Checking instruments and measuring method for detecting vehicle door hinge accuracy

A door hinge and hinge technology, which is applied in the direction of mechanical clearance measurement, etc., can solve the problems affecting the installation effect of the door hinge and the inability to effectively detect the accuracy of the door hinge, and achieve the effect of simple measurement, convenient operation and good consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

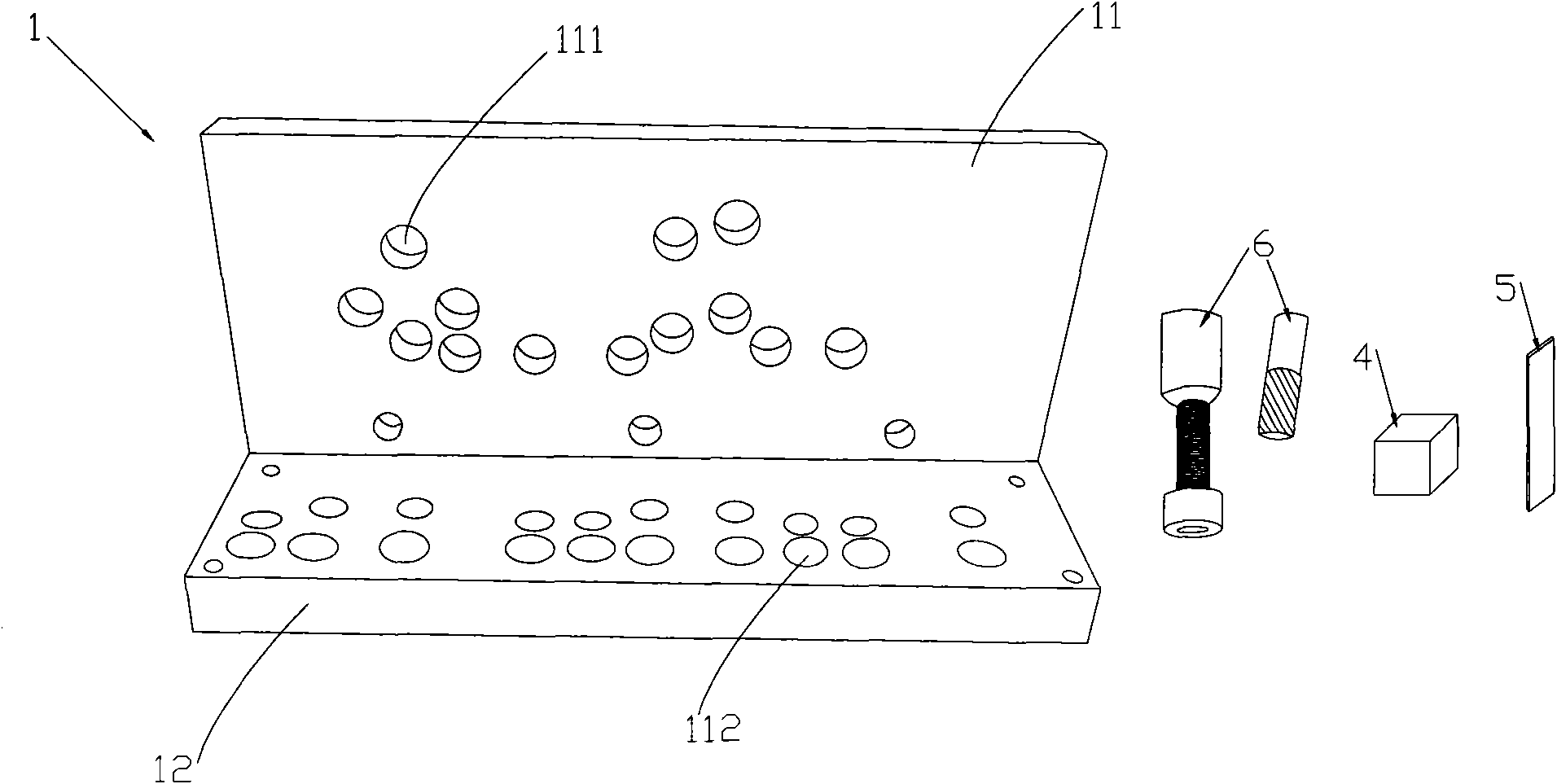

[0027] see Figure 1 to Figure 3 As shown, a checker for detecting the accuracy of the door hinge includes a checker body 1, a fastening screw 3, a marking pin 6, a gap feeler gauge 5, and a preset size measurement block 4. The checker body 1 includes The horizontally arranged measuring surface 12 and the vertically arranged tightening surface 11 connected thereto are provided with a plurality of first hinge mounting holes 211 corresponding to the positions of the first hinge mounting holes 211 on the longitudinal mounting surface 21 of the hinge 2 on the tightening surface 11. A mounting hole 111, a plurality of second mounting holes 121 corresponding to the positions of the second hinge mounting holes 221 on the horizontal mounting surface 22 of the hinge 2 are provided on the measuring surface 12; the first mounting holes 111 and the first hinge mounting holes 211 are fastened and connected by fastening screws 3;

[0028] The scribe pin 6 is inserted into the first install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com