Impedance test method and device for battery pole piece

An impedance test, battery pole piece technology, applied in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problem of not considering the contact area and contact pressure of the pole piece, inaccurate test results, and consistent data problems such as poor performance, to achieve the effect of improving test accuracy, small error and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

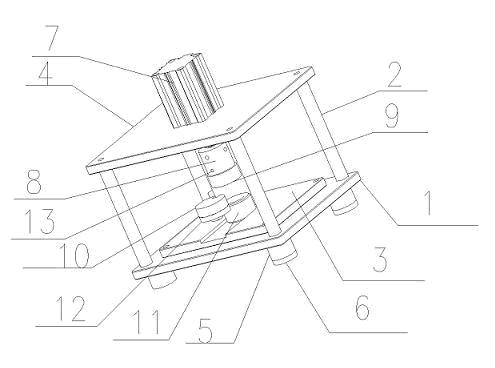

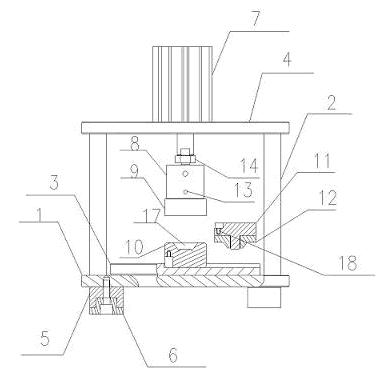

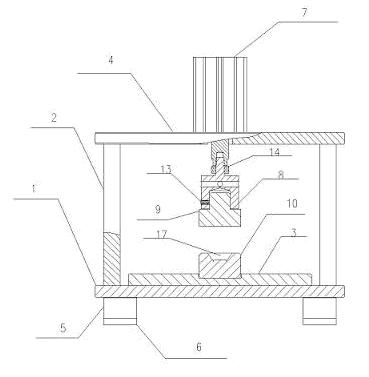

[0030] Embodiment: A method for testing the impedance of battery pole pieces. The impedance tester provides a DC constant voltage source for testing. After an external load is connected, the loop current can be automatically detected (such as Figure 9 ), so as to obtain the total resistance of the external load. The probe of the impedance tester is short-circuited to measure the internal resistance of the instrument itself, and then the probes are respectively connected to the probe mounting holes of the upper indenter and the lower indenter, and the upper indenter and the lower indenter are made of brass material It has good conductivity and has a resistance value, so it is necessary to measure the resistance of the upper and lower indenters. The upper and lower indenters are in contact with each other to form a loop with the impedance tester, and the upper and lower indenters are measured. The total resistance of the indenter and the lower indenter. After the above test is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com