Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262results about How to "Realize winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning type cable winding device

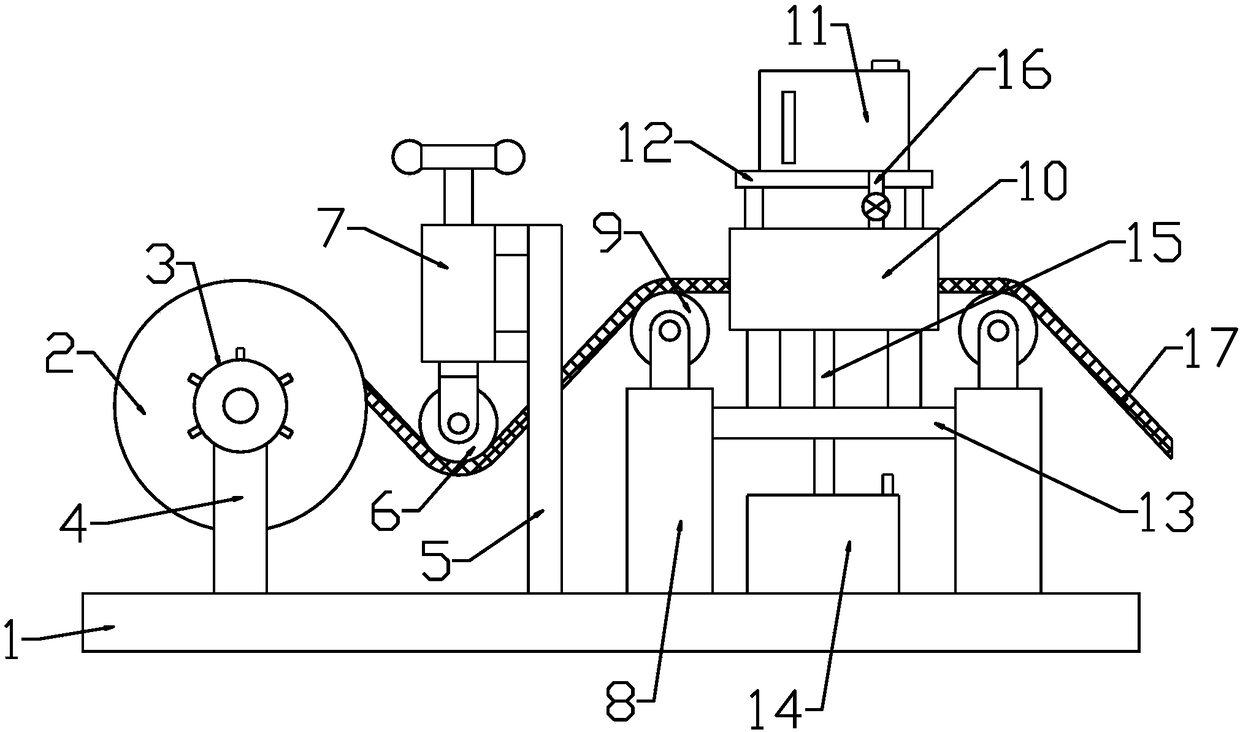

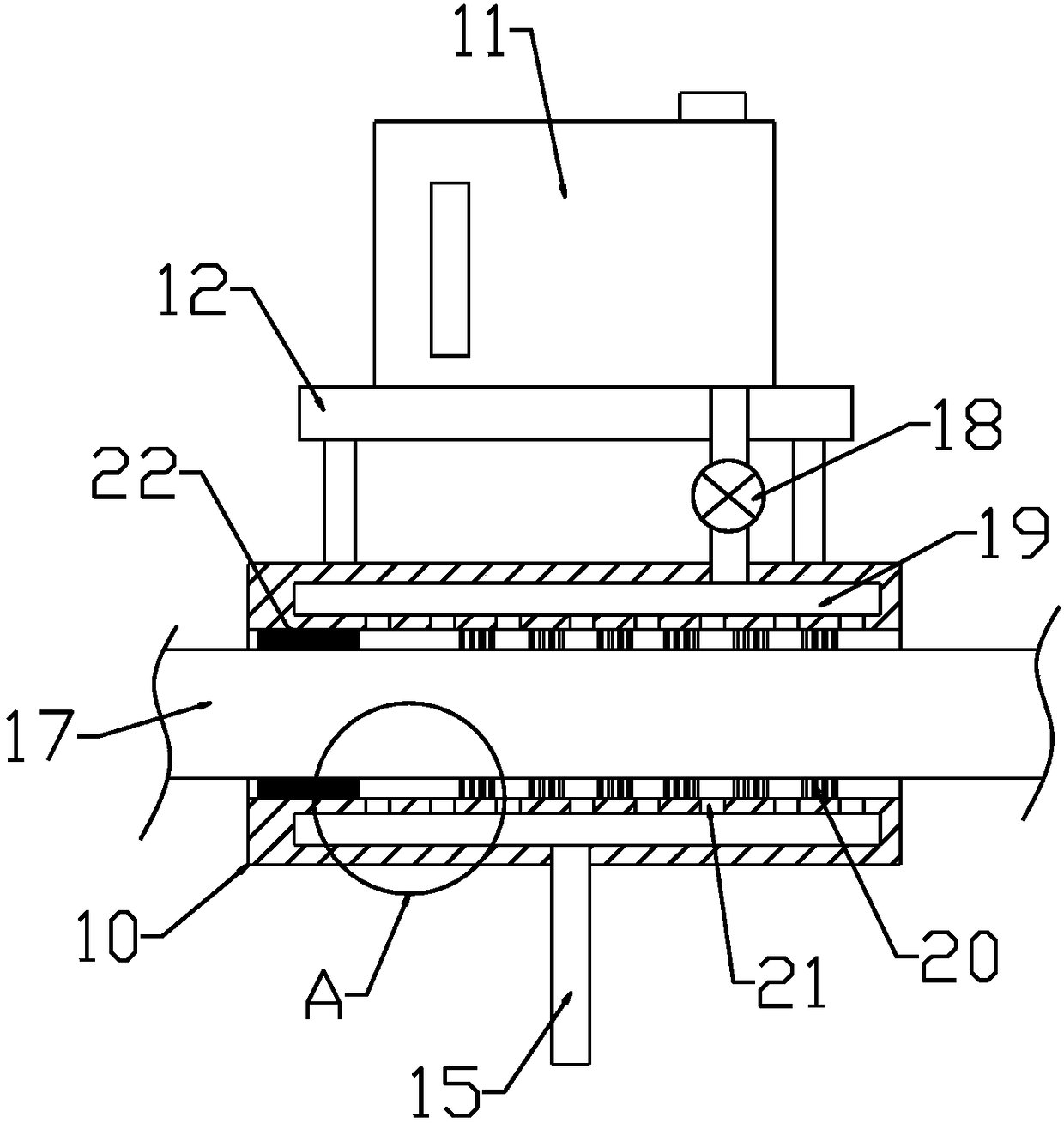

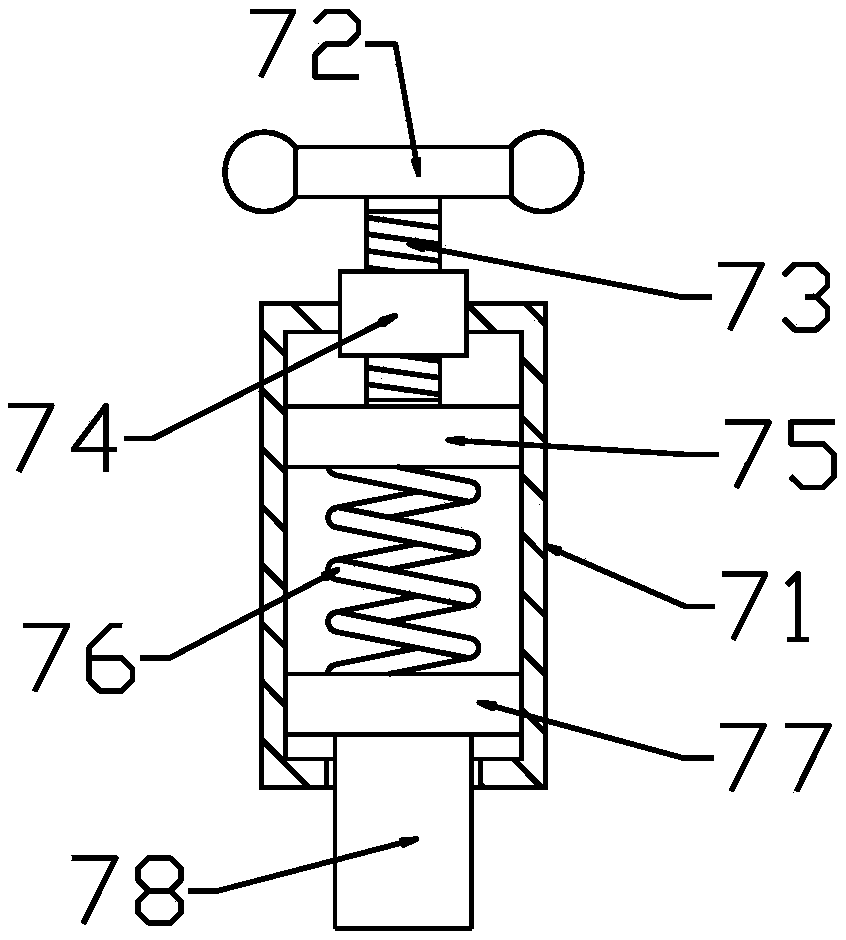

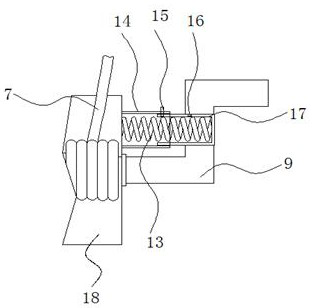

The invention discloses a cleaning type cable winding device. The cleaning type cable winding device comprises a base, a winding roller, a guide movable pulley, an elastic supporting piece, guide fixed pulleys and a cleaning box; supporting stand columns are fixedly arranged at the top of the left end of the base, the winding roller is rotationally arranged at the top end of the supporting stand columns, and supporting stand columns are symmetrically and fixedly welded to the top end of the right portion of the base; an annular cavity is formed in the inner portion of a shell of the cleaning box, a plurality of through holes communicating with the inner cavity of the cleaning box are formed in the inner wall of the annular cavity, and a plurality of cleaning brushes are uniformly distributed on the inner wall of the right portion of the cleaning box; and the left portion of the cleaning box is provided with a rubber sleeve, a support is fixedly arranged at the top end of the cleaning box, a cleaning fluid box is fixedly arranged on the support, and the bottom of the inner cavity of the cleaning fluid box is in communication with the annular cavity through an infusion tube. According to the cleaning type cable winding device, the structure is simple and reasonable, the labor intensity of workers is greatly reduced, and the winding effect of the cable is good, the cleaning of thesurface of the cable is guaranteed, and the device is suitable for popularization and use.

Owner:NANTONG MILANTE ELECTRIC

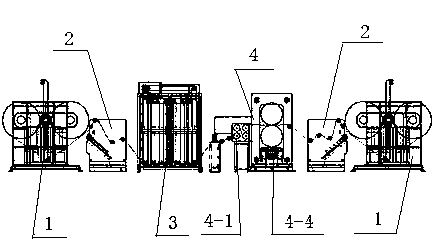

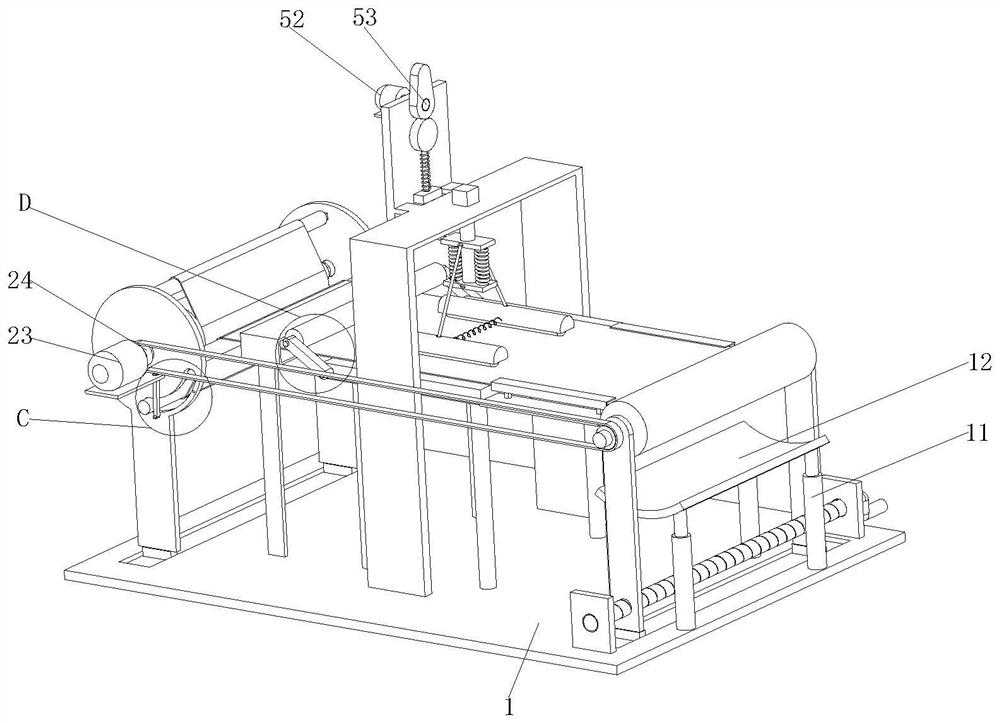

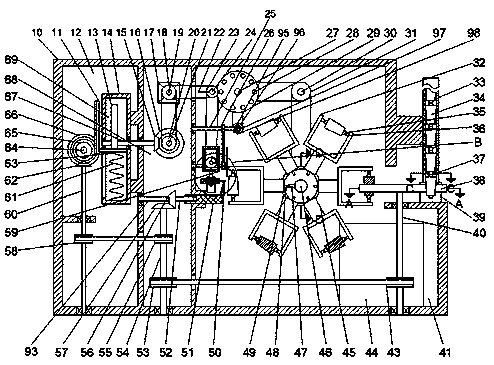

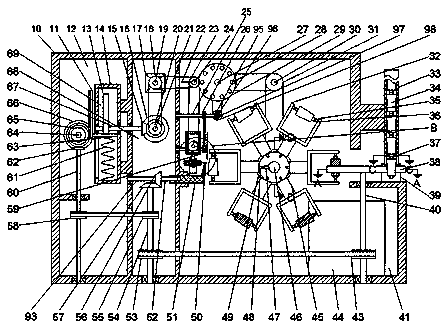

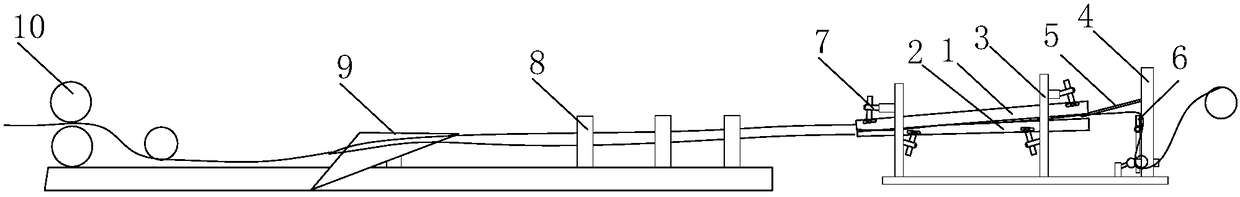

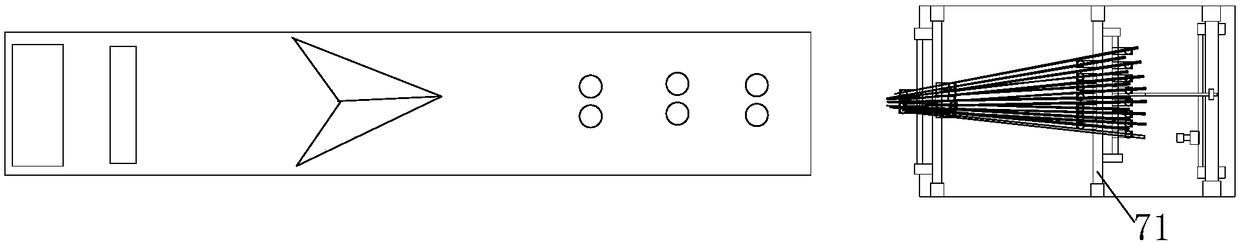

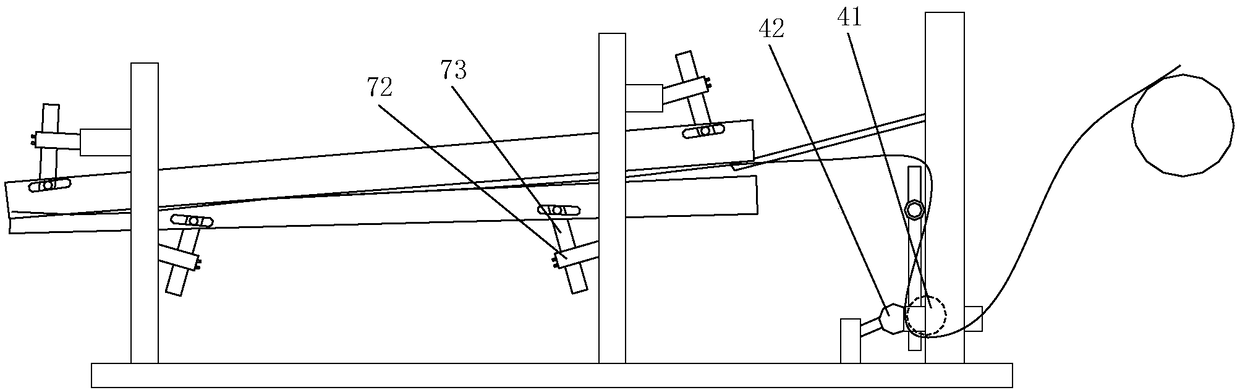

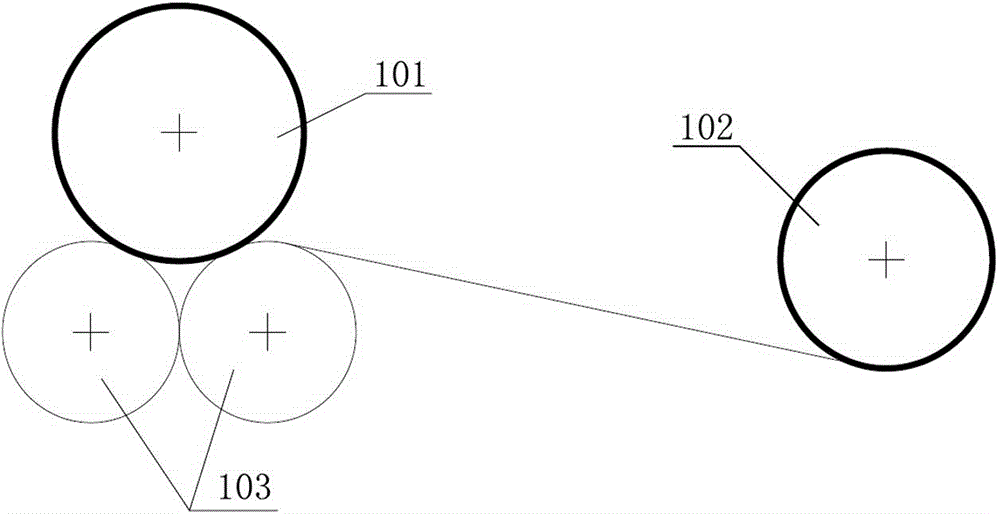

Single-sided continuous winding magnetron sputtering coating automatic production line for flexible substrate

ActiveCN104651792AReduce wasteRealize continuous platingVacuum evaporation coatingSputtering coatingProduction lineMaterials preparation

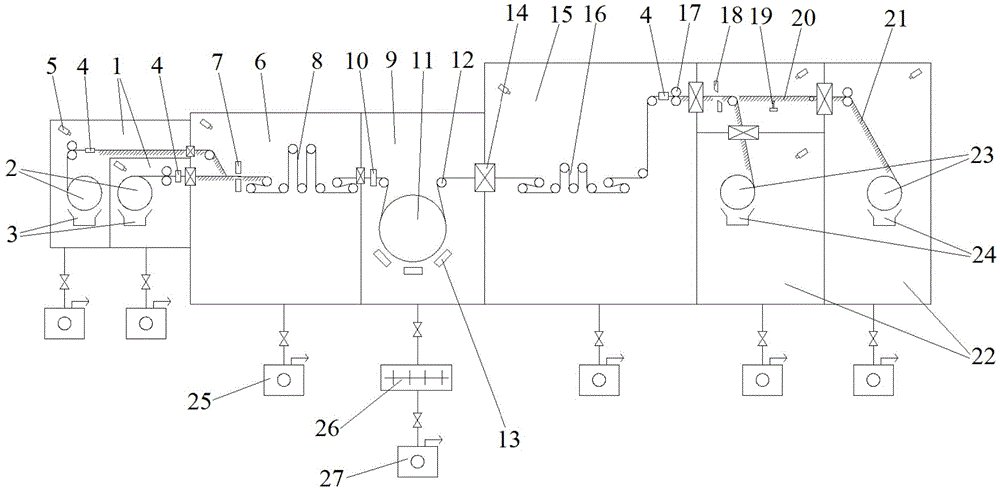

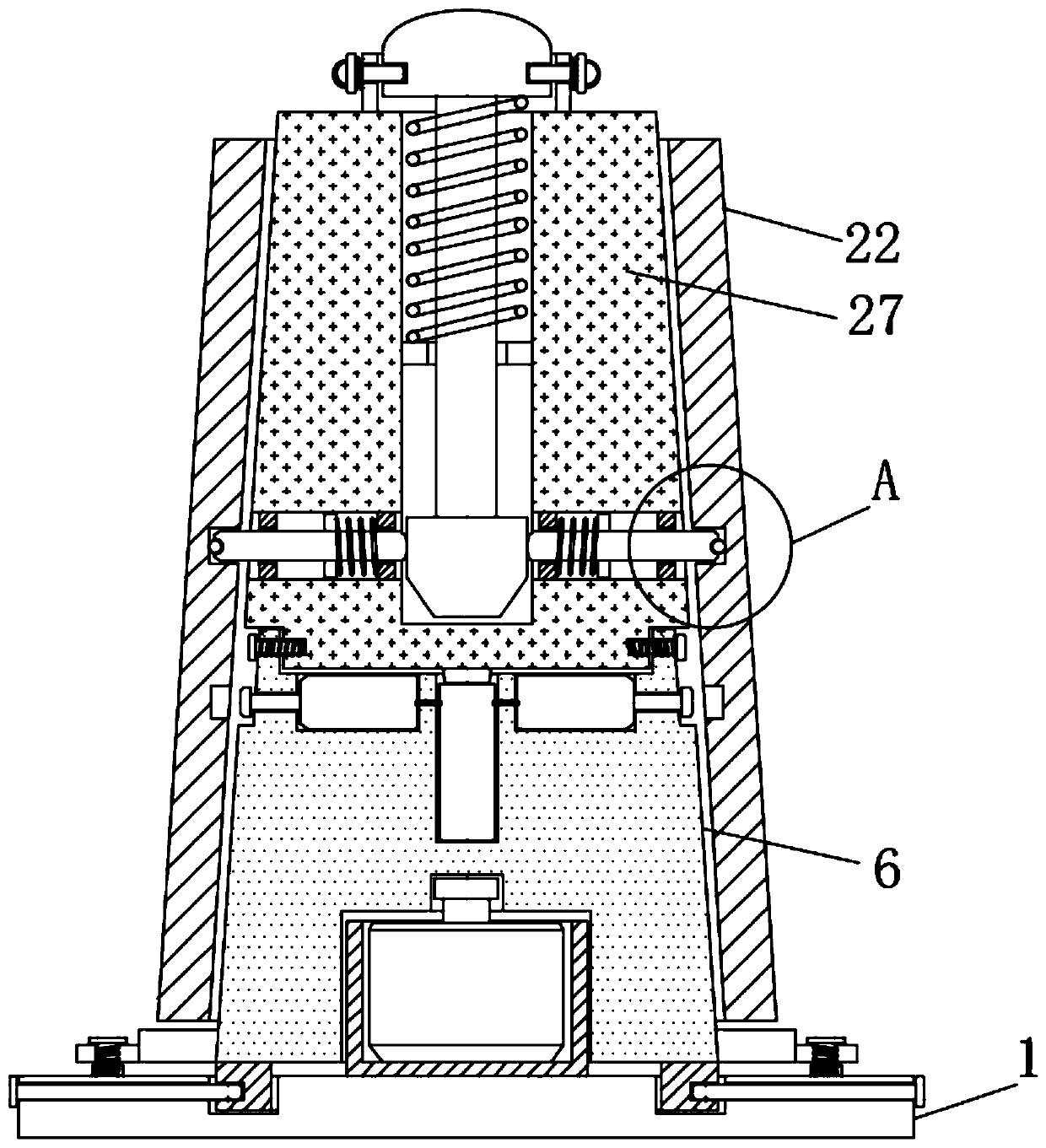

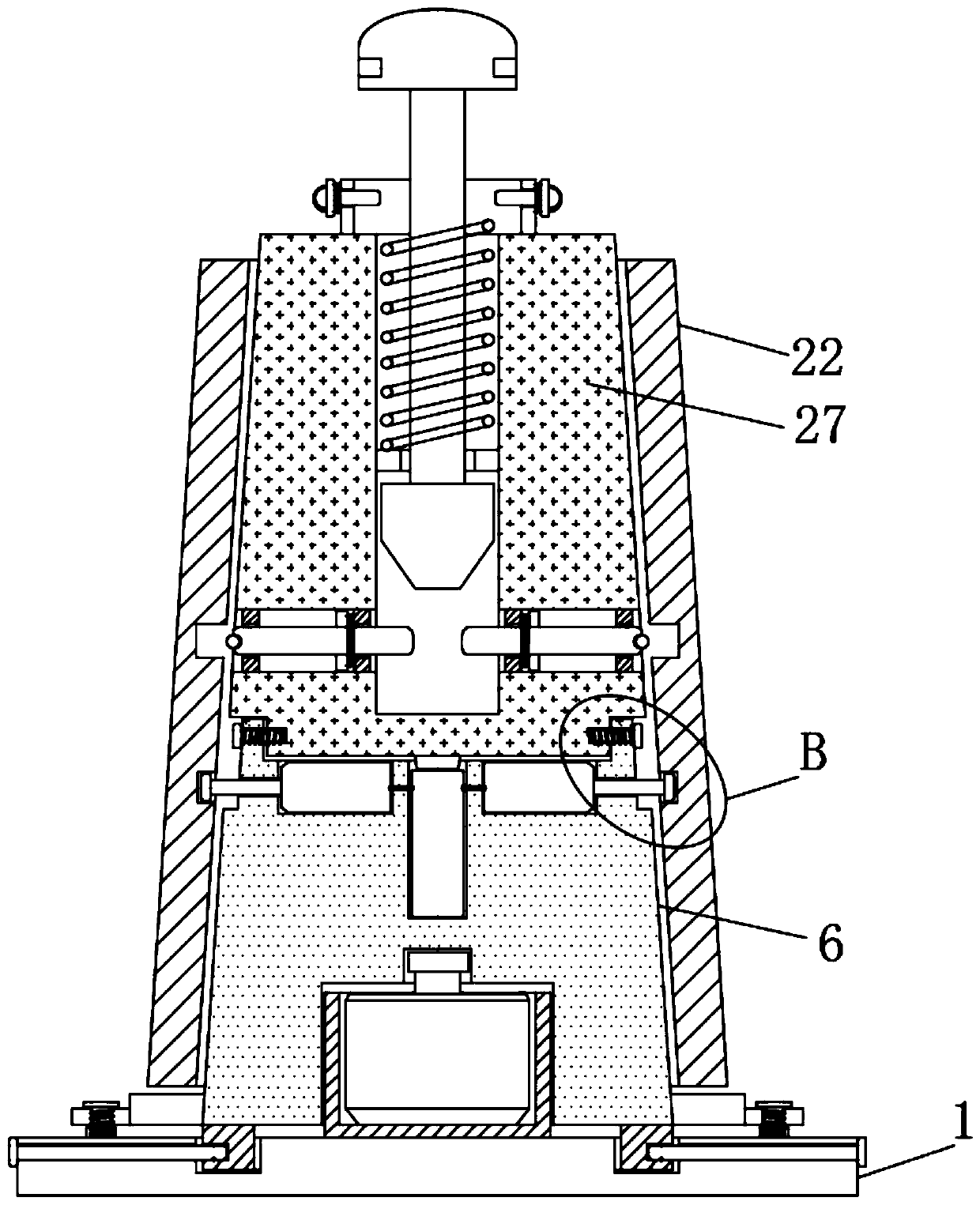

The invention discloses a single-sided continuous winding magnetron sputtering coating automatic production line for a flexible substrate and belongs to the field of coating equipment. The production line comprises an uncoiling room, a rolling room and a coating vacuum room, wherein an unreeling storage room is further arranged between the uncoiling room and the coating vacuum room; a rolling storage room is further arranged between the rolling room and the coating vacuum room; a heat seal mechanism is arranged in front of the unreeling storage mechanism; a cutting mechanism and a substrate steering mechanism are sequentially arranged behind the rolling storage mechanism; one end of a substrate wound on an uncoiling roller is wound on a rolling roller sequentially through the heat seal mechanism, the unreeling storage mechanism, a pre-treatment mechanism, a cold roller, a rolling storage mechanism and the cutting mechanism as well as the substrate steering mechanism. By virtue of material preparation in advance for uncoiling and roller preparation in advance for rolling, multiple substrates are continuously coated by combining the unreeling storage mechanism and the rolling storage mechanism, so that the time for changing rolls and vacuumizing is shortened, and the coating efficiency is greatly improved.

Owner:常州常工院技术转移有限公司

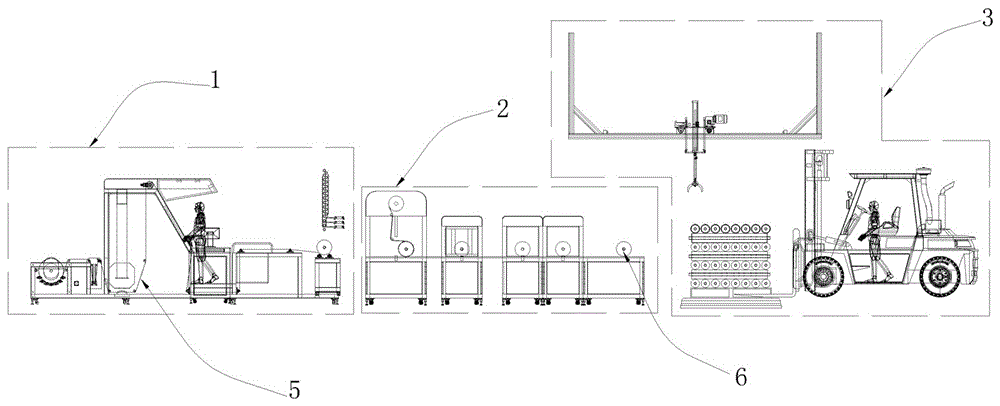

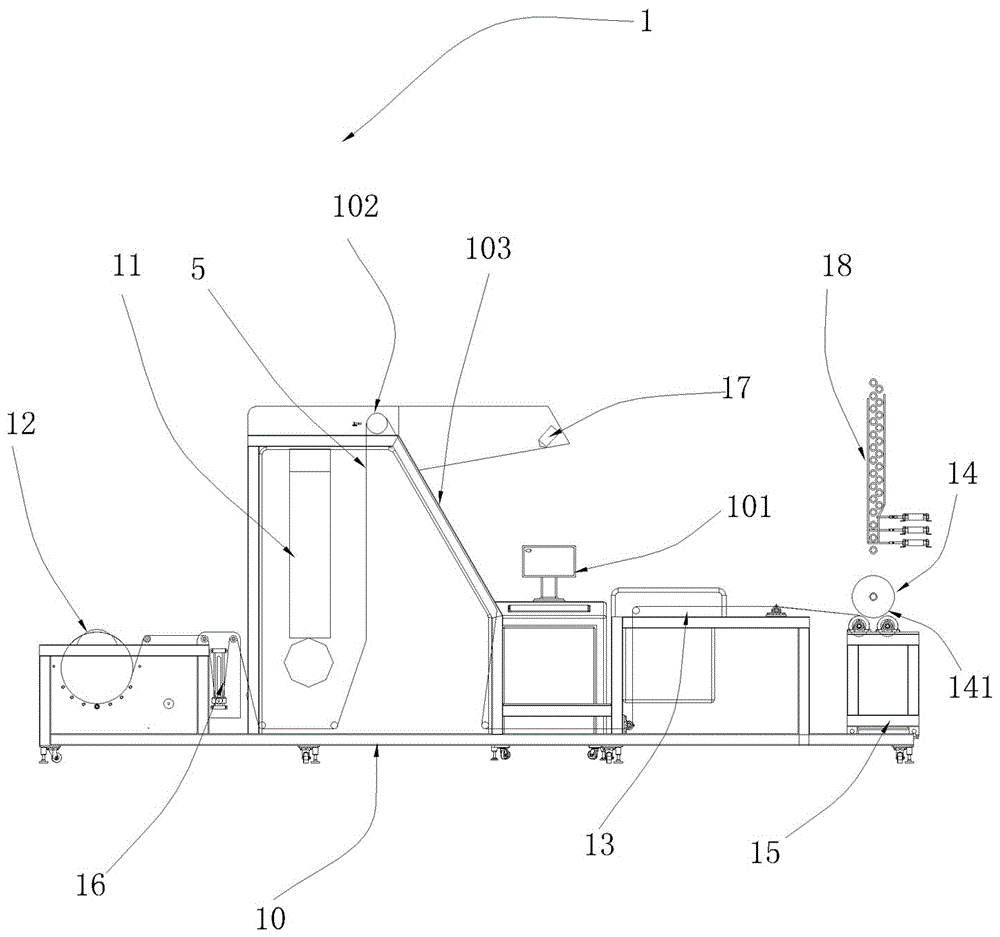

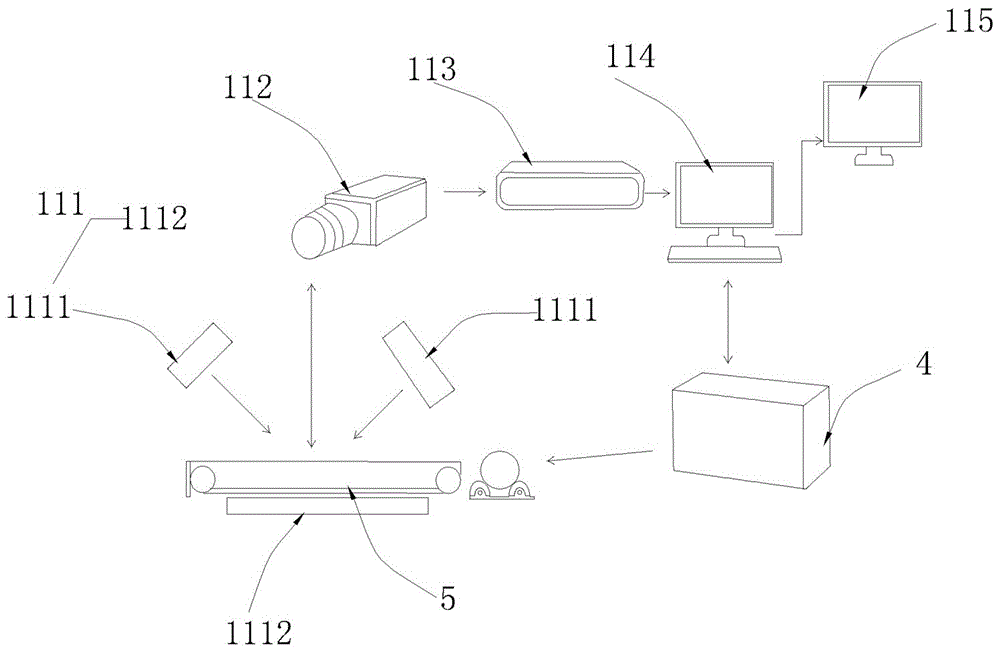

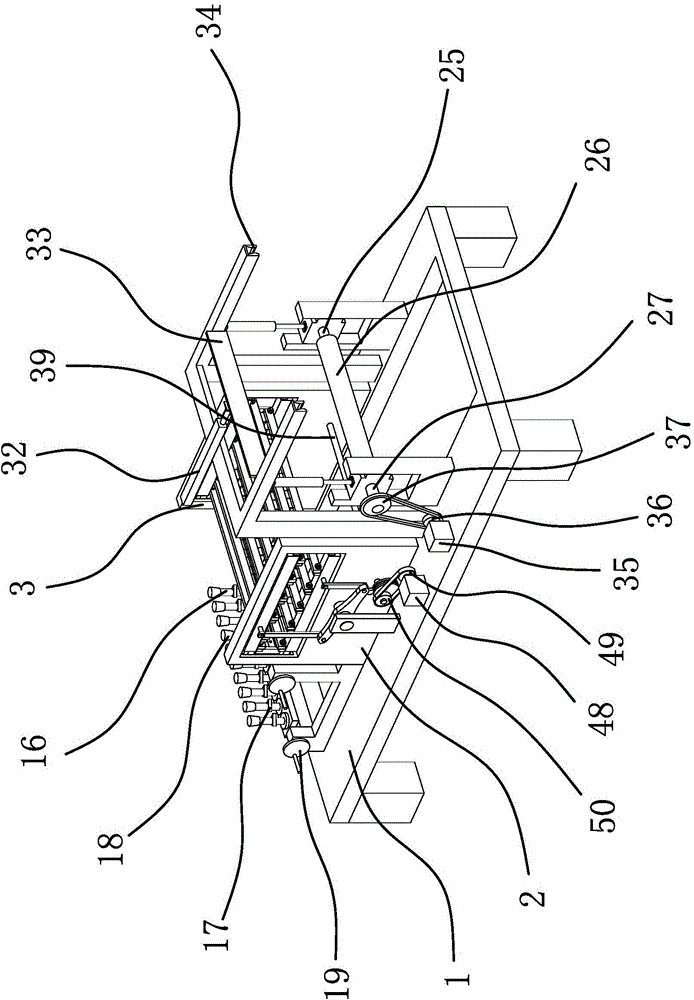

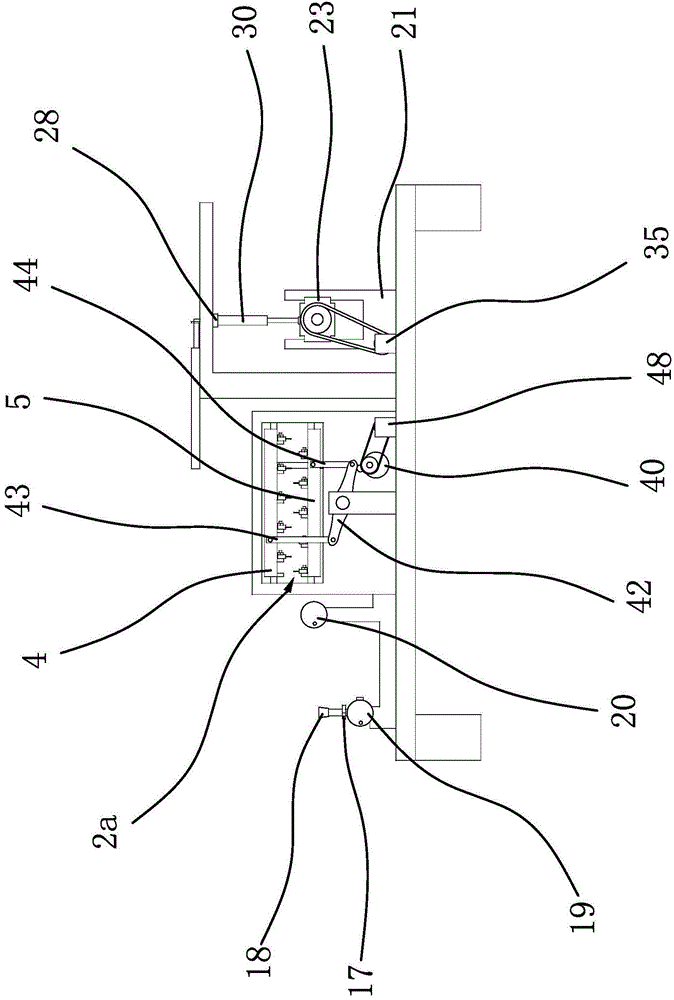

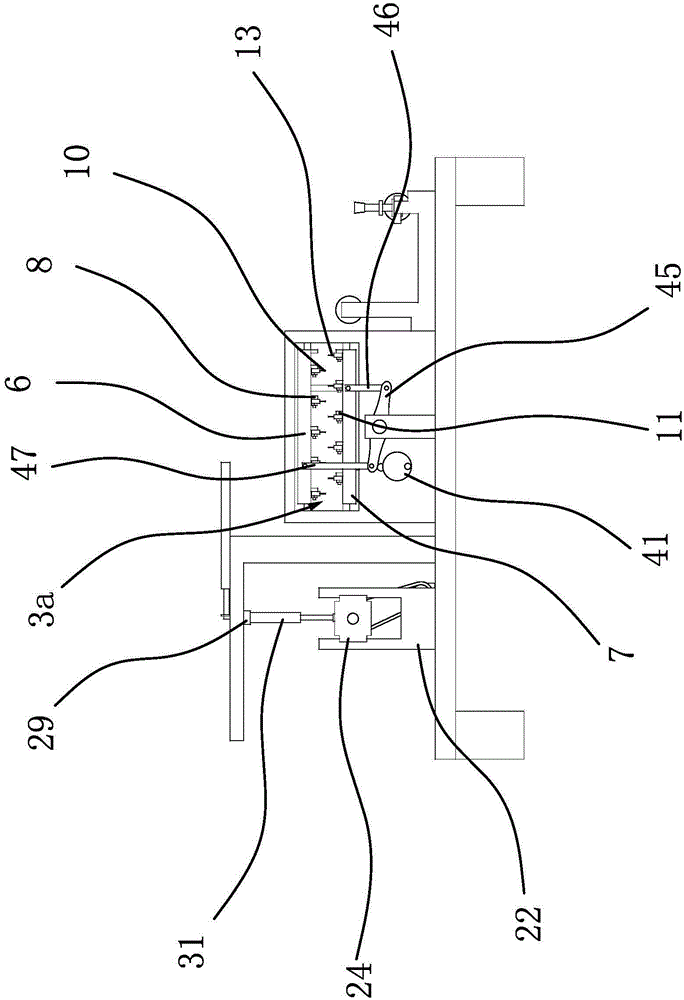

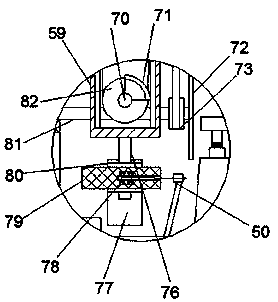

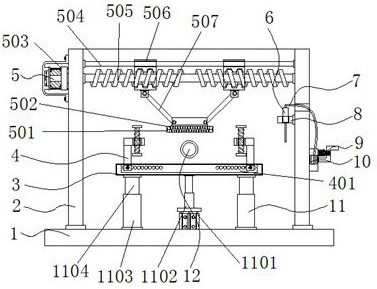

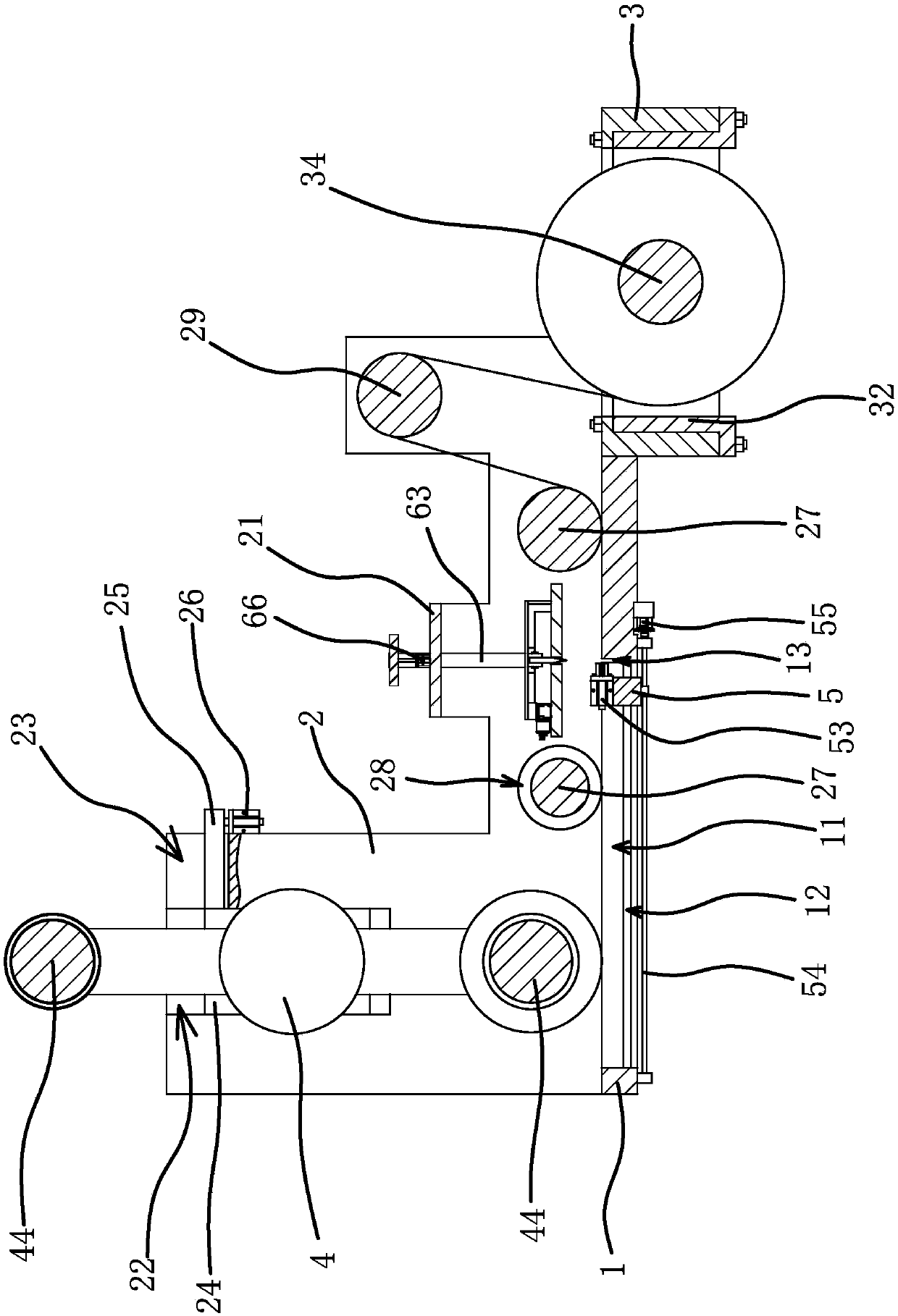

Intelligent cloth inspecting machine and cloth inspecting method thereof

ActiveCN105699392AImprove detection efficiencyImprove efficiencyMaterial analysis by optical meansEngineeringMechanical engineering

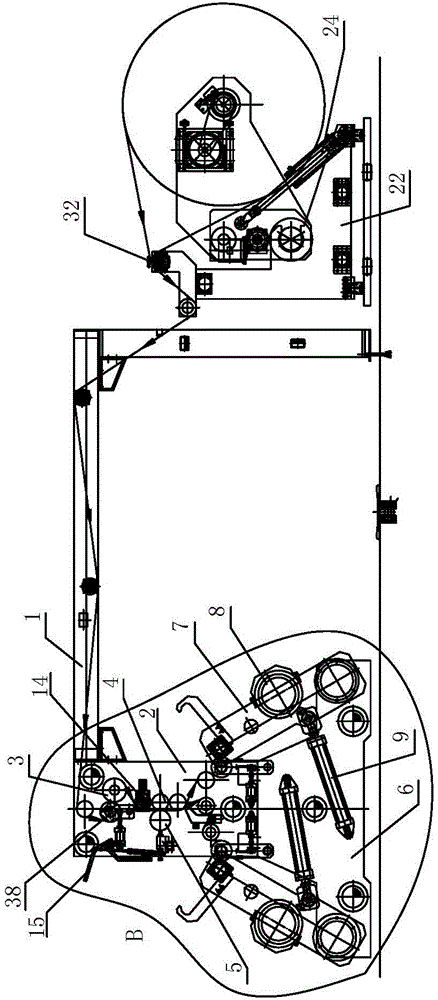

The invention discloses an intelligent cloth inspecting machine and a cloth inspecting method thereof.The intelligent cloth inspecting machine comprises a defect inspection device used for conducting defect inspection on cloth, a shrink-packaging device used for conducting hot shrinkage forming on cloth rolls which have been detected and formed, and a stacking and transporting device used for stacking and transporting the cloth rolls which have been subjected to hot shrinkage forming.The defect detection device, the shrink-packaging device and the stacking and transporting device are sequentially connected.By means of the intelligent cloth inspecting machine and the cloth inspecting method, automatic defect detection is achieved, the labor intensity is lowered, and the omission ratio and false inspection rate are decreased.The precision of cloth defect detection is improved.An automatic winding mechanism, an automatic edge cutting mechanism and the shrink-packaging device can be used in cooperation for winding the detected cloth, the cloth automatically enters the shrink-packaging device to be subjected to hot shrinkage forming after being wound, and therefore automatic cloth cutting, winding and automatic packaging are achieved when a roll of cloth is wound.

Owner:SHENZHEN MAIKESITAI CO LTD

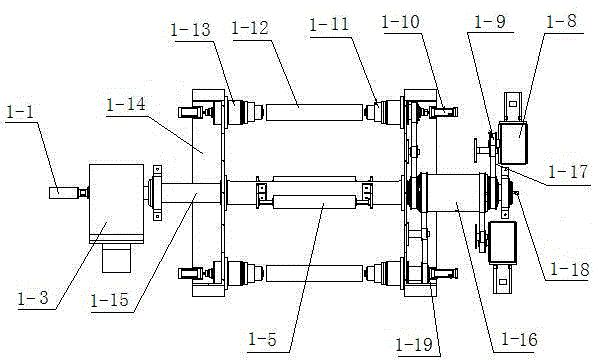

Device used for rolling battery pole piece at high speed

ActiveCN104190708AImprove productivityIncrease productivityElectrode manufacturing processesMetal rolling arrangementsControl systemPole piece

The invention discloses a device used for rolling a battery pole piece at a high speed. The device comprises a control system, two double-station automatic winding and unwinding machines, a band connecting device, a piece storage mechanism and a rolling mechanism. The double-station automatic winding and unwinding machines are arranged at an initial end and a tail end respectively. The band connecting device is arranged on the side face of the output end of a battery pole piece band roll of the double-station automatic winding and unwinding machine arranged at the initial end. The piece storage mechanism and the rolling mechanism are sequentially arranged behind the output end of the band connecting device. The output end of the rolling mechanism is connected with the double-station automatic winding and unwinding machine arranged at the tail end. An automatic roll replacing and band connecting mechanism, the piece storage mechanism and the rolling mechanism are all connected with a control system. According to the device, rolling accuracy can be guaranteed, shutdown is not required in the rolling process, roll replacement and band connection are automatically completed, and therefore automated production is achieved.

Owner:邢台纳科诺尔精轧科技股份有限公司

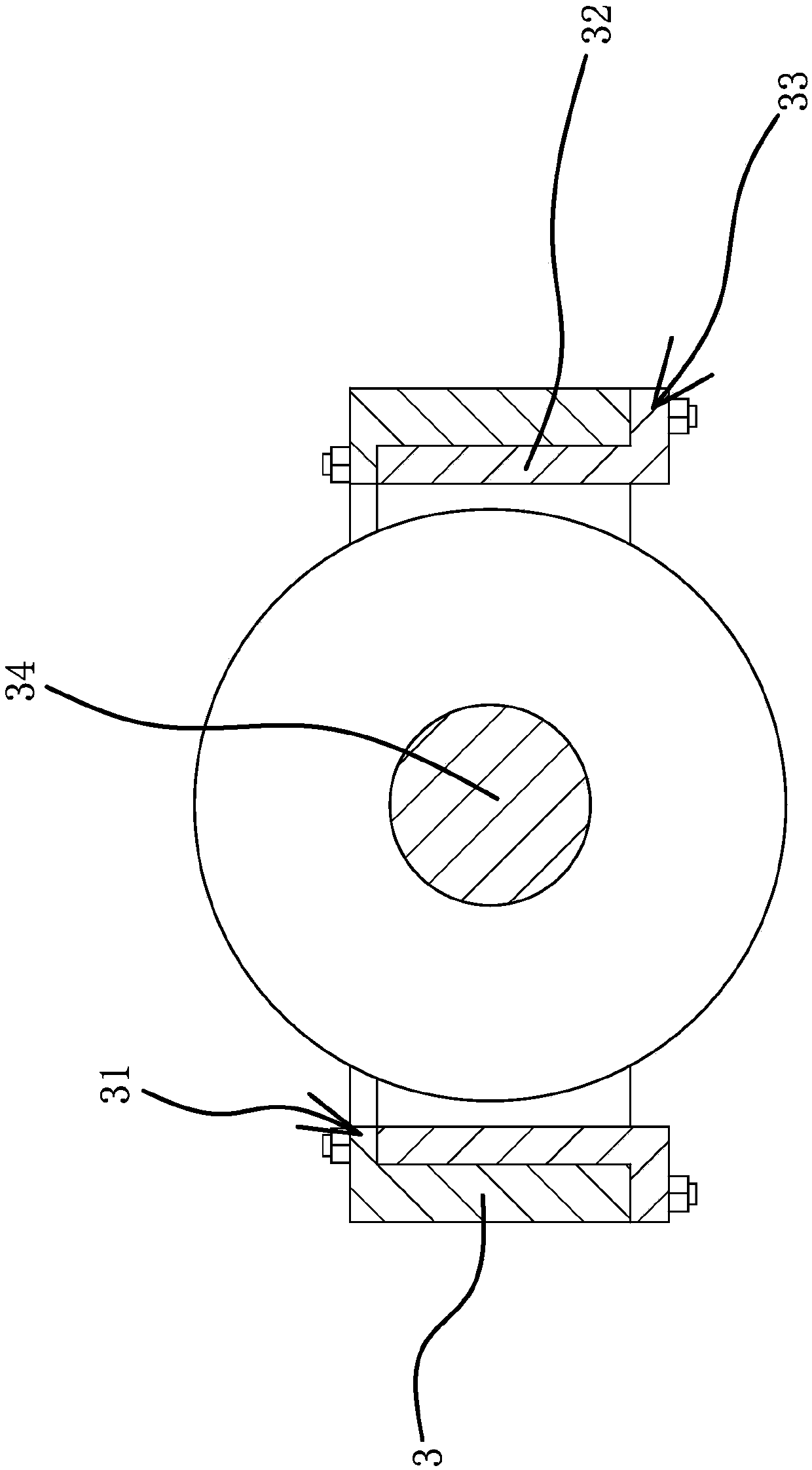

Safe electricity ground wire stand convenient to use

The invention discloses an easy-to-use electric safety grounding wire rack. The first bracket and the second bracket are fixed by a cross bar, and the first bracket is also movably connected to one end of a bobbin through a bearing seat, and the bobbin The left and right relative positions of the left and right are respectively sleeved with a first line retaining plate and a second line retaining plate, the bobbin is movably connected with the second support through a bearing seat arranged on the second support, and a turntable is fixed on the right end of the bobbin , and the edge of the turntable is movably connected to the handle through the bearing seat, the side wall of the second bracket is also fixed with a spring seat, and the spring seat is fixedly connected with the locking spring, and the second wire retaining plate is evenly opened with A locking hole suitable for the locking spring, the winding shaft is evenly wound with a grounding wire, and the other end of the grounding wire is fixedly connected to the clip, and the clip is sleeved on the fixing tube, and one end of the fixing tube Also secured with a ground spike. The ground wire frame has a simple structure and is more convenient to use.

Owner:STATE GRID CORP OF CHINA +1

Anti-wrinkle processing equipment for PE (polyethylene) antibacterial preservative film production

The invention relates to anti-wrinkle processing equipment for PE (polyethylene) antibacterial preservative film production. The anti-wrinkle processing equipment for PE antibacterial preservative film production comprises a base, a supporting device, a winding device, a working table and a flattening device. According to the anti-wrinkle processing equipment for PE antibacterial preservative film production provided by the invention, through the winding device, a driving motor is started, and the output end of the driving motor drives a winding shaft to rotate, so that a preservative film is conveyed and wound at the same time; through the arranged flattening device, a flattening motor is started, the output end of the flattening motor drives a flattening shaft to rotate, and the flattening shaft rotates to drive a cam to rotate; when a reciprocating plate moves up and down, push rods on the two sides move relatively, so that vertical rollers on the two sides are driven to transversely remove wrinkles when the preservative film is wound; and when the reciprocating plate moves upwards, the reciprocating plate is pushed to ascend due to the acting force of a jacking spring, and the two vertical rollers are quickly close to each other through supporting rods on the two sides when the reciprocating plate ascends, so that the situation that when transverse wrinkle removal is conducted on the preservative film from the middle to the two sides, wrinkle removal and winding of the preservative film are affected is avoided.

Owner:王福江

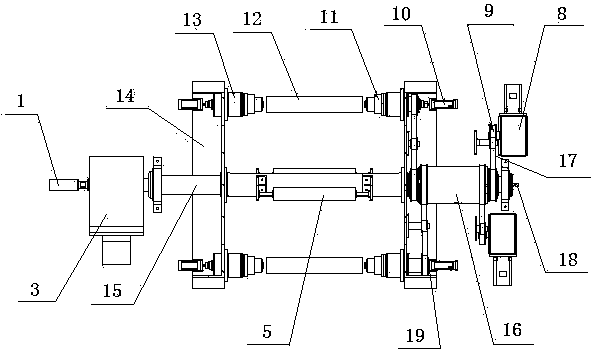

Automatic roll replacing and strip connecting system for battery pole pieces

ActiveCN104150256AAchieve bondingHigh degree of production automationWebs handlingAutomatic controlControl system

The invention discloses an automatic roll replacing and strip connecting system for battery pole pieces. The automatic roll replacing and strip connecting system comprises an unreeling machine and a strip connecting device. The unreeling machine is an automatic double-position unreeling machine. The automatic double-position unreeling machine comprises a first working position and a second working position, wherein the second working position is the position where a strip roll is placed when the automatic double-position unreeling machine operates normally. The position of the strip roll at the first working position and the position of the strip roll at the second working position are changed through large rotation. The strip connecting device is arranged on the side face of the second working position of the unreeling machine. The unreeling machine and the strip connecting device are both connected with an automatic control system. According to the automatic roll replacing and strip connecting system, roll replacement and strip connection are integrated, and roll replacement and strip connection of the battery pole pieces can be automatically achieved without a halt, so the automation degree of production and the production efficiency of the battery pole pieces are greatly improved, the labor intensity is lowered, and the product quality is improved.

Owner:邢台纳科诺尔精轧科技股份有限公司

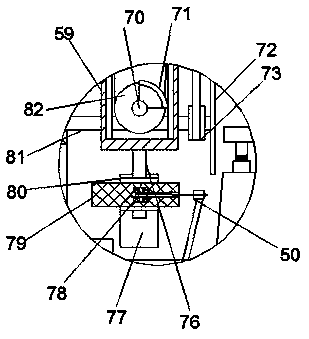

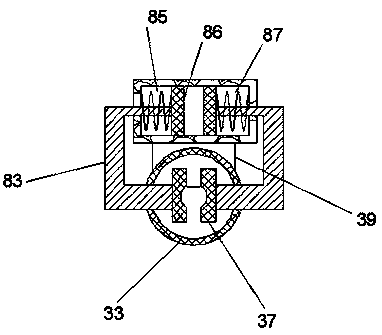

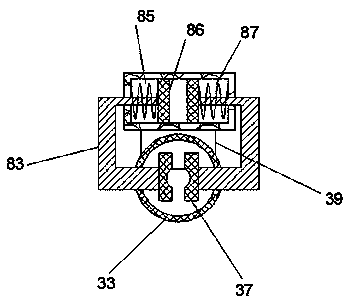

New energy vehicle charging protection device

ActiveCN109130915APrevent the phenomenon of tearing off the charging gun headAchieve separationCharging stationsElectric vehicle charging technologyFriction lossNew energy

The invention discloses a new energy vehicle charging protection device, including a charging pile shell. A safety sensing mechanism is fixedly connected to the inside of the rewinding wheel near thebottom end at the shaft center. A charging wire is wound in the middle of the surface of the rewinding wheel. A CPU is fixedly connected with an intermediate position inside that housing of the charging pile. The charging lead is fixedly connected with a charging gun head at one end outside the charging pile shell, the upper and lower sides of the charging gun head are fixedly connected with a safety pushing mechanism, and the left side of the charging pile shell and the lower rail of the storage slot are connected with a gun head slot. The invention relates to the technical field of new energy. The new energy vehicle charging protection device achieves the purpose of preventing the new energy vehicle from breaking the charging gun head caused by mistakes, improving the safety factor during charging, reducing the accident probability, reducing the friction loss in the wire transmission, realizing the automatic winding of the charging wire, and avoiding the external obstruction of thewire to pedestrians.

Owner:深电能科技集团有限公司

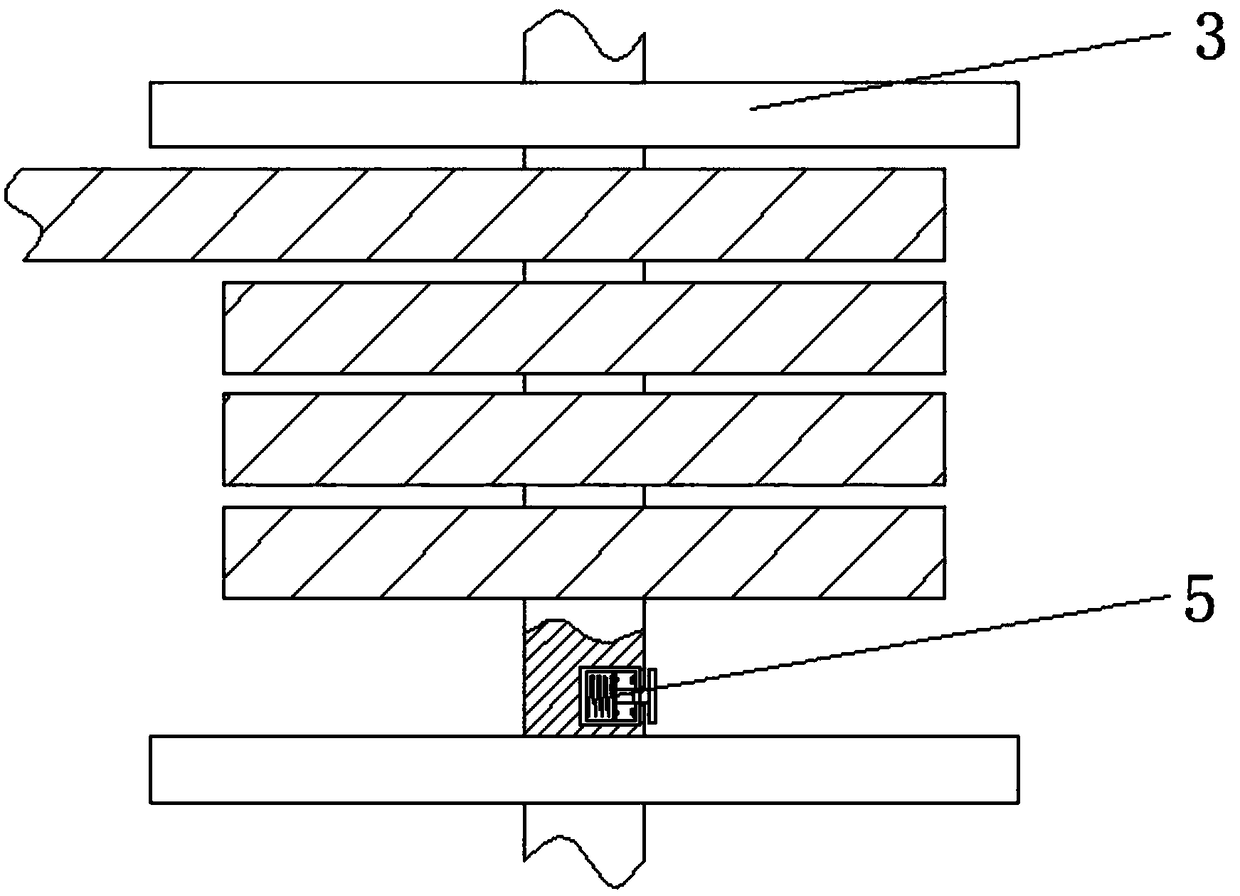

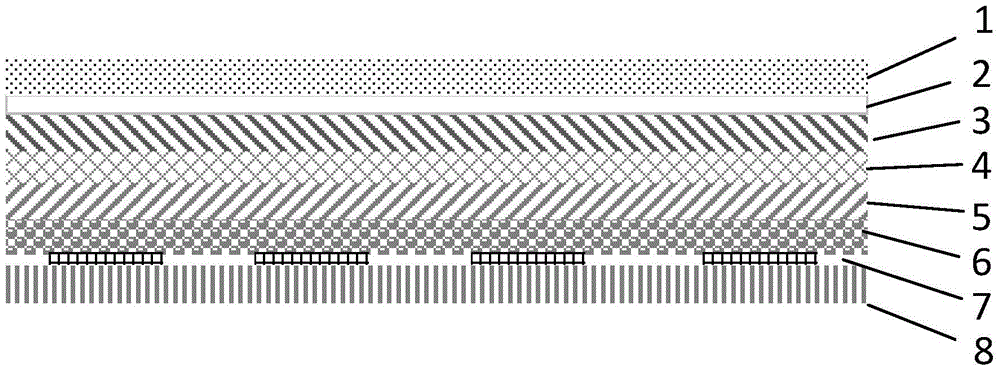

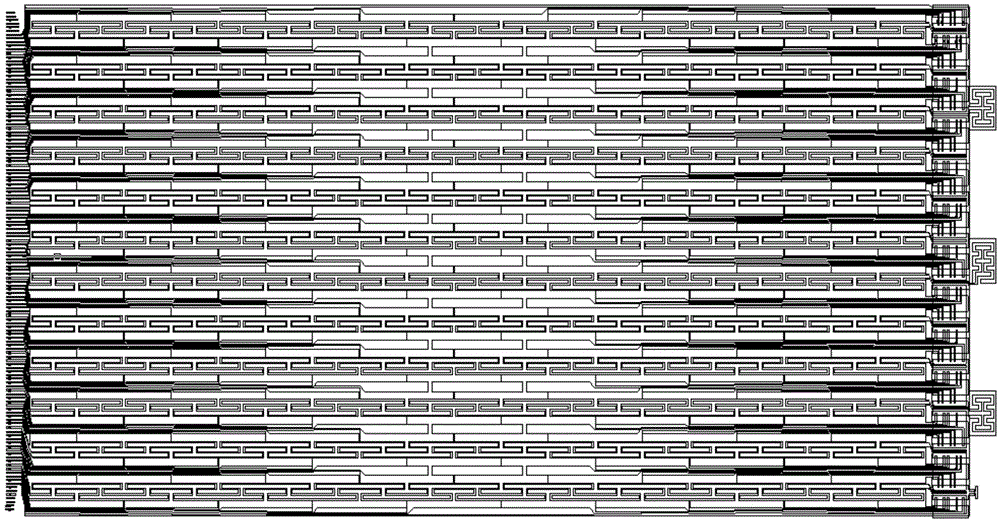

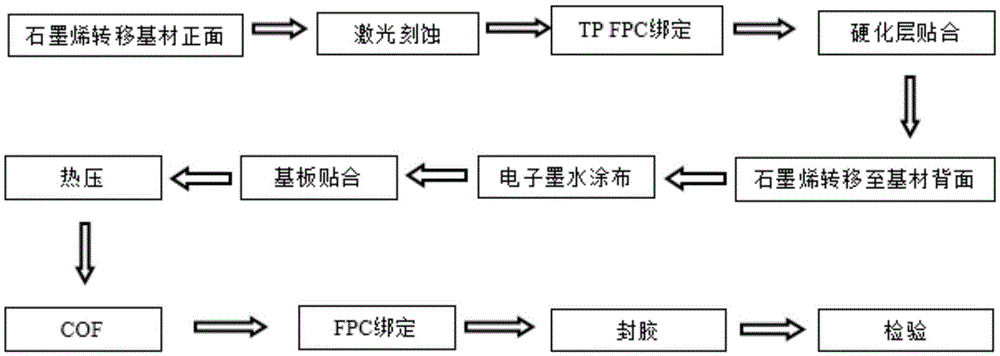

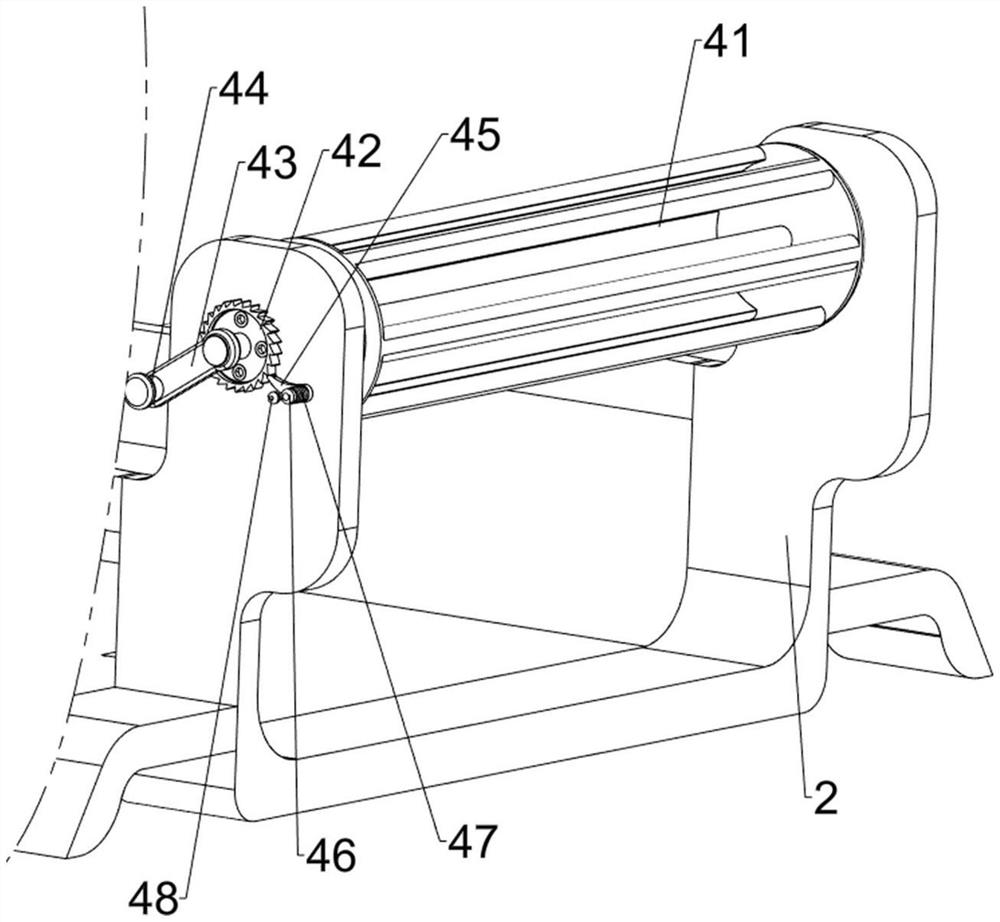

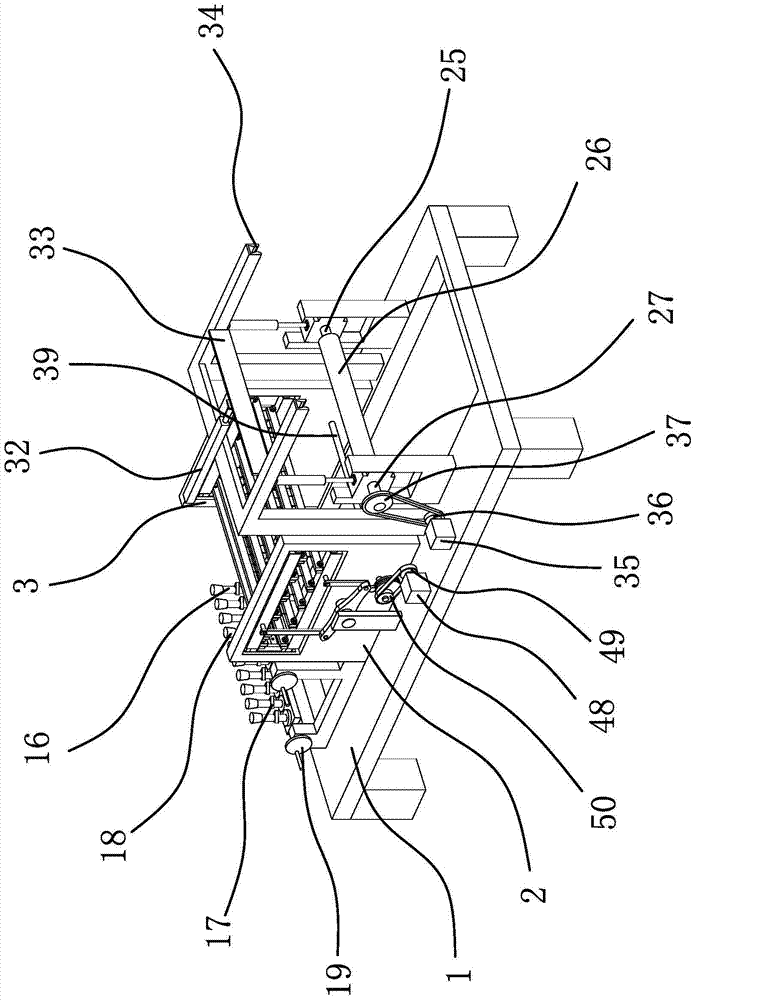

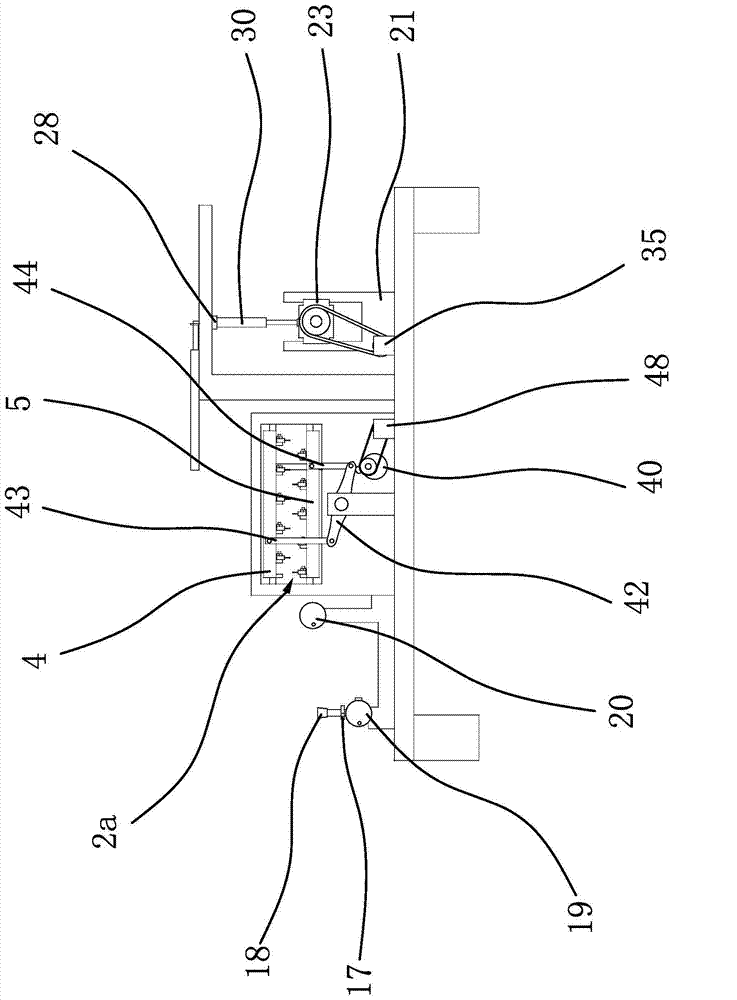

Ultrathin flexible electronic ink touch display screen and manufacturing method

InactiveCN105487708ASimple structureRealize windingNon-linear opticsInput/output processes for data processingEngineeringTouchscreen

The invention discloses an ultrathin flexible electronic ink touch display screen. The display screen comprises a touch layer and a display layer, wherein the touch layer comprises a substrate, an electrode pixel layer, an electronic ink layer and a graphene transparent conductive layer; the electrode pixel layer is arranged on the substrate; the electronic ink layer is arranged on the electrode pixel layer; the graphene transparent conductive layer is arranged on the electronic ink layer; and the display layer is arranged on the graphene transparent conductive layer. According to the display screen, graphene replaces ITO to serve as a transparent electrode of the display screen; a flexible graphene touch screen is manufactured; effective combination of flexible touch and flexible display is realized by a double-sided graphene structure; and the ultrathin flexible electronic ink touch screen is manufactured, so that the screen is lighter and thinner, the flexing can be realized to a greater extent, and a simple structure on the electronic ink layer makes a reading image clear.

Owner:CHONGQING GRAPHENE TECH

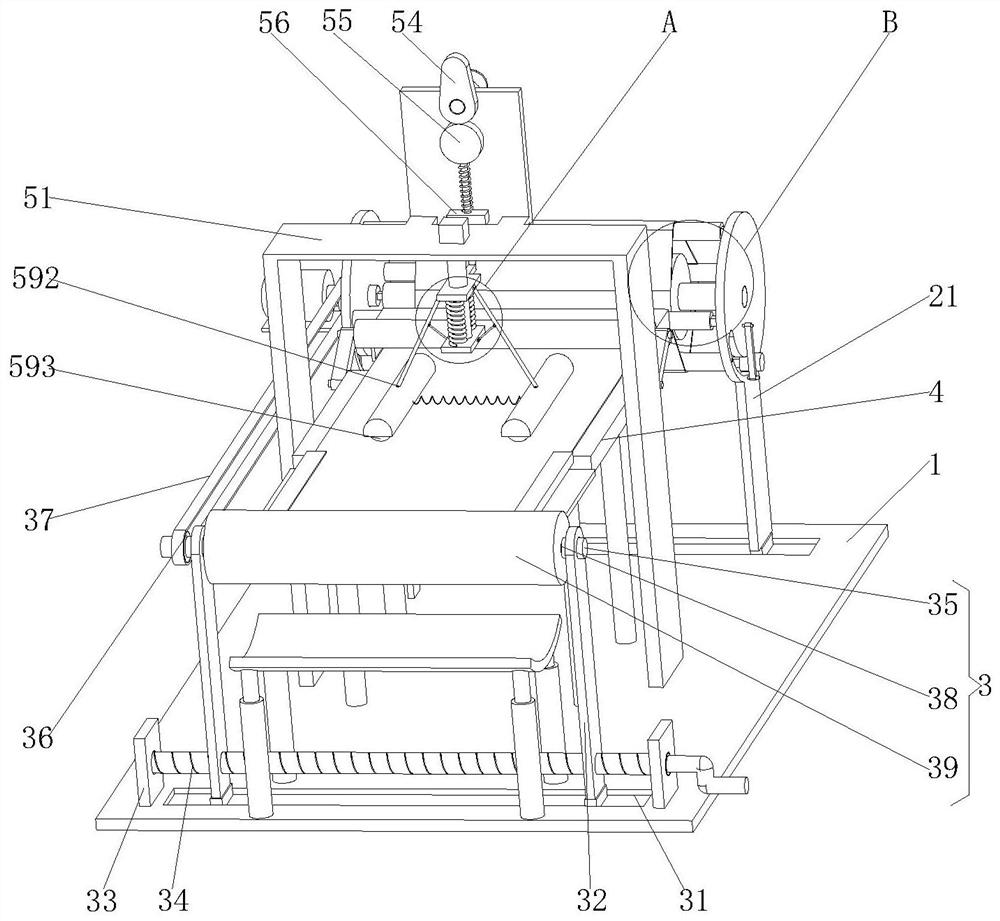

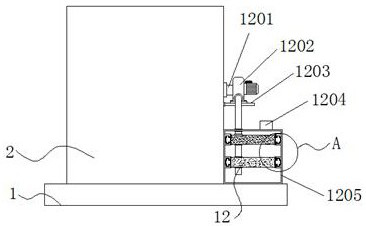

Automatic cloth edge cutting equipment for garment production

ActiveCN112647273ARealize windingAchieve normal workSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention relates to edge cutting equipment, in particular to automatic cloth edge cutting equipment for garment production. According to the automatic cloth edge cutting equipment for garment production, cloth for garment production can be wound, meanwhile, the cloth for garment production can be quickly cut into the specified width, and redundant cloth for garment production can be shaken off at intervals. The automatic cloth edge cutting equipment for garment production comprises a base, supporting frames and rolling columns, the supporting frames are fixedly connected to the base, the rolling columns are rotationally connected between the upper portions of the supporting frames, a material rolling mechanism is installed between the upper portions of the supporting frames, a cutting mechanism is arranged at the top of the base, and the material rolling mechanism is matched with the cutting mechanism. By arranging the material rolling mechanism, the material rolling mechanism is matched with the cutting mechanism, and cloth rolling and edge cutting for garment production can be achieved; through cooperation of a reciprocating mechanism and the material rolling mechanism, rolling of cloth for garment production can be achieved; and through cooperation of a material conveying mechanism and the reciprocating mechanism, cloth for garment production can be conveyed at intervals.

Owner:江西美硕实业有限公司

Fabric winding mechanism of jacquard fabric transmission equipment

The invention provides a fabric winding mechanism of jacquard fabric transmission equipment, and belongs to the technical field of textile machinery. The fabric winding mechanism solves the problem that automatic moving cannot be conducted on a rewound rewinding roller in the prior art. According to the fabric winding mechanism of jacquard fabric transmission equipment, the jacquard fabric transmission equipment comprises a frame and a first fixing plate and a second fixing plate which are arranged on the frame, a first opening is formed in the first fixing plate, a first bearing is arranged in the first opening, a second opening is formed in the second fixing plate, a second bearing is arranged in the second opening, a rewinding shaft is fixedly arranged between the two bearings, a rewinding roller is installed on the rewinding shaft, and the rewinding shaft is connected with an actuating mechanism; a first sliding block and a second sliding block are arranged on the frame, a first lifting air cylinder is fixed to the first sliding block, a second lifting air cylinder is fixed to the second sliding block, and the first sliding block and the second sliding block are connected with a sliding mechanism. The fabric winding mechanism of the jacquard fabric transmission equipment has the advantage that automatic moving can be conducted on the rewound rewinding roller.

Owner:HAINING TIANYI TEXTILE

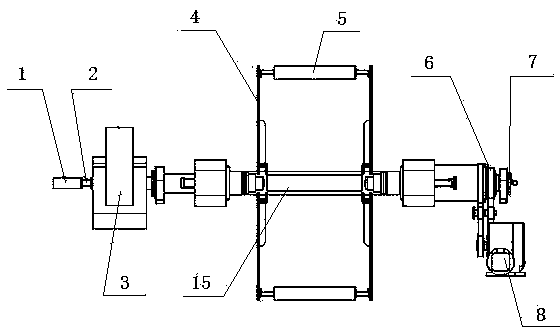

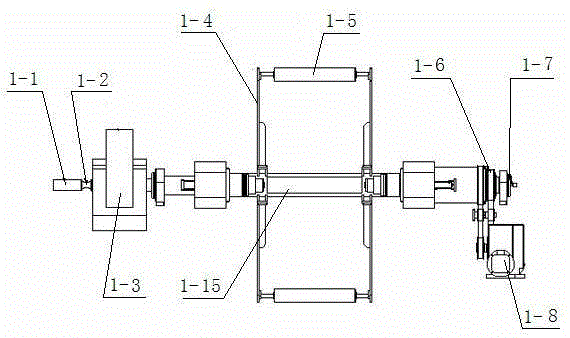

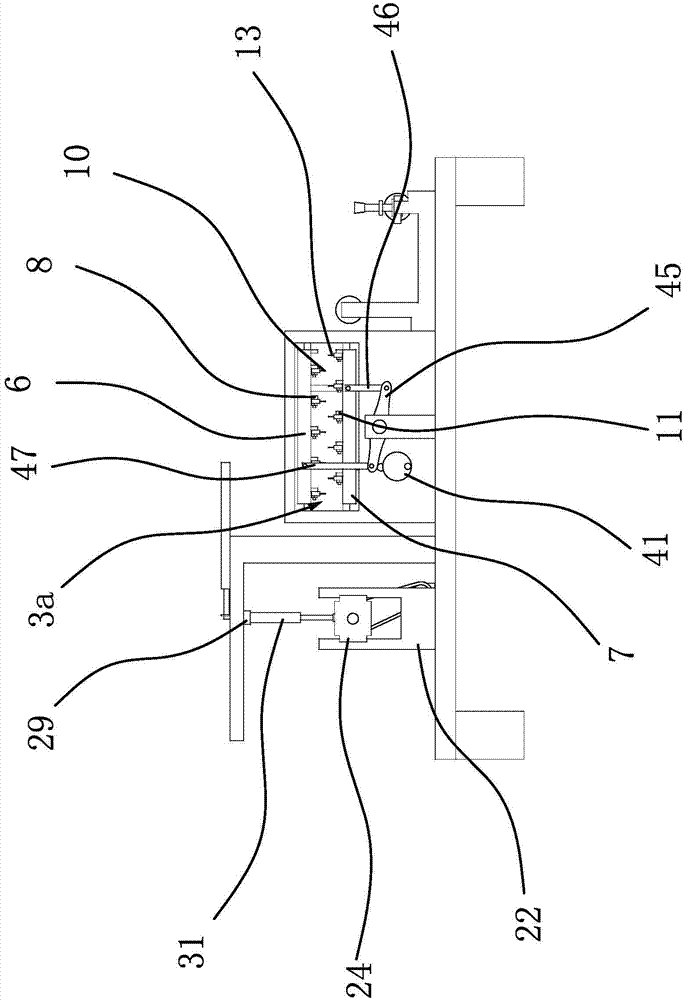

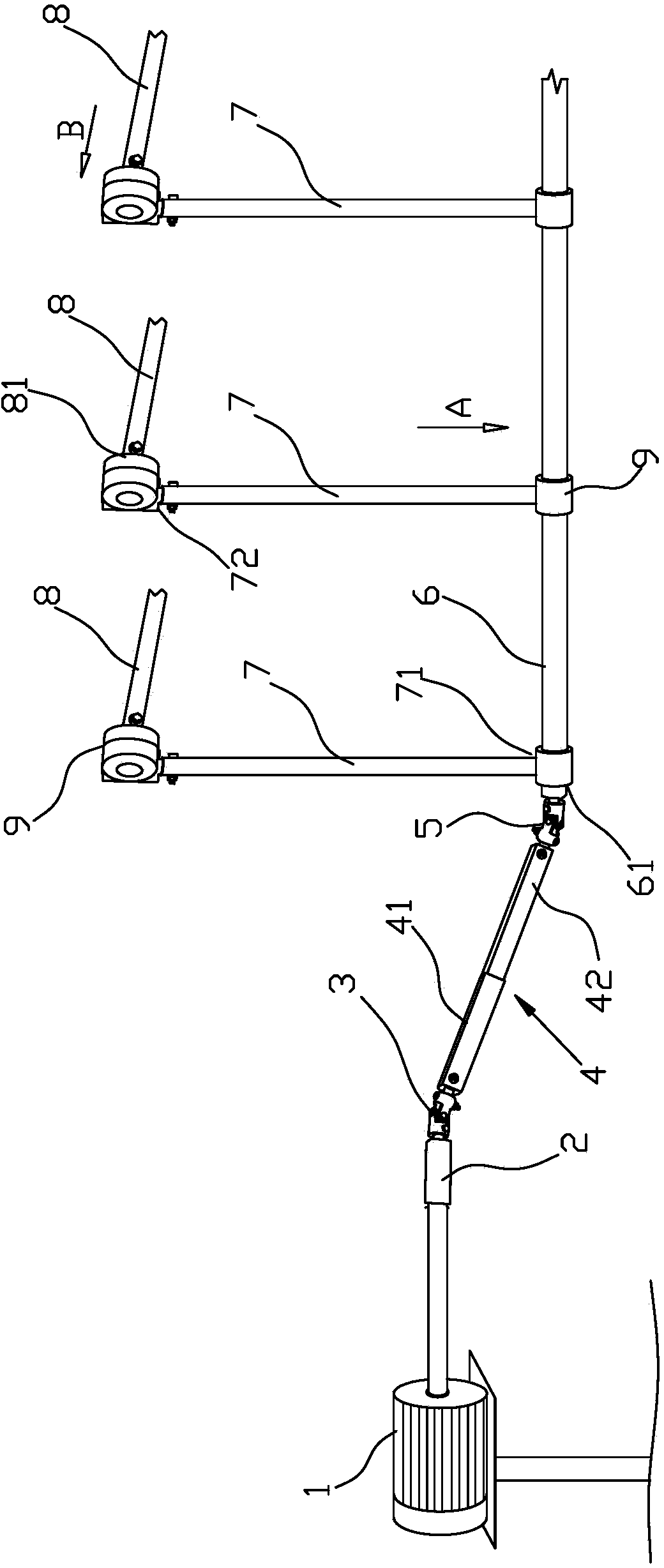

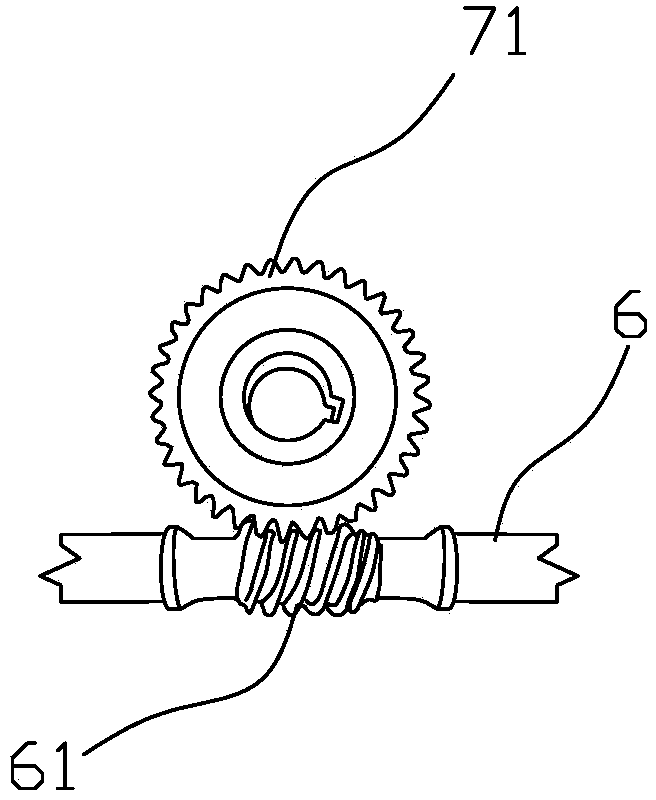

Roller blind device for greenhouse

ActiveCN103503727ARealize unwindingRealize windingClimate change adaptationGreenhouse cultivationAxial displacementDrive shaft

The invention provides a roller blind device for a greenhouse. The roller blind device for the greenhouse comprises a motor, a transmission shaft, a first universal joint, a stretchable rod, a second universal joint, a main shaft, an auxiliary shaft and a reeling shaft. The output end of the motor, the transmission shaft, the first universal joint, the stretchable rod, the second universal joint and the main shaft are connected in sequence, and the auxiliary shaft is connected with the main shaft and the reeling shaft through a non-parallel shaft gear pair. According to the roller blind device, torque is provided by the motor for the main shaft, the main shaft enables the torque to be transmitted to the reeling shaft through rotation of gears, a plastic thin film reels on the reeling shaft, and unreeling and reeling of a thin film roller blind for the greenhouse are electrically controlled. Meanwhile, the multiple universal joints are used in the roller blind device for compensating axial angle differences, the stretchable rod capable of transmitting the torque is further adopted to compensate the axial displacement, the reeling shaft of the roller blind device can depend on the outer contour of a greenhouse support in the reeling process to move, and the roller blind device is suitable for the roller blind of the greenhouse.

Owner:王爱冬

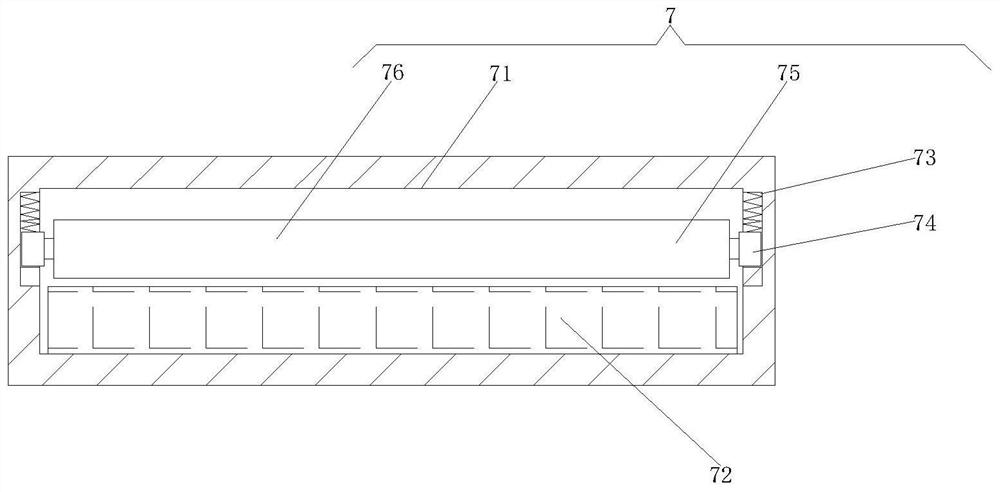

Multi-stage treatment and recovery system and method for PET release films

ActiveCN110435044AReach the purpose of recyclingIncrease profitPlastic recyclingDrying gas arrangementsRecovery methodEngineering

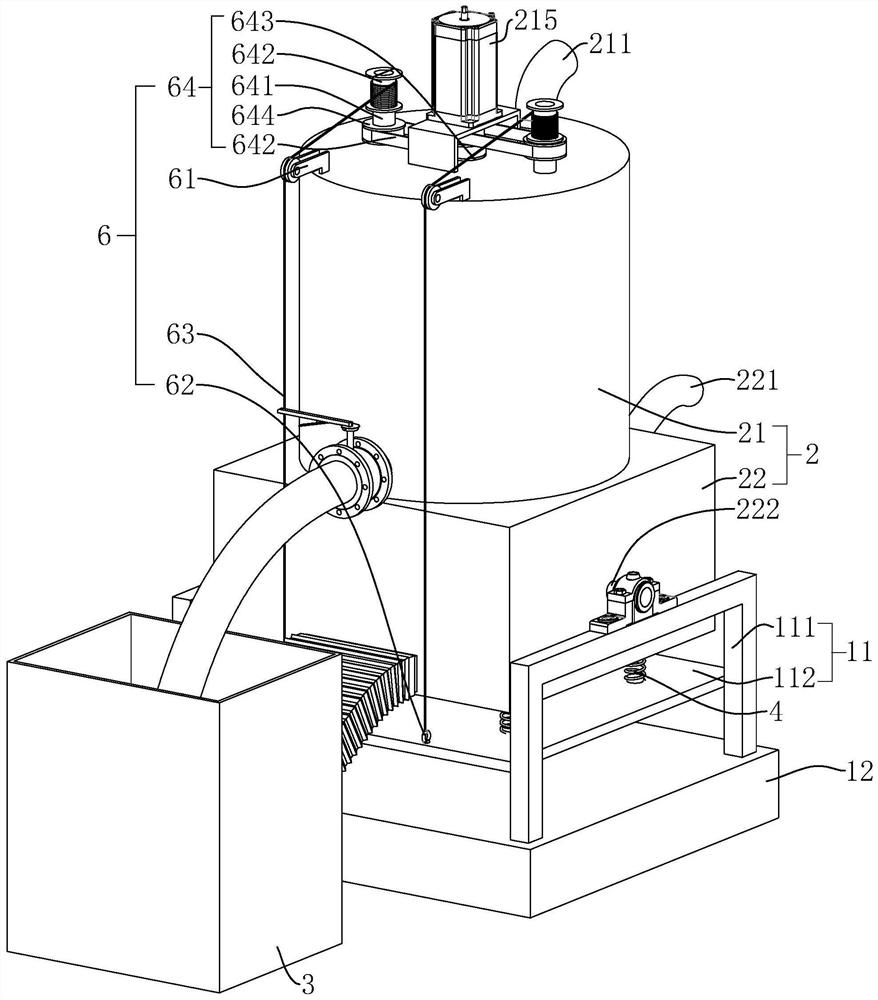

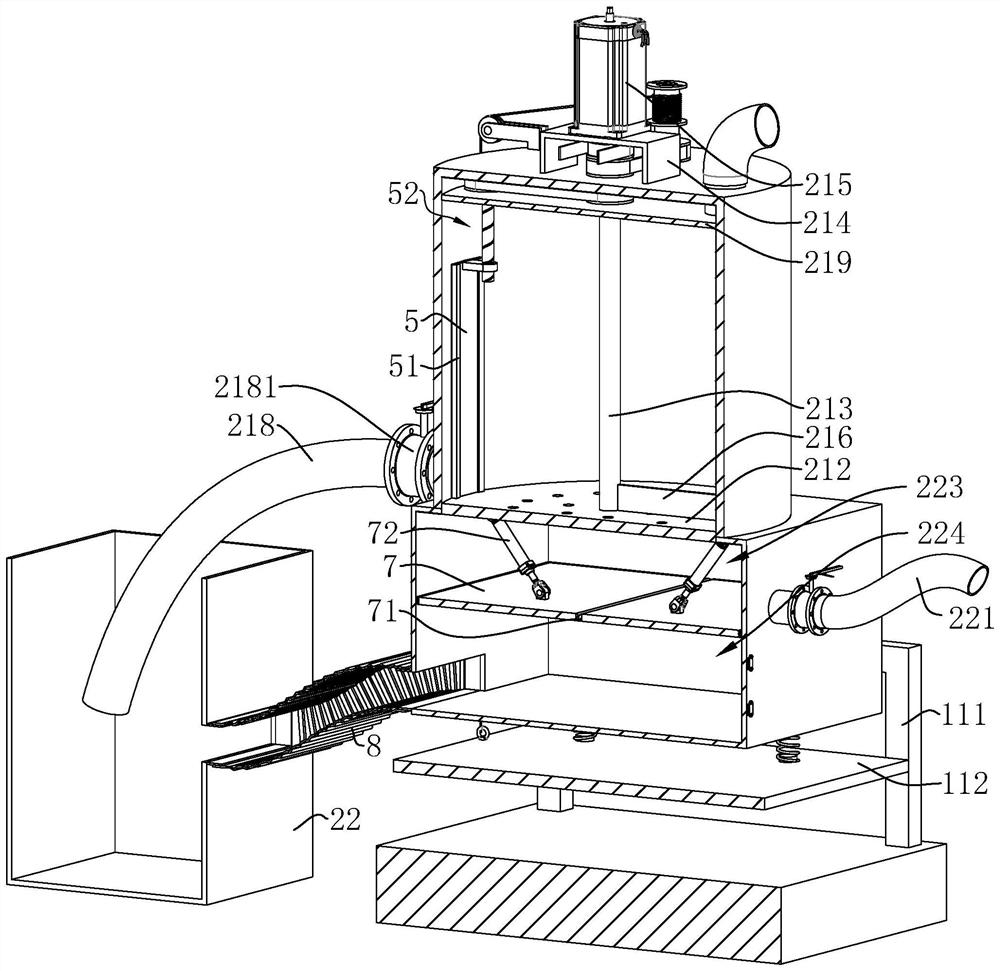

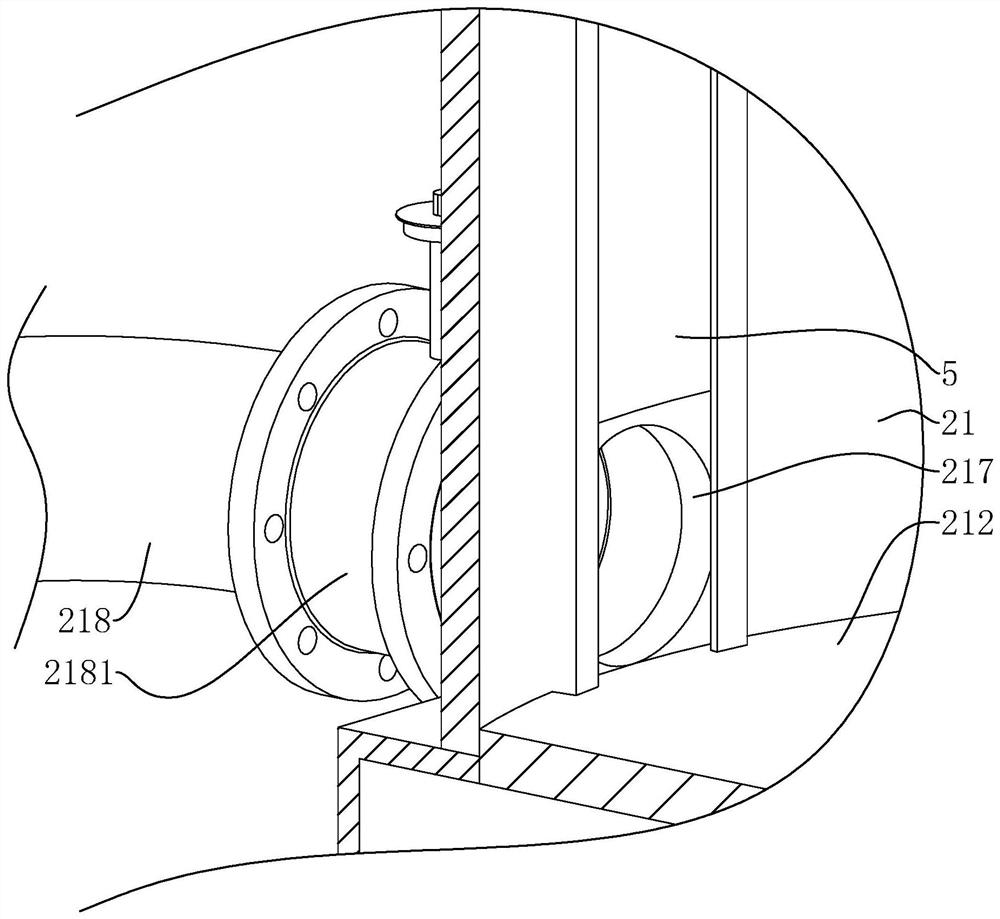

A multi-stage treatment and recovery system for PET release films comprises a mechanical dust removal mechanism, a cleaning mechanism, a drying mechanism and a winding mechanism, wherein the release film sequentially passes through the mechanical dust removal mechanism, the cleaning mechanism and the drying mechanism and is wound on the winding mechanism; traveling of the release films in the mechanical dust removal mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism and transition among the mechanisms are guided by a guide roller in rolling fit with the release films; and the actions of the mechanical dedusting mechanism, the cleaning mechanism, the drying mechanism and the winding mechanism are uniformly and coordinately controlled by an electric control system. According to the multi-stage treatment and recovery system for the PET release films, the release films are subjected to dust removal, cleaning, drying and winding in sequence, so that surface impurities of the used release films can be effectively removed, wound and recycled, the purpose of recycling the release films is achieved, the utilization rate of the release films is improved, and the production cost is reduced. The invention also provides a multi-stage treatment and recovery method for the PET release films.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

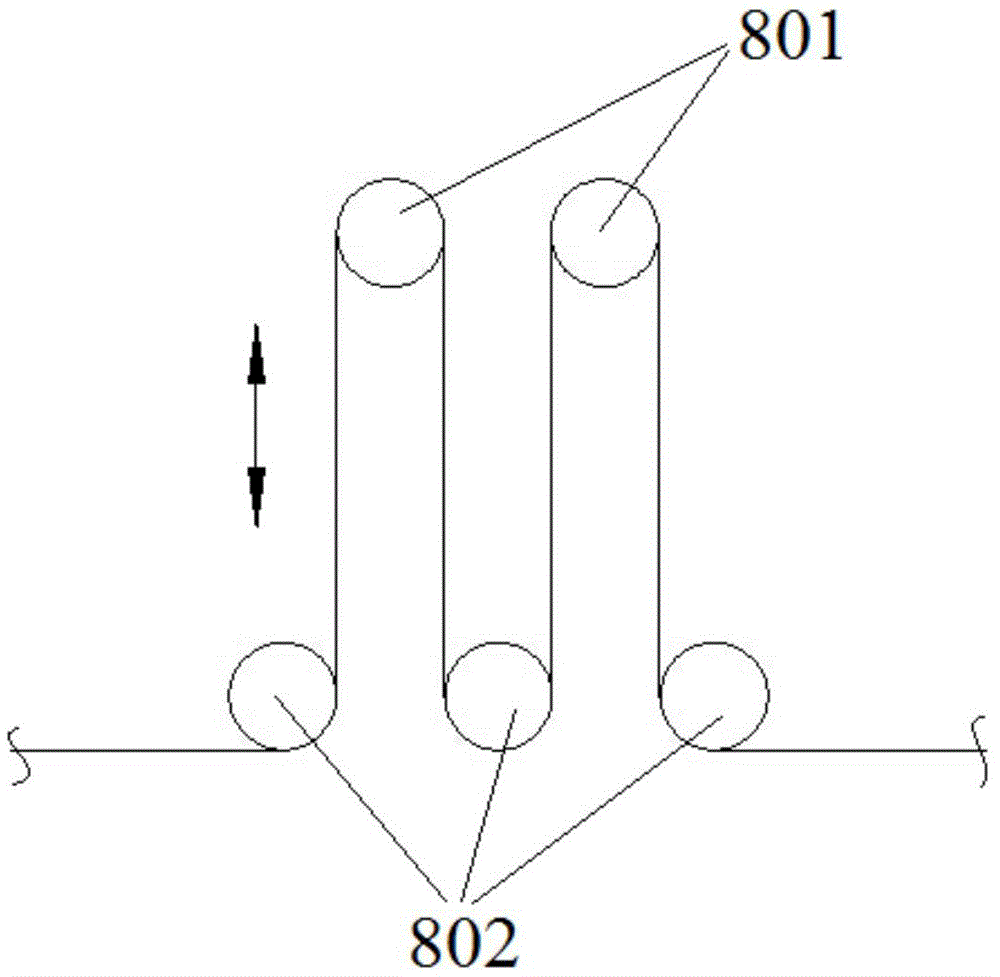

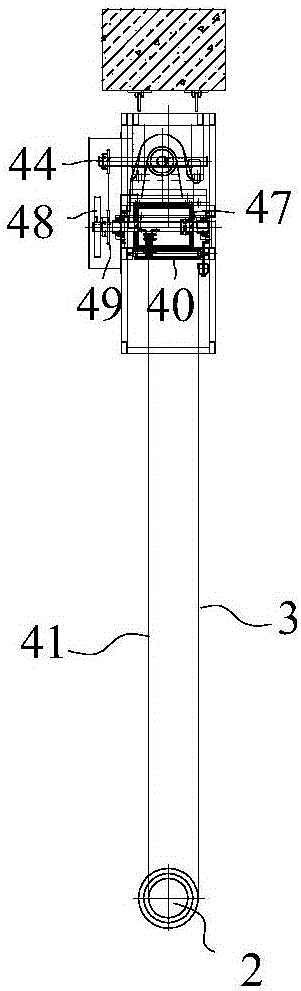

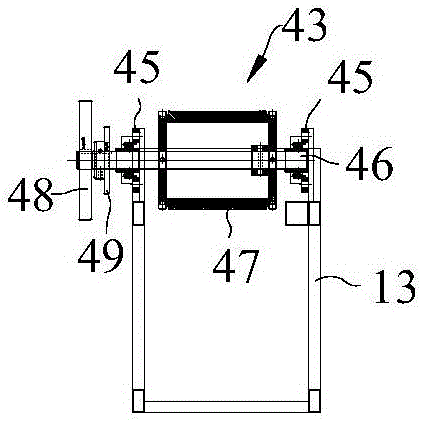

Winding mechanism and operating method thereof

InactiveCN109250569ARealize windingAutomation reductionFilament handlingEngineeringMechanical engineering

Owner:余名宪

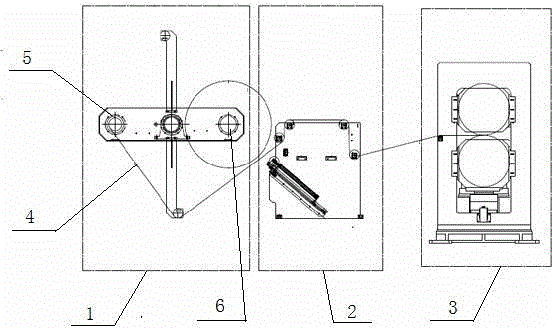

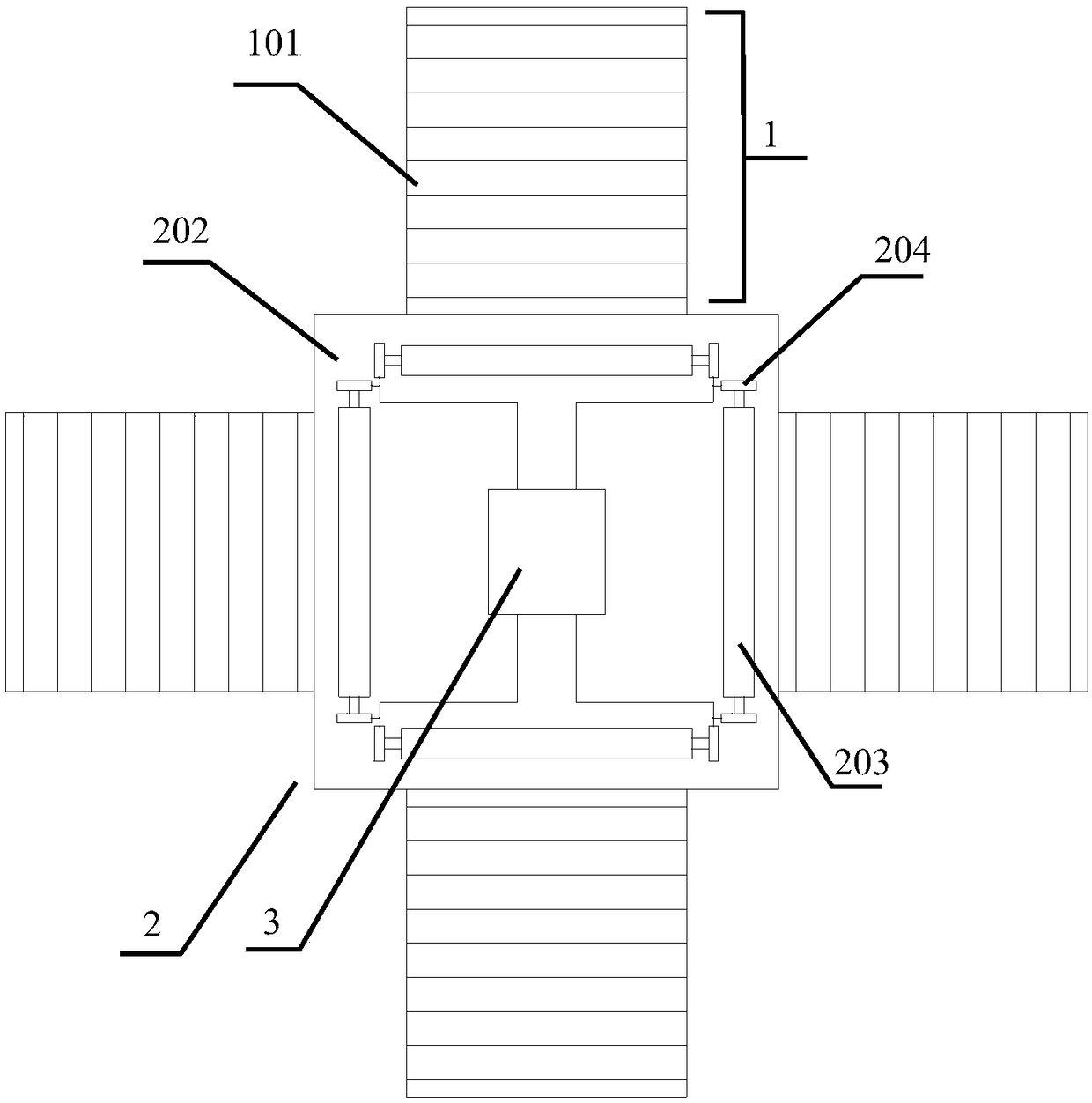

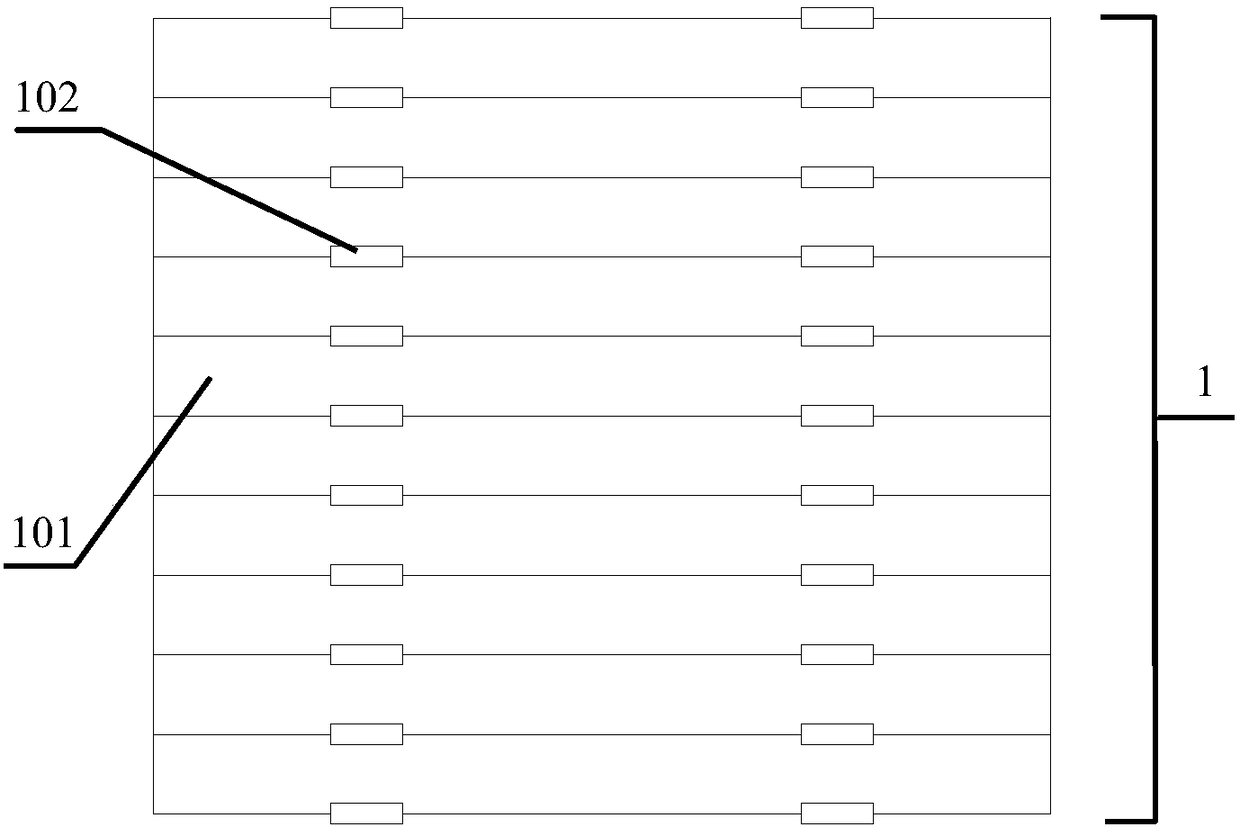

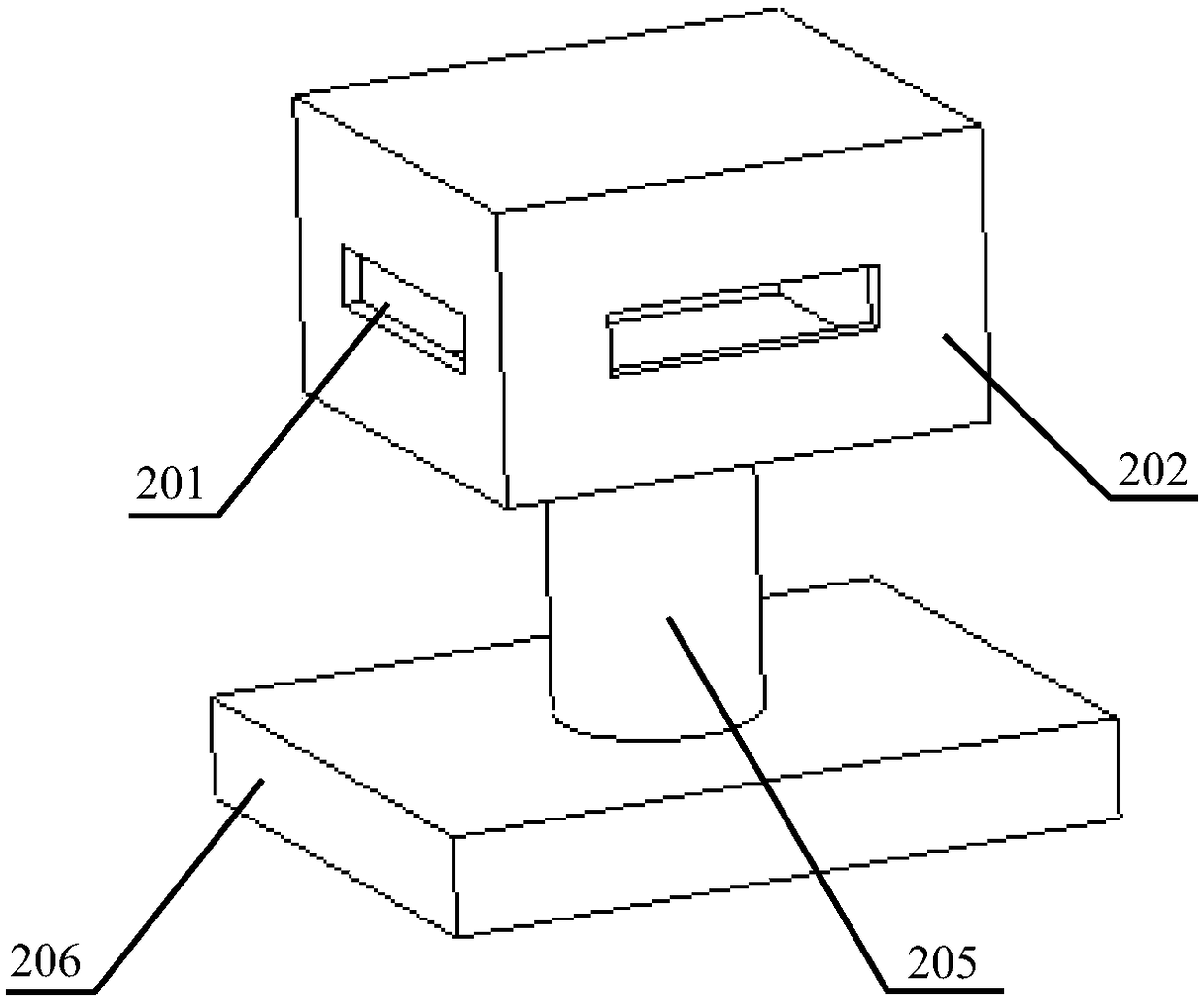

Electric vehicle solar charging device with folding and storing function

InactiveCN108466563AWith retractable functionRealize windingCharging stationsElectric vehicle charging technologyElectric vehicleEngineering

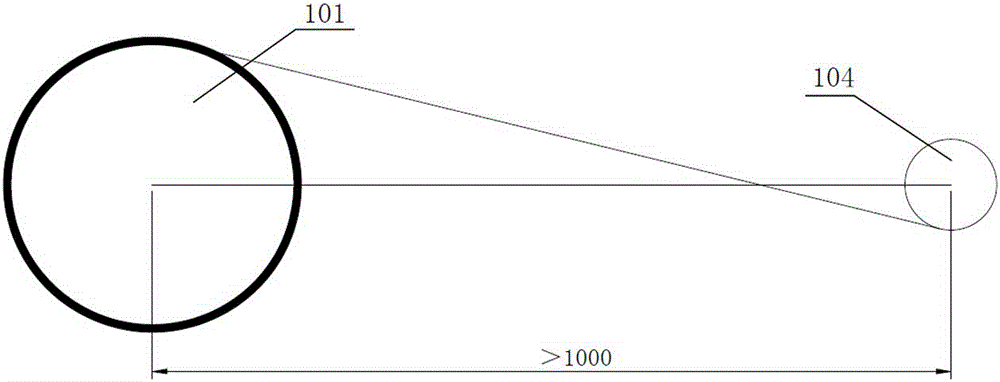

The invention relates to an electric vehicle solar charging device with a folding and storing function. The electric vehicle solar charging device with the folding and storing function comprises a solar cell panel (1), a folding and storing mechanism (2) and a controller (3); the bottom of the folding and storing mechanism (2) is fixed together with a roof; a plurality of ports (201) for the solarcell panel (1) to be folded and stored are formed in the side surface of the folding and storing mechanism (2) in different directions; the solar cell panel (1) is in a shape of a roller blind and isformed by hinging a plurality of battery panel modules (101); the folding and storing mechanism (2) is connected with the solar cell panel (1) and used for driving the solar cell panel (1) to executewinding and unfolding actions; and the controller (3) is used for controlling the folding and storing mechanism (2) to operate. The electric vehicle solar charging device with the folding and storingfunction has the advantages that public lands do not need to be occupied, any area of solar cell panel can be laid according to charging demands, the electric vehicle charging power is increased, thecharging time is reduced, and the solar cell panel is convenient to fold and store by being designed in a modularized manner.

Owner:杨旭海

Transmission equipment for jacquard fabric

The invention provides transmission equipment for a jacquard fabric and belongs to the technical field of textiles to solve the problems that the weaving and transmission of the jacquard fabric cannot be stably and effectively finished in the prior art. The transmission equipment for the jacquard fabric comprises a frame, wherein a left supporting plate and a right supporting plate are fixed on the frame; a through hole (1) is formed in the left supporting plate; a left upper griffe rest and a left lower griffe rest are arranged in the through hole (1); a through hole (2) is formed in the right supporting plate; a right upper griffe rest and a right lower griffe rest are arranged in the through hole (2); an upper griffe arm is fixed on each of the left upper griffe rest and the right upper griffe rest; an upper griffe is arranged on each upper griffe arm; an upper jacquard needle is arranged on the upper griffe; a lower griffe arm is fixed on each of the left lower griffe rest and the right lower griffe rest; a lower griffe is detachably arranged on each lower griffe arm; a lower jacquard needle is arranged on the lower griffe; a swing mechanism is arranged on the frame; a yarn releasing mechanism is arranged in front of the frame; and a fabric winding mechanism is arranged behind the frame. The transmission equipment provided by the invention has the advantages of guiding the yarns to weave the jacquard fabric and orderly winding and tidying.

Owner:HAINING TIANYI TEXTILE

Winding mechanism

InactiveCN109230826ARealize windingAutomation reductionFilament handlingConductor CoilMechanical engineering

Owner:余名宪

Electric roll-down projection screen

ActiveCN106527032ANovel structureMeet large or very large projection screen requirementsProjectorsEngineeringClockwise

The invention discloses an electric roll-down projection screen used for the technical field of projection screens. The electric roll-down projection screen comprises a housing, a reel pipe, a curtain and a reel pipe mechanism, wherein the top end of the curtain is fixedly connected with the housing; the bottom end of the curtain is rolled on the reel pipe along an anti-clockwise direction of the reel pipe; the reel pipe mechanism comprises a rope winder arranged on the housing and a pulling rope led out from the rope winder; the upper end of the pulling rope is connected with the rope winder; and the lower end of the pulling rope is rolled on the reel pipe along a clockwise direction of the reel pipe. When the curtain needs to be put down, the rope winder releases the pulling rope, the reel pipe rotationally falls under the action of gravity, the pulling rope is rolled on the reel pipe, and meanwhile, the curtain on the reel pipe is gradually unfolded; and when the curtain is folded, the rope winder tightens the pulling rope, the pulling rope is driven to rotate in a rolling manner when taken off from the reel pipe, the curtain is gradually rolled on the reel pipe under the action of rotating action force, and rolling of the curtain is finally achieved during lifting. The electric roll-down projection screen is novel in structure and can meet the large or ultra-large projection screen requirements.

Owner:广州市雄云视听设备有限公司

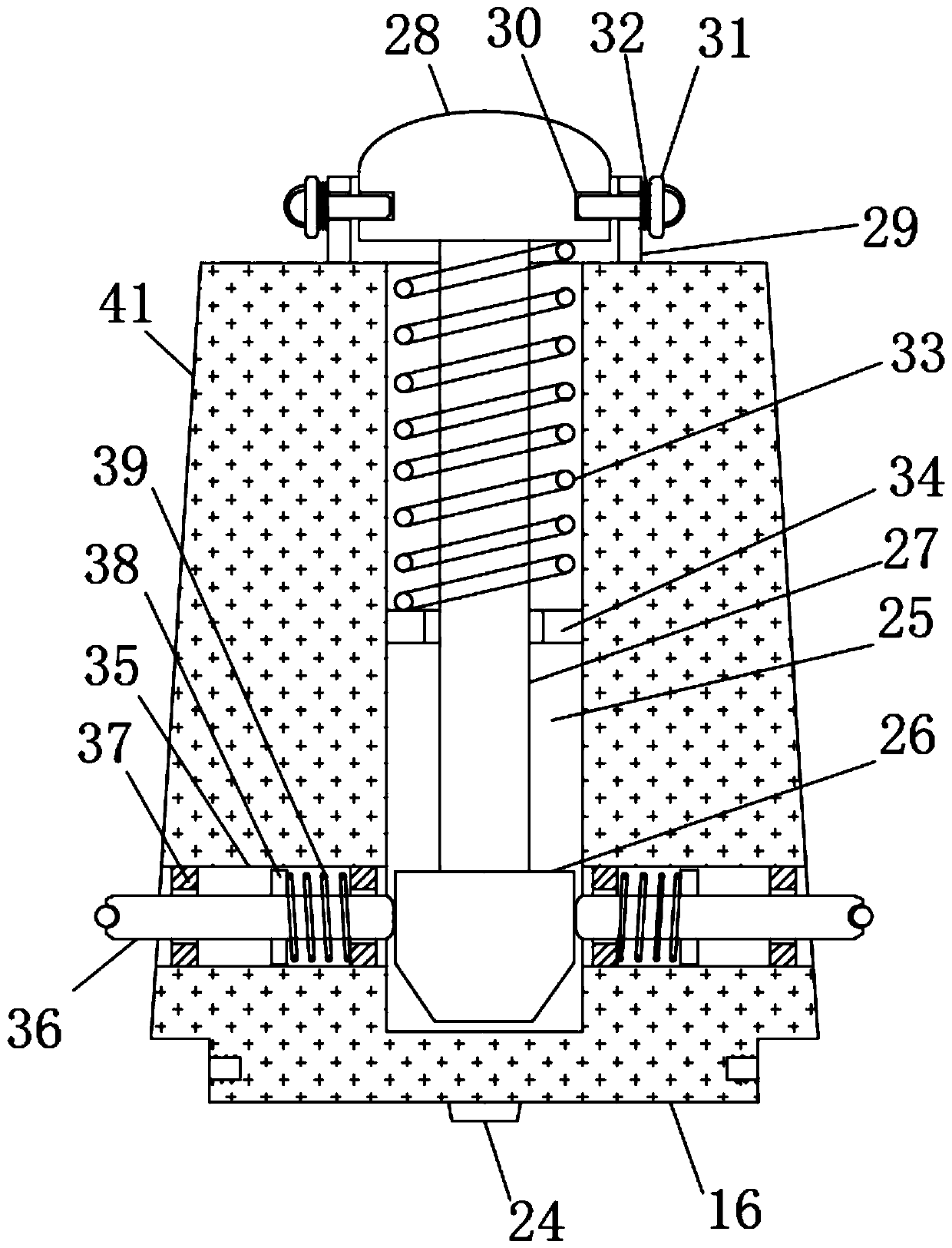

Circuit board welding device

InactiveCN112620864AEasy to liftImprove practicalityHeating appliancesSoldering auxillary devicesPhysicsActivated carbon

The invention discloses a circuit board welding device, and particularly relates to the technical field of welding equipment. The circuit board welding device comprises a bottom plate and supporting frames, wherein the two sides and one end of the top end of the bottom plate are fixedly connected with the supporting frames correspondingly, a preheating mechanism is arranged at the top end of one side of each supporting frame, and a workbench is arranged at the top end of the bottom plate. According to the circuit board welding device, by arranging an exhaust pipe, an exhaust fan, a supporting plate, a gas outlet, a purifying box, an activated carbon particle plate, a photocatalyst plate, a cross-shaped clamping block and a cross-shaped clamping groove, harmful gas can be generated when a welding head is used for welding a circuit board, the exhaust fan is started, and the exhaust fan sucks the gas into the inner bottom end of the purifying box through the exhaust pipe; and because the activated carbon particle plate and the photocatalyst plate are arranged in the purifiying box, when gas gets away from the purifiying box through the gas outlet, the activated carbon particle plate and the photocatalyst plate can purify the gas purified to prevent the gas from pulluting the environment and further prevent the gas from causing harm to the bodies of workers.

Owner:永康市质量技术监测研究院

Garden sewage treatment equipment

InactiveCN112426777AImplement automatic cleanupReduce adhesionStationary filtering element filtersElectric machinerySewage treatment

The invention discloses garden sewage treatment equipment, and relates to the technical field of sewage treatment. The garden sewage treatment equipment comprises a supporting frame, a filter cartridge and a collecting barrel. An elastic assembly used for enabling the filter cartridge to be in a vertical state is arranged between the filter cartridge and the supporting frame. A filter plate is fixedly arranged in an inner cavity of the filter cartridge, the filter cartridge is communicated with a water inlet pipe above the filter plate, the filter cartridge is communicated with a drain pipe below the filter plate, a rotating shaft coaxially rotates in the inner cavity of the filter cartridge, a motor for driving the rotating shaft to rotate is fixedly arranged on the filter cartridge, anda scraper is fixedly arranged on the rotating shaft. A power mechanism used for enabling the filter cartridge to rotate towards one side of the supporting frame around the rotating shaft is arranged between the filter cartridge and the supporting frame, and the filter cartridge is communicated with a communicating pipeline used for enabling an inner cavity of the filter cartridge to be communicated with the collecting barrel. The sewage treatment equipment has the effects that the filter plate is automatically cleaned, the attachment of impurities to the filter plate is reduced, and the normaluse of the sewage treatment equipment is ensured to the maximum extent.

Owner:周杰

Cloth folding machine and cloth folding method

The invention discloses a cloth folding machine and a cloth folding method. The head ends of upper folding plates are higher than the head ends of lower folding plates, the tail ends of the upper folding plates are parallel and level to the tail ends of the lower folding plates, the head ends of the upper folding plates and the head ends of the lower folding plates are unfolded, the tail ends of the upper folding plates and the tail ends of the lower folding plates are folded, the head end and the tail end of each upper folding plate and the corresponding lower folding plate are separately hoisted on a support frame through clamping pieces; a fixing rack is positioned at feeding positions of the head ends of the upper folding plates and the lower folding plates; the head end of a picking rod is fixed on the fixing rack while the tail end is positioned between the head ends of the upper folding plates and the head ends of the lower folding plates; a guiding rod which extends upwards andis used for guiding cloth is arranged at the tail end of the picking rod; two ends of a feeding rod are fixed on the fixing rack; and an arc-shaped expansion portion which is used for expanding the cloth is arranged on the top of the feeding rod. The cloth folding machine is simple in structure and convenient to use, the cloth can be automatically folded and rolled, meanwhile, the follow-up clothtreatment procedure can be reduced, and the cloth folding machine is simple and convenient.

Owner:安徽普尔德无纺科技有限公司

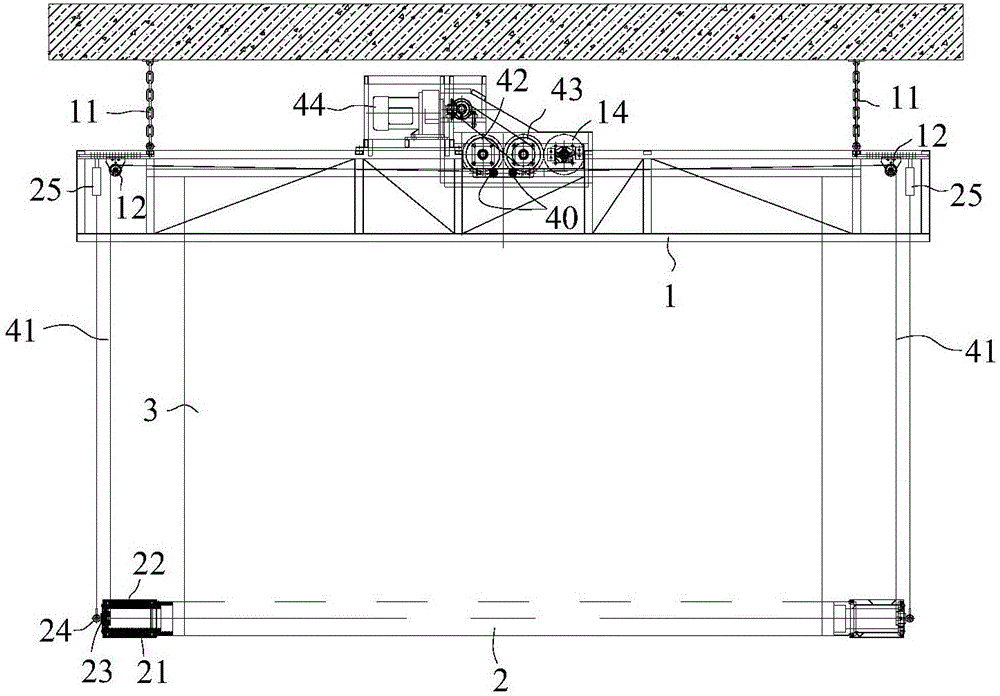

Gantry type large-diameter paper dividing and cutting machine

ActiveCN104891248AIncrease the lengthRealize windingArticle deliveryWebs handlingPulp and paper industry

The invention discloses a gantry type large-diameter paper dividing and cutting machine which comprises a gantry type rack, a traction dividing and cutting mechanism arranged at the other end of the gantry type rack, an unwinding device arranged at one end of the gantry type rack, and N pressing type winding devices arranged on the lower portion of the traction dividing and cutting mechanism, wherein N is an integer larger than or equal to 2. The pressing type winding devices are distributed on the two sides of the traction dividing and cutting mechanism in the width direction of paper, and the paper is wound on the pressing type winding devices on the two sides of the traction dividing and cutting mechanism in a staggered mode. The gantry type large-diameter paper dividing and cutting machine has the advantages that the technical defects that in the prior art, paper absorbs dust on the bottom face easily, the surface of the paper can not be well protected, the paper needs to be wound on the same winding shaft and then the winding shaft is cut after winding, and winding efficiency is low are overcome, the structure is simple, and use is convenient.

Owner:NANJING JIA XU MACHINERY MFG

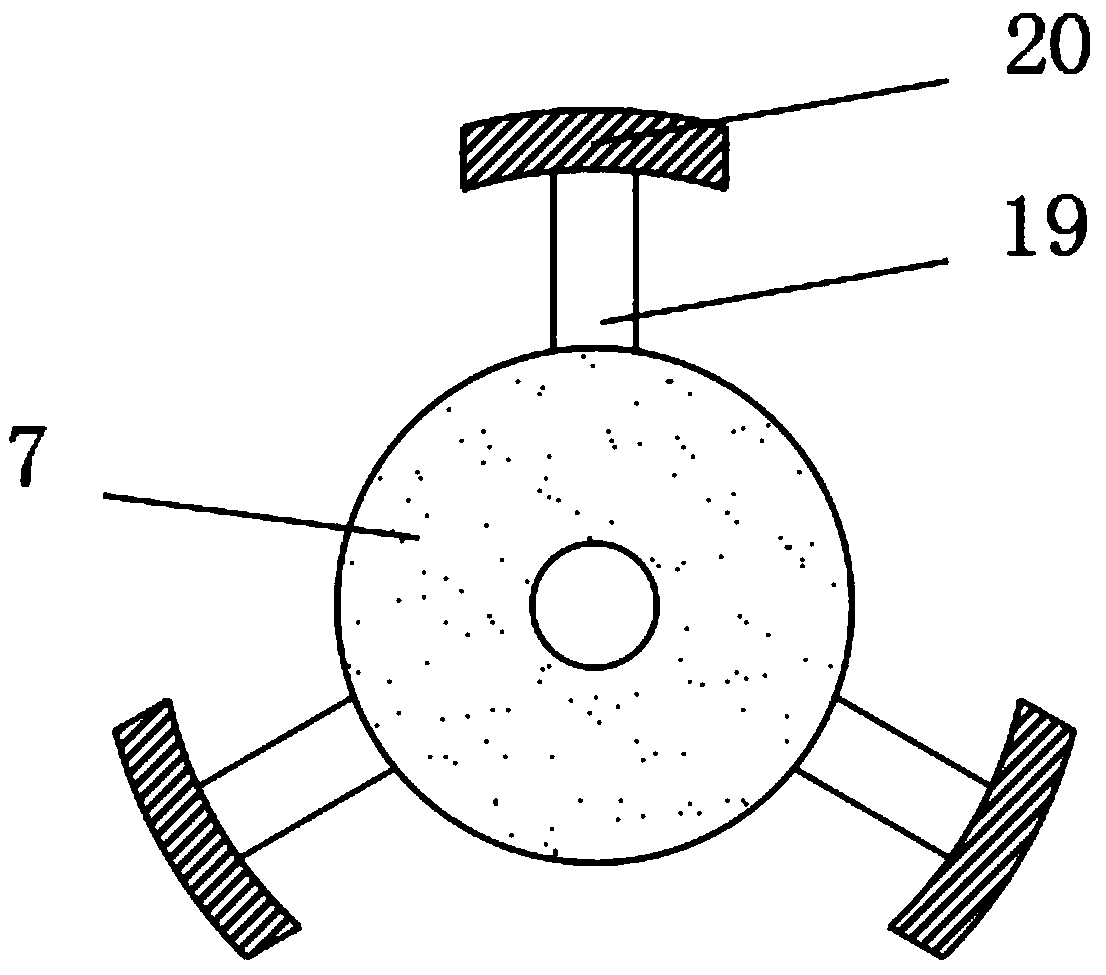

Rapid positioning device for textile machinery

The invention relates to the technical field of spool positioning devices, in particular to a rapid positioning device for textile machinery. The rapid positioning device comprises a fixed plate, wherein a base is arranged on the upper portion of the fixed plate, a rotating connecting assembly is arranged between the fixed plate and the base, a mounting ring is sleeved on the outer side of the base, a fixing piece is arranged on the surface of the mounting ring, a locking screw is arranged on the surface of the fixing piece, the end of the locking screw is screwed in a sleeve, the sleeve is fixed to the surface of the fixed plate, a butting groove is formed in the bottom surface of the base, a fixing frame is inserted into the butting groove, and the fixing frame is fixed on the surface ofthe fixed plate. The rapid positioning device for textile machinery has the beneficial effects that the structure is simple, the assembly is convenient, a yarn barrel can rotate around a middle cylinder body when a thread is pulled, and the middle cylinder body is driven to rotate by means of a driving device after the cylinder body and the yarn barrel are connected through a telescopic connecting structure, thereby realizing the rotation of the yarn barrel.

Owner:海宁市恒通经编有限公司

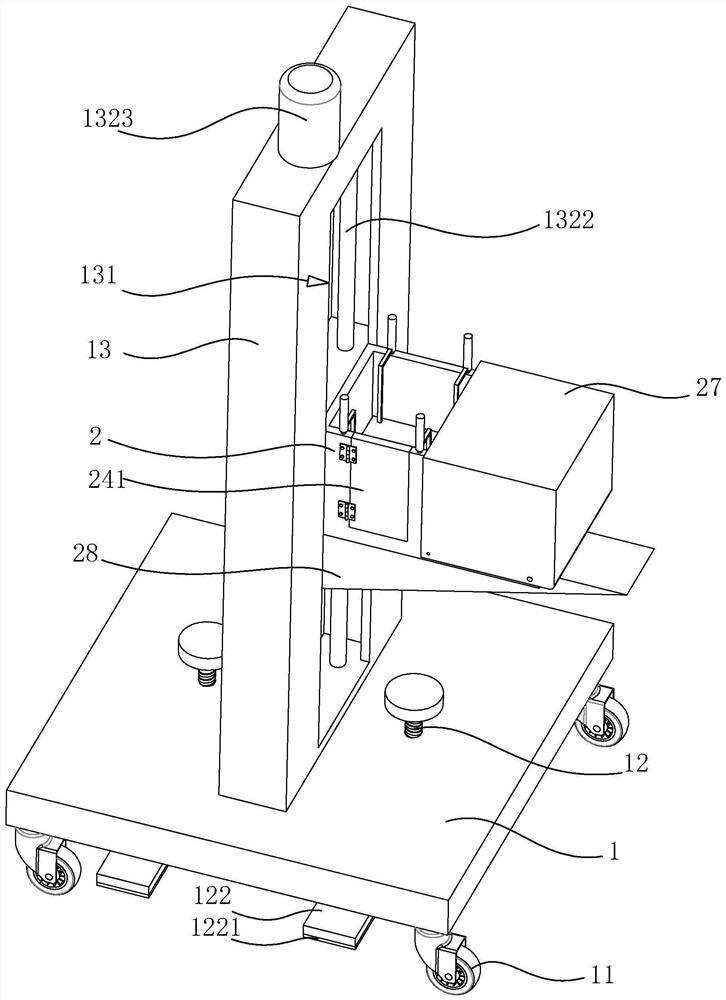

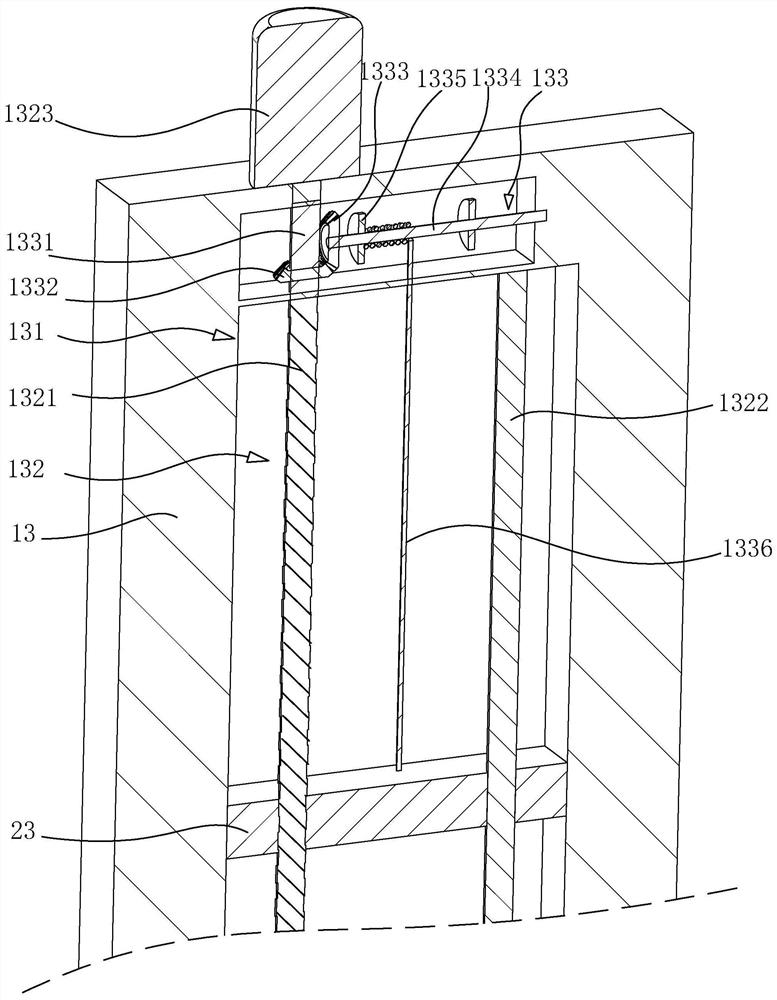

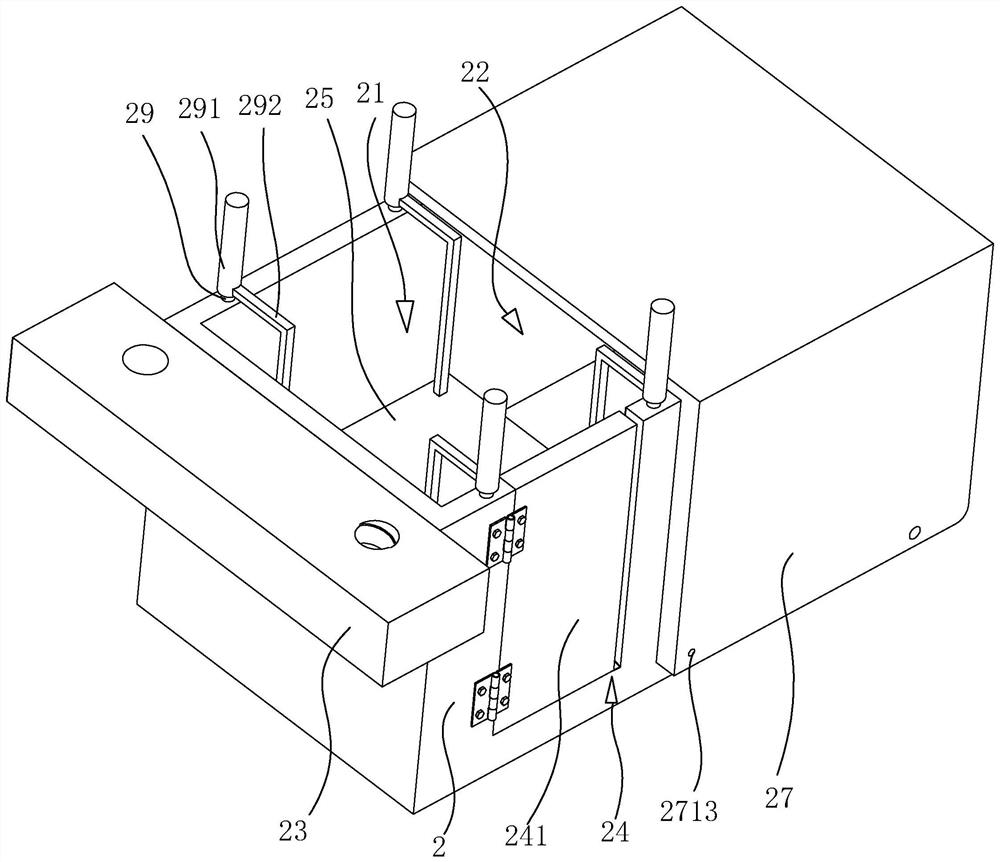

Crawling device for electromechanical equipment installation

The invention relates to a crawling device for electromechanical equipment installation, and relates to the technical field of crawling equipment. The device comprises a supporting ladder assembly, one side of the supporting ladder assembly is slidably connected with a supporting hanging basket in the height direction of the supporting ladder assembly, the supporting ladder assembly is provided with a first lifting assembly used for driving the supporting hanging basket to ascend and descend in a reciprocating mode in the height direction of the supporting ladder assembly, and the supporting hanging basket internally comprises a standing area and a tool containing area. The device has the effects that the crawling burden of operators is relieved, and the construction efficiency is improved.

Owner:南通通博设备安装集团有限公司

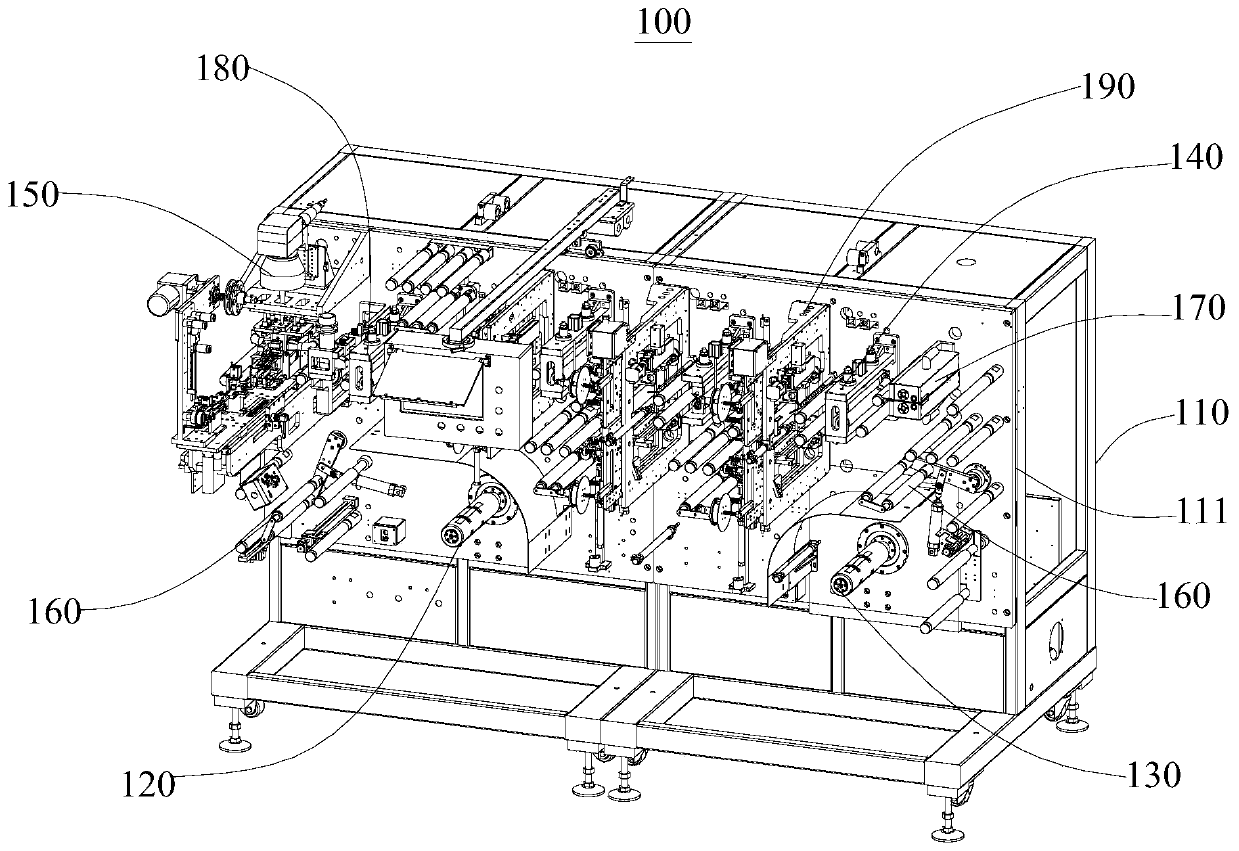

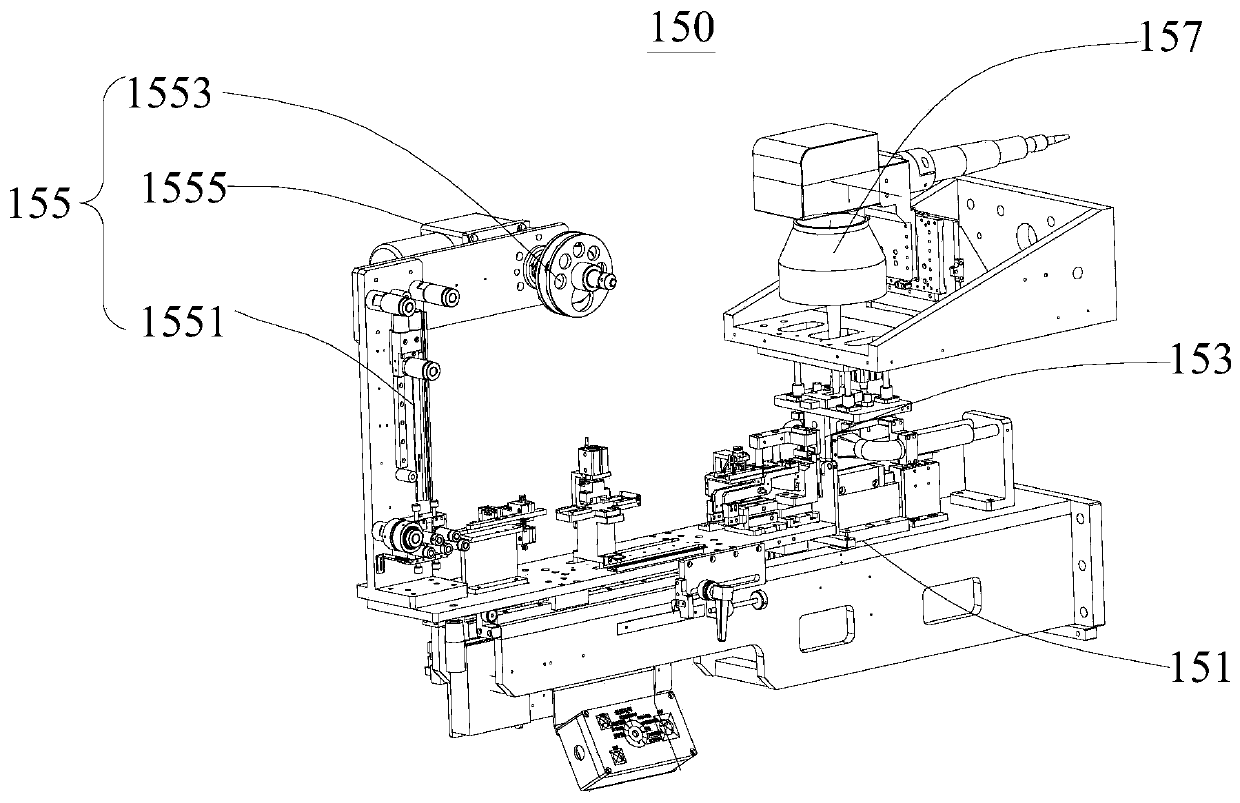

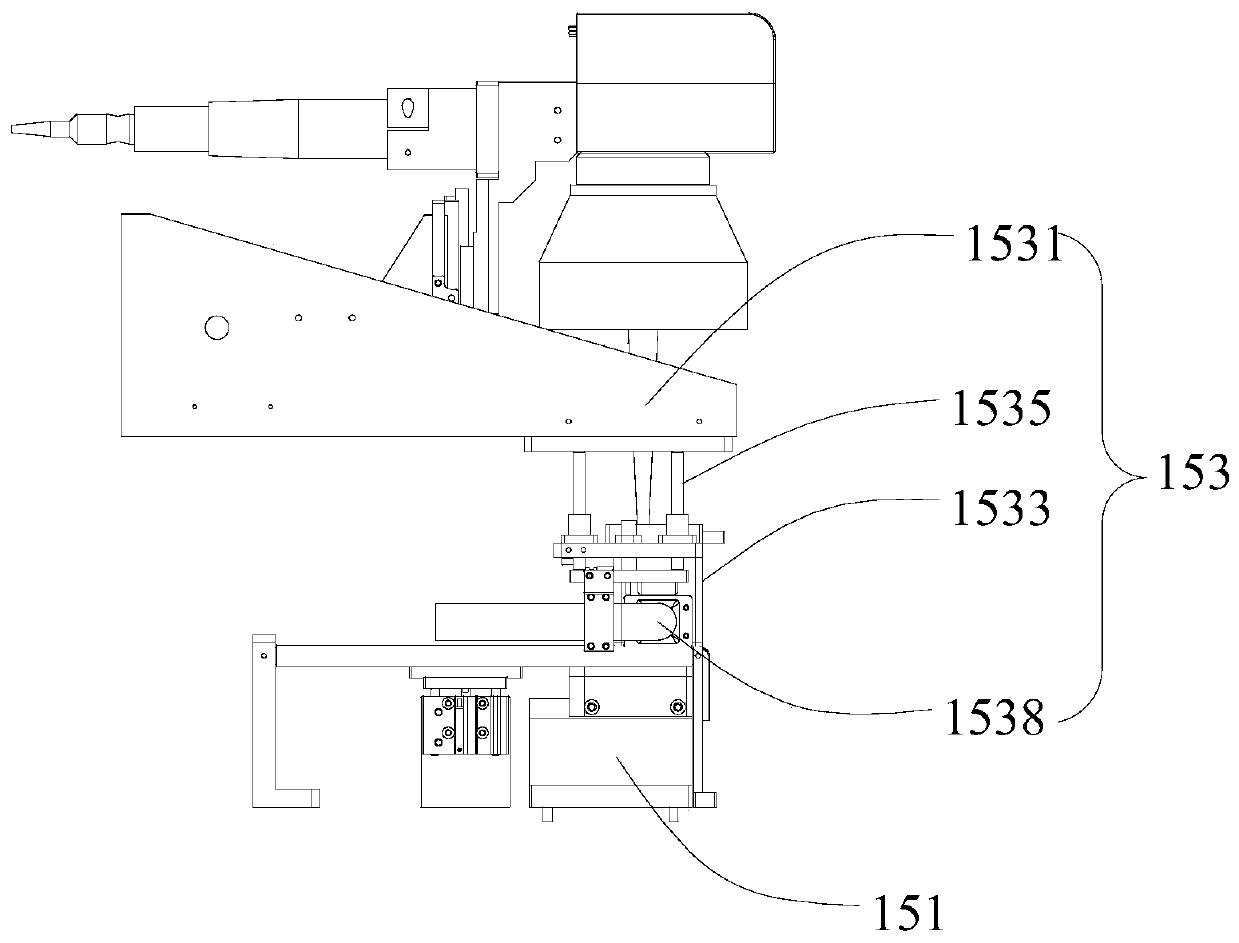

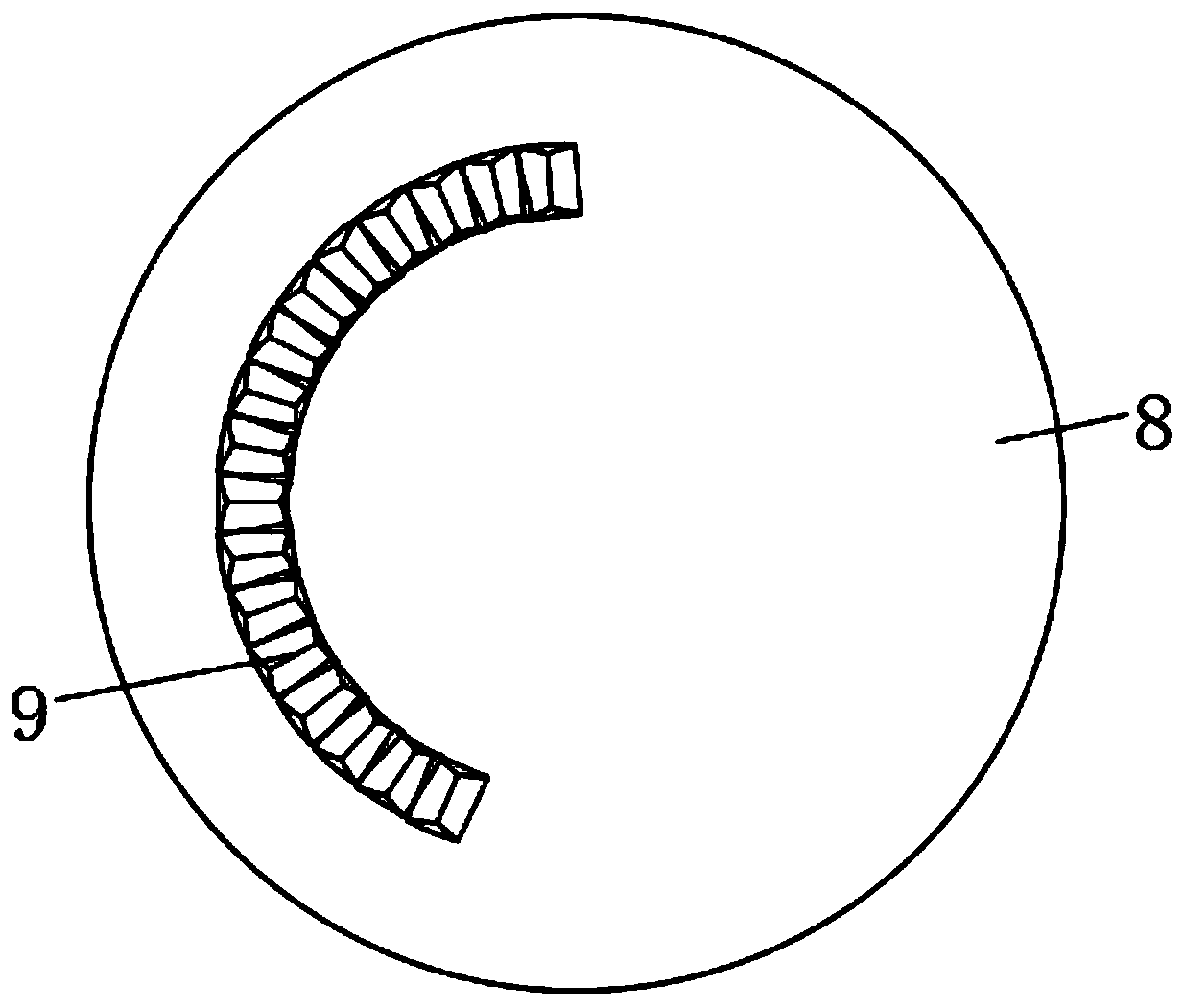

Tab laser welding equipment

PendingCN110711942ARealize windingGuaranteed virtual soldering rateWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingCell fabrication

The invention provides tab laser welding equipment and relates to the technical field of lithium battery manufacturing. The tab laser welding equipment comprises a machine body, an automatic unwindingdevice, an automatic winding device, a drive device and a tab laser welding device; the automatic unwinding device is arranged on the machine body and is used for bearing and unwinding a pole piece coil; the automatic winding device is arranged on the machine body and is used for bearing and winding the pole piece coil; the drive device is arranged between the automatic unwinding device and the automatic winding device and is used for driving the pole piece to move to the automatic winding device from the automatic unwinding device; and the tab laser welding device is arranged on the machinebody and is used for performing laser welding on a pole piece. Compared with the prior art, for the tab laser welding equipment provided by the invention, through a laser welding mode, by adopting non-contact welding, a welding head does not need to be replaced like ultrasonic welding, indexes, such as the virtual welding rate, the residual rate after welding and the tension, can be effectively ensured, and the welding problem caused by ultrasonic welding is solved.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Leg fixing clamp for orthopedic surgery

ActiveCN111481305AFully trainedSpeed up recoveryPneumatic massageInstruments for stereotaxic surgeryOrthopedics surgeryAtrophy

The invention discloses a leg fixing clamp for orthopedic surgery. The leg fixing clamp includes a clamp, the inner wall of the clamp is fixedly connected with an air bag; the surface of the clamp isfixedly connected with a training device; the training device comprises a bracket fixed on the bed frame; the left side of the support is fixedly connected with a transverse plate. A motor is fixedlyconnected to the upper surface of the transverse plate, a first shaft is fixedly connected to the top of an output shaft on the motor, a rotary disc is fixedly connected to the top of the first shaft,an arc-shaped rack is fixedly connected to the upper surface of the rotary disc, a second shaft is rotatably connected to the left side, close to the top, of the support in a limited mode, and two gears are fixedly connected to the surface of the second shaft. According to the leg fixing clamp, through the cooperative use of the structures, the problems that in the actual use process, the air bagtightly wraps the shank for a long time, so that the blood circulation of the shank part is easily unsmooth, the atrophy of shank muscles is easily caused, the postoperative shank recovery time is prolonged, and the inconvenience is brought to the use are solved.

Owner:朱凤堂

Rolling mechanism of film cutting rolling machine

The invention provides a rolling mechanism of a film cutting rolling machine, belongs to the technical field of machinery and solves the technical problems that an existing film cutting rolling machine is low in efficiency and the like. The film cutting rolling machine comprises a worktable and fixed plates located on two sides of the worktable; one end of the worktable is connected to an unrolling structure of an unrolling roller. The rolling structure is arranged above the other end of the worktable and comprises a rotary rack and two rolling rollers; the rotary rack is rotatably connected to the corresponding fixed plate; the rotary rack is provided with two supporting rods; mounting seats are fixed on the end portions of the two supporting rods; one end of each of the two rolling rollers penetrates through the corresponding mounting seat and is rotatably connected to the corresponding mounting seat through a bearing; driven gears are fixed at one ends, penetrating through the mounting seats, of the two rolling rollers; a rolling motor is fixed on each of the mounting seats; a driving gear is fixed on a motor shaft of each of the rolling motors; and the driving gears and the driven gears are engaged. The rolling mechanism has the advantage of rolling a film efficiently.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Winding device for processing electric cable

The invention discloses a winding device for processing an electric cable. The winding device comprises a winding machine body. Four corners of the bottom end of the winding machine body are providedwith support legs. Two sides of the top end of the winding machine body are fixedly provided with a first support column. One side of the outer surface of the first support column is provided with a fixing block. One side of the interior of the fixing block is provided with a support rotating rod. One side of the outer surface of the first support column is fixedly provided with a first motor. Oneside of the output end of the first motor is fixedly provided with a winding plate. One side of the top end of the first support column is fixedly provided with a hydraulic cylinder. One side of theoutput end of the hydraulic cylinder is provided with a hydraulic telescopic rod. One side of the top end of the hydraulic telescopic rod is fixedly provided with a second support column. The windingdevice for processing the electric cable is capable of enabling the whole device to be more labor-saving for winding and using the electric cable, enabling the electric cable to be more tidily winded,and bringing better application prospect.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

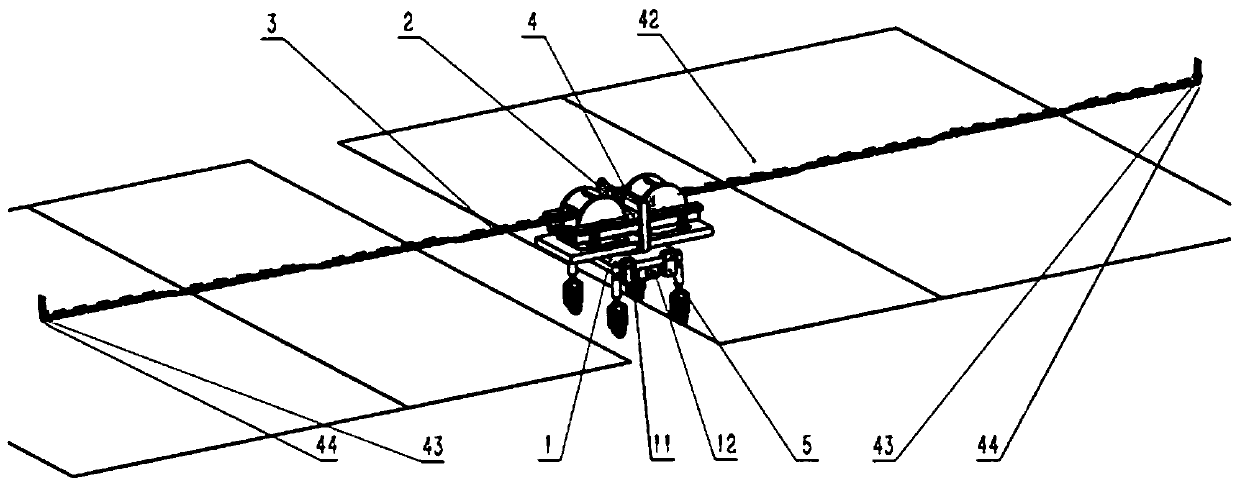

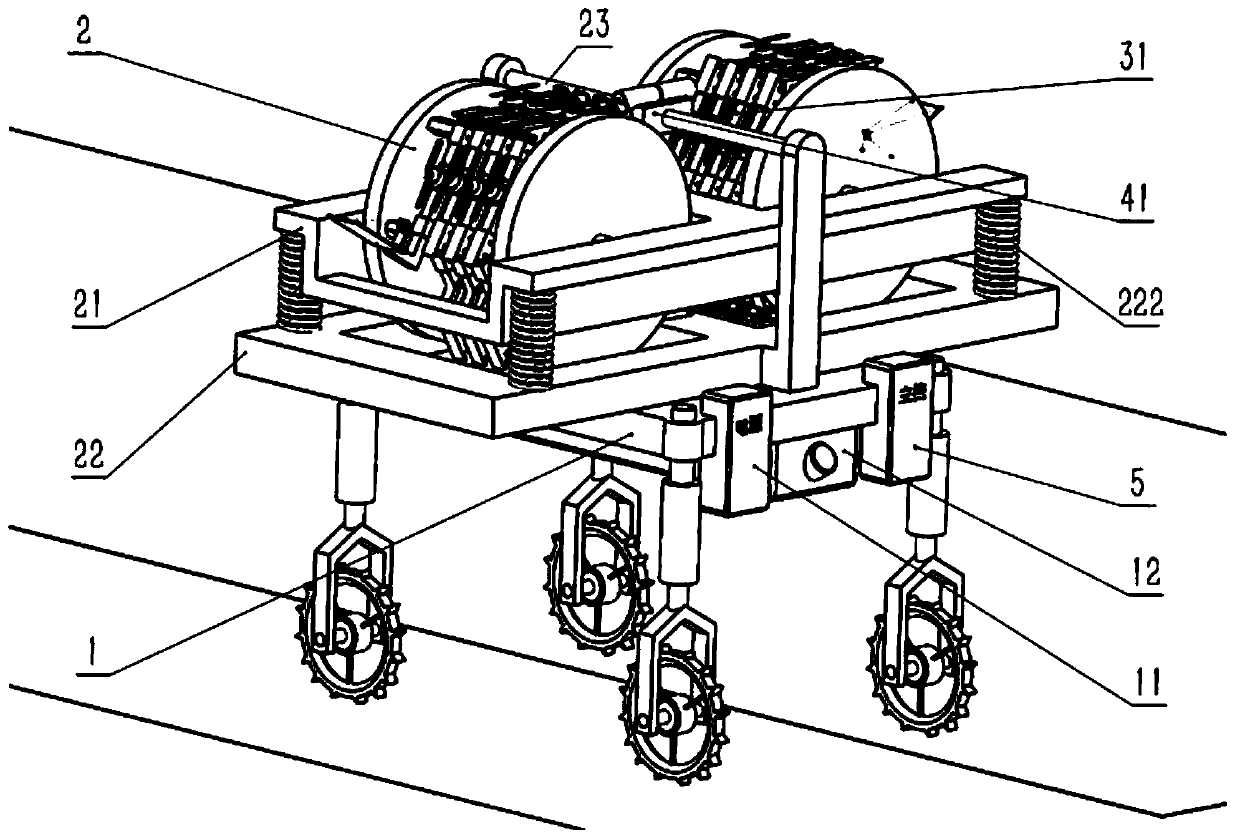

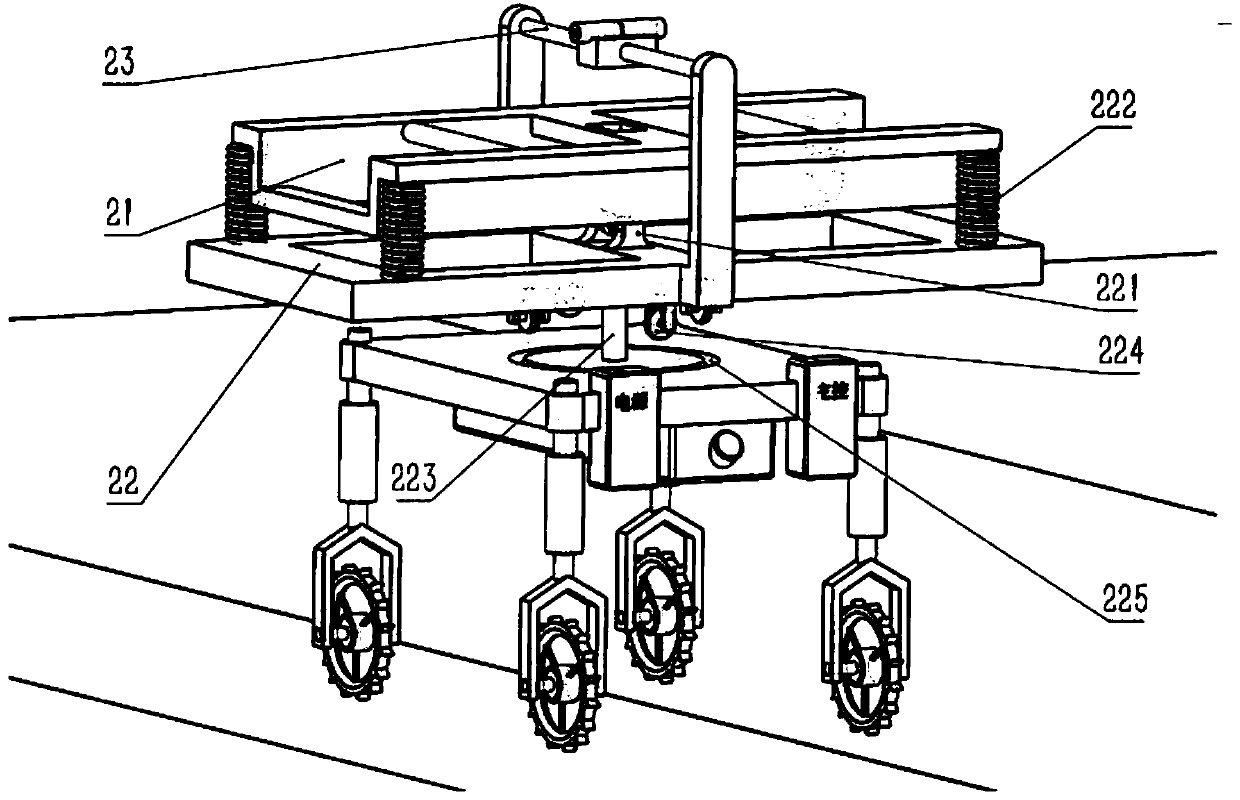

Rotor wing suspension width spraying rod spraying machine and control method thereof

PendingCN109937996AIncrease payloadImprove work efficiencySpray nozzlesLiquid spraying apparatusPropellerEngineering

The invention discloses a rotor wing suspension width spraying rod spraying machine and a control method thereof. The spraying machine comprises a spraying machine body, a pair of polygon rollers aremounted on the spraying machine body, rotor wing width spraying rods are arranged on the polygon rollers and positioned on two sides of the spraying machine body after being unfolded, the rotor wing width spraying rods comprise motors, propellers, a plurality of rotor wing spraying rod units and a plurality of sprayers, the propellers are connected with the motors, the rotor wing spraying rod units are connected, the sprayers are arranged on the rotor wing width spraying rods, the rotor wing spraying rods are unfolded and folded by the polygon rollers, self-balancing height setting systems arearranged on the rotor wing spraying rods and used for acquiring height information to adjust and control balance of the spraying rod and the height between the spraying rod and the ground, and a maincontrol system connected with the polygon rollers, the motors and the self-balancing height setting systems is mounted on the spraying machine body. According to the spraying machine, horizontal states of the width spraying rod can be ensured in the various postures of the body, contact between the sprayer and the ground caused by long spraying rod and wide spraying swath is avoided when the bodyrotates, the rotor wings provide lifting power for width spraying rod, a complex and expanded truss structure is avoided when the spraying rod is enlarged.

Owner:SOUTH CHINA AGRI UNIV

Production process of laminated kraft paper

InactiveCN111270557AAffect teleportationFfect processabilityPaper coatingPaper/cardboardPulp and paper industryKraft paper

The invention relates to a production process of laminated kraft paper. The production process comprises the following steps: step 1, preparing kraft paper; step 2, napping kraft paper; step 3, compounding the laminating master batch; step 4, laminating and compounding the kraft paper; step 5, trimming the laminating kraft paper; and step 6, collecting the laminating kraft paper. The production process has the advantages that the moisture content of the kraft paper can be effectively adjusted during production of the kraft paper coated paper so that the reliability of the kraft paper during subsequent coating production is guaranteed and the production quality is guaranteed.

Owner:济南文海包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com