Method for detecting ampoule bottle appearance quality through medical visual inspection robot

A technology of visual inspection and inspection method, which is applied in the direction of optical inspection for defects/defects, and can solve the problems of low efficiency, low precision, and poor consistency of manual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

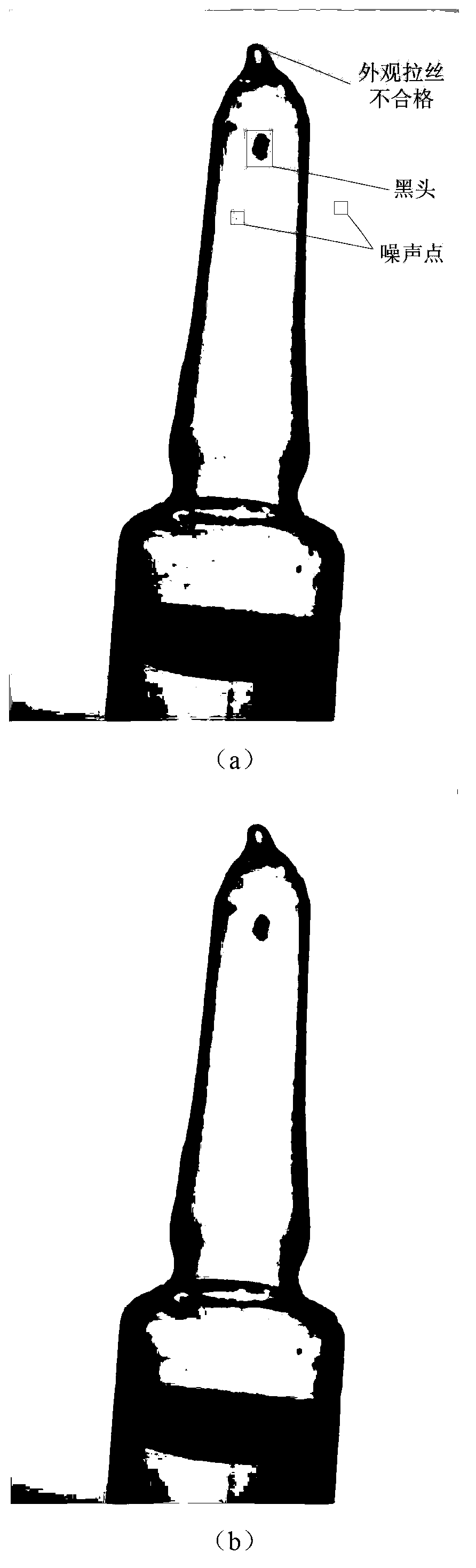

[0104] Once the position of the system for detecting the appearance of ampoules is fixed, the imaging position of ampoules in the system is also relatively fixed, such as figure 1 Shown is the imaging of a qualified ampoule in the detection system, where S1 is the width of the head of the ampoule, S2 is the height from the top of the ampoule to the neck of the bottle, the width of the head of the ampoule is the cross section where S1 is located, and the distance from the ampoule The top of the bottle is S2 / 4;

[0105] Establish a coordinate system, take the upper left corner of the image as the coordinate origin, the x-axis is the uppermost line of the image, and the y-axis is the leftmost line of the image;

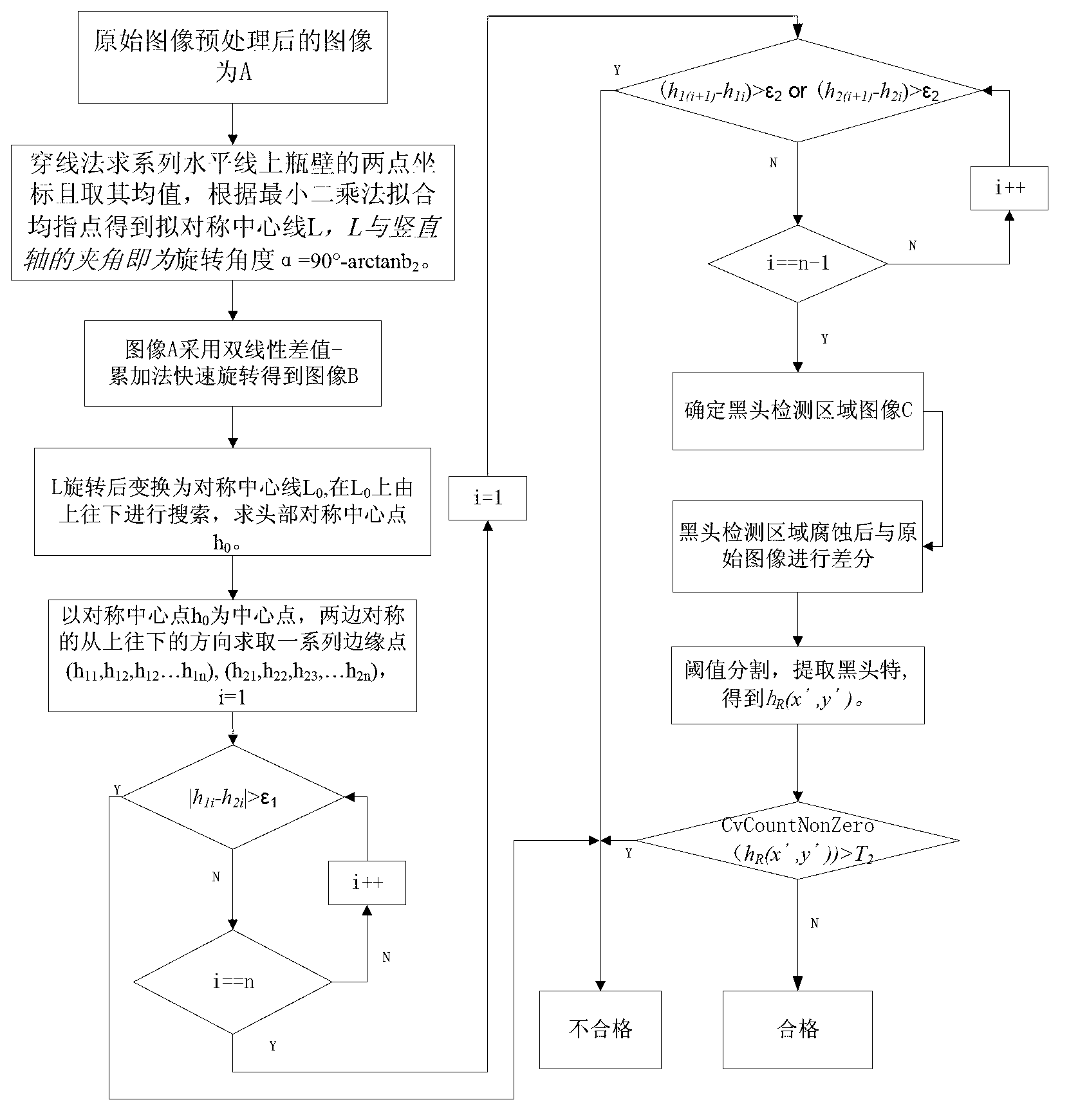

[0106] The inspection method for the appearance quality of ampoules by the medical visual inspection robot, the specific proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com