Full-automatic pipe clamp and nail assembling machine

A fully automatic and card group technology, applied in the field of machinery, can solve the problem of low efficiency of manual assembly, and achieve the effect of preventing the inconsistency of feeding speed and assembly speed, improving work speed and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

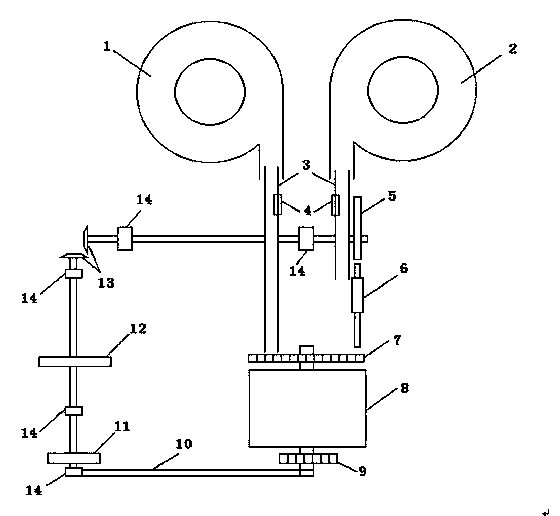

[0018] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. as attached figure 1 As shown, the automatic nailing assembly machine includes: nailing plate (1), pipe chuck (2), material channel (3), sensor (4), eccentric wheel (5), pipe clamping mold (6 ), dial (7), spindle frame (8), ratchet (9), connecting rod (10), adjustment disc (11), transmission pulley (12), bevel gear (13), bearing seat (14). It is characterized in that the nails and plastic pipe clamps are screened by the two vibrating discs of the nail plate (1) and the pipe chuck (2) respectively and enter the two material channels (3), and two induction tubes are respectively placed above the two material channels (3). device (4), when the nails or plastic pipe clamps in the material channel (3) are full, the nail plate (1) or pipe chuck (2) stops vibrating and feeding, and the sensor below the nail plate (1) ( 4) It is the combination of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com