Pervious straw fiber concrete and production method thereof

A permeable concrete and straw fiber technology, applied in the field of building materials, can solve the problems of not being able to withstand high-strength loads, low strength, and reduced water seepage capacity, and achieve high-value comprehensive utilization, increase concrete strength, and enhance cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

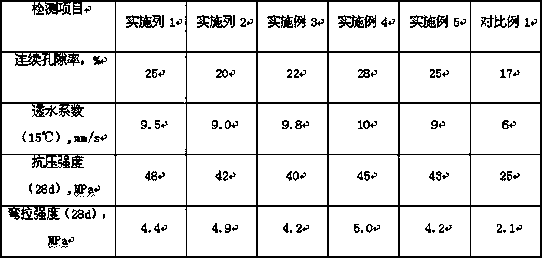

Examples

Embodiment 1

[0033] A method for preparing straw fiber permeable concrete, the preparation process is as follows:

[0034](1) Crush natural plant straw, pass through a 20-mesh sieve, mix with hydrogen chloride solution, stir evenly at room temperature, disperse at high speed with a disperser for 40 minutes, filter with suction, wash the filter cake until neutral, add water, add surfactant sulfated castor Sesame oil, high-speed dispersion for 80 minutes, ultrasonic treatment for 20 minutes, high-speed dispersion for 20 minutes, suction filtration, washing and drying to obtain unbundled and dispersed straw fibers; the mass fraction of the hydrogen chloride solution is 5%; in the hydrogen chloride dispersion of the straw, The mixing mass ratio of straw and hydrogen chloride solution is 1:25; the amount of sulfated castor oil is 0.5% of the mass of straw;

[0035] (2) Mix the oxidatively condensed silica micropowder in the electric furnace flue gas with the unbundled and dispersed straw fibers...

Embodiment 2

[0039] A method for preparing straw fiber permeable concrete, the preparation process is as follows:

[0040] (1) Crush the natural plant straw, pass through a 20-mesh sieve, mix with hydrogen chloride solution, stir evenly at room temperature, disperse at high speed with a disperser for 40 minutes, filter with suction, wash the filter cake until neutral, add water, and add surfactant lauryl alcohol sulfuric acid Sodium, high-speed dispersion for 100 minutes, ultrasonic treatment for 30 minutes, high-speed dispersion for 40 minutes, suction filtration, washing and drying to obtain unbundled and dispersed straw fibers; the mass fraction of the hydrogen chloride solution is 8%; in the hydrogen chloride dispersion of the straw, The mixing mass ratio of straw and hydrogen chloride solution is 1:20; the dosage of sodium lauryl sulfate is 0.5% of the mass of straw;

[0041] (2) Mix the oxidized and condensed silica micropowder in the electric furnace flue gas with the unbundled and ...

Embodiment 3

[0045] A method for preparing straw fiber permeable concrete, the preparation process is as follows:

[0046] (1) Crush natural plant straw, pass through a 20-mesh sieve, mix with hydrogen chloride solution, stir evenly at room temperature, disperse at high speed with a disperser for 50 minutes, filter with suction, wash the filter cake until neutral, add water, add surfactant sulfated castor Sesame oil, high-speed dispersion for 80 minutes, ultrasonic treatment for 20 minutes, high-speed dispersion for 30 minutes, suction filtration, washing and drying to obtain unbundled and dispersed straw fibers; the mass fraction of the hydrogen chloride solution is 5%; in the hydrogen chloride dispersion of the straw, The mixing mass ratio of straw and hydrogen chloride solution is 1:25; the amount of sulfated castor oil is 0.5% of the mass of straw;

[0047] (2) Mix the oxidatively condensed silica micropowder in the electric furnace flue gas with the unbundled and dispersed straw fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com