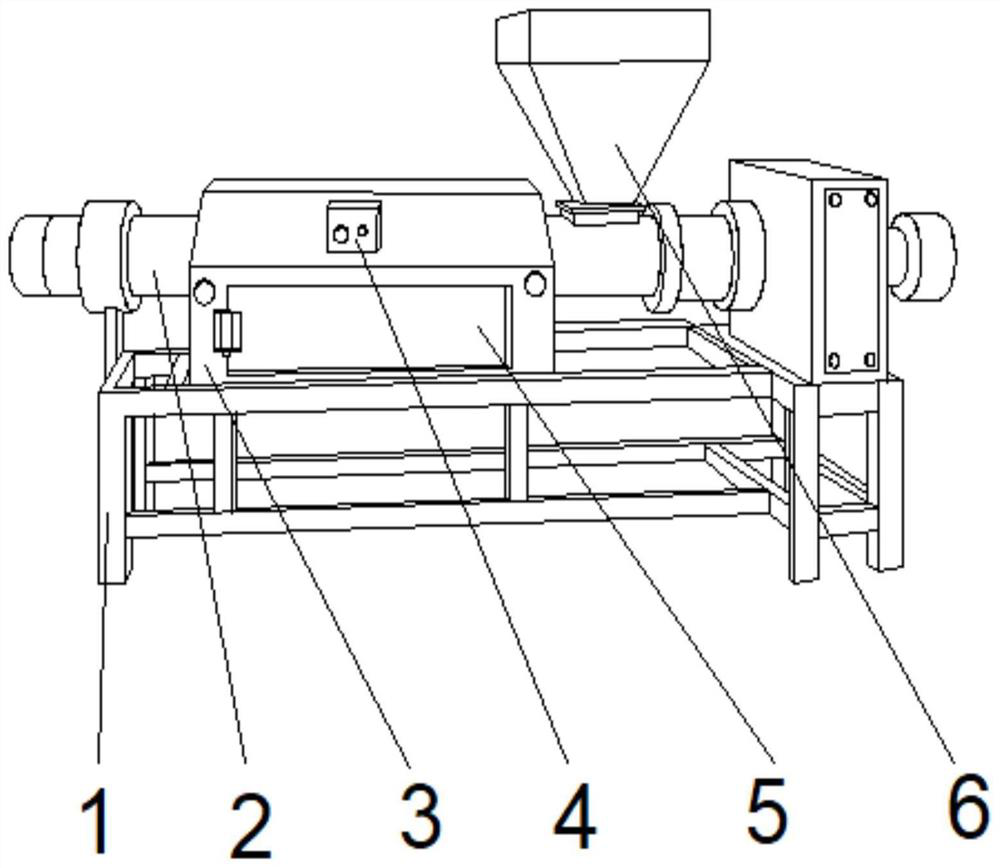

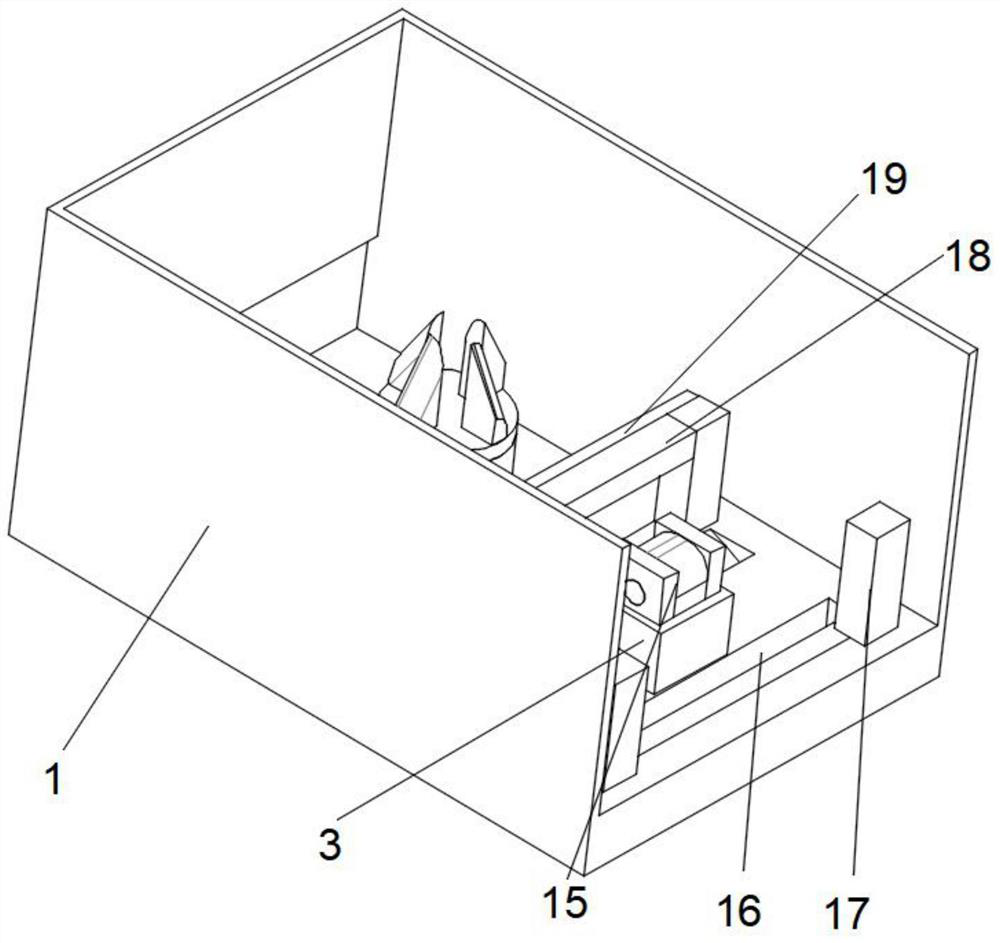

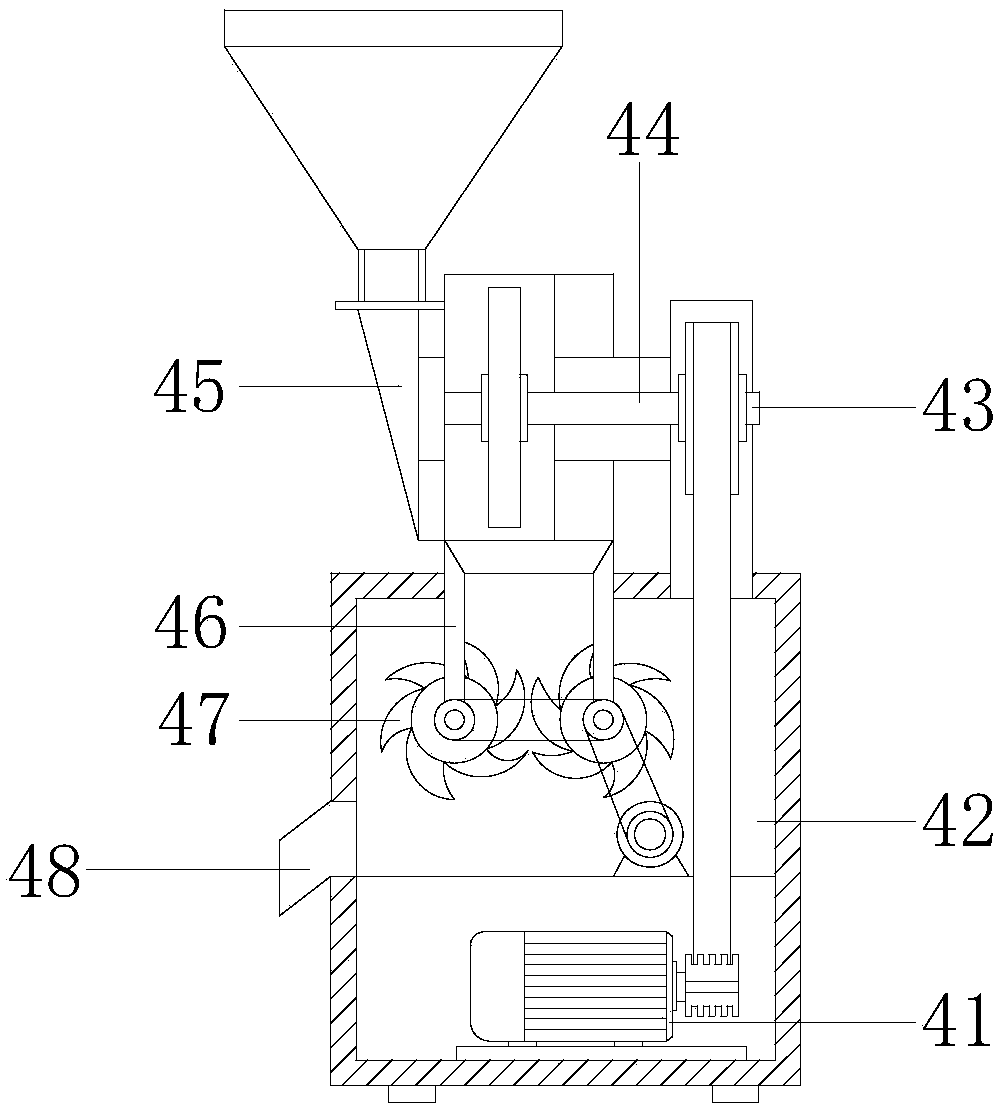

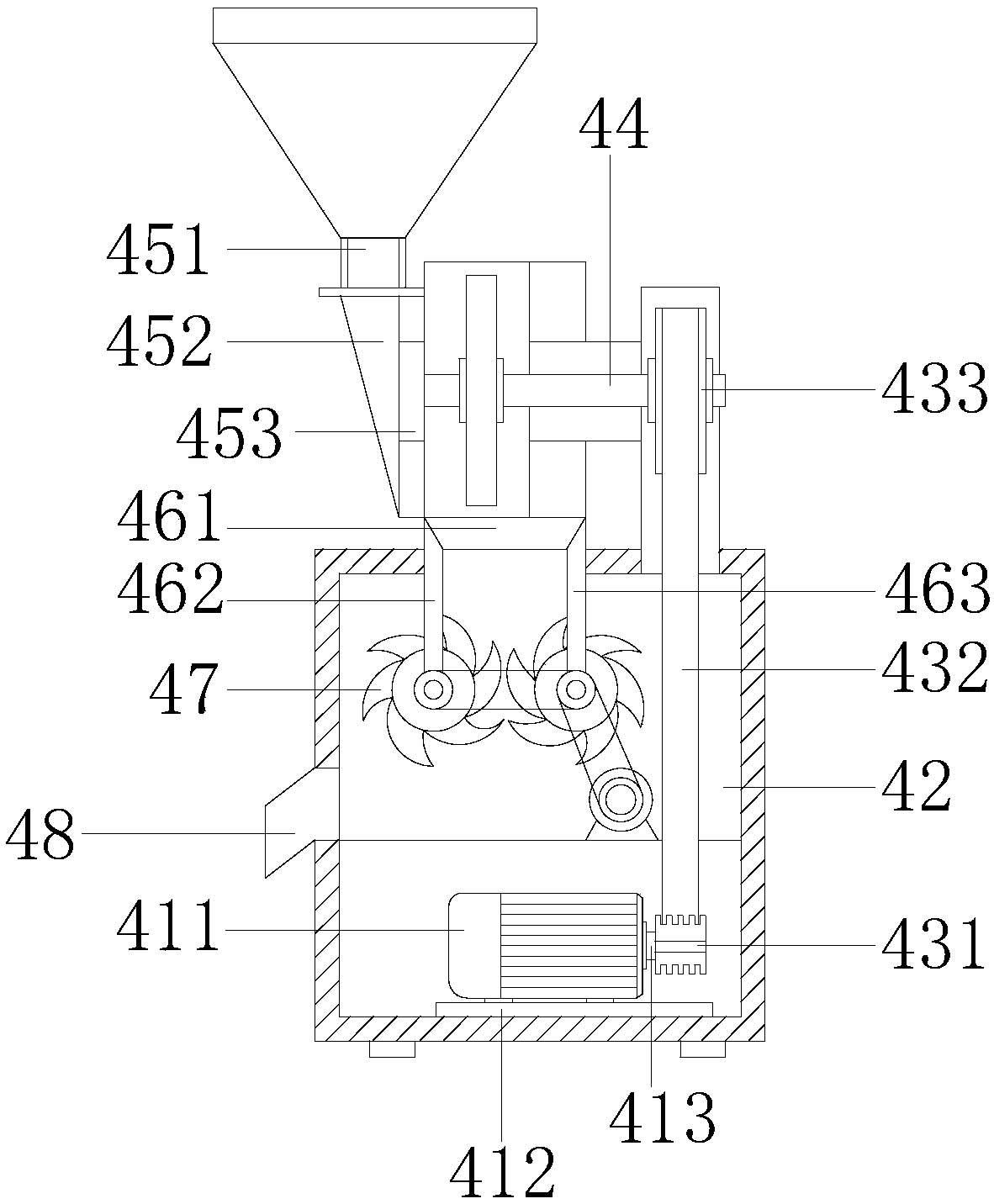

Granulator

PendingCN112693021AIncrease extrusion areaSave internal spaceSievingScreeningInterior spaceEngineering

The invention discloses a granulator. The granulator comprises a base, a cooling box is fixedly connected to the middle of the top of the base, a box door is arranged in the middle of the bottom of the front face of the cooling box, a controller is fixedly connected to the middle of the top of the front face of the cooling box, an extrusion device is arranged on the outer walls of the two sides of the cooling box, the middle of the extrusion device penetrates through the cooling box, and a heating hopper is arranged at the position, located on the right side of the cooling box, of the middle of the extrusion device. The granulator relates to the technical field of granulation equipment. The granulator is provided with the heating hopper, the extrusion device and the cooling box, rubber is heated and melted in the heating hopper and then enters the extrusion device, and manufactured rubber particles are uniform; during extrusion, the extrusion device makes contact with the rubber at first, shrinking is conducted, the internal space is reduced, and therefore the extrusion area of the rubber is increased, and unqualified rubber particles are treated; and the working efficiency is improved, the cutting efficiency is improved, and the situation of cutting omission is avoided.

Owner:李会娟

Extrusion recovery device for kitchen garbage treatment

InactiveCN112264443ASpeed up fermentationImprove filtration efficiencySolid waste disposalTransportation and packagingEngineeringStructural engineering

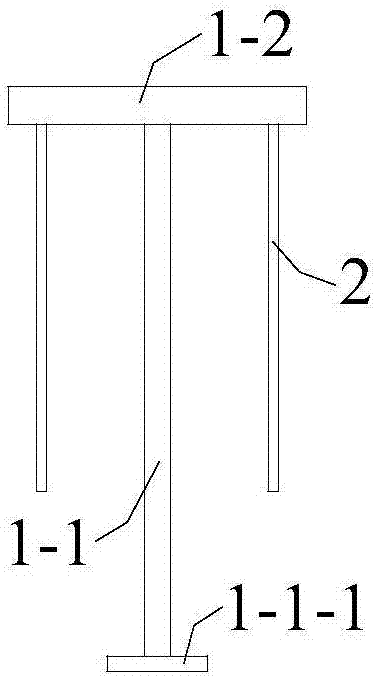

The invention is applicable to the technical field of garbage treatment, and provides an extrusion recovery device for kitchen garbage treatment. The extrusion recovery device comprises an outer box,symmetrically distributed support columns are arranged on the inner wall of the bottom, close to the edge of one side, of the outer box, support plates are placed on the outer walls of the top ends ofthe support columns, symmetrically-distributed fixing blocks are arranged on the outer walls, close to the middles, of the bottoms of the supporting plates, extension rods of electric telescopic rodsare connected to the outer walls of the opposite sides of the fixing blocks through plug pins, the outer walls of the bottoms of the electric telescopic rods are fixed to the inner wall of the bottomof the outer box, a top cover is arranged on the outer wall of the top end of the outer box, symmetrically-distributed hydraulic ejector rods are arranged at the positions, close to the electric telescopic rods, of the outer wall of the bottom of the top cover, a top plate is fixed to the ends, close to the supporting plates, of the hydraulic ejector rods, hydraulic oil cylinders are arranged atthe positions, close to the hydraulic ejector rods, of the outer wall of the bottom of the top cover, and kitchen garbage can be conveniently extruded through the arranged hydraulic ejector rods and the top plate.

Owner:梅皓

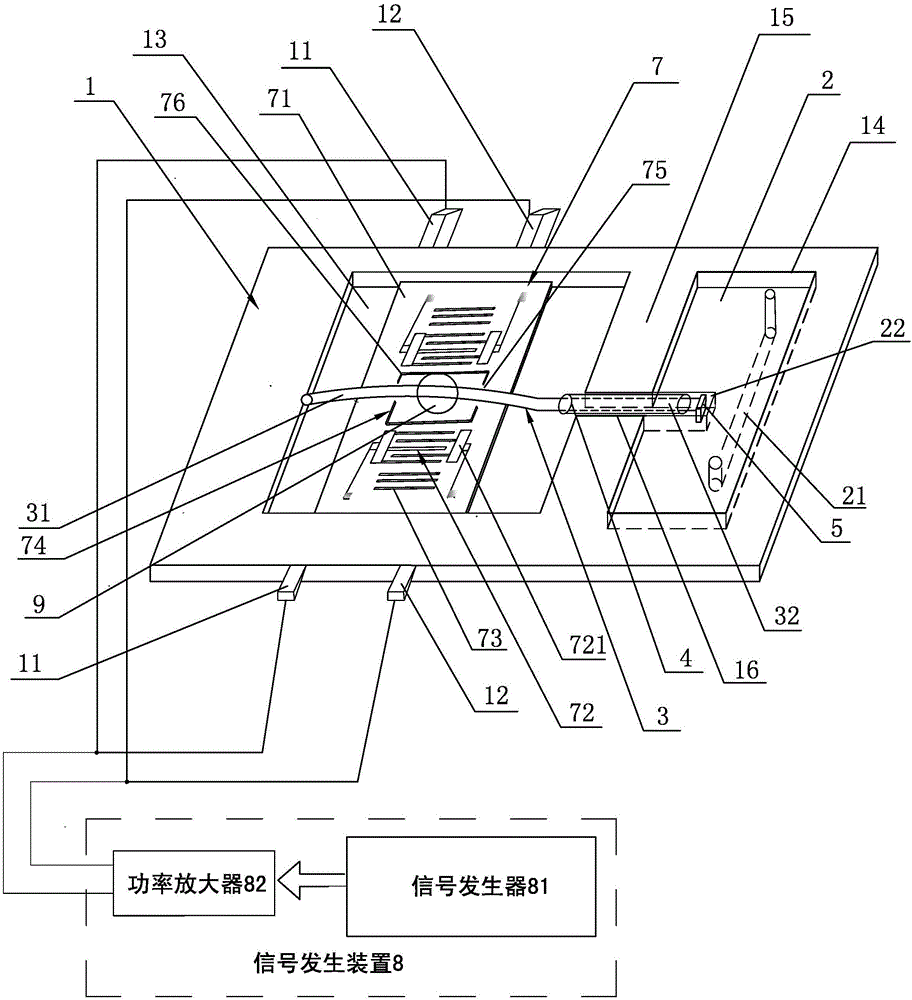

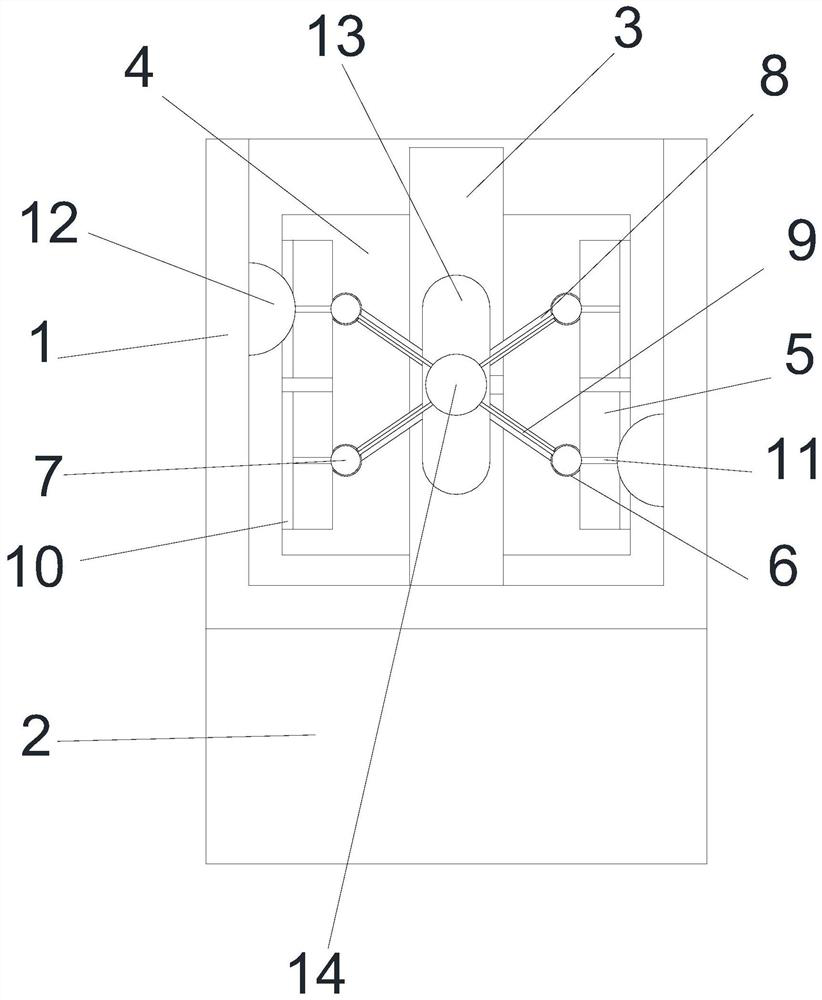

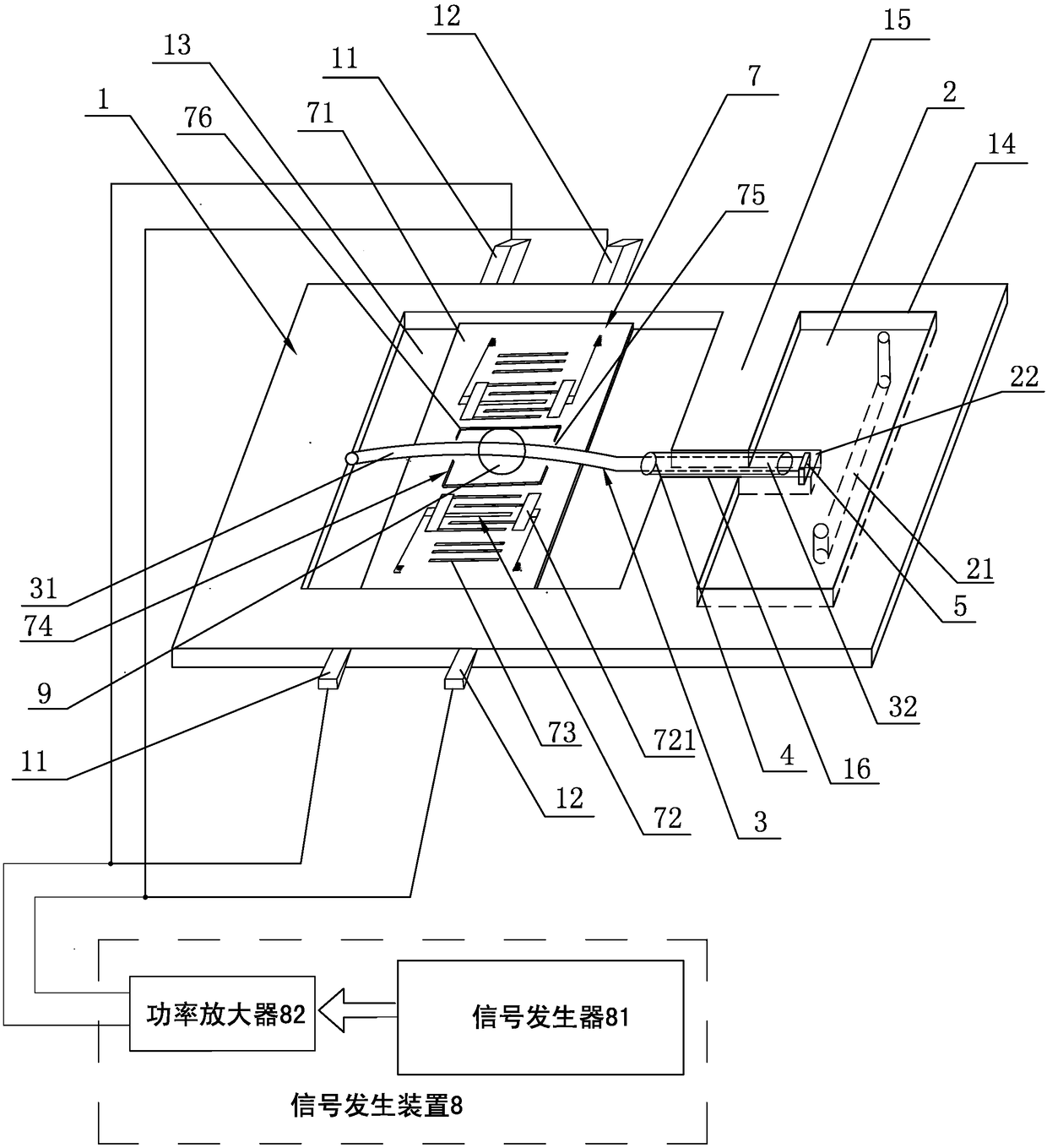

Shape memory alloy micro valve based on acoustic surface waves and control method of shape memory alloy micro valve

The invention discloses a shape memory alloy micro valve based on acoustic surface waves and a control method of the shape memory alloy micro valve. The shape memory alloy micro valve comprises a PCB, an acoustic surface wave excitation device, a PDMS coagulating body with a micro-channel and a shape memory alloy line formed by a first crooked section at the indoor temperature and a second straight section at the indoor temperature; the acoustic surface wave excitation device and the PDMS coagulating body are installed on the PCB, a groove is formed in the PDMS coagulating body, and the other end of the shape memory alloy line is connected with the PCB; the section, stretching across a propagation path of the acoustic surface waves excited by the acoustic surface wave excitation device and located on the propagation path, of the shape memory alloy line is covered with paroline micro liquid on the propagation path; and the second section of the shape memory alloy line is sleeved with a guide pipe connected with the PCB, and a plastic sheet is connected to the other end of the second section of the shape memory alloy line and extrudes a part, located between the groove and the micro-channel, of the PDMS coagulating body and the under pushing force to deform so as to block the micro-channel. The shape memory alloy micro valve has the beneficial effects of being simple in structure, small in size and easy to integrate.

Owner:NINGBO UNIV

Cable connecting device with firm connection

ActiveCN114361824AFirmly connectedEasy to holdElectric connection structural associationsWind energy generationStructural engineeringElectric cables

The invention relates to the technical field of cable connection, in particular to a firm-connection cable connecting device which comprises a fixing shell, connecting mechanisms are installed in the two ends of the fixing shell, two protection mechanisms are installed on the fixing shell, two closing mechanisms are installed on the fixing shell, and abutting mechanisms are installed on the closing mechanisms. Two groups of locking mechanisms are mounted on the fixed shell; through cooperative installation of the connecting mechanism and the fixing shell, two cables can be conveniently clamped and connected, and the cables are firmly connected and are not easy to loosen. Through the cooperation of the protection mechanism and the connection mechanism, the connection mechanism is not easy to loosen and clamp and fasten, through the cooperation of the closing mechanism and the abutting mechanism, the cable can be wound on the fixing shell in a J shape, the anti-pulling effect is achieved, the cable connection part is broken and slipped by reducing the pulling force, and the service life of the cable is prolonged. The importance of the locking mechanism is beneficial to locking protection of the closing mechanism, and cable loosening and breaking caused by opening of the closing mechanism are prevented.

Owner:徐州华隆热电有限公司

Stirring device for paint processing

ActiveCN112808070AImprove stirring and mixing effectIncrease extrusion areaShaking/oscillating/vibrating mixersTransportation and packagingPhysicsEngineering

The invention discloses a stirring device for paint processing, belonging to the field of paint processing. The stirring device for paint processing comprises a stirring box, wherein an equipment box is fixedly installed at the bottom of the stirring box; a driving device is arranged in the equipment box; a driving shaft is fixedly installed on an output shaft of the equipment box; and stirring blades are fixedly mounted on an annular gap in the side wall of the driving shaft. According to the stirring device for paint processing, through rotation of the stirring blades, elastic clamping rods on the stirring blades can be intermittently limited by clamping blocks on limiting balls and conduct stretching so a tilting rod drives a movable ball to conduct adjustment, then an inner ball in the driving shaft is limited by an adjusting rod and is synchronously adjusted, the inner ball limits a limiting rod to drive the limiting rod to be synchronously adjusted, and an upper block and a lower block move in paint in an up-and-down overturning manner; and therefore, the paint undergoes overturning in the stirring process, and the stirring and mixing effect of the paint is further improved.

Owner:山东申王工业科技有限公司

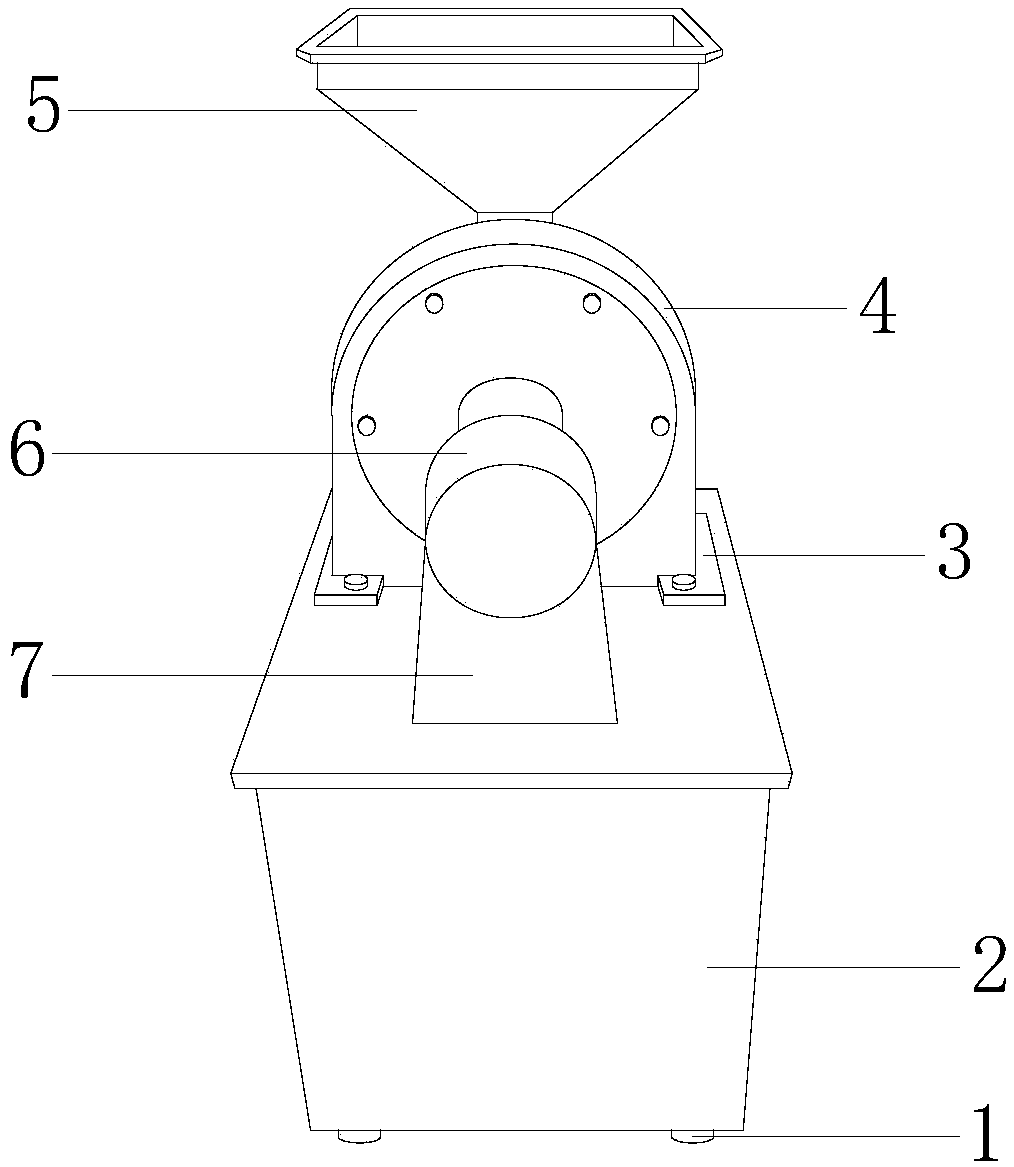

Oil paint raw material grinder

InactiveCN108855397AIncrease extrusion areaUniform particle sizeGrain treatmentsPulverizerMain bearing

The invention discloses an oil paint raw material grinder. The oil paint raw material grinder structurally comprises four supporting feet, a base, two limiting plate blocks, a grinding device, a feeding hopper, a main bearing and a stand; the supporting feet are uniformly mounted at the bottom end of the base in a clearance fit mode, the cross section of the base is of a rectangular structure, thebase is vertically fixed to the upper ends of the supporting feet and is of an integral structure with the grinding device, and the two limiting plate blocks are vertically attached to the top end ofthe base and fixed to the grinding device through nuts. The improved grinding device is reasonable in structure, and can bear the extremely high rotational inertia and the impact grinding force of agrinding plate hammer, the oil paint raw materials can be more uniformly ground through secondary grinding, and the oil paint raw material grinder has the advantages that less energy is consumed, andthe grinding efficiency is higher, and the oil paint raw material grinder is beneficial for large-scale production and application.

Owner:湖州御筵科技有限公司

Sticker attaching equipment for surface of solid wood door

ActiveCN110116447AReduce workloadReduce frictionWood working apparatusSolid woodElectrical and Electronics engineering

The invention relates to the field of wooden door production and particularly discloses sticker attaching equipment for the surface of a solid wood door. The sticker attaching equipment comprises a positioning mechanism and an extruding mechanism which are transversely arranged in sequence, wherein the positioning mechanism comprises a positioning block; a first channel and a second channel are arranged on the positioning block; the section of the second channel in the vertical direction is U-shaped; the first channel and the second channel transversely penetrate through the positioning block;glue adheres to two side walls and the bottom wall of the first channel; the bottom wall of the second channel is lower than that of the first channel; the two side walls of the first channel are positioned between those of the second channel; the extruding mechanism comprises a vertical extruding assembly and a transverse extruding assembly; the vertical extruding assembly comprises two verticalextruding rolls; the two vertical extruding rolls are correspondingly positioned on the upper and lower sides of the first channel, and transversely arranged; the transverse extruding assembly comprises two transverse extruding rolls; and the two transverse extruding rolls are correspondingly positioned on two sides of the first channel. By the adoption of the sticker attaching equipment disclosed by the invention, a sticker can be automatically attached to a door frame.

Owner:重庆市丰泽室内套装门有限责任公司

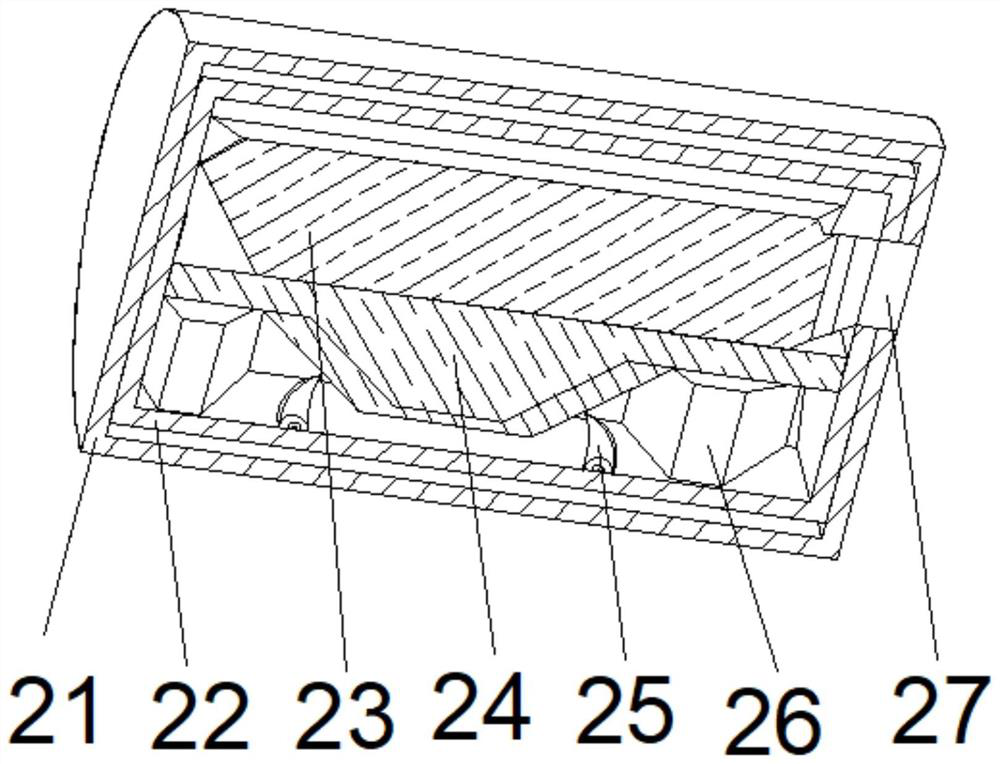

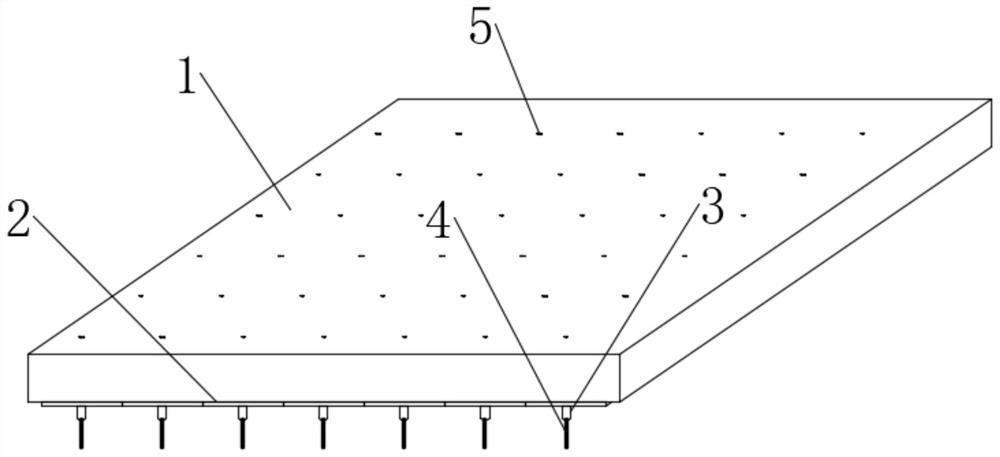

Water diversion shaking self-deoiling type water surface oil stain adsorption floating plate

InactiveCN111910600AIncrease extrusion areaImprove the effect of extrusion deoilingWater cleaningGeneral water supply conservationFiberOil separation

The invention discloses a water diversion shaking self-deoiling type water surface oil stain adsorption floating plate, and belongs to the technical field of environmental governance. The water diversion shaking self-deoiling type water surface oil stain adsorption floating plate can realize adsorption and recovery of water surface oil stains through a multi-section oil adsorption piece in a specially-made shape, and then centralize the water surface oil stains into a deoiling tank. An oil separation pipe extending out of the multi-section oil adsorption piece is matched with an oil passing water guiding fiber rod to penetrate through an oil layer to enter water, water is continuously sucked and conveyed to a main water retaining joint and then dispersed to a plurality of secondary water retaining net points, by means of the characteristic that a shaking oil pressing rod reacts when encountering water, the shaking oil pressing rod actively gets close to the multi-section oil adsorptionpiece to be extruded, the multi-section oil adsorption piece is forced to release absorbed oil liquid, then the oil liquid is recycled, meanwhile, the multi-section oil adsorption piece subjected tooil stain desorption can continuously adsorb oil stains on the water surface, oil suction and water suction are achieved at the same time, the sucked water serves as a power raw material, and shakingextrusion deoiling is conducted on the multi-section oil adsorption piece subjected to oil suction, so that oil suction amount of the multi-section oil adsorption piece is remarkably increased, and the treatment efficiency of the water surface oil stains is greatly improved.

Owner:方剑

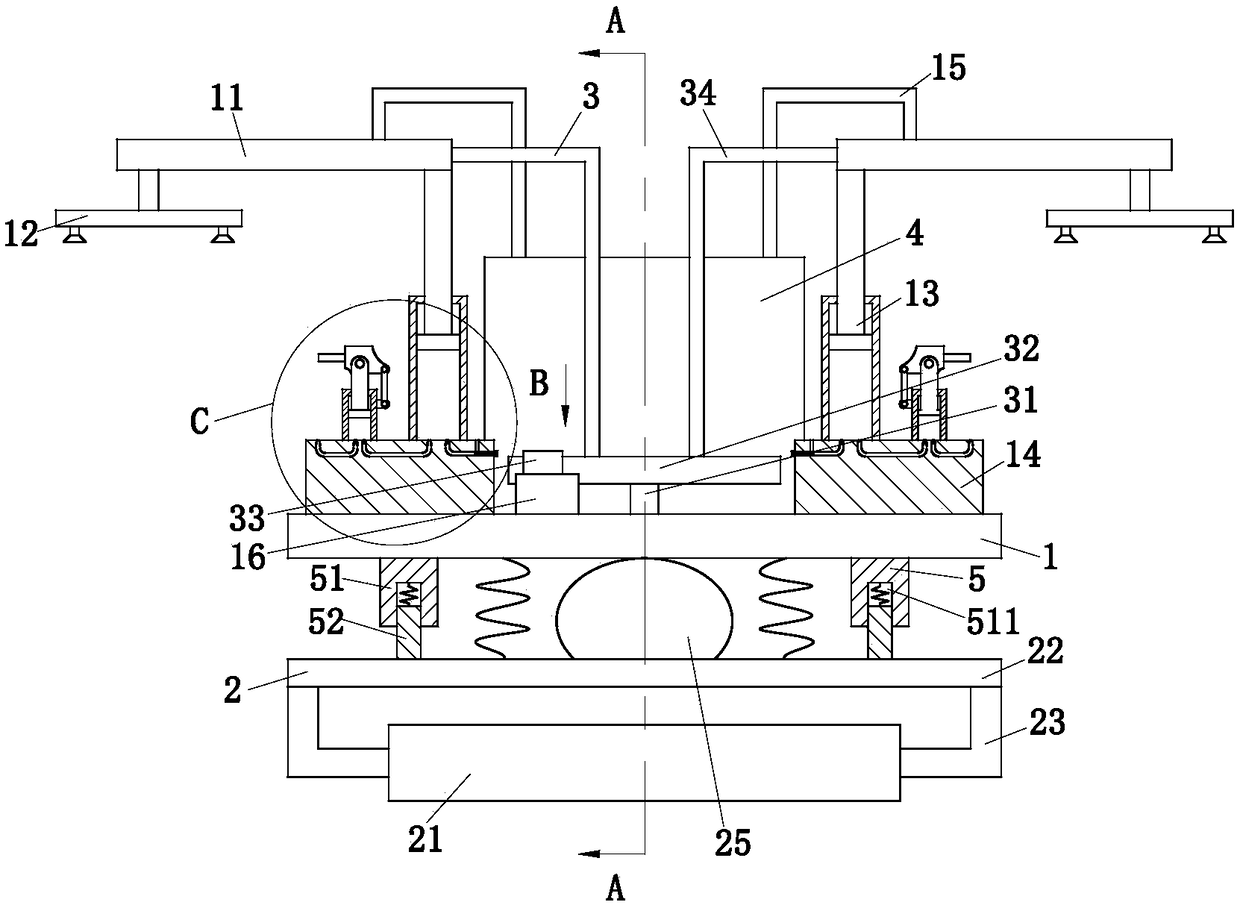

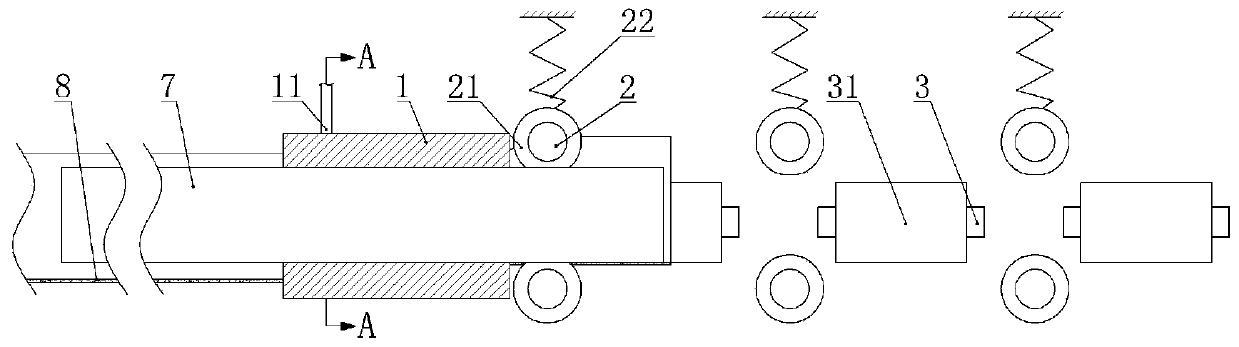

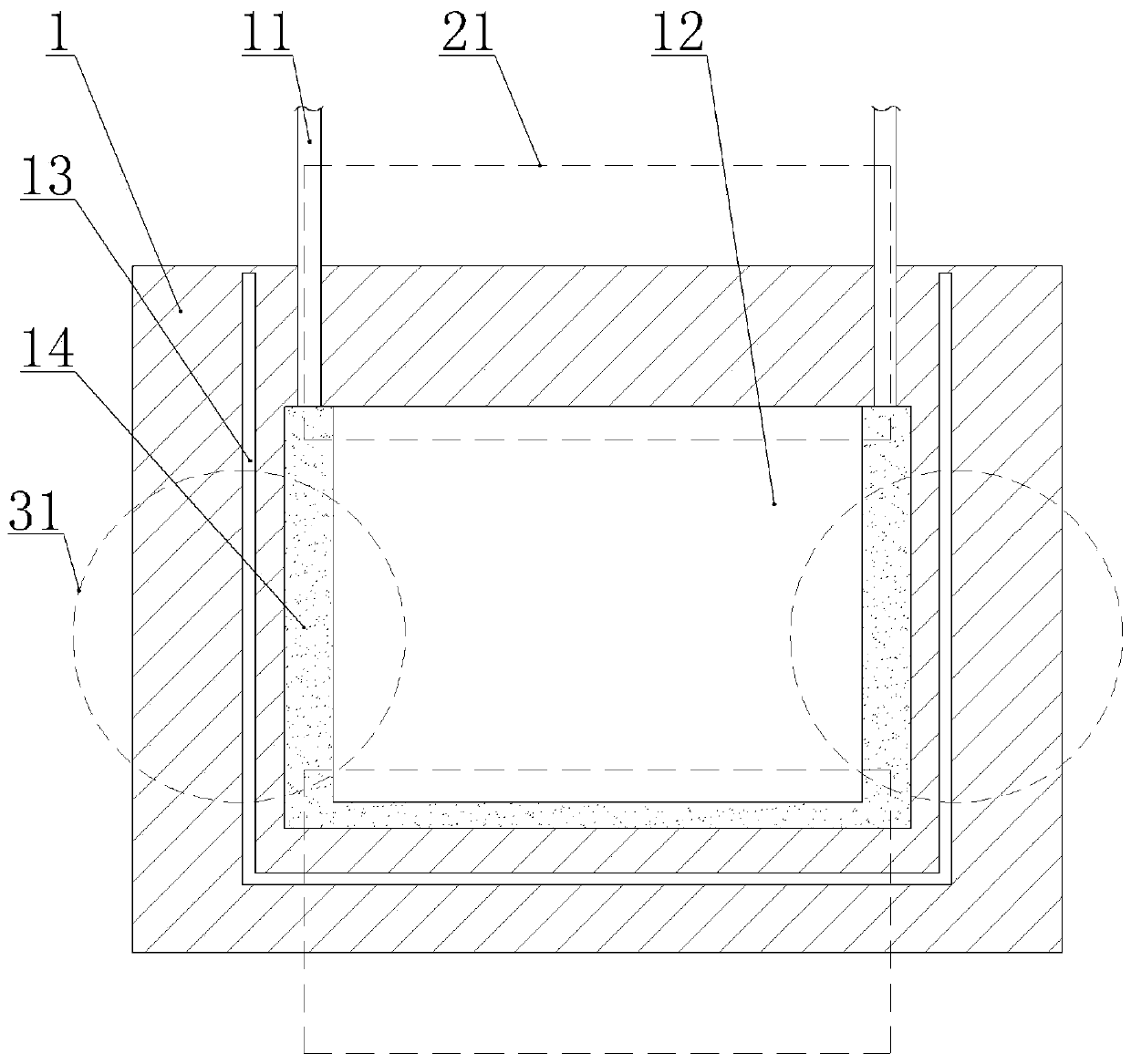

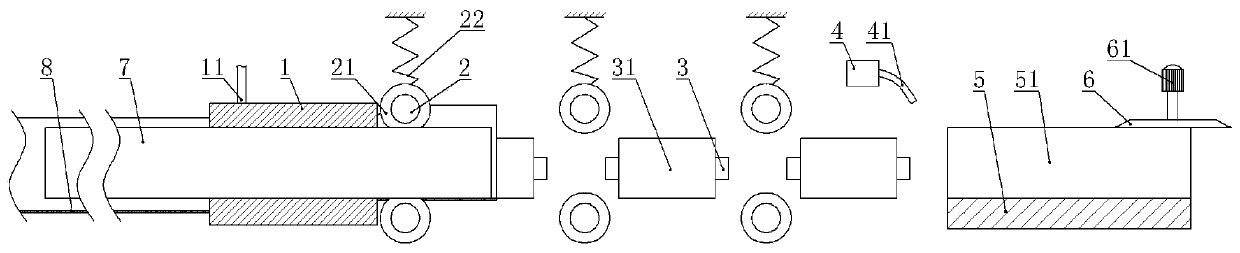

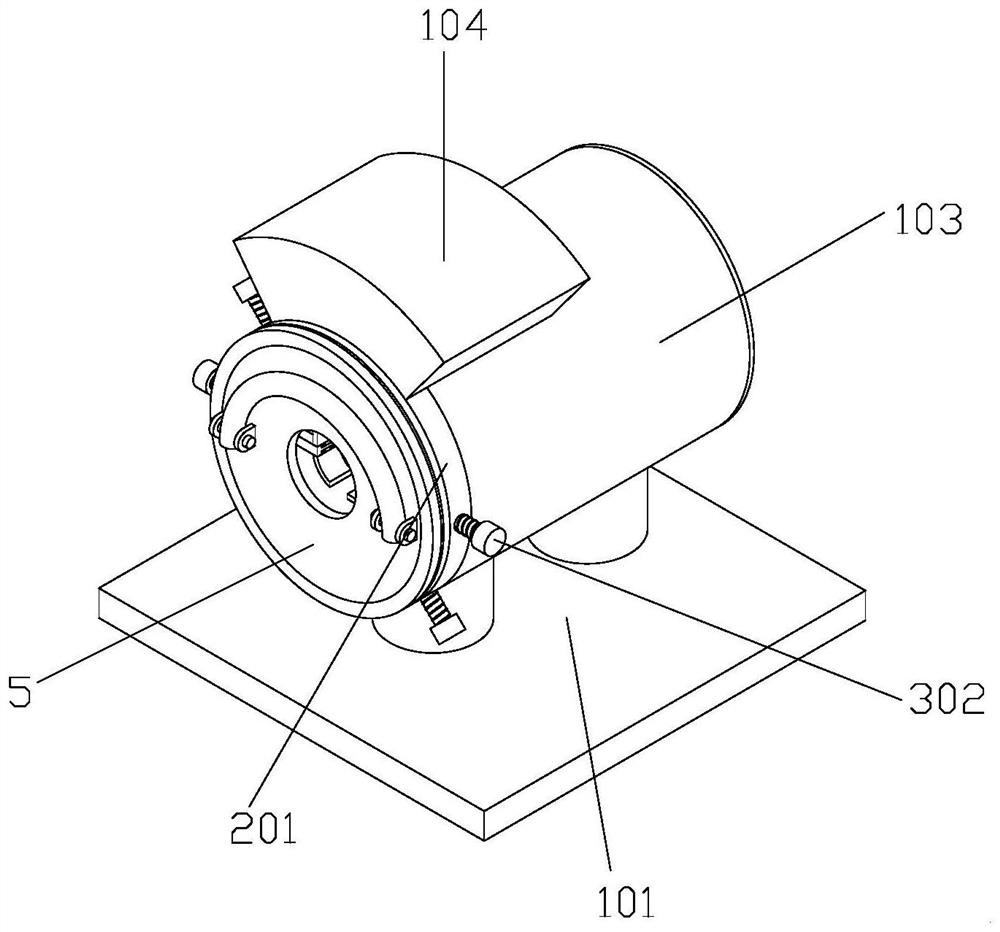

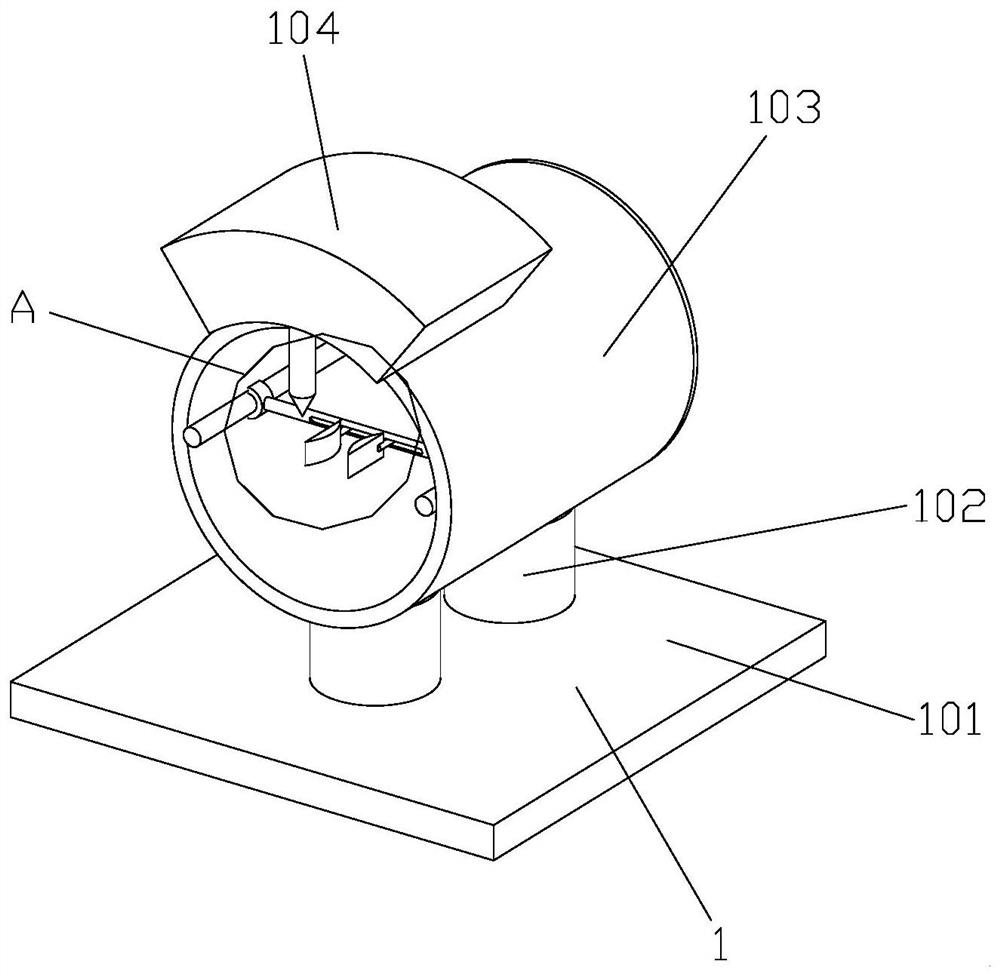

Disease and insect pest control equipment for agricultural and forest crops

ActiveCN109156458AAvoid harmImprove the effect of prevention and controlInsect catchers and killersDiseaseAgricultural engineering

The invention belongs to the technical field of agricultural equipment and particularly relates to disease and insect pest control equipment for agricultural and forest crops. The equipment comprisesa vehicle body, a water passage pipe and a sprinkling assembly. The equipment further comprises a driving unit, a swinging unit, an air cylinder I, a fixing block I, a fixing block II, a water tank and a hose. The driving unit is used for moving the vehicle body; and the swinging unit is used for enabling the sprinkling assembly to sprinkle uniformly. The driving unit and the swinging unit are matched with each other, so that on one hand, an insecticide solution is sprinkled to the agricultural and forest crops according to actual conditions, the sprinkling is uniform, the damage to the agricultural and forest crops caused by plant diseases and insect pests is avoided, and thus, the effect of disease and insect pest control on agriculture and forestry is improved; and on the other hand, apower source of the equipment is utilized, so that the utilization ratio of resources is increased, meanwhile, external power equipment is reduced, and thus, the manufacturing cost of the equipment isreduced.

Owner:会泽县国权种植有限责任公司

A kind of agricultural and forestry crop disease and insect pest control equipment

ActiveCN109156458BAvoid harmImprove the effect of prevention and controlInsect catchers and killersAgricultural scienceCrop pest

The invention belongs to the technical field of agricultural equipment, and is specifically a kind of equipment for controlling diseases and insect pests of agricultural and forestry crops, including a car body, a water pipe and a spraying assembly; block, tank and hose. The driving unit is used for the movement of the vehicle body; the swing unit is used for uniform spraying of the spraying assembly. Through the mutual cooperation between the driving unit and the swing unit, on the one hand, the agricultural and forestry crops are sprayed with the pesticide solution according to the actual situation, and the spraying is uniform, so as to avoid the damage of the agricultural and forestry crops by the pests and diseases, thereby improving the effect of the prevention and control of the agricultural and forestry pests and diseases; On the one hand, the power source of the agricultural and forestry pest control equipment is utilized, thereby improving the utilization rate of resources, and at the same time reducing the external power equipment, thereby reducing the manufacturing cost of the agricultural and forestry pest control equipment.

Owner:会泽县国权种植有限责任公司

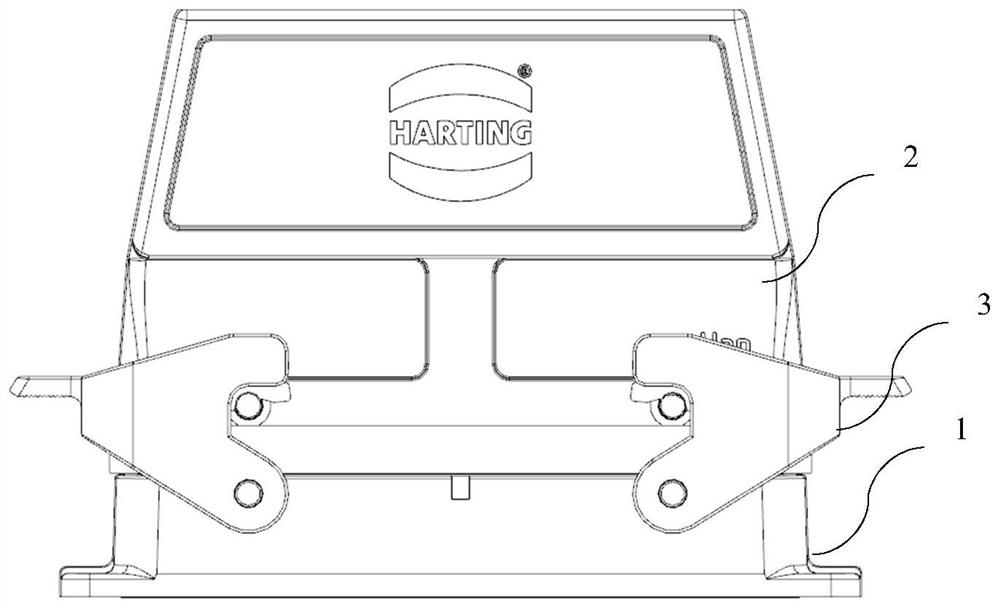

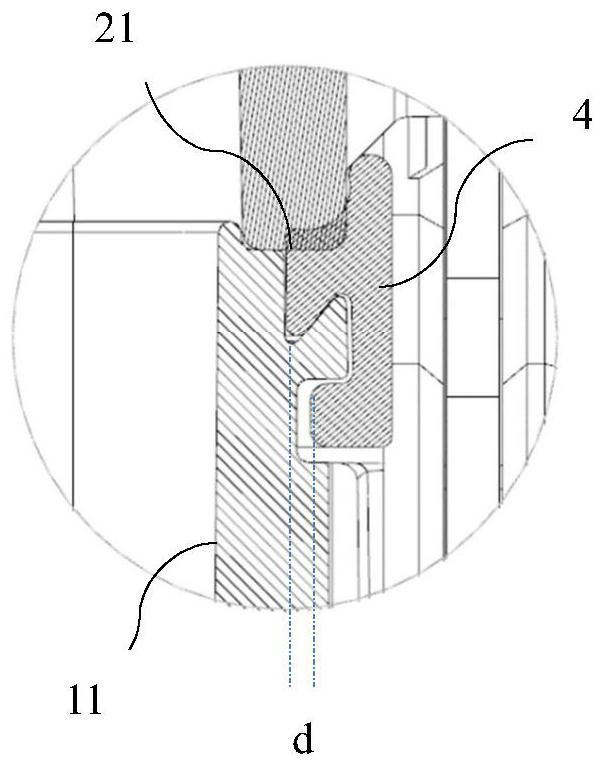

Connector housing assembly and connector housing including same

PendingCN112242630AHigh electromagnetic shieldingImprove waterproof sealing performanceCouplings bases/casesCoupling protective earth/shielding arrangementsStructural engineeringElectromagnetic shielding

Disclosed is a connector housing assembly, comprising a housing (1) having a housing end (1) surrounding an opening (12) thereof, and a sealing ring (4); one side surface of the shell end part (11) isbuckled and matched with one side surface of the sealing ring (4). Furthermore, a connector housing is disclosed, comprising a connector housing assembly and a cover (2); when the cover (2) and the housing (1) are in a closed state, an end face (21), which surrounds the opening thereof, of the cover (2) is partially in direct contact with the end face of the housing end (11) and partially pressesagainst the arcuate edge of the first projection (411); the first bulge (411) is completely combined with the first groove (111) in shape. Therefore, the electromagnetic shielding performance and thewaterproof sealing performance of the whole connector shell are improved.

Owner:HARTING ELECTRIC GMBH & CO KG

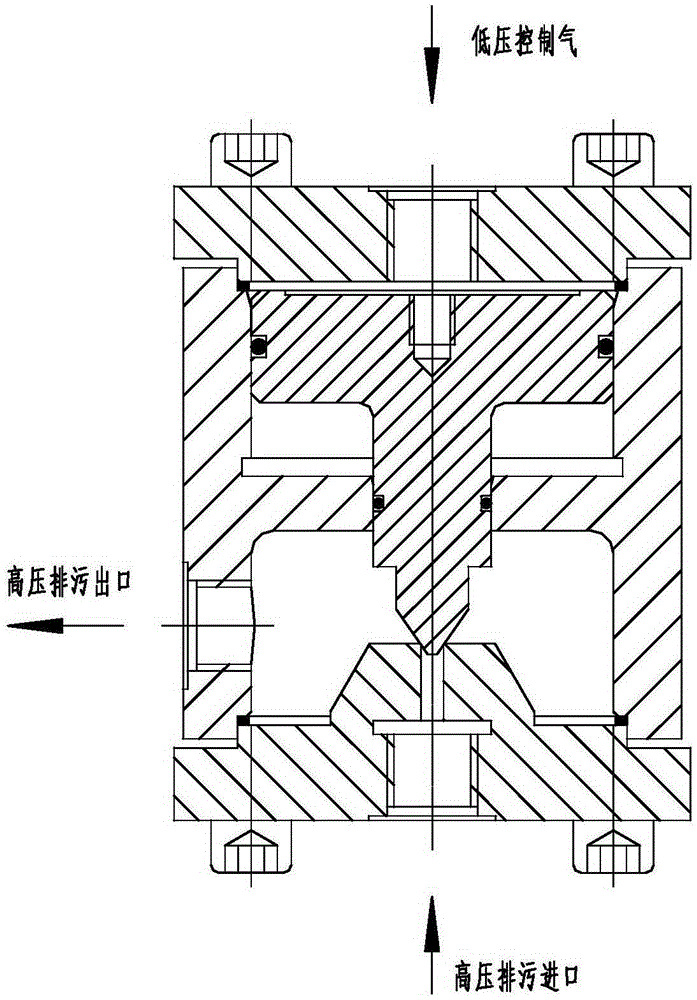

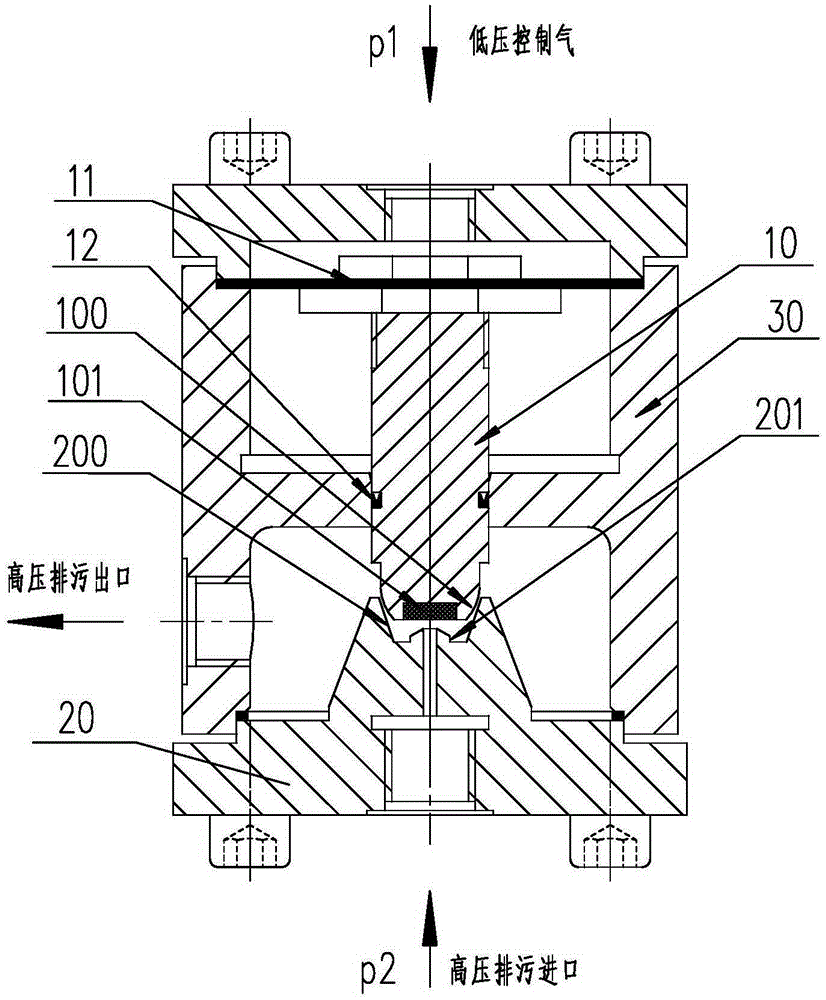

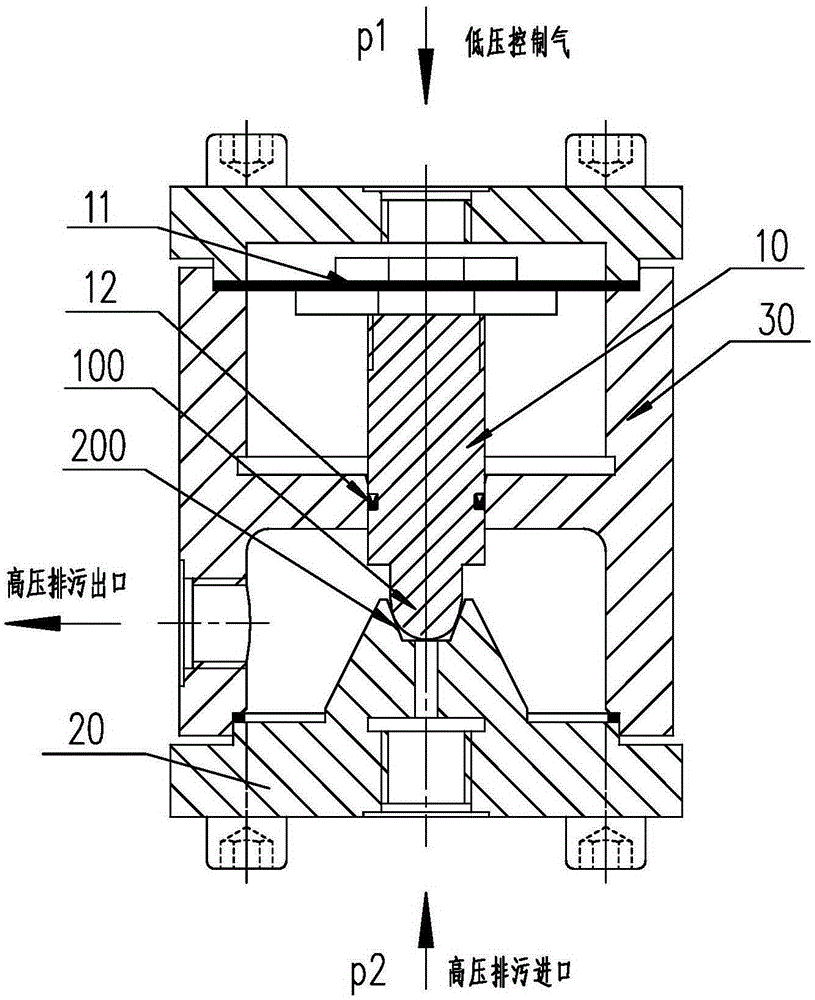

High-pressure pollution discharge pneumatic valve

ActiveCN105299303AImprove sealingReduce misalignmentOperating means/releasing devices for valvesLift valvePneumatic valveHigh pressure

The invention discloses a high-pressure pollution discharge pneumatic valve. The high-pressure pollution discharge pneumatic valve comprises a valve element, a valve seat and a valve body. The valve element is of a diaphragm type structure penetrating a rubber diaphragm to be connected with the rubber diaphragm through a locknut. The valve element is provided with a Y-shaped sealing ring, and the frictional resistance of the sealing ring during motion of the valve element can be effectively controlled while sealing between the valve element and the valve body is achieved. A valve seat sealing part matched with the sealing face of the lower end of the valve element to form sealing fit is arranged on the valve seat. The outer edge of the sealing face of the lower end of the valve element is arranged as a valve element spherical surface. The valve seat sealing part is matched with the valve element spherical surface through a valve seat inclined guiding surface to form primary sealing in the tangential direction of the spherical surface. The middle of the sealing face of the lower end of the valve element is provided with a plastic valve element filling block, and the valve seat sealing part is matched with the valve element filling block through a valve seat protruding block to form secondary sealing in the stroke direction of the valve element. The sealing performance of the pneumatic valve can be remarkably improved, and the problem that the pneumatic valve is not smoothly opened is effectively solved.

Owner:HEFEI GENERAL MACHINERY RES INST

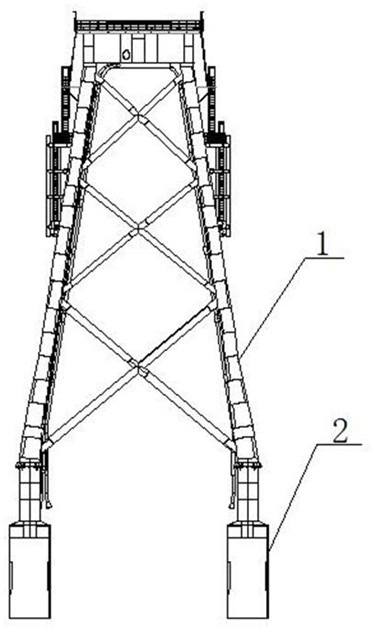

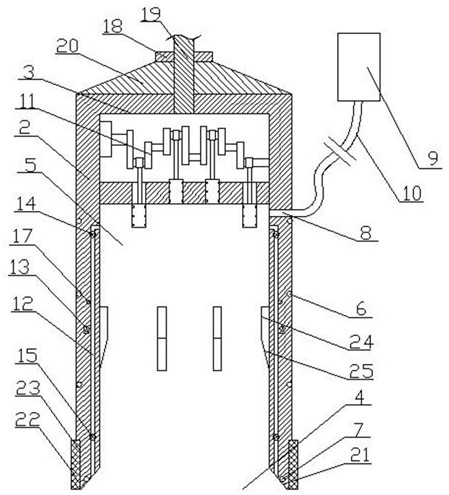

Liquefaction prevention method of offshore wind power jacket liquefaction prevention suction cylinder device

ActiveCN113502843AGuaranteed lateral stabilityReduce pore water pressureArtificial islandsFoundation testingSuction forceStructural engineering

The invention relates to a liquefaction prevention method of an offshore wind power jacket liquefaction prevention suction cylinder device. The suction cylinder device comprises a plurality of suction cylinder bodies arranged on the periphery of the lower end of a jacket, wherein a plurality of vertically distributed first pressure sensors are arranged on the outer side end faces of the suction cylinder bodies, a plurality of second pressure sensors are arranged at the lower end positions of the suction cylinder bodies, drainage holes communicating with a cavity are formed in the upper ends of the suction cylinder bodies, an extrusion assembly is arranged at the upper end position of the inner side of the cavity, a plurality of conduction pipes are arranged in the suction cylinder bodies, one ends of the conduction pipes are located at the upper end position of the inner side of the cavity, the other ends of the conduction pipes are located at the lower end positions of the suction cylinder bodies, and vacuum pumps are connected to the conduction pipes. The liquefaction prevention method has the following beneficial effects that efficient and rapid liquefaction prevention under the limit environment is achieved, and therefore the building stability of the jacket is guaranteed.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

Five-axis servo numerical control punching machine and working method thereof

PendingCN114160690AEasy to operatePrecise positioningMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a five-axis servo numerical control punching machine and a working method thereof, and relates to the technical field of numerical control machine tools. According to the five-axis servo numerical control punching machine and the working method thereof, the five-axis servo numerical control punching machine comprises a base device, the base device comprises a base, the upper surface of the base is fixedly connected with a bottom column, the upper end of the bottom column is fixedly connected with a rear base, a frame device is arranged in front of the rear base and comprises a frame ring, and the rear end face of the frame ring is fixedly connected to a front port of the base; a punching hole is formed in the middle of the upper side of the frame ring, the position of the punching column is right opposite to the punching hole, the lower end of the punching column is inserted into the punching hole, a first threaded hole and a second threaded hole are formed in the side wall of the frame ring, two adsorption rods are fixedly connected to the inner side wall of the frame ring, and the two adsorption rods are arranged in a central symmetry mode; the adsorption rod is in an L shape, the end, away from the frame ring, of the adsorption rod is fixedly connected with a pressing block, and the five-axis servo numerical control punching machine and the working method thereof are easy and fast to operate.

Owner:张永伟

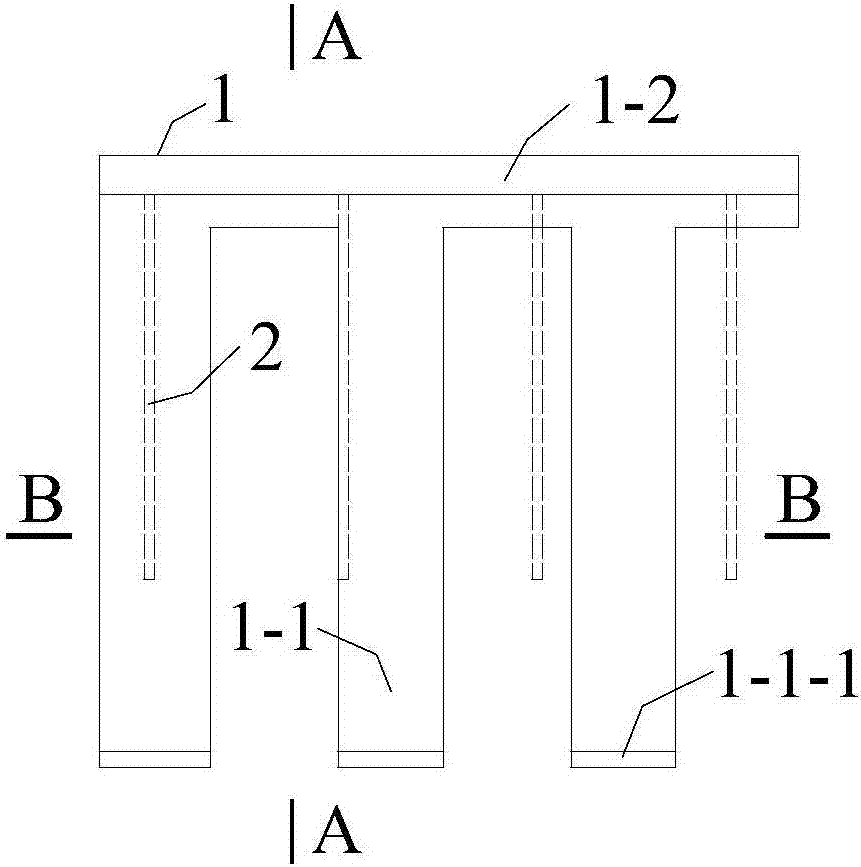

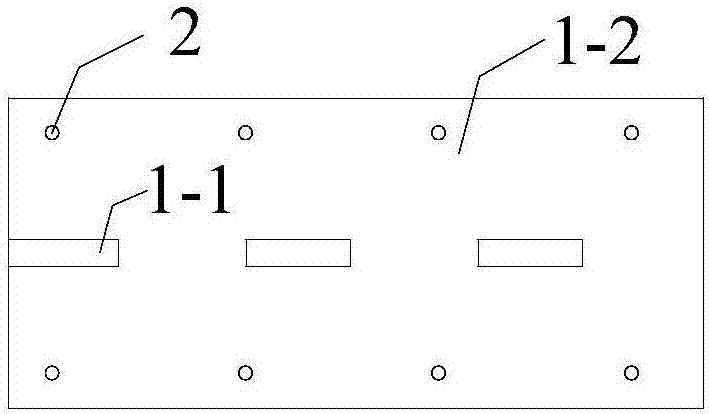

High performance pre-embedded steel anchor plate

The invention discloses a high performance pre-embedded steel anchor plate. The high performance pre-embedded steel anchor plate comprises toothed T-shaped plates and anchor bars. Webs of the toothed T-shaped plates are toothed. A hooping is passed through the gap between every two teeth. The width of one single tooth is smaller than the net spacing of the hooping. The anchor bars are welded to two side flanges of the webs of the toothed T-shaped plates. each toothed T-shaped plate is formed by cutting a web of I-shaped steel in a staggered mode, and the toothed webs of the toothed T-shaped plates and the flanges are formed in a whole. Lower anchor plates are welded to the ends of the T-shaped plates or the protruding plates are bent to form L-shaped anchor plates, so that the anchoring capacity in concrete is enhanced. The protruding plates of the T-shaped plates correspond to joint plates in position and force can be more effectively transmitted; the "integral molding" mode of staggered cutting is mature in process, materials are saved, the cost is reduced, welding can be avoided and the performance is improved; the space of cutting can be flexibly adjusted according to the location of the concrete component hooping to reduce the difficulty of construction.

Owner:SOUTHEAST UNIV

A shape memory alloy microvalve based on surface acoustic wave and its control method

ActiveCN106247006BAchieve closureIncrease in sizeValve arrangementsShape-memory alloySurface acoustic wave sensor

The invention discloses a shape memory alloy micro valve based on acoustic surface waves and a control method of the shape memory alloy micro valve. The shape memory alloy micro valve comprises a PCB, an acoustic surface wave excitation device, a PDMS coagulating body with a micro-channel and a shape memory alloy line formed by a first crooked section at the indoor temperature and a second straight section at the indoor temperature; the acoustic surface wave excitation device and the PDMS coagulating body are installed on the PCB, a groove is formed in the PDMS coagulating body, and the other end of the shape memory alloy line is connected with the PCB; the section, stretching across a propagation path of the acoustic surface waves excited by the acoustic surface wave excitation device and located on the propagation path, of the shape memory alloy line is covered with paroline micro liquid on the propagation path; and the second section of the shape memory alloy line is sleeved with a guide pipe connected with the PCB, and a plastic sheet is connected to the other end of the second section of the shape memory alloy line and extrudes a part, located between the groove and the micro-channel, of the PDMS coagulating body and the under pushing force to deform so as to block the micro-channel. The shape memory alloy micro valve has the beneficial effects of being simple in structure, small in size and easy to integrate.

Owner:NINGBO UNIV

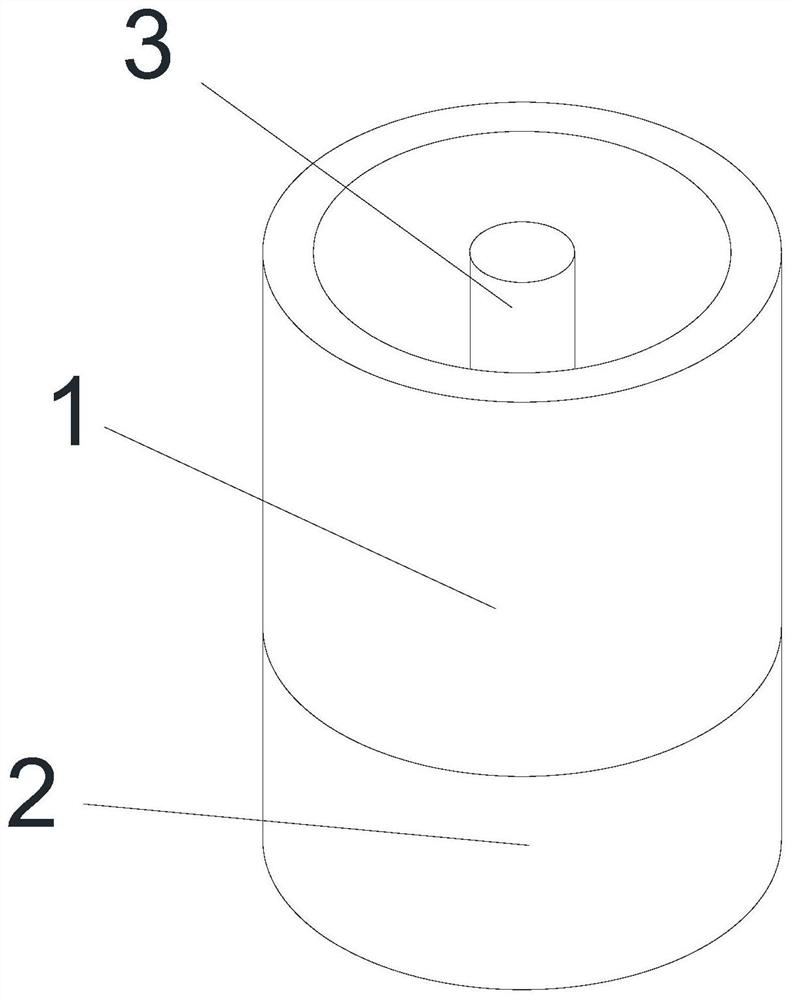

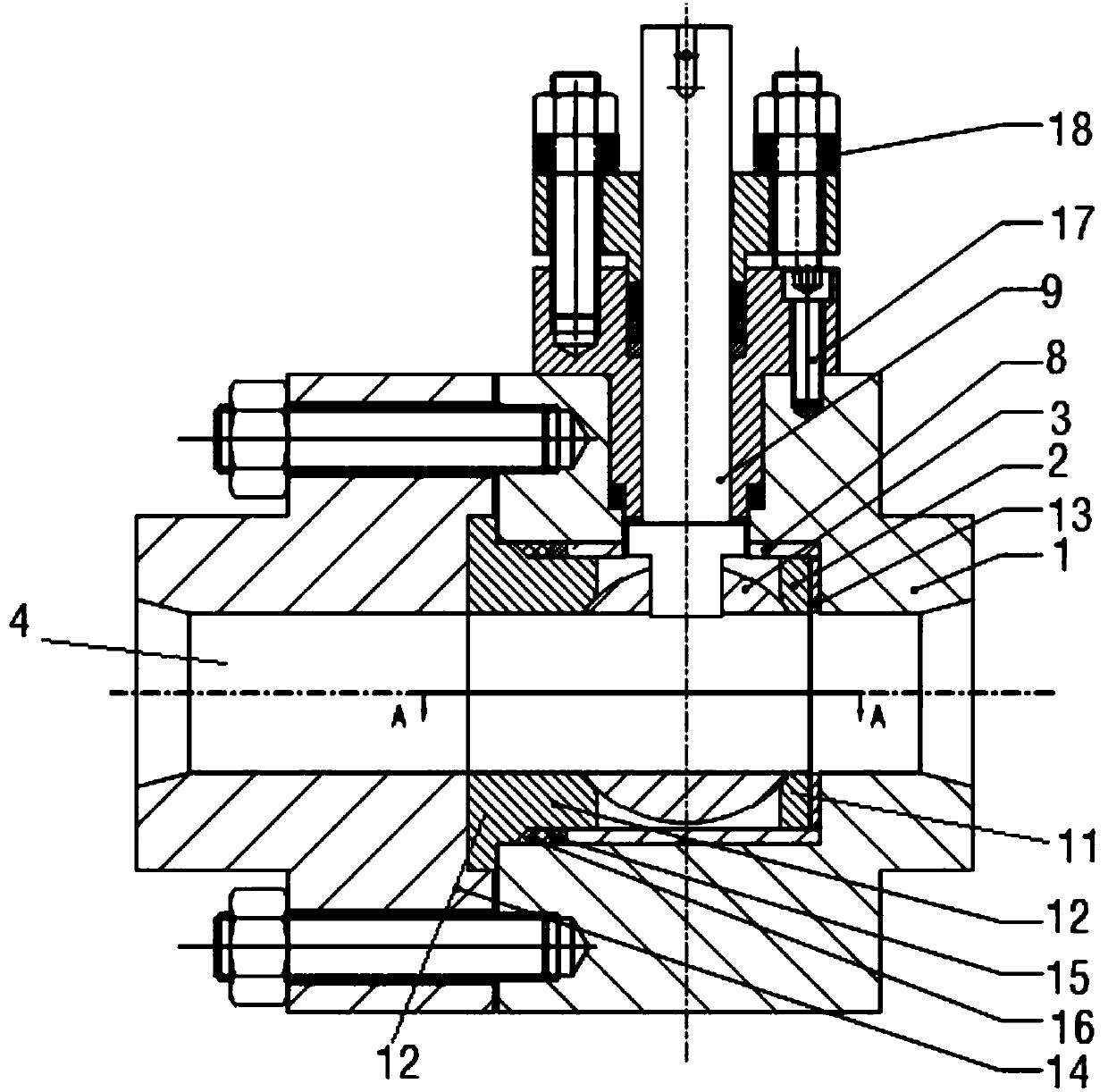

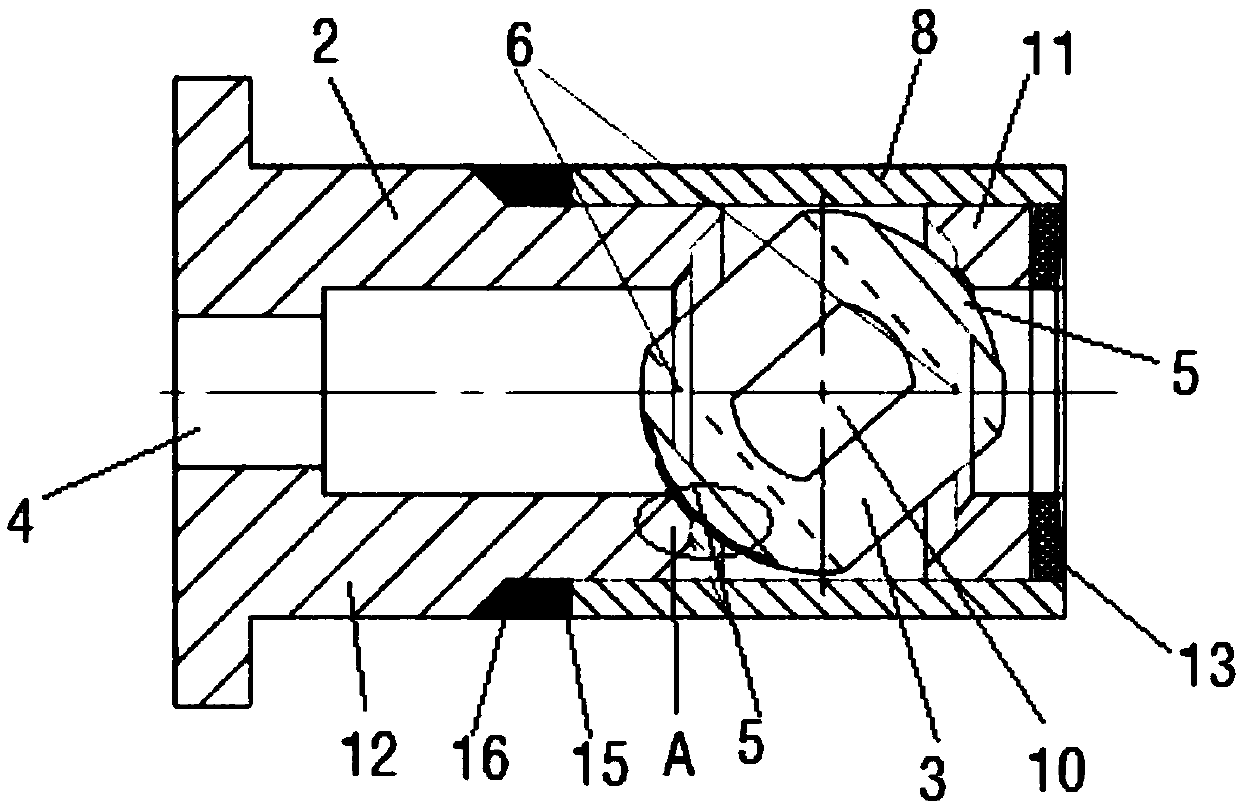

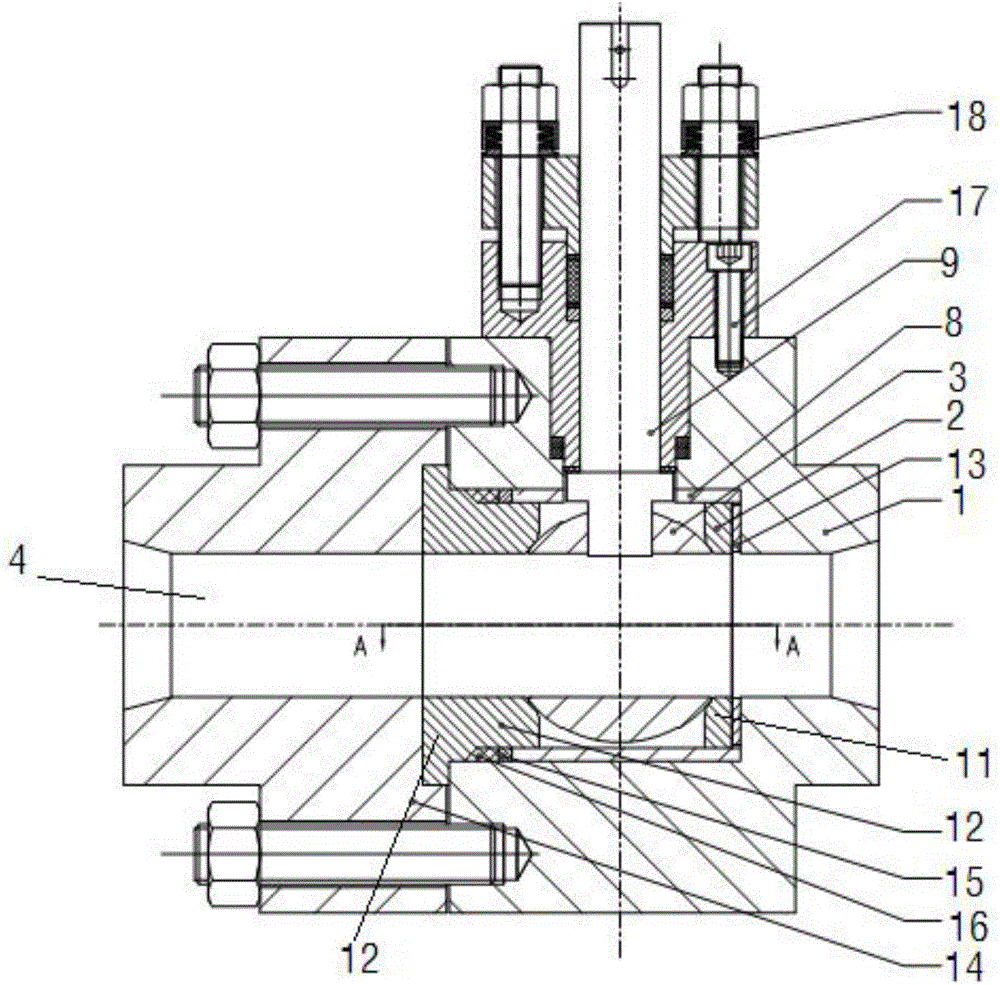

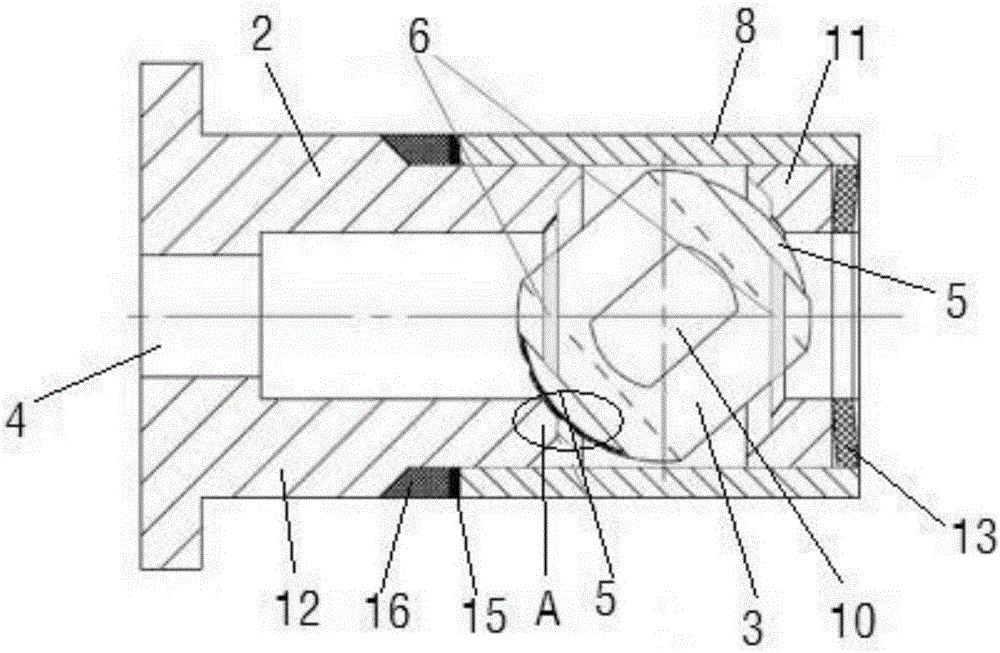

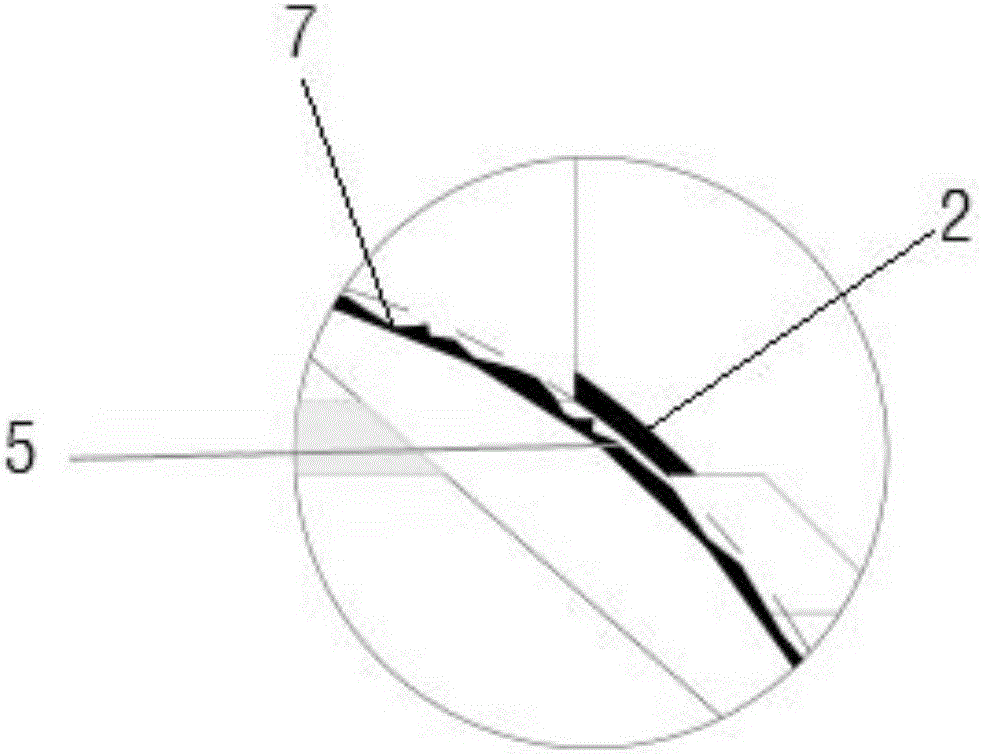

A semi-contact sealed ball valve

ActiveCN105972241BExtended service lifeReduce impactSpindle sealingsPlug valvesEngineeringContact type

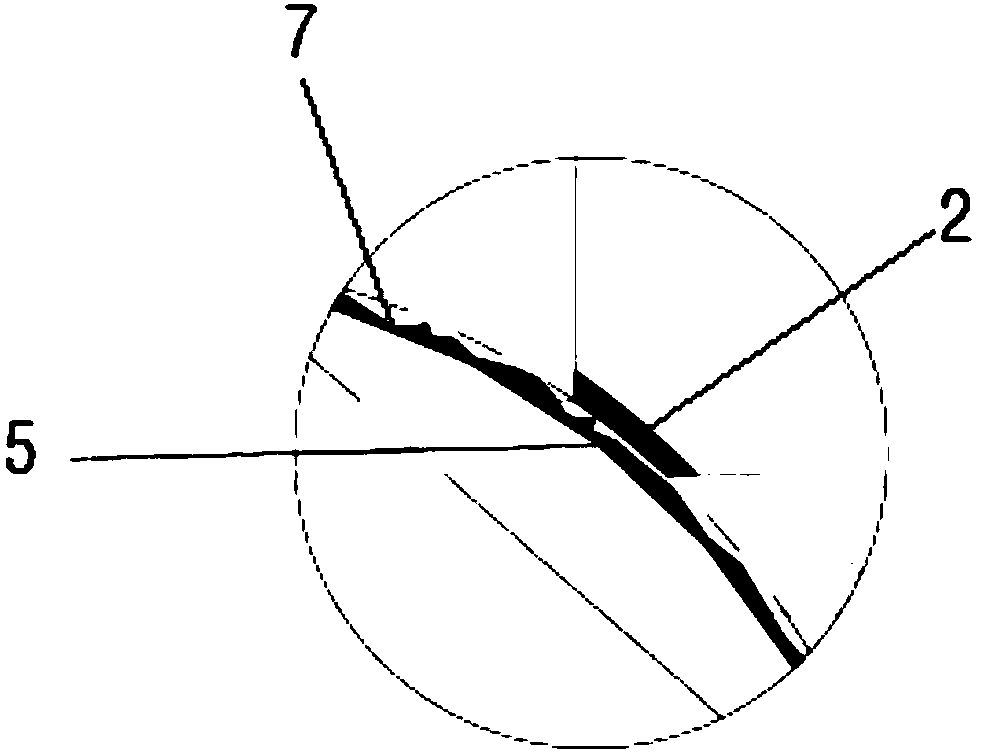

The invention discloses a semi-contact type sealing ball valve which comprises a valve body (1), valve seats (2) and a ball body (3). A fluid channel (4) is arranged in the valve body (1). The two opposite valve seats (2) are arranged on the fluid channel (4). The ball body (3) is arranged between the two valve seats (2) in a sealed manner. The surface of the ball body (3) is a non-continuous ball surface. The non-continuous ball surface comprises first ball surface bodies (5) located on the inner rings of sealing lines of the valve seats (2), and second ball surface bodies (6) making contact with the sealing lines of the valve seats (2) and having a sealing effect. The diameter of the first ball surface bodies (5) is smaller than the diameter of the second ball surface bodies (6). By means of the semi-contact type sealing ball valve, damage of corrosive media and media likely to be crystallized to the ball valve can be extremely effectively removed, and the service life of the valve is greatly prolonged.

Owner:KUSN WEISA VALVE

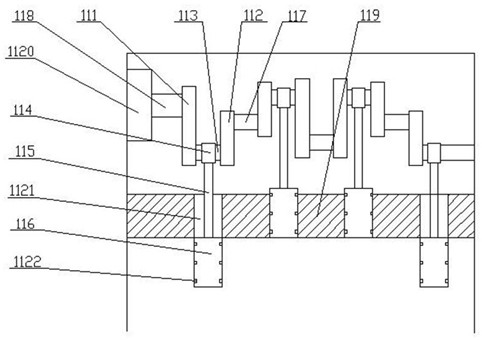

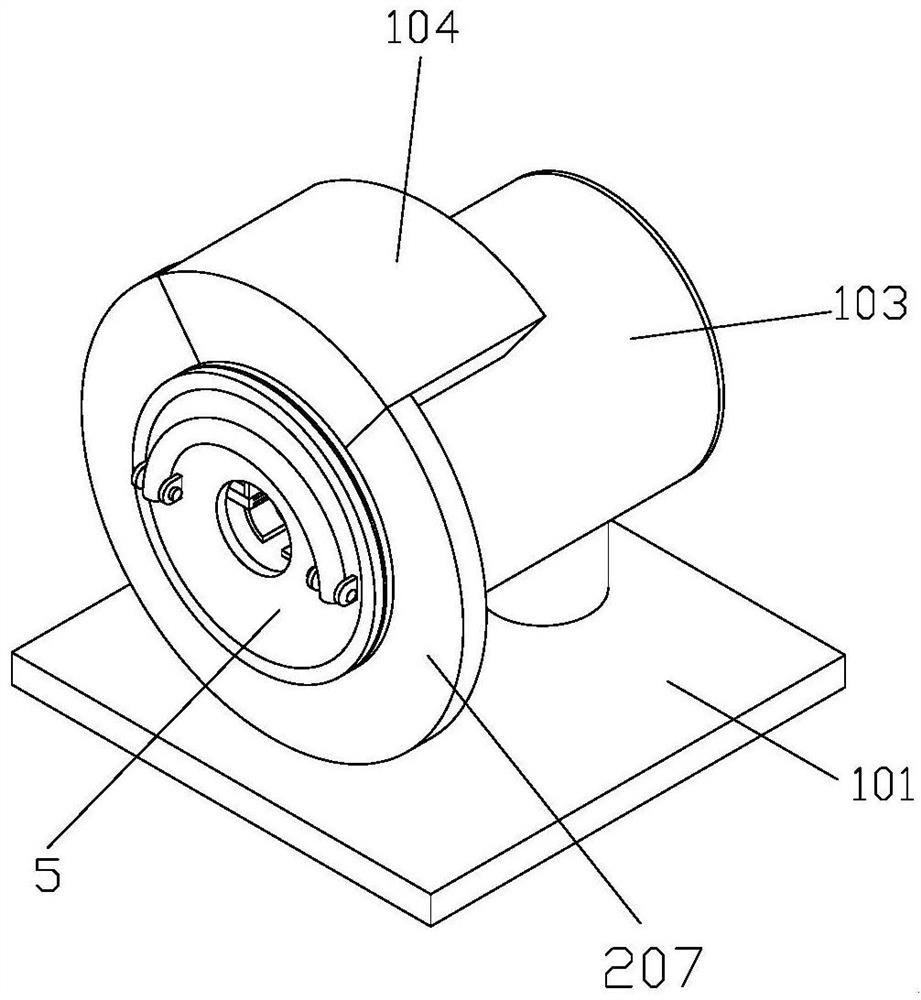

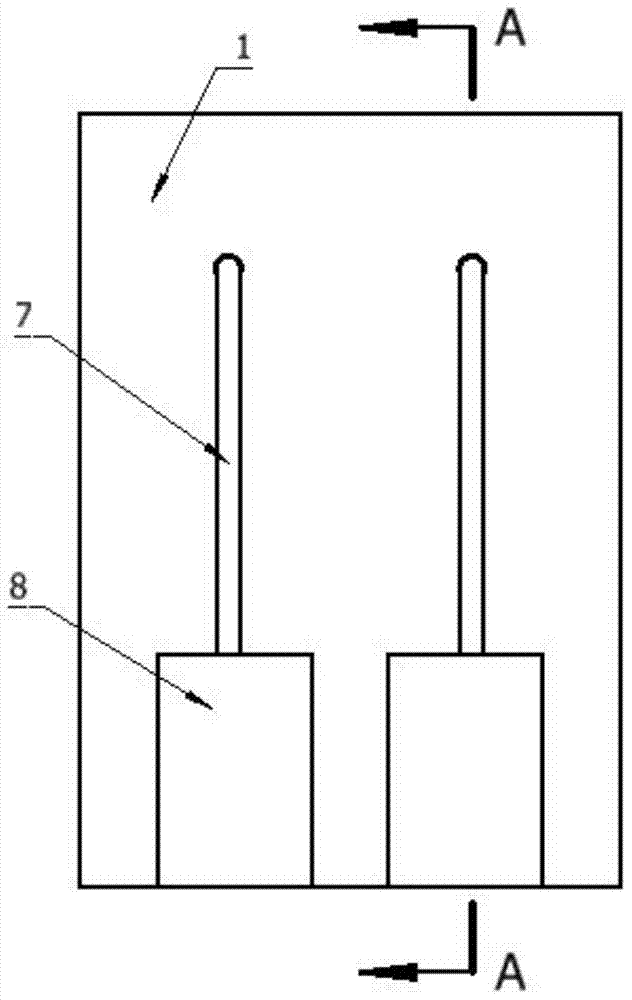

Engagement cooling apparatus of extruder

The invention relates to an engagement cooling apparatus of an extruder. The apparatus comprises a driving shaft and a driven shaft which are horizontal and are arranged in a mutual parallel manner; gear sleeves are sleeved on the driving shaft and the driven shaft respectively; a plurality of water slots are arranged between the driving shaft or the driven shaft and the gear sleeves; one end of each of the driving shaft and the driven shaft is provided with a water inlet hole, and the other end of each of the driving shaft and the driven shaft is provided with a water outlet hole; water inlet holes and water outlet holes are respectively connected with two ends of the water slots; the driving shaft and the driven shaft are correspondingly arranged on a support; the bottom of the support is provided with a water tank; one side of the support close to the water inlet holes is provided with at least one cooling water pump; the cooling water pumps are connected with the water tank through water suction holes; the cooling water pumps are respectively connected with the water inlet holes through water inlet tubes; and each of the water outlet holes is connected with the water tank through a water outlet tube. The apparatus improves the product cooling speed by increasing the extrusion area.

Owner:苏州普勒新材料有限公司

Semi-contact type sealing ball valve

ActiveCN105972241AExtended service lifeReduce impactSpindle sealingsPlug valvesEngineeringContact type

The invention discloses a semi-contact type sealing ball valve which comprises a valve body (1), valve seats (2) and a ball body (3). A fluid channel (4) is arranged in the valve body (1). The two opposite valve seats (2) are arranged on the fluid channel (4). The ball body (3) is arranged between the two valve seats (2) in a sealed manner. The surface of the ball body (3) is a non-continuous ball surface. The non-continuous ball surface comprises first ball surface bodies (5) located on the inner rings of sealing lines of the valve seats (2), and second ball surface bodies (6) making contact with the sealing lines of the valve seats (2) and having a sealing effect. The diameter of the first ball surface bodies (5) is smaller than the diameter of the second ball surface bodies (6). By means of the semi-contact type sealing ball valve, damage of corrosive media and media likely to be crystallized to the ball valve can be extremely effectively removed, and the service life of the valve is greatly prolonged.

Owner:KUSN WEISA VALVE

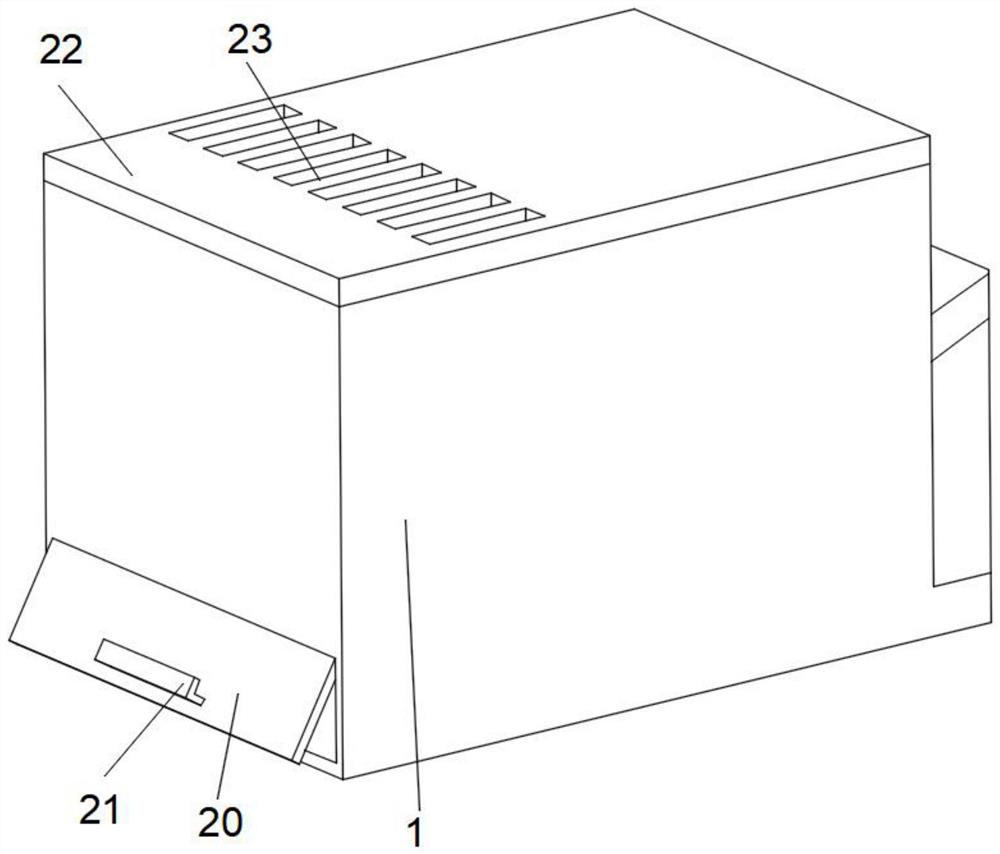

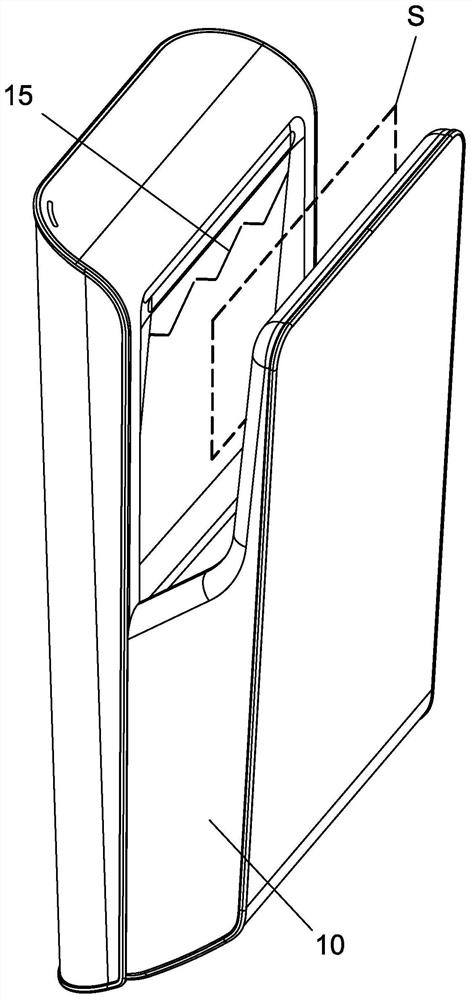

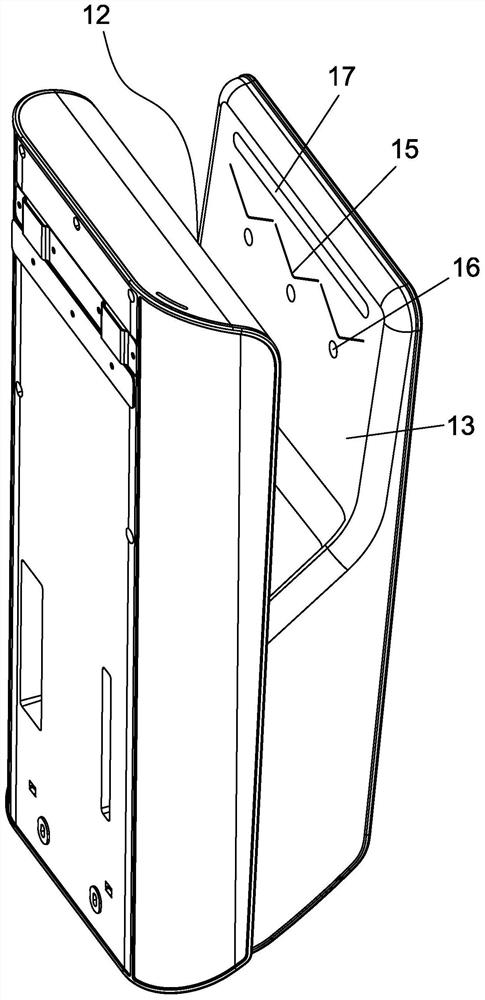

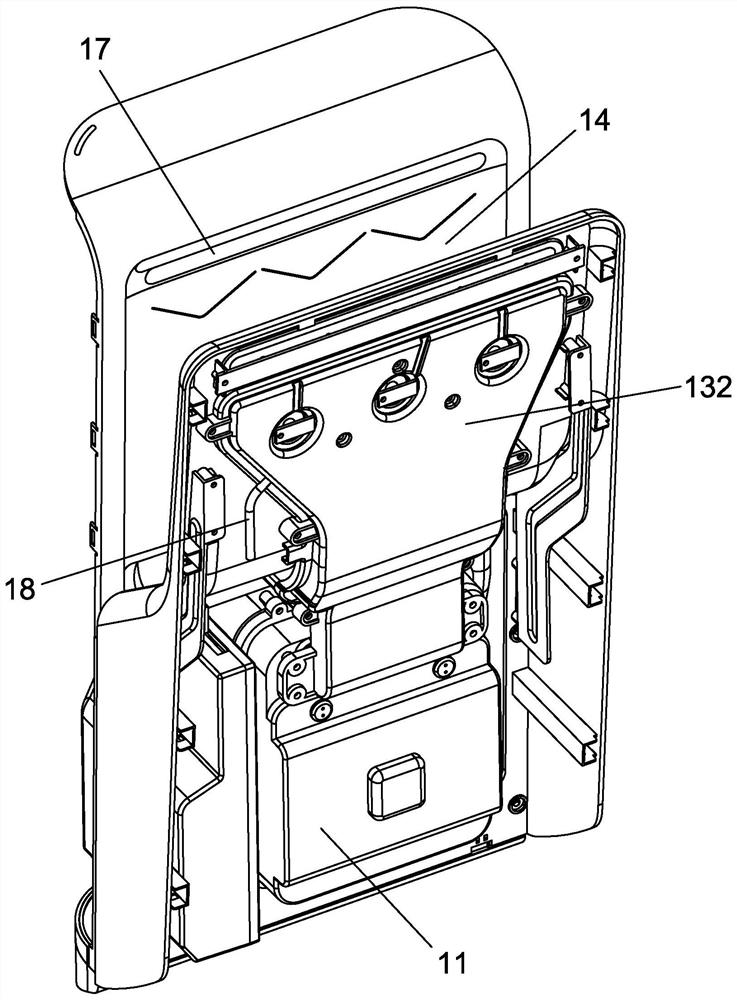

Washing and drying integrated hand dryer

PendingCN111870167AImprove drying efficiencyFeel comfortableLighting elementsBathroom accessoriesWashing handsHand parts

The invention provides a washing and drying integrated hand dryer, which comprises a shell, an air blower is arranged in the shell, a hand drying groove with an upward opening and penetrating throughthe left side and the right side of the shell is formed in the shell; the positions, close to a top opening, of the front groove wall and the rear groove wall of the hand drying groove are each provided with an air outlet channel, the section of each air outlet channel is wavy and is arranged from left to right or a plurality of air outlet channels are arranged from left to right, and the sectionof each single air outlet channel is V-shaped and is arranged from left to right; a front air distribution channel used for supplying air to the air outlet channel in the front groove wall is formed in the face, back to the rear groove wall, of the front groove wall, and a rear air distribution channel used for supplying air to the air outlet channel in the rear groove wall is formed in the face,back to the front groove wall, of the rear groove wall. Water supply pipes are arranged in the front air distribution channel and the rear air distribution channel, water distribution pipes are arranged on the water supply pipes, and a plurality of capillary pipes communicated into the air outlet channel are arranged on the water distribution pipes. The washing and drying integrated hand dryer hasthe advantages of being capable of being used for washing hands, low in water consumption, high in drying efficiency and capable of increasing air flow and guaranteeing orderly blowing of water dropson the hands.

Owner:제지앙인터하사인텔리전트테크놀로지컴퍼니리미티드

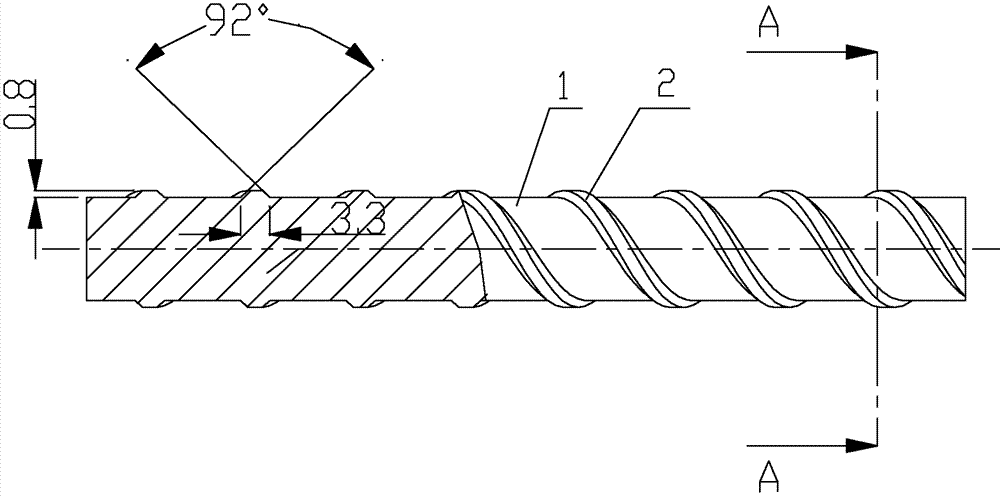

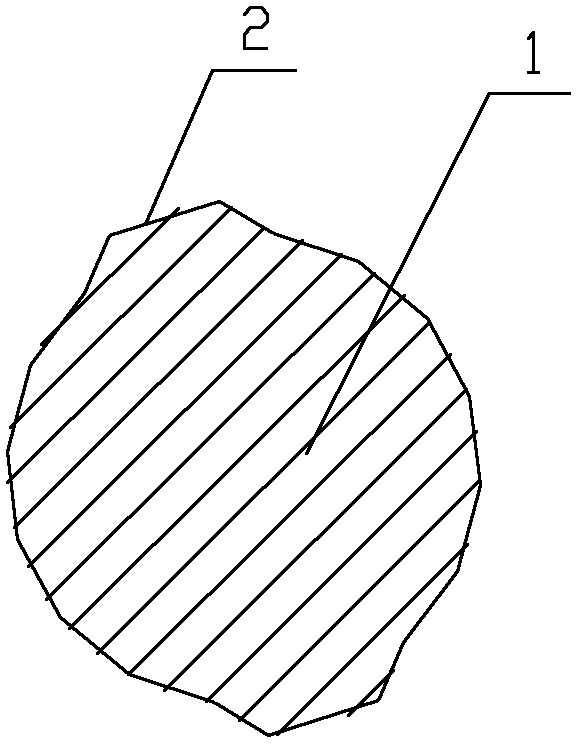

High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

The invention relates to a reinforcing steel bar and a processing method thereof, in particular to a high-strength reinforcing steel bar with spiral fins and a processing method of the high-strength reinforcing steel bar. The high-strength reinforcing steel bar consists of following components including, in weight percentage, from 0.25 to 0.4% of C, from 0.1 to 0.2% of Si, from 0.3 to 0.45% of Mn, from 0.04 to 0.05% of Nb, from 0.08 to 0.09% of Cr, from 0.01 to 0.04% of V, from 0.002 to 0.003% of B, from 0.001 to 0.003% of Mo, from 0.015 to 0.03 of Al, from 0.002 to 0.003% of S, from 0.008 to0.009% of Ti, from 0.004 to 0.005% of Ni, from 3 to 5% of composite rear earth and the balance Fe. The processing method includes using a roll to roll a reinforcing steel bar into a reinforcing steelbar with the continuous spiral fins on the surface in a hot state; feeding the reinforcing steel bar with the continuous spiral fins on the surface after hot rolling into a heating furnace and heating the reinforcing steel bar to the temperature of 880-990 DEG C; then fast cooling the reinforcing steel bar to the temperature of 650-680 DEG C by an online cooling device via compressed air or vaporous quenching liquid; quenching in a quenching device by water or quenching liquid for 15-25 seconds; and tempering after heating the reinforcing steel bar to the temperature of 500-550 DEG C via a tempering heating furnace. The high-strength reinforcing steel bar with the spiral fins has a good anchoring property, fine ductility and a high yielding-to-tensile ratio.

Owner:TIANSHUN GROUP +2

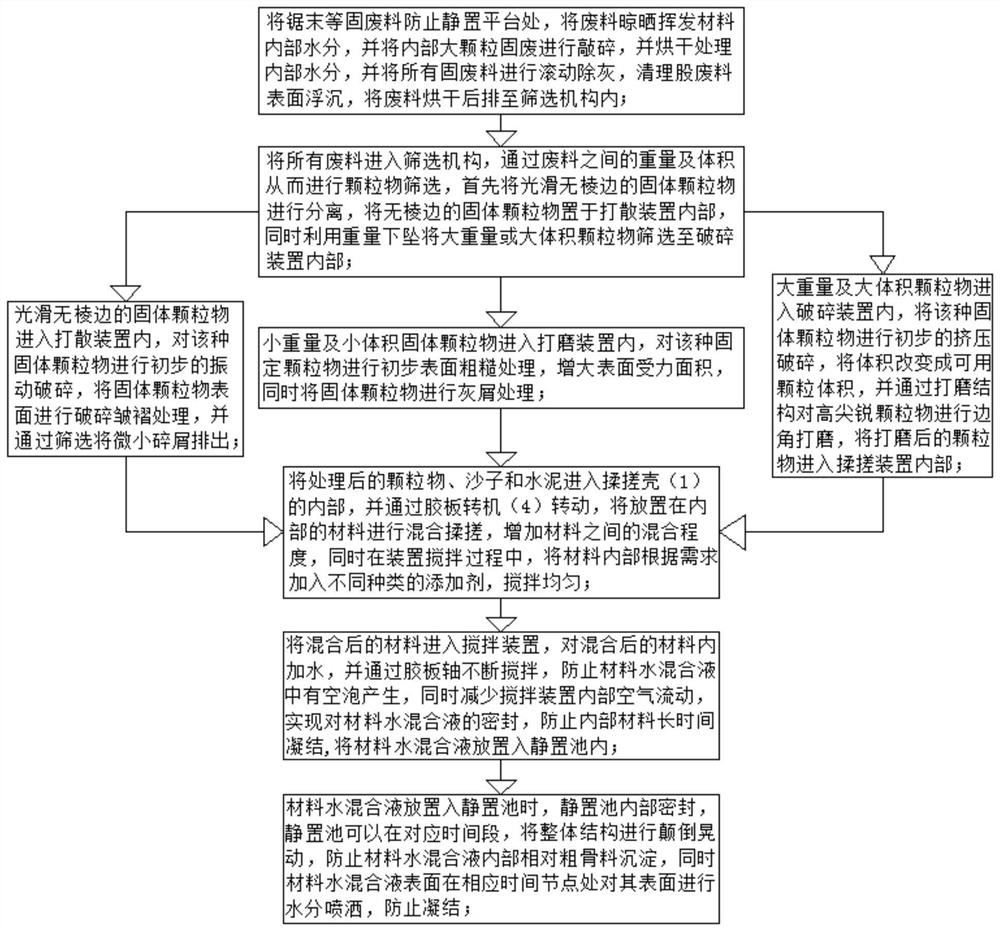

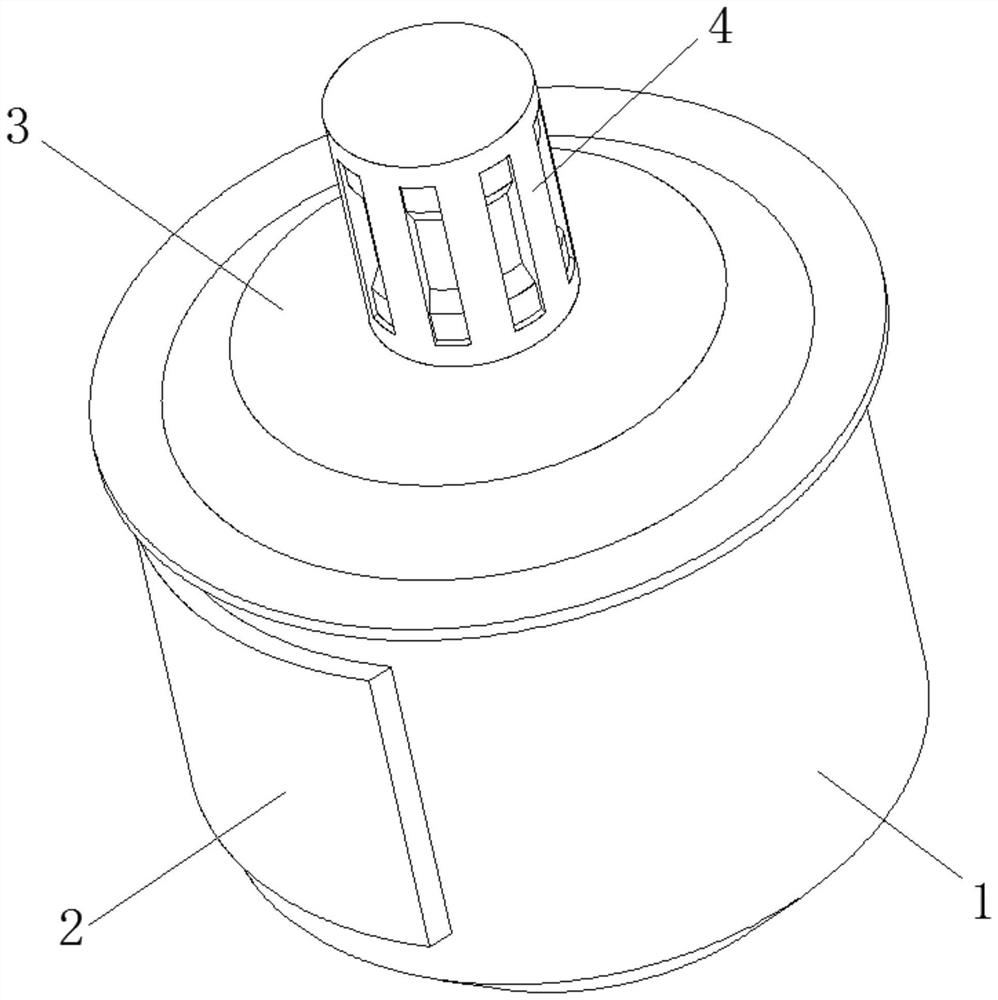

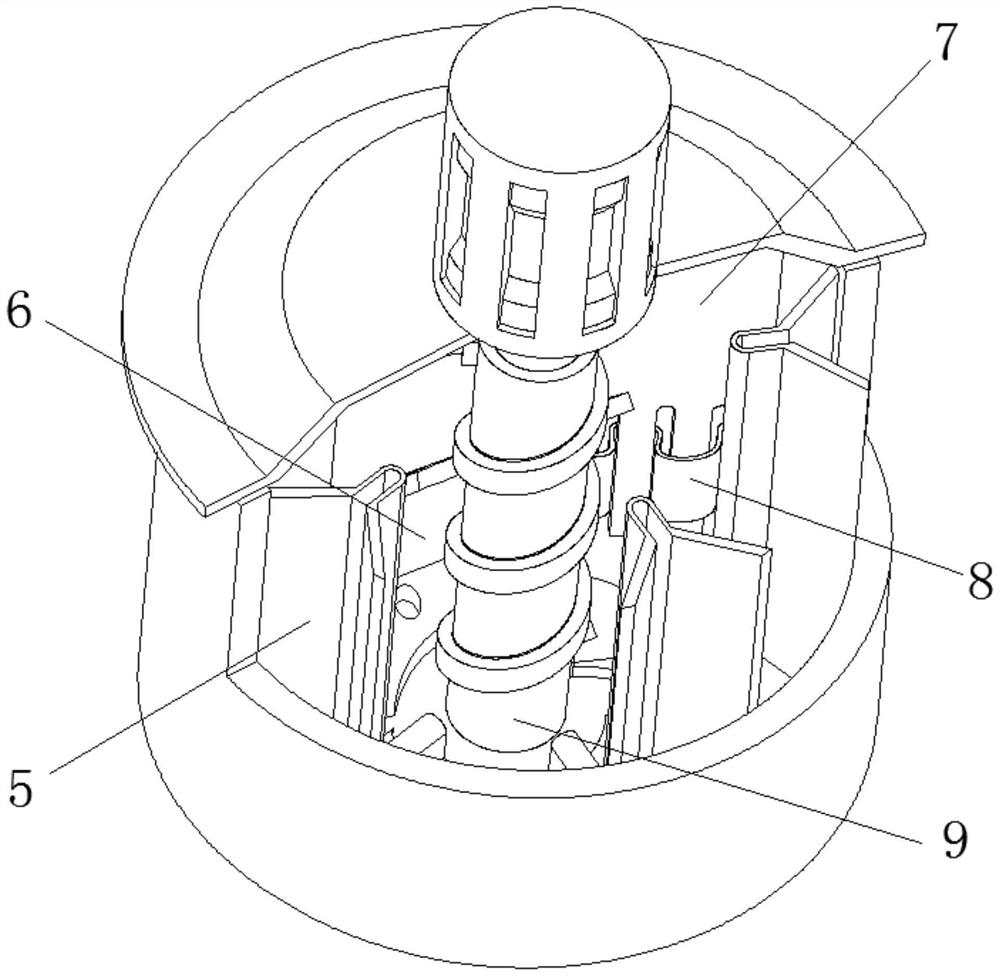

Method for producing thin wall plastering mortar for buildings by using artificial stone, marble and granite sawdust solid waste

InactiveCN114043629AImprove adhesionIncrease contact areaSievingSolid waste managementArtificial stoneMechanical engineering

The invention discloses a method for producing thin wall plastering mortar for buildings by using artificial stone, marble and granite sawdust solid waste, and the method comprises a rubbing shell, the outer surface of the rubbing shell is fixedly connected with an operation panel, the top of the rubbing shell is sleeved with a splash-proof top plate, the middle of the splash-proof top plate is rotatably connected with a stirring machine, the output end of the bottom of the stirring machine is fixedly connected with a stirring shaft device, and the inner wall of the rubbing shell is fixedly connected with a friction device and an extrusion cavity. The invention relates to the technical field of comprehensive utilization of solid waste. According to the method for producing the thin wall plastering mortar for buildings by using the artificial stone, marble and granite sawdust solid waste, the extrusion cavity and a screening plate are arranged, when the stirring shaft device rotates, the extrusion cavity can enable internal materials to be tightly attached to the stirring shaft device, the material rubbing effect is improved, and meanwhile, an elastic plate can improve the internal mixing effect of the materials through elastic vibration when the materials are extruded.

Owner:孔志明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com