Edge polishing machine for irregular edges

A sanding machine and special-shaped technology, which is applied in the direction of machine tools, grinding machines, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, can solve the problem of not meeting the high-quality and high-quality requirements of furniture products, and the quality of the edge surface of the board. Difficult to guarantee, high labor intensity and other problems, to achieve the effect of good consistency, reasonable design, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

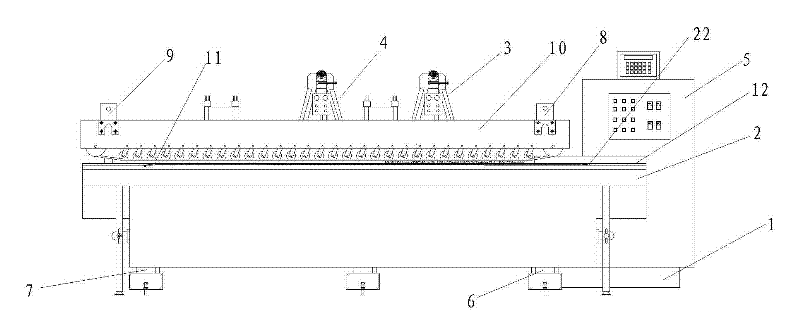

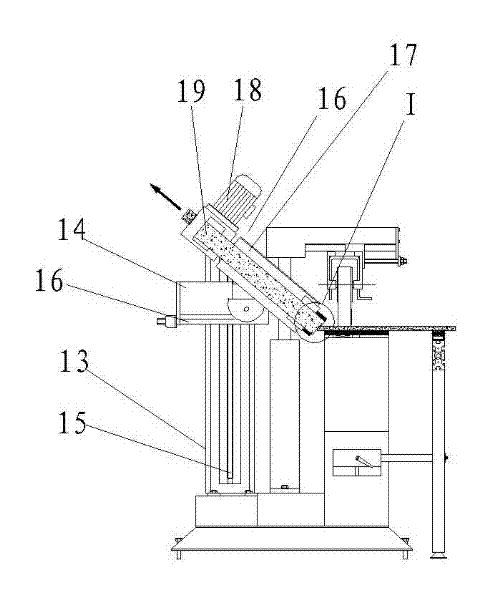

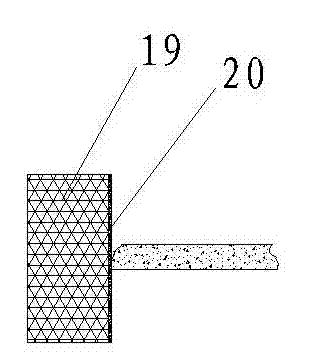

[0012] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0013] see Figure 1-4 , a special-shaped sand edge machine of the present invention, comprising a base 1, a frame 2, a control cabinet 5 and special-shaped sand edge units 3, 4, the frame 2 is fixed on the base 1; the frame 2 The two ends of the inner base 1 are provided with two straight columns 6,7, and the tops of the vertical columns stretch out the fixing frames 8,9 forward, and the lower ends of the two fixing frames 8,9 are provided with a lower pressure beam 10, which presses down. The bottom of the beam 10 corresponds to the working platform 12 on the frame 2 and is provided with a roller belt 11 for conveying workpieces; the middle part of the outer base 1 of the straight columns 6, 7 is provided with two special-shaped sand edge units 3, 4, so Described special-shaped sand edge unit 3 comprises elevating frame 13, feed pallet 14 and special-shaped sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com