Oil atomizer pull-out tooling

A fuel injector and tooling technology, which is applied in the field of fuel injector pull-out tooling, can solve problems such as inconvenient use and difficulty in dismantling quickly and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

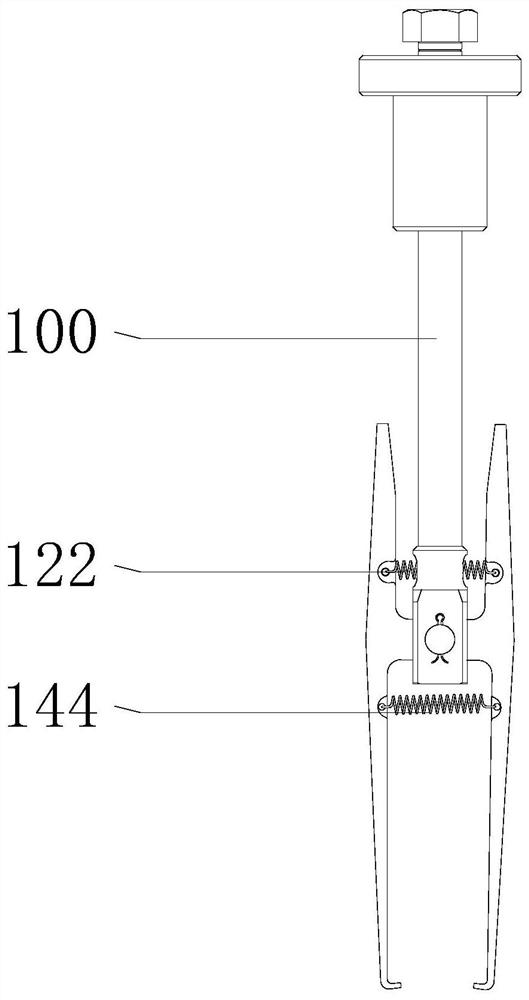

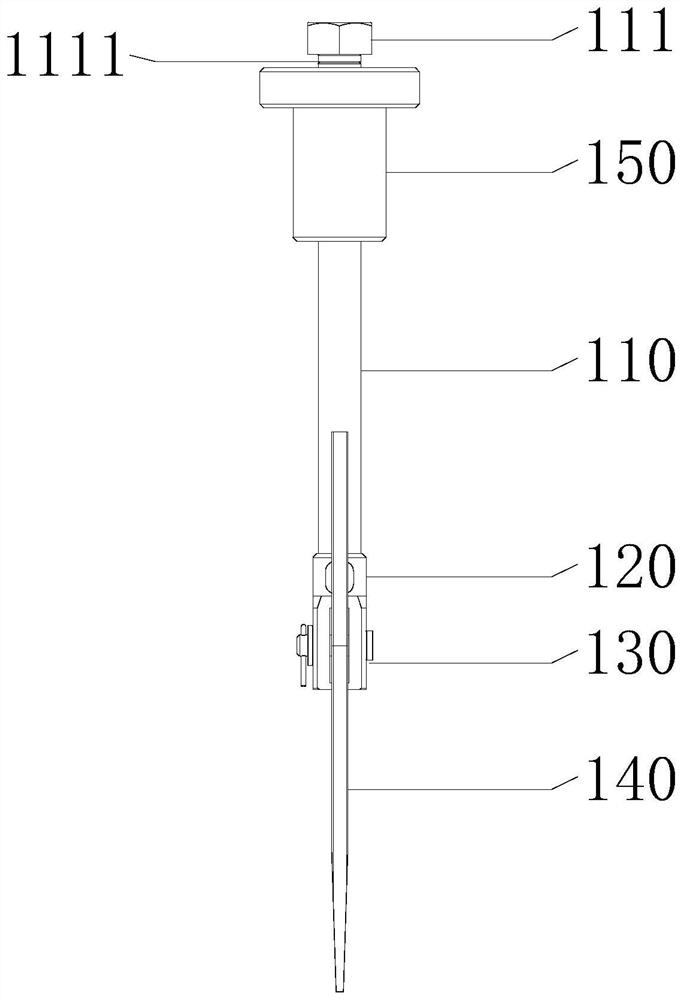

[0035] see Figure 1-7 , The present invention provides a technical solution: a pull-out tool for a fuel injector includes a pull-off tool body (100).

[0036] The pull-out frock body (100) is used to pull out the fuel injector.

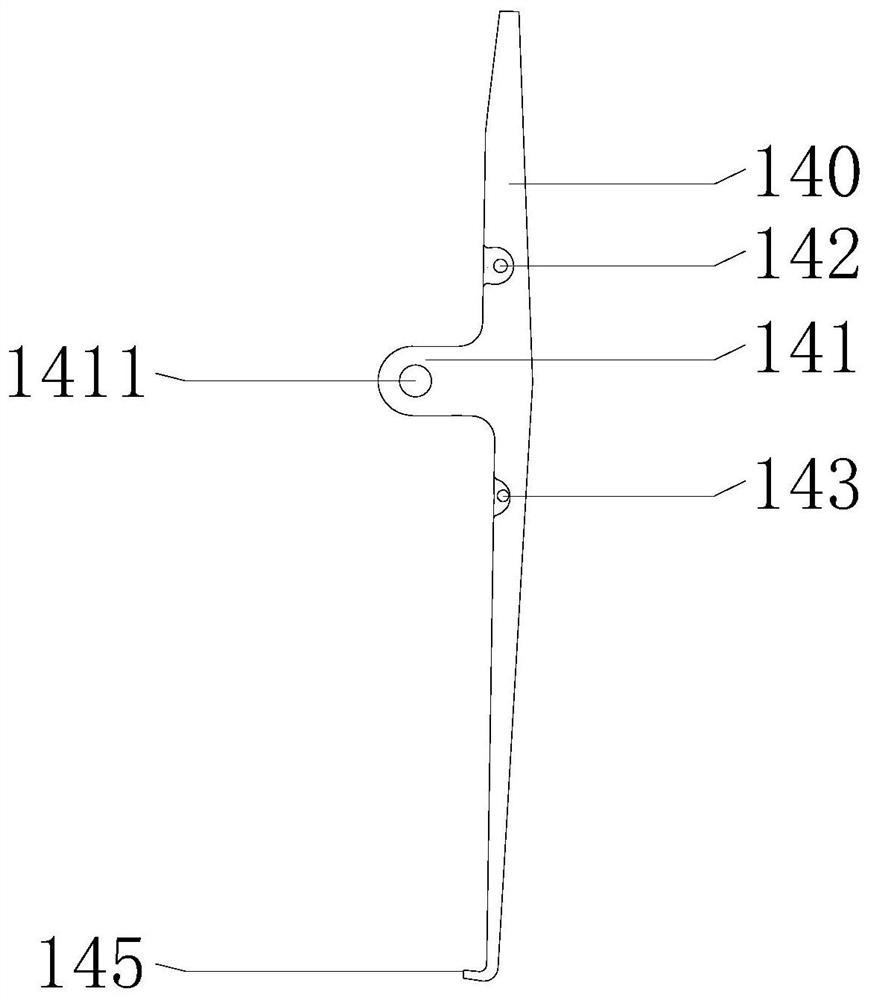

[0037] see figure 1 , 2, 3, 4, 5, 6 and 7, the pull-out tooling body 100 includes a pull rod 110, a connecting block 120, a fixed block 130, a jaw 140 and a drawing hammer 150, the connecting block 120 is fixedly connected to one end of the pull rod 110, and the fixed block 130 Fixedly connected to the end of the connecting block 120 away from the pull rod 110, the pull rod 110, the connecting block 120 and the fixed block 130 are integrally formed to enhance the firmness and meet the subsequent rigid requirements. The fixed block 130 is provided with a first through hole 131, and the jaw 140 is provided with Two, specifically, one end of the jaw 140 is provided with a claw hook 145, and one end of the jaw 140 is integrally formed with a claw hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com