Filling sealing machine of bag-mouth-free standing bags

A stand-up pouch and sealing machine technology, used in packaging sealing/fastening, external support, transport packaging, etc., can solve the problems of low production efficiency, low production efficiency of automatic filling and sealing machines, and slow filling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

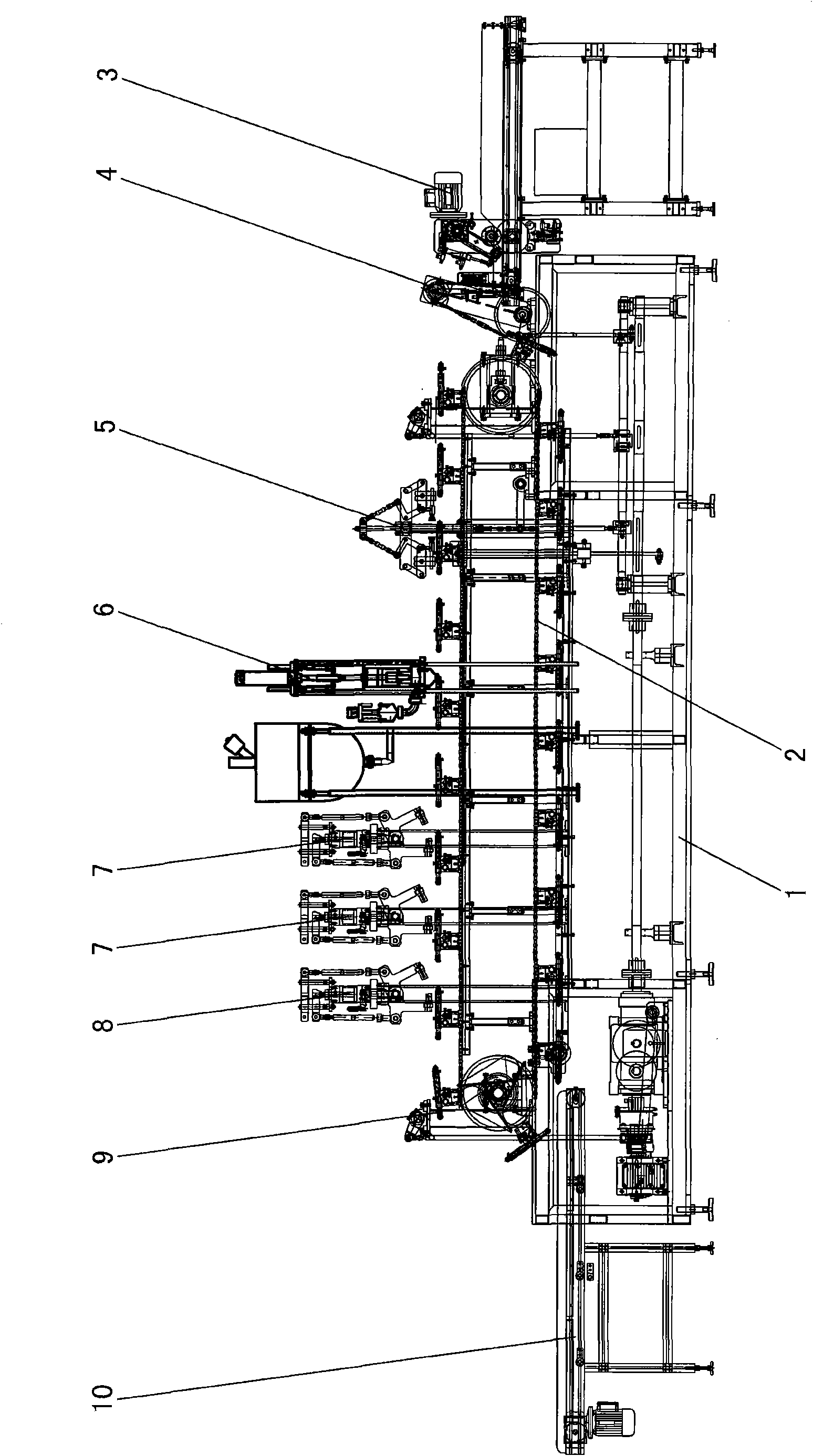

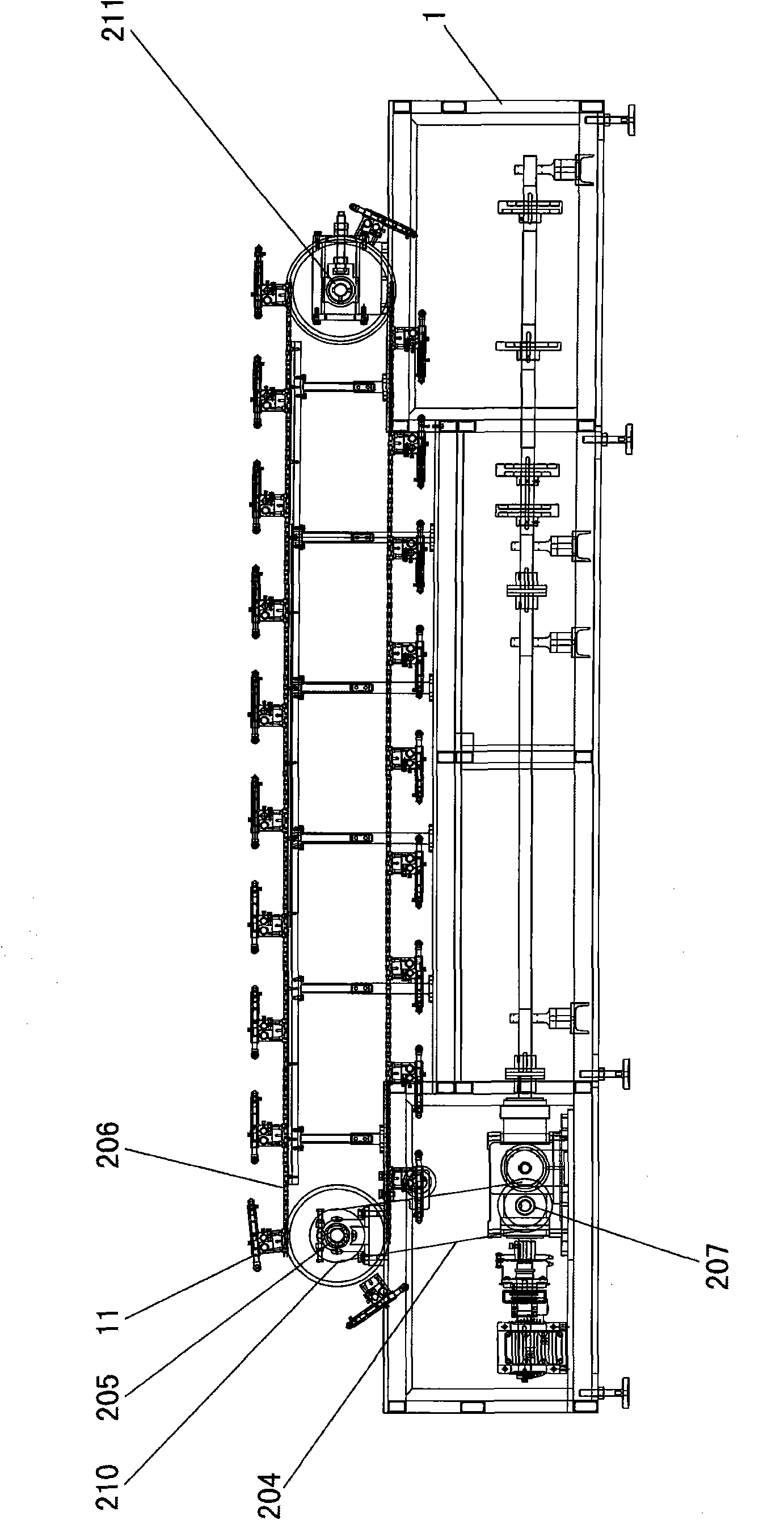

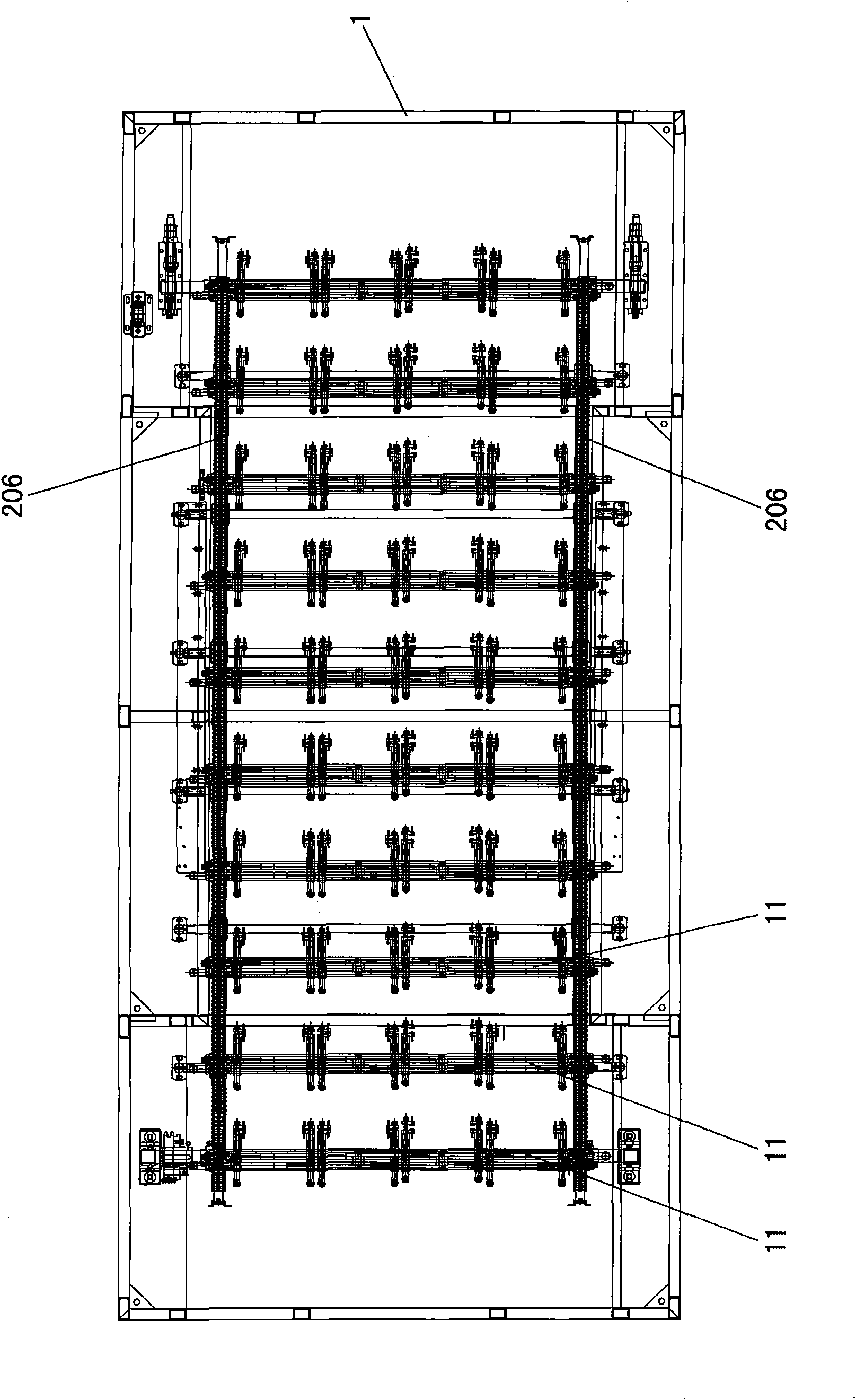

[0047] Such as Figure 1-11 As shown, a non-spout stand-up pouch filling and sealing machine in this preferred embodiment includes a frame 1, a conveying mechanism 2, a filling mechanism 6, and two heat-sealing mechanisms 7, the conveying mechanism 2, the filling mechanism 6 and Both heat-sealing mechanisms 7 are installed on the frame 1, and the filling mechanism 6 and the two heat-sealing mechanisms 7 are distributed sequentially along the conveying mechanism 2 from back to front (the entrance of the conveying mechanism 2 is the rear, and the exit is the front). The filling and sealing machine for stand-up pouches without bag nozzles also includes a bag feeding mechanism 3 , a bag loading mechanism 4 , an air blowing mechanism 5 , a cooling and sealing mechanism 8 , a belt unwinding mechanism 9 and a finished product conveyor belt 10 .

[0048] The bag feeding mechanism 3 is located outside the entrance of the conveying mechanism 2 . The bag loading mechanism 4, the cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com