Porcelain plate containing green body texture and manufacturing method of porcelain plate

A manufacturing method and texture technology, which is applied in the field of architectural ceramic tiles, can solve the problems of insufficient randomness and naturalness of imitation stone texture effects, high requirements, and low efficiency, and achieve more consistent colors, simple equipment structure, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

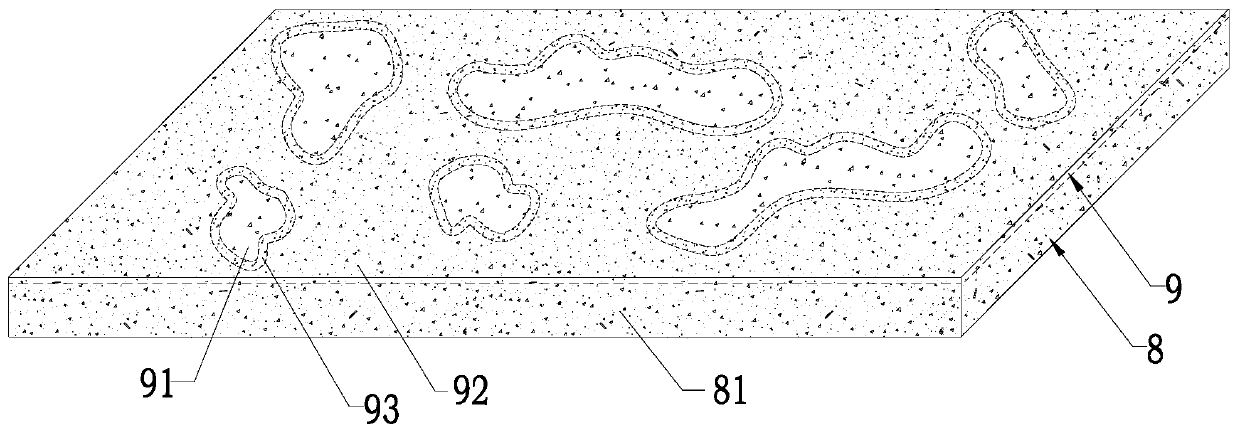

[0055] refer to figure 1 , this embodiment discloses a porcelain plate with body texture, including a main body layer 8 and a texture layer 9, the main body layer 8 is formed by a main body blank to form a main color area 81, and the main body blank is a single-color porcelain raw material, or is Porcelain raw materials with at least 2 different colors mixed, or at least 2 different colors of porcelain raw materials without mixing, the texture layer 9 is independent of the main body layer 8 and located on the main body layer 8, or the texture layer 9 Embedded in the upper surface layer of the main body layer 8, the thickness of the texture layer 9 is at least 1mm, and the texture layer 9 includes at least one texture color area 91, the texture color area 91 is formed by a texture blank, and the texture blank is more than two different single Color blanks, or blanks with two or more different shades of the same color, or blanks with two or more different colors and each color h...

Embodiment 2

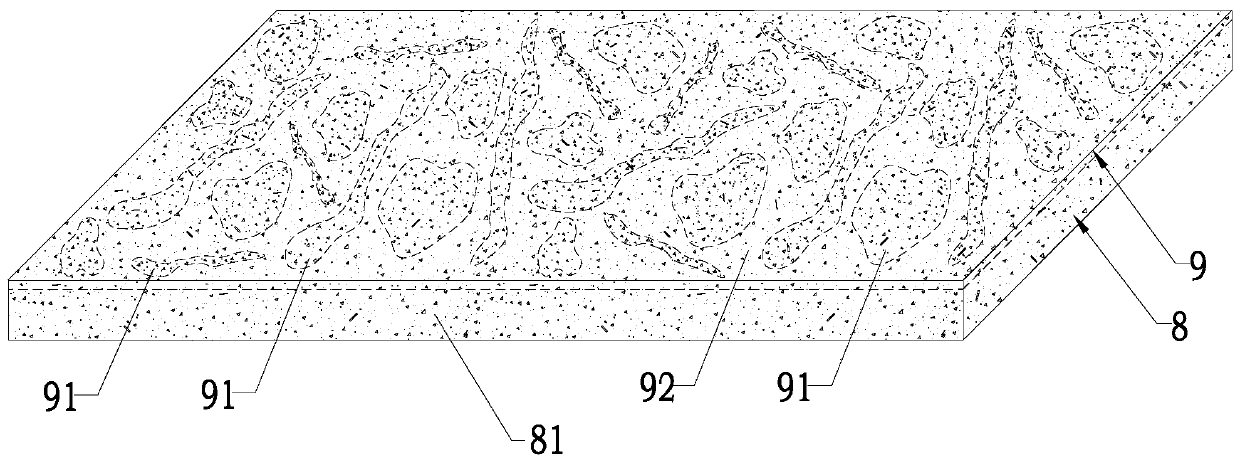

[0059] refer to figure 2 , based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that the shape of the texture color area 91 is one or more of lines, stripes and lumps.

Embodiment 3

[0061] refer to image 3 , Based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that the main body layer 8 and the texture layer 9 are of a whole-body type, that is, the texture of the porcelain plate from the bottom surface to the upper surface is consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com