Automatic roll replacing and strip connecting system for battery pole pieces

A battery pole piece and automatic control system technology, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems that the overall line speed cannot be guaranteed, and the mechanical structure is complicated, so as to improve the degree of production automation and Production efficiency, production cost reduction, and the effect of continuous and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

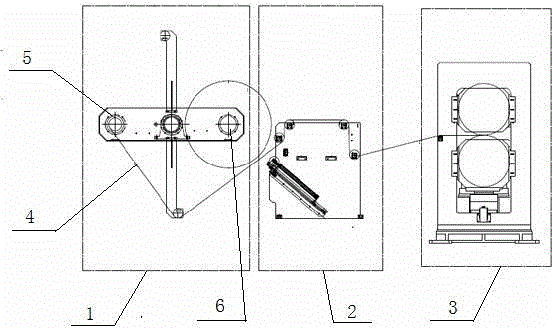

[0025] The structure of the battery pole piece automatic roll changing system is as follows: figure 1 As shown, it includes an automatic control system, an unwinding machine 1 and a splicing device 2 . The automatic control system controls the operation of the unwinding machine 1 and the splicing device. The unwinding machine 1 is used to complete the reel change, and the splicing device 2 completes the cutting of the original tape roll and the bonding of the original tape roll and the new tape roll. The battery pole piece automatic roll-changing and connecting system is set at the front of the roller press 3, and the tape-connecting device 2 is set on the side of the unwinding machine 1, and the unwinding machine 1 and the tape-connecting device 2 are connected with the automatic control system connected.

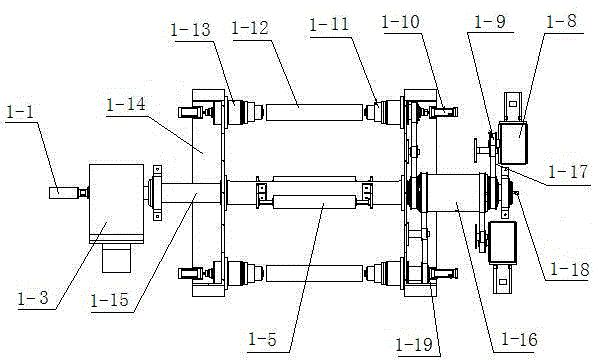

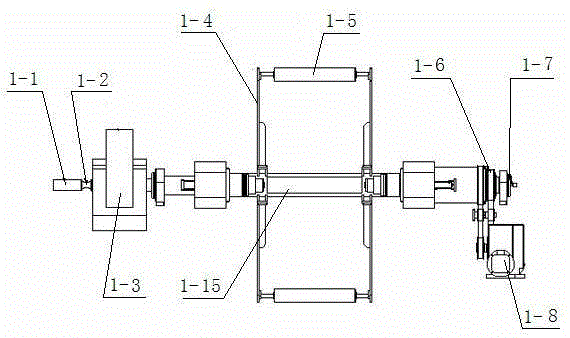

[0026] The unwinder 1 is a double-statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com