Dust removal device for welding wire drawing

A dust removal device and wire drawing technology are applied in the direction of dust removal, liquid separation agent, cleaning method and utensils, etc., which can solve problems such as easy to block cloth bags or filter cartridges, pollute the environment, and be easy to fly, so as to avoid secondary pollution and purify Workshop environment, the effect of high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

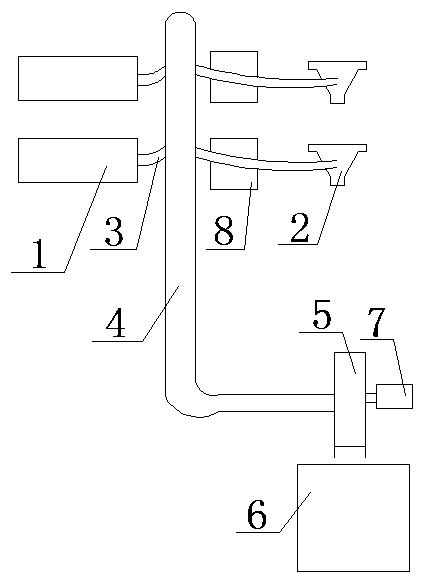

[0012] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises several wire drawing machines 1 arranged side by side, and each wire drawing machine 1 front end is provided with a wire grinding machine 2 respectively, and the wire drawing machine 1 and the wire grinding machine 2 are respectively connected with the dust removal main pipe 4 through the dust removal branch pipe 3, and the dust removal main pipe A centrifugal blower 5 is arranged at the outlet of 4, and a pool 6 is arranged below the outlet of the dust removal main pipe 4. Centrifugal fan 5 is connected with motor 7 . A tension frame 8 is provided between the wire drawing machine 1 and the wire grinding machine 2 .

[0013] Adopt a kind of welding wire drawing dedusting device of the present invention, start motor 7 to drive centrifugal fan 5 to rotate and draw dust removal main pipe 4 and dust removal branch pipe 3 into negative pressure, the dust that welding wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com