Formation method of lithium battery

A chemical formation method and lithium battery technology, which are applied in the manufacture of secondary batteries, electrochemical generators, and electrolyte storage batteries, can solve problems such as large loss of electrolyte, and achieve excellent chemical formation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

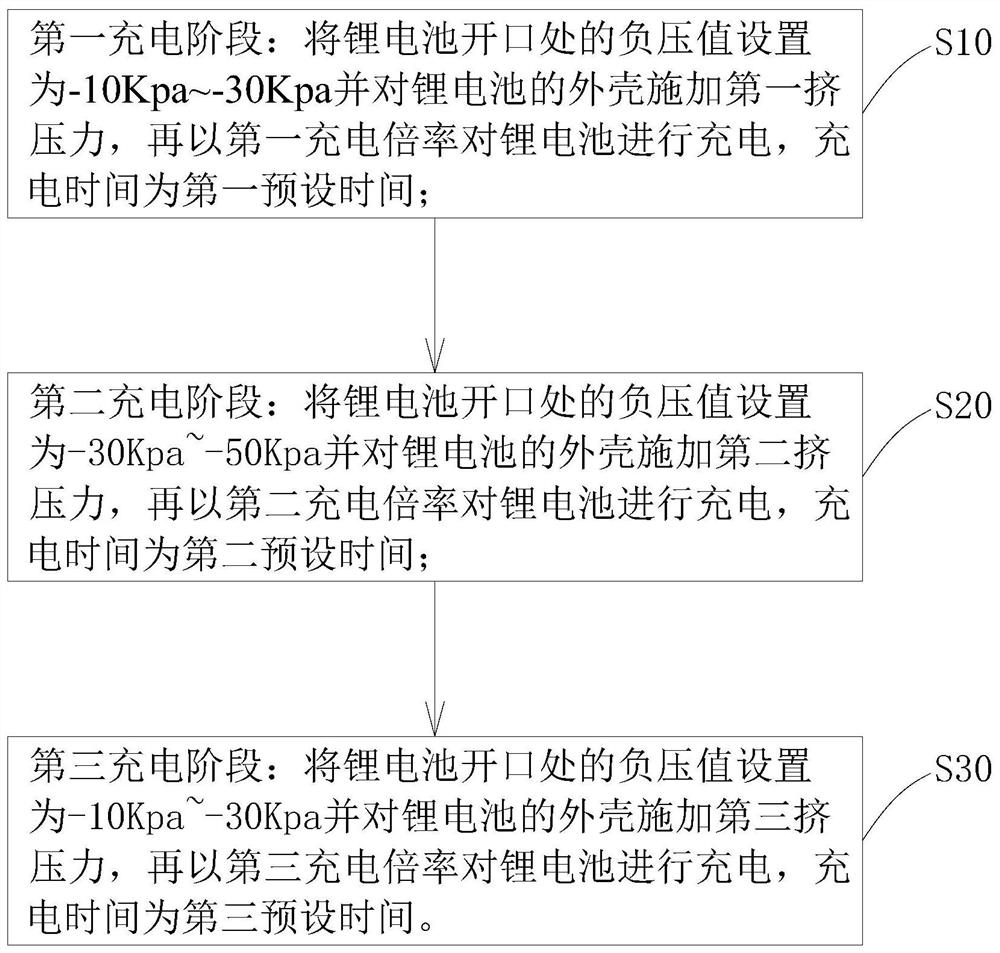

[0048] S10: The first charging stage: set the negative pressure at the opening of the lithium battery to -30Kpa and apply 0.2 Mpa to the shell of the lithium battery, and then charge the lithium battery at a charging rate of 0.1C for 7 minutes;

[0049] S20: The second charging stage: set the negative pressure at the opening of the lithium battery to -50Kpa and apply 0.4 Mpa to the shell of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 80 minutes;

[0050] S30: The third charging stage: set the negative pressure at the opening of the lithium battery to -20Kpa and apply 0.2 Mpa to the casing of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 50 minutes.

Embodiment 2

[0052] S10: The first charging stage: set the negative pressure at the opening of the lithium battery to -20Kpa and apply 0.1 Mpa to the shell of the lithium battery, and then charge the lithium battery at a charging rate of 0.1C for 7 minutes;

[0053] S20: The second charging stage: set the negative pressure at the opening of the lithium battery to -40Kpa and apply 0.3 Mpa to the shell of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 80 minutes;

[0054] S30: The third charging stage: set the negative pressure at the opening of the lithium battery to -30Kpa and apply 0.1Mpa to the casing of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 50 minutes.

Embodiment 3

[0056] S10: The first charging stage: set the negative pressure at the opening of the lithium battery to -30Kpa and apply 0.2Mpa to the shell of the lithium battery, and then charge the lithium battery at a charging rate of 0.1C for 7 minutes;

[0057] S20: The second charging stage: set the negative pressure at the opening of the lithium battery to -30Kpa and apply 0.2 Mpa to the casing of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 80 minutes;

[0058] S30: The third charging stage: set the negative pressure at the opening of the lithium battery to -30Kpa and apply 0.1Mpa to the casing of the lithium battery, and then charge the lithium battery at a charging rate of 0.26C for 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com