Engagement cooling apparatus of extruder

A technology of cooling device and extruder, which is applied in the field of intermeshing cooling devices, can solve the problems of insufficient heat exchange, prolonging the residence time of cooling water, and short residence time, so as to improve service life, reduce stress, increase The effect of extrusion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

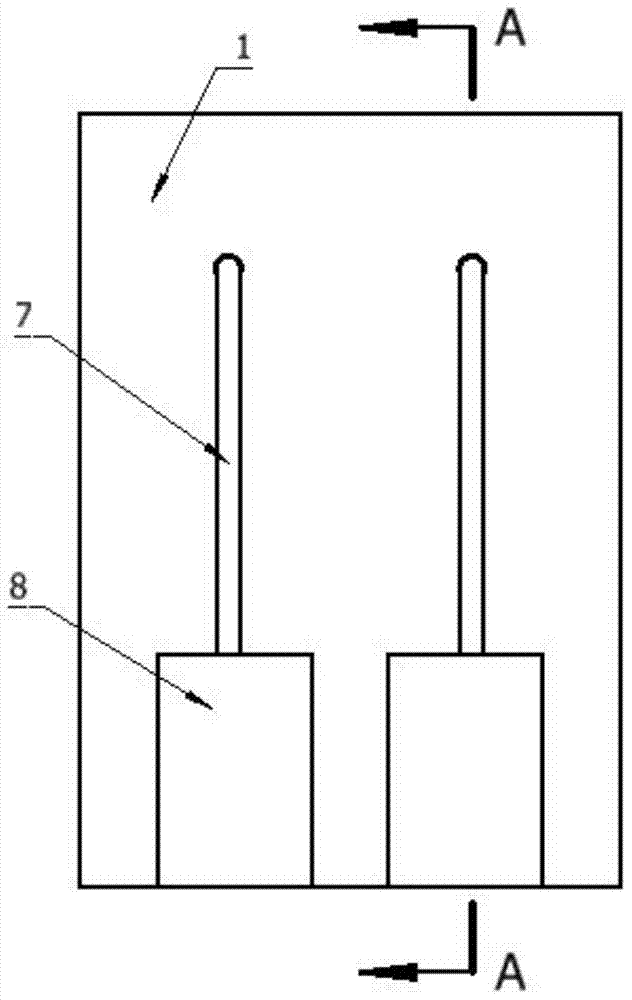

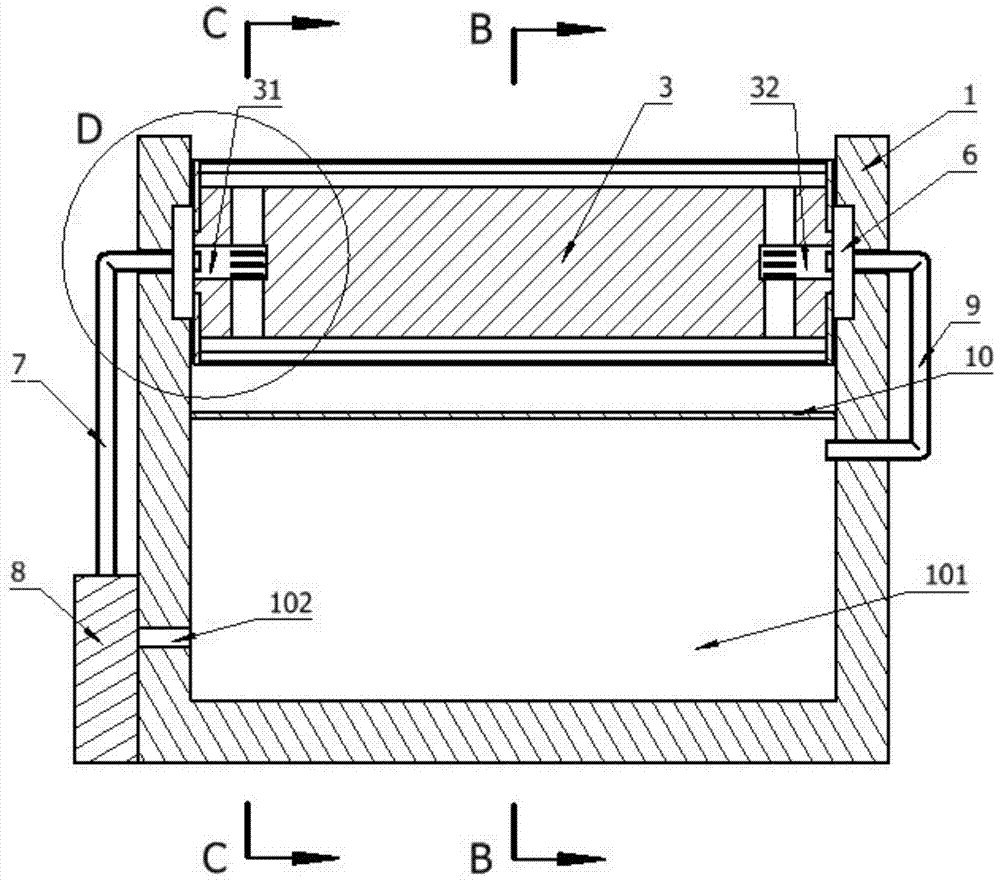

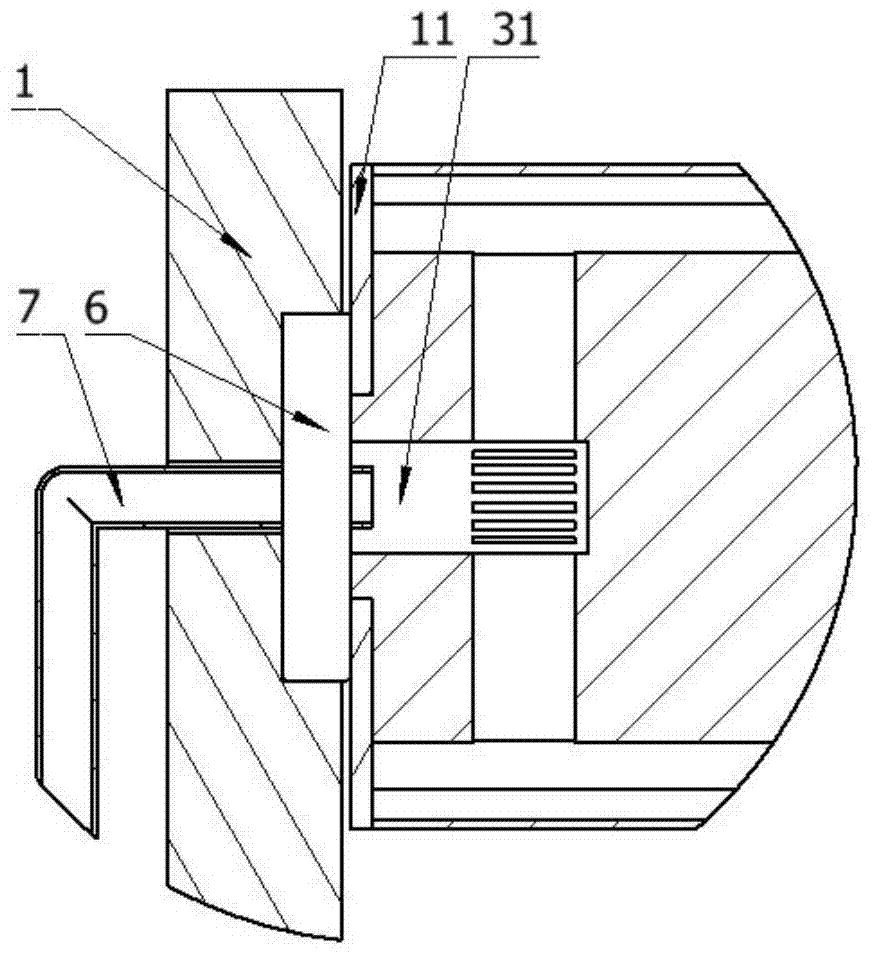

[0025] attached Figure 1-7 It is an intermeshed cooling device for an extruder according to the present invention, which includes a driving shaft 2 and a driven shaft 3 placed horizontally and parallel to each other; the driving shaft 2 and the driven shaft 3 are sleeved with meshing gear sleeves cylinder 4; the driving shaft 2 and the driven shaft 3 are fixedly connected to the gear sleeve 4 through a plurality of support plates 5, and the number of support plates 5 is consistent with the number of teeth of the gear sleeve 4; the adjacent two A water tank 33 is formed between the support plates 5; the two ends of each gear sleeve 4 are respectively provided with sealed end caps 11, and each gear sleeve 4 is fixedly connected with the end caps 11 by welding to prevent water from The two ends of the gear sleeve 4 flow out; one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com