Double-S-curve soft drafting device

A soft drafting and curve technology, applied in the field of double S-curve soft drafting device, can solve the problems of asynchrony of movement speed, difference in speed of upper and lower aprons, affecting yarn index, etc., and achieve reasonable distribution of friction force and not easy to regenerate. Better neps and yarn quality levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

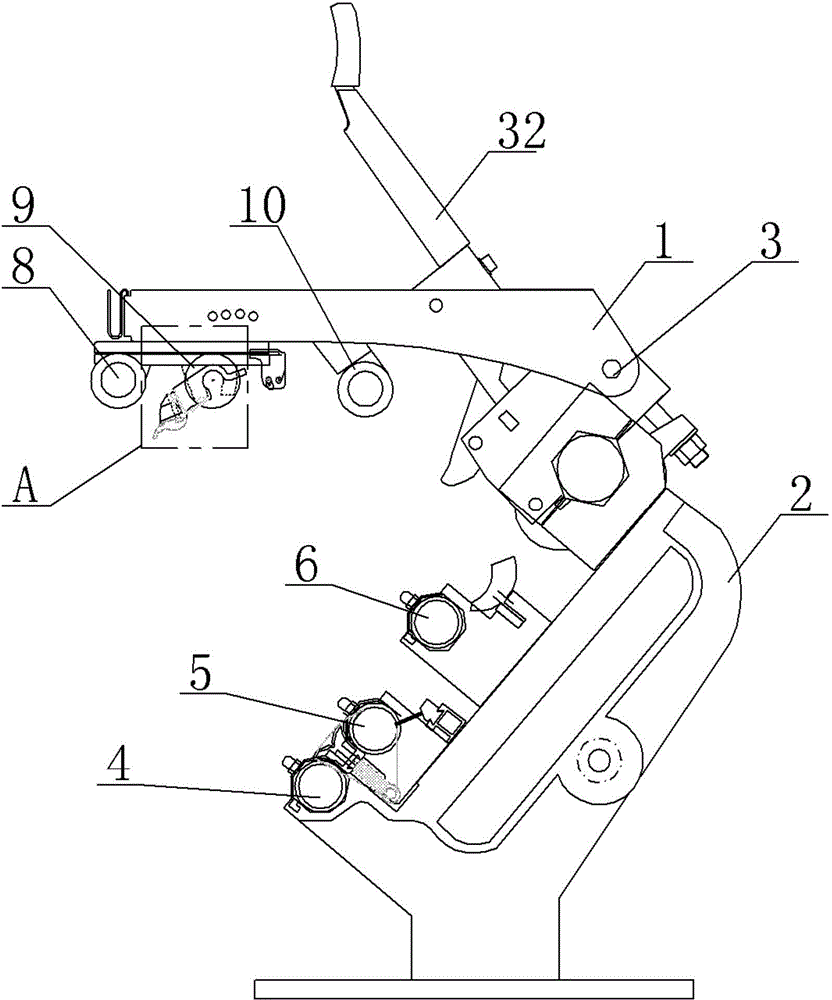

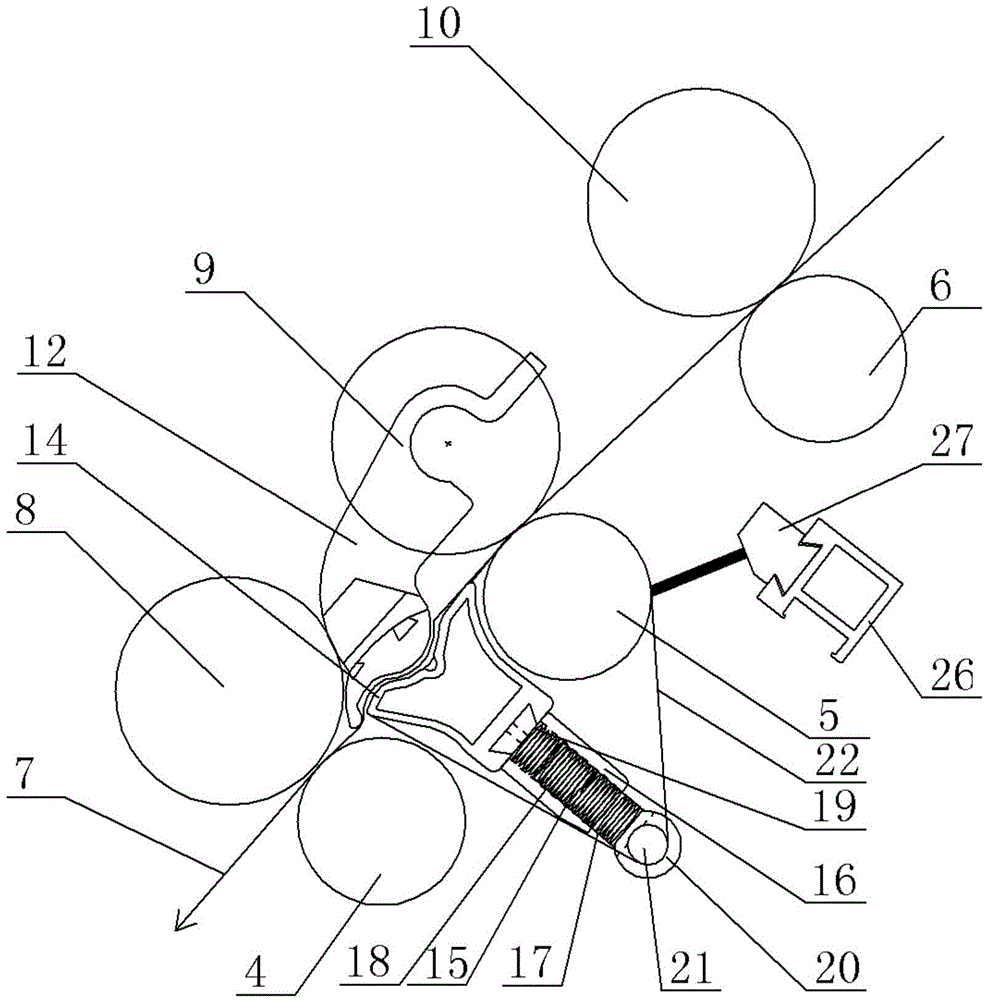

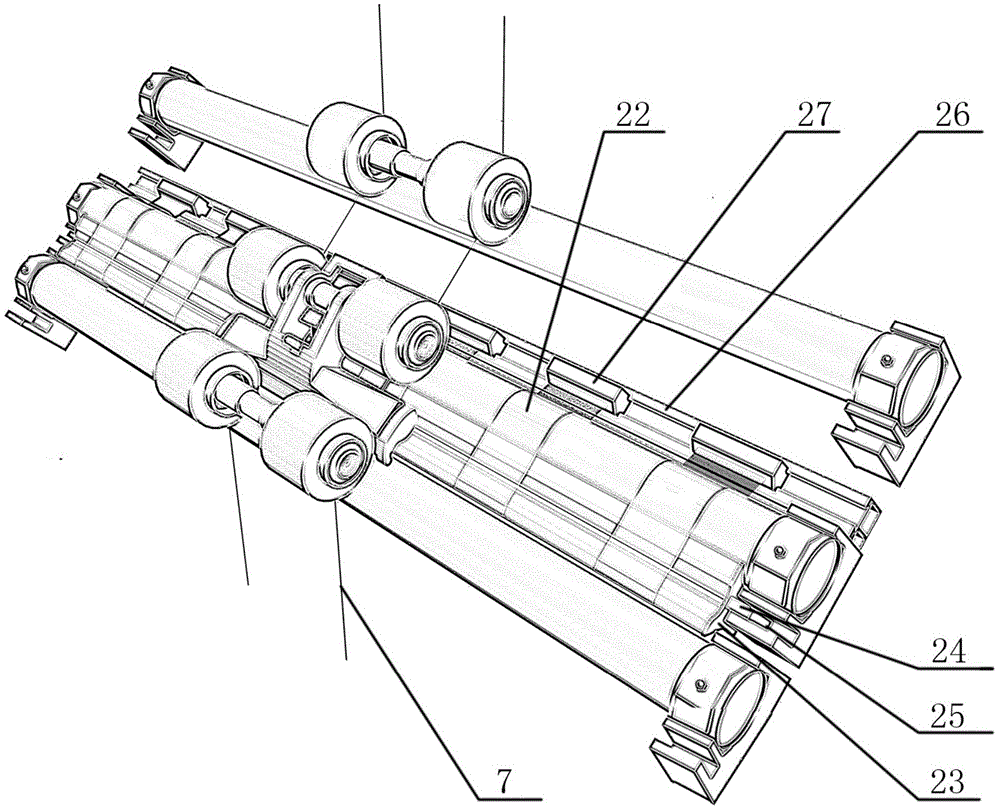

[0026] A double S-curve soft drafting device, see Figure 1 to Figure 5: It comprises an upper support 1 and a lower base 2, one end of the upper support 1 is connected to one end of the lower base 2 through a rotating shaft 3, and the upper end surface of the lower base 2 is arranged with a front roller 4, a middle roller 5, and a rear roller 6 in sequence. The advance direction of the yarn 7 is the front, and the lower end surface of the upper support 1 is respectively arranged with a front top roller 8, a middle top roller 9, and a rear top roller 10 at positions corresponding to the front roller 4, the middle roller 5, and the back roller 6, Nylon bracket 12 is set on the central shaft 11 of middle top roller 9, and the rear portion of nylon bracket 12 is sleeved on the central shaft 11 of middle top roller 9, and the front portion of nylon bracket 12 is provided with S curve plate 13, and the S curve plate 13 The lower end surface of the cross section is an S-shaped curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com