Automatic state detection device and method for railway track spring bar fastener

An automatic detection device and technology for railway tracks, which are applied in the directions of tracks, track maintenance, roads, etc., can solve problems such as difficulties, lack of devices or equipment for railway track fastener detection, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

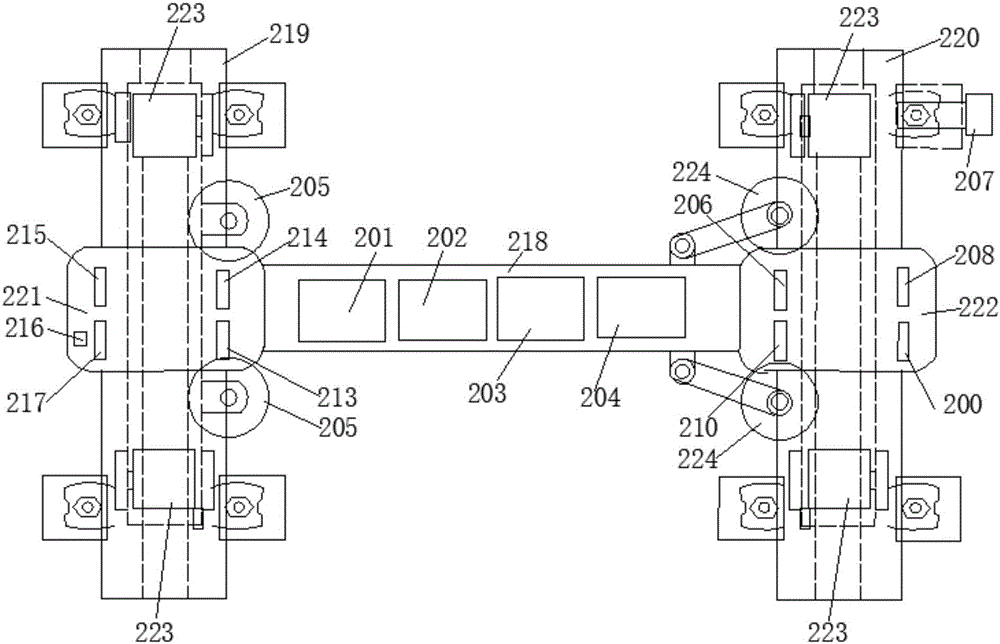

[0082] like figure 2 In the second embodiment shown, in the automatic detection device for the state of the rail clip fastener in this embodiment, the running mechanism includes: a patrol trolley;

[0083]The patrol trolley includes: a car body, the car body includes: a crossbeam 218, a left longitudinal beam 219, a right longitudinal beam 220 and at least four traveling wheels 223, the traveling wheels 223 are in close contact with the top surface of the rail to prevent the car body from bumping up and down , the above-mentioned car body is also provided with a positioning wheel 205 and a tensioning wheel 224, wherein the positioning wheel 205 is always close to the inner surface of the rail; the tensioning wheel 224 adjusts the degree of tension as the gauge of the track changes to avoid The body shakes left and right; the central positions of the above-mentioned left longitudinal beam 219 and right longitudinal beam 220 are respectively connected with the left and right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com