Pebble removing device for flour production

A technology for flour and box installation, applied in cleaning methods and utensils, solid separation, smoke and dust removal, etc. It can solve the problems of single screening method and general screening effect, and achieve the effect of improving the workshop environment, convenient operation, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

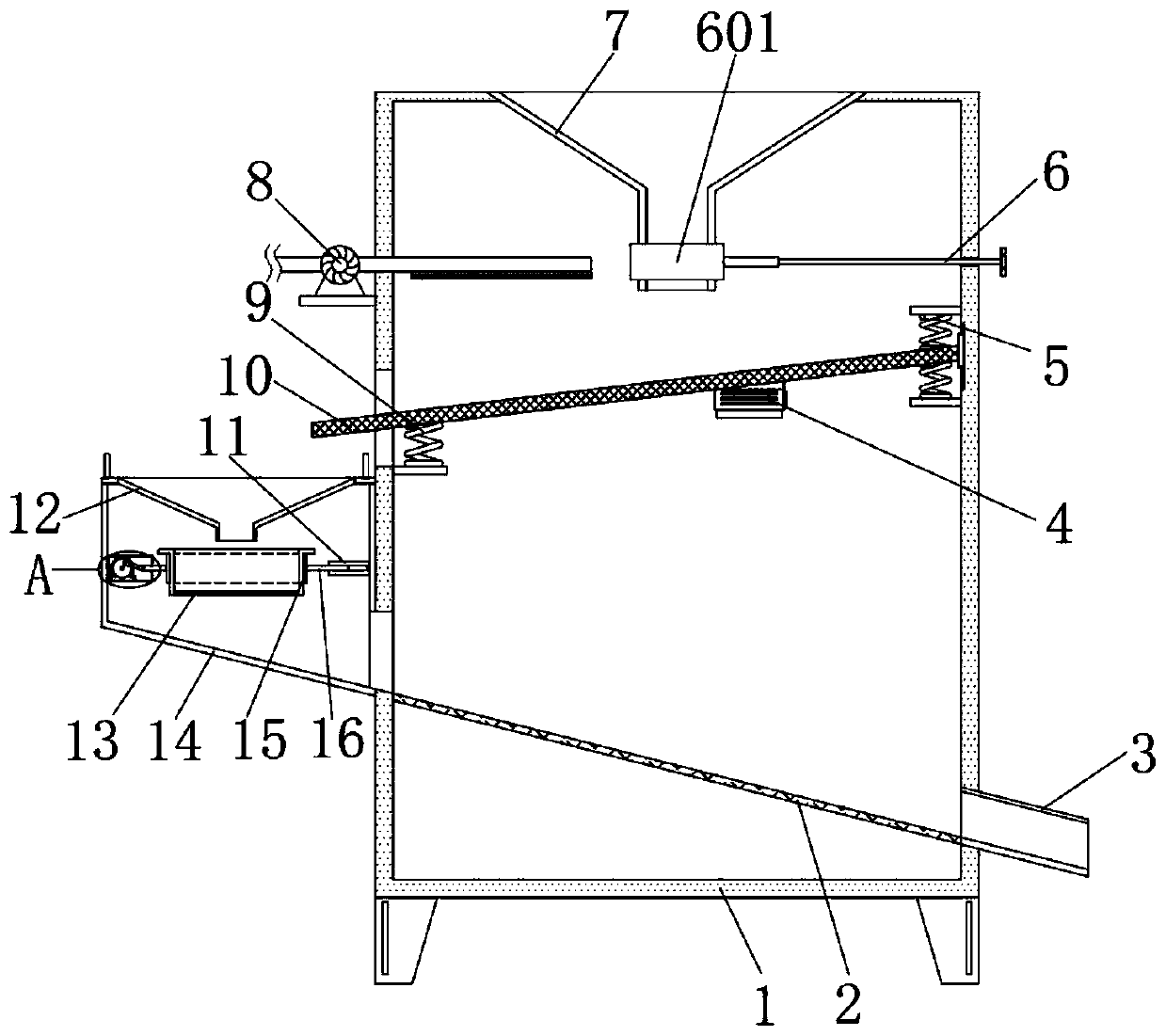

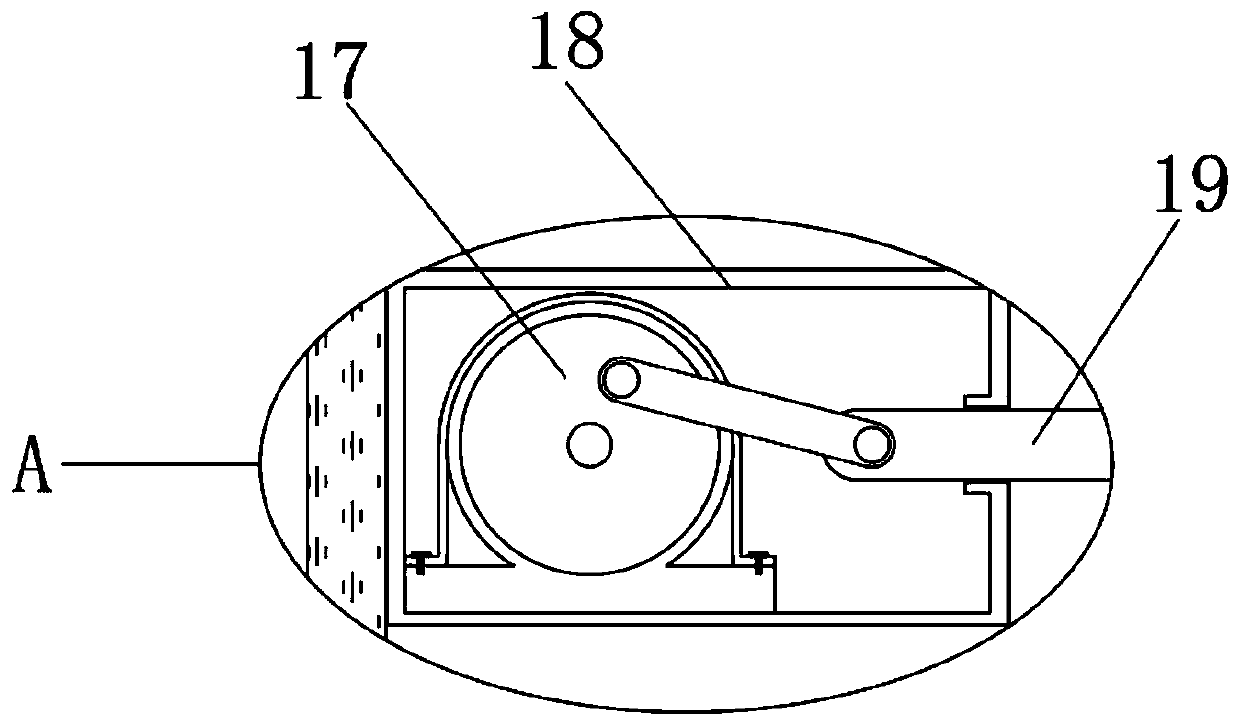

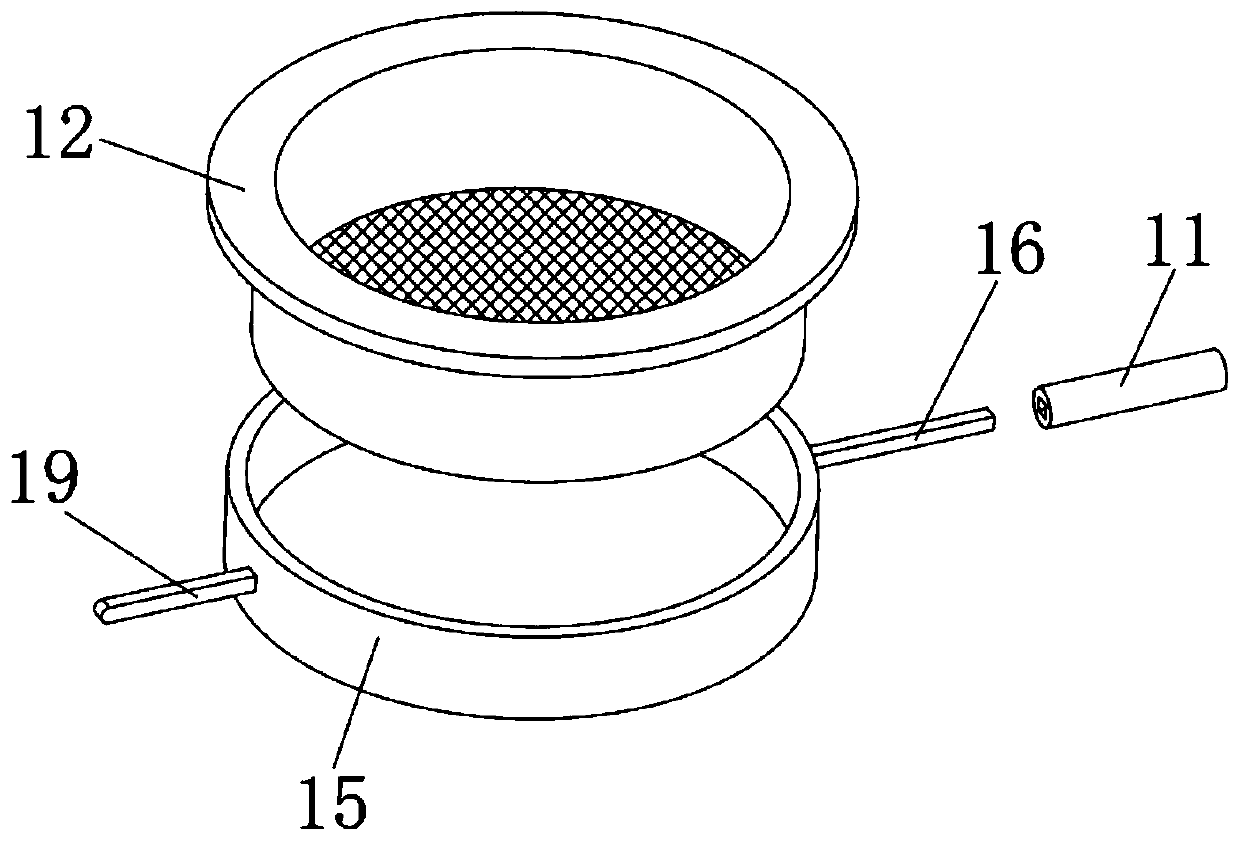

[0027] refer to Figure 1-3 , a stone removal device for flour production, comprising a shell 1 with legs welded at the four corners of the bottom and an installation box 14 welded to one side of the shell 1, the top of the installation box 14 and the shell 1 are respectively clamped with a receiving hopper 12 And the feeding hopper 7 is welded, and the inside of the housing 1 and the installation box 14 are respectively equipped with a vibration screening mechanism and a secondary screening mechanism. Both ends of one side close to the sieve plate 10 are welded with a fixed block 1, and the opposite side of the fixed block 1 and the sieve plate 10 is welded with the same vibrating spring 15, and the housing 1 is opened near the other end of the sieve plate 10. There is a feeding port, and the inner wall of one side of the feeding port is welded with a fixed block 2, and the opposite side of the fixed block 2 and the sieve plate 10 is welded with the same vibrating spring 2 9,...

Embodiment 2

[0035] refer to figure 1 , a stone removal device for flour production. In order to ensure the screening effect of the device, compared with Embodiment 1, this embodiment also includes that the bottom end of the hopper 7 is threadedly connected with a regulating valve 601, and the regulating valve 601 is welded with an extension The screw rod 6 is rotatably connected with the casing 1 by extending the screw rod 6 .

[0036] Working principle: When in use, the operator can twist the extension screw 6 to adjust the regulating valve 601 inside the casing 1, thereby achieving the purpose of controlling the feeding speed of wheat, preventing the feeding speed of wheat from being too fast and affecting the wheat filter effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com