Device for collecting metal dust during electrolytic manganese stripping

A technology of electrolytic manganese stripping and metal dust, applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problems of wasting metal resources, damaging human health, polluting workshop air, etc., to save resources, realize recycling, reduce The effect of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

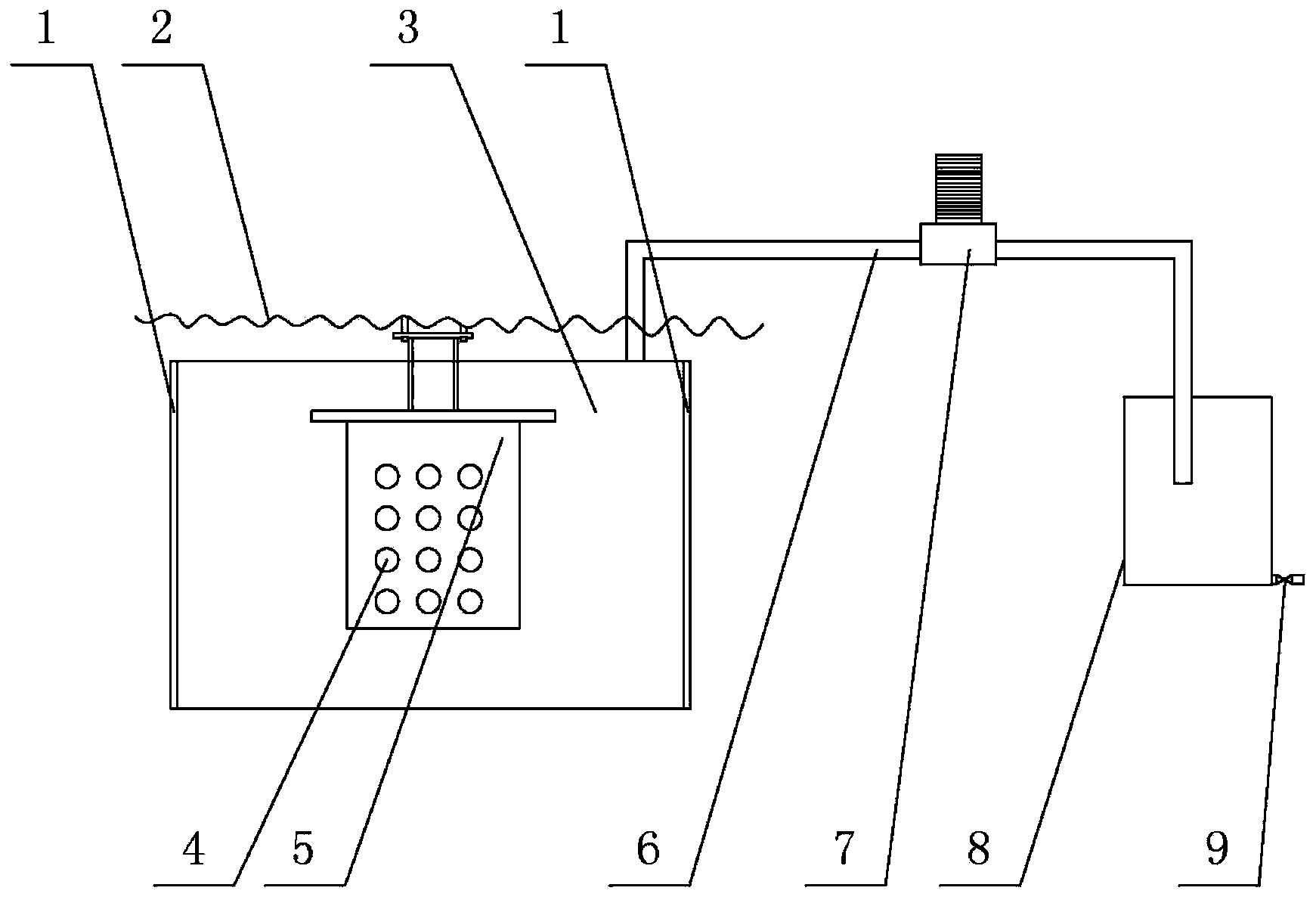

[0015] like figure 1 As shown, the present invention comprises electrolytic manganese stripping box 3, dust collecting box 8, blower fan 7, pipeline 6, adopts one end of pipeline 6 of acid and alkali corrosion-resistant material to be connected with electrolytic manganese stripping box 3 tops, and the other end of pipeline 6 is connected with dust The collection box 8 is connected, and the pipeline 6 is provided with a blower fan 7 . Both sides of the electrolytic manganese stripping box 3 are provided with a sealing rubber plate 1, the middle part of the sealing rubber plate 1 is provided with a gap, and a conveyor chain 2 is arranged on the top of the outside of the electrolytic manganese stripping box 3, and a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com