Workpiece apparent defect detection method based on machine vision

A technology of appearance defect and detection method, which is applied in the direction of instrumentation, image data processing, calculation, etc., and can solve the problems of high false detection of the system, poor detection effect of small scratches, indentations and blistering defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

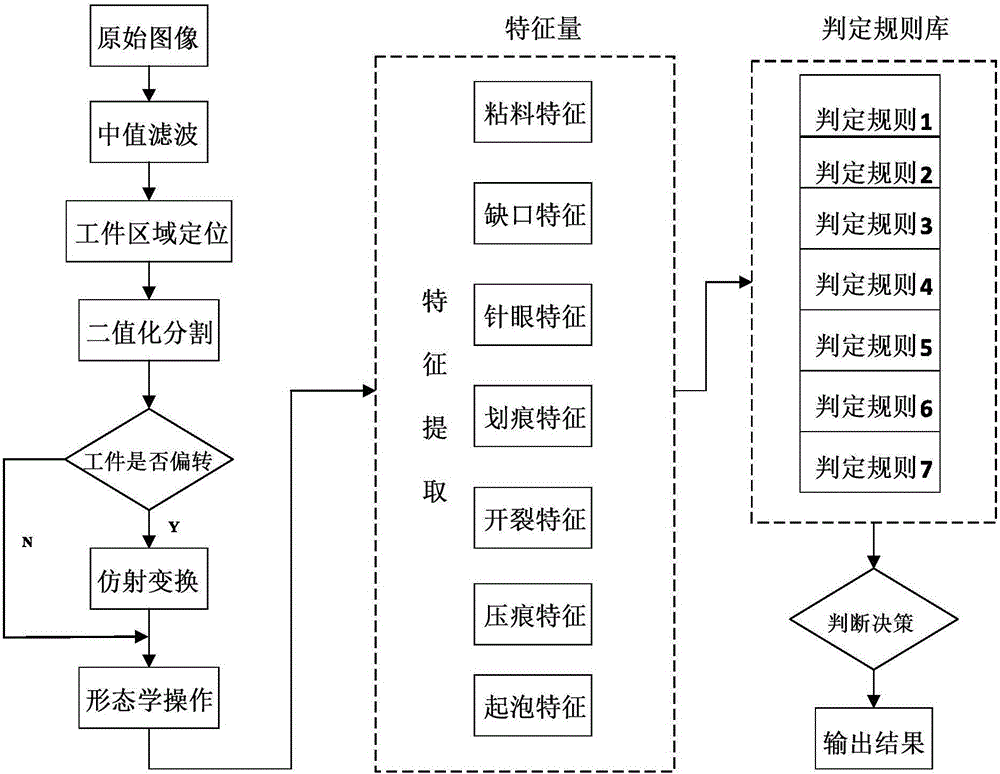

[0102] Such as figure 1 , a method for detecting workpiece appearance defects based on machine vision, comprising the following steps:

[0103] Step 1: Work piece image acquisition and preprocessing;

[0104] Step 2: Image segmentation and workpiece pose correction;

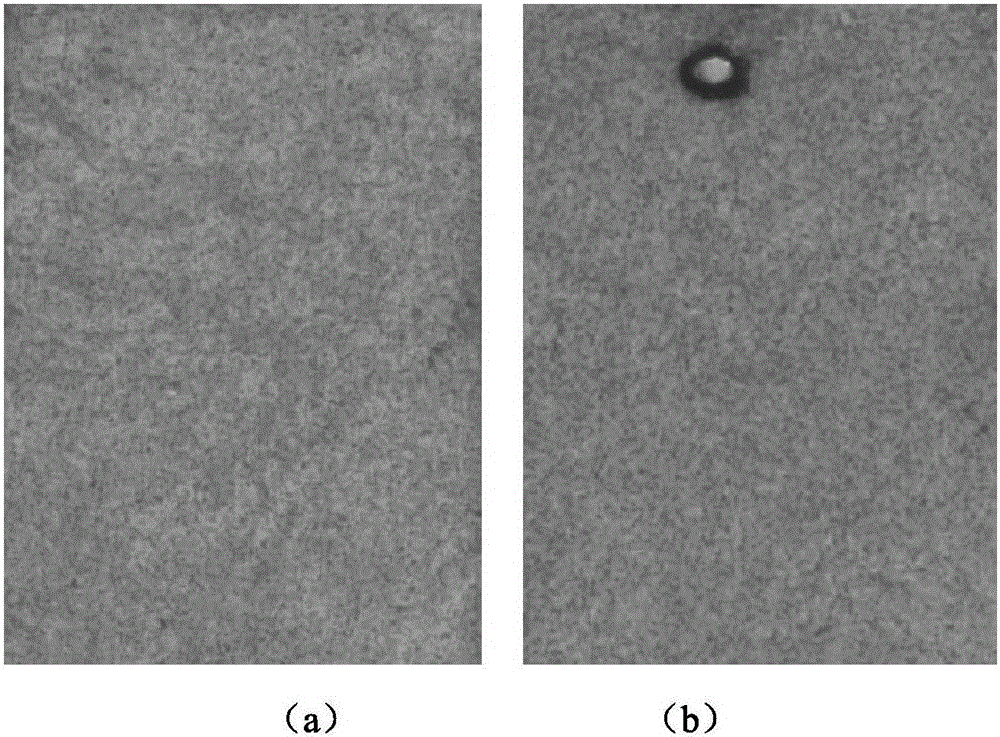

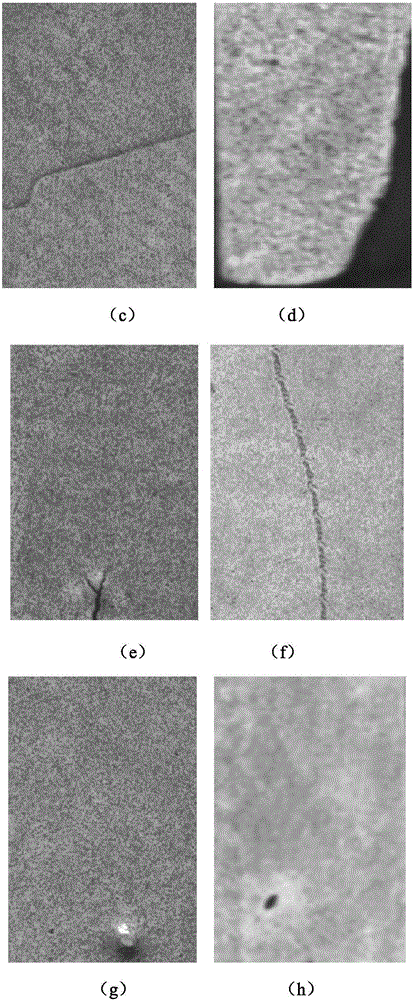

[0105] Step 3: Inspect for the following cosmetic defects: nicks, sticks, cracks, indentations, pinholes, scratches, and blisters.

[0106] In step 1, the workpiece image f(x, y) is collected by using the CCD industrial camera and the image acquisition card through the coaxial light source, and the workpiece image is a grayscale image, and then the workpiece image is sent to the industrial computer for preprocessing, and the preprocessing is Perform median filter processing on the collected workpiece images to remove the noise that may be caused during image capture and transmission, and improve the image signal-to-noise ratio.

[0107] In step 2:

[0108] (1) Image segmentation:

[0109] Segment the preproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com