Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491results about How to "High degree of production automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

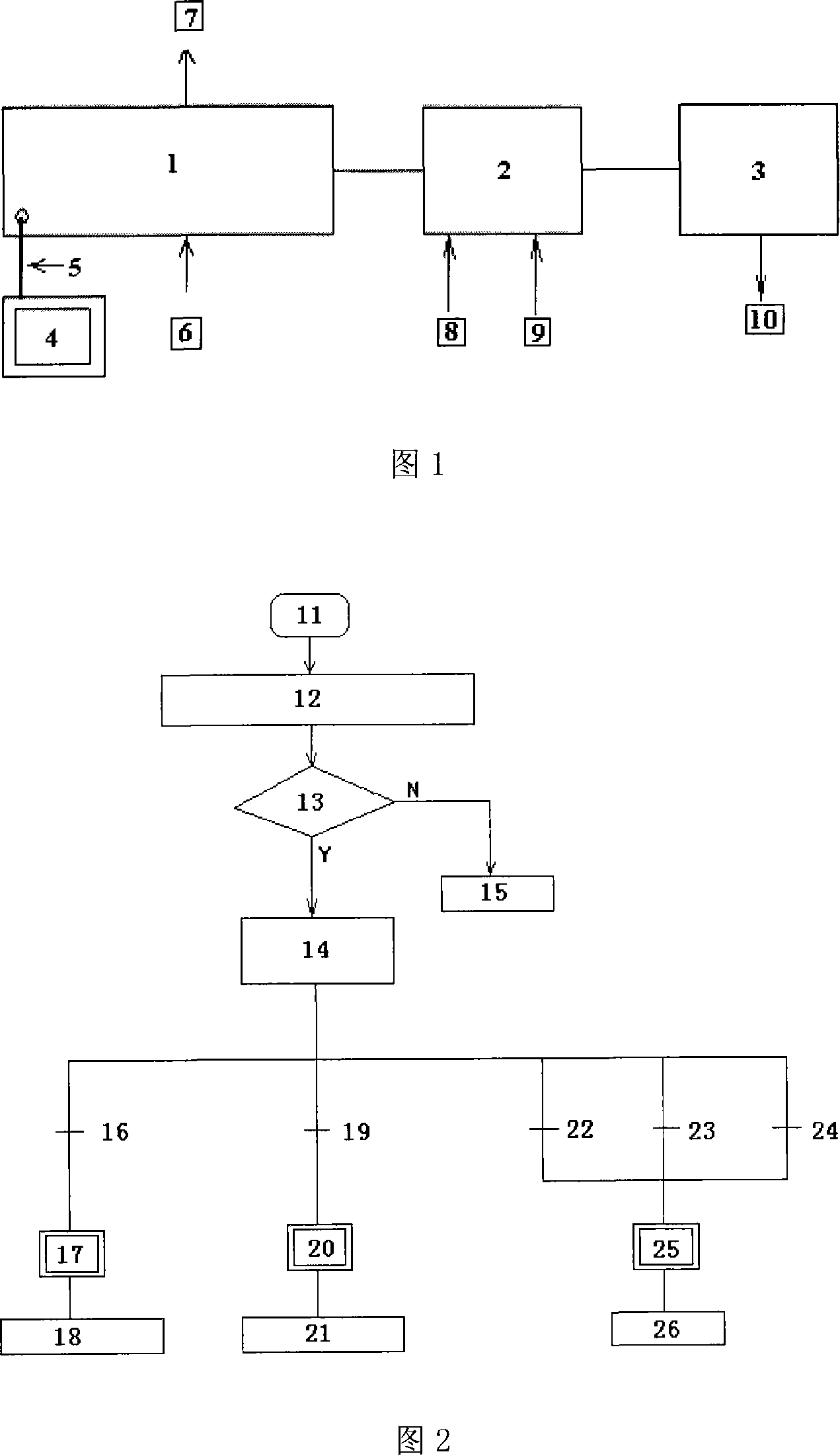

System for visually detecting workpiece appearance defects based on image processing

ActiveCN106053479AFast positioningHigh precisionImage enhancementImage analysisDiffuse reflectionVisual perception

The invention discloses a system for visually detecting workpiece appearance defects based on image processing, comprising an industrial personal computer, a coaxial light source, a CCD (charge coupled device) industrial camera, an image acquisition card and a rejecting mechanism; both the coaxial light source and the rejecting mechanism are connected with the industrial personal computer; the CCD industrial camera is connected with the industrial personal computer through the image acquisition card; wherein the coaxial light source is used for providing a diffuse reflection light source for a workpiece to be detected; the CCD industrial camera is used for taking an image of the workpiece at a detection station; the rejecting mechanism is used for rejecting from a production line, workpieces detected to be defective; the industrial personal computer has a defect detection module based on image processing; the system is high in detection efficiency and easy to implement.

Owner:XIANGTAN UNIV

Workpiece apparent defect detection method based on machine vision

ActiveCN106204614AFast positioningHigh precisionImage enhancementImage analysisTemplate matchingVisual system

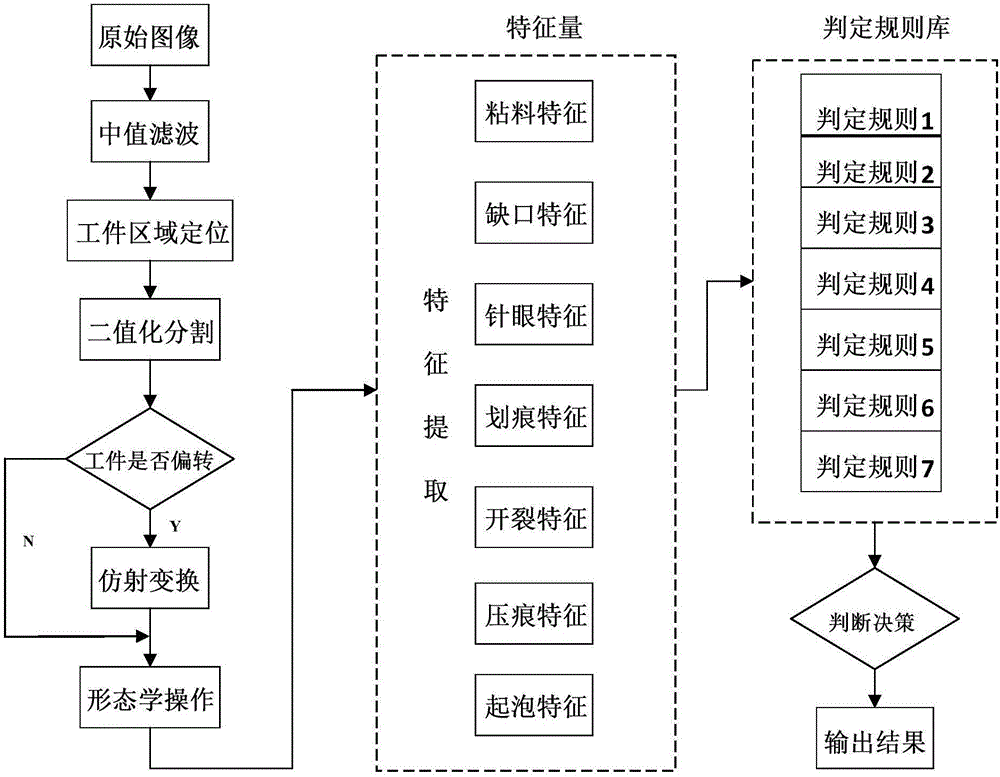

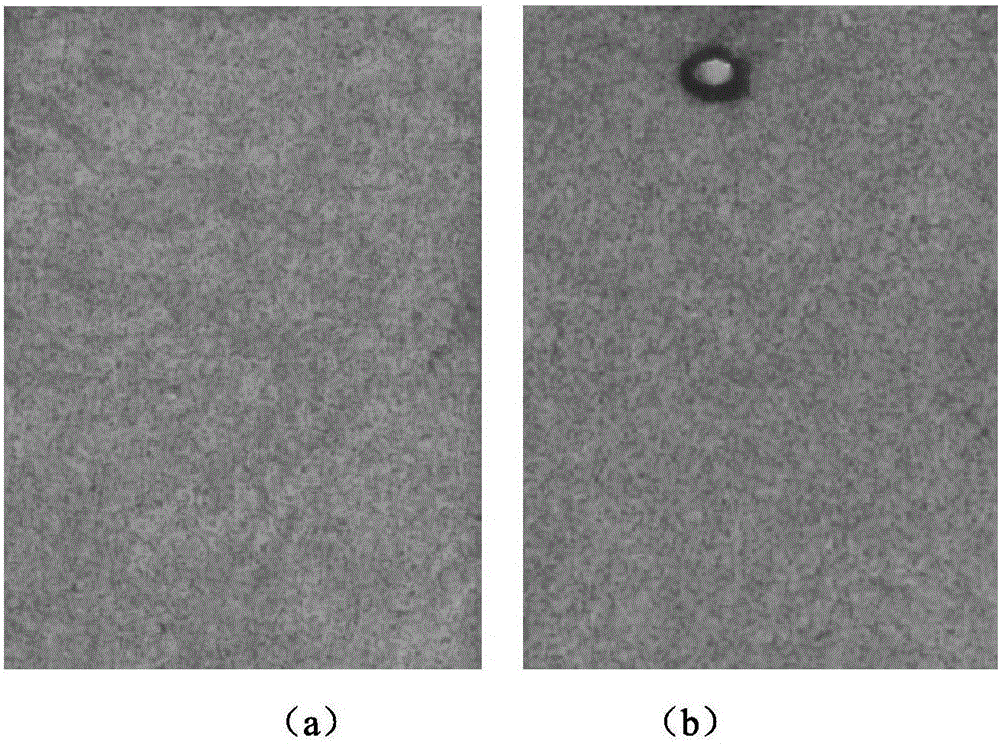

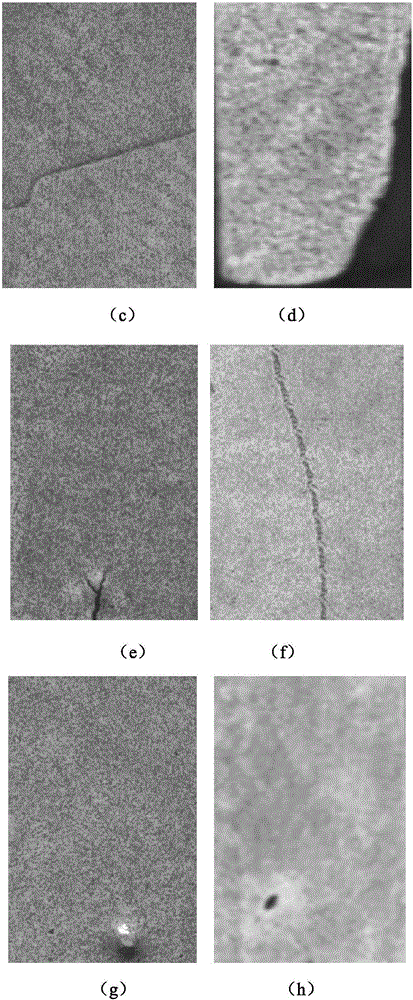

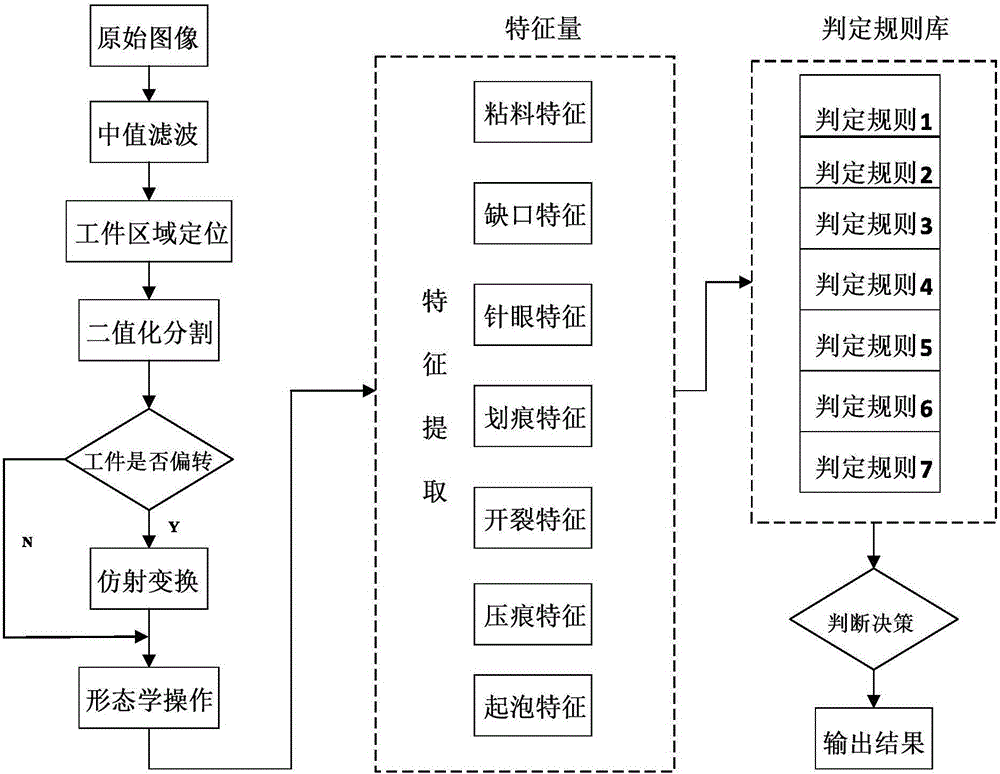

The invention discloses a workpiece apparent defect detection method based on machine vision. Firstly, a visual system is used for guiding a robot, the pose of a target workpiece is precisely positioned according to a template matching algorithm based on a gray value, and then workpiece apparent defect detection is carried out and comprises the steps that firstly, a workpiece image is acquired and pretreated through median filtering; secondly, the target workpiece is divided through a global threshold value, and workpiece pose correction is carried out; thirdly, burr interference of the edge of the workpiece is removed through mathematical morphology open operation; fourthly, notches, material sticking, cracking, indentation, needle eyes, scratches and foaming apparent defects are detected. The method solves the problems that the artificial detection speed is slow, the efficiency is low and precision is poor; the problems that according to current vision detection, defect types are singular, the imaging quality is poor, and the false drop rate is high are solved, and the automation degree of precise workpiece production and product quality are improved.

Owner:XIANGTAN UNIV

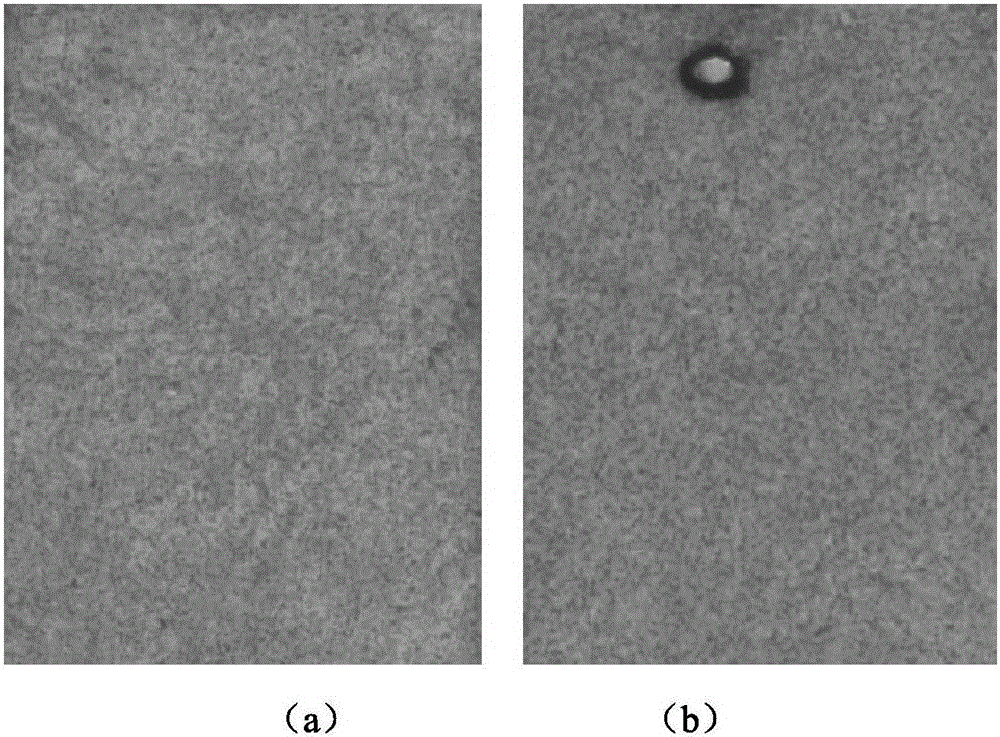

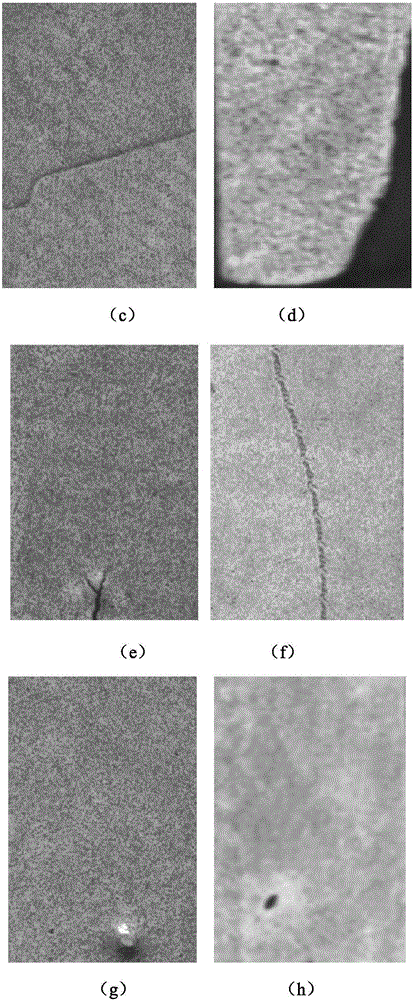

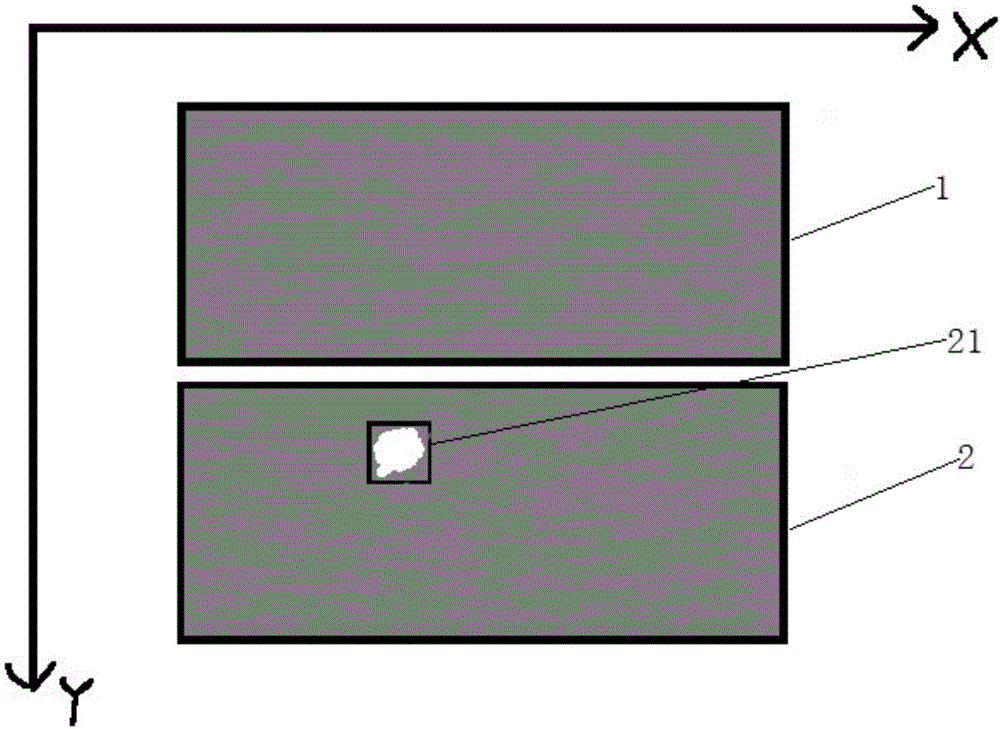

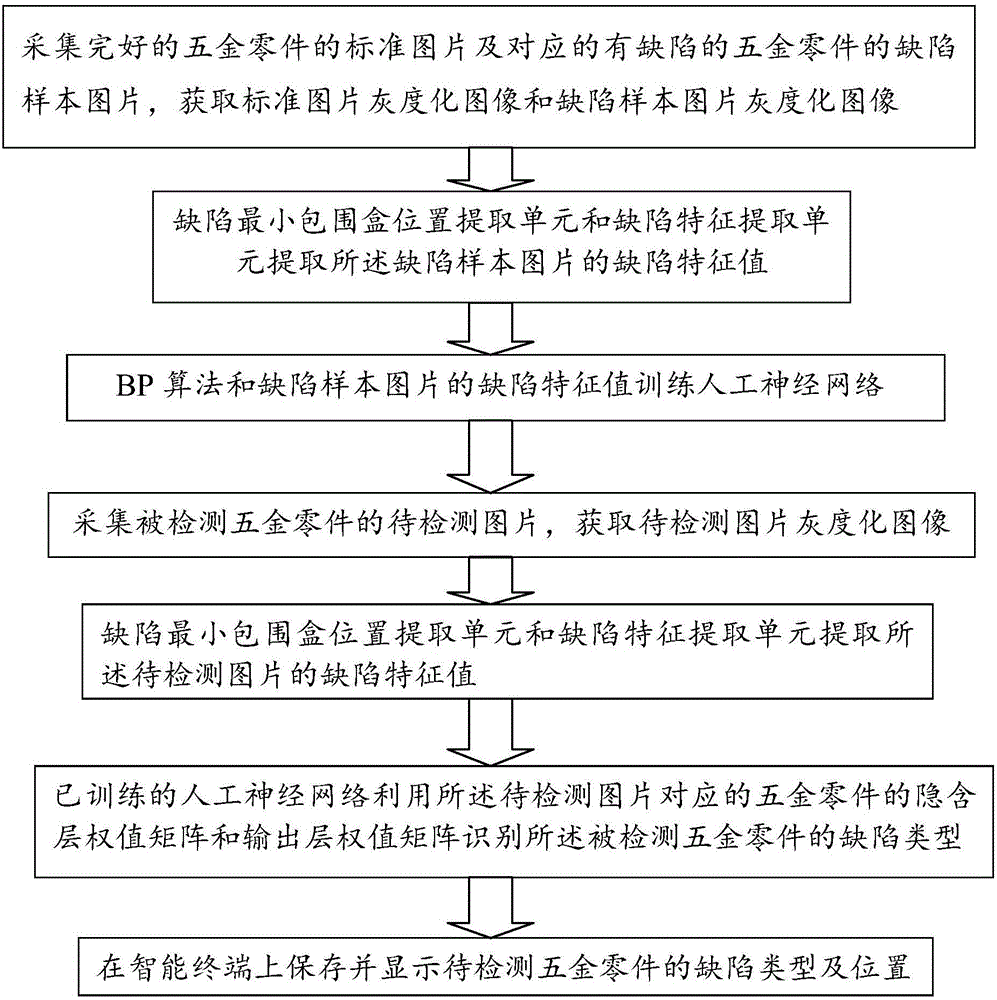

Hardware part defect detecting system and method

ActiveCN106568783AImprove detection efficiencyRealize automated detectionOptically investigating flaws/contaminationMinimum bounding boxMaterial resources

The invention provides a hardware part defect detecting system and a method. The hardware part defect detecting system comprises an image acquisition module, a defect information extraction module, a artificial neural network training module, and a defect identification module; the image acquisition module is used for acquiring standard images of hardware parts and corresponding defect sample images, performing image gray-scale treatment and image de-noising processing, and obtaining standard images and defect sample image gray-scale treated images; the defect information extraction module is used for extracting defect characteristic values of defect sample images using a defect minimum bounding box position extraction unit and a defect characteristic extraction unit; the artificial neural network training module is used for training artificial neural network via BP algorithm and the defect characteristic values of the defect sample images. According to the hardware part defect detecting system, the trained artificial neural network is used for identifying the defect kinds and defect positions of the hardware parts to be detected, hardware part surface defect automatic detection is realized, hardware part surface defect detection efficiency is increased, and manpower, material resources, and financial resources are saved.

Owner:GUANGDONG UNIV OF TECH +1

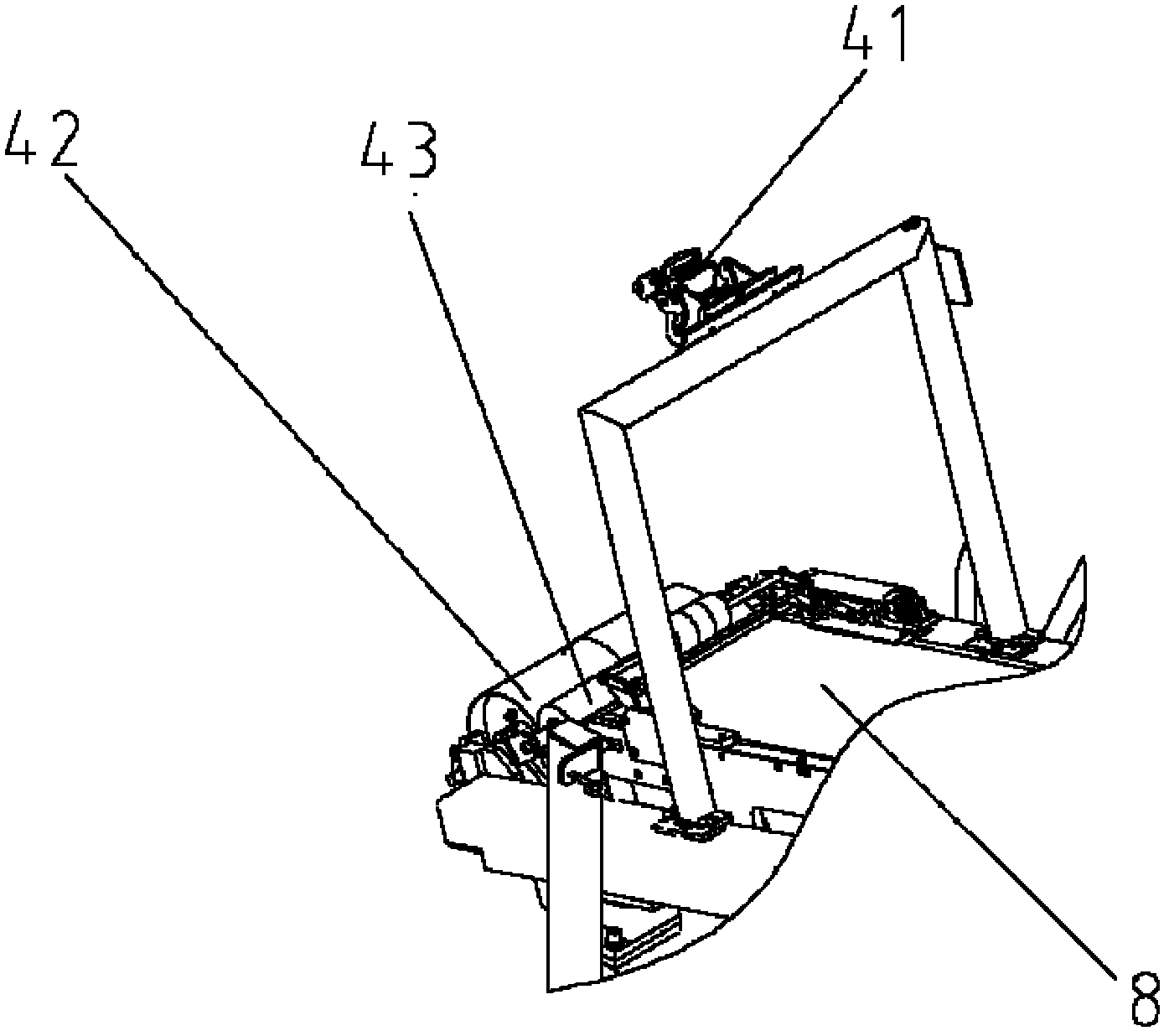

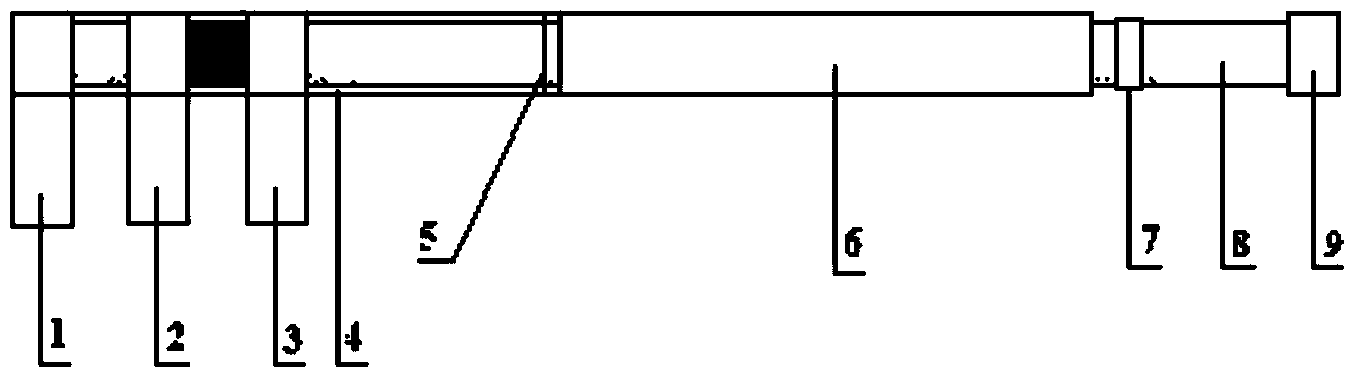

Automatic reel changing device for pole pieces

ActiveCN106006128AHigh degree of automationImprove work efficiencyWebs handlingPole pieceEngineering

The invention relates to an automatic reel changing device for pole pieces. The automatic reel changing device for the pole pieces comprises a substrate, wherein a main material reel mechanism and a standby material reel mechanism which back up for each other are respectively mounted on two sides of the substrate; a plurality of rollers which are arrayed in two rows and facilitate free suspending of the pole pieces are respectively mounted in the middle of the substrate; a left upper side adsorption positioning mechanism and a right upper side adsorption positioning mechanism which adsorb side surfaces of upper parts of the guided-out pole pieces are mounted on the upper part of the substrate; a left lower side adsorption positioning mechanism and a right lower side adsorption positioning mechanism which adsorb side surfaces of lower parts of the guided-out pole pieces are mounted on the lower part of the substrate; a pole piece shearing mechanism which cuts off the pole pieces from the middles simultaneously is mounted on the substrate and positioned between the right upper side adsorption positioning mechanism and the right lower side adsorption positioning mechanism; a left side pole piece changeover mechanism and a right side pole piece changeover mechanism which are used for adhering two sides of a head part of each new pole piece to two sides of the tail part of a corresponding running pole piece are respectively mounted on two corresponding sides of the substrate; and a main waste material reeling mechanism and a standby waste material reeling mechanism which are used for reeling and withdrawing the waste materials of the head parts of the new pole pieces are mounted on sides of the top of the substrate.

Owner:ZHUHAI HIGRAND ELECTRONICS TECH

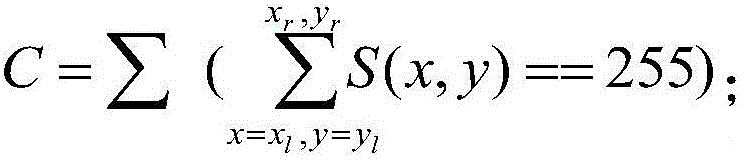

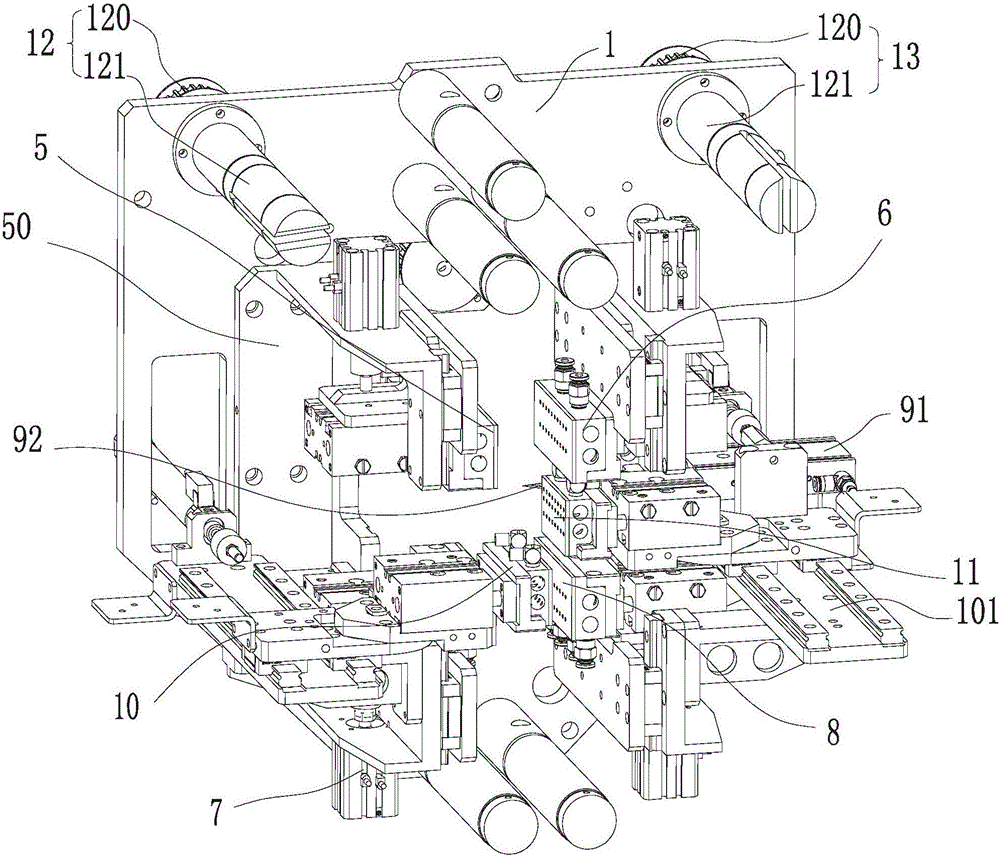

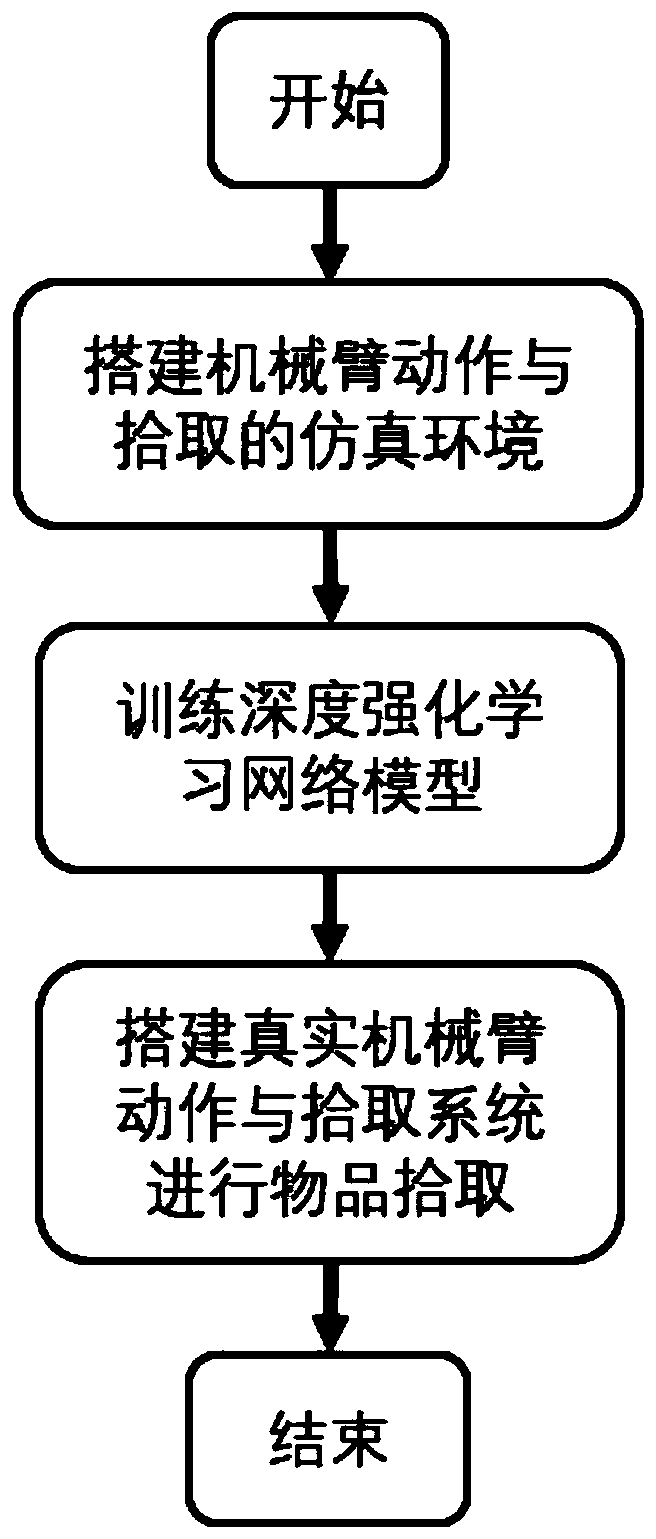

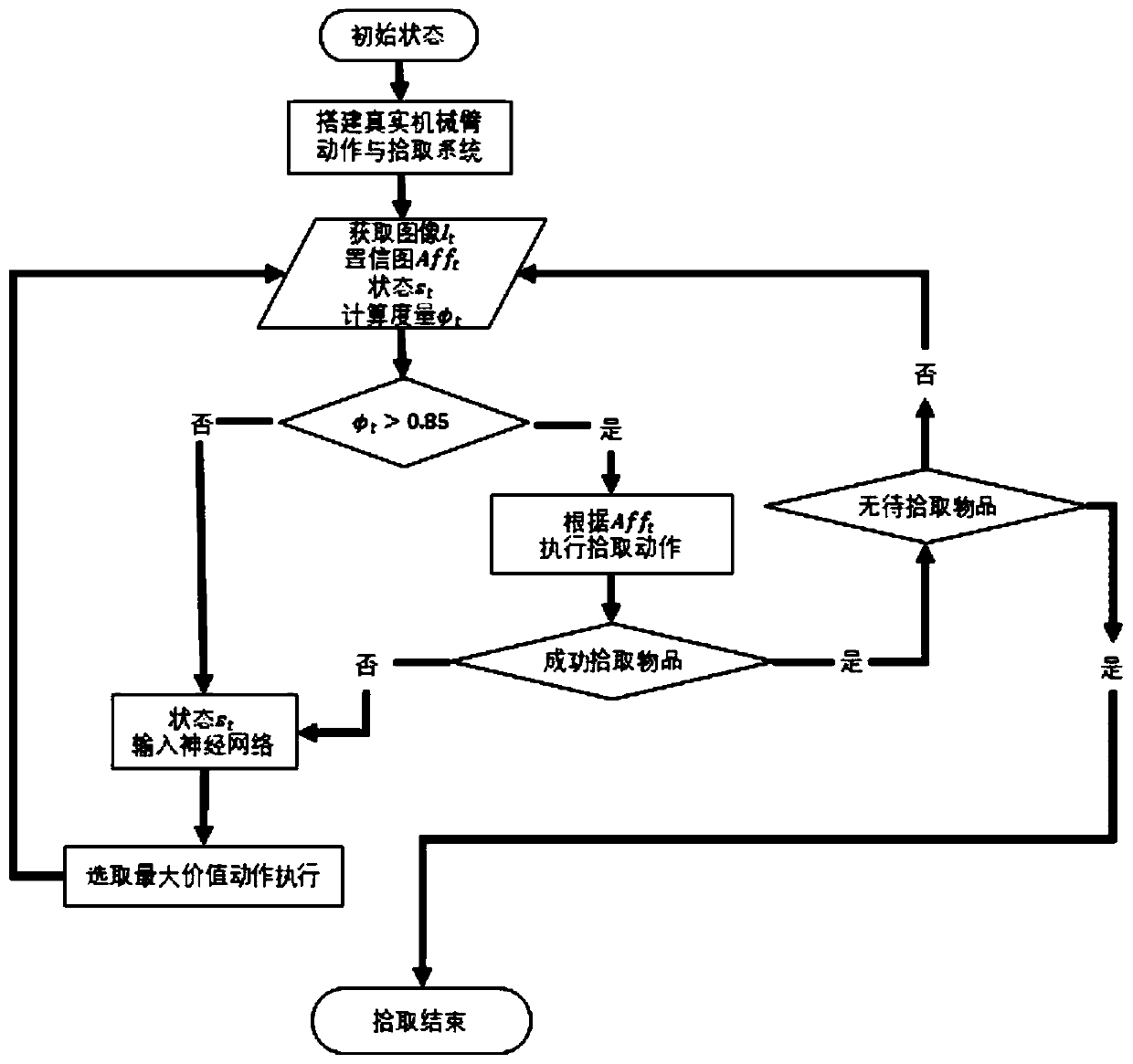

Item active pick-up method through mechanical arm based on deep and reinforced learning

ActiveCN110450153AEfficient extractionPick up scene optimizationProgramme-controlled manipulatorRoboticsColor image

The invention provides an item active pick-up method through a mechanical arm based on deep and reinforced learning, and belongs to the field of artificial intelligence and robotics applications. Themethod comprises the following steps of firstly establishing a simulation environment containing the machine arm and an item pick-up scene; establishing a deep Q learning network NQ based on multipleparallel U-Nets; carrying out multiple robot grabbing action policy tests in the simulation environment to perform training on the NQ, thus obtaining a trained deep learning network; establishing an item pick-up system in actual pick-up use, utilizing the trained deep learning network, inputting deep color images, and determining to utilize an action policy of actively changing a scene or pick upan item through the mechanical arm according to a measurement defined on a confidence image. According to the item active pick-up method disclosed by the invention, by actively changing an item pick-up environment through the mechanical arm and adapting to different pick-up conditions, a high success rate of pick-up can be achieved.

Owner:TSINGHUA UNIV

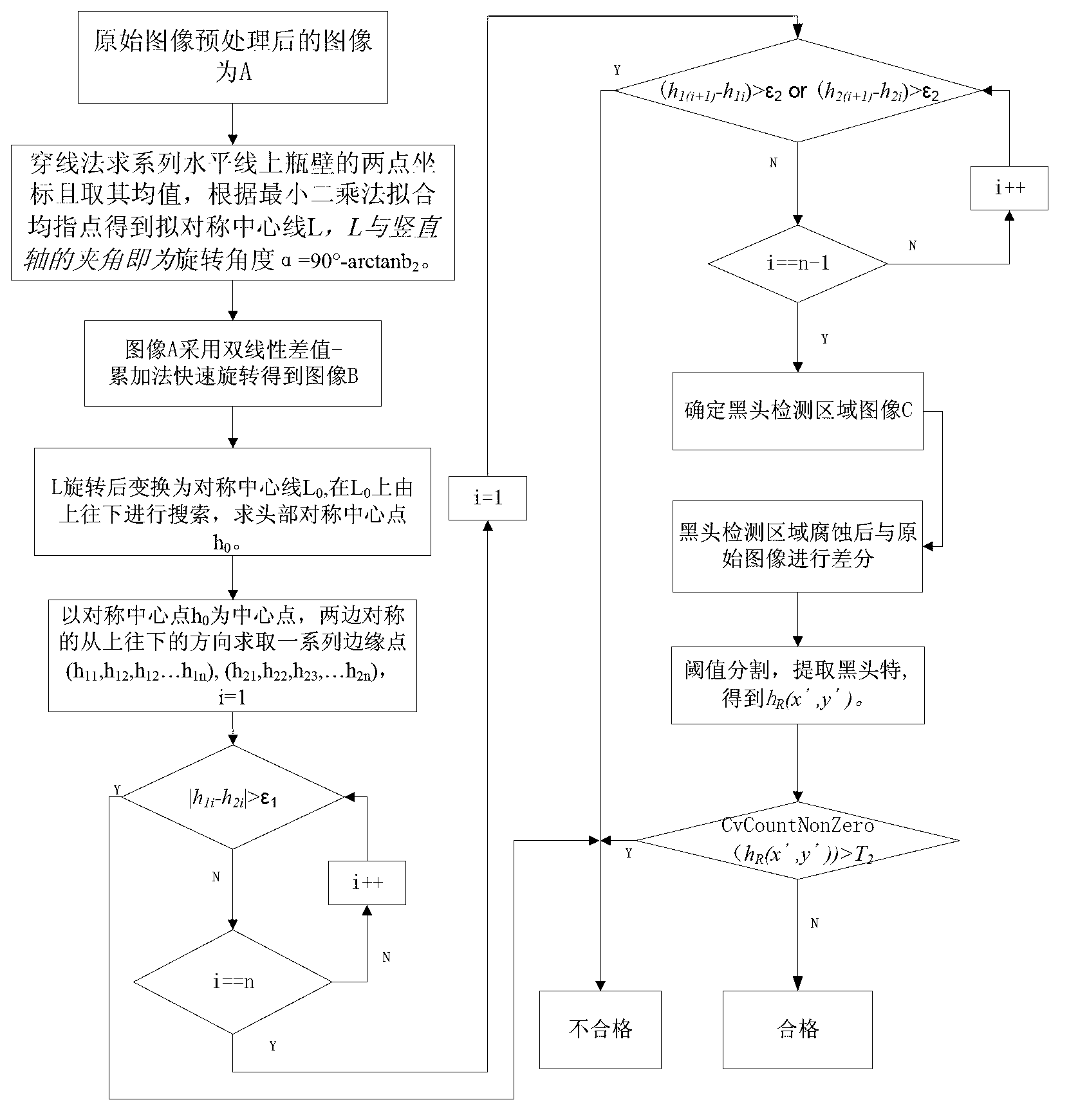

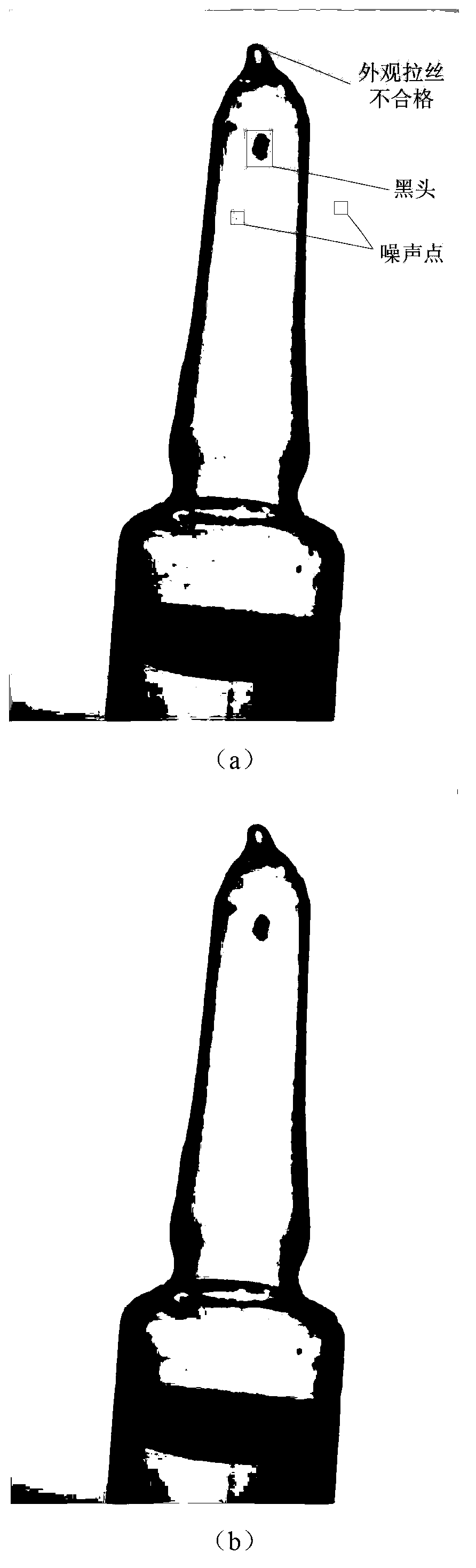

Method for detecting ampoule bottle appearance quality through medical visual inspection robot

ActiveCN103018253AImplement automatic detectionSave resourcesOptically investigating flaws/contaminationSpin imageSymmetry line

The invention discloses a method for detecting ampoule bottle appearance quality through a medical visual inspection robot. The method comprises the steps of (1) acquiring an ampoule bottle image, and preprocessing the image through a median filter; (2) solving an ampoule bottle mimic symmetry line by employing a threading method to obtain a rotating angle alpha; (3) rotating the image by using a bilinear interpolation-summation method; (4) solving a symmetry center line, wherein the intersection of the symmetry center line and the head is a symmetry center point h0; (5) solving a head edge point; (6) enabling the outer curve at the head of the ampoule bottle to have the characteristic of a symmetrical variable trend in a lower parabola shape, and judging whether the ampoule bottle appearance wire-drawing quality is qualified; (7) positioning a black head detection rectangular area; (8) judging whether the black head ampoule bottle appearance is qualified by employing a difference method; and (9) integrating the appearance drawing and black head quality detection result. According to the method, the problems that the manual detection efficiency is low, the consistency is low and the leakage detection rate is high and the like are overcome, and the degree of automation and product quality of the ampoule bottle medicine production are improved.

Owner:HUNAN UNIV

Method for separating single tocopherol from mixed tocopherol

InactiveCN101220018AReduce consumptionHigh purityOrganic chemistryChemical reactionSimulated moving bed

The invention relates to a method for separating single tocopherol from mixed tocopherol, which takes the mixed tocopherol with a content of 50 percent to 100 percent as a raw material and adopts a four-area simulated moving bed chromatography system to separate a d-alpha-tocopherol, a d-beta-tocopherol, a d-gamma-tocopherol and a d-delta tocopherol with the purity and yield all more than 98 percent. As the simulated moving bed chromatography separation is a continuous process, the method has the advantages of high degree of production automation, simple technique, high production efficiency, continuous production and stable product quality. As an adsorbent and a solvent have low consumption, the whole separating device does not relate to chemical reactions.

Owner:ZHEJIANG UNIV

Rubber product one-step injection, hollowing and vulcanization forming production method

The invention discloses a rubber product one-step injection, hollowing and vulcanization forming production method, which belongs to the technical field of rubber product processes. By adopting the rubber product one-step injection, hollow and vulcanization forming production method, the injection, hollowing and vulcanization procedures can be completed in a same mold cavity, the mold cavity comprises an upper half mold, a lower half mold and a mold core, the mold core sets a foundation for the hollowing of the mold cavity, after the hollowing, the condition for introducing the high-temperature high-pressure gas for the vulcanization can be satisfied, the injection molding, hollowing and vulcanization apparatus can be integrated, the heat loss caused by the procedure circulation and the procedure circulation cost in the prior art can be avoided, and the traditional defects of the traditional rubber product production process such as re-pressurizing, heating, energy consumption, time consumption and high cost can be solved.

Owner:东营睿港招商服务有限责任公司

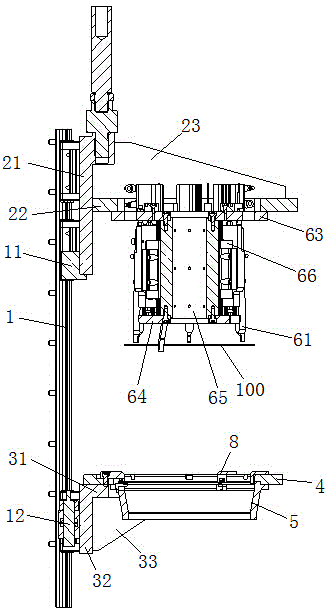

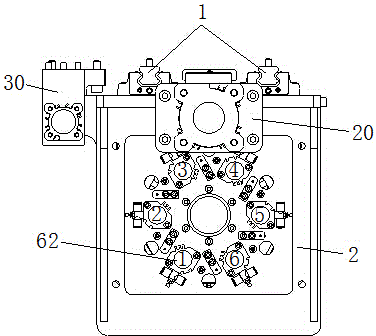

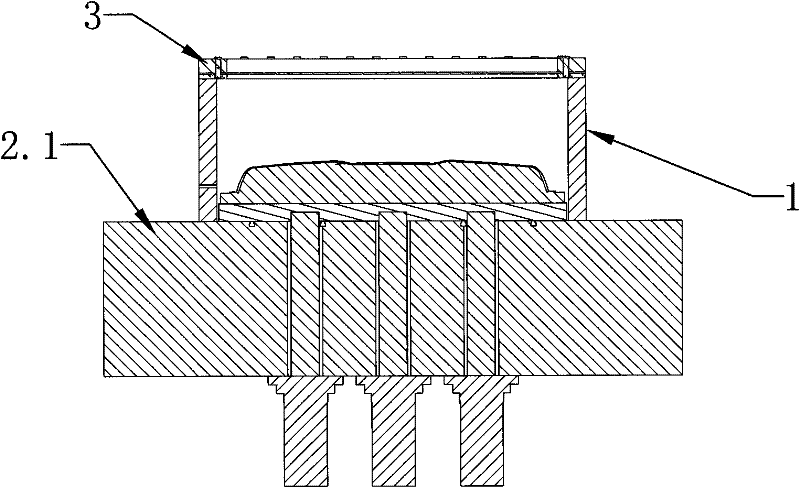

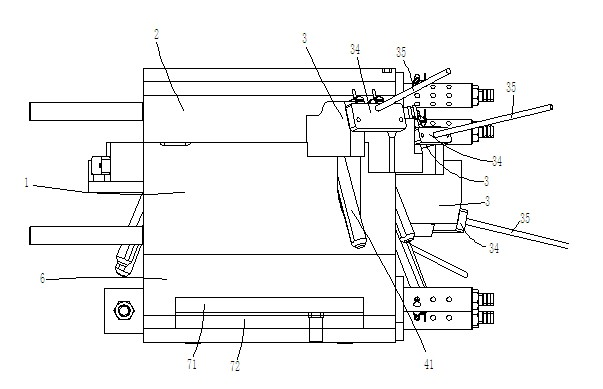

Snap spring automatic press fitting mechanism on clutch driving disk

ActiveCN104959806AReduce labor intensityIncrease productivityMetal working apparatusEngineeringClutch

The invention relates to a snap spring automatic press fitting mechanism on a clutch driving disk. The mechanism comprises slide rails provided with an upper sliding table and a lower sliding table, a supporting plate used for containing a snap spring is arranged on the lower sliding table, the lower portion of the supporting plate is connected with a guiding conical barrel, the inner diameter of a lower opening of the guiding conical barrel is matched with the diameter of a snap spring groove inlet of the clutch driving disk, the upper sliding table is provided with a press fitting assembly used for pressing the snap spring to the clutch driving disk, the press fitting assembly comprises press fitting fingers and cylinders driving the press fitting fingers to move, and the press fitting fingers move downwards under the action of the cylinders so that the snap spring placed on the supporting plate can be pressed into a snap spring groove of the clutch driving disk along the inner wall of the guiding conical barrel. Due to the technical scheme, the lower sliding table is pre-pressed to the clutch driving disk through a lower cylinder, then the upper sliding table is driven to an assigned position through an upper cylinder, the six press fitting fingers are drive to sequentially move downwards through the cylinders, the action of manually installing the snap spring is simulated, and the snap spring is pressed in place in sequence.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

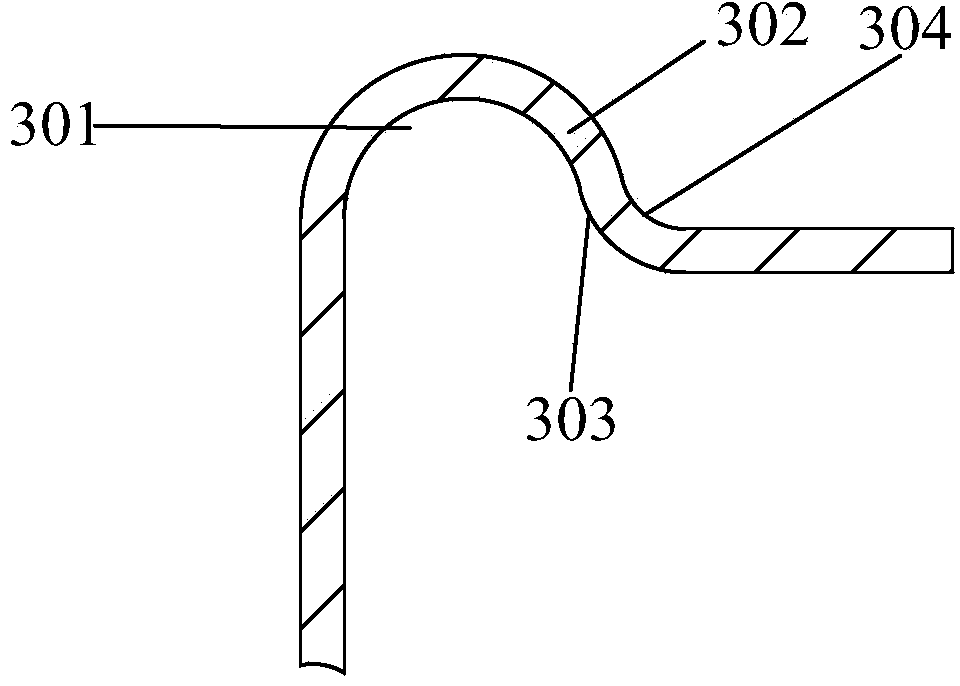

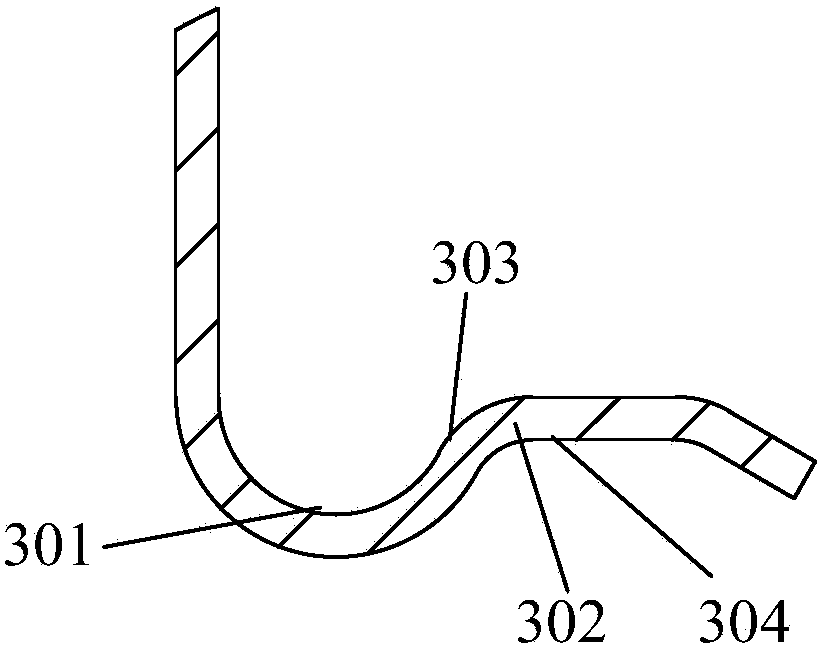

Combined thermoplastic elastic body for automotive glass guide groove sealing strip and production method thereof

ActiveCN101670771AReduce wearReduce coefficient of frictionEngine sealsVehicle sealing arrangementsThermoplastic elastomerEngineering

The invention relates to a combined thermoplastic elastic body for an automotive glass guide groove sealing strip and a production method thereof. The combined thermoplastic elastic body comprises a thermoplastic elastic body A, a thermoplastic elastic body B and a thermoplastic elastic body C, wherein the thermoplastic elastic body A and the thermoplastic elastic body B are subjected to coextrusion lamination to form a linear sealing strip; the thermoplastic elastic body C and the linear sealing strip formed by the coextrusion lamination of the thermoplastic elastic bodies A and B are subjected to thermal injection molding adhesion to form an angular sealing strip through thermal injection molding; because the thermoplastic elastic body A has the characteristics of low friction coefficient and high abrasion resistance, the manufactured sealing strip is abrasion-resistant and has low abrasion to the glass; because the thermoplastic elastic body B has high elasticity, weather resistanceand sealing property and can carry out coextrusion lamination with the thermoplastic elastic body A, the manufactured sealing strip has high sealing property, strong anti-ageing performance and longservice life; and because the thermoplastic elastic body C has higher adhesive property and can form firm thermal injection molding adhesion with a coextrusion lamination product of the thermoplasticelastic bodies A and B, the sealing strip has the reliable performance.

Owner:南通江洲工程材料科技有限公司

Vacuum adsorption forming device

ActiveCN102189675AReliable moldingRealize continuous productionDomestic articlesVacuum extractionEngineering

The invention discloses a vacuum adsorption forming device which can be suitable for mass production of formed pieces through polypropylene cavity plates. The device comprises a vacuum extraction module, a vacuum box, a hydraulic machine and a heating module, wherein the vacuum extraction module is connected with the vacuum box; the vacuum box is arranged on a fixed plate of the hydraulic machine; a load bearing lifting module which is used for arranging molds and can vertically lift or lower the molds is arranged in the vacuum box; a press frame which can fix a polypropylene cavity plate at the opening of the vacuum box is arranged at the opening of the vacuum box; the heating module is arranged on one side of the hydraulic machine and comprises a heating unit and a moving unit which canbe used for moving the heating unit to the upper side of the fixed polypropylene cavity plate to heat the polypropylene cavity plate and can be deviated from the polypropylene cavity plate after the polypropylene cavity plate is heated; and the heating unit is connected with the moving unit.

Owner:NINGBO SUNLIGHT MOTOR PARTS

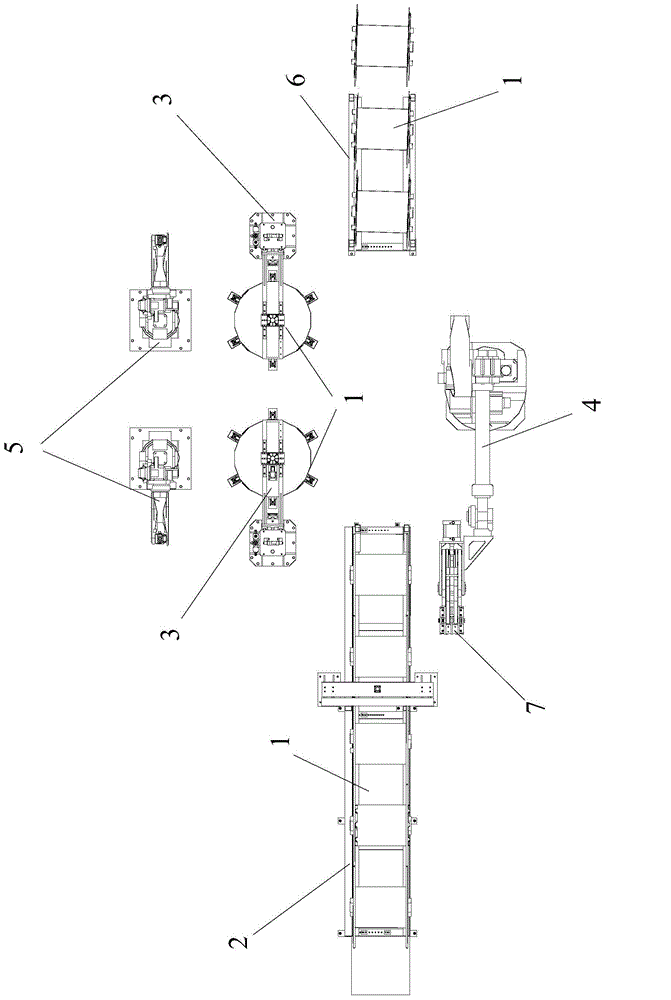

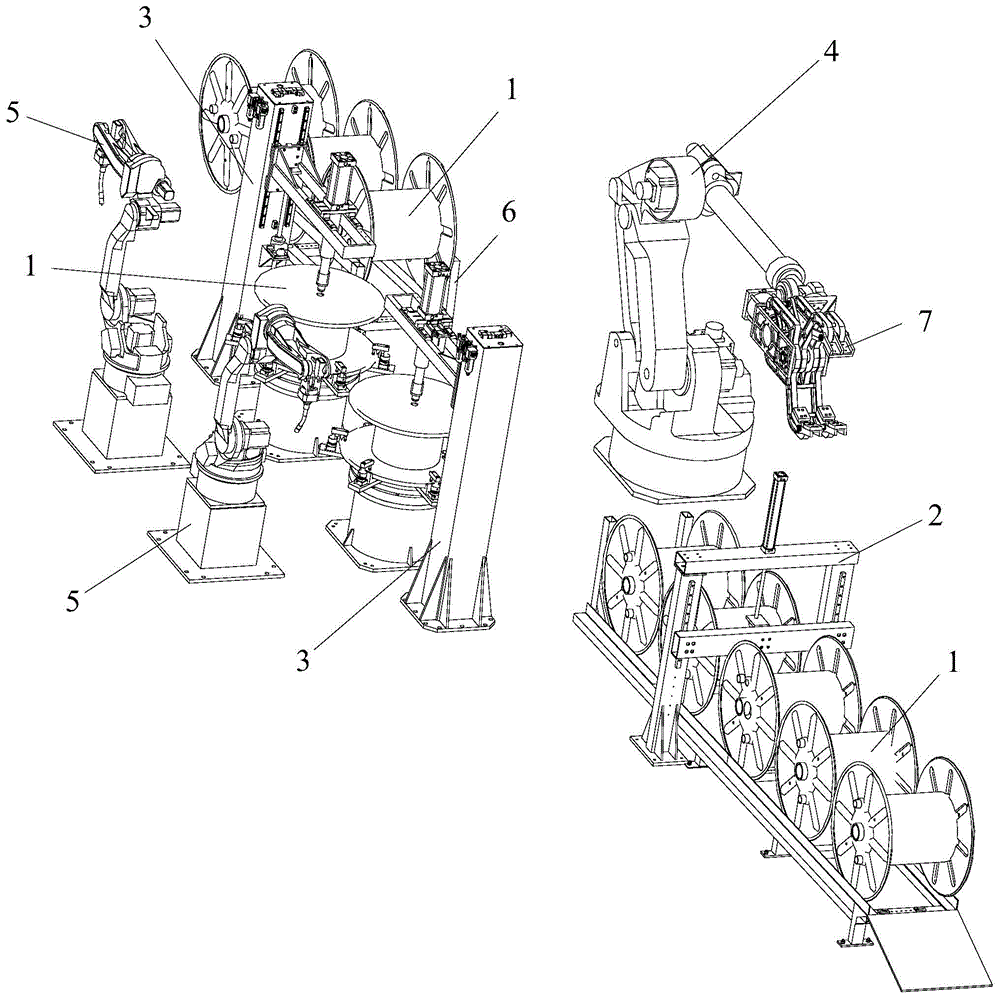

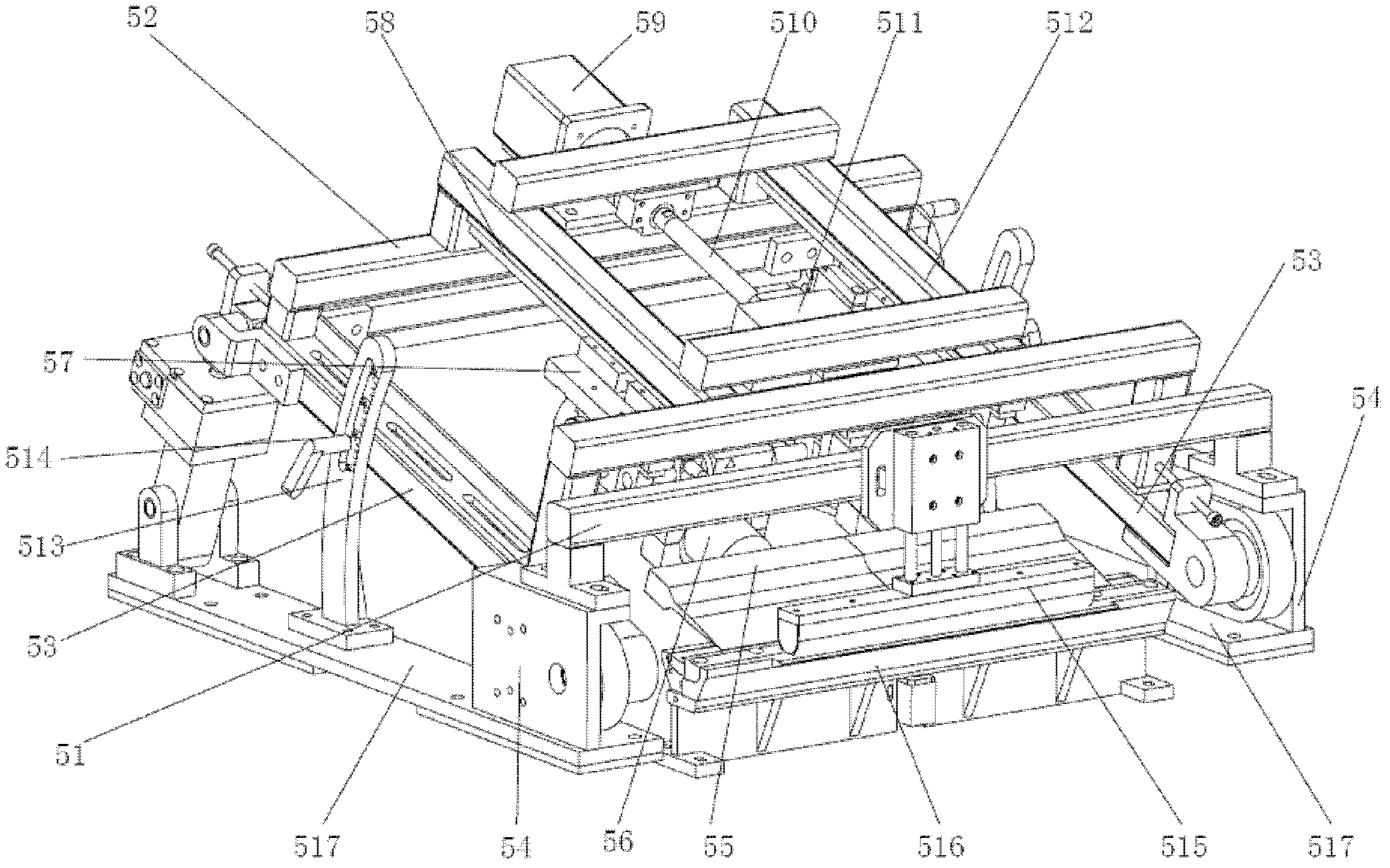

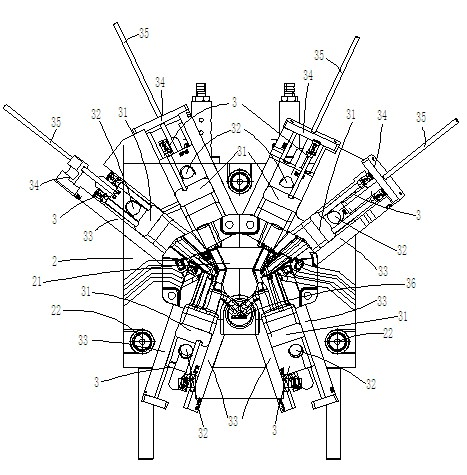

Automatic welding production line and automatic welding method for wire coils

ActiveCN104625454AHigh precisionHigh speedWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention provides an automatic welding production line for wire coils. The production line comprises a feeding and conveying mechanism, a pressing and positioning mechanism, a transferring manipulator, a welding manipulator, a discharging and conveying mechanism and a control mechanism in signal connection with the feeding and conveying mechanism, the pressing and positioning mechanism, the transferring manipulator and the welding manipulator. The production line is simple in structure, high in welding speed and high in welding quality stability, the phenomenon that welding of welded junctions is not uniform because of manual welding can be effectively avoided, and therefore welding efficiency, welding precision and welding quality of the wire coils can be improved. The invention further provides an automatic welding method for the wire coils. The method includes a feeding procedure, a transferring and positioning procedure, a welding procedure and a discharging procedure which are all performed in sequence, wherein in the transferring and positioning procedure, the transferring manipulator is controlled to clamp, move and overturn the wire coils, meanwhile, the pressing and positioning mechanism is used for pressing, positioning and rotating the wire coils, and the welding procedure starts. The method can be used for solving the problem that the automation degree in the current welding industry is low.

Owner:佛山市慧智智能装备有限公司

High gel protein powder and its production method and uses

ActiveCN101305767AIncrease elasticityEasy to stretchAnimal proteins working-upFood preparationMaillard reactionCompound (substance)

The invention provides a method for preparing high-gelation protein powder combining chemical methods including a Maillard reaction, a fermentation sugar removal method and physical methods such as microwave radiation, dry heat-treating, etc. The prepared high-gelation protein powder has ultrahigh protein powder gel strength and stability with a highest up to2,400g and wide application.

Owner:NANTONG KANGDE BIOLOGICAL PROD

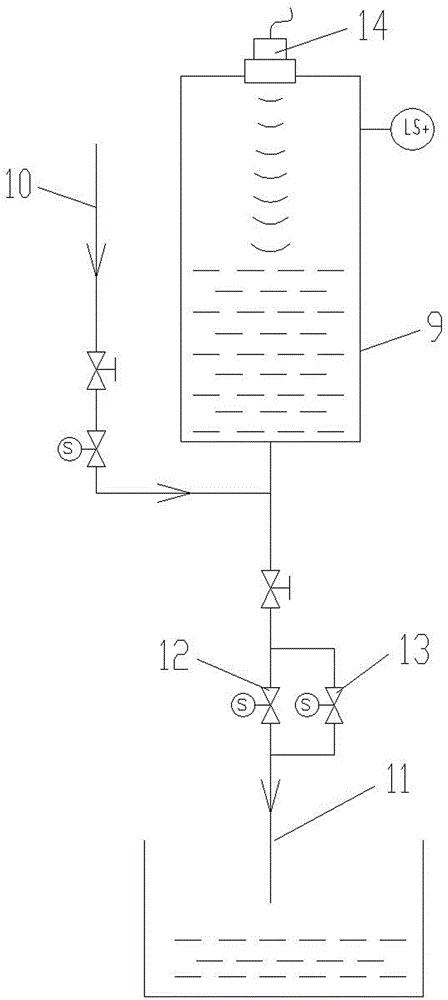

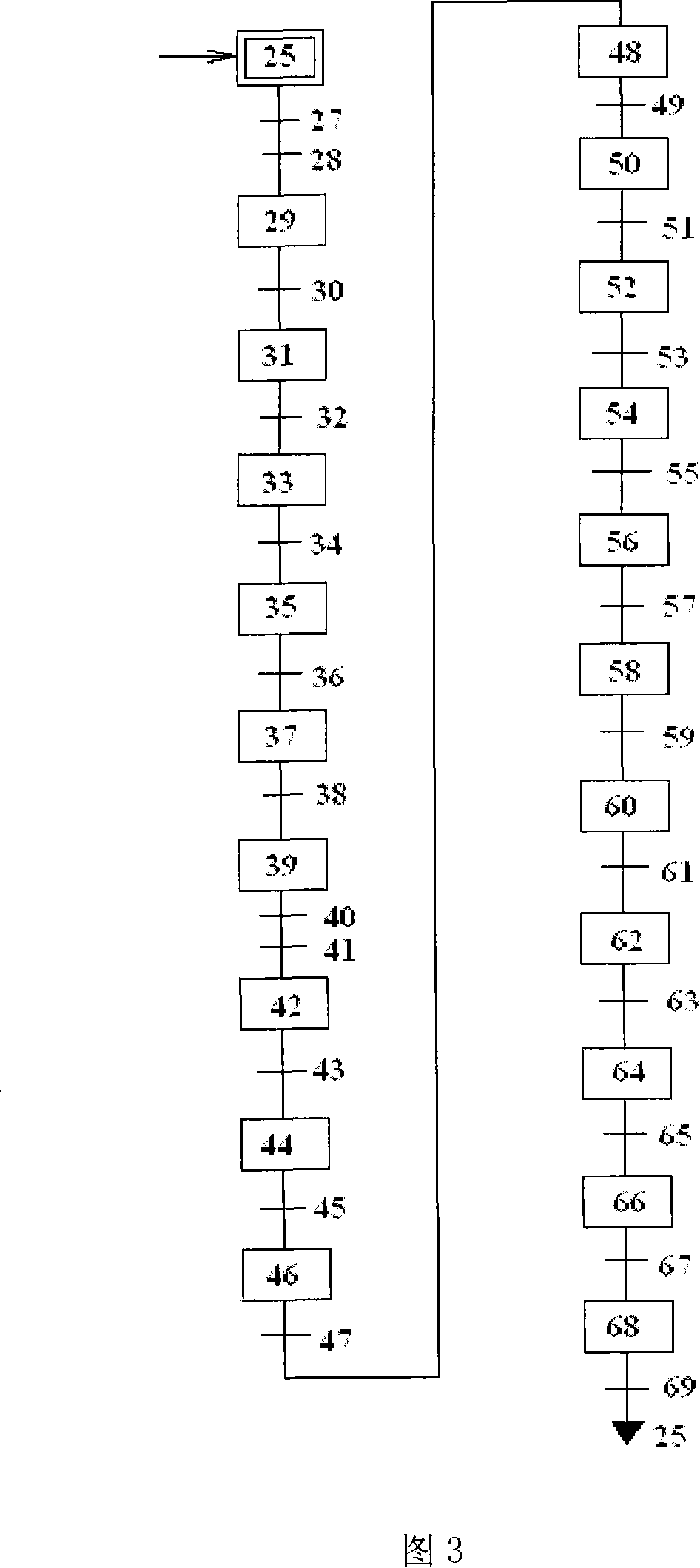

Method and equipment for automatically cooking silkworm cocoons

InactiveCN101824659AStrengthen scientific managementHigh degree of production automationSilk filament obtainingAutomatic controlMan machine

The invention relates to an intelligent method and equipment for automatically cooking silkworm cocoons, which can effectively improve the cooking uniformity of silkworm cocoons. The equipment used for realizing the method of the invention for automatically cooking silkworm cocoons comprises a silkworm cocoon treatment tank, a top cover of the treatment tank and a silkworm cocoon storage tank and is characterized in that a water replenishing tank is also arranged between the silkworm cocoon treatment tank and the silkworm cocoon storage tank. By variably setting different technological parameters, operating man-machine conversation by a touch screen and automatically controlling the time, the water level and the temperature for soaking, steaming and cooking cocoons by a computer and an actuating mechanism, the invention completes the whole processes of feeding, permeating, cocoon steaming, cocoon cooking, cooling protection and cocoon forming in the same barrel, changes the traditional mode of constant action of each section in the traditional circulating cocoon cooking machine, and overcomes the defects of high operation requirements on workers, untimely manual operation and unstable cocoon cooking quality.

Owner:广西立盛茧丝绸有限公司

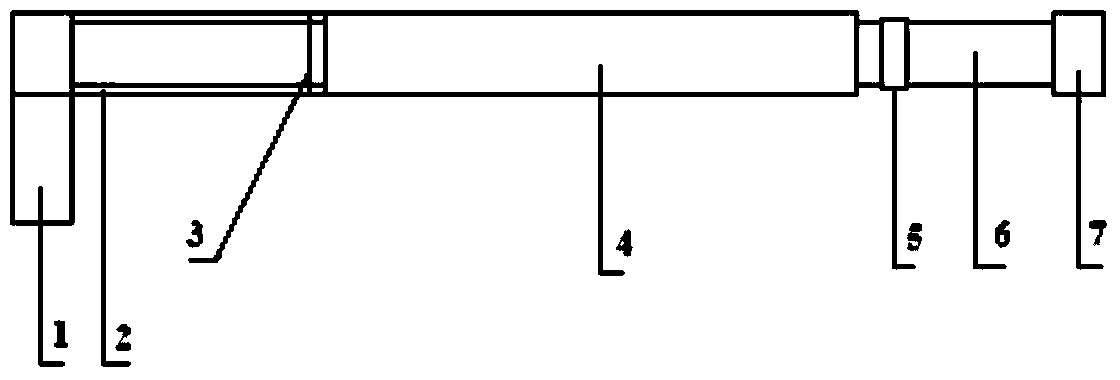

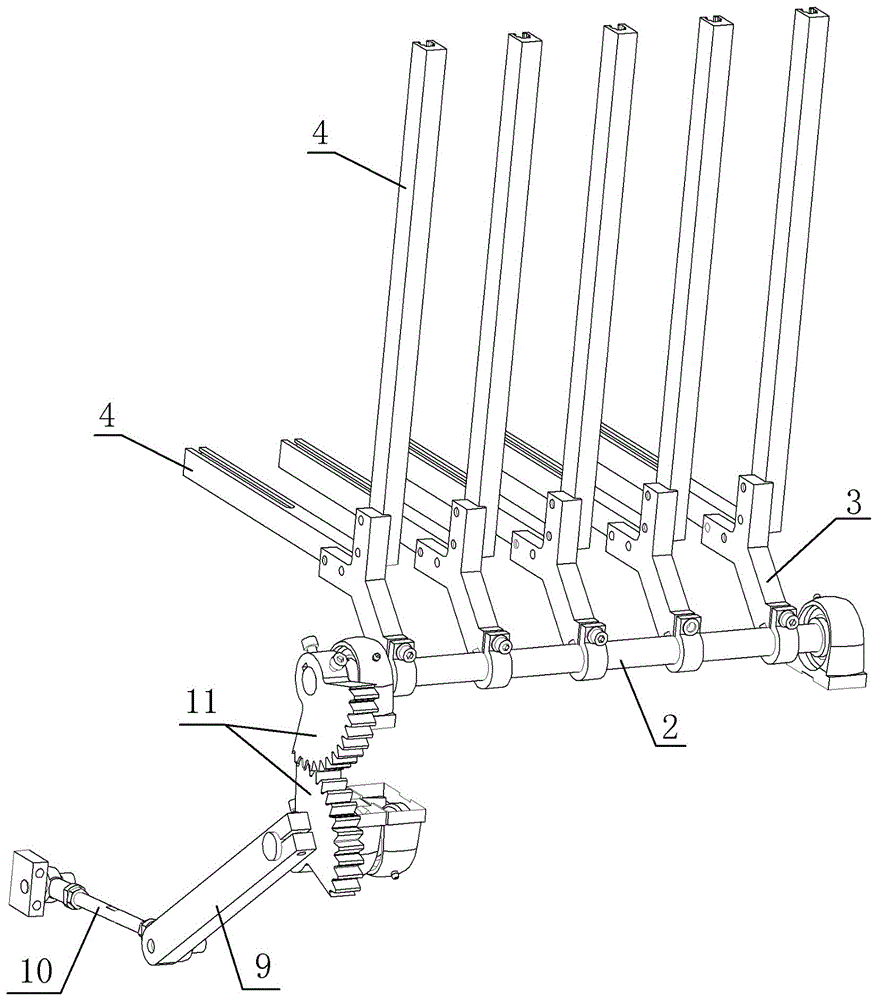

Tread feed rack and feed method thereof

InactiveCN103182790AControl fit qualityEliminate the effects of precise centeringTyresTire uniformityEngineering

A tread feed rack and a feed method thereof of the invention can simultaneously satisfy centering and length control demands for tread materials. In a cutting process, a cutter slides on a sliding track of a cutter carrier by a driving mechanism, and in a process that the cutter slides downwards, the cutter cuts off the tread by a shoveling manner. The cutter carrier of the feed rack is fixed on a frame at two sides of a conveying template, the sliding track is arranged on the cutter carrier, the sliding track forms a certain included angle with the tread conveying direction, and the cutter is slidingly connected with the sliding track. The tread feed rack and feed method thereof of the invention can eliminate the influence on centering in the cutting process, simultaneously eliminates length control error influence on the tyre homogeneity.

Owner:MESNAC

Processing system and technology for natural fibrous composite felt used for automotive trim plate core layer

The invention discloses a processing system and technology for natural fibrous composite felt used for an automotive trim plate core layer. The system comprises a fiber net generating device. The fiber net generating device is connected with a drying oven through a bottom curtain, the bottom curtain is provided with a driving structure, fiber nets which come out of the drying oven pass through a hot pressing device and extends to a winding device, a cloth guide roller used for winding the fiber nets to be in a S shape and a supporting conveying roller are arranged in the drying oven, the hot pressing device is a pair of heating and compressing rotary rollers, the fiber net generating device comprises an opening device, a carding device and a net paving device, and the opening device, the carding device and the net paving device are connected in sequence. The processing system and technology for the natural fibrous composite felt used for the automotive trim plate core layer are low in cost, high in performance, environmentally friendly and capable of greatly improving the strength and tenacity of the natural fibrous composite felt, and the natural fibrous composite felt can be used as base materials of various automobile trim plates with high strength requirements.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +2

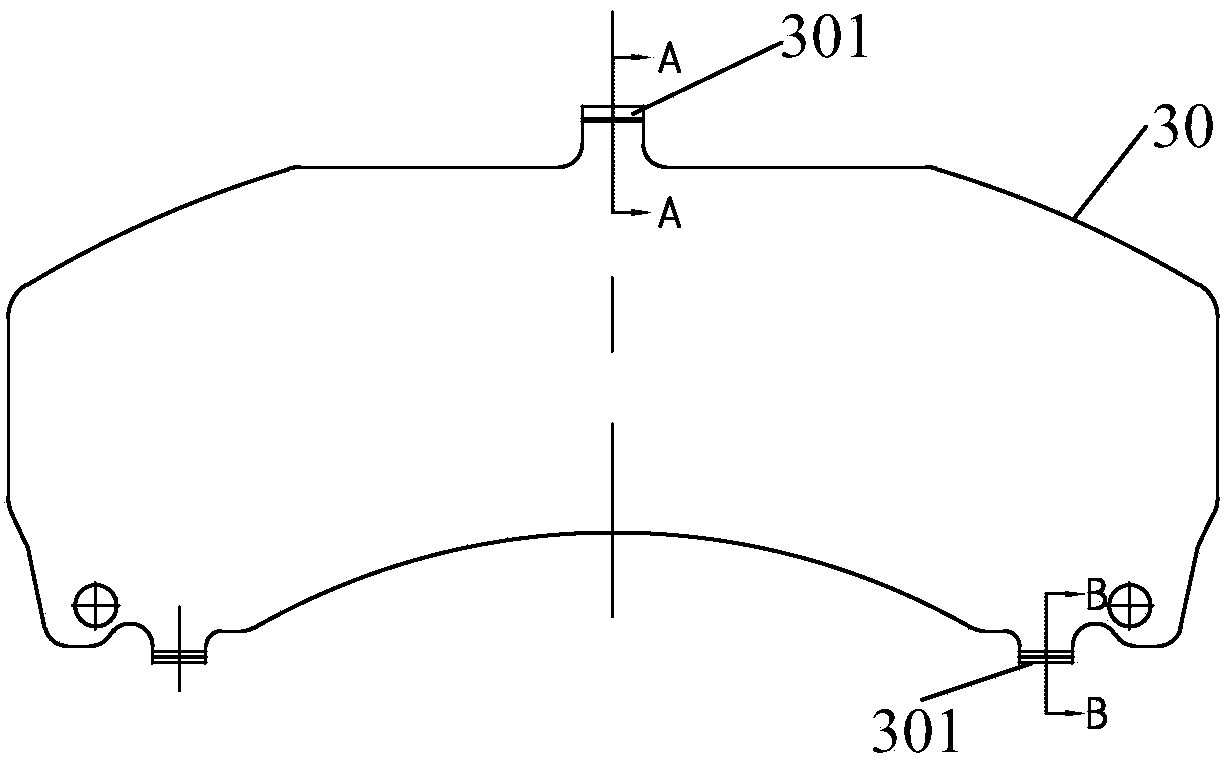

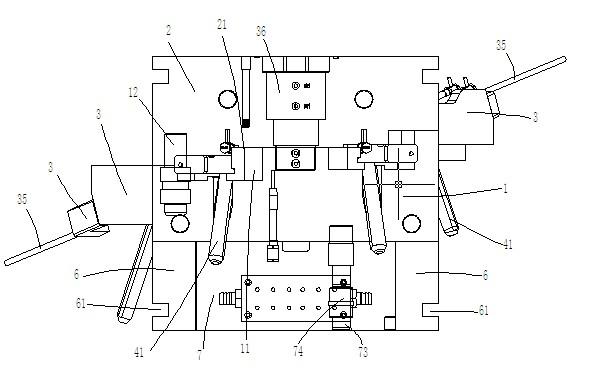

Progressive die of concave bayonet bloop and production method of concave bayonet bloop

ActiveCN103506492AImprove operational safetyStrong order response abilityShaping toolsPunchingEngineering

The invention discloses a progressive die of a concave bayonet bloop and a production method of the concave bayonet bloop. The progressive die of the concave bayonet bloop comprises an upper die and a lower die matched with the upper die, and a bloop material strap goes forward between the upper die and the lower die; in the advancing direction of the bloop material strap, the lower die is sequentially provided with a lower die punching insert core used for punching the bloop material strap, a lower die pre-bending insert core used for concave bayonet half forming, and a lower die blocking foot bending insert core used for blocking foot forming; the upper die is provided with a punching plunger chip matched with the lower die punching insert core, a pre-bending insert core matched with the lower die pre-bending insert core, and a blocking foot bending plunger chip matched with the lower die blocking foot bending insert core. The progressive die is high in production automation degree, productivity and quality of products are greatly promoted, manual operation safety is high, labor intensity is also greatly weakened, manpower and drilling crews are saved, production management is convenient and fast, and customer order response ability is high.

Owner:韶关德嘉汽车零部件有限公司

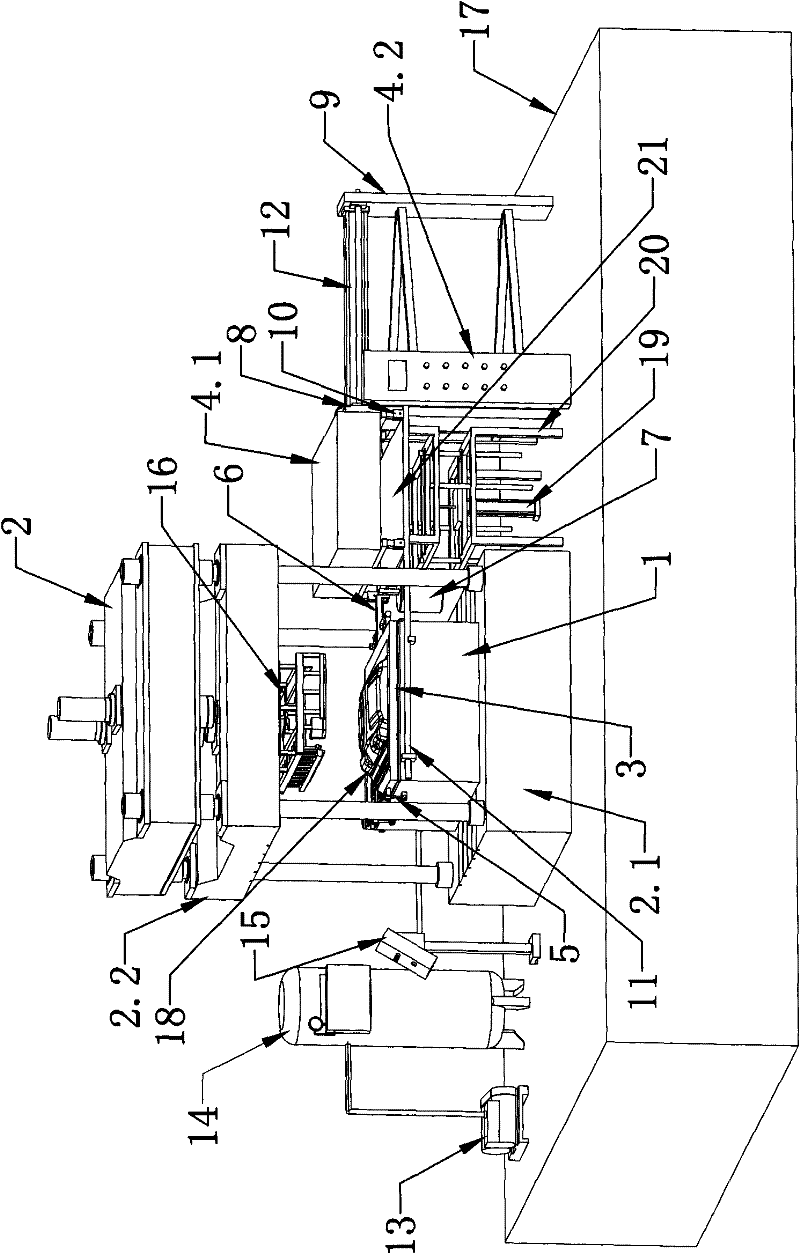

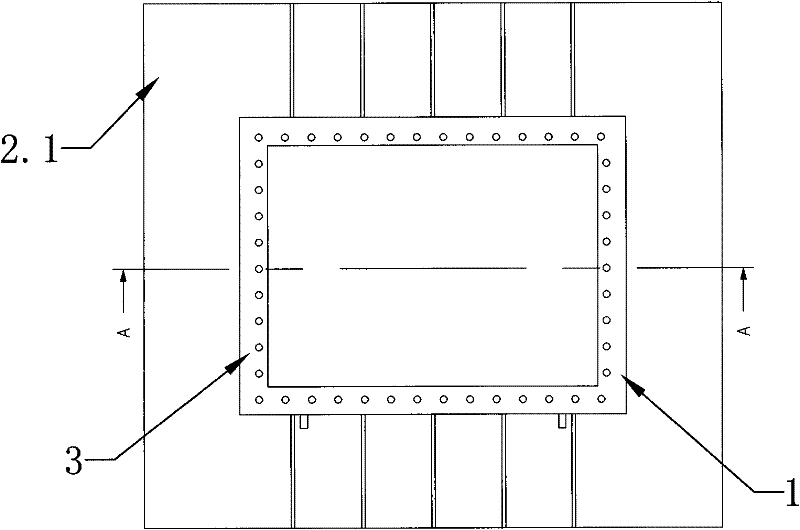

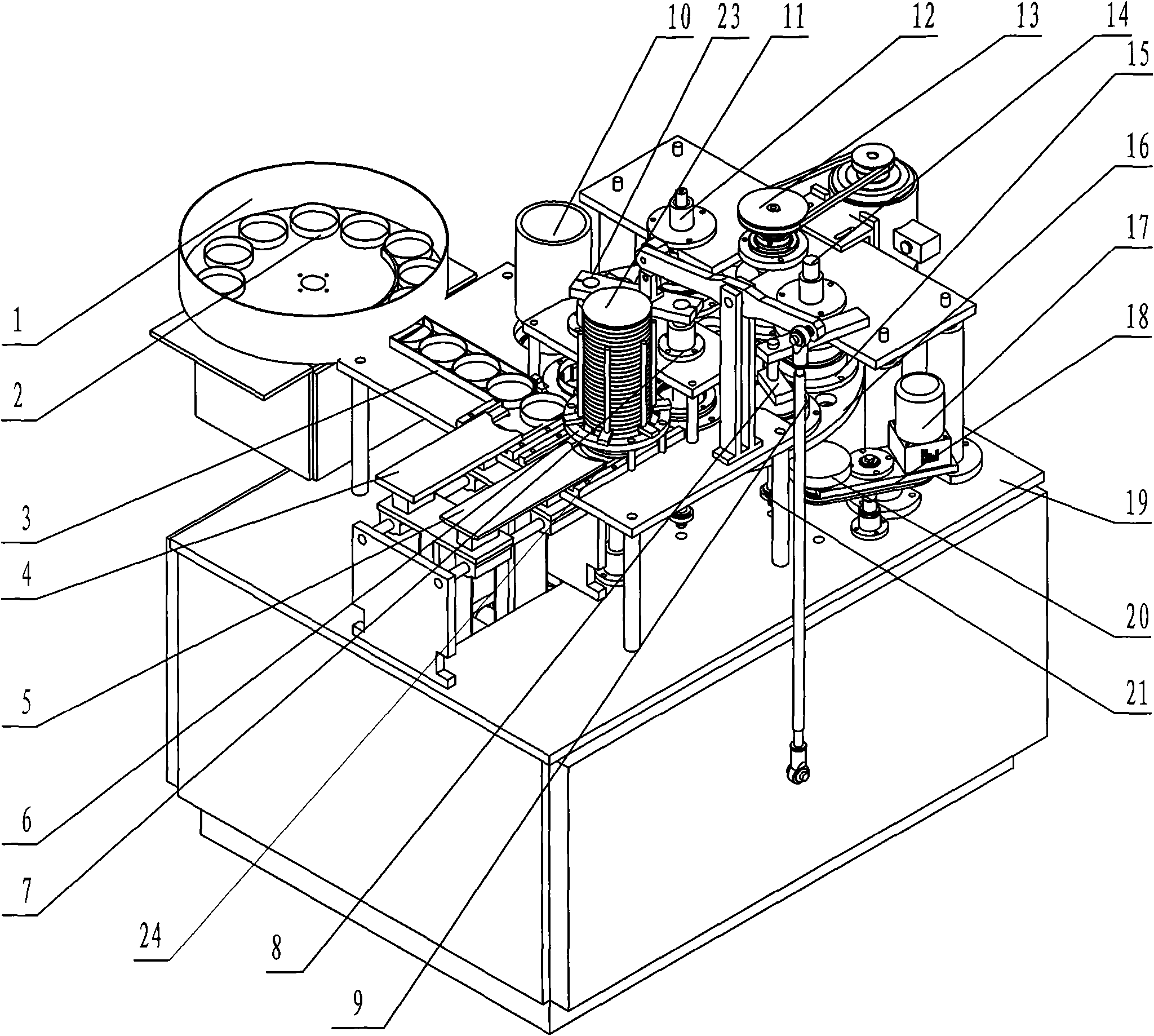

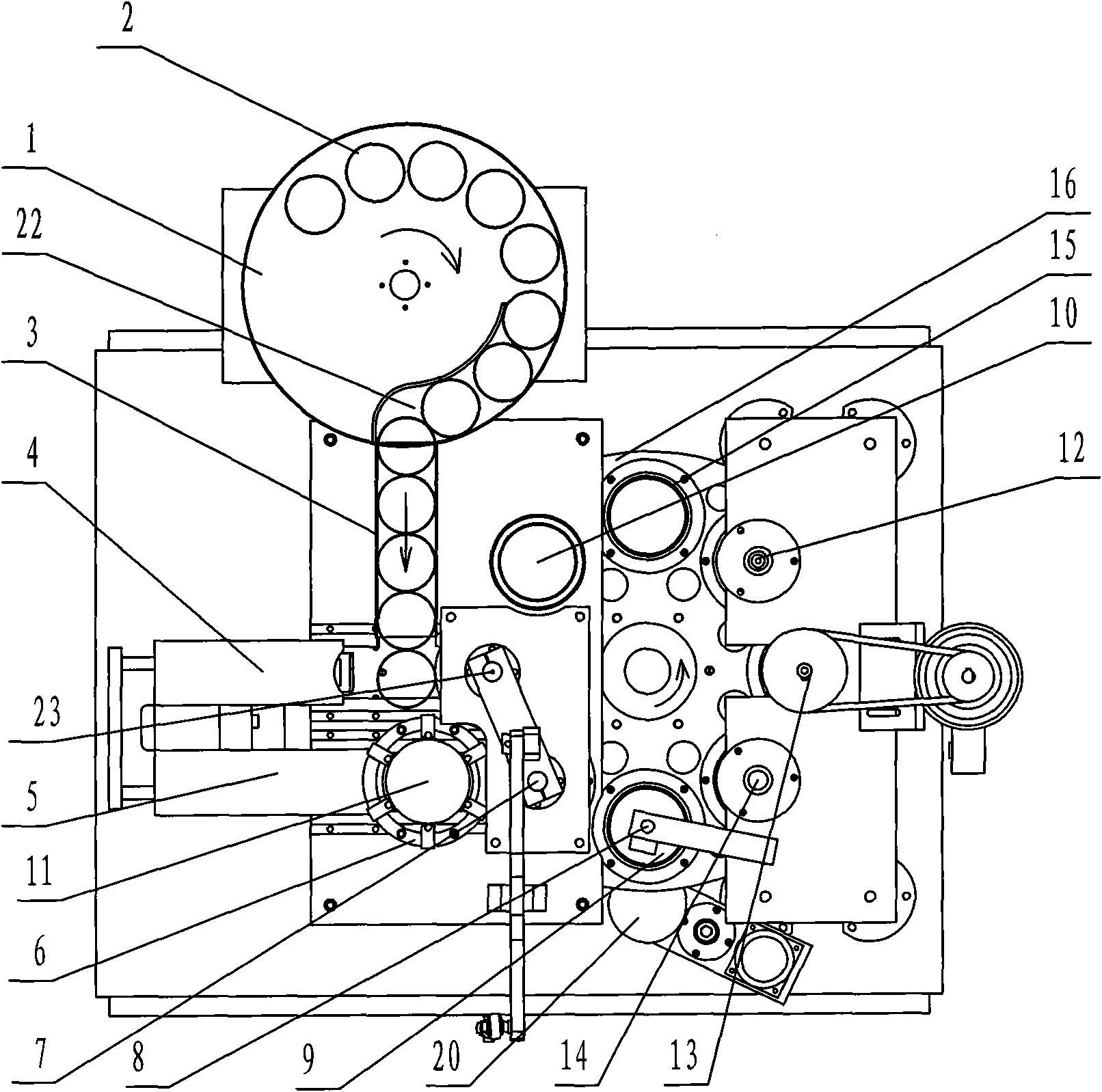

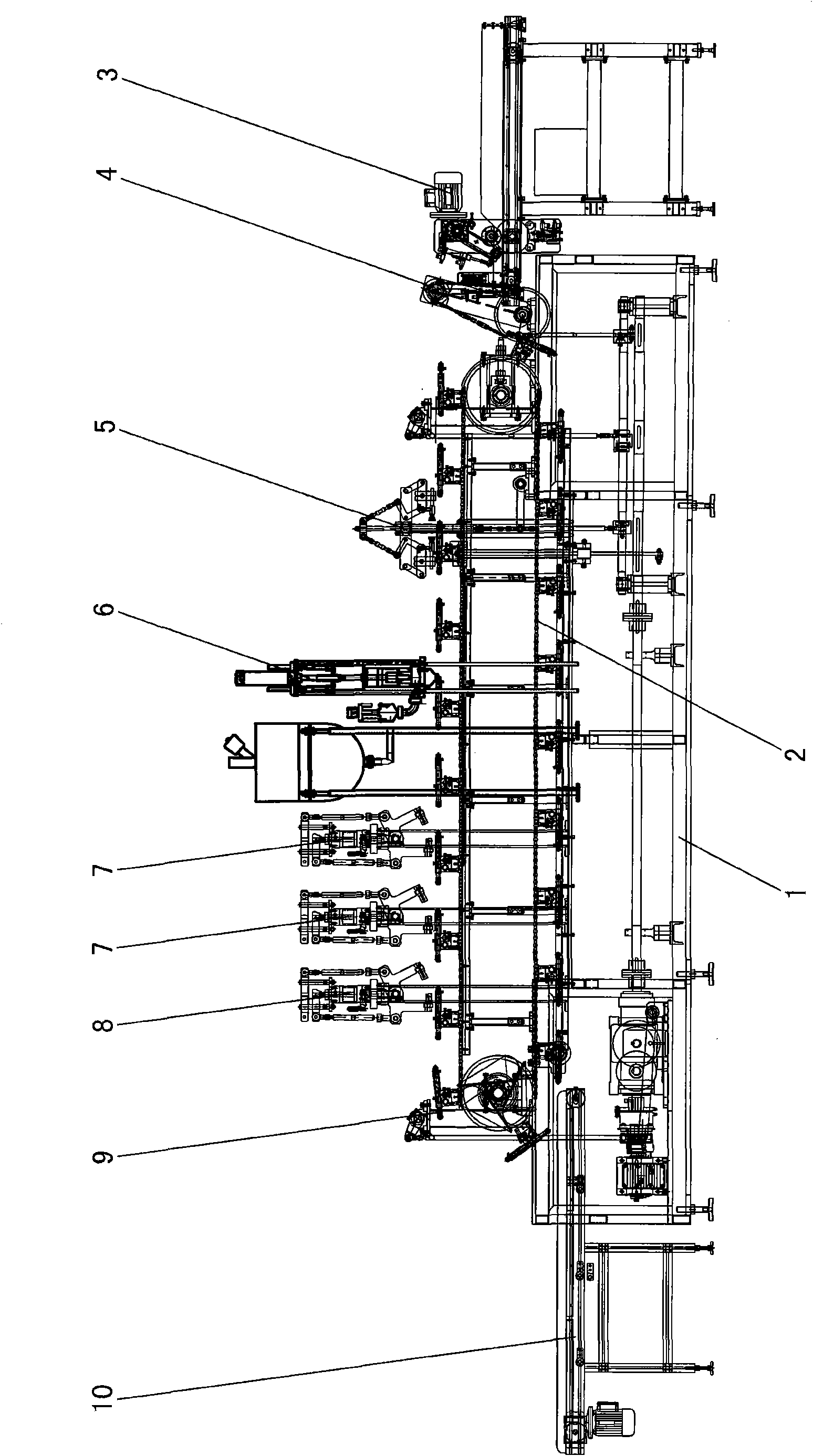

Equipment for manufacturing paper cover for paper cup and paper bowl

ActiveCN101823352AIncrease productivityHigh degree of production automationPaper/cardboard wound articlesPulp and paper industryPaper cup

The invention discloses equipment for manufacturing a paper cover for a paper cup and a paper bowl, which is provided with a machine body (19) and is characterized in that the machine body (19) is respectively provided with a rotating disc (16) and a paper ring feeding device, wherein the rotating disc (16) is provided with indexing holes; compound moulds (15) are arranged in the indexing holes; the machine body (19) is also provided with a paper storage rack (6); one side of the paper storage rack (6) is provided with a paper pusher; a paper ring pushing mechanism (23) and a paper pushing mechanism (7) which correspond to the indexing holes are arranged above the rotating disc (16); and the machine body (19) is also provided with a glue feed mechanism (8), an oil feed mechanism (13) and an edge curling mechanism. The paper cover manufactured by the manufacture equipment is used for replacing a plastic cover, and thus, the environmental-protection requirement is satisfied, whereas the equipment can automatically manufacture the paper cover and has the characteristics of high efficiency and good stability.

Owner:ZHEJIANG RUIDA MACHINERY

Method for making precoating sensitization etching printing plate

ActiveCN101387828AIncreased sensitivityQuality improvementSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusResistEngineering

The invention discloses a production method of precoated photosensitive etching printed board, which precoats a durable photo-induced etching-resist material of stable photochemical property on the surface of a two-layer or multilayer metal plate synthesized by electric plating, vacuum deposition and the like, to prepare a precoated photosensitive etching printed board. In board making, the precoated photosensitive etching printed board can be burnt, developed, etched and removed with film to product a metal printed board. The produced precoated board can be stored without light for at least one year to satisfy the printing demands of anti-false products with large printed mass such as bank notes and valuable securities and the like. The board making can adopt large power UV light source direct board making device (CTcP), to improve the quality of printed boards and the consistence of repeated production. The precoated photosensitive board can reduce the production period of printed boards and improve production efficiency.

Owner:石家庄印钞有限公司 +1

Efficient continuous crackless flattening method of bamboo

ActiveCN105751334AImprove physical and mechanical propertiesBeautiful colorCane mechanical workingPre treatmentUltimate tensile strength

The invention discloses an efficient continuous crackless flattening method of bamboo. The method includes following process steps: (1), pre-treating fresh bamboo tubes; (2), enabling the bamboo tubes to enter a heating pipeline for heating treatment; (3), flattening the bamboo tubes in a heat-insulating space connected with the heating pipeline; (4), post-treating flattened bamboo chips. The method has the advantages that when the fresh bamboo tubes are placed in a high-temperature separated pipeline with temperature of 130-160 DEG C, quick heating and heat-moisture treatment of high-temperature overheated steam are utilized to enable temperature of the bamboo tubes to reach softening points of lignin, cellulose and hemicellulose, and in a subsequent section of the heat-insulating space for high-temperature heating, multiple bamboo tubes or bamboo chips with certain radian are sequentially flattened, cooled and set through flattening rollers which widens progressively. By using the method, treatment temperature for bamboo flattening and labor intensity of workers during operation are lowered, harsh environment for the workers during operation is improved, and production automation level is high; finished products do not need de-yellowing treatment, flattened bamboo is better in physical and mechanical performance, attractive in color and luster and suitable for being used for making artware and furniture and home decoration.

Owner:NANJING FORESTRY UNIV

Manufacturing technology for copper-clad aluminum composite busbar

ActiveCN104733133AGeneration of controlReduce the number of brittle phasesCable/conductor manufactureMolten stateCopper plating

The invention discloses a manufacturing technology for a copper-clad aluminum composite busbar, and belongs to the technical field of metal processing. The manufacturing technology solves the problem that by means of an existing manufacturing technology for a copper-clad aluminum composite busbar, the copper and aluminum bonding strength is low, the uniformity of a copper plating layer is poor, and a copper layer is too thick. According to the manufacturing technology for the copper-clad aluminum composite busbar, a continuous passing type induction heating furnace is used for conducting high-temperature induction heating on a copper-clad aluminum pipe blank, the heating temperature ranges from 600 DEG C to 900 DEG C, and the heating time ranges from 30s to 300s. A molten aluminum film in a semi-molten state or semi-solid state is formed on the outer surface of an aluminum bar, the inside of the aluminum bar and a copper pipe keep solid, hot forging and pressing with the single-stroke reduction ratio being equal to or smaller than 40% is conducted on the heated copper-clad aluminum pipe blank, the molten aluminum film is diffused and permeated into the copper pipe, and a copper and aluminum atom composite layer is formed. Accordingly, the bonding strength of copper and aluminum is improved.

Owner:ZHEJIANG HAILIANG

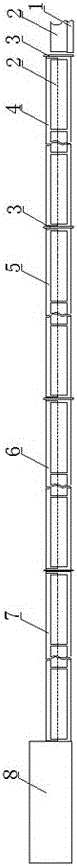

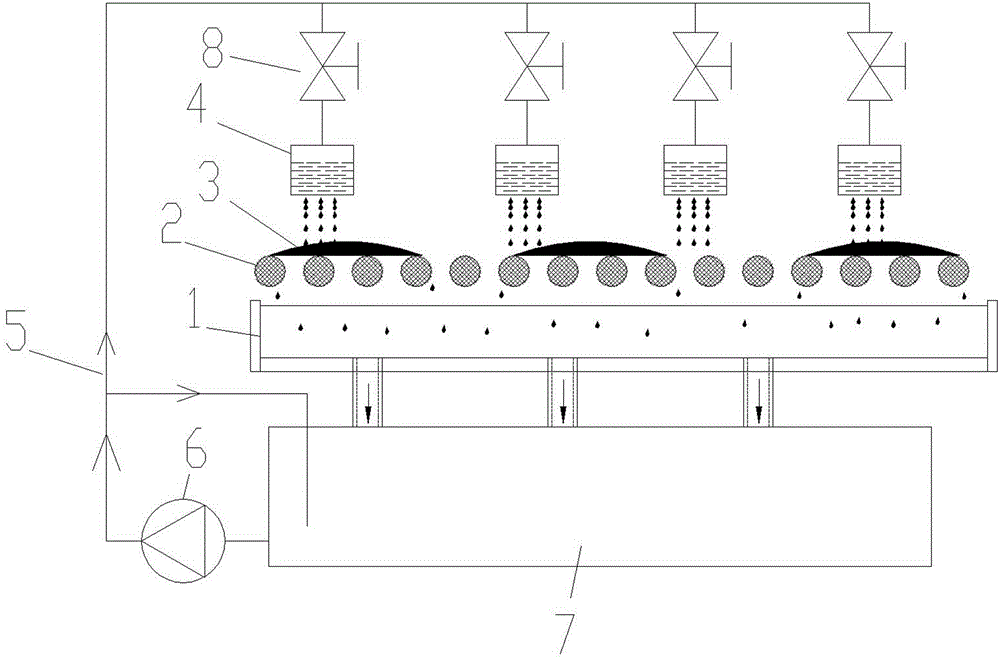

Showering-type wet-process velvet making equipment with solar silicon chips and method

ActiveCN104538503ATake advantage ofImprove product qualityFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon chip

The invention discloses showering-type wet-process velvet making equipment with solar silicon chips. The showering-type wet-process velvet making equipment comprises a conveying component for conveying the silicon chips forwards, a spraying component arranged above the conveying component and a liquid supplying component arranged under the conveying component. The silicon chips are placed on the conveying component at interval, and are conveyed forwards by the conveying component, and a spraying box sprays liquid medicine downwards; and the liquid medicine flowing from the conveying component is polymerized in a liquid receiving groove. The invention also provides a method for carrying out wet-process velvet making by utilizing the showering-type wet-process velvet making equipment. The showering-type wet-process velvet making equipment and method disclosed by the invention have the advantages that corrosive liquid is sprayed or dripped on the silicon chips by a showering mode, and redundant liquid medicine and reaction products flow to the liquid receiving groove, so that the corrosive uniformity of the silicon chips is guaranteed.

Owner:CHANGZHOU S C EXACT EQUIP

Die-casting die structure with combination of multiple angle pins and loose core for connecting pipes

The invention discloses a die-casting die structure with a combination of multiple angle pins and a loose core for connecting pipes. The die-casting die comprises an upper die frame and a lower die frame which are assembled on a die-casting machine and can be matched in a folded manner, wherein the upper die frame and the lower die frame are respectively equipped with a lower die core and an upper die core which form a casting forming die after being folded; slide blocks running in a sliding manner are built in tail bracket units; angle pin holes are manufactured on the slide blocks; angle pins which bulge outwards are assembled on tail bracket driving units and can be matched with corresponding angle pin holes in an inserted and buckled manner; and after the slide blocks slide, front endbodies of the slide blocks are simultaneously embedded and inserted into connected outer edges of the upper and the lower die cores. By adopting a forming cavity structure with a combination of the multiple angle pins and the loose core to replace a sand core, the whole process of using the sand core during gravity casting is removed, and the market prospect is wide; and the die-casting die can bear the impact force of aluminum liquid and can be produced on a cold chamber die casting machine; the production efficiency is greatly improved, the production automaticity is promoted, the labor intensity is reduced, the cost is saved and the production period is shortened.

Owner:NINGBO HUASHUO MOLDING & MACHINE

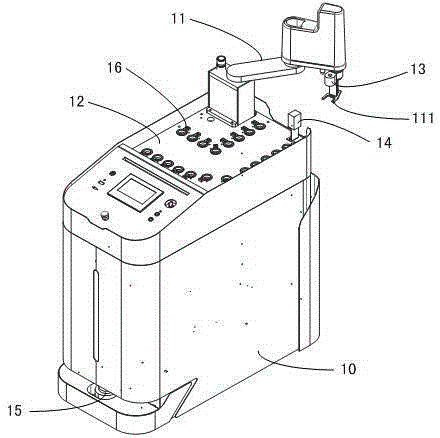

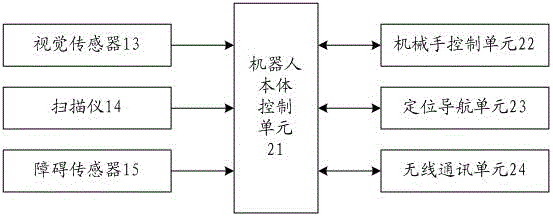

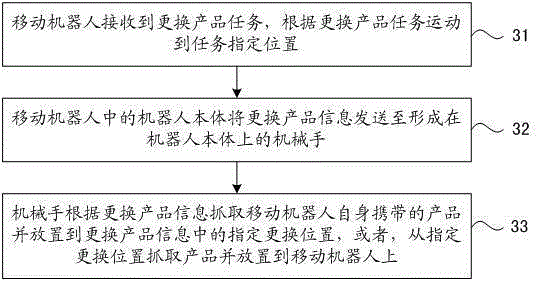

Mobile robot and method for changing products based on mobile robot

ActiveCN105397812AIncrease the level of automationHigh degree of production automationProgramme-controlled manipulatorSimulationProduct base

The invention discloses a mobile robot and a method for changing products based on the mobile robot. The mobile robot comprises a robot body, a robot body control unit and a robot body positioning and navigation unit, and also comprises a product tray formed on the robot body and used for holding a product, a manipulator formed on the robot body and used for grabbing the product in the production tray and / or putting the product to the product tray, and a manipulator control unit communicating with the robot body control unit and controlling the manipulator to grab the product in the product tray and / or put the product to the product tray according to a control command transmitted by the robot body control unit. By applying the mobile robot and the method, the effect that the robot is used for delivering and changing products is achieved, and the automation level of enterprises is improved.

Owner:苏州海通机器人系统有限公司

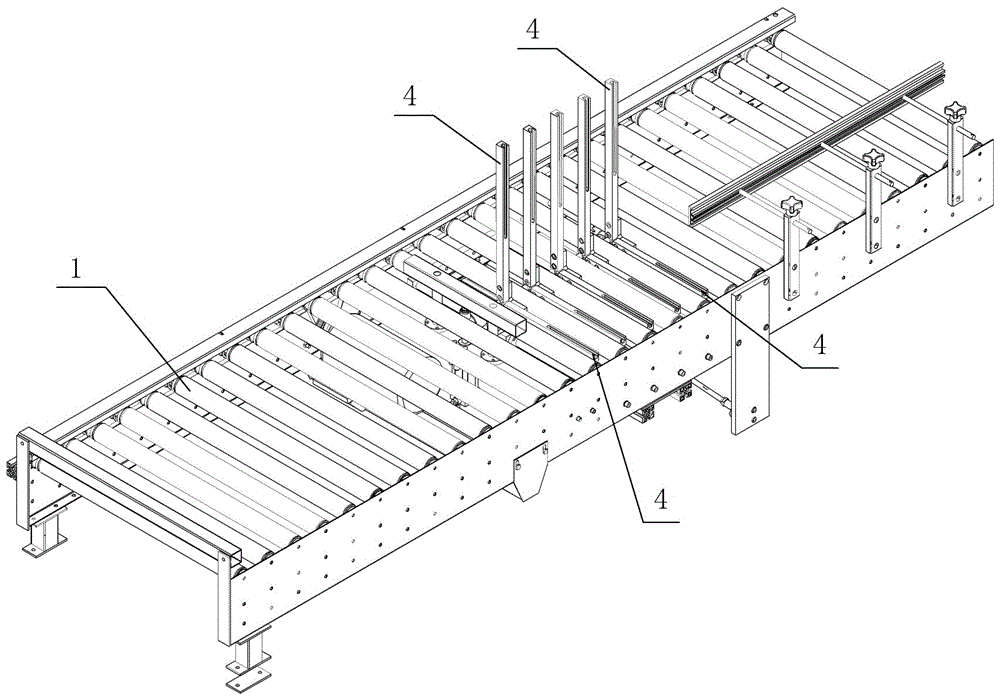

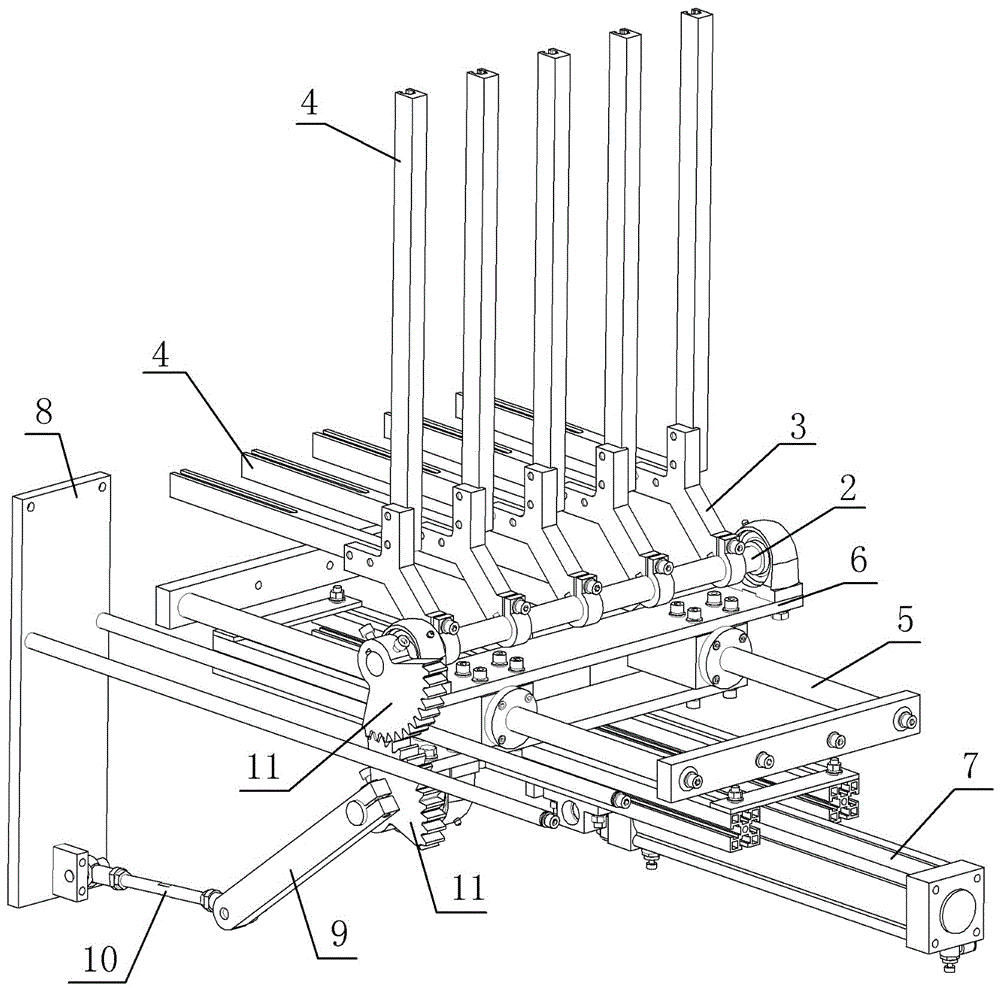

Box turnover device

The invention discloses a box turnover device. Two turnover rods perpendicular to each other are mounted at the position, arranged below each conveying belt roller, of a rotary shaft. A sliding seat is driven by a driver to move along guide shafts. On one hand, the turnover rods are driven by the rotary shaft mounted on the sliding seat to be turned over, and therefore boxes are turned over by the turnover rods; on the other hand, a rotating arm and an adjusting screw are driven by a gear pair to move; and in the process, the sliding seat moves to the other side of a conveying belt from one side of the conveying belt, and the turned-over boxes are approximately kept at the positions before turnover. The box turnover device is simple in structure, ingenious in design and easy to manufacture, and the production cost can be effectively reduced; the box turnover device is fast and convenient to work, and the production efficiency and the automation degree can be greatly increased; and meanwhile, the boxes cannot be damaged, and products can be effectively protected.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

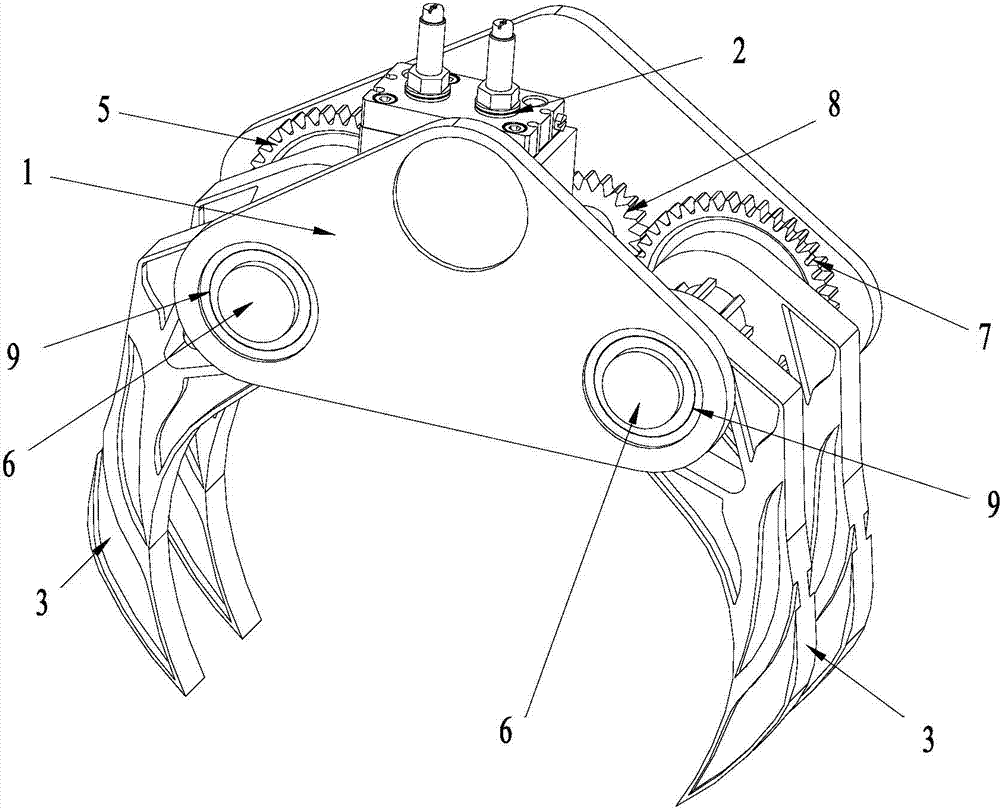

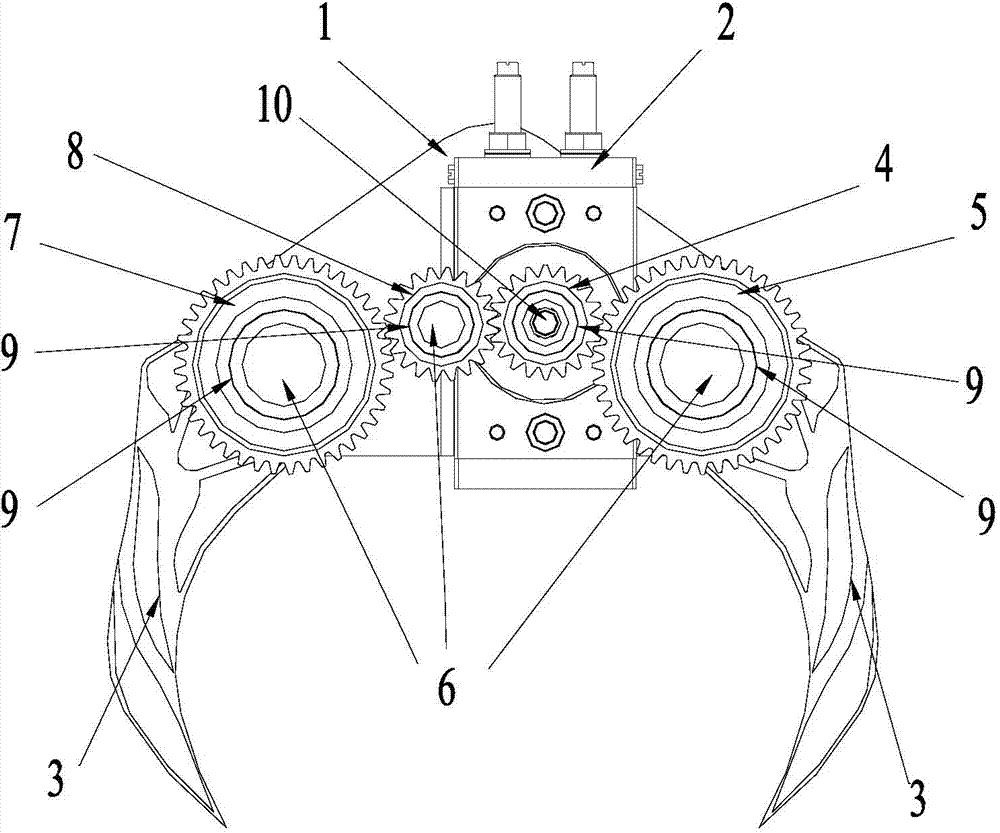

Robot gripper driven by gear

InactiveCN104772769AIncrease flexibilityImprove general performanceProgramme-controlled manipulatorGripping headsGear driveGear wheel

The invention provides a robot gripper driven by a gear. The robot gripper driven by the gear is connected with a moving section of a robot. The robot gripper comprises a bracket, a gear drive device, a driving device and at least two moving rods, wherein the bracket is connected with the moving section of the robot; the gear drive device is erected on the bracket; the driving device is connected with the gear drive device; the moving rods are connected with the gear drive device; each of the moving rods can carry out opening and closing movements. The robot gripper driven by the gear, which is provided by the invention, is simple in structure, high in universality, high in flexibility, strong in clamping force and quick in gripping speed, and the quick gripping of a workpiece and the firm clamping of the workpiece in the process that the robot moves quickly can be realized, so as to effectively solve the problem of matching the gripper with the workpiece, decrease production cost and manufacturing cost, and improve production efficiency.

Owner:广东泰格威机器人科技有限公司

Middle-small modulus gear high-frequency hardening production line automatic control system and method

InactiveCN101139650AAccurate control of quenching temperatureHigh degree of production automationFurnace typesHeat treatment process controlAutomatic controlHigh frequency

The invention provides an automatic controlling system and controlling method for a hi-frequency hardening production line for middle- / small-modulus gears, which comprises a PLC host, an AD and DA functional module and a touch screen. After an input terminal of the PLC host and the AD module collect and process signals from the production line, an output terminal and the DA functional module control the links in the production line, so as to achieve real-time controlling of the production line. The invention is of two modes, namely automatic and manual. The touch screen allows real-time monitoring while adjusting the process parameters easily, making statistics about output of current shift and accumulated output, recording production, and displaying alarm. The invention is of high automation, can accurately control the hardening temperature of gears, improve obviously product quality and output, also improves the work environment, lightens labor intensity of workers, reduces production cost, and is especially suitable for massive production.

Owner:JINING POLYTECHNIC

Filling sealing machine of bag-mouth-free standing bags

ActiveCN102085924AIncrease the number ofAvoid collisionWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a filling sealing machine of bag-mouth-free standing bags, comprising a stand, a conveying mechanism, a filling mechanism and at least one heat-sealing mechanism. The conveying mechanism, the filling mechanism and at least one heat-sealing mechanism are mounted on the stand, the filling mechanism and at least one heat-sealing mechanism are sequentially distributed from back to front along the conveying mechanism which comprises two ring cycle transmission mechanisms, a driving mechanism and at least one bag tightening mechanism, and the two ring cycle transmission mechanisms are respectively arranged on the stand, are mutually parallel and respectively fixed at both ends of the bag tightening mechanism, both ends of the bag tightening mechanism are respectively fixed on the two ring cycle transmission mechanisms. In addition, the filling sealing machine of the bag-mouth-free standing bags comprises a bag supply mechanism, a bag feeding mechanism, a blowing mechanism, a cooling sealing mechanism, a bag withdrawing mechanism and a finished product conveying belt. Compared with the prior art, the invention has the advantages that the number of bag-mouth-free standing bags which can be synchronously transmitted by the transmission mechanisms is greatly increased, the production efficiency is greatly increased, and the invention has the advantages of simplestructure, easiness of implementation and high cost performance ratio.

Owner:GUANGDONG YUEDONG MECHANICAL IND

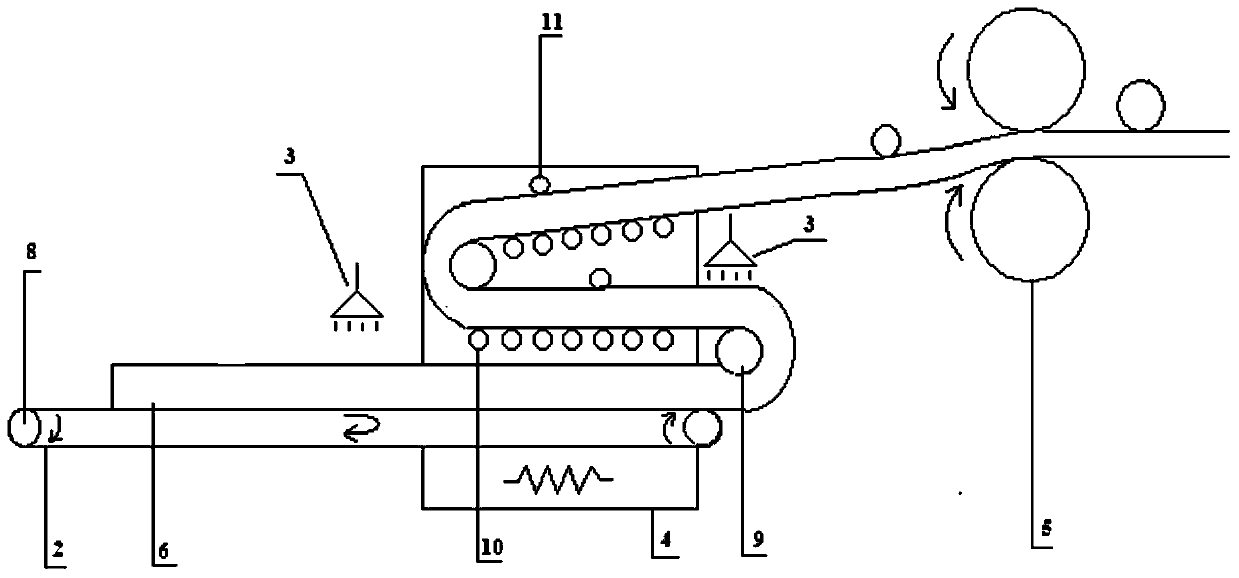

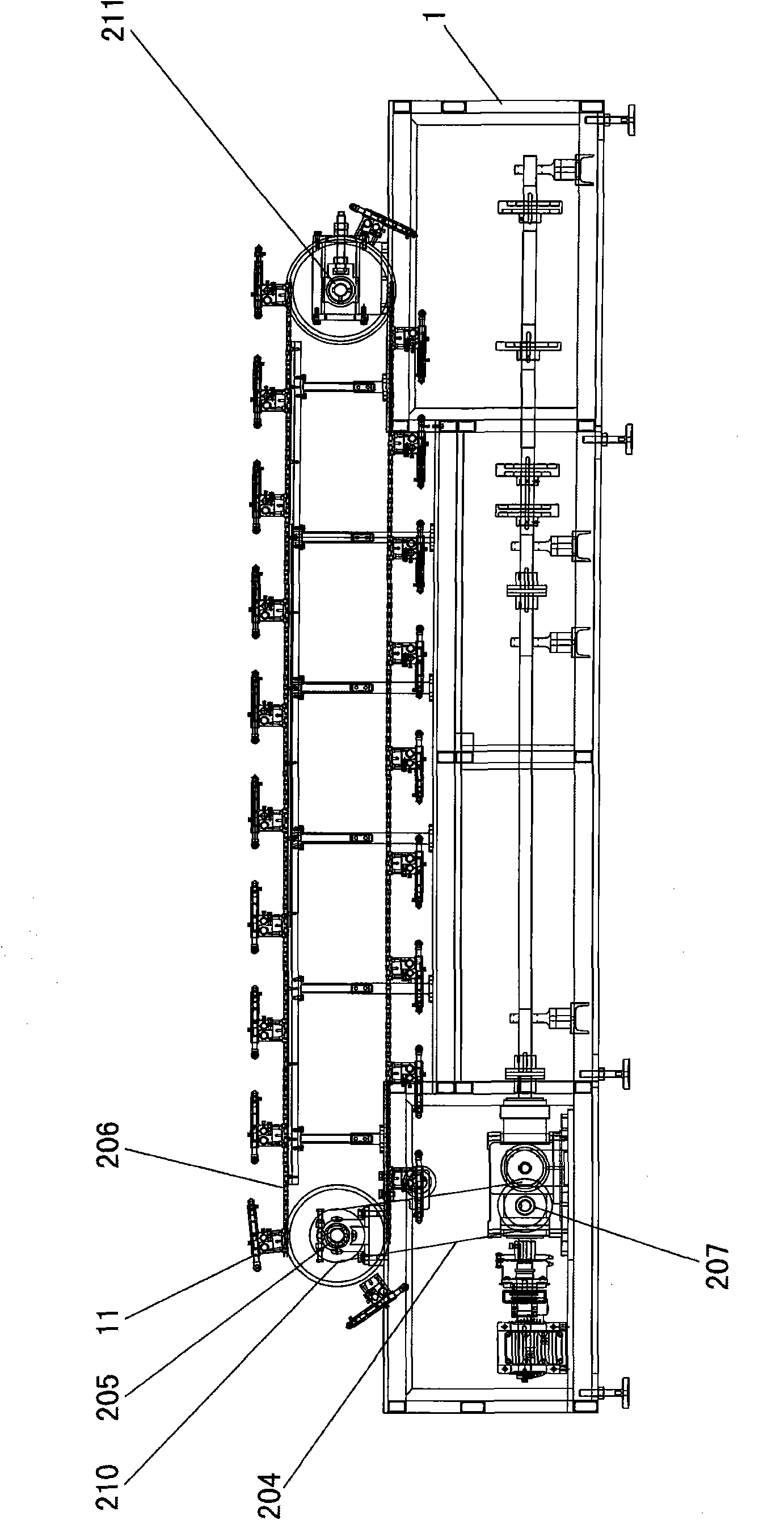

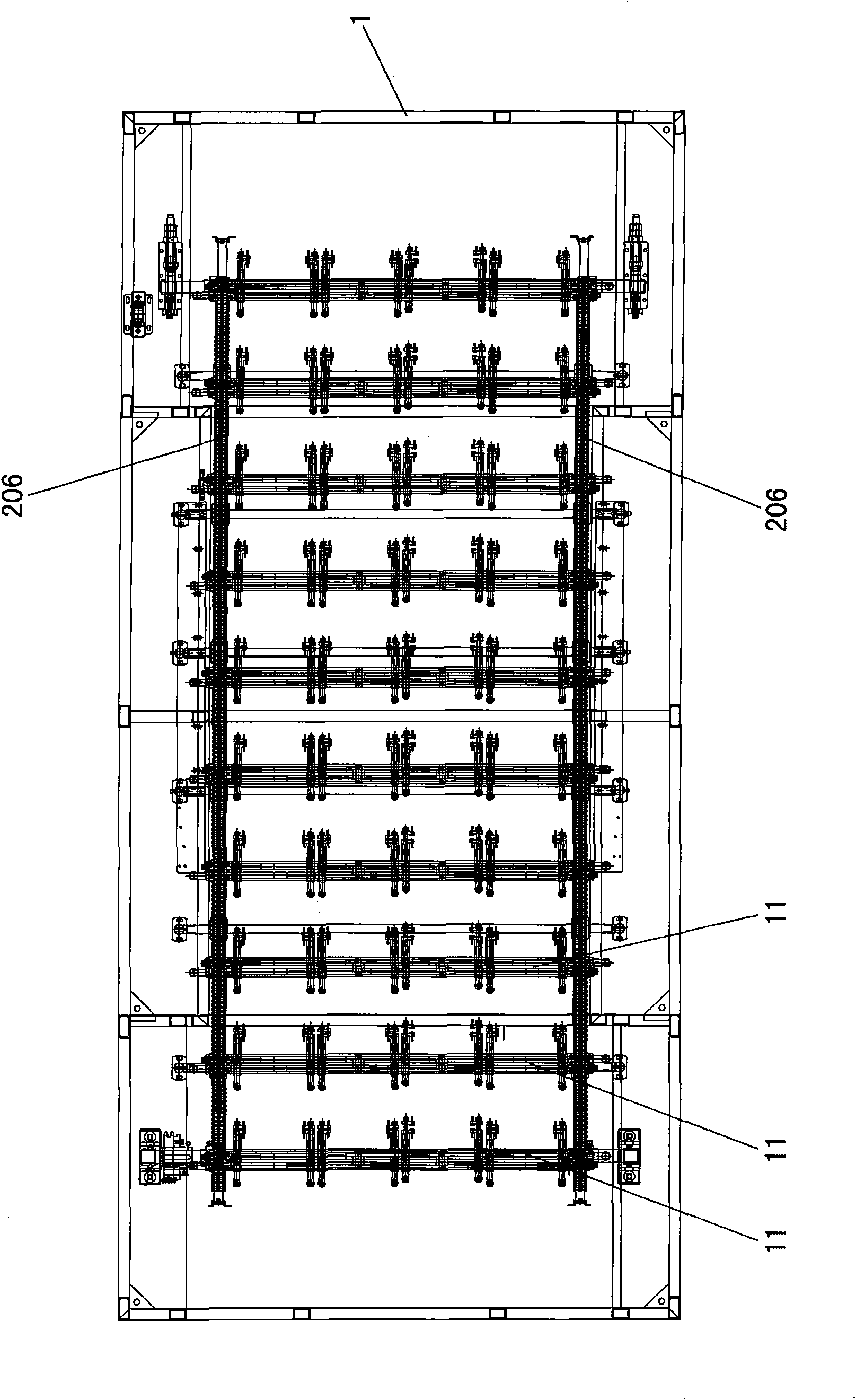

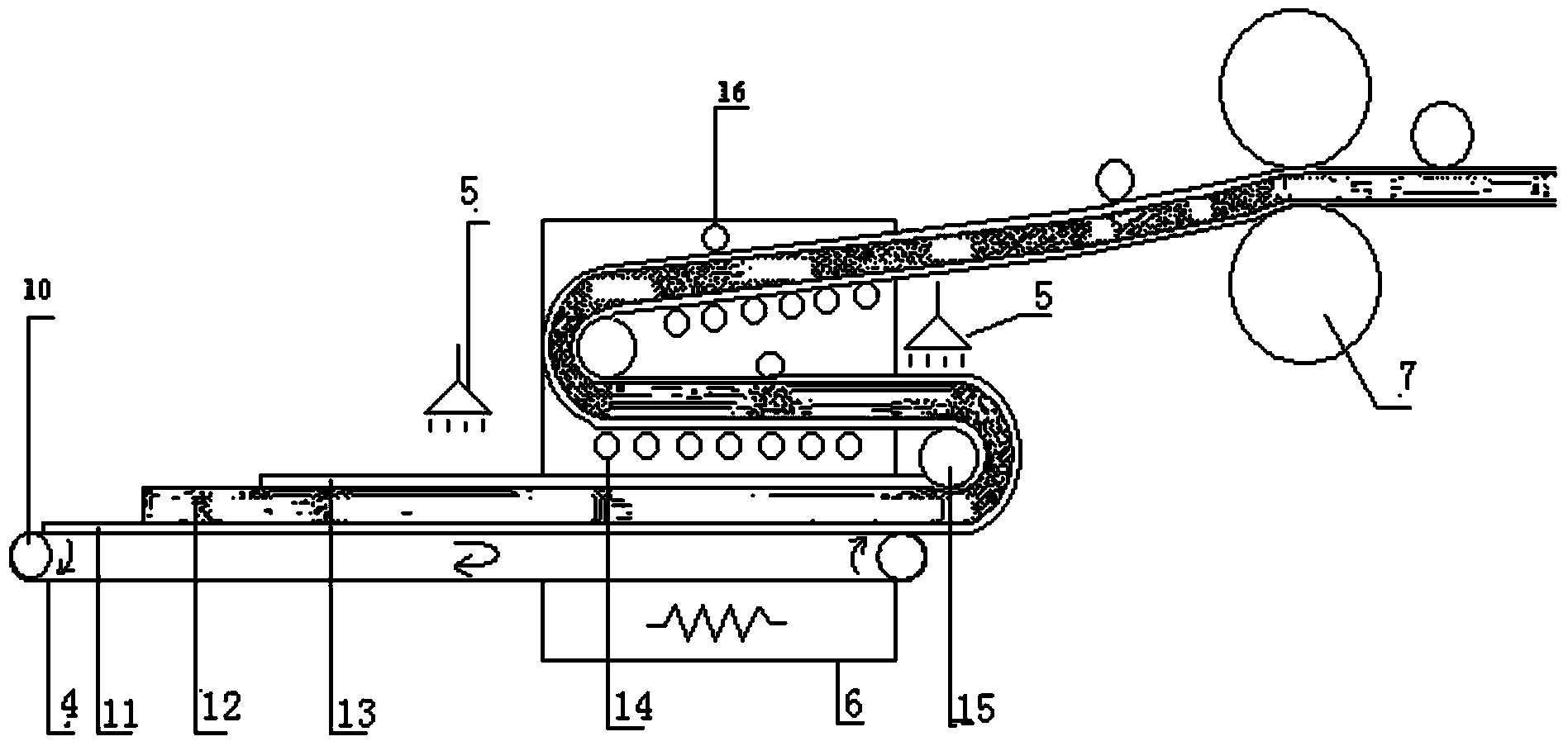

Hot melting bonding processing system and process of environment-friendly multilayer fiber composite felt

ActiveCN103469490AFacilitate subsequent molding processingHigh degree of production automationNon-woven fabricsAdhesivesEngineeringHot melt

The invention discloses a hot melting bonding processing system and process of environment-friendly multilayer fiber composite felt. The system comprises a plurality of parallel fiber net generating devices which are connected with a baking oven through a bottom curtain, the bottom curtain is arranged below the fiber net generating devices and provided with driving structures, and the baking oven passes through a hot pressing device and extends to winding devices. Cloth guide rollers and supporting conveying rollers are arranged in the baking oven, wherein the cloth guide rollers are used for winding a plurality of fiber nets fed by the bottom curtain into an S shape. The hot pressing device is a pair of heating pressurizing rotating rollers. Each fiber net generating device comprises an opening device, a combing device and a lapping device, wherein the opening device, the combing device and the lapping device are sequentially connected. The continuous strip-shaped multilayer fiber composite felt is produced in a one-time stacking lapping and hot melting bonding mode, follow-up forming is conveniently conducted, and the production automation degree is improved. In the multilayer fiber composite felt, components, performance and thickness of any layer can be different from components, performance and thickness of another layer, and all layers and positions between all the layers are formed in a low-melting-point skin core type fiber hot melting bonding mode.

Owner:SHANDONG UNIV

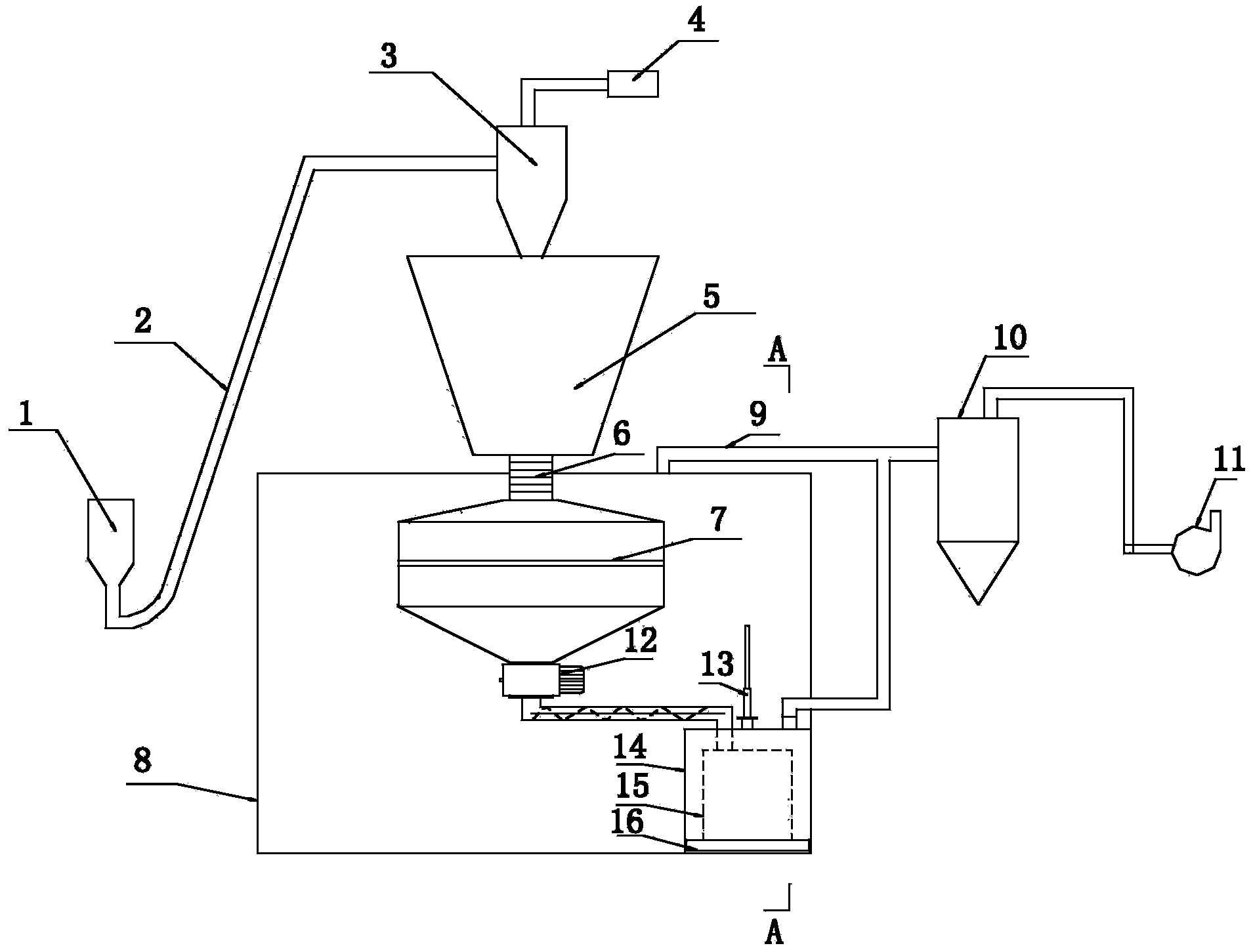

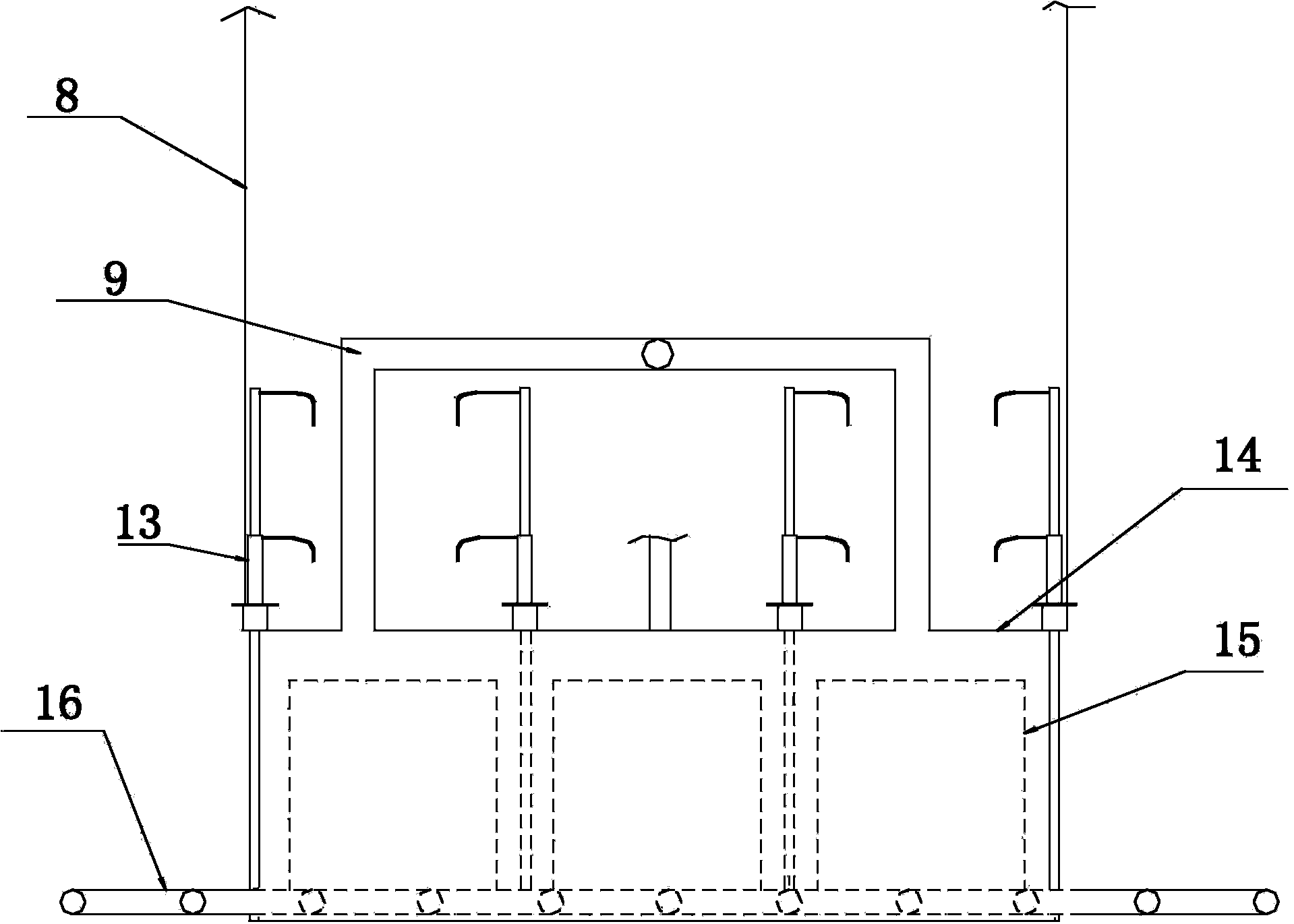

Powder material processing and integration device

InactiveCN104044875AIncrease productivityHigh degree of production automationBulk conveyorsLoading/unloadingMaterials processingWorking environment

The invention discloses a powder material processing and integration device. The to-be-solved technical problem is to improve the production efficiency and improve the working environment. The powder material processing and integration device is provided with a ground surface material cabin, a material transporting pipeline, a negative pressure cabin, a mixing cabin, a classifying screen, a quantitative discharging valve and a discharging cabin which are sealed and connected in order, wherein the classifying screen, the quantitative discharging valve and the discharging cabin are arranged inside a sealed cavity, the lower part of the discharging cabin is provided with a frequency changing speed regulation metering conveyor, a transmission belt of the frequency changing speed regulation metering conveyor extends out of the sealed cavity, the sealed cavity is connected with a dust removal box through a dust removal pipeline, and the dust removal box is connected with a draught fan. Compared with the prior art, the powder material processing and integration device integrates charging, mixing, screening and discharging equipment, the producing efficiency and the automation degree of powder materials in the charging, mixing, screening and discharging working procedures are improved, the dust quantity elevated in the producing process is lowered, the working environment is improved, the dust recycled by a dust remover is effectively used, the emission of the dust is reduced, and the production cost is reduced.

Owner:KOCEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com