Production process of flywheel assembly for automobile engine

A technology of automobile engine and production process, which is applied in the field of automobile parts manufacturing, can solve the problems of complex flywheel disc structure, low material utilization rate, and high manufacturing difficulty, so as to save labor and energy, high material utilization rate, and material consumption low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

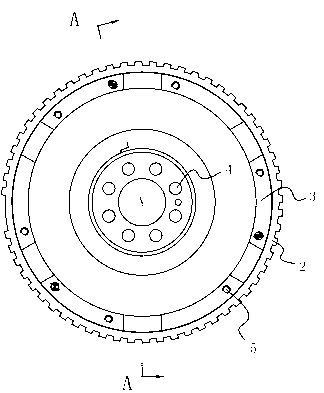

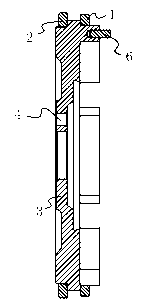

[0018] Such as figure 1 , 2 As shown, it is an assembly drawing of the flywheel assembly of the present invention, which includes a signal disc 1, a ring gear 2 and a flywheel body 3, and a flywheel mounting hole 4 is provided on the flywheel body 3 for connecting the flywheel body 3 to the crankshaft of the engine. Flywheel installation pin holes 5 and positioning pins 6 are also set on the flywheel body 3 for the positioning of the installation of the clutch cover. A production process for a flywheel assembly for an automobile engine is characterized in that it includes the following steps:

[0019] (1) Production of signal discs: Take steel plates of corresponding thickness, blank and punch holes on the die, and punch out signal disc blanks with crankshaft holes at one time, then position the signal disc blanks and punch out the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com