Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

388results about "Casting apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

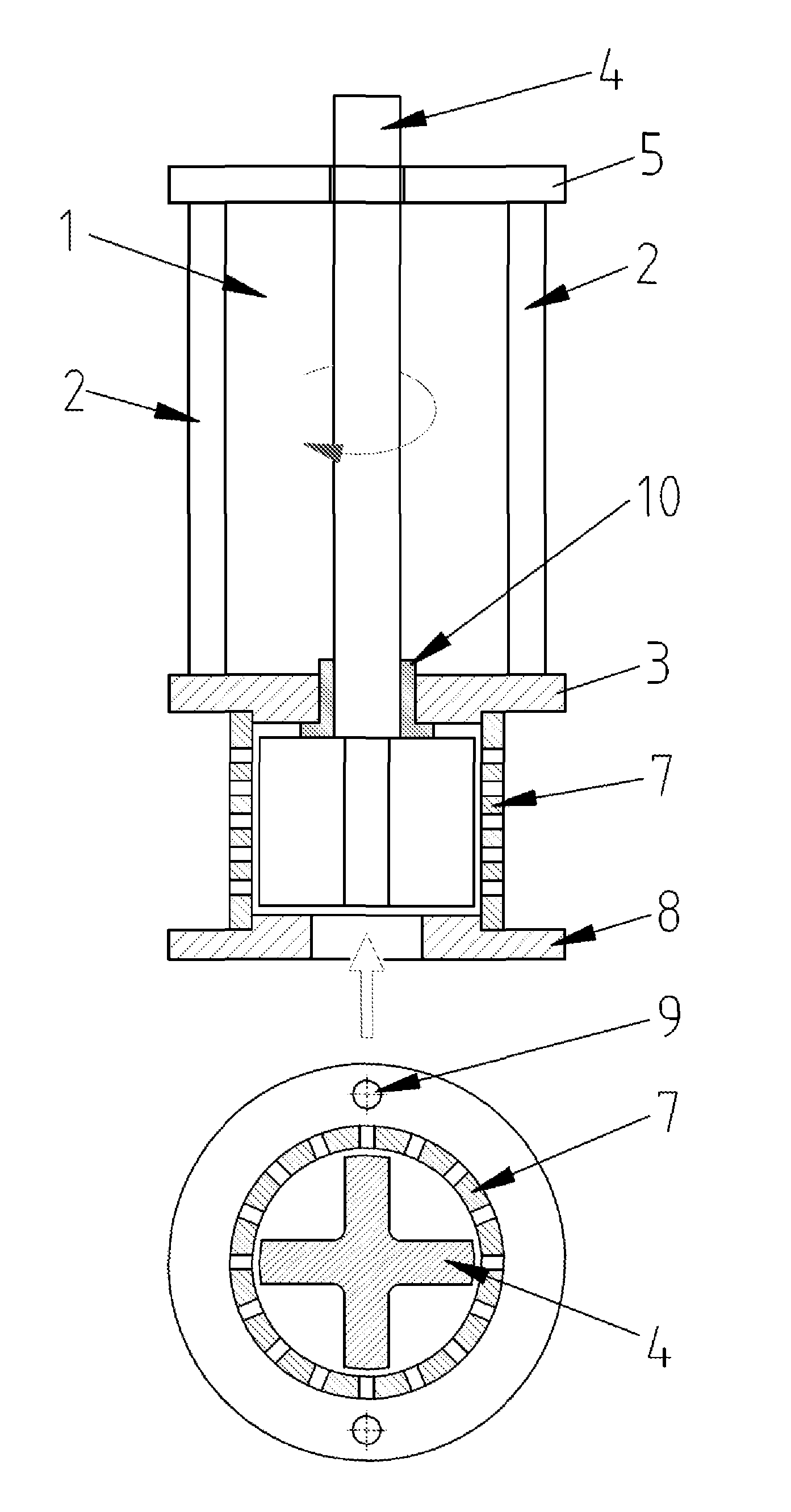

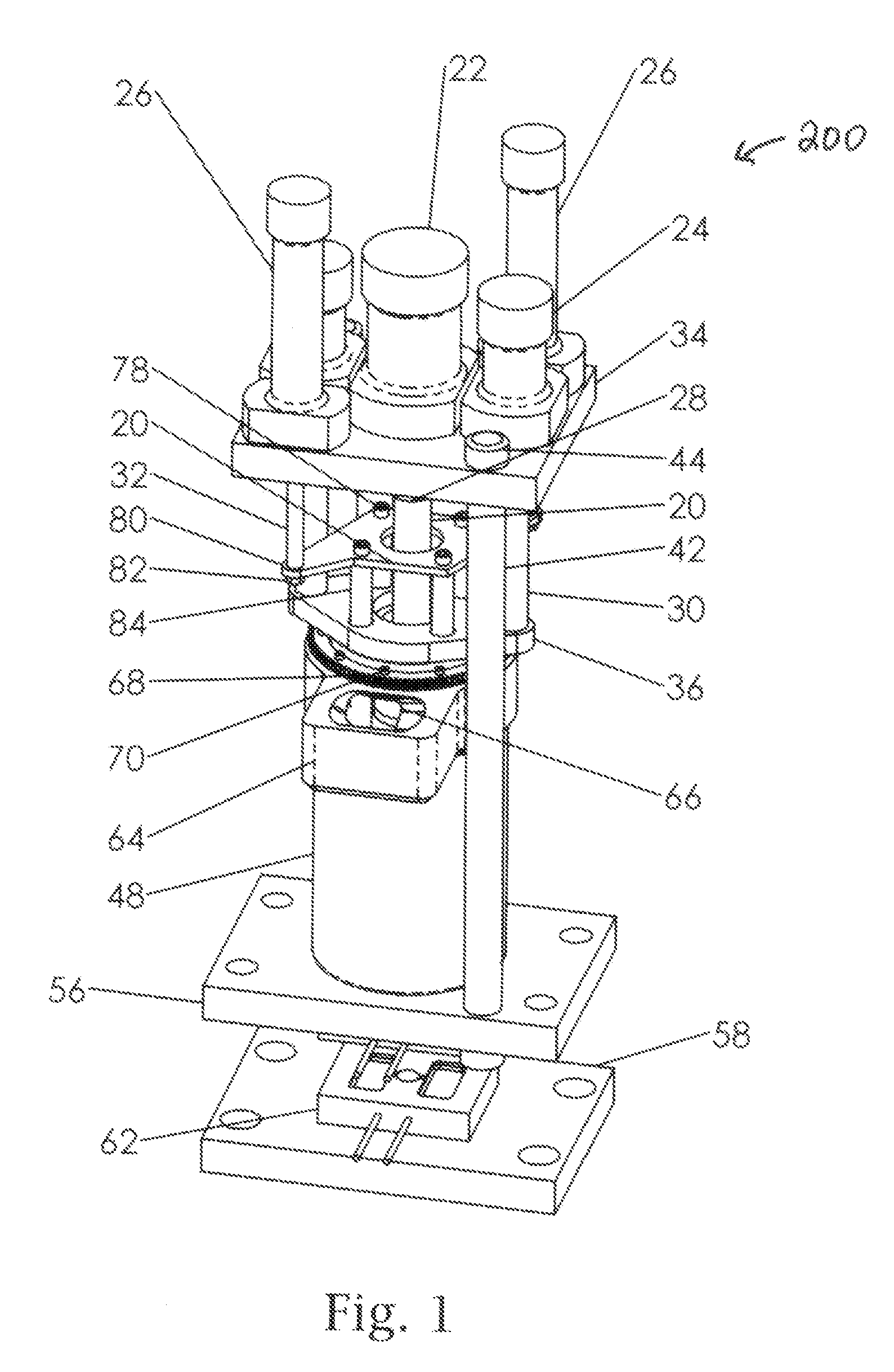

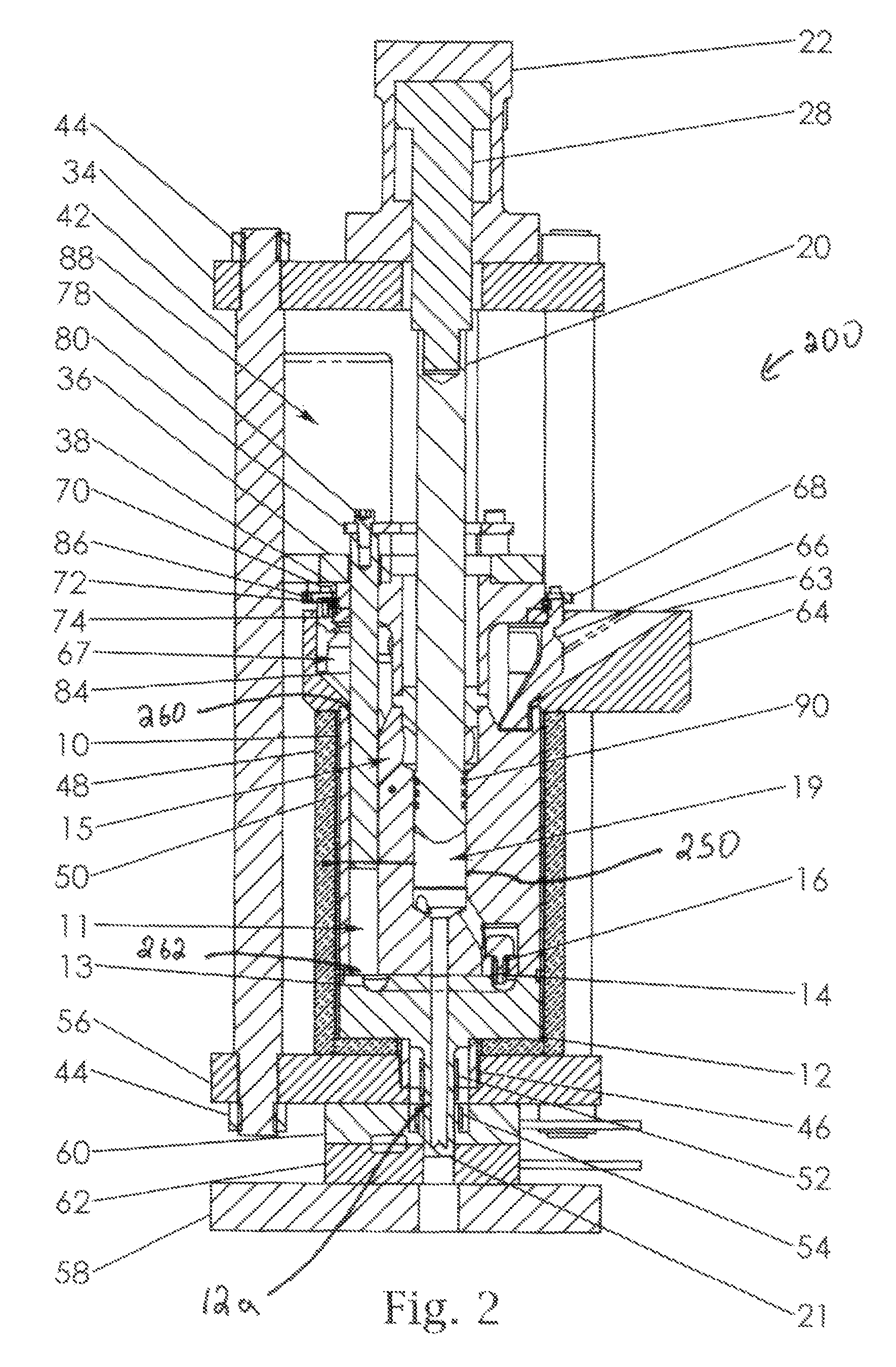

Transfer pump launder system

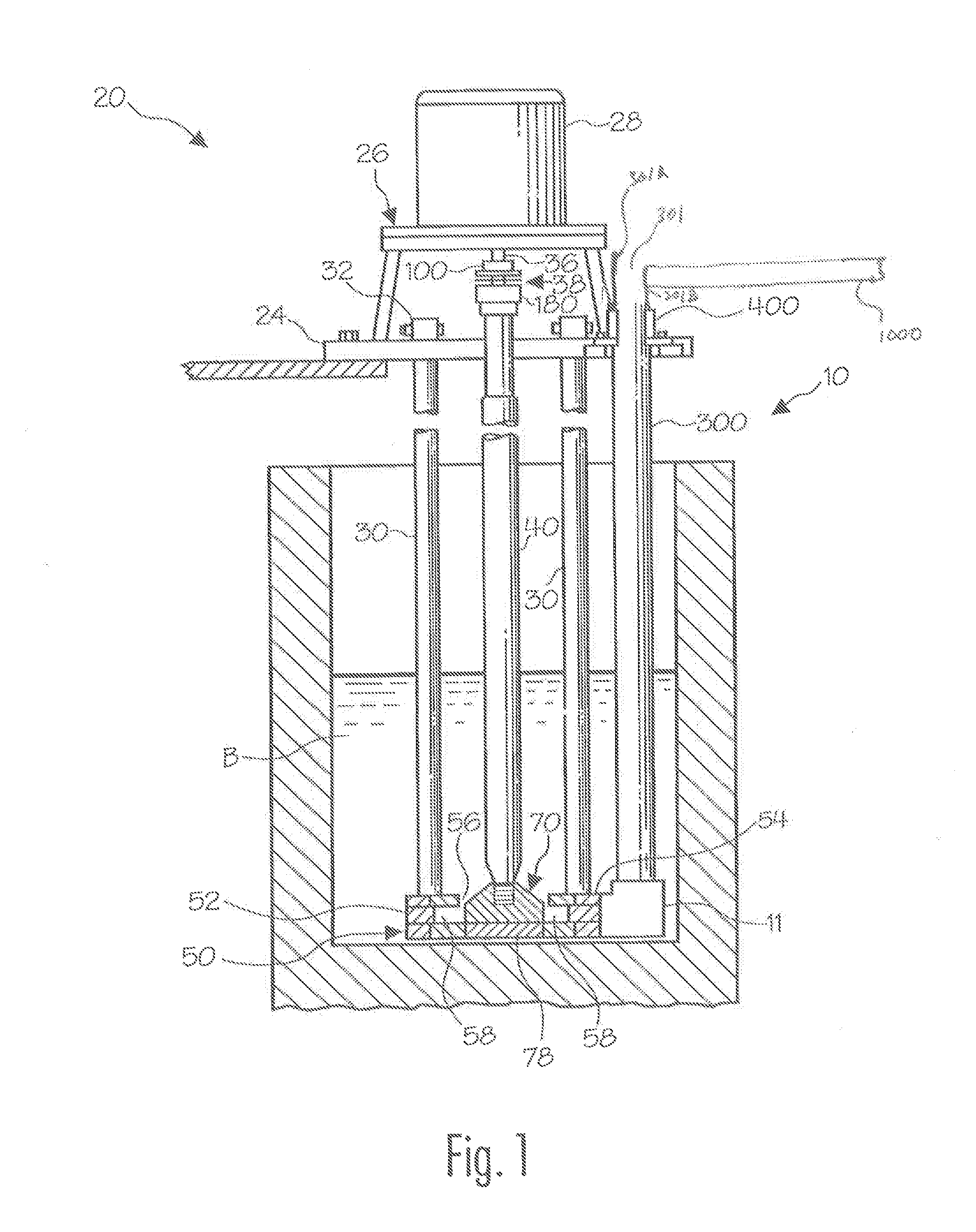

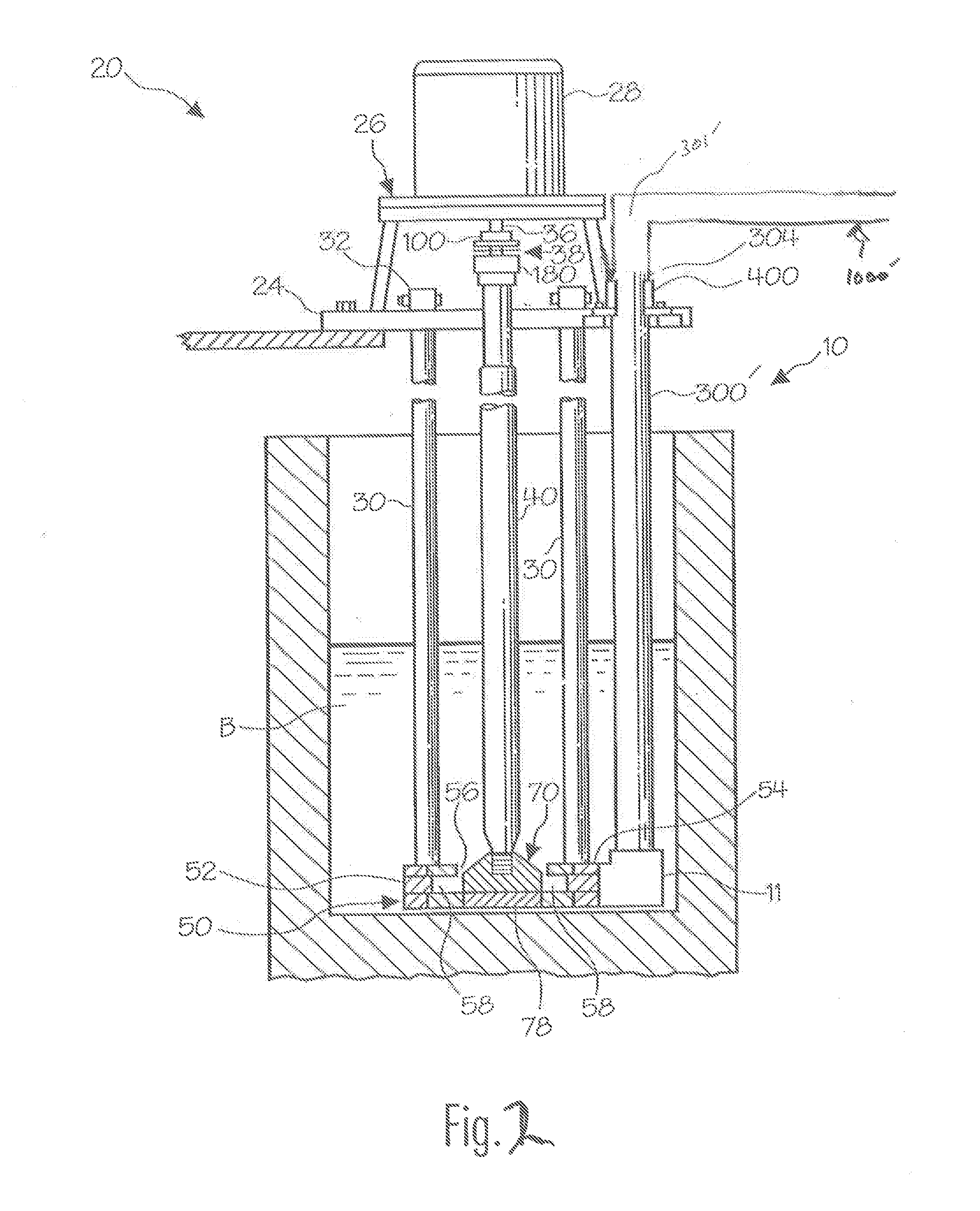

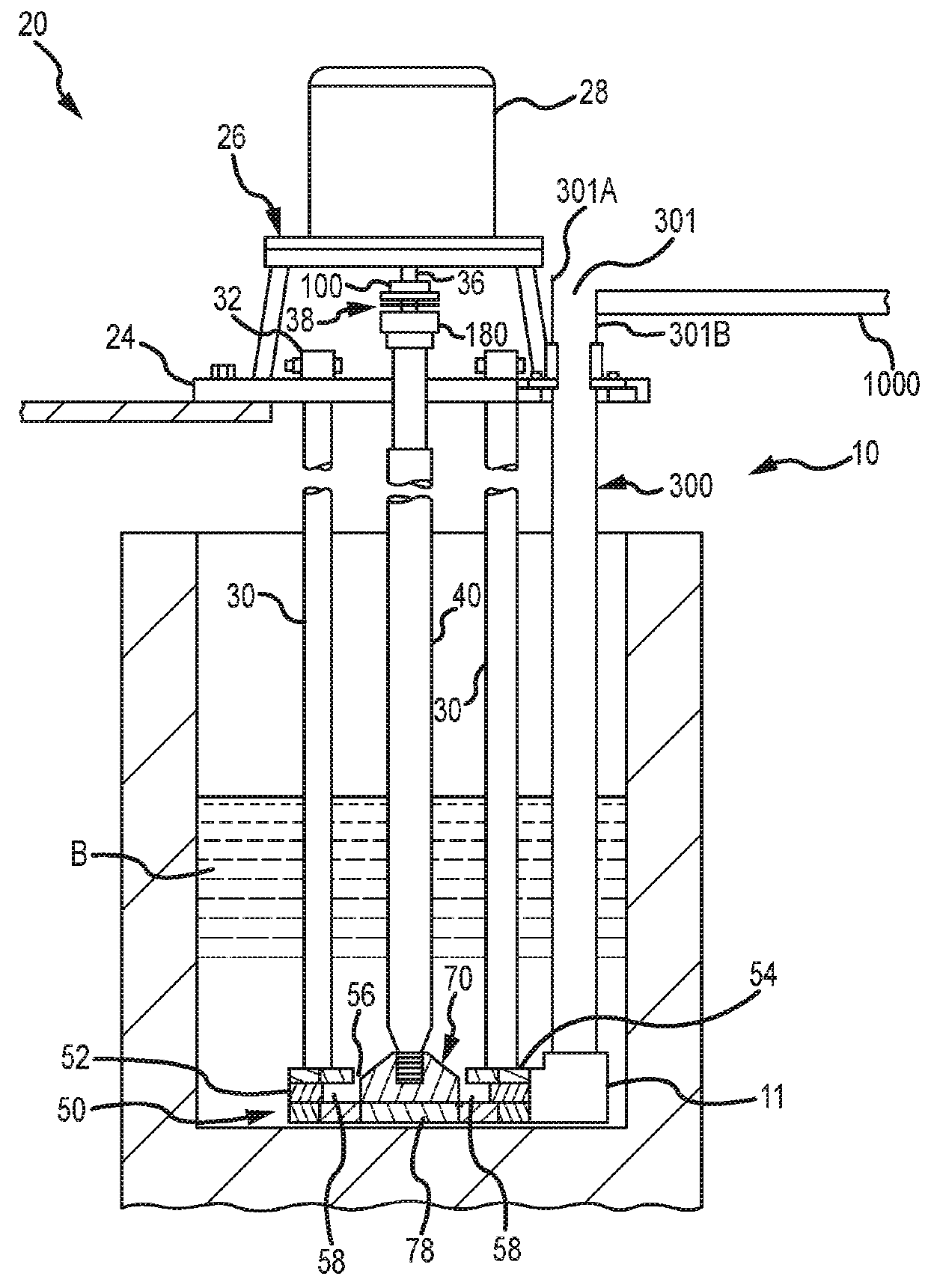

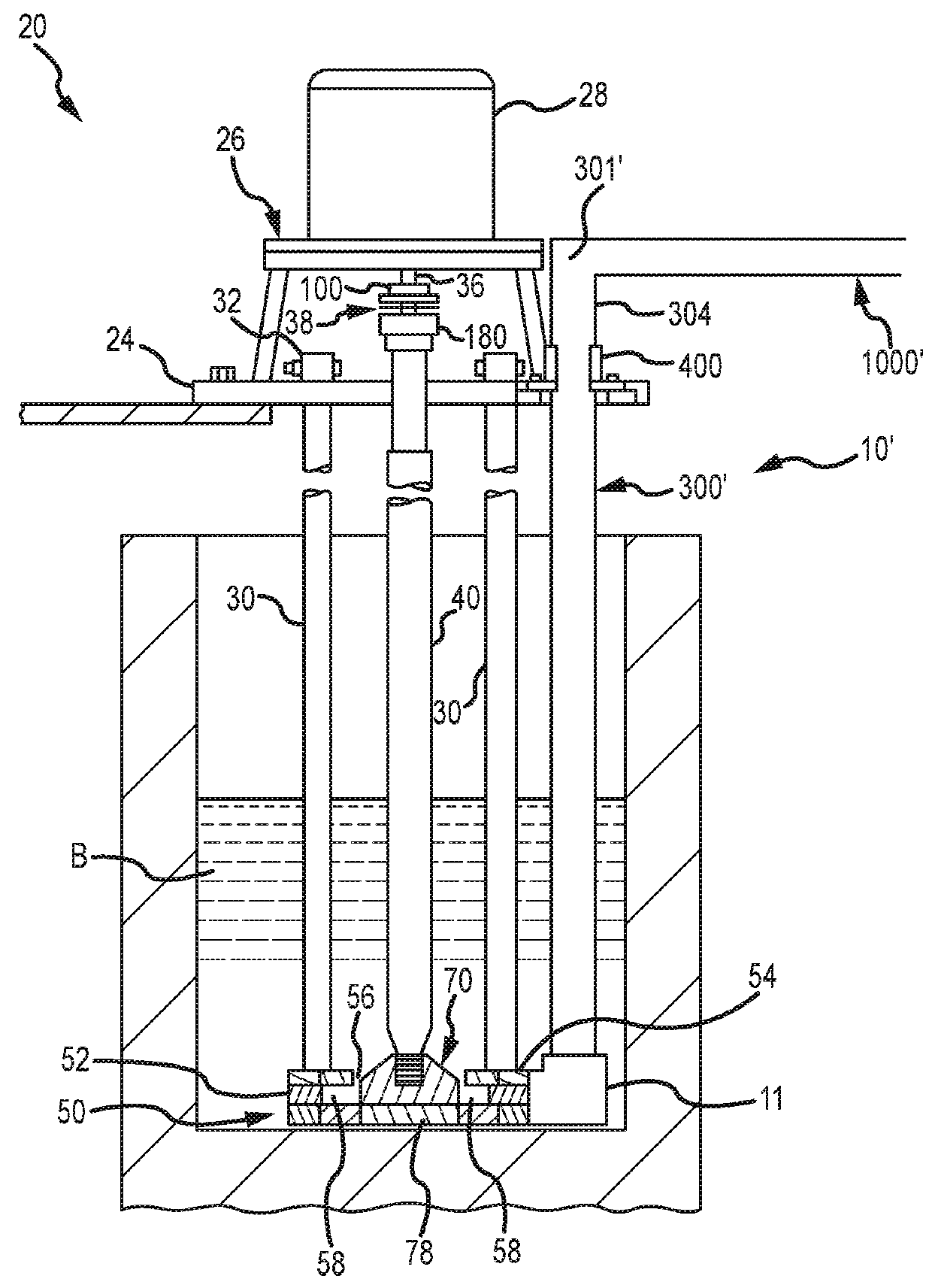

Disclosed is a transfer pump having a pump base with a pump chamber, tangential discharge and an outlet in the top surface of the pump base. A riser tube extends from the outlet and terminates at a launder in order to move molten metal out of a vessel with relatively little turbulence.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer pump launder system

A pump having a motor, a pump base with a pump chamber, a tangential discharge and an outlet in the pump base. A riser tube extends upward from the outlet and terminates at or above a launder in order to move molten metal out of a vessel with relatively little turbulence.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Transfer pump launder system

Disclosed is a transfer pump having a pump base with a pump chamber, tangential discharge and an outlet in the top surface of the pump base. A riser tube extends from the outlet and terminates at a launder in order to move molten metal out of a vessel with relatively little turbulence.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

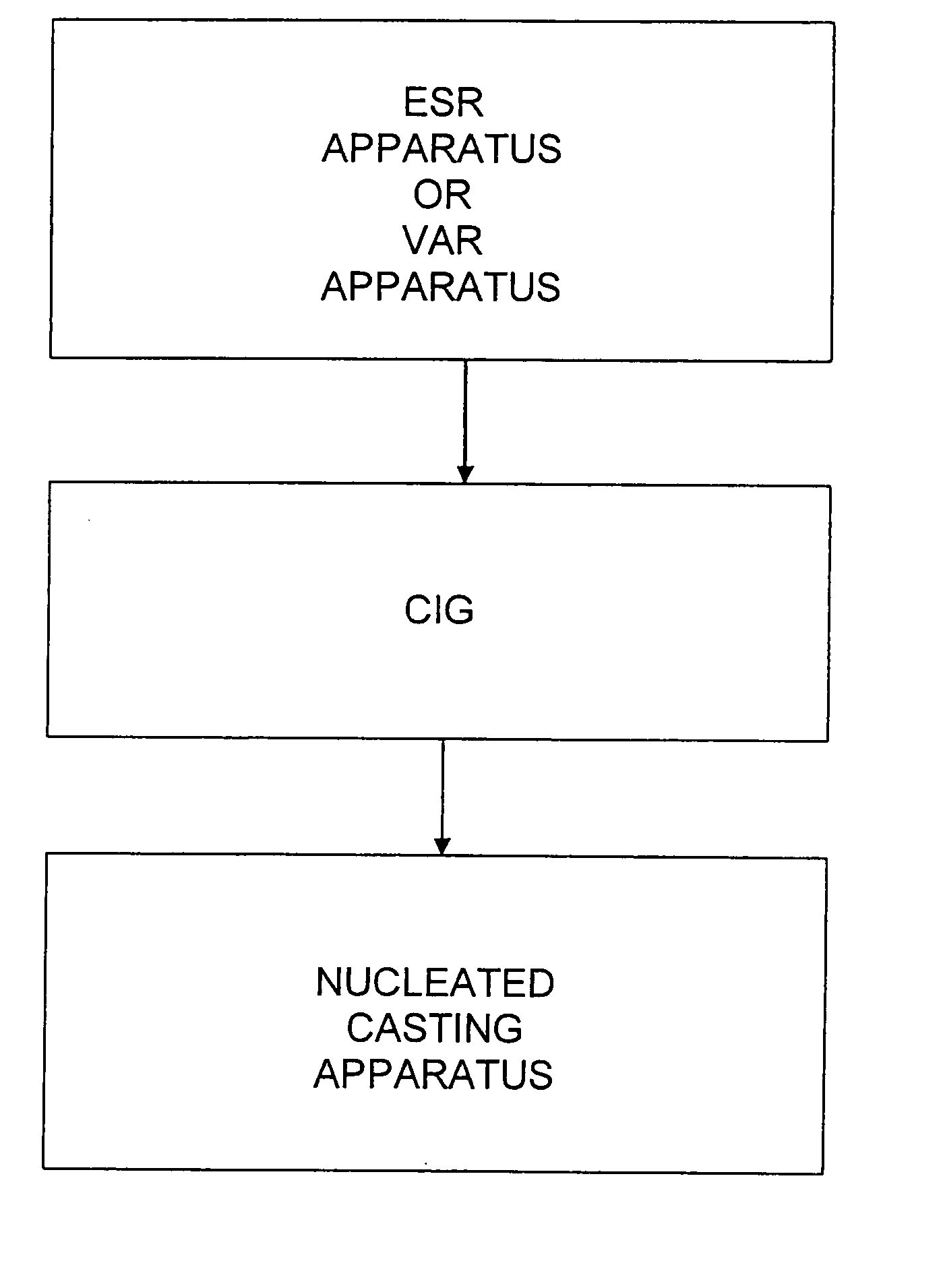

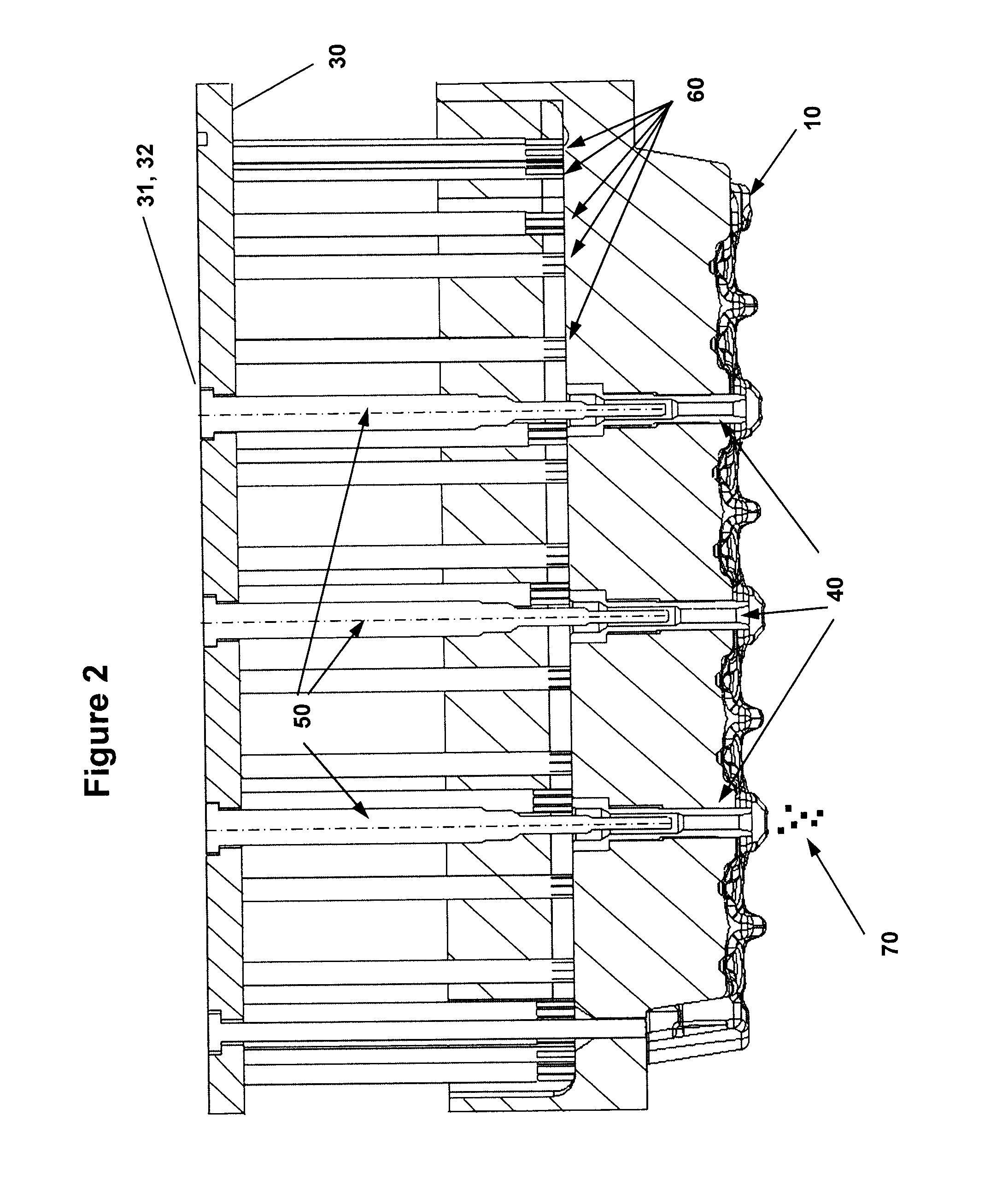

Refining and casting apparatus and method

ActiveUS20080115905A1Improve processing efficiencyAvoid excessive interruptionCasting apparatusMetalMaterials science

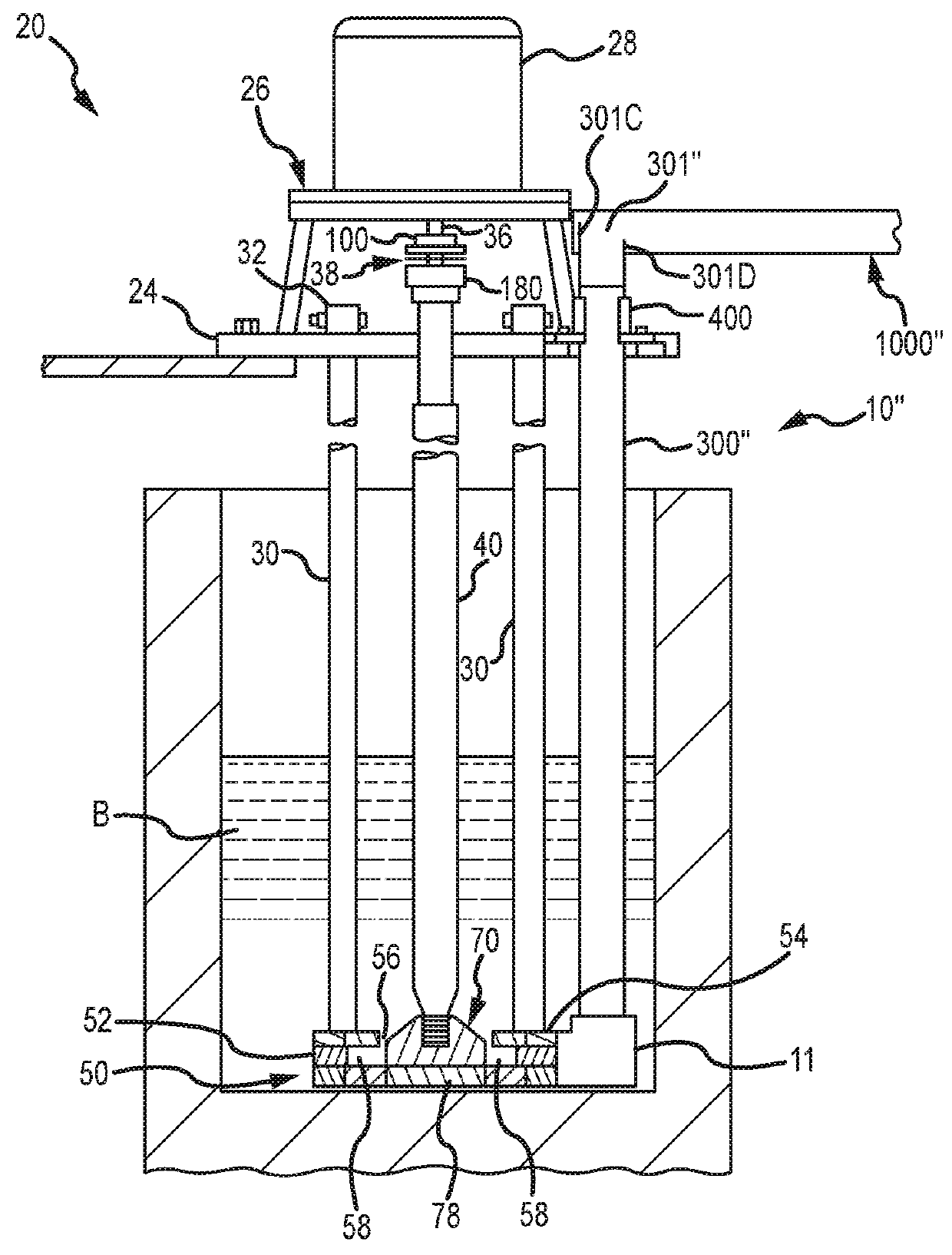

An apparatus for casting metals by a nucleated casting technique to create a preform, the apparatus including a mold having a base and a side wall where the base can be moved relative to the side wall to withdraw the preform as it is being created. In various circumstances, portions of a droplet spray created by an atomizing nozzle, i.e., overspray, may accumulate on a top surface of the side wall and prevent or inhibit the preform from being moved relative to the side wall. The atomizing nozzle can be oriented such that the droplet spray passes over the top of the side wall to remelt and remove at least a portion of the overspray that has accumulated thereon. The mold can be rotated such that the overspray formed on a region of or on the entire perimeter of the top surface can pass through the droplet spray and can be removed from the side wall.

Owner:ATI PROPERTIES LLC

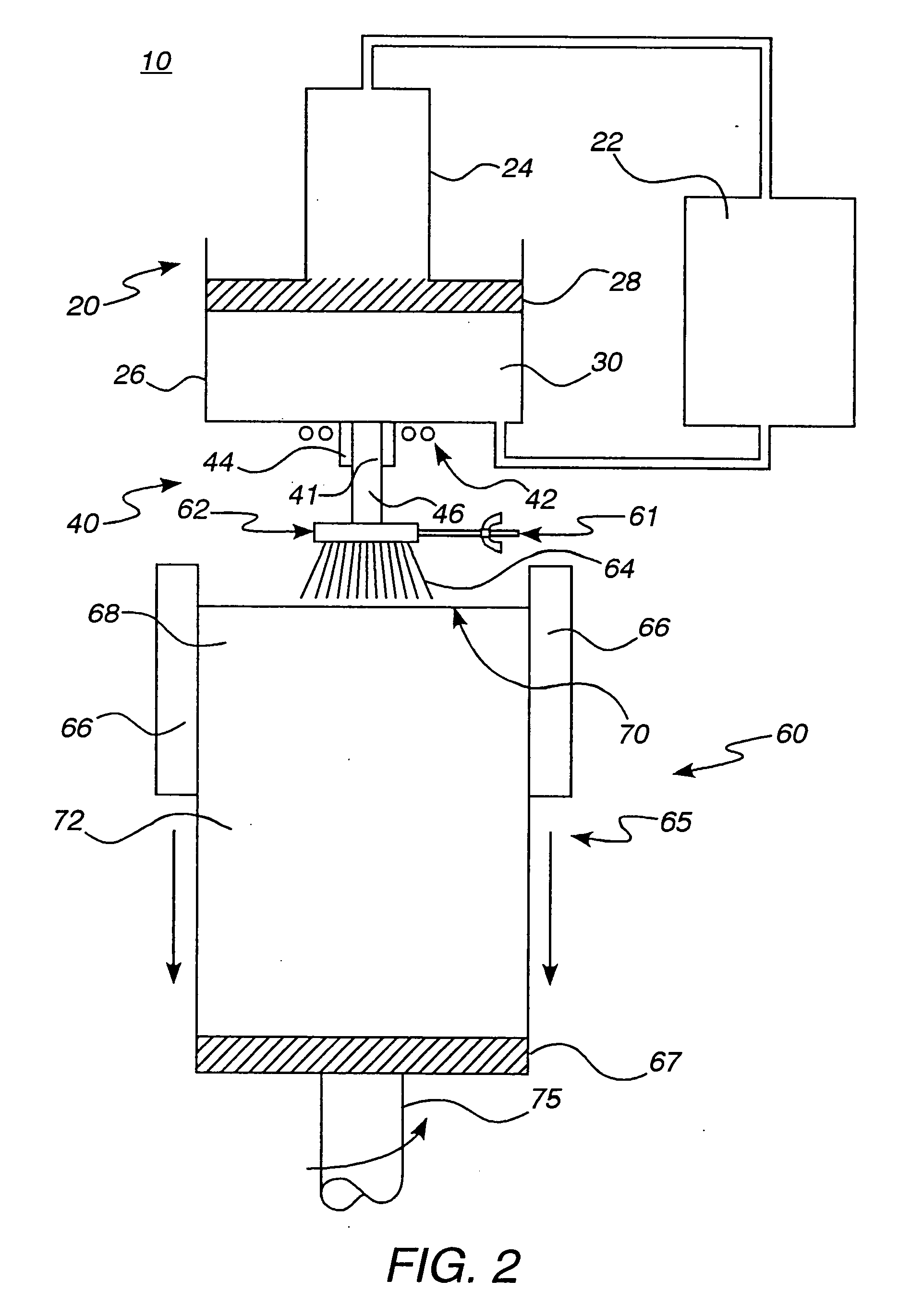

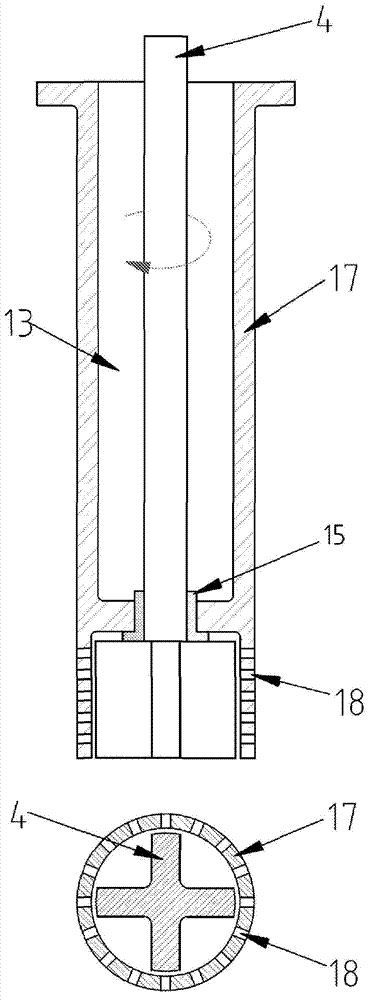

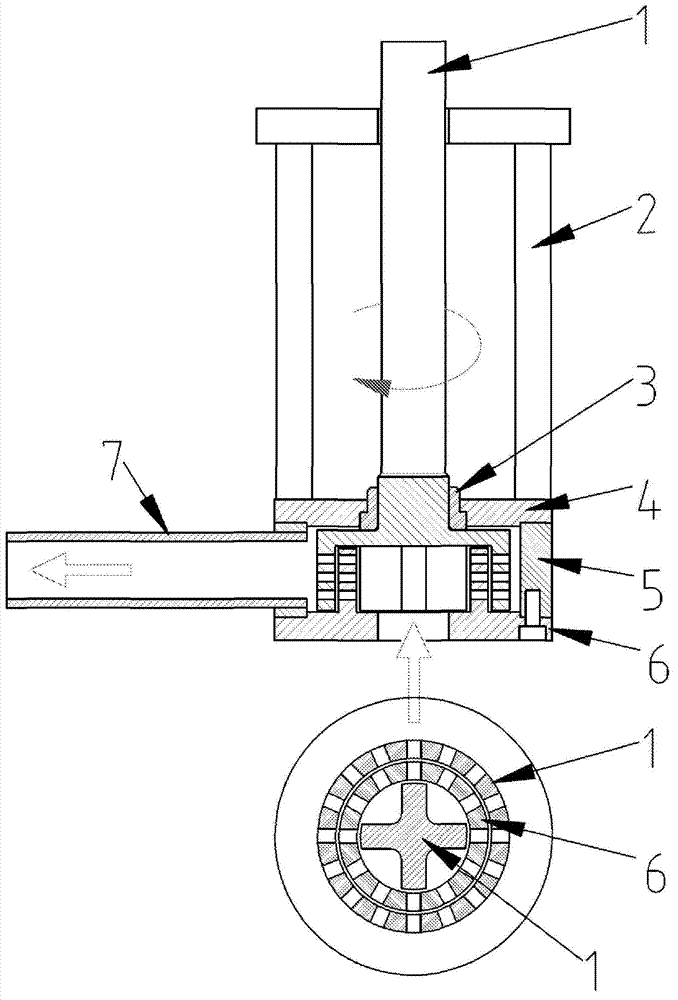

Apparatus and method for liquid metals treatment

ActiveUS20130228045A1Improve efficiencySpeed up chemical reactionsStirring devicesCasting apparatusParticulatesGas phase

This invention relates to an apparatus (high shear device) and method for treating liquid metals by intensive melt shearing. The apparatus comprises a stator and a rotor with a small gap between them to provide intensive melt shearing for dispersing efficiently and distributing uniformly gas, liquid and solid phases in liquid metals without severe turbulence at the melt surface. The device can be extended to a multistage high shear pump by arranging individual rotor / stator assemblies either concentrically (one in another) or vertically. The device and high shear pump can be readily integrated into existing casting processes. The device is suitable for use in casting processes including high pressure die casting, low pressure die casting, gravity die casting, sand casting, investment casting, direct chill casting, twin roll casting, and any other casting process which requires liquid metal as a feedstock. In addition, the device is particularly suitable for providing conditioned liquid metal for both shape casting and continuous (or semi-continuous) casting of metallic materials, preparing high quality semi-solid slurries, solidification processing of particulate reinforced metal matrix composites, mixing immiscible metallic liquids and degassing of liquid metals prior to any casting processes.

Owner:BRUNEL UNIVERSITY

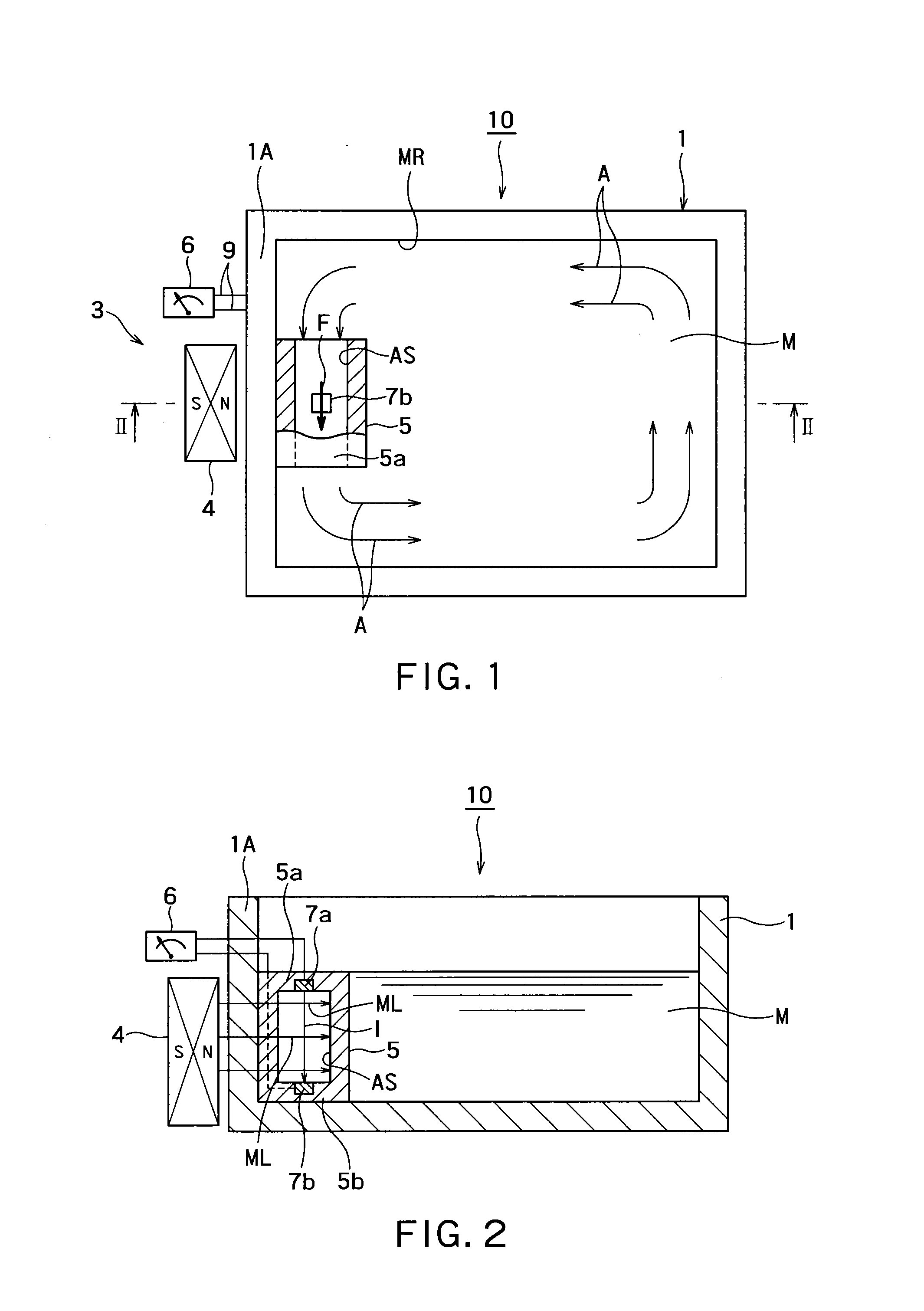

Agitator, agitating method, and melting furnace with agitator

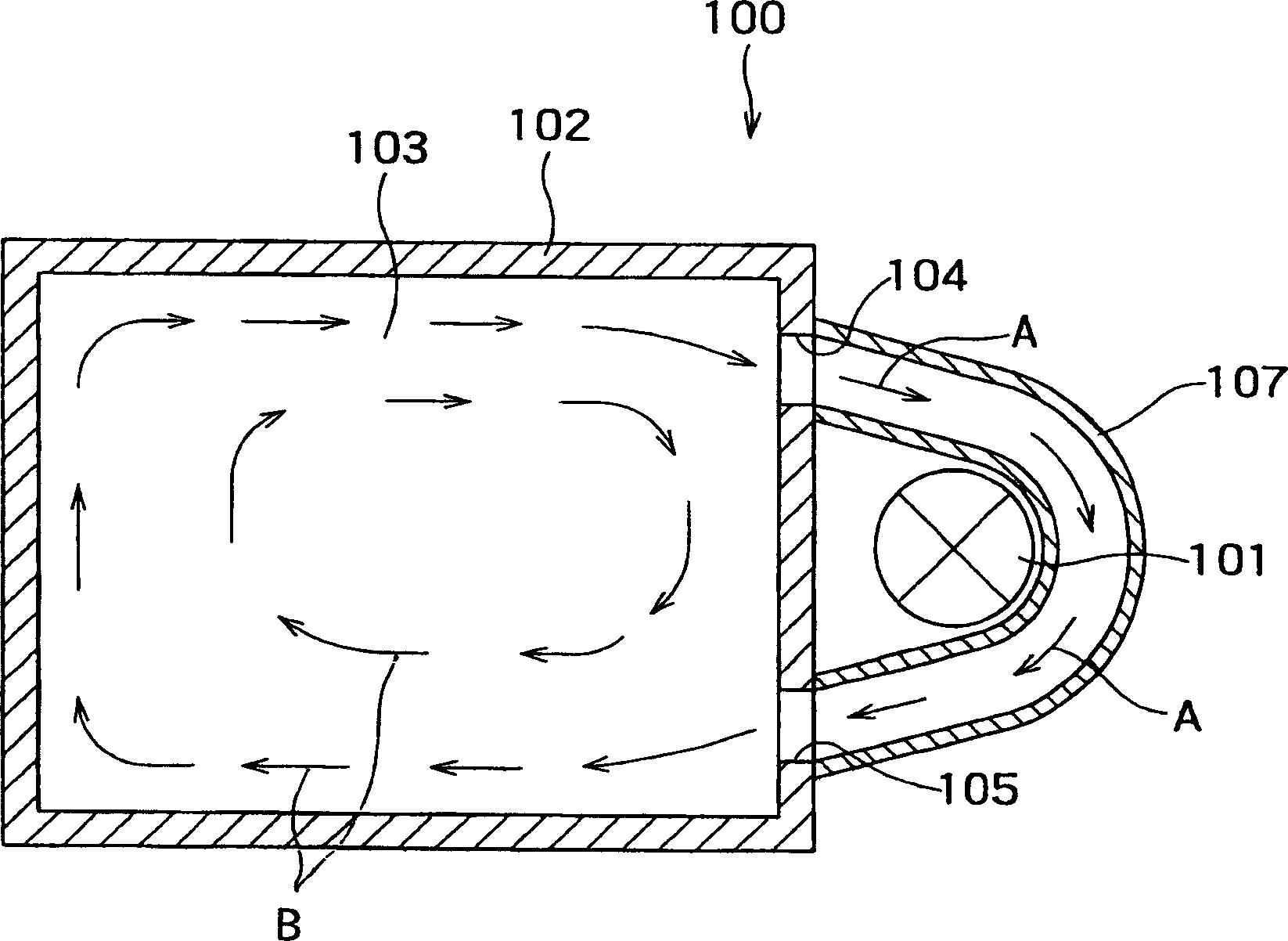

An agitator for agitating a melt includes a heat-resistive container having a blast opening through which cooling air is blown and an exhaust opening for exhausting air having been subjected to heat exchange, and a rotating magnet assembly composed of a permanent magnet housed in the heat-resistive container in a rotatable manner, magnetic lines of force emitted from the permanent magnet penetrating through the heat-resistive container to exit outside, and then penetrating the heat-resistive container again to return to the permanent magnet.

Owner:高桥谦三

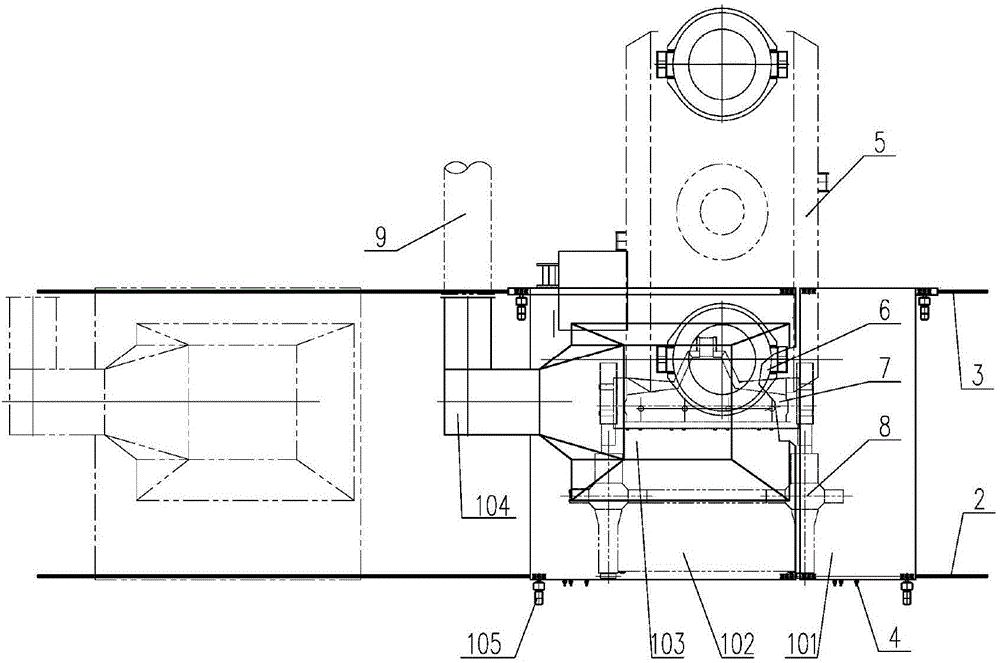

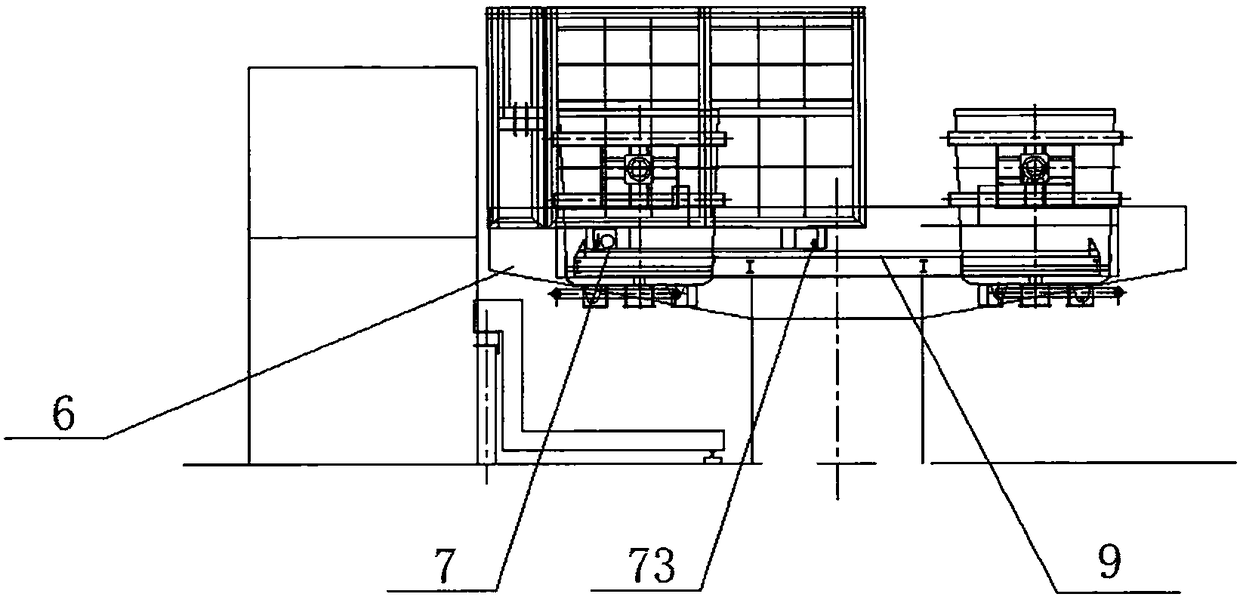

Casting area moving type dust removing device for continuous casting machine

ActiveCN104815830AImprove dust removal effectWill not affect normal casting operationsCasting apparatusDirt cleaningMaterials scienceContinuous casting

A casting area moving type dust removing device for a continuous casting machine belongs to the technical field of steel-making continuous casting. The casting area moving type dust removing device for the continuous casting machine comprises a dust collecting cover, moving rails, and a workshop dust removing system. The moving rails comprise high rails and low rails which are arranged in parallel. The dust collecting cover consists of two independent cover bodies including a main dust collecting cover and an auxiliary dust collecting cover that are arranged on bilateral sides of a casting site steel ladle rotary table. Each cover body is independently supported on the low rails and the high rails by its own wheels, and the cover body can move linearly along the rails. Adjacent sides of the two cover bodies are open without a sealing wall. A flow guidance cone and a dust removing pipeline moving along with it are arranged on the top of the main dust collecting cover. The main dust collecting cover and the auxiliary dust collecting cover move to the casting site upon casting; the cover bodies cover above the entire casting area, thereby forming a relatively complete dust removing space. The dust removing pipeline belonging to the main dust removing cover is communicated with the workshop dust removing system. The workshop dust removing system finishes the fume purification and discharges the purified fume. The casting area moving type dust removing device for the continuous casting machine has the advantages that the dust removing space covers the steel ladle and the intermediate ladle, thereby the quickly ascending fume and dust can be collected as much as possible; and accordingly the dust removing effect is good; the equipment layout is reasonable; the structure is simple; and the operation is convenient.

Owner:BEIJING SHOUGANG INT ENG TECH

Method for casting sand mould by utilizing vacuum-assist pouring

InactiveCN101869975AEasy to manageHarm reductionCasting apparatusDirt cleaningStable stateVacuum assisted

The invention relates to a method for casting sand mould by utilizing vacuum-assist pouring. The technological process thereof includes: the sand mould after moulding, modelling, core setting and mould assembling is placed above a vacuum purification smoke pouring table, a vacuum system is started, negative pressure is applied to the sand mould by virtue of the vacuum purification smoke pouring table, liquid steel is injected into the sand mould by a pouring cup and then solidified, thus the casting process is completed. In the invention, the sand mould is in negative pressure state before pouring, when liquid metal enters into the cavity, sand core and the sand mould can produce gas under the action of high temperature liquid metal, and negative pressure can cause the produced gas to be exhausted at any time, especially the sand core gradually coated in the liquid metal exhausts the gas by virtue of a plurality of core prints, and the whole operation process can be carried out in safe and stable state.

Owner:姚会元

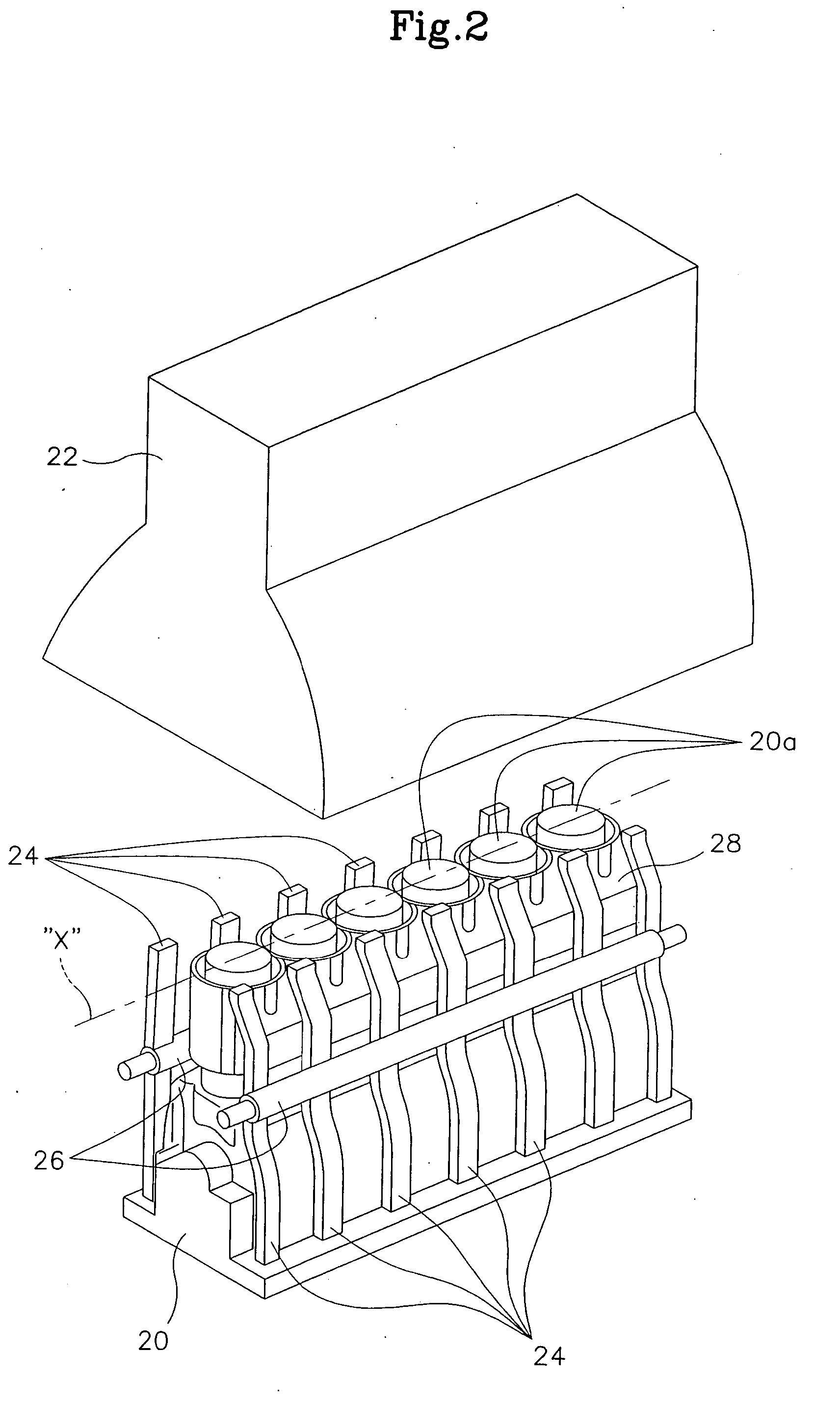

Oil drain passage structure of cylinder block and core structure thereof

ActiveUS20060144353A1Reduce engine noiseReduce vibrationCasingsCylinder headsEngineeringCylinder block

The present invention provides an apparatus for achieving precise manufacturing of drain passages such as those used for oil return and blow-by gas discharge in a cylinder block. Grid-like oil drain passage and corresponding core structures are disclosed herein; the oil drain passage structure comprises a plurality of vertical passages that are arranged longitudinally with respect to the cylinder block, wherein the vertical passages are interconnected by a connecting passage that runs longitudinally through the central portions of the vertical passages.

Owner:HYUNDAI MOTOR CO LTD

Whole vacuum negative pressure impregnation equipment and method for die casting type shell

ActiveCN103785575ANot easy to bumpNot easy to scratch and damageLiquid surface applicatorsCasting apparatusAdhesiveDie casting

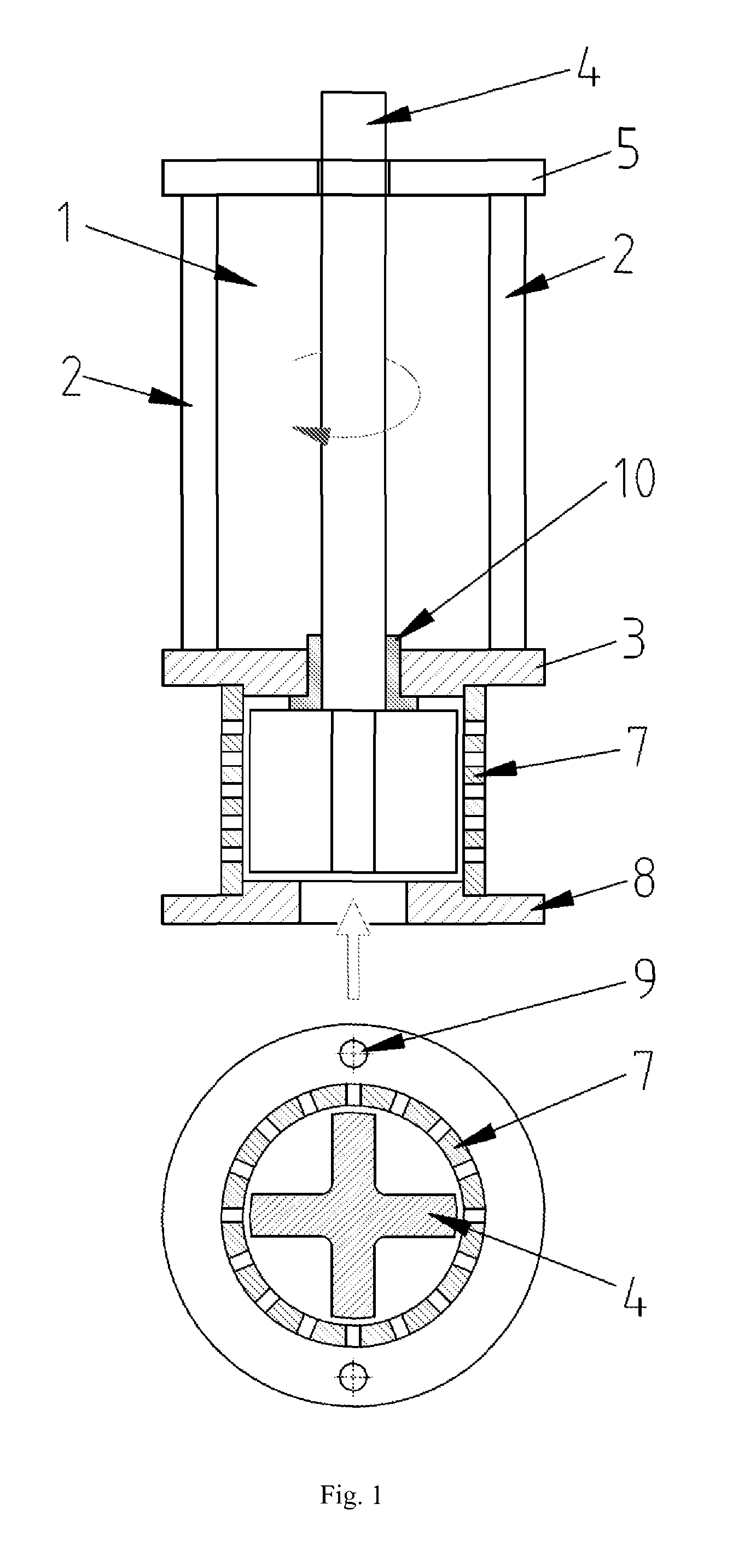

The invention discloses whole vacuum negative pressure impregnation equipment and method for a die casting type shell. The equipment comprises an impregnant box (3), an air storage tank (7), an oil cylinder (8) which is arranged above the impregnant box (3) and of which a piston end is connected with the impregnant box (3), a sealing mechanism (1) positioned between the oil cylinder (8) and the impregnant box (3), a control box (4) connected with the oil cylinder (8), and also comprises a vacuum meter (5) and a vacuum pump (6) which are arranged on the control box (4). A cavity inside a die casting type shell (2) can be completely closed by the sealing mechanism (1); the vacuum pump (6) is communicated with the sealing mechanism (1) through the air storage tank (7). All inner cavities of the die casting type shell to be impregnated are sealed before impregnation, so that the problems that die castings, such as shells which are partially assembled, shells of which impregnating adhesives are difficultly cleaned, and shells with large boundary dimensions cannot be subjected to conventional overall impregnation are effectively solved.

Owner:徐州金澄精密制造有限公司

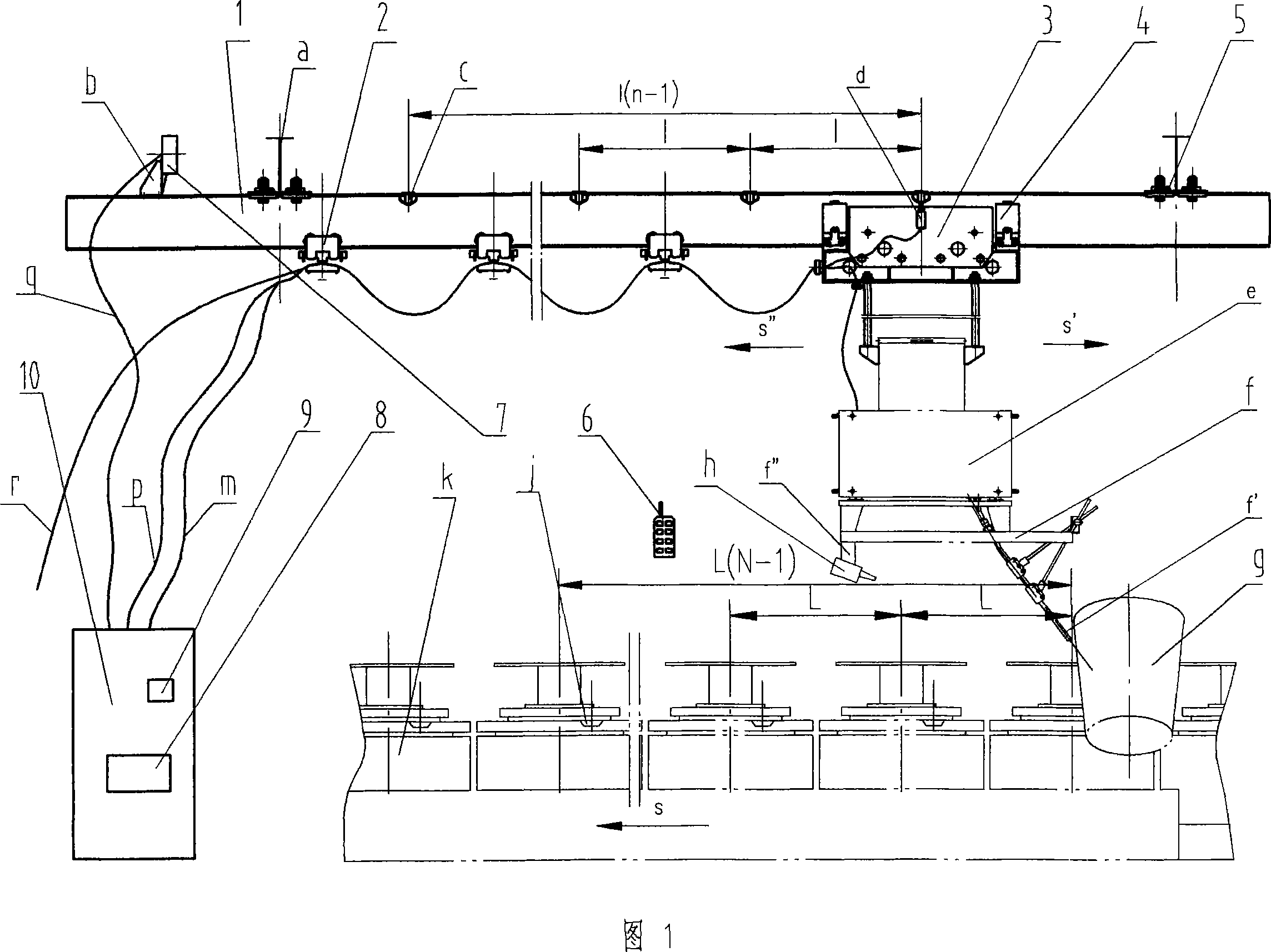

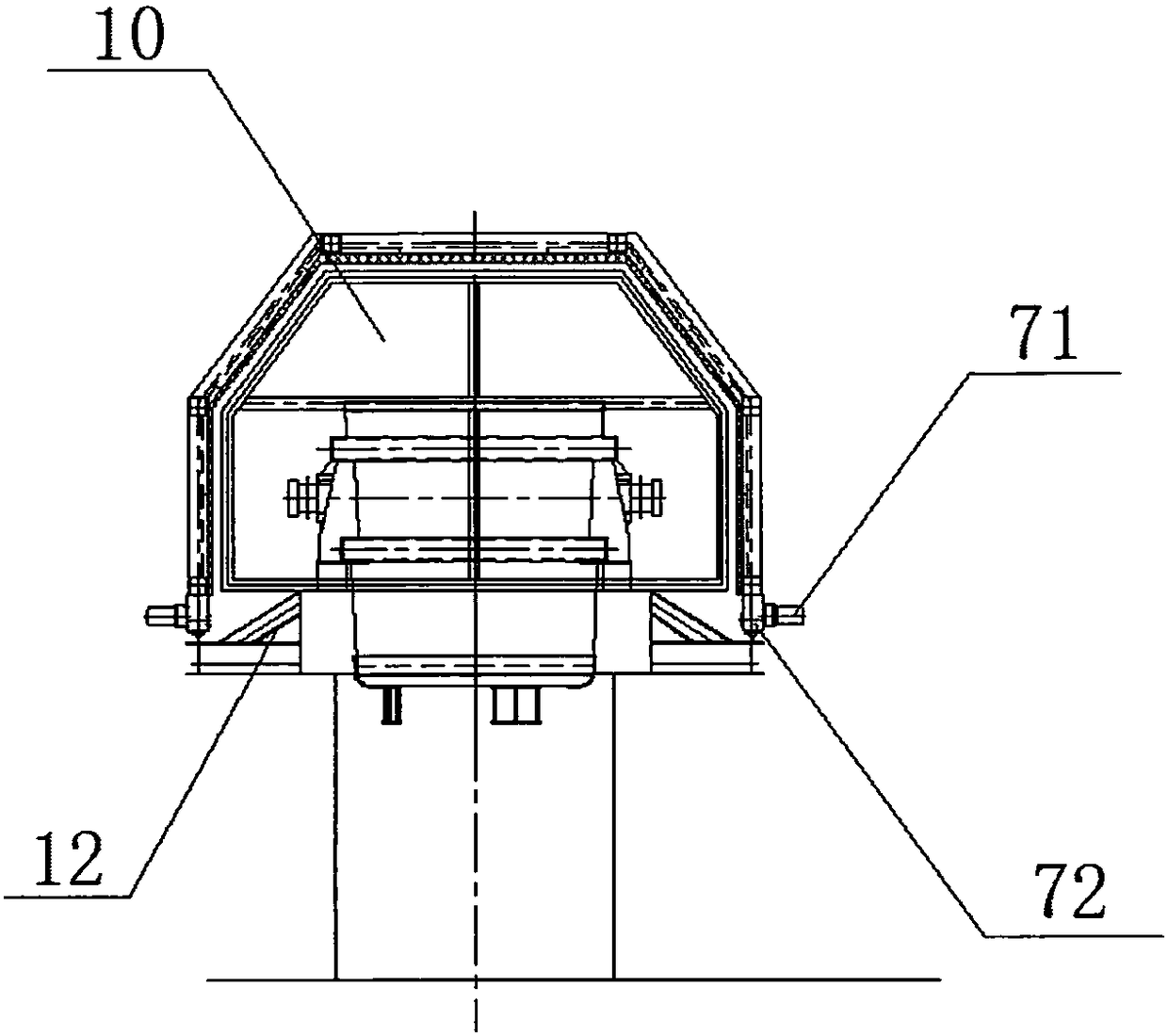

Program control operation mechanism for a hand dropping flow-following gestating device

InactiveCN101134239ASolve the problem of setting up the incubator with the flowSolve process problemsCasting apparatusBogieRemote control

The program controlled running mechanism for manually casting flow inoculation apparatus includes one I-steel rail assembly, one cable tackle, one running bogie, four adjustable idler wheel assemblies, one rail press board assembly, one remote controlled emitter, one remote controlled receiver and one control cabinet. By means of the control panel in the electric control cabinet and the remote controlled emitter, the present invention completes the running of the mechanism, the on / off-feeding of the flow inoculation apparatus, and manual pouring and flow inoculation. The mechanism can realize interlock control, and has reliable performance and simple operation.

Owner:CHINA YITUO GROUP

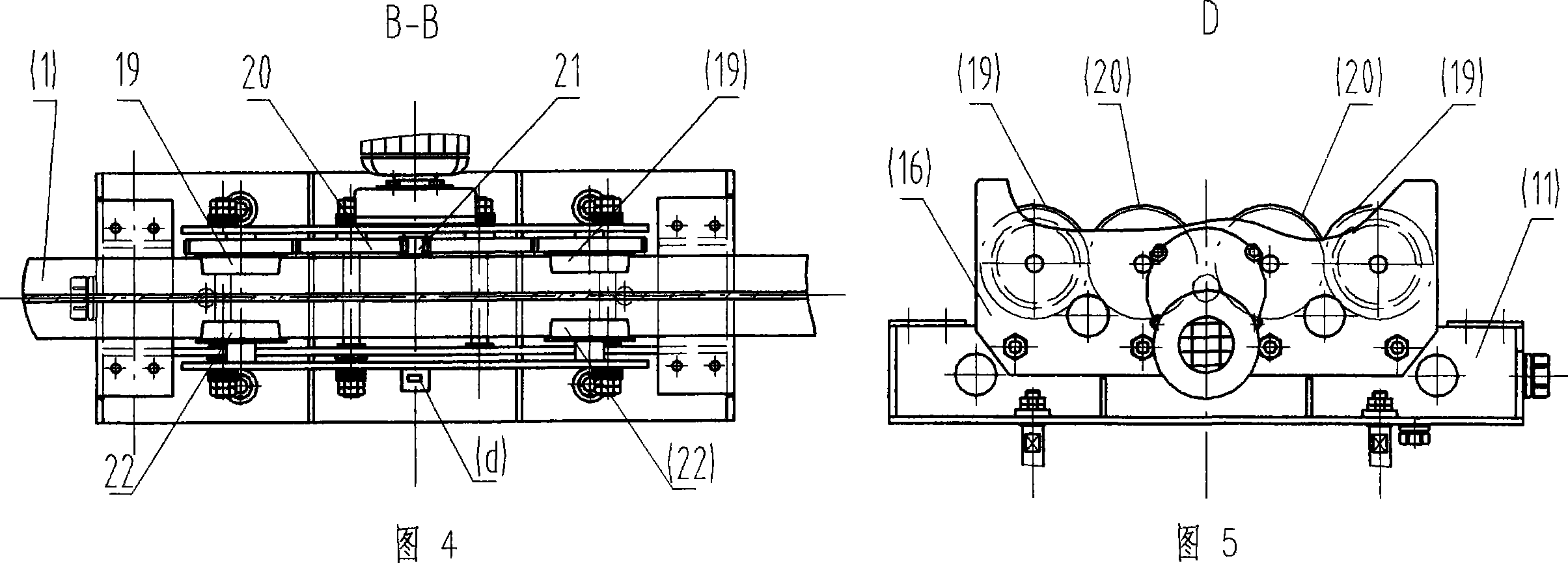

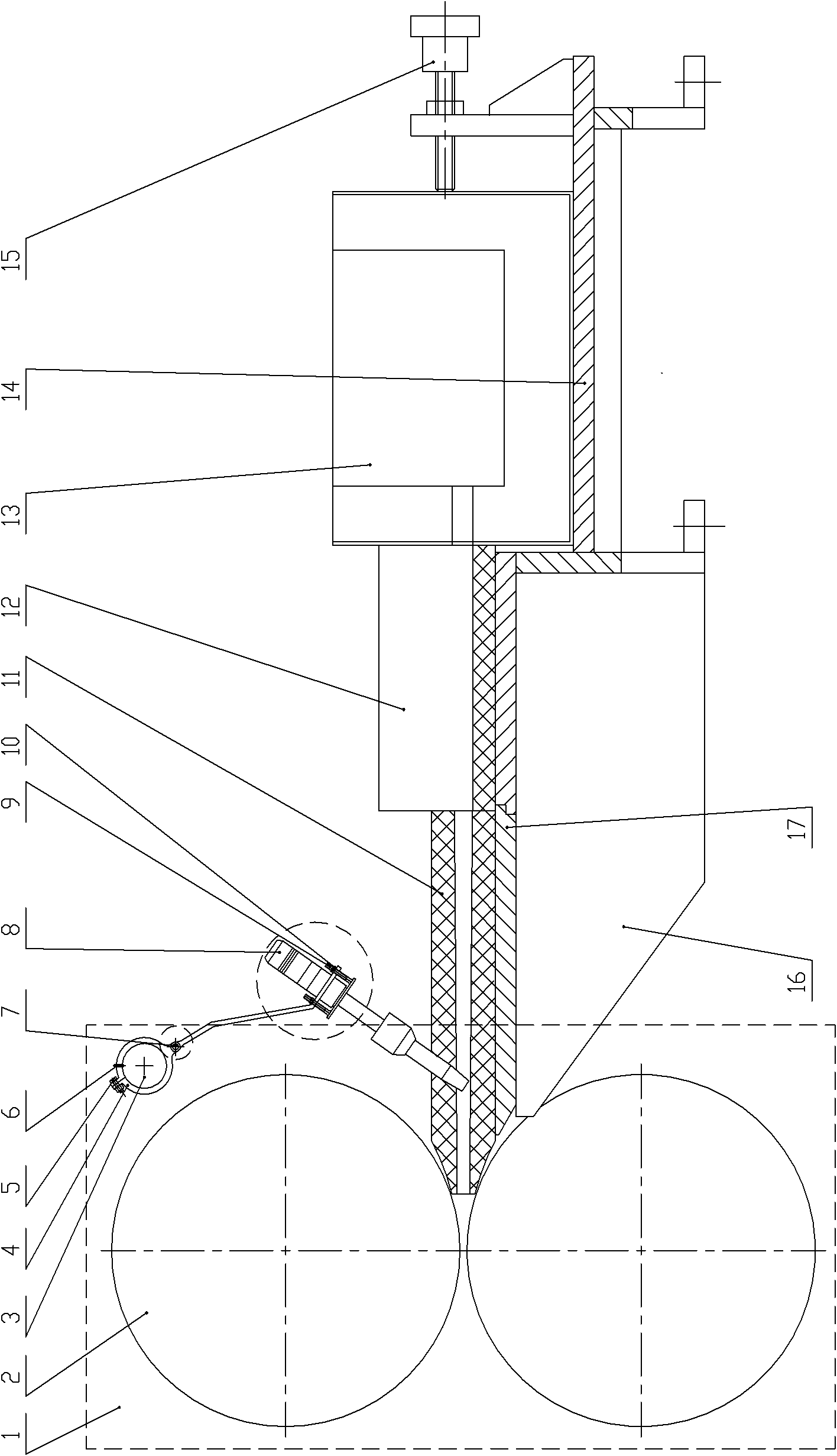

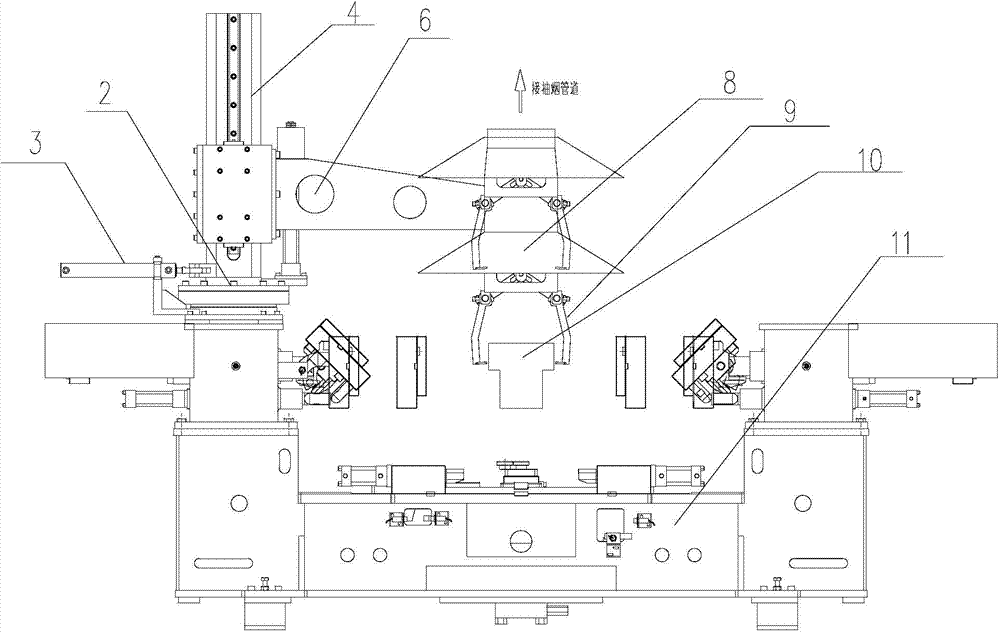

Ultrasonic external field continuous casting and rolling machine

InactiveCN101850362AUniform tissueImprove organizationCasting apparatusMetal rolling arrangementsMechanical propertyContinuous casting

The invention discloses an ultrasonic external field continuous casting and rolling machine, which comprises a casting mouth (11) and a roller support column (1). The roller support column (1) is provided with a cross beam (3). An ultrasonicator (8) is slantways mounted in front of the casting mouth (11) in the direction vertical to the casting and rolling direction. Guiding bars of the ultrasonicator (8) are inserted into the aluminium alloy fused masses of the casting mouth (11). The invention provides the ultrasonic external field continuous casting and rolling machine which can refine the casting and rolling mechanisms, improve mechanical property and anisotropy, reduce or eliminate segregation, macro-defects and micro-defects in the process of continuous casting and rolling of aluminium alloy plate blank. The machine is convenient for maintenance and can realize standardization and serialization.

Owner:CENT SOUTH UNIV

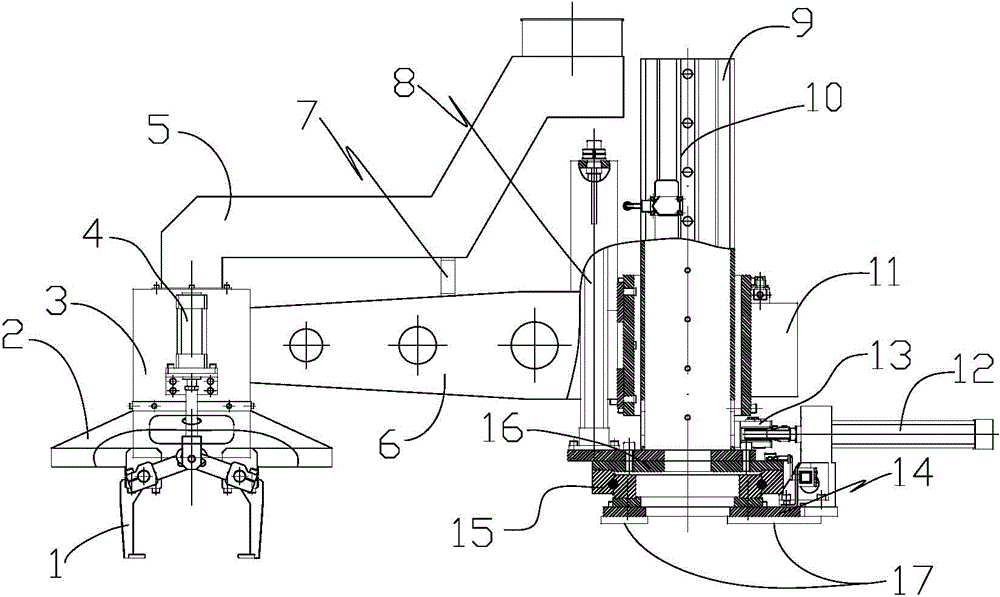

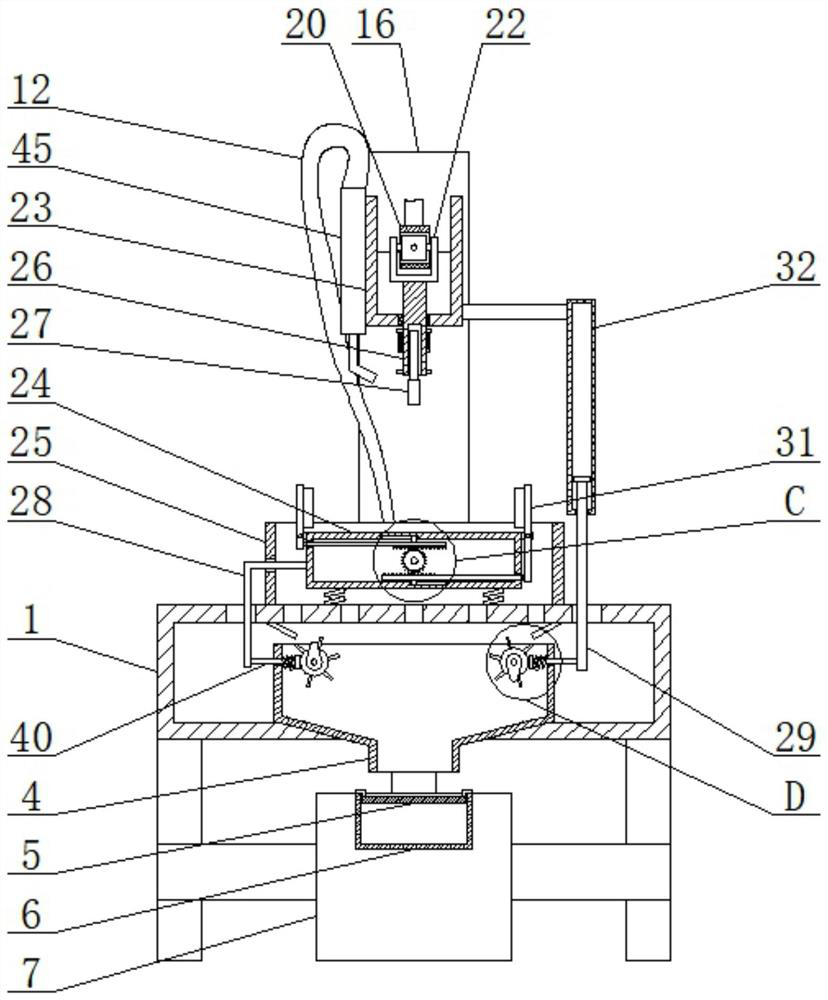

Workpiece-taking manipulator with smoke discharge function

ActiveCN104399953AReduce physical labor intensityImprove working conditionsCasting apparatusEngineeringSmoke hood

The invention provides a workpiece-taking manipulator with a smoke discharge function, and applies to the field of casting production of metal parts of an automobile. The workpiece-taking manipulator structurally comprises a gripper, wherein a smoke hood is arranged above the gripper, the gripper and the smoke hood are connected with a head box, and the smoke hood is communicated with a smoke discharge pipeline; a gripper drive cylinder is arranged on one side of the head box, and a spiral arm is connected with the outer surface of the head tank and a lifting oil cylinder which is mounted on a supporting seat; a stand column and a rotary oil cylinder are further arranged on the supporting seat, a linear guideway is arranged on the stand column, and the rotary oil cylinder is connected with the rotary arm through a rotating joint seat. With the adoption of the workpiece-taking manipulator, dust and smoke produced in a casting process can be collected as far as possible, and meanwhile, the automatic workpiece taking function is achieved.

Owner:JINAN SUNRISE MACHINERY ENG

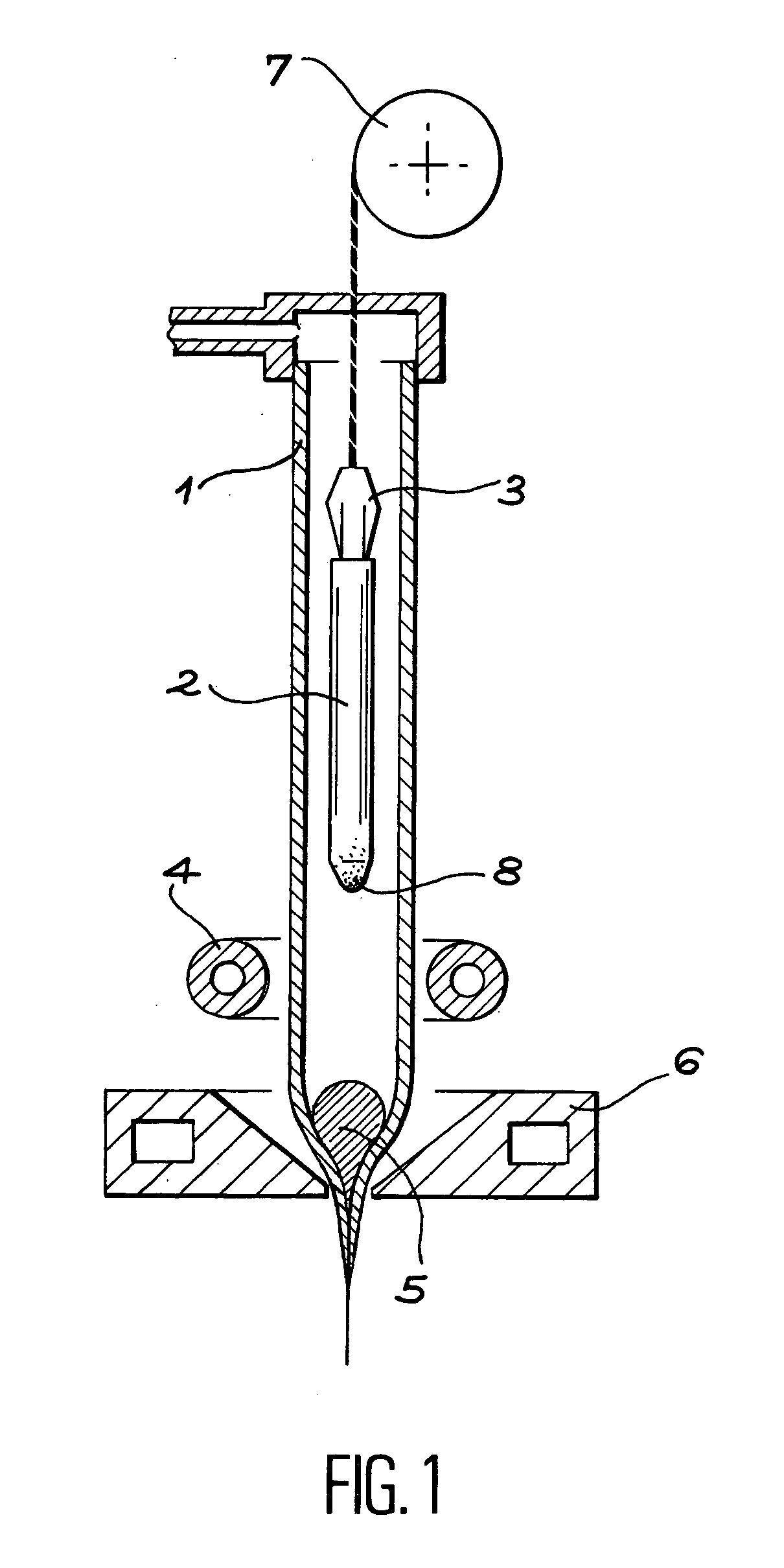

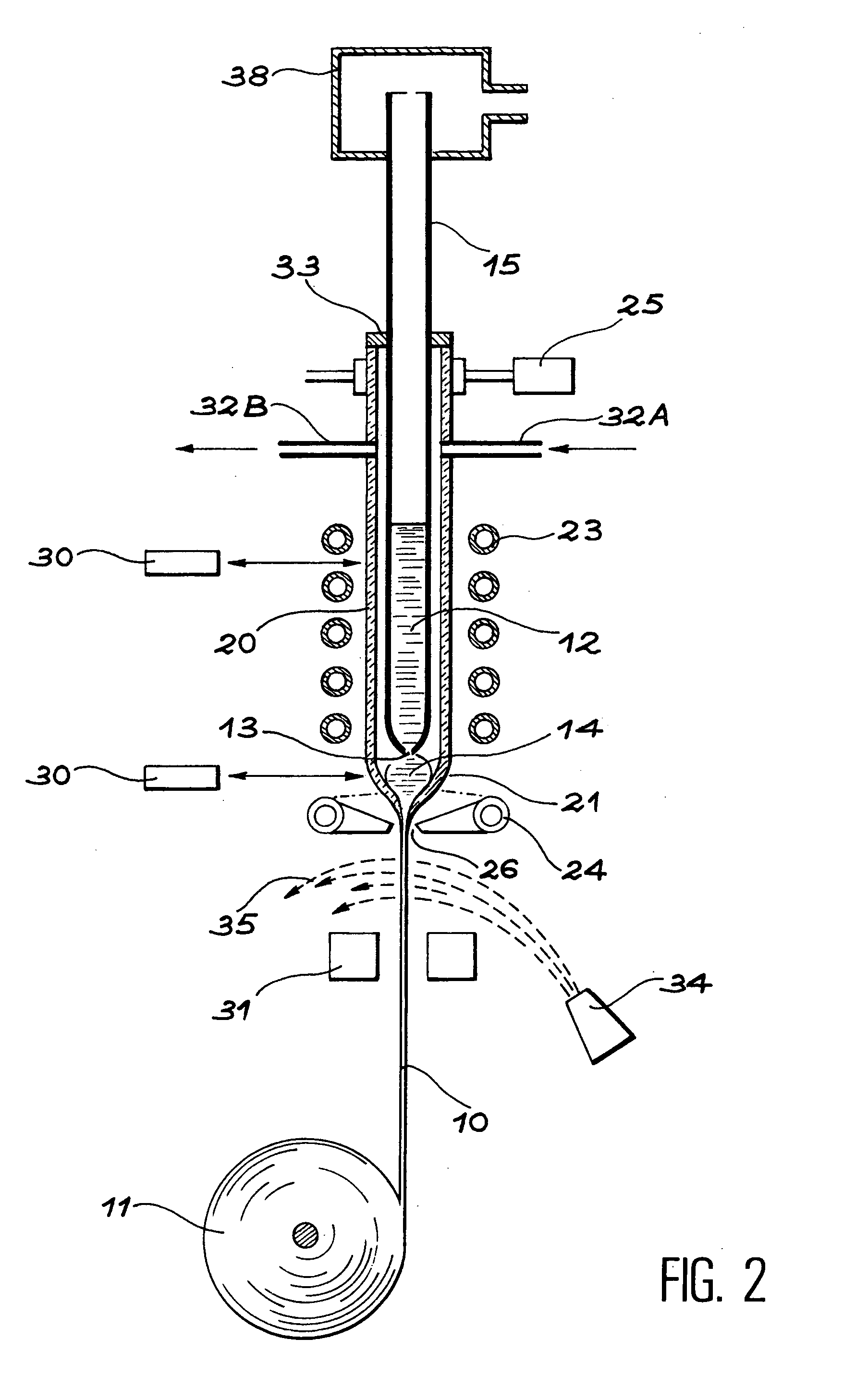

Method and device for continuous production of glass-sheathed metal wires

The device and process allow for continuous processing of metal wire sheathed in glass (10) of considerable length. Normally a feed pipe (15) containing all the necessary metal, itself placed into a glass tube (20), so as to continuously supply a bead (14) to the lower part of the glass tube (20). Heat from a first inductor (23) around the glass tube (20) and a second inductor (24) under the glass tube (20) allow to maintain a bead (14) at a stable temperature and in a continuous manner and to obtain the continuous drawing process of a metal wire sheathed in glass (10).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

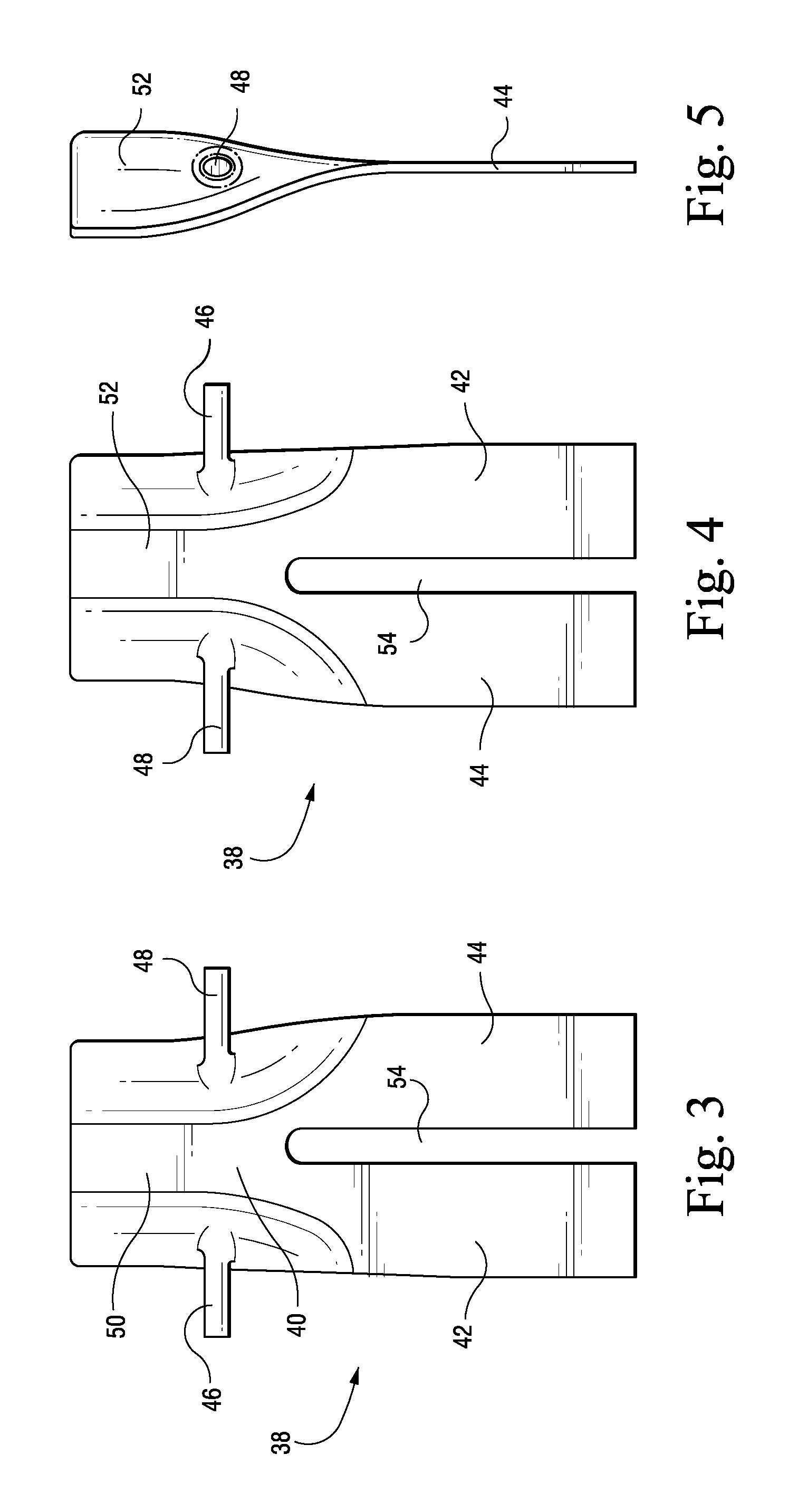

Perimeter-cooled stage 1 bucket core stabilizing device and related method

InactiveUS20050000674A1Relieve pressureStresses, particularly at the intersection of the printoutsFoundry mouldsCasting apparatusEngineeringGas turbines

A core for use in casting a gas turbine bucket, the core comprising a solid upper body portion and a pair of legs extending downwardly from the solid upper body portion, the pair of legs separated by an elongated slot, and a pair of pegs projecting axially from opposite sides of the upper body portion, above the elongated slot but spaced from an upper edge of the upper body portion.

Owner:GENERAL ELECTRIC CO

Apparatus and method for liquid metals treatment

ActiveCN103097846AImprove uniformityGrain refinementStirring devicesCasting apparatusParticulatesGas phase

Owner:BRUNEL UNIVERSITY

Permanent magnet type cylindrical molten-metal agitator and melting furnace with permanent magnet type suction pump

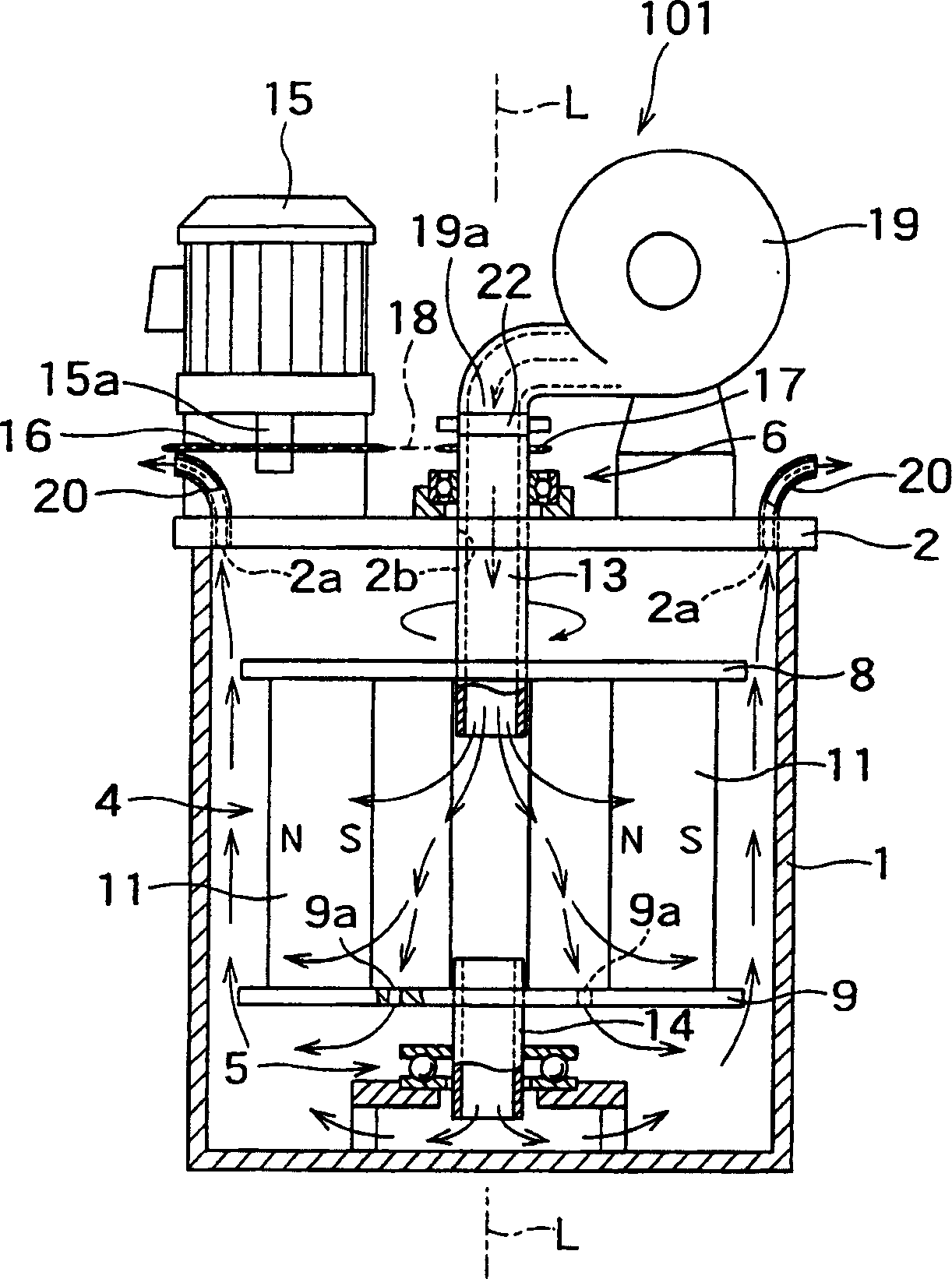

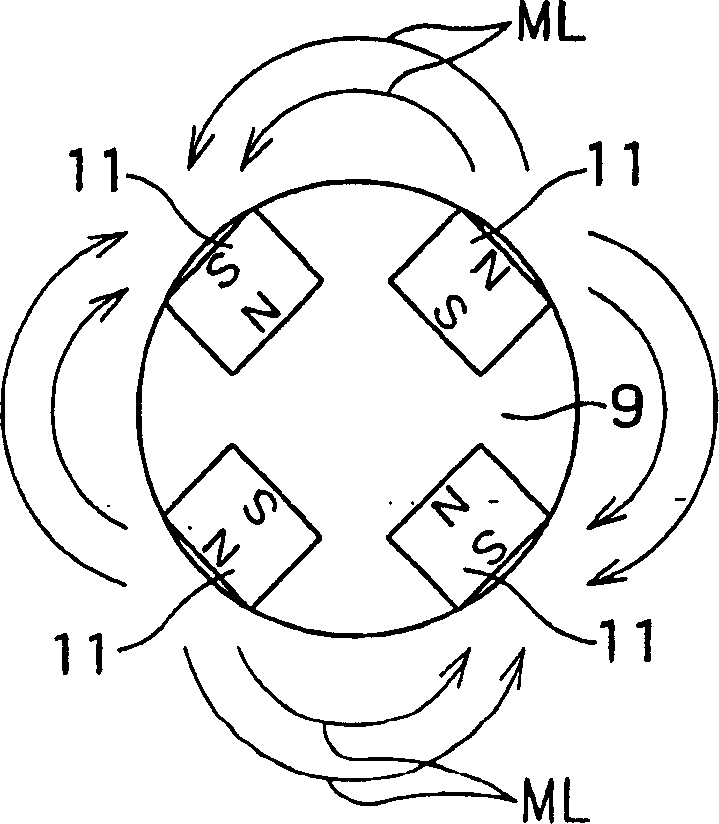

ActiveUS20140079561A1Inhibit heat generationEasy to useStirring devicesCasting apparatusMolten metalMagnetic line

There is provided an energy-saving agitator that suppresses the amount of generated heat, is easy to use and carry out maintenance, has flexibility in an installation position, and can also adjust an agitating ability. The agitator includes a furnace body that includes a molten metal room storing a molten metal, and an agitating unit that agitates the molten metal stored in the furnace body. The agitating unit includes a molten-metal driving room-forming part that is disposed in the molten metal room, applies a driving force to the molten metal, and forms a driving room of which both ends are opened; a pair of electrodes that is disposed in the driving room and makes current flow in the driving room under the presence of the molten metal; and a magnetic field unit which is formed of a permanent magnet disposed outside the furnace body, of which one pole of an N pole and an S pole faces the furnace body so that magnetic lines of force generated from the one pole cross the current, and which generates an electromagnetic force for driving the molten metal from one end toward the other end in the driving room.

Owner:TAKAHASHI KENZO

Pouring flue gas dust removal process for continuous casting big ladles

ActiveCN108500224AIncrease capture rateImprove the workshop environmentCasting apparatusFlue gasTuyere

The invention relates to a pouring flue gas dust removal process for continuous casting big ladles. The process comprises the following steps: putting a full pack of steel ladles into a revolving table; rotating the revolving table to a pouring position; moving a movable cover on the upper parts of pouring steel ladles; performing sealing and closure between a fixed cover and the movable cover; beginning to pour the full pack of steel ladles; sucking away flue gas produced in a pouring process by a fan arranged above an operation platform through an air suction hole formed in the fixed cover,and simultaneously, preparing the full pack of steel ladles on a hoisting position; rotating the revolving table to 180 degrees when the pouring is carried out; enabling empty steel ladles to enter into the hoisting position and the full pack of steel lades to enter into the pouring position, and moving the movable cover to the upper part of the pouring position to make room for hoisting; and then repeatedly carrying out the steps. According to the pouring flue gas dust removal process for the continuous casting big ladle disclosed by the invention, through a flue gas collection device with the revolving table for the continuous casting big ladles, dispersion of flue gas is hindered in a process of pouring the big ladles, a flue gas collection ratio is increased, and a workshop environment is improved; and compared with a conventional roofing cover, the pouring flue gas dust removal process disclosed by the invention has the advantages that one-time investment and operation expenses are greatly reduced.

Owner:江苏朗润环保科技有限公司

Die casting mold and method of manufacturing and casting the same

ActiveUS20090260773A1Reduce generationPromote repairFoundry mouldsCasting apparatusDie castingMaterials science

In a die-casting mold used in a casting method, a fixed insert includes a recessed cavity portion, and a fixed mold body is arranged to hold the fixed insert. The fixed insert includes a first insert and a second insert. The first insert is held with the fixed mold body. The second insert is fitted and held within a recess formed on the first insert. The size of the second insert is minimized so as to just surround the recessed cavity portion.

Owner:YAMAHA MOTOR CO LTD

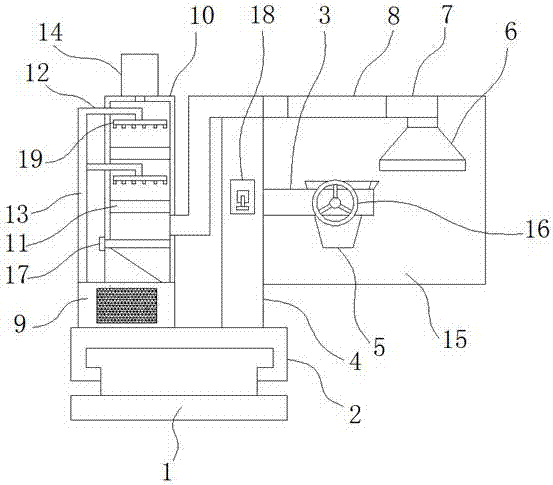

Mold-free casting forming device capable of automatically discharging sand

InactiveCN107282883AReasonable structurePracticalFoundry mouldsCasting apparatusWorking environmentEngineering

The invention discloses a moldless casting molding equipment capable of automatic sand discharge, which comprises a bottom plate, four electric telescopic rods 1 are arranged on the upper surface of the bottom plate, and a workbench is arranged on the top of the electric telescopic rod 1 . Two fixing plates are arranged on the upper surface of the workbench close to the rear side, and a through hole is arranged on the side of the fixing plate close to the upper surface. There are three servo motors. The moldless casting molding equipment that can automatically discharge sand has a reasonable structure and strong practicability. The dust floating during work can be cleaned and removed through the atomizer and vacuum cleaner, and the sand discharge tank and waste box The waste sand generated during work can be collected and processed to ensure a clean and hygienic working environment. The height of the workbench can be easily adjusted through the electric telescopic rod, and the device can be moved and braked through universal wheels and brakes. It is suitable for Promotional use.

Owner:吴大江

Exhaustion valve assembly in die-casting mold

InactiveCN106180630AGuaranteed not to shiftPrecise positioningOperating means/releasing devices for valvesFoundry mouldsExhaust valveEngineering

To provide an exhaustion valve assembly in a die-casting mold manufactured relatively inexpensively even while having abrasion resistance. The valve assembly 1 includes a valve housing 2 divided into two parts. Exhaust ducts 3 and 5 closable by an exhaust valve 7 are provided in the front housing part 2a, an actuator 14 for operating the valve piston 8 of the exhaust valve 7 is housed in the housing 2, and the actuator 14 includes a force converter 15 operated by a casting material, and a force transmission member 20 for transmitting the closing motion of the force converter 15 to the valve piston 8 of the exhaust valve 7, and further includes a laminate spring assembly 23 for returning the actuator 14 and / or discharging a riser.

Owner:FONDAREX

Dust removal device of mobile casting machine for foundry industry

ActiveCN107321968AHighlight substantive featuresSignificant progressCasting apparatusFoundryAir pump

The invention discloses a dust removal device of mobile casting machine for the foundry industry. The dust removal device comprises sliding rails, a pulley and a casting mechanism arranged on the pulley, and the casting mechanism comprises a standing plate arranged on the pulley; one side of the standing plate is connected to a casting ladle through a bracket, and the upper part, far away from one side of the standing plate, of the casting ladle is provided with a dust hood; an air suction pipe is fixed to the upper end of the standing plate, and the dust hood is connected to a dust removal mechanism through the air suction pipe; the air suction pipe is connected to an annular pipe horizontally arranged above the casting ladle, and the upper end of the pulley is provided with a heat dissipating water tank; the dust removal mechanism is arranged at the upper end of the heat dissipating water tank, and comprises a tank body fixedly installed on the heat dissipating water tank; the tank body is internally provided with at least one layer of filler, and a uniform distribution device is arranged above each layer of the filler. According to the dust removal device disclosed by the invention, not only metal dust filtered can be recycled, but also sucked smoke can be cooled at the same time; and the influence of high temperature on the service life of a suction pump can be avoided.

Owner:QINSHUI COUNTY SHUNSHIDA CASTING CO LTD

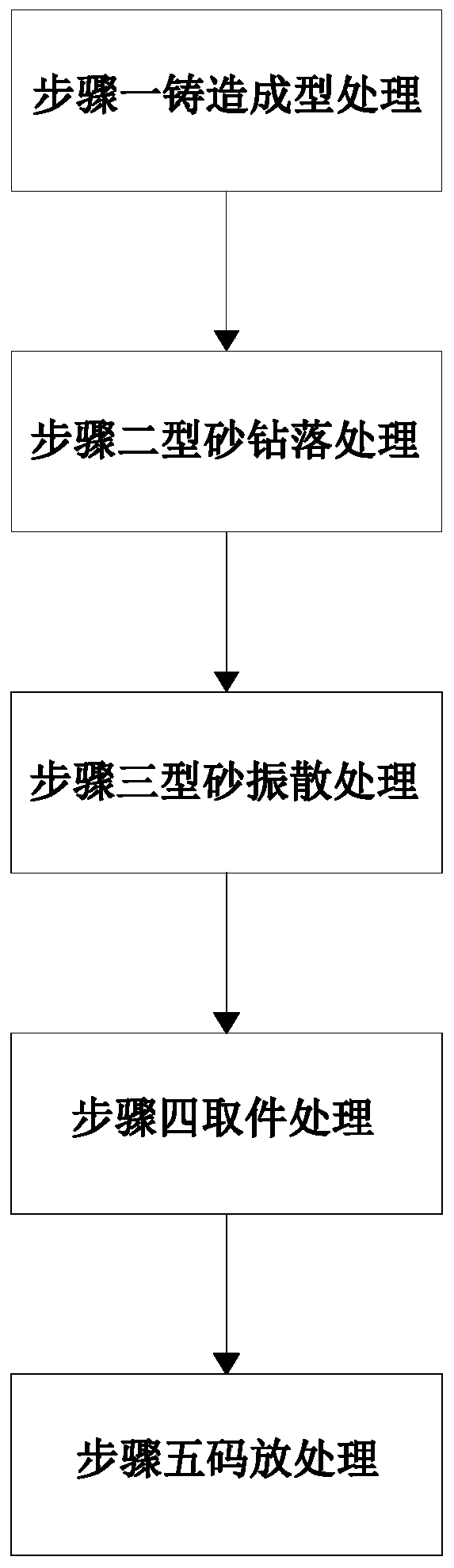

Sand discharging treatment method used after casting molding of castings

InactiveCN110802217AAchieve the purpose of vibratingAchieve the purpose of looseningCasting apparatusMechanical engineeringManufacturing engineering

The invention relates to a sand discharging treatment method used after the casting molding of castings. The method mainly comprises the following procedures of casting molding treatment, molding sanddrilling-off treatment, molding sand ramming treatment, casting fetching treatment, casting stacking treatment and the like. The following problems, namely that a, in the process that molding sand iscleared by adopting a common manual sand clearing mode after the casting of the castings is finished, high worker labor intensity, incomplete sand clearing and inconvenient casting fetching result from firm molding sand bonding and difficult manual clearing, and b, in the process that the molding sand is cleared after the casting of the castings is finished, the existence of molding sand residuesin a sand box after sand clearing causes the following difficult repeated use of the sand box and the increase of clearing cost, which occur in the existing casting processing process, can be solved.

Owner:合肥集知匠心科技发展有限公司

Apparatus for production of metallic slab using electron beam, and process for production of metallic slab using the apparatus

InactiveUS20110308760A1Easy to changeReduce pressureLighting and heating apparatusCasting apparatusMelting temperatureElectron

An apparatus and method allows the width of high-melting temperature reactive metallic slabs produced in an electron beam melting furnace to be easily changed. The apparatus for production of the metallic slabs by the electron beam melting has a metal melting part and a metal extraction part mutually separated by an air tight valve; a metal melting part has a melting chamber, electron gun, hearth, a mold of variable wall distance, and an air tight valve; and the metal extraction part has a slab chamber, an extraction base, an extracting shaft, and an drive unit for extracting the metal slab. The method for production of the metallic slab using this apparatus has a step of pulling a previous metallic slab produced in the rectangular mold out of the rectangular mold, a step of moving the short mold wall(s) of the rectangular mold to change the width of the rectangular mold, and a step of producing a subsequent metallic slab.

Owner:TOHO TITANIUM CO LTD +1

Device for Casting

InactiveUS20090000758A1Simple designEconomic and practical to reproduceCasting apparatusActuatorMetal mold

The present invention is a casting machine for casting parts in a mold out of a metal using a metal feed stock. The machine includes a processing cylinder formed in a thermally conductive block, said processing cylinder having a processing chamber and opposite first and second ends, the first end of the processing cylinder being configured to receive the metal feed stock. The machine further includes an injector cylinder formed in the thermally conductive block adjacent the processing cylinder, the injector cylinder having a shooting pot coupled to the second end of the processing cylinder by a passage configured to permit feed stock to pass from the processing cylinder into the shooting pot, a nozzle coupled to the injector cylinder configured to couple to the mold. The device includes a processing drive for driving the feed stock from the first end of the processing cylinder through the passage into the shooting pot and a heater thermally coupled to the processing cylinder. The heater and processing cylinder are configured to heat the feed stock such that the feed stock becomes progressively more liquid as it passes from the first to the second end of the processing cylinder. The machine further includes an injector plunger coupled to an injector actuator for driving the plunger sufficiently to force the metal from the shooting pot through the nozzle and into the mold.

Owner:STONE ASHLEY

Casting gap repair method

The invention provides a casting gap repair method. Repair liquid flows in deep holes and tiny air holes of a casting through vacuum diffusion, carbon dioxide reacts with the repair liquid, and retained silicon dioxide is generated for filling repair. The repair liquid to which water-soluble sodium silicate flows is vacuumized, the diffusion rate of molecules of the repair liquid is multiplied, diffusion time is greatly shortened, the air molecule number of the repair liquid is close to zero in a vacuum state, gaps in the casting are in a vacuum suction state, and the deep holes and the tiny air holes of the casting are quickly and fully filled with the water-soluble sodium silicate. Before carbon dioxide flows in, vacuumization is conducted again, the carbon dioxide fully reacts with the water-soluble sodium silicate in a closed container, finally, silicon dioxide is generated and retained in the air holes of the casting, and therefore the hardening repair effect is achieved.

Owner:遵义金业机械铸造有限公司

Port cleaning device for casting mold and using method

InactiveCN112934809AAvoid damageExpand the scope of cleaningCasting apparatusCleaning using liquidsGear wheelElectric machinery

The invention discloses a port cleaning device for a casting mold. The port cleaning device comprises a workbench, wherein two supporting rods are fixedly connected to the positions, close to the left side and the right side, of the bottom of the workbench; the two supporting rods are arranged one after the other; the workbench is hollow; a motor is fixedly connected to the position, close to the right side, of the bottom of an inner cavity of the workbench; a threaded rod is fixedly connected to the power output end of the top of the motor; a frame is fixedly connected to the position, close to the right side, of the top of the workbench; the top of the frame is enclosed; and a bearing matched with the threaded rod is fixedly connected to the top of the workbench. According to the port cleaning device, a second rotating shaft is rotated to drive circular gears to rotate, and the circular gears are meshed with tooth blocks to drive movable plates to move, so that clamping plates are driven to deflect, the mold is clamped to prevent the mold from moving, and damage to the mold due to misplacement of a mold port and a cleaning head is avoided.

Owner:李伟宝

Low pressure cylinder head outer die components for core gas removal

An apparatus for core gas removal in a low-pressure cylinder head die casting operation includes an upper die, a lower die, an ejector plate disposed above the upper die to eject a part that has been cast, a plurality of tight plugs fastened into cavities formed in the upper die, and a plurality of clean pins attached to the ejector plate, each clean pin corresponding to a location of one of the tight plugs. The clean pins and the tight plugs have matching geometries. The ejector plate lowers to eject a casted cylinder head from the upper die such that a portion of the clean pins extend axially into the tight plugs to clean core gas residue formed on inner walls of the tight plugs during the casting cycle.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

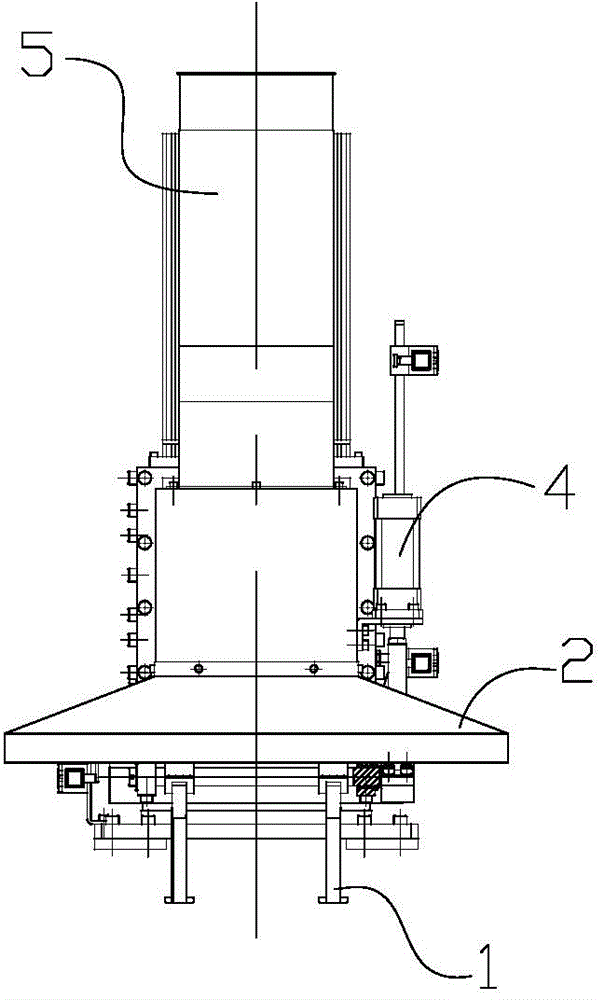

Device, integrating workpiece taking and smoke suction, for casting machine

InactiveCN104841922AImprove absorption rateCasting apparatusDirt cleaningEngineeringMechanical engineering

The invention provides a device, integrating workpiece taking and smoke suction, for a casting machine. The device comprises a mounting seat, a rotating mechanism, a smoke suction mechanism, a gripping mechanism for workpiece taking and a lifting mechanism, wherein the mounting seat is used for fixing the device on the casting machine; the rotating mechanism comprises a rotary disc and a rotating air cylinder driving the rotary disc to rotate, and the rotary disc is rotatably disposed on the mounting seat; the smoke suction mechanism comprises a smoke suction hood, a chimney connected with the smoke suction hood, and an air suction mechanism which is disposed at the tail end of the chimney and used for sucking; the gripping mechanism is disposed on the air suction hood; the lifting mechanism is disposed on the rotary disc, the air suction hood is connected with the lifting mechanism and driven by the same to move up and down so as to drive the gripping mechanism to move up and down to complete workpiece taking. By the device, a workpiece can be taken out during die assembling and die sinking, smoke can be sucked at the same time, and smoke suction rate is increased.

Owner:KOLBENSCHMIDT PIERBURG SHANGHAI NONFERROUS COMPONENTS

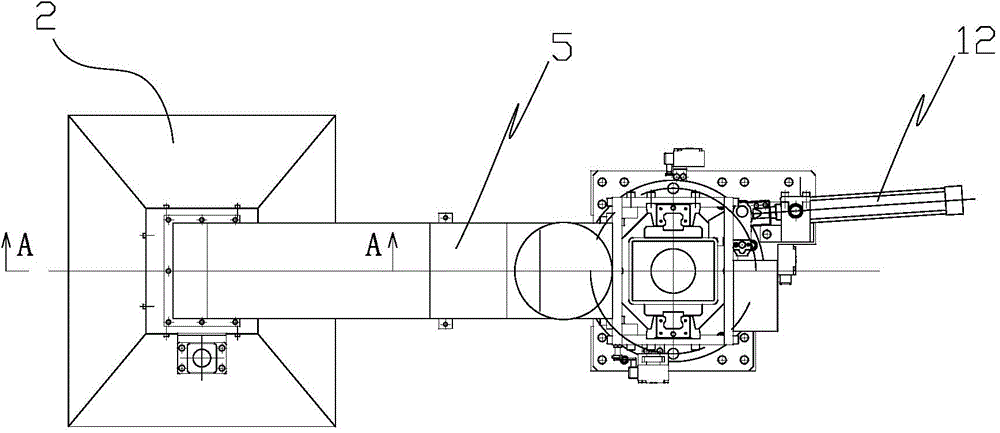

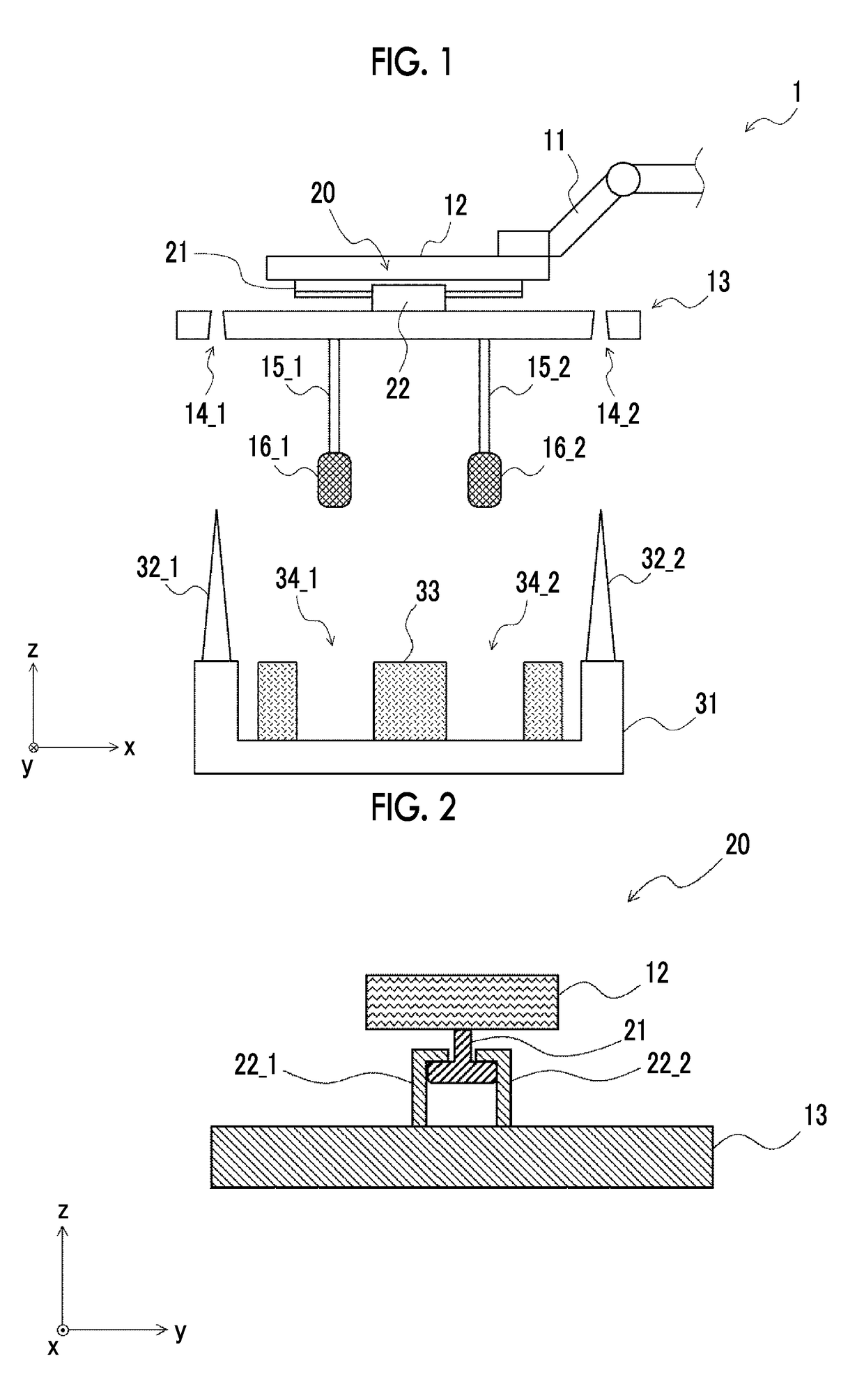

Core conveying device and core conveying method

ActiveUS20180170688A1Proper disposalConvey accuratelyMoulding toolsJointsEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com