Gantry type large-diameter paper dividing and cutting machine

A gantry-type, large-diameter technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low winding efficiency, poor paper surface protection, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

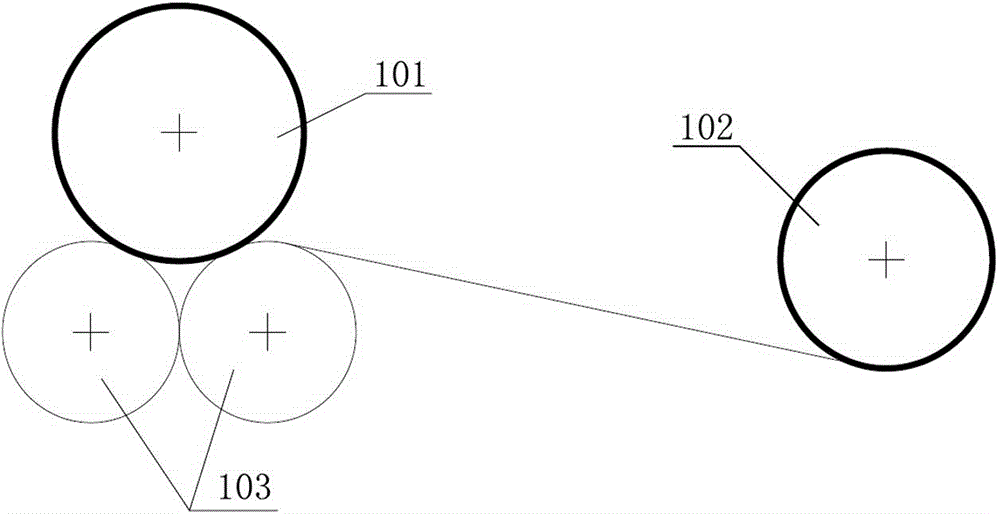

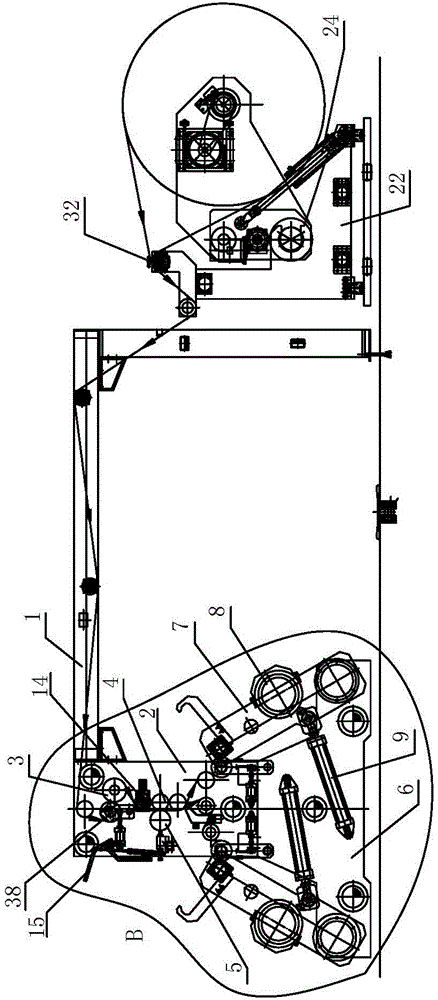

[0054] Such as image 3 and Figure 13 The gantry-type large-diameter paper slitting machine shown includes a gantry-type frame 1, a traction and slitting mechanism, an unwinding device arranged at one end of the gantry-type frame 1, and a traction and slitter arranged at the other end of the gantry-type frame 1. mechanism, a manual adjustment guide roller device 32, and N pressure-type winding devices arranged at the lower part of the traction and slitting mechanism, wherein N is an integer greater than or equal to 2, and the pressure-type winding devices are arranged along the width direction of the paper Distributed on both sides of the traction and slitting mechanism, the pressure-type winding devices on both sides of the traction and slitting mechanism are misplaced, and are respectively the inner pressure-type winding device on the side close to the unwinding device and the one far away from the unwinding device. One side of the external pressing type winding device, th...

Embodiment 2

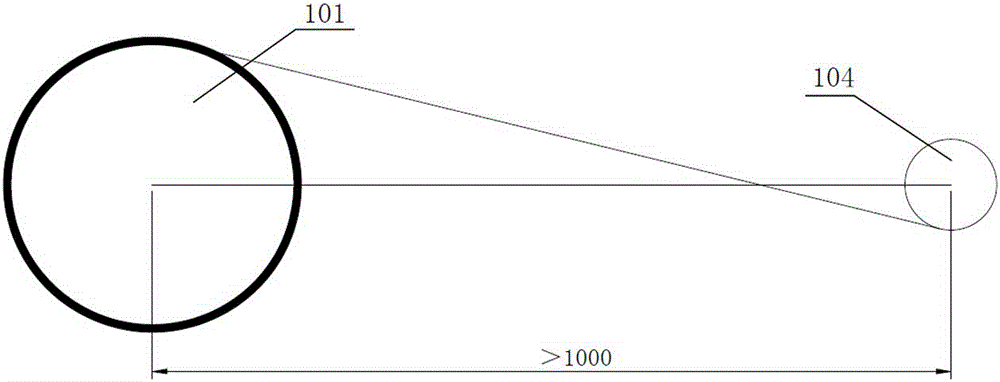

[0064] The pressure type winding devices on both sides of the traction and slitting mechanism described in this embodiment share a winding shaft 10 respectively, as Figure 14 As shown, the two ends of the winding shaft 10 are the winding shaft swing arms 7 respectively (there are only two winding shaft swing arms 7 on each side of the traction and cutting mechanism in this embodiment). After the paper is cut, it is wound on two take-up shafts 10 respectively, and the paper 39 on the two take-up shafts is staggered and wound, and the distance between adjacent papers on the same take-up shaft 10 is the same as The width of the corresponding paper on the other winding shaft 10 is equal. Since the pressure-type winding devices on both sides of the traction and slitting mechanism in this embodiment share a take-up shaft 10 respectively, the length of the take-up shaft 10 is relatively large, and wider paper can be curled, and the width of the paper only needs to be adjusted. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com